-

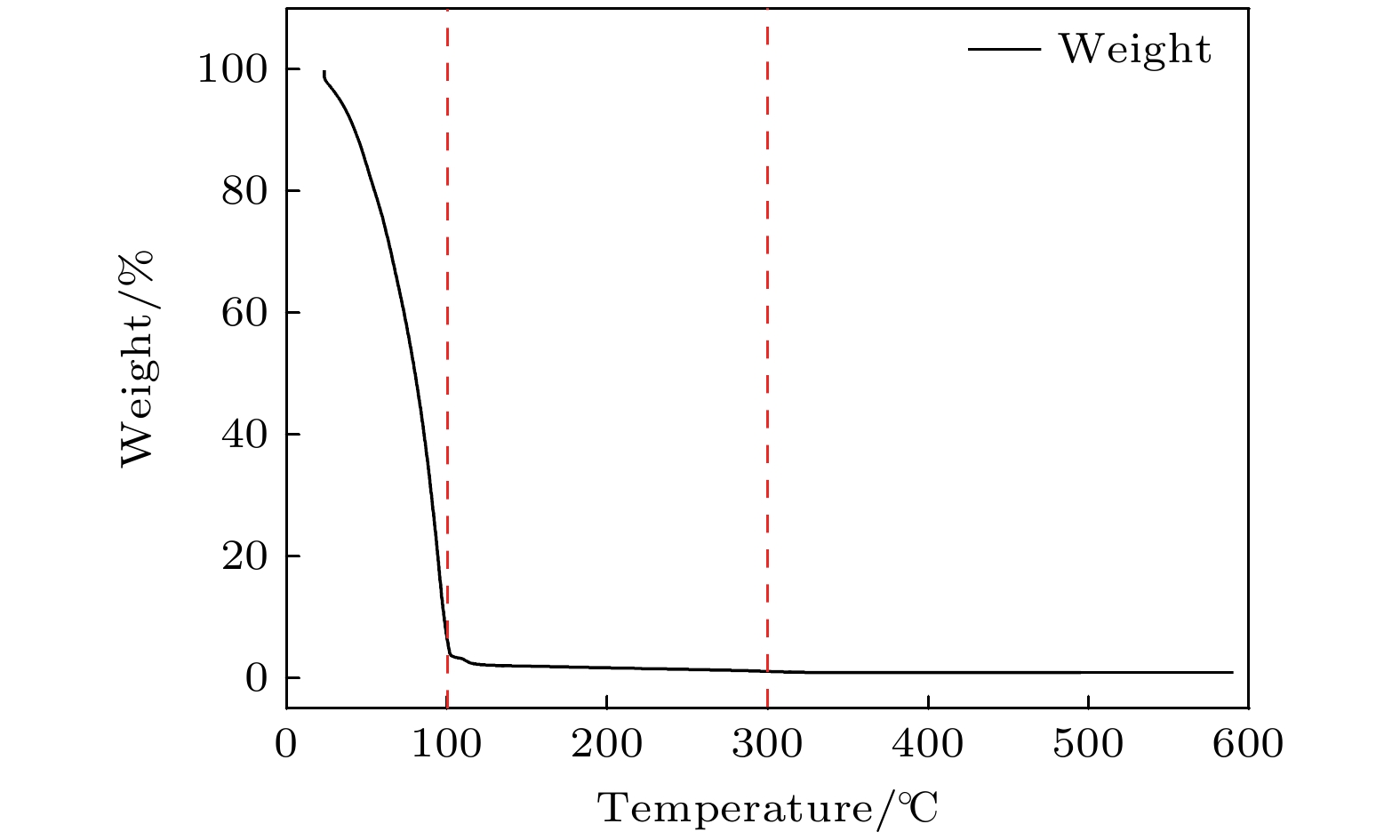

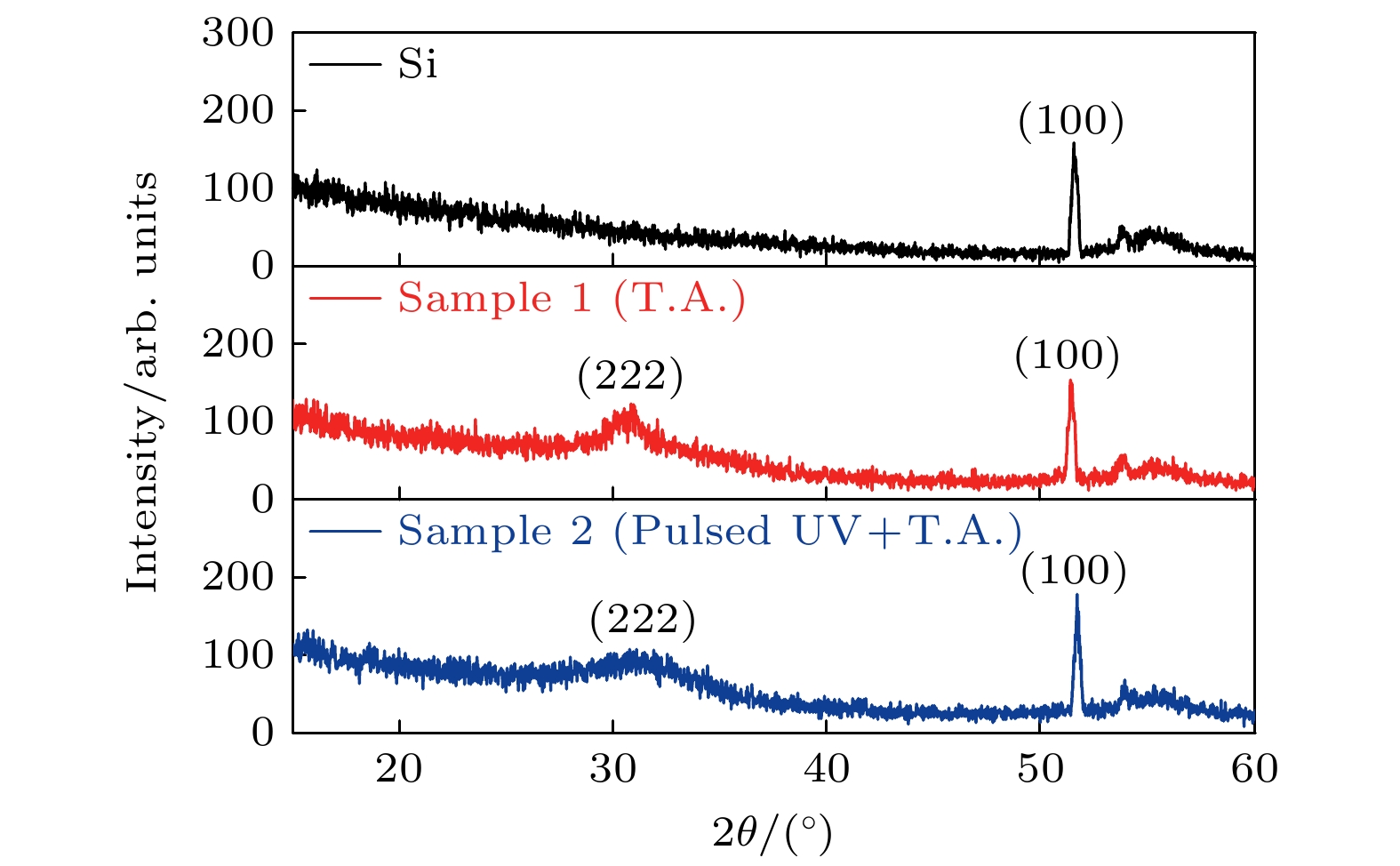

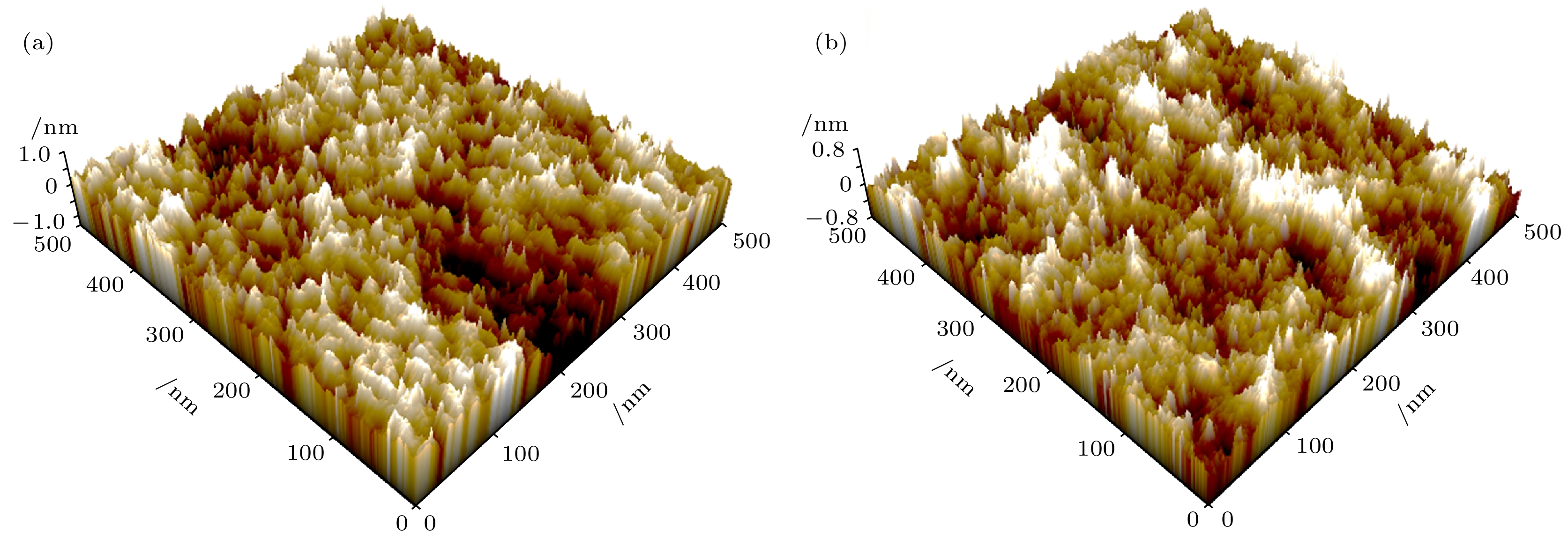

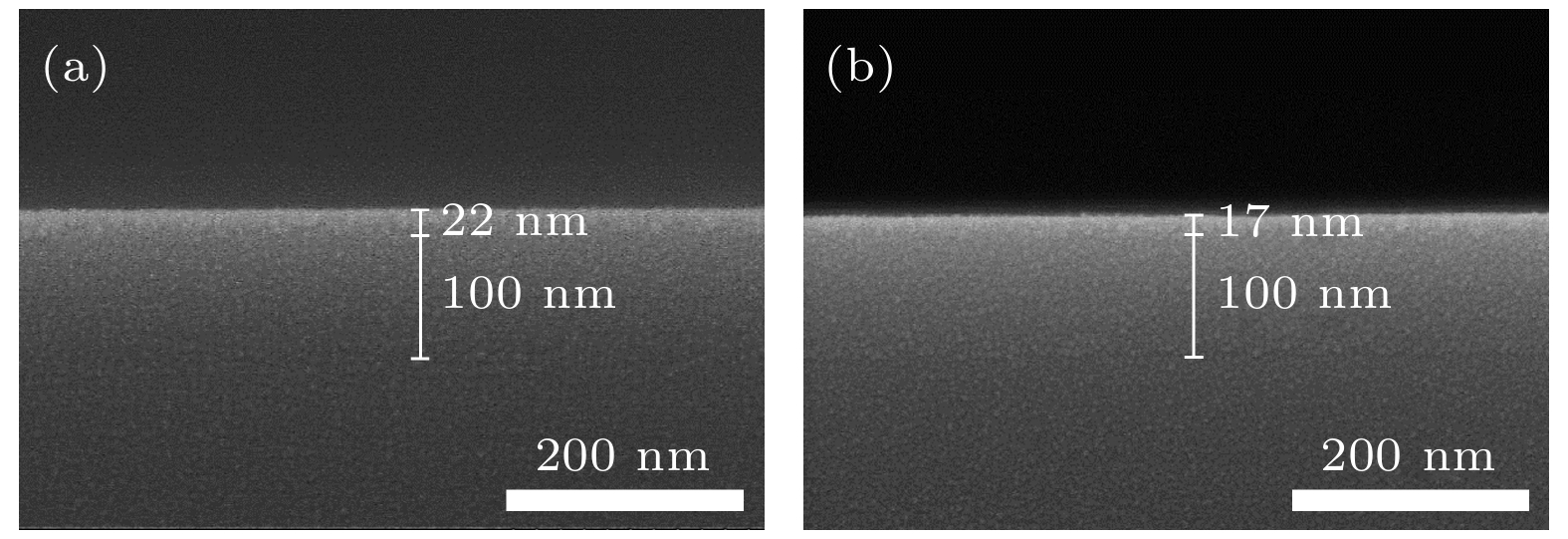

利用脉冲紫外线辅助热退火在200 ℃的低温条件下, 5 min内制备了基于溶液工艺的氧化铟薄膜及薄膜晶体管. 对比传统热退火, 研究了脉冲紫外线辅助热退火对氧化铟薄膜的表面形态、化学结构和电学特性的影响. 实验结果表明, 脉冲紫外线辅助热退火方式能够在短时间内实现改善氧化铟薄膜的质量及薄膜晶体管的性能. 原子力显微镜和场发射扫描电子显微镜结果显示该薄膜表面较传统热退火制备薄膜表面更为致密平坦. X 射线光电能谱测试表明, 脉冲紫外线辅助热退火处理后会产生氧空位, 从而提高载流子浓度, 改善了氧化铟薄膜的导电性. 此外, 对比研究了紫外线辅助热退火对氧化铟薄膜晶体管电气性能的影响. 结果表明器件的电学特性得到了明显改善, 亚阈值摆幅降低至0.12 mV/dec, 阈值电压为7.4 V, 电流开关比高达1.29×107, 场效应迁移率提升至1.27 cm2/(V·s). 因此, 脉冲紫外线辅助热退火是一种简单、快速的退火方式, 即使在低温条件下也能快速提高氧化铟薄膜和薄膜晶体管的性能.

-

关键词:

- 脉冲紫外线辅助热退火 /

- 氧化铟 /

- 溶液法 /

- 薄膜晶体管

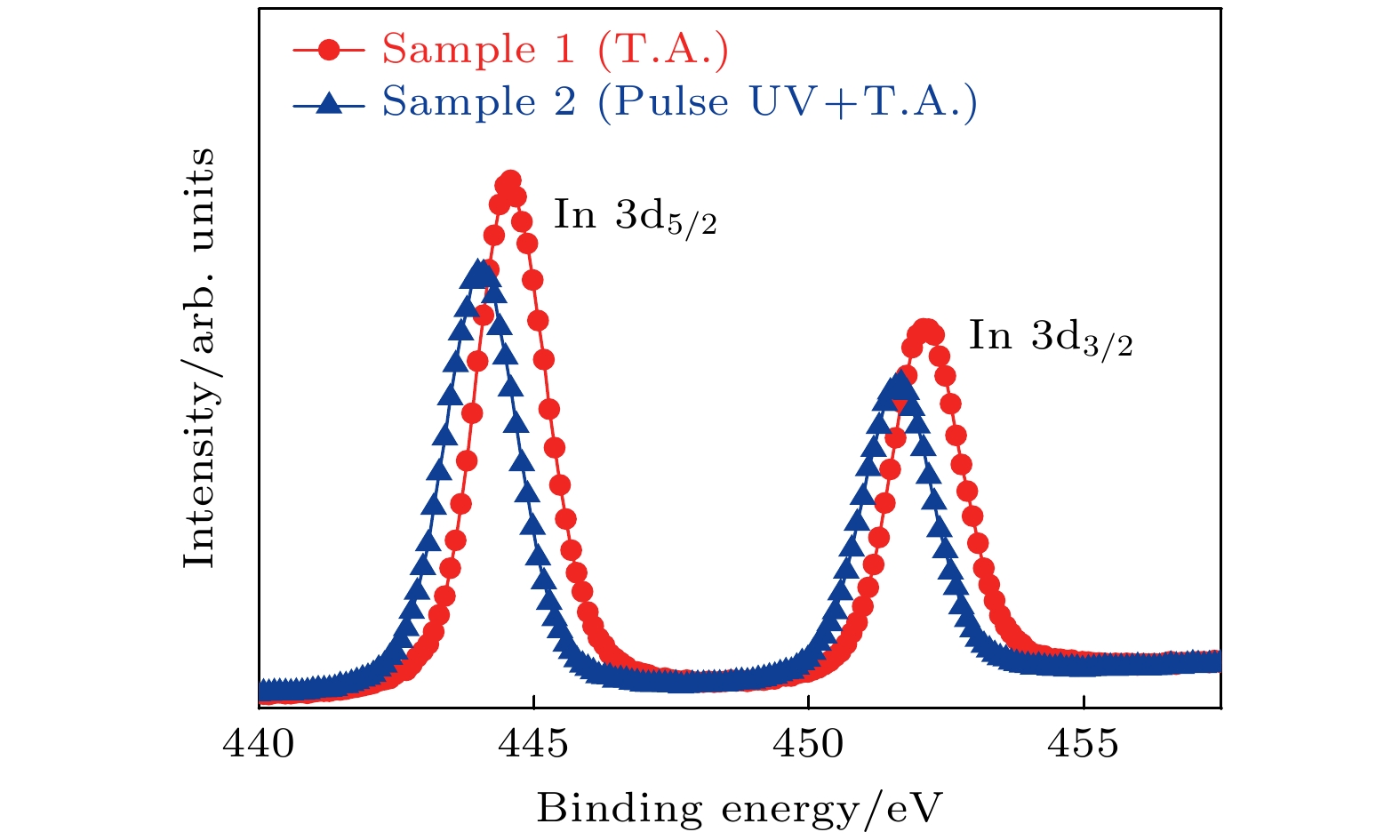

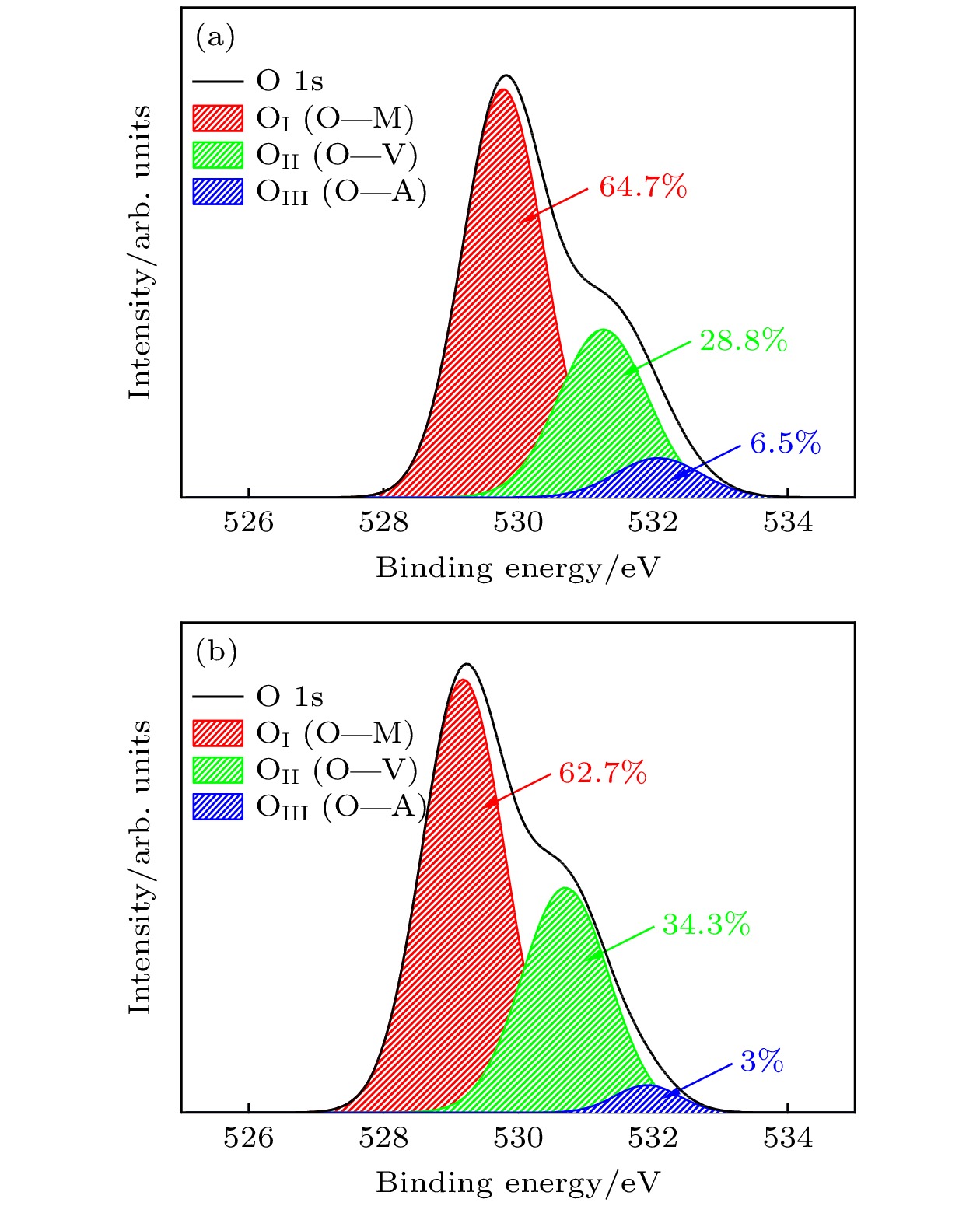

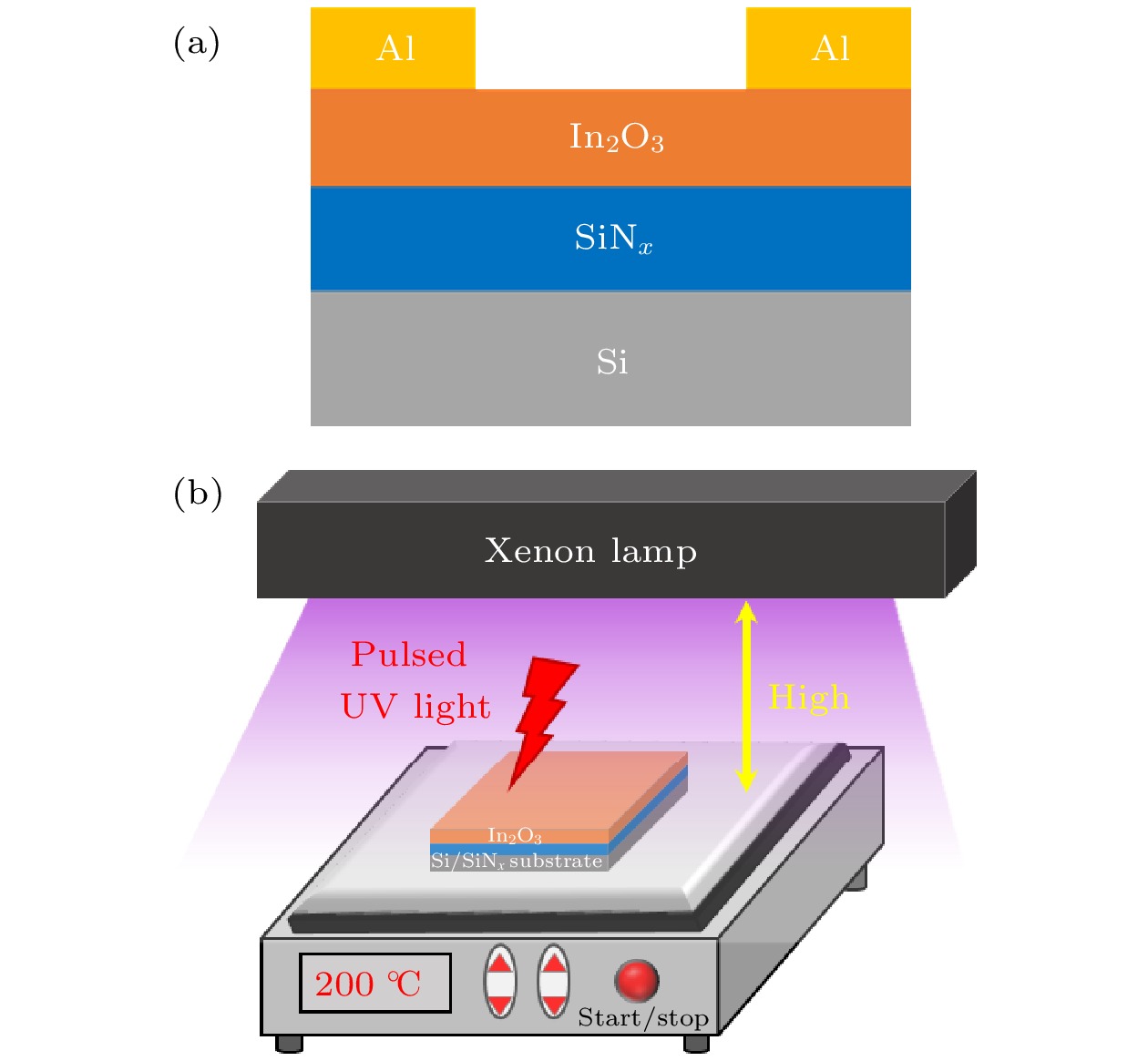

Indium oxide (In2O3) thin films and thin-film transistors (TFTs) based on the solution process are prepared by pulsed UV-assisted thermal annealing at a low temperature (200 ℃) for 5 min. The effects of pulsed UV-assisted thermal annealing on the surface morphology, chemical structure, and electrical properties of the In2O3 thin films are investigated, and they are compared with those of conventional thermal annealing (300 ℃, 30 min). The experimental results show that the pulsed UV-assisted thermal annealing method can improve the quality of In2O3 thin film and the performance of TFT in a short period. The results of atomic force microscopy and field emission scanning electron microscopy show that the surface of the In2O3 film is denser and flatter than that of the conventional thermally annealed film, and X-ray photoelectron spectroscopy tests show that the pulsed UV-assisted thermal annealing process generates oxygen vacancies, which increases the carrier concentration and improves the electrical conductivity of the In2O3 film. In addition, the effect of pulsed UV-assisted thermal annealing on the electrical characteristics of In2O3 TFTs is investigated in a comparative way. The results show that the electrical characteristics of the device are significantly improved: the subthreshold swing decreases to 0.12 mV/dec, the threshold voltage is 7.4 V, the current switching ratio is as high as 1.29×107, and the field effect mobility is enhanced to 1.27 cm2·V–1·s–1. Therefore, pulsed UV-assisted thermal annealing is a simple and fast annealing method, which can rapidly improve the performances of In2O3 thin film and TFTs, even under low-temperature conditions.-

Keywords:

- pulsed UV-assisted thermal annealing /

- indium oxide /

- solution process /

- thin film transistor

[1] He Y L, Wang X Y, Gao Y, Hou Y H, Wan Q 2018 J. Semicond. 39 011005

Google Scholar

Google Scholar

[2] Zhou Y, Roy V A L, Xu Z X, Kwong H Y, Wang H B, Lee C S 2011 Appl. Phys. Lett. 98 092904

Google Scholar

Google Scholar

[3] Liang K, Wang Y, Shao S S, Luo M M, Pecunia V, Shao L, Zhao J W, Chen Z, Mo L X, Cui Z 2019 J. Mater. Chem. C 7 6169

Google Scholar

Google Scholar

[4] Kim S J, Yoon S H, Kim H J 2014 J. Appl. Phys. 53 02BA02

Google Scholar

Google Scholar

[5] Choi C H, Han S Y, Su Y W, Fang Z, Lin L Y, Cheng C C, Chang C H 2015 J. Mater. Chem. C 3 854

Google Scholar

Google Scholar

[6] Kim M G, Kanatzidis M G, Facchetti A, Marks T J 2011 Nat. Mater. 10 382

Google Scholar

Google Scholar

[7] Hwang Y H, Seo J S, Yun J M, Park H J, Yang S H, Park S H K, Bae B S 2013 NPG Asia Mater. 5 e45

Google Scholar

Google Scholar

[8] Lee H J, Jyothi C, Baang S K , Kwon J H, Bae J H 2016 J. Korean. Phys. Soc. 69 1688

Google Scholar

Google Scholar

[9] Zhang X, Lee H J, Kwon J H, Kim E J, Park J H 2017 Materials 10 880

Google Scholar

Google Scholar

[10] Park J H, Park W, Na J H, Lee J U, Eun J S, Feng J H, Kim D K, Bae J H 2023 Nanomaterials 13 2568

Google Scholar

Google Scholar

[11] 谢应涛, 蔡坤林, 陈鹏龙, 刘愈, 王东平 2022 中国激光 49 0703001

Google Scholar

Google Scholar

Xie Y T, Cai K L, Chen P L, Liu Y, Wang D P 2022 Chin. J. Lasers 49 0703001

Google Scholar

Google Scholar

[12] Kim W G, Tak Y J, Ahn B D, Jung T S, Chung K B, Kim H J 2016 Sci. Rep. 6 23039

Google Scholar

Google Scholar

[13] Rahman M K, Lu Z, Kwon K S 2018 AIP Adv. 8 095008

Google Scholar

Google Scholar

[14] Lee H W, Choi H S, Cho W J 2019 J. Nanosci. Nanotechno. 19 6164

Google Scholar

Google Scholar

[15] Huang H Y, Wang S J, Wu C H, Lu C Y 2014 Electron. Mater. Lett. 10 899

Google Scholar

Google Scholar

[16] Kim D W, Park J H, Hwang J U, Kim H D, Ryu J H, Lee K B, Baek K H, Do L M, Choi J S 2015 Electron. Mater. Lett. 11 82

Google Scholar

Google Scholar

[17] Park S C, Kim D W, Shin H J, Lee D K, Zhang X, Park J H, Choi J S 2016 J. Inf. Disp. 17 179

Google Scholar

Google Scholar

[18] Huet K, Aubin J, Raynal P E, Curvers B, Verstraete A, Lespinasse B, Mazzamuto F, Sciuto A, Lombardo S F, Magna A L, Acosta-Alba P, Dagault L, Licitra C, Hartmann J M, Kerdilès S 2020 Appl. Surf. Sci. 505 144470

Google Scholar

Google Scholar

[19] Lee H J, Zhang X, Kim J W, Kim E J, Park J H 2018 Materials 11 2103

Google Scholar

Google Scholar

[20] Azianty S, Saadah A R, Boon T G 2018 Mater. Today 5 S186

Google Scholar

Google Scholar

[21] Xing R Q, Xu L, Song J, Zhou C Y, Li Q L, Liu D L, Song H W 2015 Sci. Rep. 5 10717

Google Scholar

Google Scholar

[22] Tetzner K, Isakov I, Regoutz A, Payne D J, Anthopoulos T D 2017 J. Mater. Chem. C 5 59

Google Scholar

Google Scholar

[23] Shinde D, Ahn D Y, Jadhav V, Lee D Y, Shrestha N K, Lee J K, Lee H, Mane R S, Han S H 2014 J. Mater. Chem. A 2 5490

Google Scholar

Google Scholar

[24] Lin Y H, Liu Y S, Lin Y C, Wei Y S, Liao K S, Lee K R, Lai J Y, Chen H M, Jean Y C, Liu C Y 2013 J. Appl. Phys. 113 033706

Google Scholar

Google Scholar

[25] Ide K, Nomura K, Hosono H, Kamiya T 2019 Phys. Status Solidi A 216 1800372

Google Scholar

Google Scholar

[26] Biswas P, Ainabayev A, Zhussupbekova A, Jose F, O’Connor R, Kaisha A, Walls B, Shvets I V 2020 Sci. Rep. 10 7463

Google Scholar

Google Scholar

[27] Tsay C Y, Liang S C 2017 Mat. Sci. Semicon. Proc. 71 441

Google Scholar

Google Scholar

-

表 1 不同热退火方式制备In2O3 TFTs的电学特性参数

Table 1. Electrical parameters of In2O3 TFTs prepared by different thermal annealing methods.

样品 亚阈值摆幅 电流比 阈值电压 迁移率 S.S./(mV·dec–1) Ion/Ioff VTH/V μsat/(cm2·V–1·s–1) 样品1 (T.A.) 0.17 1.88×106 7.6 0.22 样品2 (Pulsed UV +T.A.-5 min) 0.12 1.29×107 7.4 1.27 样品3 (Pulsed UV +T.A.-10 min) — -2.52 2.43 -

[1] He Y L, Wang X Y, Gao Y, Hou Y H, Wan Q 2018 J. Semicond. 39 011005

Google Scholar

Google Scholar

[2] Zhou Y, Roy V A L, Xu Z X, Kwong H Y, Wang H B, Lee C S 2011 Appl. Phys. Lett. 98 092904

Google Scholar

Google Scholar

[3] Liang K, Wang Y, Shao S S, Luo M M, Pecunia V, Shao L, Zhao J W, Chen Z, Mo L X, Cui Z 2019 J. Mater. Chem. C 7 6169

Google Scholar

Google Scholar

[4] Kim S J, Yoon S H, Kim H J 2014 J. Appl. Phys. 53 02BA02

Google Scholar

Google Scholar

[5] Choi C H, Han S Y, Su Y W, Fang Z, Lin L Y, Cheng C C, Chang C H 2015 J. Mater. Chem. C 3 854

Google Scholar

Google Scholar

[6] Kim M G, Kanatzidis M G, Facchetti A, Marks T J 2011 Nat. Mater. 10 382

Google Scholar

Google Scholar

[7] Hwang Y H, Seo J S, Yun J M, Park H J, Yang S H, Park S H K, Bae B S 2013 NPG Asia Mater. 5 e45

Google Scholar

Google Scholar

[8] Lee H J, Jyothi C, Baang S K , Kwon J H, Bae J H 2016 J. Korean. Phys. Soc. 69 1688

Google Scholar

Google Scholar

[9] Zhang X, Lee H J, Kwon J H, Kim E J, Park J H 2017 Materials 10 880

Google Scholar

Google Scholar

[10] Park J H, Park W, Na J H, Lee J U, Eun J S, Feng J H, Kim D K, Bae J H 2023 Nanomaterials 13 2568

Google Scholar

Google Scholar

[11] 谢应涛, 蔡坤林, 陈鹏龙, 刘愈, 王东平 2022 中国激光 49 0703001

Google Scholar

Google Scholar

Xie Y T, Cai K L, Chen P L, Liu Y, Wang D P 2022 Chin. J. Lasers 49 0703001

Google Scholar

Google Scholar

[12] Kim W G, Tak Y J, Ahn B D, Jung T S, Chung K B, Kim H J 2016 Sci. Rep. 6 23039

Google Scholar

Google Scholar

[13] Rahman M K, Lu Z, Kwon K S 2018 AIP Adv. 8 095008

Google Scholar

Google Scholar

[14] Lee H W, Choi H S, Cho W J 2019 J. Nanosci. Nanotechno. 19 6164

Google Scholar

Google Scholar

[15] Huang H Y, Wang S J, Wu C H, Lu C Y 2014 Electron. Mater. Lett. 10 899

Google Scholar

Google Scholar

[16] Kim D W, Park J H, Hwang J U, Kim H D, Ryu J H, Lee K B, Baek K H, Do L M, Choi J S 2015 Electron. Mater. Lett. 11 82

Google Scholar

Google Scholar

[17] Park S C, Kim D W, Shin H J, Lee D K, Zhang X, Park J H, Choi J S 2016 J. Inf. Disp. 17 179

Google Scholar

Google Scholar

[18] Huet K, Aubin J, Raynal P E, Curvers B, Verstraete A, Lespinasse B, Mazzamuto F, Sciuto A, Lombardo S F, Magna A L, Acosta-Alba P, Dagault L, Licitra C, Hartmann J M, Kerdilès S 2020 Appl. Surf. Sci. 505 144470

Google Scholar

Google Scholar

[19] Lee H J, Zhang X, Kim J W, Kim E J, Park J H 2018 Materials 11 2103

Google Scholar

Google Scholar

[20] Azianty S, Saadah A R, Boon T G 2018 Mater. Today 5 S186

Google Scholar

Google Scholar

[21] Xing R Q, Xu L, Song J, Zhou C Y, Li Q L, Liu D L, Song H W 2015 Sci. Rep. 5 10717

Google Scholar

Google Scholar

[22] Tetzner K, Isakov I, Regoutz A, Payne D J, Anthopoulos T D 2017 J. Mater. Chem. C 5 59

Google Scholar

Google Scholar

[23] Shinde D, Ahn D Y, Jadhav V, Lee D Y, Shrestha N K, Lee J K, Lee H, Mane R S, Han S H 2014 J. Mater. Chem. A 2 5490

Google Scholar

Google Scholar

[24] Lin Y H, Liu Y S, Lin Y C, Wei Y S, Liao K S, Lee K R, Lai J Y, Chen H M, Jean Y C, Liu C Y 2013 J. Appl. Phys. 113 033706

Google Scholar

Google Scholar

[25] Ide K, Nomura K, Hosono H, Kamiya T 2019 Phys. Status Solidi A 216 1800372

Google Scholar

Google Scholar

[26] Biswas P, Ainabayev A, Zhussupbekova A, Jose F, O’Connor R, Kaisha A, Walls B, Shvets I V 2020 Sci. Rep. 10 7463

Google Scholar

Google Scholar

[27] Tsay C Y, Liang S C 2017 Mat. Sci. Semicon. Proc. 71 441

Google Scholar

Google Scholar

计量

- 文章访问数: 4530

- PDF下载量: 68

- 被引次数: 0

下载:

下载: