-

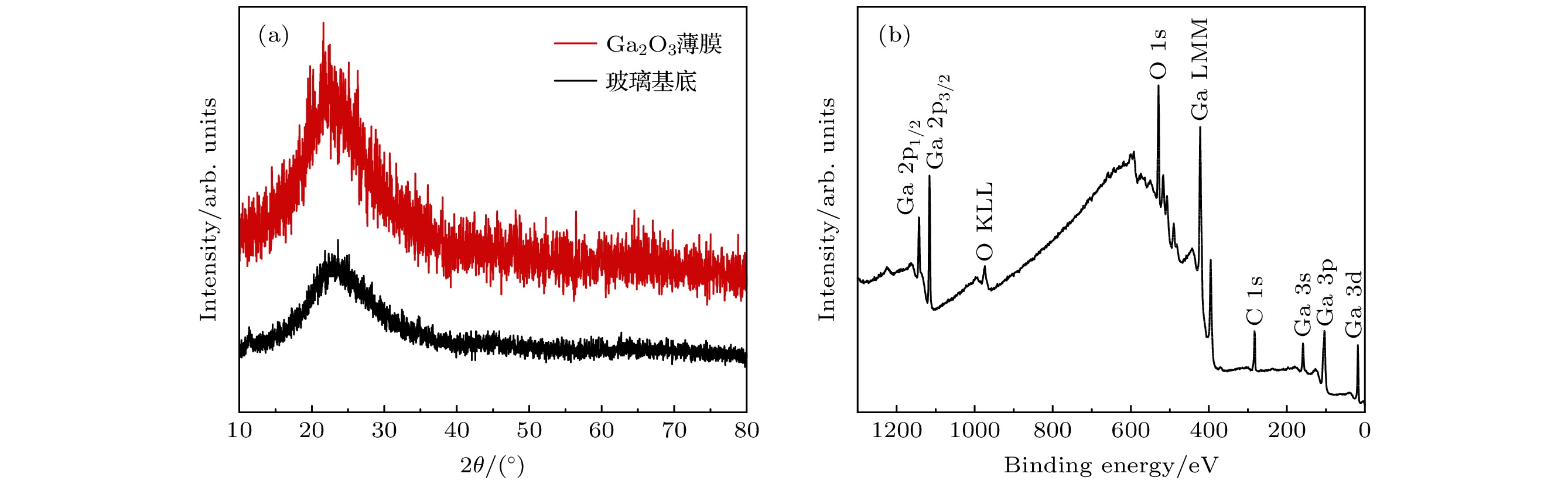

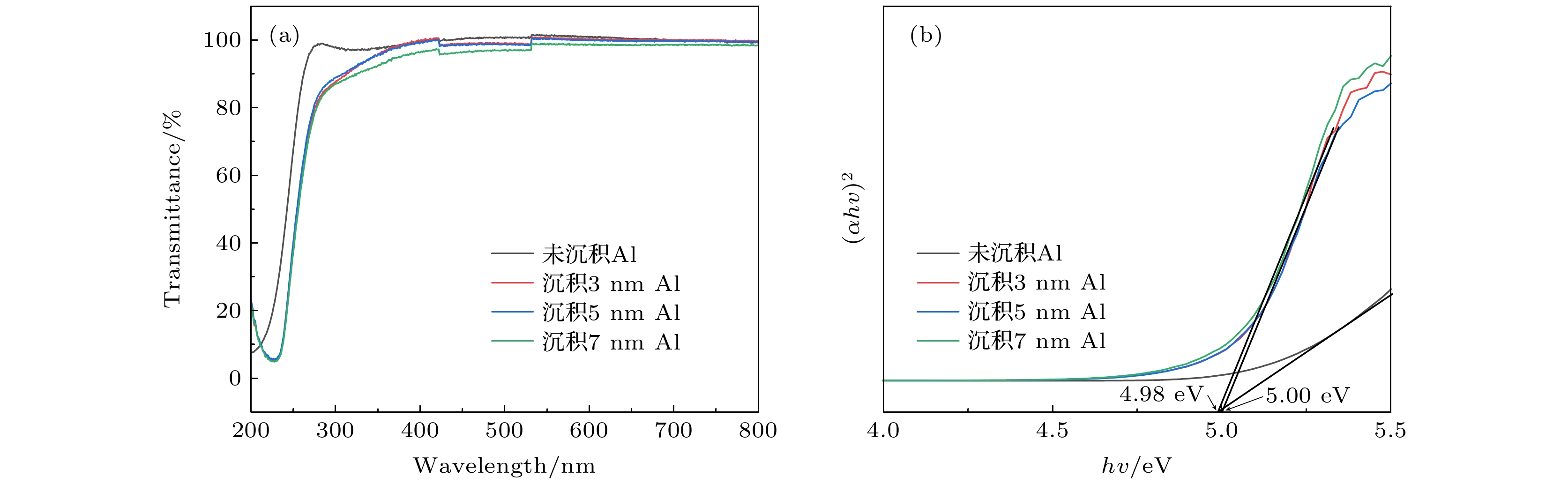

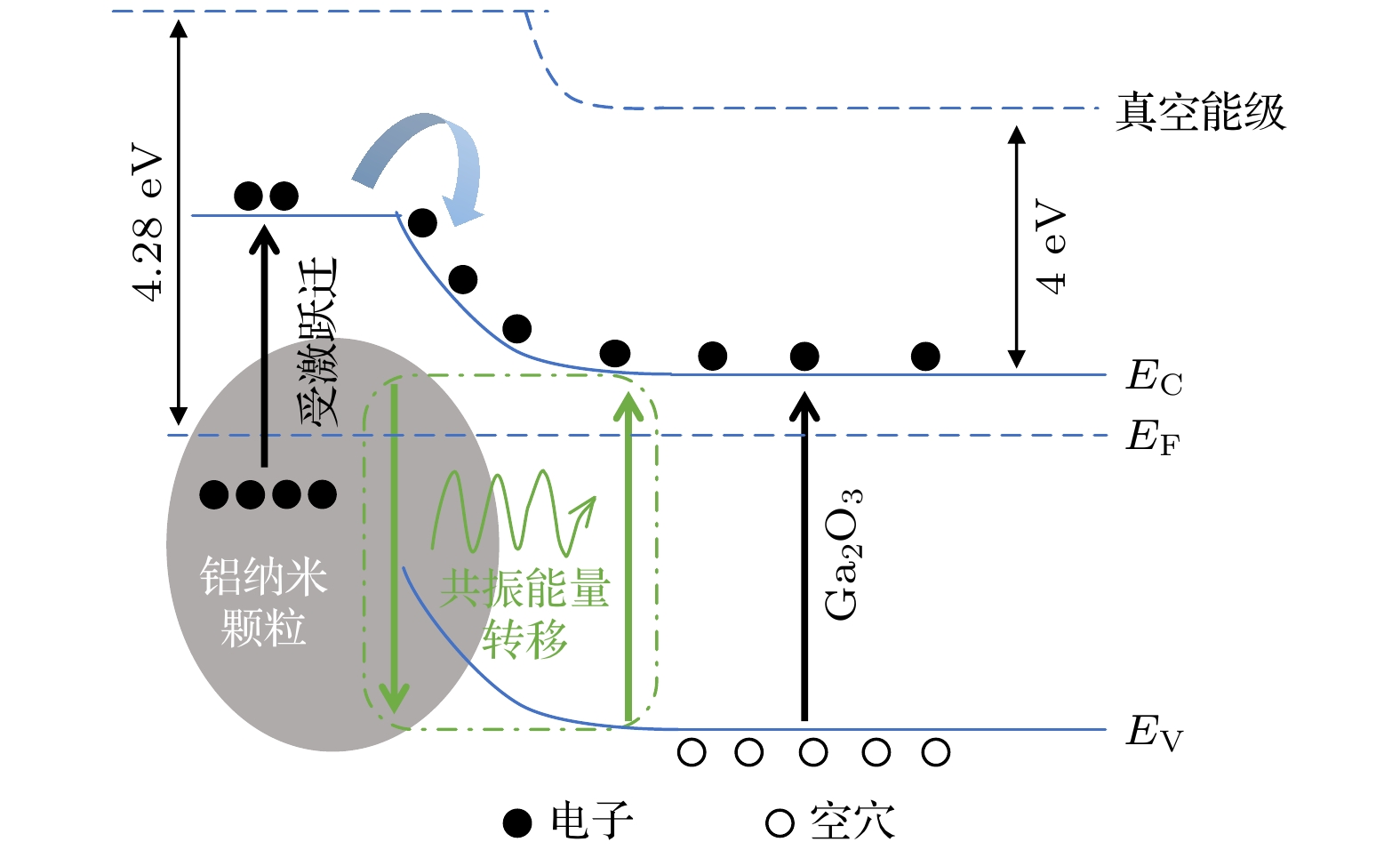

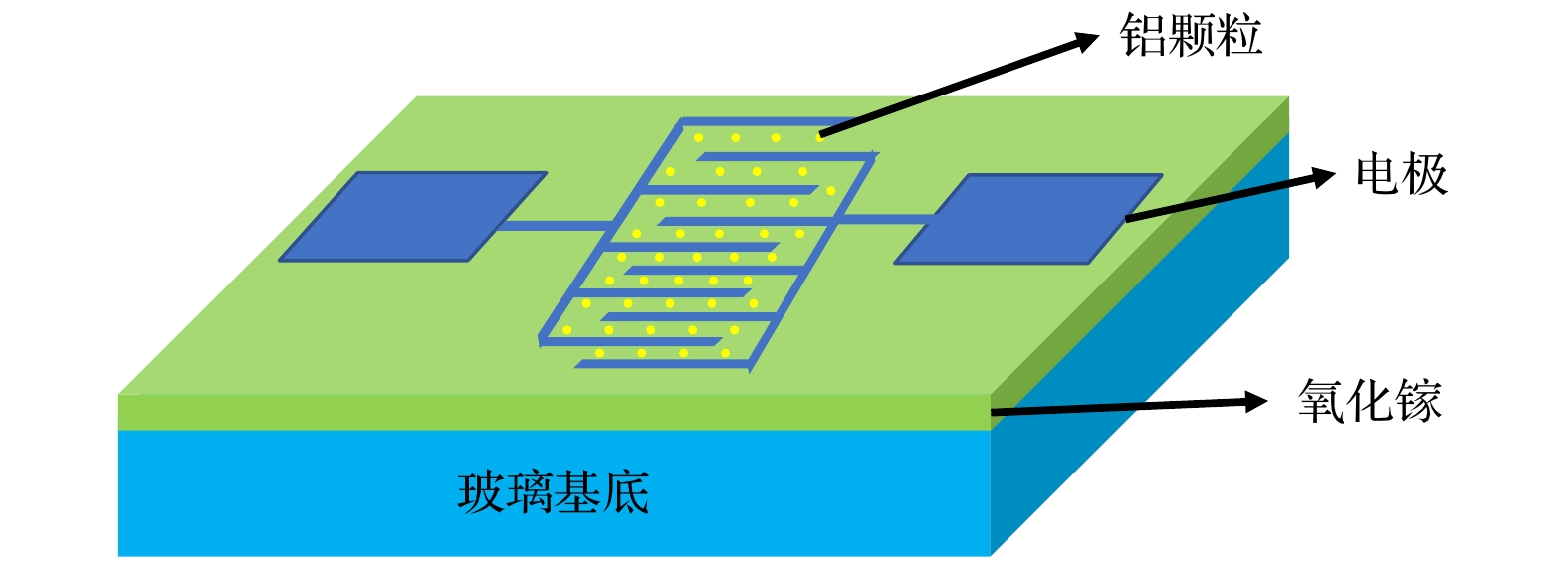

Gallium oxide (Ga2O3) as a wide bandgap semiconductor material has attracted much attention in the field of solar blind ultraviolet photodetection recently. Localized surface plasmon resonance is considered an effective way to improve the performance of optoelectronic devices by decorating the materials with metal particles. Al nanoparticle is a potential candidate for ultraviolet photodetectors because its suitable resonance wavelength is located in the ultraviolet wavelength range. In this work, the preparation temperature of the Ga2O3 thin film is reduced by ultraviolet photo-annealing, and the amorphous Ga2O3 thin film is prepared by using the solution method. In addition, aluminum (Al) nanoparticles are used to decorate the surface of Ga2O3 thin film through thermal evaporation of aluminum film and then annealing, which improves the optoelectrical performance in the solar-blind wavelength spectrum. The X-ray diffraction (XRD) is employed to demonstrate the amorphous Ga2O3 thin film. The surface roughness and the diameters of Al nanoparticles are analyzed by atomic force microscope (AFM). When the thickness of the deposited Al layer is about 3–5 nm, Al particles with the diameters in a range of 2–3 nm can be obtained. When the thickness of the deposited Al layer is more than 7 nm, Al nanoparticles turn into the particles with non-identical diameters and distribute in the form of agglomeration. Transmittance spectrum and absorption spectrum are employed to characterize the optical properties. The bandgaps of different samples are obtained, and the results are consistent with the theoretical ones. The Ga2O3 thin film shows excellent optoelectrical performance and solar blind rejection ratio. Under 254 nm illumination, the maximum photo-to-dark current ratio is 2.55×104, and the rejection ratio of I254 nm/I365 nm is 2.2×104. The best responsivity and detectivity of prepared samples are 0.771 A/W and 1.13×1011 Jones, which are about 34 times and 36 times higher than those without Al decoration. The improvement is attributed to the scattering effect of surface Al nanoparticles for illumination, which enhances the Ga2O3 thin film absorption of solar blind ultraviolet light. Meanwhile, owing to the localized surface plasma resonance, the local electromagnetic fields generated near the Al nanoparticles promote the transfer of carriers in the film. Furthermore, the point about how the Al nanoparticles decorated on the surface of Ga2O3 thin film influence the time response is also discussed in this work. As a result, the introduction of defect states will lead to an increase of fall time due to the Al deposition. In this work, the effect of Al nanoparticles decoration on the optoelectrical performance of amorphous Ga2O3 thin film solar blind ultraviolet photodetectors is studied based on a simple preparation, which provides a possible pathway for developing the flexible solar blind electronic devices in the future.

-

Keywords:

- gallium oxide /

- solar blind ultraviolet photodetector /

- solution method /

- Al nanoparticles

[1] Chen H, Liu K, Hu L, Al-Ghamdi A A, Fang X 2015 Mater. Today 18 493

Google Scholar

Google Scholar

[2] Razeghi M 2002 Proc. IEEE 90 1006

Google Scholar

Google Scholar

[3] Sang L, Liao M, Sumiya M 2013 Sensors (Basel) 13 10482

Google Scholar

Google Scholar

[4] Liao M, Wang X, Teraji T, Koizumi S, Koide Y 2010 Phys. Rev. B 81 033304

Google Scholar

Google Scholar

[5] Cicek E, McClintock R, Cho C Y, Rahnema B, Razeghi M 2013 Appl. Phys. Lett. 103 051102

Google Scholar

Google Scholar

[6] Suzuki R, Nakagomi S, Kokubun Y, Arai N, Ohira S 2009 Appl. Phys. Lett. 94 222102

Google Scholar

Google Scholar

[7] Yang J L, Liu K W, Shen D Z 2017 Chin. Phys. B 26 047308

Google Scholar

Google Scholar

[8] Wu Z H, Qian L X, Sheng T, Zhang Y Y, Liu X Z 2019 IEEE International Conference on Electron Devices & Solid-state Circuits Xi'an China, June 12–14, 2019 p82

[9] Chang K W, Wu J J 2005 Adv. Mater. 17 241

Google Scholar

Google Scholar

[10] Guo D Y, Wu Z P, Li P G, An Y H, Liu H, Guo X C, Yan H, Wang G F, Sun C L, Li L H, Tang W H 2014 Opt. Mater. Express 4 1067

Google Scholar

Google Scholar

[11] Yu F P, Ou S L, Wuu D S 2015 Opt. Mater. Express 5 1240

Google Scholar

Google Scholar

[12] He H Y, Orlando R, Blanco M A, Pandey R, Amzallag E, Baraille I, Rérat M 2006 Phys. Rev. B 74 195123

Google Scholar

Google Scholar

[13] Gottschalch V, Merker S, Blaurock S, Kneiß M, Teschner U, Grundmann M, Krautscheid H 2019 J. Cryst. Growth 510 76

Google Scholar

Google Scholar

[14] Pearton S J, Yang J C, Cary P H, Ren F, Kim J, Tadjer M J, Mastro M A 2018 Appl. Phys. Rev. 5 011301

Google Scholar

Google Scholar

[15] Dong L P, Yu J G, Jia R X, Hu J C, Zhang Y M, Sun J W 2019 Opt. Mater. Express 9 1191

Google Scholar

Google Scholar

[16] Qian L X, Wang Y, Wu Z H, Sheng T, Liu X Z 2017 Vacuum 140 106

Google Scholar

Google Scholar

[17] Liu X Z, Guo P, Sheng T, Qian L X, Zhang W L, Li Y R 2016 Opt. Mater. 51 203

Google Scholar

Google Scholar

[18] Alema F, Hertog B, Ledyaev O, Volovik D, Thoma G, Miller R, Osinsky A, Mukhopadhyay P, Bakhshi S, Ali H, Schoenfeld W V 2017 Phys. Status Solidi A 214 1600688

Google Scholar

Google Scholar

[19] Wang H, Chen H, Li L, Wang Y, Su L, Bian W, Li B, Fang X 2019 J. Phys. Chem. Lett. 10 6850

Google Scholar

Google Scholar

[20] Mayer K M, Hafner J H 2011 Chem. Rev. 111 3828

Google Scholar

Google Scholar

[21] Zhang Y, Lin N, Li Y, Wang X, Wang H, Kang J, Wilks R, Bar M, Mu R 2016 Sci. Rep. 6 23106

Google Scholar

Google Scholar

[22] 刘伦涛 2020 博士学位论文 (济南: 山东大学)

Liu L T 2020 Ph. D. Dissertation (Jinan: Shandong University) (in Chinese)

[23] An Y, Chu X, Huang Y, Zhi Y, Guo D, Li P, Wu Z, Tang W 2016 Prog. Nat. Sci. 26 65

Google Scholar

Google Scholar

[24] Shi X, Yang Z, Yin S, Zeng H 2016 Mater. Technol. 31 544

Google Scholar

Google Scholar

[25] Chang Y T, Chuang T H, Tsai M W, Chen L C, Lee S C 2007 J. Appl. Phys. 101 054305

Google Scholar

Google Scholar

[26] Rafique S, Han L, Zhao H 2016 Phys. Status Solidi A 213 1002

Google Scholar

Google Scholar

[27] Cui S, Mei Z, Hou Y, Sun M, Chen Q, Liang H, Zhang Y, Bai X, Du X 2018 Sci Chin.-Phys. Mech. Astron. 61 107021

Google Scholar

Google Scholar

[28] Zhao B, Wang F, Chen H Y, Zheng L X, Su L X, Zhao D X, Fang X S 2017 Adv. Funct. Mater. 27 1700264

Google Scholar

Google Scholar

[29] Guo D Y, Su Y L, Shi H Z, Li P G, Zhao N, Ye J H, Wang S L, Liu A P, Chen Z W, Li C R, Tang W H 2018 ACS Nano 12 12827

Google Scholar

Google Scholar

[30] Zhang D, Zheng W, Lin R C, Li T T, Zhang Z J, Huang F 2018 J. Alloys Compd. 735 150

Google Scholar

Google Scholar

-

表 1 20 V偏压下沉积3 nm /5 nm /7 nm以及未沉积样品的电学参数

Table 1. Electrical parameters of samples with 3 nm /5 nm /7 nm Al and without Al under 20 V bias.

铝层

厚度/nmIdark/A I254 nm/A I365 nm/A I254 nm/Idark I254 nm/I365 nm R254 nm/

(A·W–1)R365 nm/

(A·W–1)R254 nm/R365 nm $D_{\rm 254\;nm}^*$/Jones 未沉积 1.51×10–10 1.15×10–7 1.74×10–10 7.62×102 6.61×102 0.0228 4.56×10–6 4993 3.13×109 3 1.52×10–10 3.88×10–6 1.79×10–10 2.55×104 2.17×104 0.771 5.36×10–6 1.44×105 1.13×1011 5 1.34×10–10 3.32×10–6 1.51×10–10 2.48×104 2.20×104 0.659 3.37×10–6 1.95×105 1.03×1011 7 3.33×10–10 6.88×10–5 4.46×10–7 2.07×105 1.54×102 13.647 0.0884 154 1.35×1012 -

[1] Chen H, Liu K, Hu L, Al-Ghamdi A A, Fang X 2015 Mater. Today 18 493

Google Scholar

Google Scholar

[2] Razeghi M 2002 Proc. IEEE 90 1006

Google Scholar

Google Scholar

[3] Sang L, Liao M, Sumiya M 2013 Sensors (Basel) 13 10482

Google Scholar

Google Scholar

[4] Liao M, Wang X, Teraji T, Koizumi S, Koide Y 2010 Phys. Rev. B 81 033304

Google Scholar

Google Scholar

[5] Cicek E, McClintock R, Cho C Y, Rahnema B, Razeghi M 2013 Appl. Phys. Lett. 103 051102

Google Scholar

Google Scholar

[6] Suzuki R, Nakagomi S, Kokubun Y, Arai N, Ohira S 2009 Appl. Phys. Lett. 94 222102

Google Scholar

Google Scholar

[7] Yang J L, Liu K W, Shen D Z 2017 Chin. Phys. B 26 047308

Google Scholar

Google Scholar

[8] Wu Z H, Qian L X, Sheng T, Zhang Y Y, Liu X Z 2019 IEEE International Conference on Electron Devices & Solid-state Circuits Xi'an China, June 12–14, 2019 p82

[9] Chang K W, Wu J J 2005 Adv. Mater. 17 241

Google Scholar

Google Scholar

[10] Guo D Y, Wu Z P, Li P G, An Y H, Liu H, Guo X C, Yan H, Wang G F, Sun C L, Li L H, Tang W H 2014 Opt. Mater. Express 4 1067

Google Scholar

Google Scholar

[11] Yu F P, Ou S L, Wuu D S 2015 Opt. Mater. Express 5 1240

Google Scholar

Google Scholar

[12] He H Y, Orlando R, Blanco M A, Pandey R, Amzallag E, Baraille I, Rérat M 2006 Phys. Rev. B 74 195123

Google Scholar

Google Scholar

[13] Gottschalch V, Merker S, Blaurock S, Kneiß M, Teschner U, Grundmann M, Krautscheid H 2019 J. Cryst. Growth 510 76

Google Scholar

Google Scholar

[14] Pearton S J, Yang J C, Cary P H, Ren F, Kim J, Tadjer M J, Mastro M A 2018 Appl. Phys. Rev. 5 011301

Google Scholar

Google Scholar

[15] Dong L P, Yu J G, Jia R X, Hu J C, Zhang Y M, Sun J W 2019 Opt. Mater. Express 9 1191

Google Scholar

Google Scholar

[16] Qian L X, Wang Y, Wu Z H, Sheng T, Liu X Z 2017 Vacuum 140 106

Google Scholar

Google Scholar

[17] Liu X Z, Guo P, Sheng T, Qian L X, Zhang W L, Li Y R 2016 Opt. Mater. 51 203

Google Scholar

Google Scholar

[18] Alema F, Hertog B, Ledyaev O, Volovik D, Thoma G, Miller R, Osinsky A, Mukhopadhyay P, Bakhshi S, Ali H, Schoenfeld W V 2017 Phys. Status Solidi A 214 1600688

Google Scholar

Google Scholar

[19] Wang H, Chen H, Li L, Wang Y, Su L, Bian W, Li B, Fang X 2019 J. Phys. Chem. Lett. 10 6850

Google Scholar

Google Scholar

[20] Mayer K M, Hafner J H 2011 Chem. Rev. 111 3828

Google Scholar

Google Scholar

[21] Zhang Y, Lin N, Li Y, Wang X, Wang H, Kang J, Wilks R, Bar M, Mu R 2016 Sci. Rep. 6 23106

Google Scholar

Google Scholar

[22] 刘伦涛 2020 博士学位论文 (济南: 山东大学)

Liu L T 2020 Ph. D. Dissertation (Jinan: Shandong University) (in Chinese)

[23] An Y, Chu X, Huang Y, Zhi Y, Guo D, Li P, Wu Z, Tang W 2016 Prog. Nat. Sci. 26 65

Google Scholar

Google Scholar

[24] Shi X, Yang Z, Yin S, Zeng H 2016 Mater. Technol. 31 544

Google Scholar

Google Scholar

[25] Chang Y T, Chuang T H, Tsai M W, Chen L C, Lee S C 2007 J. Appl. Phys. 101 054305

Google Scholar

Google Scholar

[26] Rafique S, Han L, Zhao H 2016 Phys. Status Solidi A 213 1002

Google Scholar

Google Scholar

[27] Cui S, Mei Z, Hou Y, Sun M, Chen Q, Liang H, Zhang Y, Bai X, Du X 2018 Sci Chin.-Phys. Mech. Astron. 61 107021

Google Scholar

Google Scholar

[28] Zhao B, Wang F, Chen H Y, Zheng L X, Su L X, Zhao D X, Fang X S 2017 Adv. Funct. Mater. 27 1700264

Google Scholar

Google Scholar

[29] Guo D Y, Su Y L, Shi H Z, Li P G, Zhao N, Ye J H, Wang S L, Liu A P, Chen Z W, Li C R, Tang W H 2018 ACS Nano 12 12827

Google Scholar

Google Scholar

[30] Zhang D, Zheng W, Lin R C, Li T T, Zhang Z J, Huang F 2018 J. Alloys Compd. 735 150

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7705

- PDF Downloads: 177

- Cited By: 0

DownLoad:

DownLoad: