-

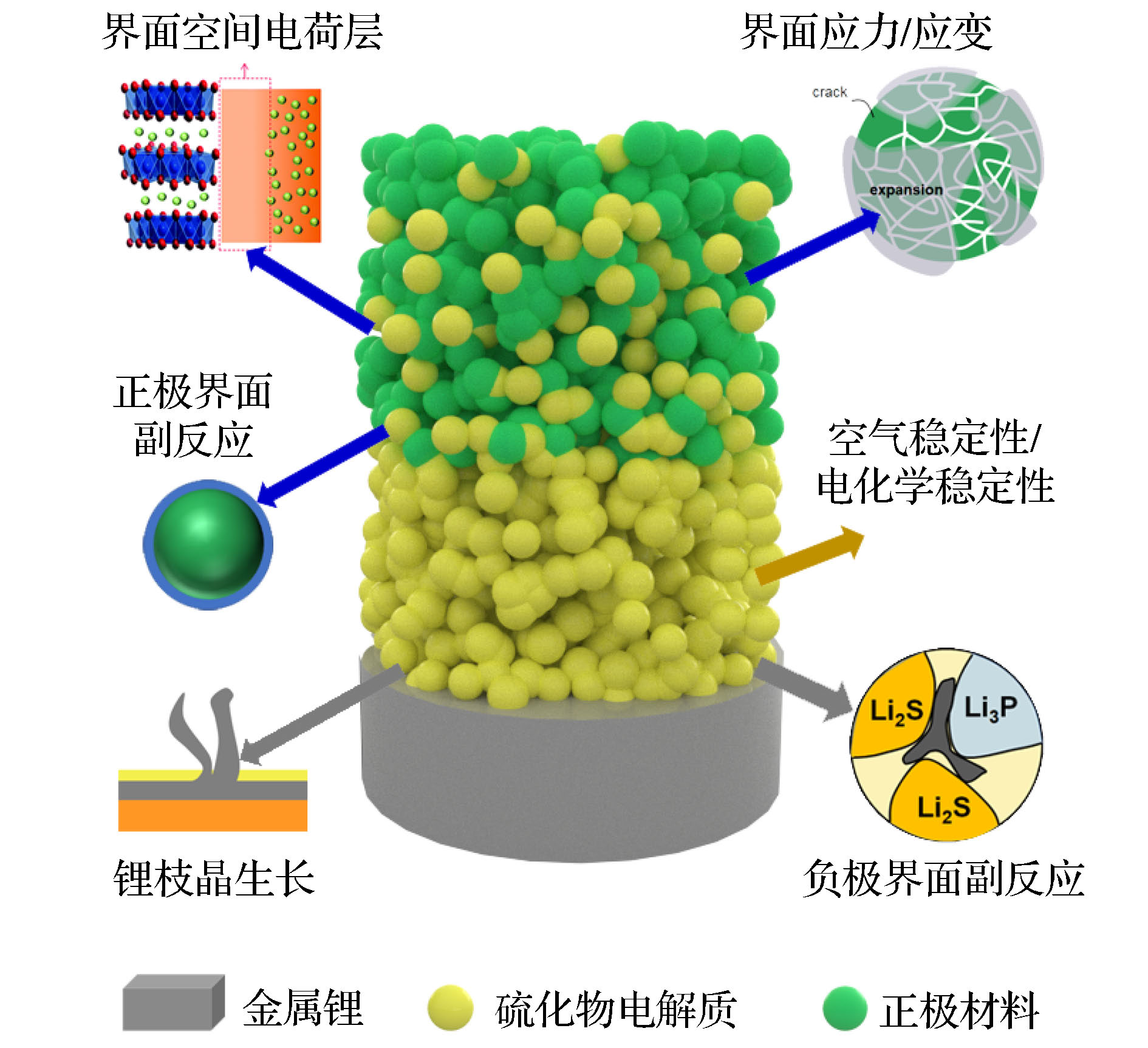

The development of high-energy density and high-safety all-solid-state lithium battery (ASSLB) technology has important practical significance for promoting the upgrading of lithium battery technology and the strengthening of technological development in this field. The solid electrolyte is a core component of the ASSLB. The sulfide solid electrolyte is regarded as one of the most promising solid electrolyte candidates for practical application in ASSLBs due to its high ionic conductivity, better mechanical ductility, and good interface contact with the electrode. However, its practical application is severely hampered by the issues of poor air stability and interface problems, including interface side reactions, lithium dendritic growth, and interface mechanical failure. In this review, we first summarize the research methods and degradation mechanisms of the air stability of sulfide solid electrolytes, and the strategies and methods to improve their air stability. Then, the electrochemical stability, interface compatibility and related interfacial modification strategies for sulfide electrolyte/electrode interface are summarized and discussed. Further, the research progress of in-situ characterization technologies for sulfide solid electrolyte/electrode interfaces in recent years is analyzed and summarized. Finally, an outlook on the future research and development of stable interfaces in sulfide solid electrolyte based ASSLBs is highlighted.

-

Keywords:

- solid-state batteries /

- sulfide solid electrolyte /

- air stability /

- electrode/electrolyte interfaces /

- in-situ characterization techniques

[1] Zheng Z, Wu H H, Liu H, Zhang Q, He X, Yu S, Petrova V, Feng J, Kostecki R, Liu P, Peng D L, Liu M, Wang M S 2020 ACS Nano 14 9545

Google Scholar

Google Scholar

[2] An W, Gao B, Mei S, Xiang B, Fu J, Wang L, Zhang Q, Chu P K, Huo K 2019 Nat. Commun. 10 1447

Google Scholar

Google Scholar

[3] Zheng Z, Li P, Huang J, Liu H, Zao Y, Hu Z, Zhang L, Chen H, Wang M S, Peng D L, Zhang Q 2020 J. Energy Chem. 41 126

Google Scholar

Google Scholar

[4] Zhang Q, Chen H, Luo L, Zhao B, Luo H, Han X, Wang J, Wang C, Yang Y, Zhu T, Liu M 2018 Energy Environ. Sci. 11 669

Google Scholar

Google Scholar

[5] Zhong S Y, Shi J, Luo W W, Lei X L 2019 Chin. Phys. B 28 078201

Google Scholar

Google Scholar

[6] Wang Y, Liu B N, Zhou G, Nie K H, Zhang J N, Yu X Q, Li H 2019 Chin. Phys. B 28 068202

Google Scholar

Google Scholar

[7] Wang H, Lan X, Huang Y, Jiang X 2019 Chin. Phys. Lett. 36 098201

Google Scholar

Google Scholar

[8] Jiang L W, Lu Y X, Wang Y S, Liu L L, Qi X G, Zhao C L, Chen L Q, Hu Y S 2018 Chin. Phys. Lett. 35 048801

Google Scholar

Google Scholar

[9] Chen R, Li Q, Yu X, Chen L, Li H 2020 Chem. Rev. 120 6820

Google Scholar

Google Scholar

[10] Banerjee A, Wang X, Fang C, Wu E A, Meng Y S 2020 Chem. Rev. 120 6878

Google Scholar

Google Scholar

[11] Wang C, Fu K, Kammampata S P, McOwen D W, Samson A J, Zhang L, Hitz G T, Nolan A M, Wachsman E D, Mo Y, Thangadurai V, Hu L 2020 Chem. Rev. 120 4257

Google Scholar

Google Scholar

[12] Xiao Y, Wang Y, Bo S H, Kim J C, Miara L J, Ceder G 2020 Nat. Rev. Mater. 5 105

Google Scholar

Google Scholar

[13] Liu L, Xu J, Wang S, Wu F, Li H, Chen L 2019 eTransportation 1 100010

Google Scholar

Google Scholar

[14] Zhao Q, Stalin S, Zhao C Z, Archer L A 2020 Nat. Rev. Mater. 5 229

Google Scholar

Google Scholar

[15] Xu J, Liu L, Yao N, Wu F, Li H, Chen L 2019 Mater. Today Nano 8 100048

Google Scholar

Google Scholar

[16] Wang H, An H, Shan H, Zhao L, Wang J 2020 Acta Phys. Chim. Sin. 36 2007070

Google Scholar

Google Scholar

[17] Jin F, Li J, Hu C, Dong H, Chen P, Shen Y, Chen L 2019 Acta Phys. Chim. Sin. 35 1399

Google Scholar

Google Scholar

[18] Minami K, Mizuno F, Hayashi A, Tatsumisago M 2007 Solid State Ionics 178 837

Google Scholar

Google Scholar

[19] Tachez M, Malugani J P, Mercier R, Robert G 1984 Solid State Ionics 14 181

Google Scholar

Google Scholar

[20] Kamaya N, Homma K, Yamakawa Y, Hirayama M, Kanno R, Yonemura M, Kamiyama T, Kato Y, Hama S, Kawamoto K, Mitsui A 2011 Nat. Mater. 10 682

Google Scholar

Google Scholar

[21] Kanno R, Murayama M 2001 J. Electrochem. Soc. 148 A742

Google Scholar

Google Scholar

[22] Kato Y, Hori S, Saito T, Suzuki K, Hirayama M, Mitsui A, Yonemura M, Iba H, Kanno R 2016 Nat. Energy 1 16030

Google Scholar

Google Scholar

[23] Deiseroth H J, Kong S T, Eckert H, Vannahme J, Reiner C, Zaiss T, Schlosser M 2008 Angew. Chem. Int. Ed. 47 755

Google Scholar

Google Scholar

[24] Wenzel S, Randau S, Leichtweiß T, Weber D A, Sann J, Zeier W G, Janek J 2016 Chem. Mater. 28 2400

Google Scholar

Google Scholar

[25] Culver S P, Koerver R, Zeier W G, Janek J 2019 Adv. Energy Mater. 9 1900626

Google Scholar

Google Scholar

[26] Lian P J, Zhao B S, Zhang L Q, Xu N, Wu M T, Gao X P 2019 J. Mater. Chem. A 7 20540

Google Scholar

Google Scholar

[27] Yang W, Tufail M K, Zhou L, Lü L, Chen R, Yang L 2020 Sci. Sin. Chim. 50 1031

Google Scholar

Google Scholar

[28] Muramatsu H, Hayashi A, Ohtomo T, Hama S, Tatsumisago M 2011 Solid State Ionics 182 116

Google Scholar

Google Scholar

[29] Kim J S, Jeon M, Kim S, Lee J H, Kim B K, Kim H 2020 Solid State Ionics 346 115225

Google Scholar

Google Scholar

[30] Sahu G, Lin Z, Li J, Liu Z, Dudney N, Liang C 2014 Energy Environ. Sci. 7 1053

Google Scholar

Google Scholar

[31] Liang J, Chen N, Li X, Li X, Adair K R, Li J, Wang C, Yu C, Norouzi Banis M, Zhang L, Zhao S, Lu S, Huang H, Li R, Huang Y, Sun X 2020 Chem. Mater. 32 2664

Google Scholar

Google Scholar

[32] Zhu Y, Mo Y 2020 Angew. Chem. Int. Ed. 59 17472

Google Scholar

Google Scholar

[33] Ohtomo T, Hayashi A, Tatsumisago M, Kawamoto K 2013 J. Solid State Electrochem. 17 2551

Google Scholar

Google Scholar

[34] Liu G, Xie D, Wang X, Yao X, Chen S, Xiao R, Li H, Xu X 2019 Energy Storage Mater. 17 266

Google Scholar

Google Scholar

[35] Hayashi A, Muramatsu H, Ohtomo T, Hama S, Tatsumisago M 2013 J. Mater. Chem. A 1 6320

Google Scholar

Google Scholar

[36] Hayashi A, Muramatsu H, Ohtomo T, Hama S, Tatsumisago M 2014 J Alloys Compd. 591 247

Google Scholar

Google Scholar

[37] Brant J A, Massi D M, Holzwarth N A W, MacNeil J H, Douvalis A P, Bakas T, Martin S W, Gross M D, Aitken J A 2014 Chem. Mater. 27 189

Google Scholar

Google Scholar

[38] Park K H, Oh D Y, Choi Y E, Nam Y J, Han L, Kim J Y, Xin H, Lin F, Oh S M, Jung Y S 2016 Adv. Mater. 28 1874

Google Scholar

Google Scholar

[39] Kimura T, Kato A, Hotehama C, Sakuda A, Hayashi A, Tatsumisago M 2019 Solid State Ionics 333 45

Google Scholar

Google Scholar

[40] Zhang Z, Zhang J, Sun Y, Jia H, Peng L, Zhang Y, Xie J 2020 J. Energy Chem. 41 171

Google Scholar

Google Scholar

[41] Zhao F, Liang J, Yu C, Sun Q, Li X, Adair K, Wang C, Zhao Y, Zhang S, Li W, Deng S, Li R, Huang Y, Huang H, Zhang L, Zhao S, Lu S, Sun X 2020 Adv. Energy Mater. 10 1903422

Google Scholar

Google Scholar

[42] Wang Y, Lü X, Zheng C, Liu X, Chen Z, Yang W, Lin J, Huang F 2019 Angew. Chem. Int. Ed. 58 7673

Google Scholar

Google Scholar

[43] Tan D H S, Banerjee A, Deng Z, Wu E A, Nguyen H, Doux J M, Wang X, Cheng J H, Ong S P, Meng Y S, Chen Z 2019 ACS Appl. Energy Mater. 2 6542

Google Scholar

Google Scholar

[44] Zhu Y, He X, Mo Y 2015 ACS Appl. Mater. Interfaces 7 23685

Google Scholar

Google Scholar

[45] Han F, Zhu Y, He X, Mo Y, Wang C 2016 Adv. Energy Mater. 6 1501590

Google Scholar

Google Scholar

[46] Sang L, Haasch R T, Gewirth A A, Nuzzo R G 2017 Chem. Mater. 29 3029

Google Scholar

Google Scholar

[47] Richards W D, Miara L J, Wang Y, Kim J C, Ceder G 2016 Chem. Mater. 28 266

Google Scholar

Google Scholar

[48] Wenzel S, Leichtweiss T, Krüger D, Sann J, Janek J 2015 Solid State Ionics 278 98

Google Scholar

Google Scholar

[49] Woo J H, Trevey J E, Cavanagh A S, Choi Y S, Kim S C, George S M, Oh K H, Lee S H 2012 J. Electrochem. Soc. 159 A1120

Google Scholar

Google Scholar

[50] Takada K, Ohta N, Zhang L, Xu X, Hang B T, Ohnishi T, Osada M, Sasaki T 2012 Solid State Ionics 225 594

Google Scholar

Google Scholar

[51] Jung S K, Gwon H, Lee S S, Kim H, Lee J C, Chung J G, Park S Y, Aihara Y, Im D 2019 J. Mater. Chem. A 7 22967

Google Scholar

Google Scholar

[52] Koerver R, Aygün I, Leichtweiß T, Dietrich C, Zhang W, Binder J O, Hartmann P, Zeier W G, Janek J 2017 Chem. Mater. 29 5574

Google Scholar

Google Scholar

[53] Zheng B Z, Liu X S, Zhu J P, Zhao J, Zhong G M, Xiang Y X, Wang H C, Zhao W M, Umeshbabu E, Wu Q H, Huang J Y, Yang Y 2020 Nano Energy 67 104252

Google Scholar

Google Scholar

[54] Wu X, Villevieille C, Novák P, El Kazzi M 2018 Phys. Chem. Chem. Phys. 20 11123

Google Scholar

Google Scholar

[55] Ohta N, Takada K, Sakaguchi I, Zhang L, Ma R, Fukuda K, Osada M, Sasaki T 2007 Electrochem. Commun. 9 1486

Google Scholar

Google Scholar

[56] Ohta N, Takada K, Zhang L, Ma R, Osada M, Sasaki T 2006 Adv. Mater. 18 2226

Google Scholar

Google Scholar

[57] Fan X, Ji X, Han F, Yue J, Chen J, Chen L, Deng T, Jiang J, Wang C 2018 Sci. Adv. 4 eaau9245

Google Scholar

Google Scholar

[58] Zheng B Z, Zhu J P, Wang H C, Feng M, Umeshbabu E, Li Y X, Wu Q H, Yang Y 2018 ACS Appl. Mater. Interfaces 10 25473

Google Scholar

Google Scholar

[59] Zhang Q, Cao D, Ma Y, Natan A, Aurora P, Zhu H 2019 Adv. Mater. 31 1901131

Google Scholar

Google Scholar

[60] Culver S P, Koerver R, Zeier W G, Janek J 2019 Advanced Energy Materials 9 1900626

[61] Wu F, Fitzhugh W, Ye L, Ning J, Li X 2018 Nat. Commun. 9 4037

Google Scholar

Google Scholar

[62] Fitzhugh W, Wu F, Ye L, Su H, Li X 2019 Small 15 1901470

Google Scholar

Google Scholar

[63] Li X, Sun Q, Wang Z, Song D, Zhang H, Shi X, Li C, Zhang L, Zhu L 2020 J. Power Sources 456 227997

Google Scholar

Google Scholar

[64] Han F, Westover A S, Yue J, Fan X, Wang F, Chi M, Leonard D N, Dudney N, Wang H, Wang C 2019 Nat. Energy 4 187

Google Scholar

Google Scholar

[65] Nagao M, Hayashi A, Tatsumisago M, Kanetsuku T, Tsuda T, Kuwabata S 2013 Phys. Chem. Chem. Phys. 15 18600

Google Scholar

Google Scholar

[66] Ma J, Chen B, Wang L, Cui G 2018 J. Power Sources 392 94

Google Scholar

Google Scholar

[67] Gao Y, Wang D, Li Y C, Yu Z, Mallouk T E, Wang D 2018 Angew. Chem. Int. Ed. 57 13608

Google Scholar

Google Scholar

[68] Zhang Z, Chen S, Yang J, Wang J, Yao L, Yao X, Cui P, Xu X 2018 ACS Appl. Mater. Interfaces 10 2556

Google Scholar

Google Scholar

[69] Garcia-Mendez R, Mizuno F, Zhang R, Arthur T S, Sakamoto J 2017 Electrochim. Acta 237 144

Google Scholar

Google Scholar

[70] Porz L, Swamy T, Sheldon B W, Rettenwander D, Frömling T, Thaman H L, Berendts S, Uecker R, Carter W C, Chiang Y M 2017 Adv. Energy Mater. 7 1701003

Google Scholar

Google Scholar

[71] Han F, Yue J, Zhu X, Wang C 2018 Adv. Energy Mater. 8 1703644

Google Scholar

Google Scholar

[72] Schlenker R, Stepien D, Koch P, Hupfer T, Indris S, Roling B, Miss V, Fuchs A, Wilhelmi M, Ehrenberg H 2020 ACS Appl. Mater. Interfaces 12 20012

Google Scholar

Google Scholar

[73] Kasemchainan J, Zekoll S, Jolly D S, Ning Z Y, Hartley G O, Marrow J, Bruce P G 2019 Nat. Mater. 18 1105

Google Scholar

Google Scholar

[74] Ong S P, Mo Y, Richards W D, Miara L, Lee H S, Ceder G 2013 Energy Environ. Sci. 6 148

Google Scholar

Google Scholar

[75] Wenzel S, Weber D A, Leichtweiss T, Busche M R, Sann J, Janek J 2016 Solid State Ionics 286 24

Google Scholar

Google Scholar

[76] Wenzel S, Sedlmaier S J, Dietrich C, Zeier W G, Janek J 2018 Solid State Ionics 318 102

Google Scholar

Google Scholar

[77] Yao X, Huang N, Han F, Zhang Q, Wan H, Mwizerwa J P, Wang C, Xu X 2017 Adv. Energy Mater. 7 1602923

Google Scholar

Google Scholar

[78] Chen T, Zhang L, Zhang Z X, Li P, Wang H Q, Yu C, Yan X L, Wang L M, Xu B 2019 ACS Appl. Mater. Interfaces 11 40808

Google Scholar

Google Scholar

[79] Tao Y, Chen S, Liu D, Peng G, Yao X, Xu X 2015 J. Electrochem. Soc. 163 A96

Google Scholar

Google Scholar

[80] Zhao F P, Sun Q, Yu C, Zhang S M, Adair K, Wang S Z, Liu Y L, Zhao Y, Liang J W, Wang C H, Li X N, Li X, Xia W, Li R Y, Huang H, Zhang L, Zhao S Q, Lu S G, Sun X L 2020 ACS Energy Lett. 5 1035

Google Scholar

Google Scholar

[81] Xu R, Han F, Ji X, Fan X, Tu J, Wang C 2018 Nano Energy 53 958

Google Scholar

Google Scholar

[82] Liang J, Li X, Zhao Y, Goncharova L V, Li W, Adair K R, Banis M N, Hu Y, Sham T K, Huang H, Zhang L, Zhao S, Lu S, Li R, Sun X 2019 Adv. Energy Mater. 9 1902125

Google Scholar

Google Scholar

[83] Wang C, Zhao Y, Sun Q, Li X, Liu Y, Liang J, Li X, Lin X, Li R, Adair K R, Zhang L, Yang R, Lu S, Sun X 2018 Nano Energy 53 168

Google Scholar

Google Scholar

[84] Davis A L, Garcia-Mendez R, Wood K N, Kazyak E, Chen K H, Teeter G, Sakamoto J, Dasgupta N P 2020 J. Mater. Chem. A 8 6291

Google Scholar

Google Scholar

[85] Sang L, Bassett K L, Castro F C, Young M J, Chen L, Haasch R T, Elam J W, Dravid V P, Nuzzo R G, Gewirth A A 2018 Chem. Mater. 30 8747

Google Scholar

Google Scholar

[86] LePage W S, Chen Y, Kazyak E, Chen K H, Sanchez A J, Poli A, Arruda E M, Thouless M D, Dasgupta N P 2019 J. Electrochem. Soc. 166 A89

Google Scholar

Google Scholar

[87] Wang C, Adair K R, Liang J, Li X, Sun Y, Li X, Wang J, Sun Q, Zhao F, Lin X, Li R, Huang H, Zhang L, Yang R, Lu S, Sun X 2019 Adv. Funct. Mater. 29 1900392

Google Scholar

Google Scholar

[88] Lee Y G, Fujiki S, Jung C, Suzuki N, Yashiro N, Omoda R, Ko D S, Shiratsuchi T, Sugimoto T, Ryu S, Ku J H, Watanabe T, Park Y, Aihara Y, Im D, Han I T 2020 Nat. Energy 5 299

Google Scholar

Google Scholar

[89] Haruyama J, Sodeyama K, Han L, Takada K, Tateyama Y 2014 Chem. Mater. 26 4248

Google Scholar

Google Scholar

[90] Takada K 2013 Langmuir 29 7538

Google Scholar

Google Scholar

[91] Chen S, Xie D, Liu G, Mwizerwa J P, Zhang Q, Zhao Y, Xu X, Yao X 2018 Energy Storage Mater. 14 58

Google Scholar

Google Scholar

[92] Otoyama M, Ito Y, Hayashi A, Tatsumisago M 2016 J. Power Sources 302 419

Google Scholar

Google Scholar

[93] Zhang J, Zheng C, Li L, Xia Y, Huang H, Gan Y, Liang C, He X, Tao X, Zhang W 2020 Adv. Energy Mater. 10 1903311

Google Scholar

Google Scholar

[94] Auvergniot J, Cassel A, Ledeuil J B, Viallet V, Seznec V, Dedryvère R 2017 Chem. Mater. 29 3883

Google Scholar

Google Scholar

[95] Zhang W, Richter F H, Culver S P, Leichtweiss T, Lozano J G, Dietrich C, Bruce P G, Zeier W G, Janek J 2018 ACS Appl. Mater. Interfaces 10 22226

Google Scholar

Google Scholar

[96] Yang J, Huang B, Yin J, Yao X, Peng G, Zhou J, Xu X 2016 J. Electrochem. Soc. 163 A1530

Google Scholar

Google Scholar

[97] Park K H, Oh D Y, Choi Y E, Nam Y J, Han L, Kim J Y, Xin H, Lin F, Oh S M, Jung Y S 2016 Advanced Materials 28 1874

[98] Park K H, Bai Q, Kim D H, Oh D Y, Zhu Y, Mo Y, Jung Y S 2018 Adv. Energy Mater. 8 1800035

Google Scholar

Google Scholar

[99] Li X, Jin L, Song D, Zhang H, Shi X, Wang Z, Zhang L, Zhu L 2020 J. Energy Chem. 40 39

Google Scholar

Google Scholar

[100] Kitaura H, Hayashi A, Tadanaga K, Tatsumisago M 2011 Solid State Ionics 192 304

Google Scholar

Google Scholar

[101] Takada K, Ohta N, Zhang L, Fukuda K, Sakaguchi I, Ma R, Osada M, Sasaki T 2008 Solid State Ionics 179 1333

Google Scholar

Google Scholar

[102] Sakuda A, Hayashi A, Tatsumisago M 2010 Chem. Mater. 22 949

Google Scholar

Google Scholar

[103] Sakuda A, Kitaura H, Hayashi A, Tadanaga K, Tatsumisago M 2008 Electrochem. Solid-State Lett. 11 A1

Google Scholar

Google Scholar

[104] Jin Y, Li N, Chen C H, Wei S Q 2006 Electrochem. Solid-State Lett. 9 A273

Google Scholar

Google Scholar

[105] Machida N, Kashiwagi J, Naito M, Shigematsu T 2012 Solid State Ionics 225 354

Google Scholar

Google Scholar

[106] Woo J H, Travis J J, George S M, Lee S H 2014 J. Electrochem. Soc. 162 A344

Google Scholar

Google Scholar

[107] Jung S H, Oh K, Nam Y J, Oh D Y, Bruener P, Kang K, Jung Y S 2018 Chem. Mater. 30 8190

Google Scholar

Google Scholar

[108] Zhang N, Ding F, Yu S, Zhu K, Li H, Zhang W, Liu X, Xu Q 2019 ACS Appl. Mater. Interfaces 11 27897

Google Scholar

Google Scholar

[109] Wang C, Li X, Zhao Y, Banis M N, Liang J, Li X, Sun Y, Adair K R, Sun Q, Liu Y, Zhao F, Deng S, Lin X, Li R, Hu Y, Sham T K, Huang H, Zhang L, Yang R, Lu S, Sun X 2019 Small Methods 3 1900261

Google Scholar

Google Scholar

[110] Banerjee A, Tang H, Wang X, Cheng J H, Nguyen H, Zhang M, Tan D H S, Wynn T A, Wu E A, Doux J M, Wu T, Ma L, Sterbinsky G E, D’Souza M S, Ong S P, Meng Y S 2019 ACS Appl. Mater. Interfaces 11 43138

Google Scholar

Google Scholar

[111] Jung S H, Kim U H, Kim J H, Jun S, Yoon C S, Jung Y S, Sun Y K 2020 Adv. Energy Mater. 10 1903360

Google Scholar

Google Scholar

[112] Deng S, Li X, Ren Z, Li W, Luo J, Liang J, Liang J, Banis M N, Li M, Zhao Y, Li X, Wang C, Sun Y, Sun Q, Li R, Hu Y, Huang H, Zhang L, Lu S, Luo J, Sun X 2020 Energy Storage Mater. 27 117

Google Scholar

Google Scholar

[113] Wang C, Liang J, Hwang S, Li X, Zhao Y, Adair K, Zhao C, Li X, Deng S, Lin X, Yang X, Li R, Huang H, Zhang L, Lu S, Su D, Sun X 2020 Nano Energy 72 104686

Google Scholar

Google Scholar

[114] Li X, Liang M, Sheng J, Song D, Zhang H, Shi X, Zhang L 2019 Energy Storage Mater. 18 100

Google Scholar

Google Scholar

[115] Lu J, Wu T, Amine K 2017 Nat. Energy 2 17011

Google Scholar

Google Scholar

[116] Yuan Y, Amine K, Lu J, Shahbazian-Yassar R 2017 Nat. Commun. 8 15806

Google Scholar

Google Scholar

[117] Xiang Y, Li X, Cheng Y, Sun X, Yang Y 2020 Mater. Today 36 139

Google Scholar

Google Scholar

[118] Boebinger M G, Lewis J A, Sandoval S E, McDowell M T 2020 ACS Energy Lett. 5 335

Google Scholar

Google Scholar

[119] Nomura Y, Yamamoto K, Hirayama T, Igaki E, Saitoh K 2020 ACS Energy Lett. 5 2098

Google Scholar

Google Scholar

[120] Wang C, Li X, Zhao Y, Banis M N, Liang J, Li X, Sun Y, Adair K R, Sun Q, Liu Y, Zhao F, Deng S, Lin X, Li R, Hu Y, Sham T K, Huang H, Zhang L, Yang R, Lu S, Sun X 2019 Small Method. 3 1900261

[121] Li X, Ren Z, Norouzi Banis M, Deng S, Zhao Y, Sun Q, Wang C, Yang X, Li W, Liang J, Li X, Sun Y, Adair K, Li R, Hu Y, Sham T K, Huang H, Zhang L, Lu S, Luo J, Sun X 2019 ACS Energy Lett. 4 2480

Google Scholar

Google Scholar

[122] Yamamoto K, Iriyama Y, Hirayama T 2017 Microscopy 66 50

Google Scholar

Google Scholar

[123] Masuda H, Ishida N, Ogata Y, Ito D, Fujita D 2017 Nanoscale 9 893

Google Scholar

Google Scholar

[124] Koerver R, Walther F, Aygün I, Sann J, Dietrich C, Zeier W G, Janek J 2017 J. Mater. Chem. A 5 22750

Google Scholar

Google Scholar

[125] Chien P H, Feng X, Tang M, Rosenberg J T, O’Neill S, Zheng J, Grant S C, Hu Y Y 2018 J. Phys.Chem. Lett. 9 1990

Google Scholar

Google Scholar

[126] Wang C, Gong Y, Dai J, Zhang L, Xie H, Pastel G, Liu B, Wachsman E, Wang H, Hu L 2017 J. Am. Chem. Soc. 139 14257

Google Scholar

Google Scholar

-

图 2 (a) 不同Li2S含量的Li2S-P2S5玻璃硫化物电解质生成的H2S量; (b), (c) 67Li2S·33P2S5 和Li2S在空气中暴露前和暴露4 min, 90 min以及一天后的拉曼光谱; (d) 75Li2S·25P2S5玻璃和 (e) 玻璃陶瓷硫化物电解质在空气中暴露前和暴露一天后的拉曼光谱; (f) 67Li2S·33P2S5和 (g) Li2S玻璃暴露于空气中的结构变化; (h) 75Li2S·25P2S5玻璃陶瓷硫化物电解质暴露于空气中电导率随着暴露时间变化图[28]

Figure 2. (a) Amounts of H2S generated from pelletized Li2S–P2S5 glasses with different Li2S contents; (b) Raman spectra of the 67Li2S·33P2S5 glass before exposure to the atmosphere and after exposure for 4 min, 90 min and 1 day; (c) Raman spectra of the Li2S crystal before exposure to the atmosphere and after exposure for 4 min, 90 min and 1 day; Raman spectra of the 75Li2S·25P2S5 glass and glass-ceramic (d) before exposure to the atmosphere and, (e) after exposure for 1 day; structural changes of the (f) 67Li2S·33P2S5 glass and (g) Li2S crystal in air; (h) conductivity of the pelletized 75Li2S·25P2S5 glass-ceramic as a function of exposure time to air at room temperature[28].

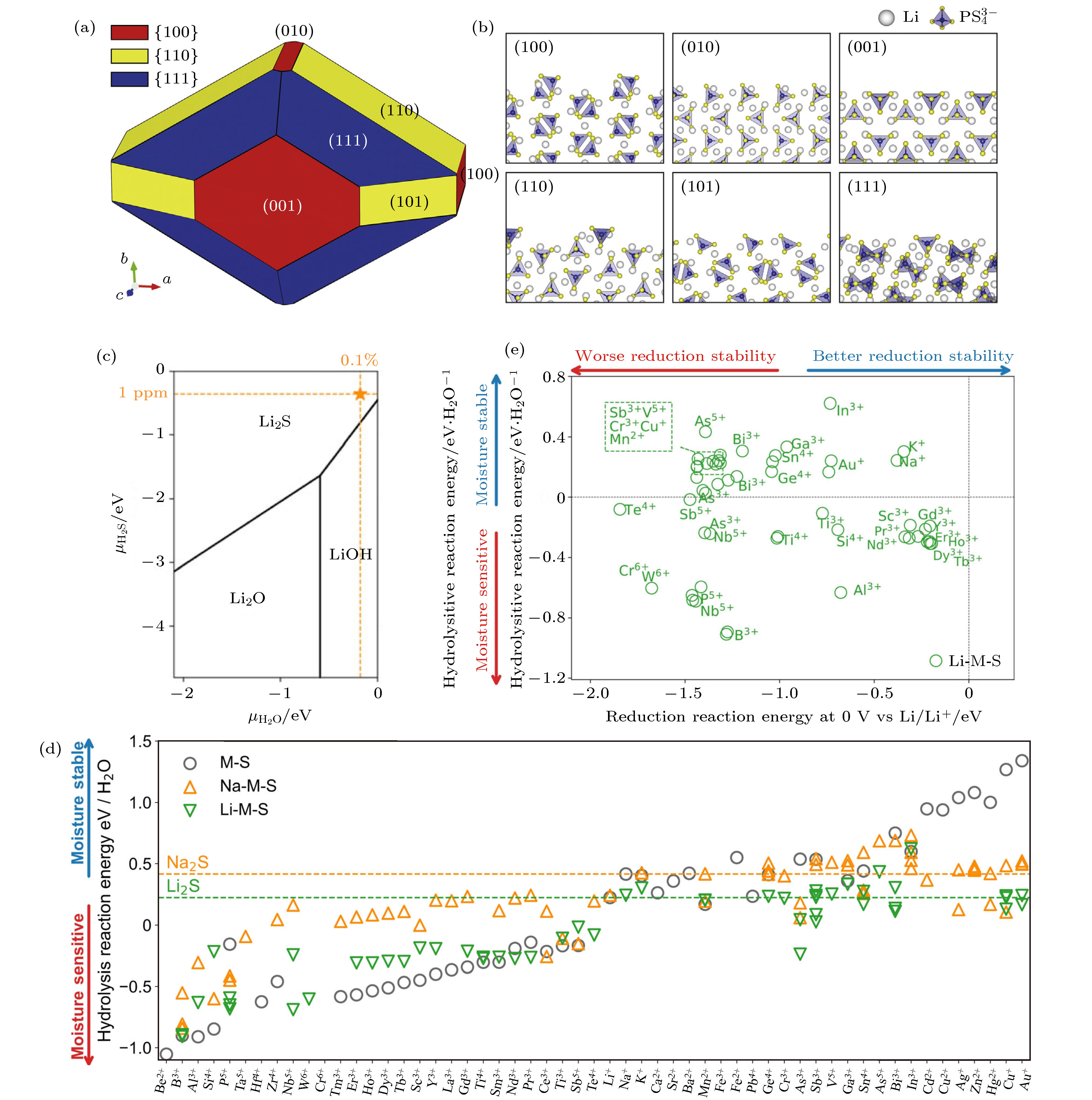

图 3 (a) 基于理论模拟预测构建的由 (100), (010), (001), (111), (110) 和(101)六个晶面组成的平衡晶体形状的β-Li3PS4模型, {100}, {110} 和 {111} 平面分别由红色、黄色和蓝色表示; (b) 平衡晶体形状中六个低指数面的原子结构图, 灰色和蓝色的四面体分别表示锂离子和

${\rm{PS}}_4^{3-}$ 阴离子, 虚线代表表面层[29]; (c) 不同水和硫化氢化学势下的优势相图; (d) 硫化物的水解反应能量, 包括46个二元金属硫化物 (灰色圆圈), 52个三元锂金属硫化物 (绿色三角形) 和65个钠金属硫化物 (橙色三角形), 作为金属阳离子的函数, 反应能量越负说明耐潮湿稳定性越差 (对湿气敏感), 而正反应能量越高, 表明耐潮湿稳定性越好(水分稳定). 水平虚线对应于水解硫化锂 (绿色)和硫化钠 (橙色) 的反应能; (e) 52种锂三元硫化物阳离子选择依据图, 耐潮湿定性 (水解反应能, y轴)与还原稳定性 (还原与碱金属的反应能, x轴)[32]Figure 3. (a) The predicted ECS of the β-Li3PS4 structure. The red, yellow, and blue colors represent the {100}, {110}, and {111} planes; (b) atomic images of six low indexed surfaces in ECS. The grey sphere and blue tetrahedron represent the Li-ion and

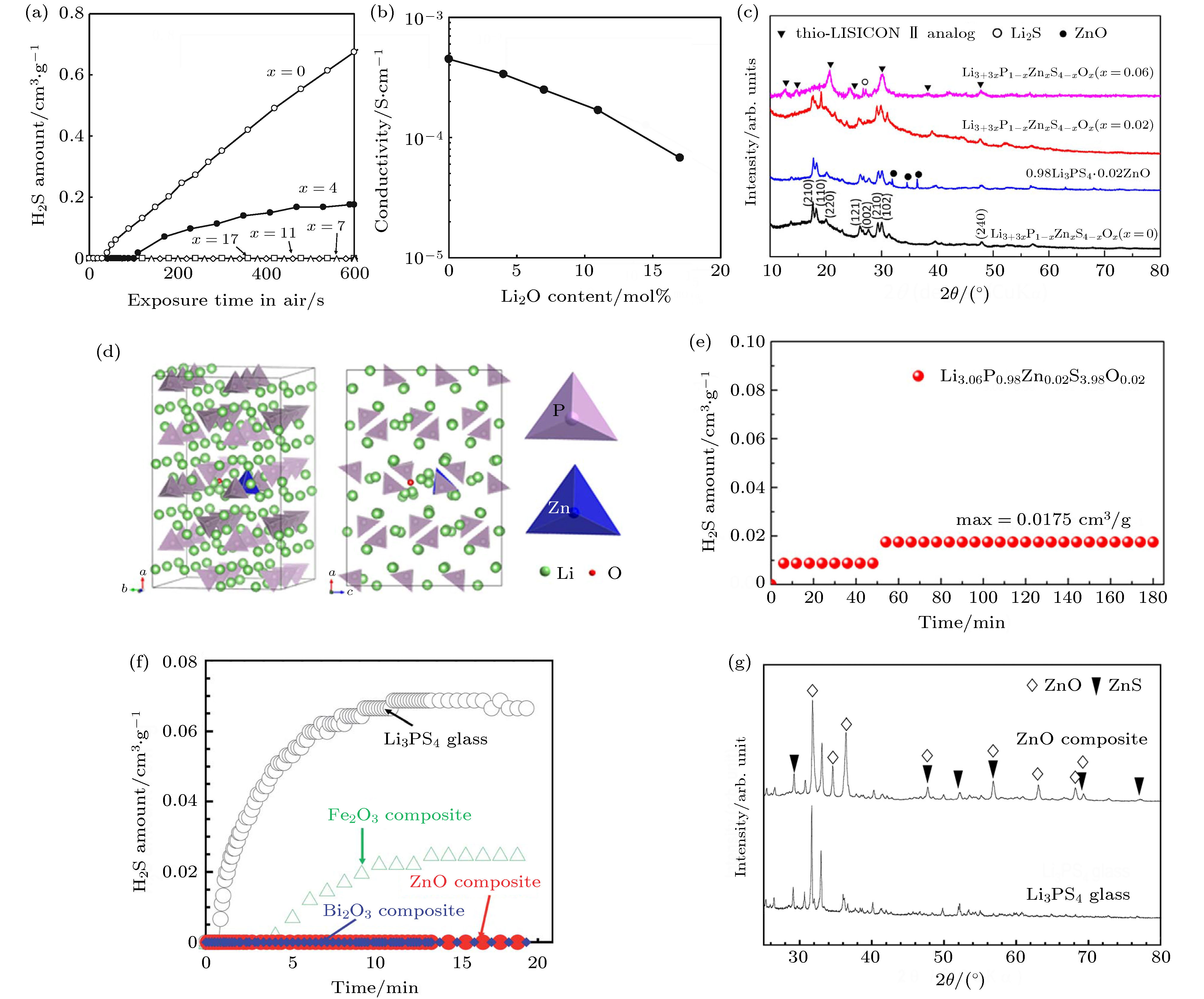

${\rm{PS}}_4^{3-} $ anion molecule, respectively[29]. The dotted line represents the surface layer; (c) predominance phase diagrams of Li2S-LiOH-Li2O under different H2O and H2S chemical potentials; (d) hydrolysis reaction energy of sulfides, including 46 binary MS (grey circles), 52 ternary LiMS (green triangles) and 65 NaMS (orange triangles), as a function of cation M. More-negative reaction energy indicates worse moisture stability (moisture sensitive), whereas more-positive reaction energy indicates better moisture stability (moisture stable). The horizontal dashed lines correspond to the hydrolysis reaction energy of Li2S (green) and Na2S (orange), respectively; (e) guiding charts for cation selection for 52 lithium ternary sulfides. The moisture stability (hydrolysis reaction energy, y-axis) versus reduction stability (reduction reaction energy with alkali metal, x-axis)[32].图 4 xLi2O·(75–x)Li2S·25P2S5 (x = 0, 4, 7, 11, 17) 在空气中暴露后产生的 (a) H2S气体的含量及 (b) 室温下的电导率[33]; (c) Li3+3xP1–xZnxS4–xOx (x = 0, 0.02, 0.06) 和0.98Li3PS4·0.02ZnO的XRD图; (d) 第一性原理计算得出的Li3+3xP1–xZnxS4–xOx (x = 0.02)结构模型图; (e) Li3.06P0.98Zn0.02S3.98O0.02暴露于潮湿空气中产生硫化氢气体量随暴露时间的变化图[34]; (f) 90Li3PS4·10MxOy (MxOy: ZnO, Fe2O3和Bi2O3)复合材料和Li3PS4玻璃在空气中暴露后产生的H2S量随暴露时间的变化图; (g) 90Li3PS4·10ZnO复合材料和Li3PS4玻璃在空气中放置一天后的XRD图谱[35]

Figure 4. (a) Amounts of H2S gas generated from the xLi2O·(75–x)Li2S·25P2S5 (x = 0, 4, 7, 11, and 17) glass powders prepared using mechanical milling; (b) electrical conductivities of the pelletized xLi2O·(75–x) Li2S·25P2S5 (x = 0, 4, 7, 11, and 17) glass powders prepared using mechanical milling at room temperature[33]; (c) XRD patterns of Li3+3xP1–xZnxS4–xOx (x = 0, 0.02, 0.06) and 0.98Li3PS4·0.02ZnO; (d) structure of Li3+3xP1–xZnxS4–xOx (x = 0.02) from DFT calculations; (e) the amount of H2S generated from Li3.06P0.98Zn0.02S3.98O0.02 when exposed in the humid air with different duration time[34]; (f) H2S amount as a function of exposure time to air for the 90Li3PS4·10MxOy (MxOy: ZnO, Fe2O3 and Bi2O3) composites and the Li3PS4 glass; (g) XRD patterns of the 90Li3PS4·10ZnO composite and the Li3PS4 glass after exposure to air for 1 day[35].

图 5 (a) 由Li3SbS4, Li3PS4和Li4SnS4粉末放出的H2S气体的量; (b) 在200和500 ℃加热条件下, 合成的Li3SbS4和其玻璃陶瓷的拉曼光谱图[39]; (c) 基于第一性原理计算的PS4和 (P/Sn)S4四面体很难被H2O氧化程度的示意图[41]; (d) Li4Cu8Ge3S12的晶体结构; (e) Li4Cu8Ge3S12固态电解质暴露于15%湿度的空气和2 M的氢氧化锂溶液前后的XRD谱图; (f) Li4Cu8Ge3S12固态电解质暴露于15%湿度的空气和2 M的氢氧化锂溶液前后的对比阿伦尼乌斯图[42]

Figure 5. (a) Amounts of H2S gas generated from the Li3SbS4 glass, Li3PS4 glass, and Li4SnS4 milled powders; (b) Raman spectra of the prepared Li3SbS4 glass and the glass-ceramic heated at 200 and 500 ℃[39]; (c) schematic diagram of the difficult degree of being oxidized by H2O of PS4 and (P/Sn)S4 tetrahedrons based on the DFT calculation[41]; (d) crystal structure of Li4Cu8Ge3S12 viewed along the [100] direction; (e) XRD patterns of Li4Cu8Ge3S12 before and after exposure in 15% moist air and a 2 M LiOH aqueous solution; (f) comparative Arrhenius plots show a minor change in conductivity and activation energy before and after exposure[42].

图 6 (a) 95%质量分数Li7P3S11硫化物固态电解质和5%质量分数的SEBS聚合物复合固态电解质的侧面扫描电子显微镜 (SEM) 图; (b) 100 mgLi7P3S11硫化物固态电解质在潮湿空气水解产生H2S气体量的检测装置; (c) 100 mg未复合和复合后的Li7P3S11硫化物固态电解质在定量体积潮湿空气中产生的H2S气体的量随暴露时间的变化图; (d) 100 mg未复合和复合后的Li7P3S11硫化物固态电解质随着去离子水中的涌入后的稳定性照片图[43]

Figure 6. (a) Cross-section SEM image of composite electrolyte film fabricated with 95 wt % Li7P3S11 and 5 wt % SEBS; (b) setup used for H2S gas measurements from 100 mg of Li7P3S11 hydrolysis in air; (c) H2S amount released vs time for fixed volume air exposed to 100 mg of bare Li7P3S11 and 100 mg of composite with hydrophobic SEBS polymer; (d) figures of bare Li7P3S11 and composite electrolyte film before and after flooding in water[43].

图 7 (a) LGPS固态电解质锂化和去锂化时的电势分布和相平衡的第一原理计算结果[45]; (b) Li/LGPS/LGPS-Pt/Pt半阻塞电极的循环伏安图, 扫描速率为0.1 mV·s–1, 电压范围为0−2.0和1.0−3.5 V[45]; (c) 原始LSPS及 (LSPS + 乙炔黑 (AB))复合材料在充电至4.2 V前、后的X-射线光电子能谱 (XPS) 谱图[53]

Figure 7. (a) The first principles calculation results of the voltage profile and phase equilibria of LGPS solid electrolyte upon lithiation and delithiation[45]; (b) cyclic voltammetry of Li/LGPS/LGPS‐Pt/Pt semiblocking electrode at a scan rate of 0.1 mV·s–1 in the voltage range of 0−2.0 and 1.0−3.5 V[45]; (c) X-ray photoelectron spectra of the pristine LSPS, (LSPS+Acetylene black (AB)) composite before and after charged to 4.2 V[53].

图 8 (a) 450, 460, 480和500 ℃退火的LSPS-Cl粉末的形貌和组成的微观结构, SEM和透射电子显微镜 (TEM) 图像显示退火的LSPS-Cl电解质具有典型的核壳结构, 扫描透射电子显微镜结合能谱分析 (STEM EDS) 分析表明, 随着退火温度的升高, 样品的壳中Si浓度不断降低, S浓度不断提高[61]; (b) 应变对LGPS电解质分解的影响机制示意图, 其中xD为LGPS分解的分数. 橙色虚线表示当施加的压力可以忽略时, 原始LGPS和任意一组分解产物(D) 二元组合的吉布斯自由能 (G0(xD)). 绿色实线表示将机械约束应用于LGPS时的吉布斯自由能曲线. 由于LGPS在分解时倾向于发生体积膨胀, 因此当施加这种机械约束时, 应变吉布斯自由能 (Gstrain) 增加. 在某个转折点 (表示为xf) 处, 系统的吉布斯自由能量超过了破坏机械约束所需的能量 (蓝色虚线). 突出显示的灰色路径为机械约束LGPS系统的基态. 如果∂xDG′ > 0, 则区域xD < xf是亚稳的[62]; (c) 在不同温度下退火的LSPS-Cl样品的循环伏安 (C-V) 曲线[61]

Figure 8. (a) Microstructural study on the morphology and composition of LSPS-Cl powders annealed at 450, 460, 480, and 500 ℃. SEM and TEM images show their typical core-shell structures. STEM EDS analyses of these samples show a continuously decreasing Si concentration and increasing S concentration in the shell of these samples versus the increasing annealing temperature[63]; (b) illustration of the impact of strain on LGPS decomposition, where xD is the fraction of LGPS that has decomposed. The dashed-orange line represents the Gibbs energy (G0(xD)) of a binary combination of pristine LGPS and an arbitrary set of decay products (D) when negligible pressure is applied. The solid-green line shows the Gibbs when a mechanical constraint is applied to the LGPS. Since LGPS tends to expand upon decomposition, the strain Gibbs (Gstrain) increases when such a mechanical constraint is applied. At some fracture point, denoted xf, the Gibbs energy of the system exceeds the energy needed to fracture the mechanical constraints (the dashed-blue line). The highlighted gray path is the suggested ground state for a mechanically constrained LGPS system. The region xD < xf is metastable if ∂xDG′ > 0[62]; (c) cyclic voltammetry (C-V) test and analyses of the LSPS-Cl samples annealed at various temperatures[63].

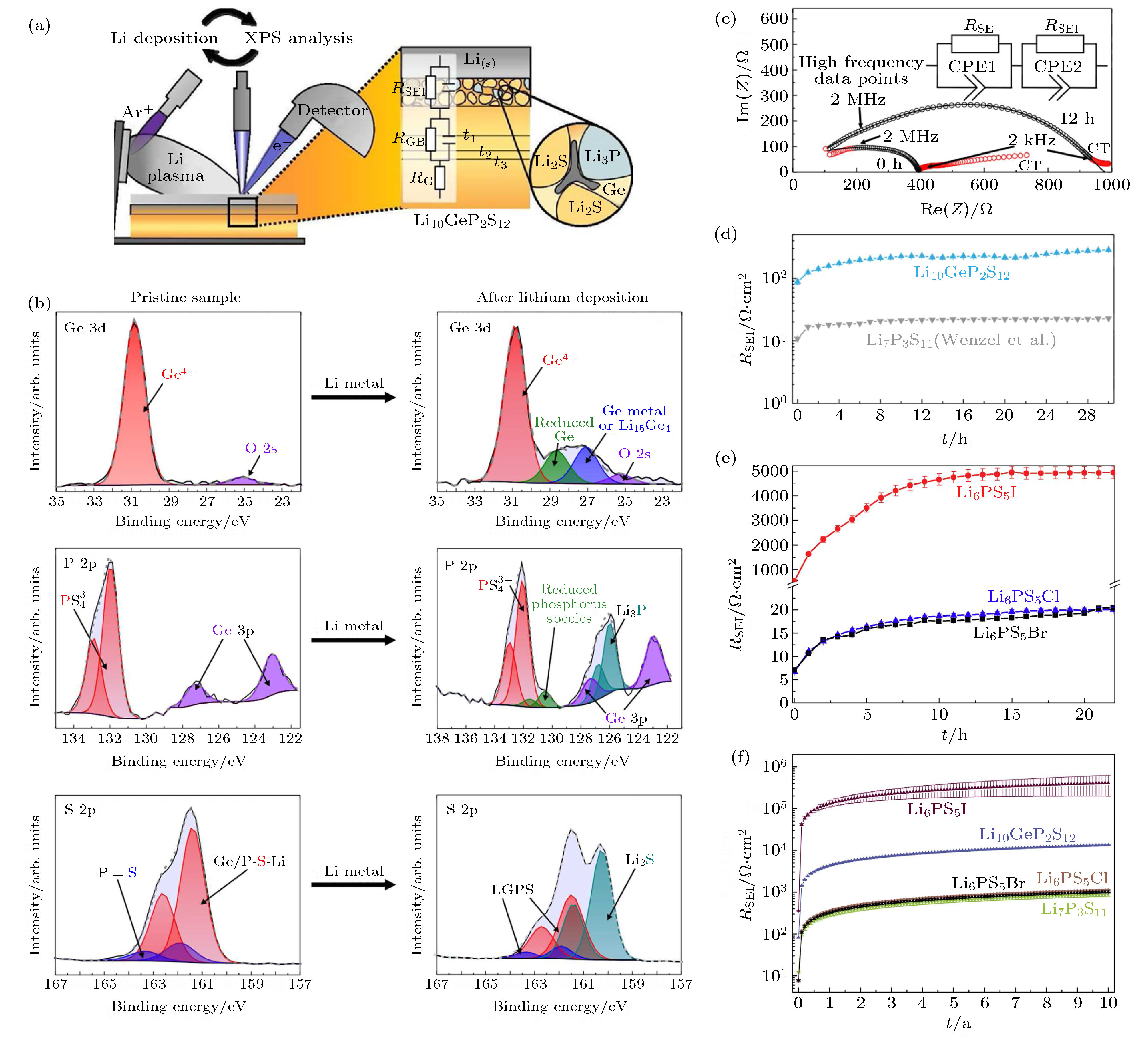

图 9 (a) 用于监测硫化物电解质与金属锂之间反应的原位XPS实验装置; (b) 原始LGPS样品以及沉积31 nm的锂金属后S 2p, Ge 3d和P 2p的XPS谱图和拟合结果. 拟合鉴定的物种以不同的颜色标记. 微弱的氧信号是由XPS腔室气氛中的微量的氧气引起的; (c) Li/LGPS/Li电池组装后 (0 h) 和组装后12 h的阻抗. 插图为用于拟合的等效电路, 拟合过程去除了红色数据点; (d) LGPS/Li与Li7P3S11/Li界面电阻增加的比较. 拟合的不确定性绘制为误差线, 通常明显小于5 Ω·cm2; (e) Li/Li6PS5X/Li电池组装后 (0 h) 和20 h后的界面电阻均增加情况. 在初始的快速增长后, 界面电阻的增加表现出渐近行为; (f) Li7P3S11, Li10GeP2S12, Li6PS5Cl, Li6PS5Br和Li6PS5I电解质10年内界面电阻的模拟结果. 误差线由拟合误差得出[24,76]

Figure 9. (a) Experimental setup of the in situ XPS experiment to monitor the reaction between sulfide and Li; (b) S 2p, Ge 3d, and P 2p XPS spectra and model fits for the pristine LGPS sample and after deposition of 31 nm Li metal. The identified species are marked and labeled in different colors. The small oxygen signal is caused by tiny fractions of oxygen in the atmosphere of the XPS chamber; (c) impedance of a Li/Li10GeP2S12/Li cell directly after assembly (0 h) and after 12 h. The equivalent circuit used as fit model is shown in the inset. Red data points were removed for the fitting process; (d) increase of the Li10GeP2S12/Li interphase resistance, in comparison to Li7P3S11/Li. The uncertainty of the fit is drawn as error bars, which are generally significantly smaller than 5 Ω·cm2; (e) the SEI resistance increase for Li/Li6PS5X/Li cells directly after assembly (0 h) and after 20 h. The increasing resistance appears to show asymptotic behavior after initial growth; (f) simulation of the SEI resistance over 10 years for Li7P3S11, Li10GeP2S12, Li6PS5Cl, Li6PS5Br and Li6PS5I. Error bars were derived from the fit errors[24,76].

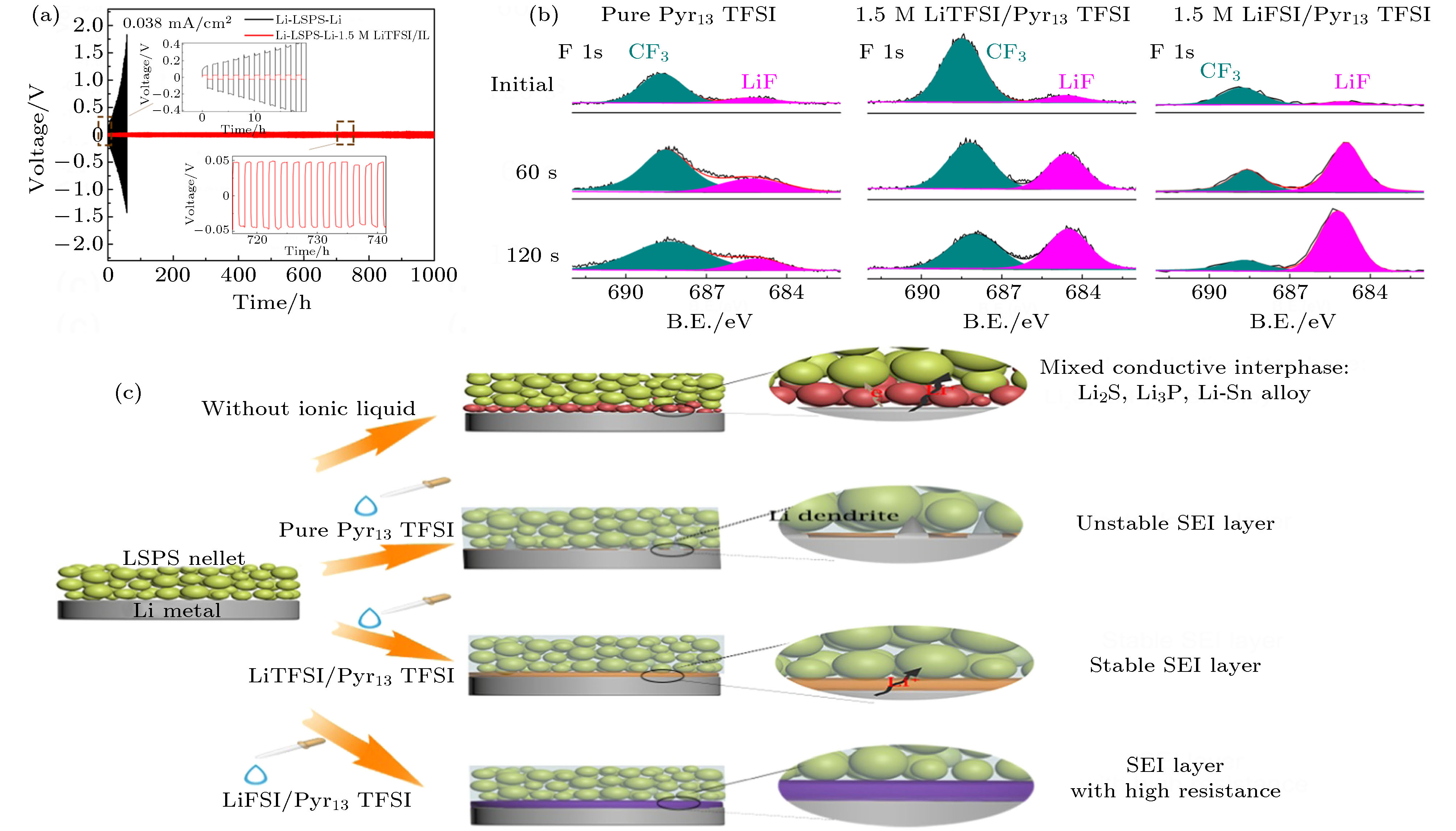

图 10 (a) 1.5 M LiTFSI/Pyr13TFSI离子液体修饰前后Li/LSPS/Li对称电池在0.038 mA·cm–2电流密度下的锂沉积-溶出曲线; (b) 加纯Pyr13TFSI离子液体修饰、1.5 M LiTFSI/Pyr13TFSI离子液体修饰和1.5 M LiTFSI/Pyr13TFSI离子液体修饰的Li/LSPS/Li对称电池循环140 h后Li金属不同刻蚀时间下的F 1s XPS谱图; (c)不同锂盐/Pyr13TFSI修饰界面的机理示意图[58]

Figure 10. (a) Li+ stripping/plating curves of Li/LSPS/Li symmetric cells with and without 1.5 M LiTFSI/IL at a current density of 0.038 mA cm–2 and the cycle performance of Li/LSPS/Li symmetric cell with 1.5 M LiTFSI/IL; (b) F 1s XPS spectra of Li metal at different etching times disassembled from (i) Li/(LSPS + pure Pyr13TFSI)/Li, (ii) Li/(LSPS + 1.5 M LiTFSI/Pyr13TFSI)/Li, and (iii) Li/(LSPS + 1.5 M LiFSI/Pyr13TFSI)/Li symmetric cells after cycling for 140 h; (c) schematic illustration of interfacial modification mechanism of different Li salt/Pyr13TFSI[58].

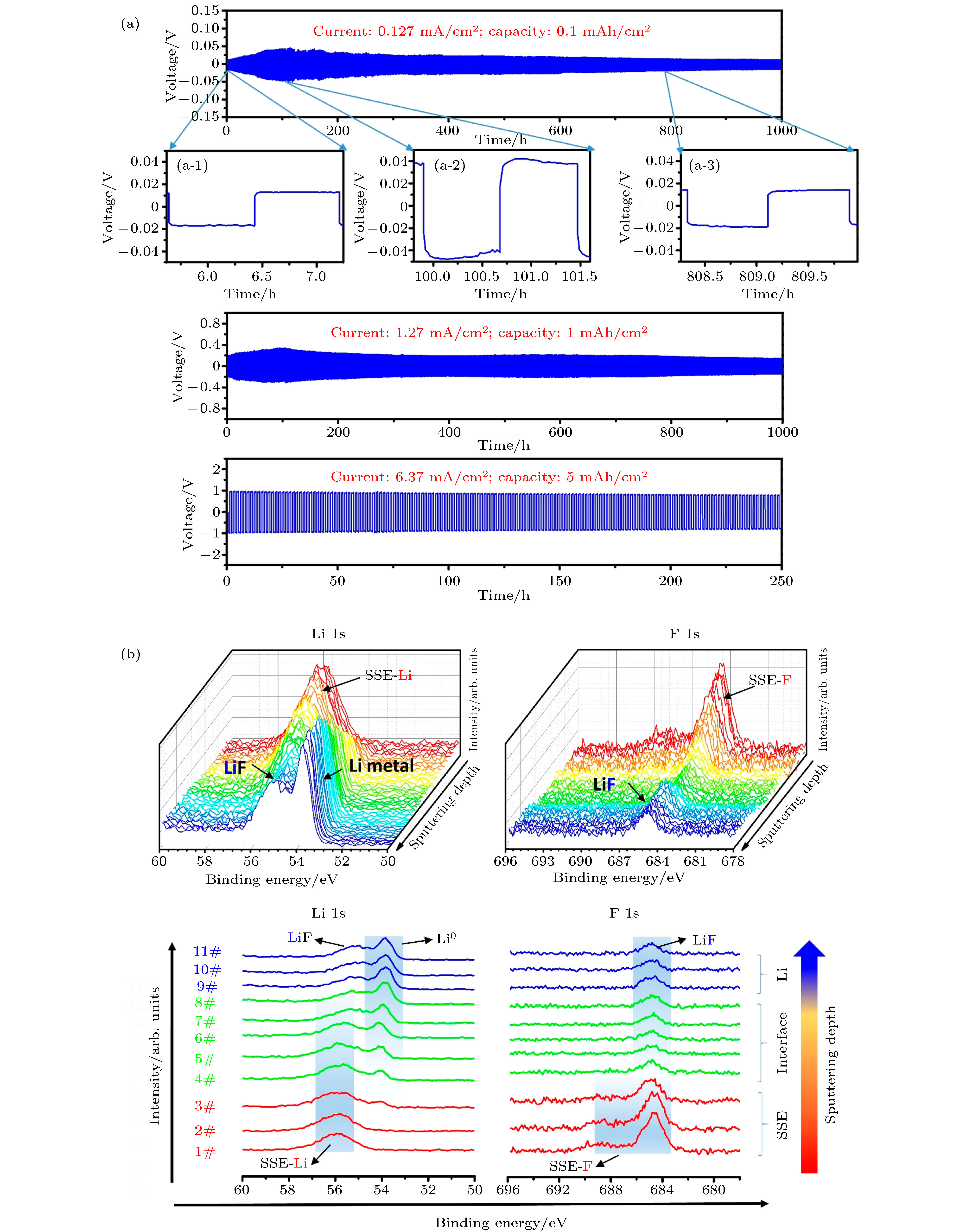

图 11 (a) Li/LPSCl0.3F0.7/Li对称电池中的锂沉积-溶出曲线; (b) Li金属/ LPSCl0.3F0.7固态电解质界面的XPS深度分析; Li/LPSCl0.3F0.7界面处Li 1s和F 1s XPS光谱随溅射深度的整体变化情况 (上面栏); 从上图提取的代表性Li 1s和F 1s XPS谱图[80]

Figure 11. (a) Li plating and stripping in Li/LPSCl0.3F0.7/Li symmetric cells; (b) XPS depth profiling analysis of the Li metal/SSE interface. Overall evolution of the Li 1s and F 1s spectra with sputtering depth at the Li/LPSCl0.3F0.7 interface. Representative Li 1s and F 1s XPS spectra extracted from the upper panel[80].

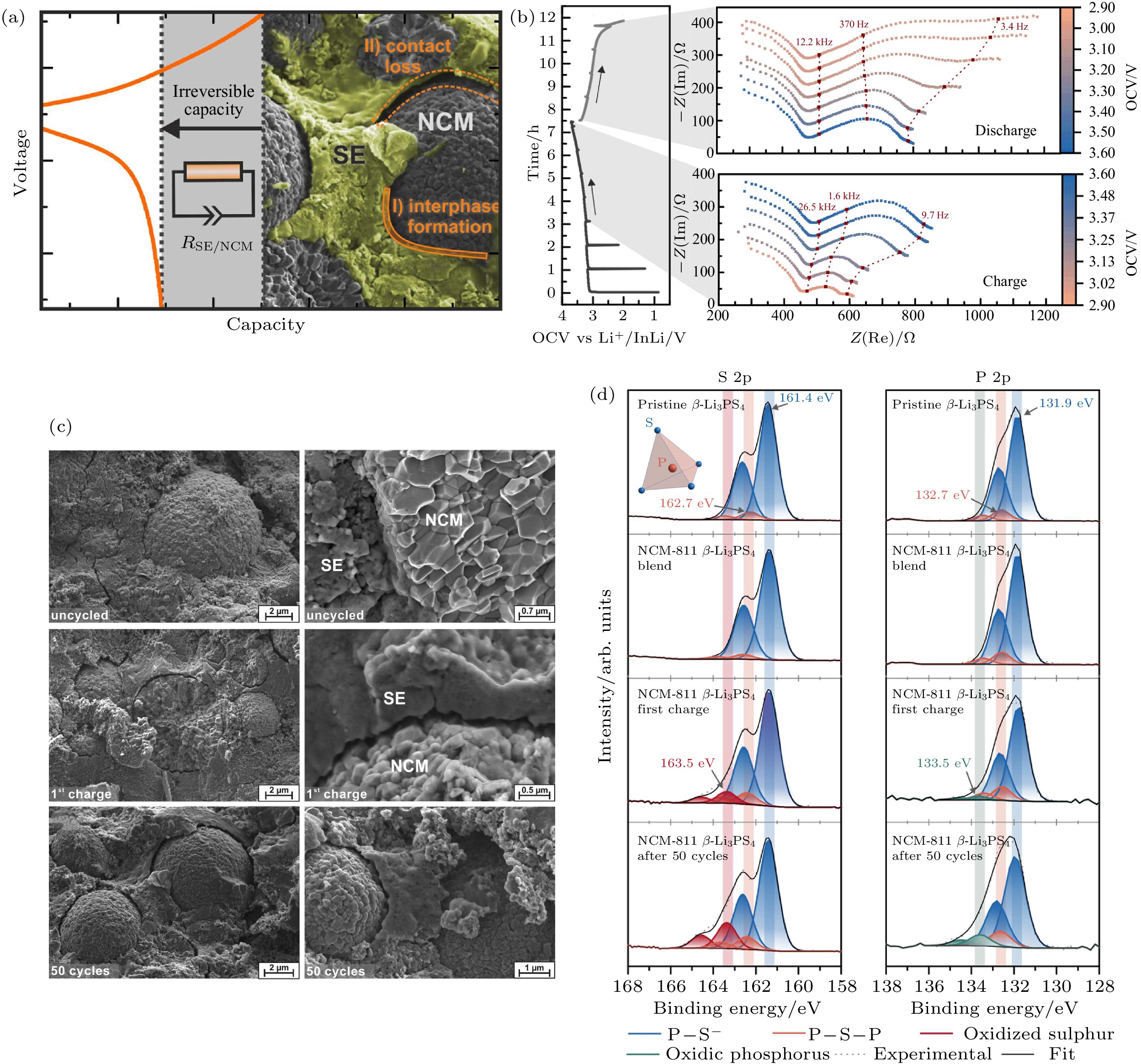

图 12 (a) LiNi0.8Co0.1Mn0.1O2 (NCM811)正极和β-Li3PS4固态电解质相间界面形成和化学机械过程的示意图; (b) Li–In|β-Li3PS4|NCM811/β-Li3PS4固态电池恒流充放电过程阻抗变化. 左图: 0.1 C下首次充放电曲线显示出与阻抗测量周期相对应的电流中断. 右: 充电期间和放电期间的阻抗谱, 分别在充电或放电1 h后进行测量, 红色点表示阻抗谱的选定频率; (c) Li–In|β-Li3PS4|NCM811/β-Li3PS4 固态电池复合正极中NCM811和β-Li3PS4的SEM图. 电池组装后未施加电流或电势的SEM图;电池在0.1 C下首次充电至4.3 V vs Li+/Li后的SEM图; 给定电池经过50个循环后, 在放电状态下的SEM图. NCM-811颗粒在脱锂 (充电) 过程中会收缩并失去与SE的接触. NCM形态在电解质上的残留痕迹表明, 活性材料和电解质之间最初紧密接触; (d) NCM811正极和β-Li3PS4固态电解质界面XPS表征. 原始β-Li3PS4; NCM811和β-Li3PS4的原始混合物, 不施加任何电流或电势; 首次充电后(0.1 C) 正极NCM811和β-Li3PS4复合残留; 50个循环后正极复合材料的S 2p和P 2p XPS谱图拟合结果. 蓝色峰归因于Pδ+—Sδ-键, 橙色峰与

${\rm{P}}_2{\rm{S}}_7^{4-}$ 单元中的P—S—P桥键相关, 红色和绿色峰归属于更高氧化态的硫和磷物种. 尽管在混合NCM811活性材料和β-Li3PS4电解质时未观察到明显的反应发生, 充电后的复合正极XPS谱图显示了硫代磷酸盐固态电解质的氧化现象[52]Figure 12. (a) Schematic illustration of interphase formation and chemomechanical processes in LiNi0.8Co0.1Mn0.1O2 cathode and β-Li3PS4 solid electrolytes; (b) impedance spectra recorded intermittently during galvanostatic battery cycling. Left: First cycle charge and discharge profile of a Li–In|β-Li3PS4|NCM811/β-Li3PS4 cell at 0.1 C showing current interruption corresponding to the periods of impedance measurement. Right: Impedance spectra during charge and discharge periods. Measurements were conducted after 1 h of charging or discharging, respectively. Red points indicate selected frequencies in the spectra; (c) scanning electron micrographs of the cathode composite of NCM811 and β-Li3PS4. As prepared in a solid-state cell but without the application of current or potential; SEM images of a Li–In | β-Li3PS4| NCM-811 /β-Li3PS4 cell after single charging to 4.3 V vs Li+/Li at 0.1 C; SEM images of a given cell after 50 full battery cycles in the discharged state. The NCM-811 particles shrink during delithiation (charge) and lose contact with the SE. The remaining imprint of the NCM morphology on the electrolyte shows the initially intimate contact between the active material and the electrolyte; (d) peak deconvolution of the S 2 p and P 2 p spectra of pristine β-Li3PS4 for the pristine mixture of NCM811 and β-Li3PS4 without any application of current or potential, the cathode composite of NCM811 and β-Li3PS4 after the first charge (0.1 C), and the cathode composite of NCM811 and β-Li3PS4 after 50 cycles. Blue peaks are attributed to equivalent Pδ+–Sδ– bonds. Orange peaks were correlated to bridged P–S–P in

${\rm{P}}_2{\rm{S}}_7^{4-} $ units. The red and green peaks are assigned to more oxidized sulfur and phosphorus species. While no reaction appears to take place just upon mixing the SE and the active material, the spectra of the charged cathodes show evidence for oxidation of the thiophosphate solid electrolyte[52].图 13 (a) CS-NCA@LiNbO3材料的结构示意图 (以LiNi0.85Co0.15O2为核心, LiNi0.6Co0.15Al0.25O2作为第一缓冲层, LiNbO3作为第二缓冲层); (b) CS-NCA@LiNbO3材料的高分辨透射电镜图像; (c) 在60 °C下循环2周后, 使用NCA, CS-NCA和CS-NCA@LiNbO3正极的全固态锂电池充电态的阻抗谱图. 阻抗测试在RT进行; (d) 使用NCA, CS-NCA和CS-NCA@LiNbO3正极的全固态锂电池中正极/电解质界面Li浓度分布的示意图; (e) 在60 °C下, 基于CS-NCA@LiNbO3正极的全固态锂电池的倍率性能和循环性能曲线. 惰性LiNbO3缓冲层的包覆量为1.37 wt%. 1 C = 200 mA·g–1[114]

Figure 13. (a) Illustration of the structure of CS-NCA@LiNbO3 (LiNi0.85Co0.15O2 as the core, LiNi0.6Co0.15Al0.25O2 as the first buffer layer and LiNbO3 as the second buffer layer); (b) HRTEM images of CS-NCA@LiNbO3 materials; (c) Nyquist plots of charged ASSLB using NCA, CS-NCA and CS-NCA@LiNbO3 cathodes after 2 cycles at 60 °C. EIS tests are conducted at RT; (d) schematic illustrations of the interfacial Li concentration distribution in ASSLB using NCA, CS-NCA and CS-NCA@LiNbO3 cathodes; (e) rate performance and cycle performance curves of CS-NCA@LiNbO3 cathodes in ASSLB at 60 °C. Coating amount of inactive LiNbO3 buffer layer is 1.37 wt.%. 1 C=200 mA·g–1[114].

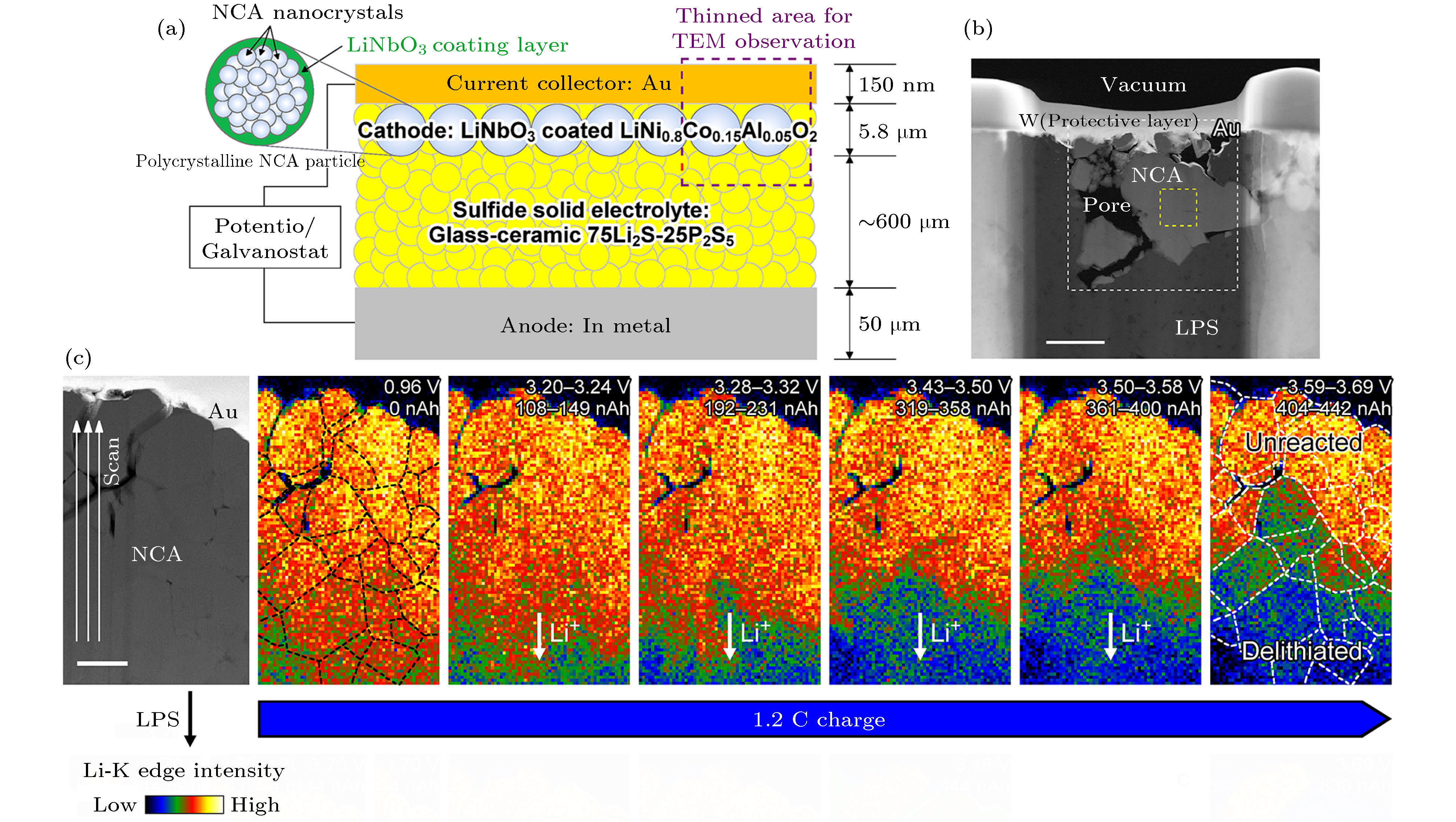

图 14 (a) 块体全固态电池示意图, 微米尺寸的多晶NCA正极是有很多堆积在一起的纳米晶组成, 紫色虚线矩形出显示用于TEM观察的减薄的区域; (b) NCA正极部分的ADF-STEM图像, 标尺是1 μm; (c) ADF-STEM图像和1.2 C充电下一系列不同状态下的NCA正极中的锂浓度分布图, 标尺是500 nm[119]

Figure 14. (a) Schematic diagram of the bulk-type SSLIB. NCA forms micrometer-sized polycrystalline particles composed of aggregated nanocrystals (top-left inset). The purple dashed rectangle shows the thinned area for TEM observation; (b) ADFSTEM image around the NCA cathodes. Scale bar: 1 μm; (c) ADF-STEM image and series of corresponding Liconcentration maps of NCA acquired during 1.2 C charging. Scale bar: 500 nm[119].

图 15 (a) 原位近边结构X射线吸收光谱法的基于硫化物固态电解质的全电池实验装置图; (b) 在大光子能量区域获得布拉格光谱图; (c) 未包覆的NCA811的原位S元素的K近边吸收谱及 (d) 相应的mapping图; (e) Ni元素的K近边吸收谱和充放电曲线, LiNbOx包覆的NMC811正极的原位; (f) S元素的K近边吸收谱及(g)相应的mapping图; (h) Ni元素的K近边吸收谱和充放电曲线[121]

Figure 15. Operando XANES study of SSLIBs with bare and LNO-coated NMC811 cathodes during cycling: (a) Schematic diagram of theoperando cell; (b) Bruker spectrum in a large photon energy region. Operando S K-edge spectra with first derivative mapping, Ni K-edge spectra, and charge/discharge profiles of (c)−(e) bare NMC811-LGPS and (f)−(h) LNO NMC811-LGPS SSLIBs[121].

图 16 (a) 正负电压扫描区间的NCM/Li6PS5Cl界面的原位拉曼光谱; (b), (c) 来自NCM/Li6PS5Cl界面在两个电压 (第一次正电压扫描时为3.6和3.7 V) 的归一化原位拉曼光谱的拟合结果; (d) 在正电压和负电压扫描期过程中, 两个拉曼峰在418和425 cm–1处的归一化峰面积百分比演变; (e), (f) 基于NCM/Li6PS5Cl界面

${\rm{PS}}_4^{3-}$ 的P-S键的不同振动状态在充放电过程中的界面演化示意图[93]Figure 16. (a) In situ Raman spectra at NCM/Li6PS5Cl interface during the positive and negative potential sweeps; (b), (c) examples of normalized peak fitting results from in situ Raman spectra at NCM/Li6PS5Cl interface at two voltages (3.6 and 3.7 V in the first positive potential sweep); (d) normalized peak area percentages evolutions of two Raman peaks at 418 and 425 cm–1 during the positive and negative potential sweeps; (e)−(h) schematic illustrations of interfacial evolution during the charge–discharge processes based on different vibration states of P-S bond in

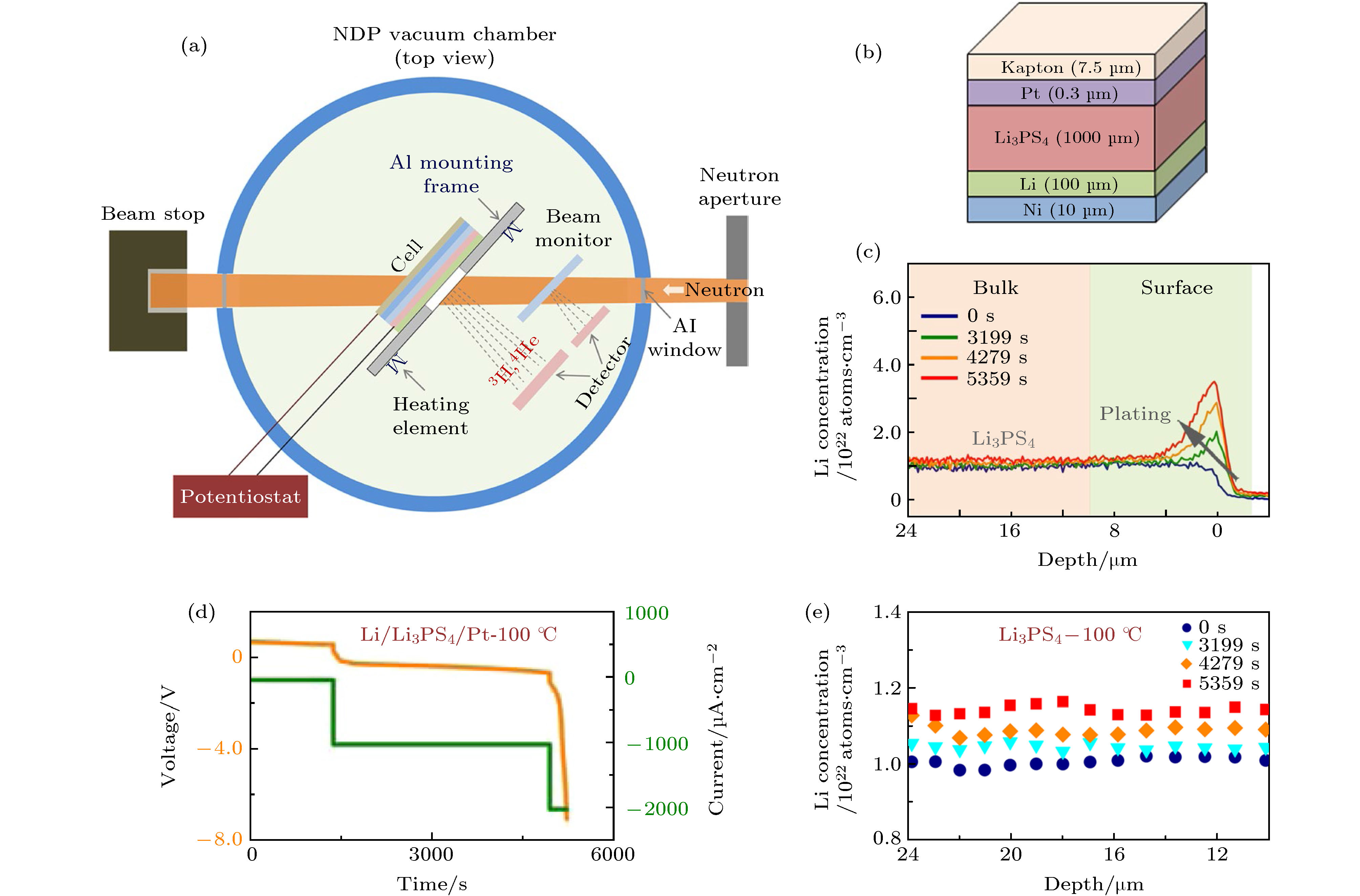

${\rm{PS}}_4^{3-} $ at NCM/Li6PS5Cl interface[93].图 17 (a) 电化学原位中子深度分析实验装置示意图; (b) Li/Li3PS4/Pt电池结构的示意图, Li沉积在Pt上, 在锂沉积过程中从电池的上表面开始进行深度剖析; (c) 在100 ℃下测试的Li/Li3PS4/Pt电池的时间分辨锂浓度曲线, 灰色箭头表示Li的连续沉积; (d) 在100 ℃下, Li/Li3PS4/Pt电池随着放电电流密度阶跃增大的电压-时间曲线; (e) 在100 ℃下锂沉积过程中, 不同时间Li3PS4中的锂浓度分布曲线[64]

Figure 17. (a) Schematic diagram of the experimental set-up for operando NDP; (b) schematic structures of Li/Li3PS4/Pt cells. Li is plated on Pt, and the depth profiles are measured from the top surfaces of the cells during plating; (c) time-resolved lithium concentration profiles for Li/Li3PS4/Pt cells tested at 100 ℃. The grey arrows indicate continuous plating of Li; (d) voltage–time curves of the Li/Li3PS4/Pt cells discharged with the magnitude of the current density increased step-wise at 100 ℃; (e) lithium concentration profiles in Li3PS4-100 ℃ at different times during lithium plating[64].

-

[1] Zheng Z, Wu H H, Liu H, Zhang Q, He X, Yu S, Petrova V, Feng J, Kostecki R, Liu P, Peng D L, Liu M, Wang M S 2020 ACS Nano 14 9545

Google Scholar

Google Scholar

[2] An W, Gao B, Mei S, Xiang B, Fu J, Wang L, Zhang Q, Chu P K, Huo K 2019 Nat. Commun. 10 1447

Google Scholar

Google Scholar

[3] Zheng Z, Li P, Huang J, Liu H, Zao Y, Hu Z, Zhang L, Chen H, Wang M S, Peng D L, Zhang Q 2020 J. Energy Chem. 41 126

Google Scholar

Google Scholar

[4] Zhang Q, Chen H, Luo L, Zhao B, Luo H, Han X, Wang J, Wang C, Yang Y, Zhu T, Liu M 2018 Energy Environ. Sci. 11 669

Google Scholar

Google Scholar

[5] Zhong S Y, Shi J, Luo W W, Lei X L 2019 Chin. Phys. B 28 078201

Google Scholar

Google Scholar

[6] Wang Y, Liu B N, Zhou G, Nie K H, Zhang J N, Yu X Q, Li H 2019 Chin. Phys. B 28 068202

Google Scholar

Google Scholar

[7] Wang H, Lan X, Huang Y, Jiang X 2019 Chin. Phys. Lett. 36 098201

Google Scholar

Google Scholar

[8] Jiang L W, Lu Y X, Wang Y S, Liu L L, Qi X G, Zhao C L, Chen L Q, Hu Y S 2018 Chin. Phys. Lett. 35 048801

Google Scholar

Google Scholar

[9] Chen R, Li Q, Yu X, Chen L, Li H 2020 Chem. Rev. 120 6820

Google Scholar

Google Scholar

[10] Banerjee A, Wang X, Fang C, Wu E A, Meng Y S 2020 Chem. Rev. 120 6878

Google Scholar

Google Scholar

[11] Wang C, Fu K, Kammampata S P, McOwen D W, Samson A J, Zhang L, Hitz G T, Nolan A M, Wachsman E D, Mo Y, Thangadurai V, Hu L 2020 Chem. Rev. 120 4257

Google Scholar

Google Scholar

[12] Xiao Y, Wang Y, Bo S H, Kim J C, Miara L J, Ceder G 2020 Nat. Rev. Mater. 5 105

Google Scholar

Google Scholar

[13] Liu L, Xu J, Wang S, Wu F, Li H, Chen L 2019 eTransportation 1 100010

Google Scholar

Google Scholar

[14] Zhao Q, Stalin S, Zhao C Z, Archer L A 2020 Nat. Rev. Mater. 5 229

Google Scholar

Google Scholar

[15] Xu J, Liu L, Yao N, Wu F, Li H, Chen L 2019 Mater. Today Nano 8 100048

Google Scholar

Google Scholar

[16] Wang H, An H, Shan H, Zhao L, Wang J 2020 Acta Phys. Chim. Sin. 36 2007070

Google Scholar

Google Scholar

[17] Jin F, Li J, Hu C, Dong H, Chen P, Shen Y, Chen L 2019 Acta Phys. Chim. Sin. 35 1399

Google Scholar

Google Scholar

[18] Minami K, Mizuno F, Hayashi A, Tatsumisago M 2007 Solid State Ionics 178 837

Google Scholar

Google Scholar

[19] Tachez M, Malugani J P, Mercier R, Robert G 1984 Solid State Ionics 14 181

Google Scholar

Google Scholar

[20] Kamaya N, Homma K, Yamakawa Y, Hirayama M, Kanno R, Yonemura M, Kamiyama T, Kato Y, Hama S, Kawamoto K, Mitsui A 2011 Nat. Mater. 10 682

Google Scholar

Google Scholar

[21] Kanno R, Murayama M 2001 J. Electrochem. Soc. 148 A742

Google Scholar

Google Scholar

[22] Kato Y, Hori S, Saito T, Suzuki K, Hirayama M, Mitsui A, Yonemura M, Iba H, Kanno R 2016 Nat. Energy 1 16030

Google Scholar

Google Scholar

[23] Deiseroth H J, Kong S T, Eckert H, Vannahme J, Reiner C, Zaiss T, Schlosser M 2008 Angew. Chem. Int. Ed. 47 755

Google Scholar

Google Scholar

[24] Wenzel S, Randau S, Leichtweiß T, Weber D A, Sann J, Zeier W G, Janek J 2016 Chem. Mater. 28 2400

Google Scholar

Google Scholar

[25] Culver S P, Koerver R, Zeier W G, Janek J 2019 Adv. Energy Mater. 9 1900626

Google Scholar

Google Scholar

[26] Lian P J, Zhao B S, Zhang L Q, Xu N, Wu M T, Gao X P 2019 J. Mater. Chem. A 7 20540

Google Scholar

Google Scholar

[27] Yang W, Tufail M K, Zhou L, Lü L, Chen R, Yang L 2020 Sci. Sin. Chim. 50 1031

Google Scholar

Google Scholar

[28] Muramatsu H, Hayashi A, Ohtomo T, Hama S, Tatsumisago M 2011 Solid State Ionics 182 116

Google Scholar

Google Scholar

[29] Kim J S, Jeon M, Kim S, Lee J H, Kim B K, Kim H 2020 Solid State Ionics 346 115225

Google Scholar

Google Scholar

[30] Sahu G, Lin Z, Li J, Liu Z, Dudney N, Liang C 2014 Energy Environ. Sci. 7 1053

Google Scholar

Google Scholar

[31] Liang J, Chen N, Li X, Li X, Adair K R, Li J, Wang C, Yu C, Norouzi Banis M, Zhang L, Zhao S, Lu S, Huang H, Li R, Huang Y, Sun X 2020 Chem. Mater. 32 2664

Google Scholar

Google Scholar

[32] Zhu Y, Mo Y 2020 Angew. Chem. Int. Ed. 59 17472

Google Scholar

Google Scholar

[33] Ohtomo T, Hayashi A, Tatsumisago M, Kawamoto K 2013 J. Solid State Electrochem. 17 2551

Google Scholar

Google Scholar

[34] Liu G, Xie D, Wang X, Yao X, Chen S, Xiao R, Li H, Xu X 2019 Energy Storage Mater. 17 266

Google Scholar

Google Scholar

[35] Hayashi A, Muramatsu H, Ohtomo T, Hama S, Tatsumisago M 2013 J. Mater. Chem. A 1 6320

Google Scholar

Google Scholar

[36] Hayashi A, Muramatsu H, Ohtomo T, Hama S, Tatsumisago M 2014 J Alloys Compd. 591 247

Google Scholar

Google Scholar

[37] Brant J A, Massi D M, Holzwarth N A W, MacNeil J H, Douvalis A P, Bakas T, Martin S W, Gross M D, Aitken J A 2014 Chem. Mater. 27 189

Google Scholar

Google Scholar

[38] Park K H, Oh D Y, Choi Y E, Nam Y J, Han L, Kim J Y, Xin H, Lin F, Oh S M, Jung Y S 2016 Adv. Mater. 28 1874

Google Scholar

Google Scholar

[39] Kimura T, Kato A, Hotehama C, Sakuda A, Hayashi A, Tatsumisago M 2019 Solid State Ionics 333 45

Google Scholar

Google Scholar

[40] Zhang Z, Zhang J, Sun Y, Jia H, Peng L, Zhang Y, Xie J 2020 J. Energy Chem. 41 171

Google Scholar

Google Scholar

[41] Zhao F, Liang J, Yu C, Sun Q, Li X, Adair K, Wang C, Zhao Y, Zhang S, Li W, Deng S, Li R, Huang Y, Huang H, Zhang L, Zhao S, Lu S, Sun X 2020 Adv. Energy Mater. 10 1903422

Google Scholar

Google Scholar

[42] Wang Y, Lü X, Zheng C, Liu X, Chen Z, Yang W, Lin J, Huang F 2019 Angew. Chem. Int. Ed. 58 7673

Google Scholar

Google Scholar

[43] Tan D H S, Banerjee A, Deng Z, Wu E A, Nguyen H, Doux J M, Wang X, Cheng J H, Ong S P, Meng Y S, Chen Z 2019 ACS Appl. Energy Mater. 2 6542

Google Scholar

Google Scholar

[44] Zhu Y, He X, Mo Y 2015 ACS Appl. Mater. Interfaces 7 23685

Google Scholar

Google Scholar

[45] Han F, Zhu Y, He X, Mo Y, Wang C 2016 Adv. Energy Mater. 6 1501590

Google Scholar

Google Scholar

[46] Sang L, Haasch R T, Gewirth A A, Nuzzo R G 2017 Chem. Mater. 29 3029

Google Scholar

Google Scholar

[47] Richards W D, Miara L J, Wang Y, Kim J C, Ceder G 2016 Chem. Mater. 28 266

Google Scholar

Google Scholar

[48] Wenzel S, Leichtweiss T, Krüger D, Sann J, Janek J 2015 Solid State Ionics 278 98

Google Scholar

Google Scholar

[49] Woo J H, Trevey J E, Cavanagh A S, Choi Y S, Kim S C, George S M, Oh K H, Lee S H 2012 J. Electrochem. Soc. 159 A1120

Google Scholar

Google Scholar

[50] Takada K, Ohta N, Zhang L, Xu X, Hang B T, Ohnishi T, Osada M, Sasaki T 2012 Solid State Ionics 225 594

Google Scholar

Google Scholar

[51] Jung S K, Gwon H, Lee S S, Kim H, Lee J C, Chung J G, Park S Y, Aihara Y, Im D 2019 J. Mater. Chem. A 7 22967

Google Scholar

Google Scholar

[52] Koerver R, Aygün I, Leichtweiß T, Dietrich C, Zhang W, Binder J O, Hartmann P, Zeier W G, Janek J 2017 Chem. Mater. 29 5574

Google Scholar

Google Scholar

[53] Zheng B Z, Liu X S, Zhu J P, Zhao J, Zhong G M, Xiang Y X, Wang H C, Zhao W M, Umeshbabu E, Wu Q H, Huang J Y, Yang Y 2020 Nano Energy 67 104252

Google Scholar

Google Scholar

[54] Wu X, Villevieille C, Novák P, El Kazzi M 2018 Phys. Chem. Chem. Phys. 20 11123

Google Scholar

Google Scholar

[55] Ohta N, Takada K, Sakaguchi I, Zhang L, Ma R, Fukuda K, Osada M, Sasaki T 2007 Electrochem. Commun. 9 1486

Google Scholar

Google Scholar

[56] Ohta N, Takada K, Zhang L, Ma R, Osada M, Sasaki T 2006 Adv. Mater. 18 2226

Google Scholar

Google Scholar

[57] Fan X, Ji X, Han F, Yue J, Chen J, Chen L, Deng T, Jiang J, Wang C 2018 Sci. Adv. 4 eaau9245

Google Scholar

Google Scholar

[58] Zheng B Z, Zhu J P, Wang H C, Feng M, Umeshbabu E, Li Y X, Wu Q H, Yang Y 2018 ACS Appl. Mater. Interfaces 10 25473

Google Scholar

Google Scholar

[59] Zhang Q, Cao D, Ma Y, Natan A, Aurora P, Zhu H 2019 Adv. Mater. 31 1901131

Google Scholar

Google Scholar

[60] Culver S P, Koerver R, Zeier W G, Janek J 2019 Advanced Energy Materials 9 1900626

[61] Wu F, Fitzhugh W, Ye L, Ning J, Li X 2018 Nat. Commun. 9 4037

Google Scholar

Google Scholar

[62] Fitzhugh W, Wu F, Ye L, Su H, Li X 2019 Small 15 1901470

Google Scholar

Google Scholar

[63] Li X, Sun Q, Wang Z, Song D, Zhang H, Shi X, Li C, Zhang L, Zhu L 2020 J. Power Sources 456 227997

Google Scholar

Google Scholar

[64] Han F, Westover A S, Yue J, Fan X, Wang F, Chi M, Leonard D N, Dudney N, Wang H, Wang C 2019 Nat. Energy 4 187

Google Scholar

Google Scholar

[65] Nagao M, Hayashi A, Tatsumisago M, Kanetsuku T, Tsuda T, Kuwabata S 2013 Phys. Chem. Chem. Phys. 15 18600

Google Scholar

Google Scholar

[66] Ma J, Chen B, Wang L, Cui G 2018 J. Power Sources 392 94

Google Scholar

Google Scholar

[67] Gao Y, Wang D, Li Y C, Yu Z, Mallouk T E, Wang D 2018 Angew. Chem. Int. Ed. 57 13608

Google Scholar

Google Scholar

[68] Zhang Z, Chen S, Yang J, Wang J, Yao L, Yao X, Cui P, Xu X 2018 ACS Appl. Mater. Interfaces 10 2556

Google Scholar

Google Scholar

[69] Garcia-Mendez R, Mizuno F, Zhang R, Arthur T S, Sakamoto J 2017 Electrochim. Acta 237 144

Google Scholar

Google Scholar

[70] Porz L, Swamy T, Sheldon B W, Rettenwander D, Frömling T, Thaman H L, Berendts S, Uecker R, Carter W C, Chiang Y M 2017 Adv. Energy Mater. 7 1701003

Google Scholar

Google Scholar

[71] Han F, Yue J, Zhu X, Wang C 2018 Adv. Energy Mater. 8 1703644

Google Scholar

Google Scholar

[72] Schlenker R, Stepien D, Koch P, Hupfer T, Indris S, Roling B, Miss V, Fuchs A, Wilhelmi M, Ehrenberg H 2020 ACS Appl. Mater. Interfaces 12 20012

Google Scholar

Google Scholar

[73] Kasemchainan J, Zekoll S, Jolly D S, Ning Z Y, Hartley G O, Marrow J, Bruce P G 2019 Nat. Mater. 18 1105

Google Scholar

Google Scholar

[74] Ong S P, Mo Y, Richards W D, Miara L, Lee H S, Ceder G 2013 Energy Environ. Sci. 6 148

Google Scholar

Google Scholar

[75] Wenzel S, Weber D A, Leichtweiss T, Busche M R, Sann J, Janek J 2016 Solid State Ionics 286 24

Google Scholar

Google Scholar

[76] Wenzel S, Sedlmaier S J, Dietrich C, Zeier W G, Janek J 2018 Solid State Ionics 318 102

Google Scholar

Google Scholar

[77] Yao X, Huang N, Han F, Zhang Q, Wan H, Mwizerwa J P, Wang C, Xu X 2017 Adv. Energy Mater. 7 1602923

Google Scholar

Google Scholar

[78] Chen T, Zhang L, Zhang Z X, Li P, Wang H Q, Yu C, Yan X L, Wang L M, Xu B 2019 ACS Appl. Mater. Interfaces 11 40808

Google Scholar

Google Scholar

[79] Tao Y, Chen S, Liu D, Peng G, Yao X, Xu X 2015 J. Electrochem. Soc. 163 A96

Google Scholar

Google Scholar

[80] Zhao F P, Sun Q, Yu C, Zhang S M, Adair K, Wang S Z, Liu Y L, Zhao Y, Liang J W, Wang C H, Li X N, Li X, Xia W, Li R Y, Huang H, Zhang L, Zhao S Q, Lu S G, Sun X L 2020 ACS Energy Lett. 5 1035

Google Scholar

Google Scholar

[81] Xu R, Han F, Ji X, Fan X, Tu J, Wang C 2018 Nano Energy 53 958

Google Scholar

Google Scholar

[82] Liang J, Li X, Zhao Y, Goncharova L V, Li W, Adair K R, Banis M N, Hu Y, Sham T K, Huang H, Zhang L, Zhao S, Lu S, Li R, Sun X 2019 Adv. Energy Mater. 9 1902125

Google Scholar

Google Scholar

[83] Wang C, Zhao Y, Sun Q, Li X, Liu Y, Liang J, Li X, Lin X, Li R, Adair K R, Zhang L, Yang R, Lu S, Sun X 2018 Nano Energy 53 168

Google Scholar

Google Scholar

[84] Davis A L, Garcia-Mendez R, Wood K N, Kazyak E, Chen K H, Teeter G, Sakamoto J, Dasgupta N P 2020 J. Mater. Chem. A 8 6291

Google Scholar

Google Scholar

[85] Sang L, Bassett K L, Castro F C, Young M J, Chen L, Haasch R T, Elam J W, Dravid V P, Nuzzo R G, Gewirth A A 2018 Chem. Mater. 30 8747

Google Scholar

Google Scholar

[86] LePage W S, Chen Y, Kazyak E, Chen K H, Sanchez A J, Poli A, Arruda E M, Thouless M D, Dasgupta N P 2019 J. Electrochem. Soc. 166 A89

Google Scholar

Google Scholar

[87] Wang C, Adair K R, Liang J, Li X, Sun Y, Li X, Wang J, Sun Q, Zhao F, Lin X, Li R, Huang H, Zhang L, Yang R, Lu S, Sun X 2019 Adv. Funct. Mater. 29 1900392

Google Scholar

Google Scholar

[88] Lee Y G, Fujiki S, Jung C, Suzuki N, Yashiro N, Omoda R, Ko D S, Shiratsuchi T, Sugimoto T, Ryu S, Ku J H, Watanabe T, Park Y, Aihara Y, Im D, Han I T 2020 Nat. Energy 5 299

Google Scholar

Google Scholar

[89] Haruyama J, Sodeyama K, Han L, Takada K, Tateyama Y 2014 Chem. Mater. 26 4248

Google Scholar

Google Scholar

[90] Takada K 2013 Langmuir 29 7538

Google Scholar

Google Scholar

[91] Chen S, Xie D, Liu G, Mwizerwa J P, Zhang Q, Zhao Y, Xu X, Yao X 2018 Energy Storage Mater. 14 58

Google Scholar

Google Scholar

[92] Otoyama M, Ito Y, Hayashi A, Tatsumisago M 2016 J. Power Sources 302 419

Google Scholar

Google Scholar

[93] Zhang J, Zheng C, Li L, Xia Y, Huang H, Gan Y, Liang C, He X, Tao X, Zhang W 2020 Adv. Energy Mater. 10 1903311

Google Scholar

Google Scholar

[94] Auvergniot J, Cassel A, Ledeuil J B, Viallet V, Seznec V, Dedryvère R 2017 Chem. Mater. 29 3883

Google Scholar

Google Scholar

[95] Zhang W, Richter F H, Culver S P, Leichtweiss T, Lozano J G, Dietrich C, Bruce P G, Zeier W G, Janek J 2018 ACS Appl. Mater. Interfaces 10 22226

Google Scholar

Google Scholar

[96] Yang J, Huang B, Yin J, Yao X, Peng G, Zhou J, Xu X 2016 J. Electrochem. Soc. 163 A1530

Google Scholar

Google Scholar

[97] Park K H, Oh D Y, Choi Y E, Nam Y J, Han L, Kim J Y, Xin H, Lin F, Oh S M, Jung Y S 2016 Advanced Materials 28 1874

[98] Park K H, Bai Q, Kim D H, Oh D Y, Zhu Y, Mo Y, Jung Y S 2018 Adv. Energy Mater. 8 1800035

Google Scholar

Google Scholar

[99] Li X, Jin L, Song D, Zhang H, Shi X, Wang Z, Zhang L, Zhu L 2020 J. Energy Chem. 40 39

Google Scholar

Google Scholar

[100] Kitaura H, Hayashi A, Tadanaga K, Tatsumisago M 2011 Solid State Ionics 192 304

Google Scholar

Google Scholar

[101] Takada K, Ohta N, Zhang L, Fukuda K, Sakaguchi I, Ma R, Osada M, Sasaki T 2008 Solid State Ionics 179 1333

Google Scholar

Google Scholar

[102] Sakuda A, Hayashi A, Tatsumisago M 2010 Chem. Mater. 22 949

Google Scholar

Google Scholar

[103] Sakuda A, Kitaura H, Hayashi A, Tadanaga K, Tatsumisago M 2008 Electrochem. Solid-State Lett. 11 A1

Google Scholar

Google Scholar

[104] Jin Y, Li N, Chen C H, Wei S Q 2006 Electrochem. Solid-State Lett. 9 A273

Google Scholar

Google Scholar

[105] Machida N, Kashiwagi J, Naito M, Shigematsu T 2012 Solid State Ionics 225 354

Google Scholar

Google Scholar

[106] Woo J H, Travis J J, George S M, Lee S H 2014 J. Electrochem. Soc. 162 A344

Google Scholar

Google Scholar

[107] Jung S H, Oh K, Nam Y J, Oh D Y, Bruener P, Kang K, Jung Y S 2018 Chem. Mater. 30 8190

Google Scholar

Google Scholar

[108] Zhang N, Ding F, Yu S, Zhu K, Li H, Zhang W, Liu X, Xu Q 2019 ACS Appl. Mater. Interfaces 11 27897

Google Scholar

Google Scholar

[109] Wang C, Li X, Zhao Y, Banis M N, Liang J, Li X, Sun Y, Adair K R, Sun Q, Liu Y, Zhao F, Deng S, Lin X, Li R, Hu Y, Sham T K, Huang H, Zhang L, Yang R, Lu S, Sun X 2019 Small Methods 3 1900261

Google Scholar

Google Scholar

[110] Banerjee A, Tang H, Wang X, Cheng J H, Nguyen H, Zhang M, Tan D H S, Wynn T A, Wu E A, Doux J M, Wu T, Ma L, Sterbinsky G E, D’Souza M S, Ong S P, Meng Y S 2019 ACS Appl. Mater. Interfaces 11 43138

Google Scholar

Google Scholar

[111] Jung S H, Kim U H, Kim J H, Jun S, Yoon C S, Jung Y S, Sun Y K 2020 Adv. Energy Mater. 10 1903360

Google Scholar

Google Scholar

[112] Deng S, Li X, Ren Z, Li W, Luo J, Liang J, Liang J, Banis M N, Li M, Zhao Y, Li X, Wang C, Sun Y, Sun Q, Li R, Hu Y, Huang H, Zhang L, Lu S, Luo J, Sun X 2020 Energy Storage Mater. 27 117

Google Scholar

Google Scholar

[113] Wang C, Liang J, Hwang S, Li X, Zhao Y, Adair K, Zhao C, Li X, Deng S, Lin X, Yang X, Li R, Huang H, Zhang L, Lu S, Su D, Sun X 2020 Nano Energy 72 104686

Google Scholar

Google Scholar

[114] Li X, Liang M, Sheng J, Song D, Zhang H, Shi X, Zhang L 2019 Energy Storage Mater. 18 100

Google Scholar

Google Scholar

[115] Lu J, Wu T, Amine K 2017 Nat. Energy 2 17011

Google Scholar

Google Scholar

[116] Yuan Y, Amine K, Lu J, Shahbazian-Yassar R 2017 Nat. Commun. 8 15806

Google Scholar

Google Scholar

[117] Xiang Y, Li X, Cheng Y, Sun X, Yang Y 2020 Mater. Today 36 139

Google Scholar

Google Scholar

[118] Boebinger M G, Lewis J A, Sandoval S E, McDowell M T 2020 ACS Energy Lett. 5 335

Google Scholar

Google Scholar

[119] Nomura Y, Yamamoto K, Hirayama T, Igaki E, Saitoh K 2020 ACS Energy Lett. 5 2098

Google Scholar

Google Scholar

[120] Wang C, Li X, Zhao Y, Banis M N, Liang J, Li X, Sun Y, Adair K R, Sun Q, Liu Y, Zhao F, Deng S, Lin X, Li R, Hu Y, Sham T K, Huang H, Zhang L, Yang R, Lu S, Sun X 2019 Small Method. 3 1900261

[121] Li X, Ren Z, Norouzi Banis M, Deng S, Zhao Y, Sun Q, Wang C, Yang X, Li W, Liang J, Li X, Sun Y, Adair K, Li R, Hu Y, Sham T K, Huang H, Zhang L, Lu S, Luo J, Sun X 2019 ACS Energy Lett. 4 2480

Google Scholar

Google Scholar

[122] Yamamoto K, Iriyama Y, Hirayama T 2017 Microscopy 66 50

Google Scholar

Google Scholar

[123] Masuda H, Ishida N, Ogata Y, Ito D, Fujita D 2017 Nanoscale 9 893

Google Scholar

Google Scholar

[124] Koerver R, Walther F, Aygün I, Sann J, Dietrich C, Zeier W G, Janek J 2017 J. Mater. Chem. A 5 22750

Google Scholar

Google Scholar

[125] Chien P H, Feng X, Tang M, Rosenberg J T, O’Neill S, Zheng J, Grant S C, Hu Y Y 2018 J. Phys.Chem. Lett. 9 1990

Google Scholar

Google Scholar

[126] Wang C, Gong Y, Dai J, Zhang L, Xie H, Pastel G, Liu B, Wachsman E, Wang H, Hu L 2017 J. Am. Chem. Soc. 139 14257

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 34148

- PDF Downloads: 1255

- Cited By: 0

DownLoad:

DownLoad: