-

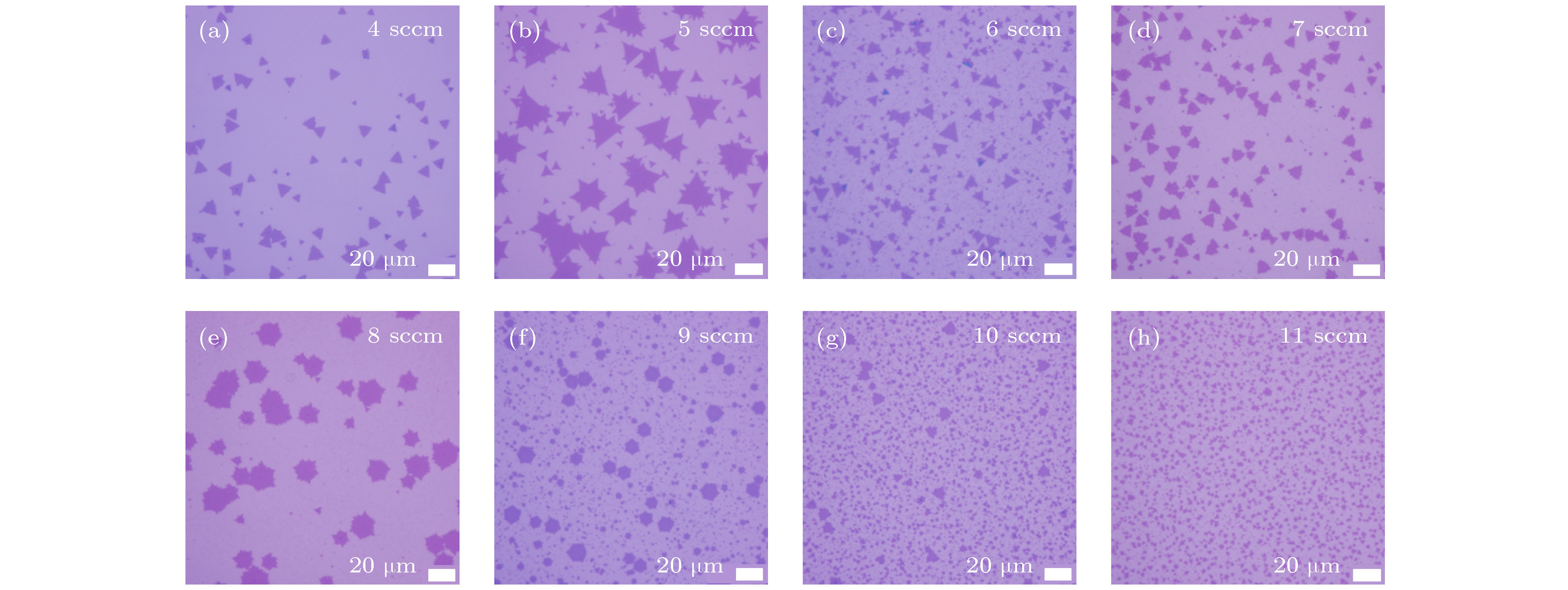

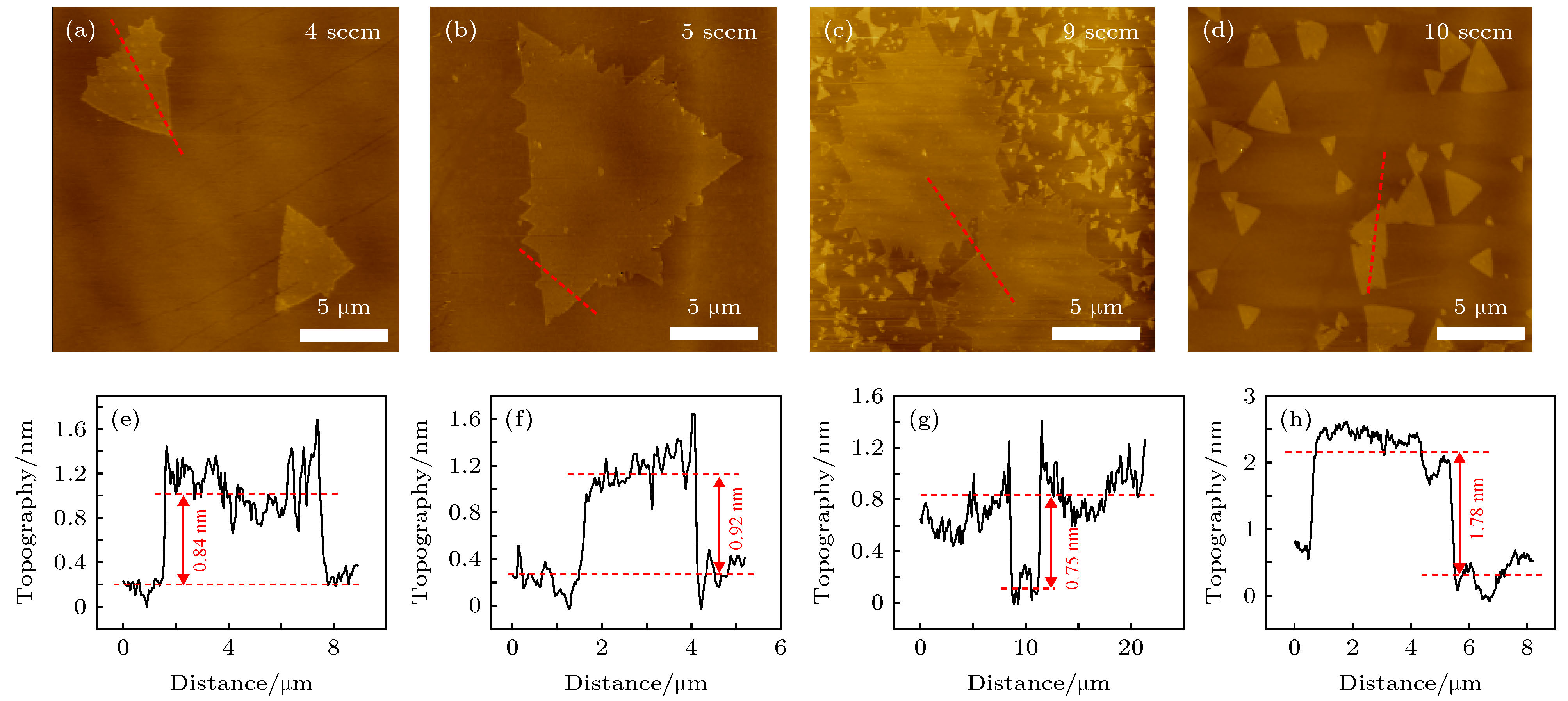

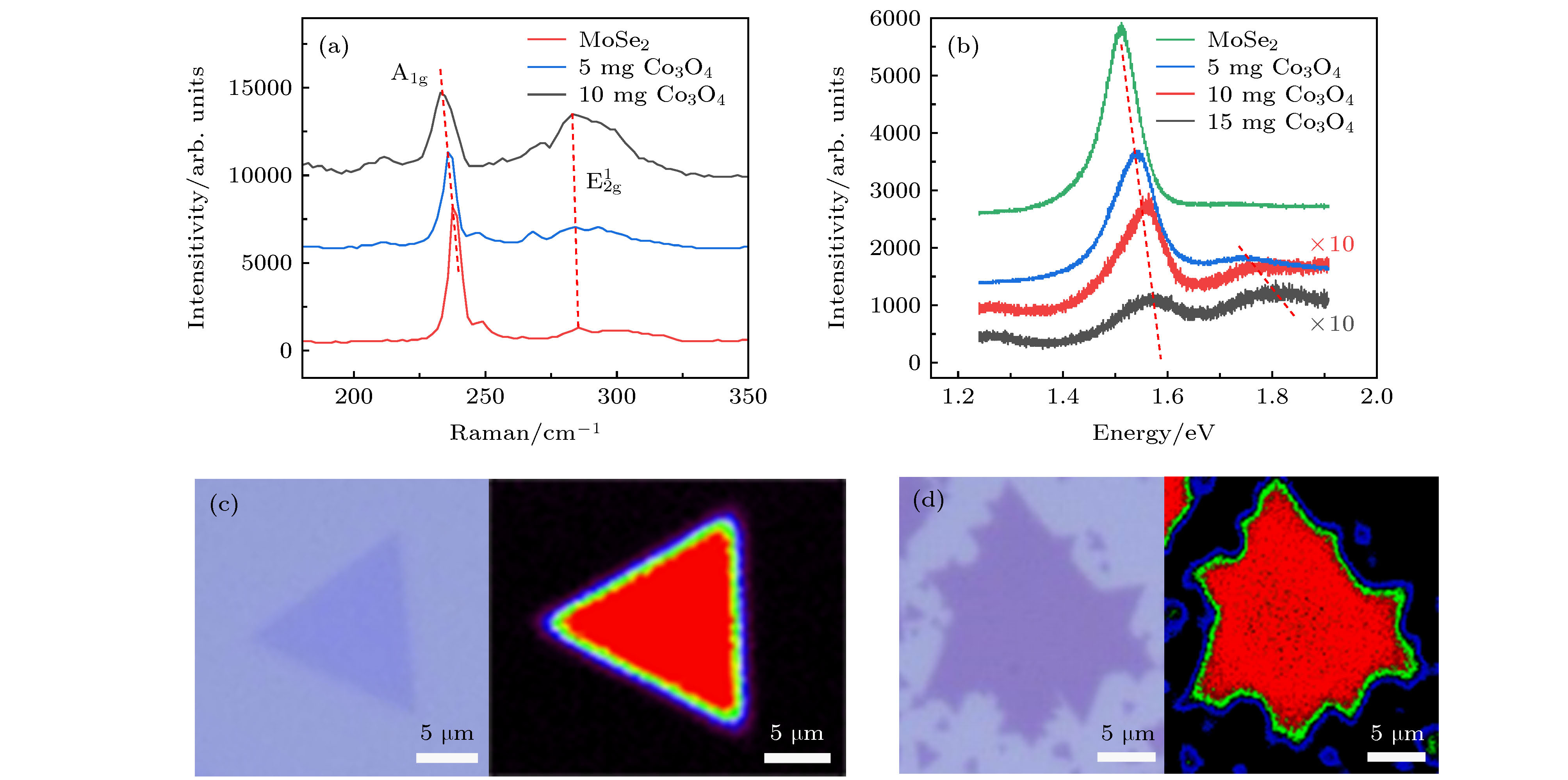

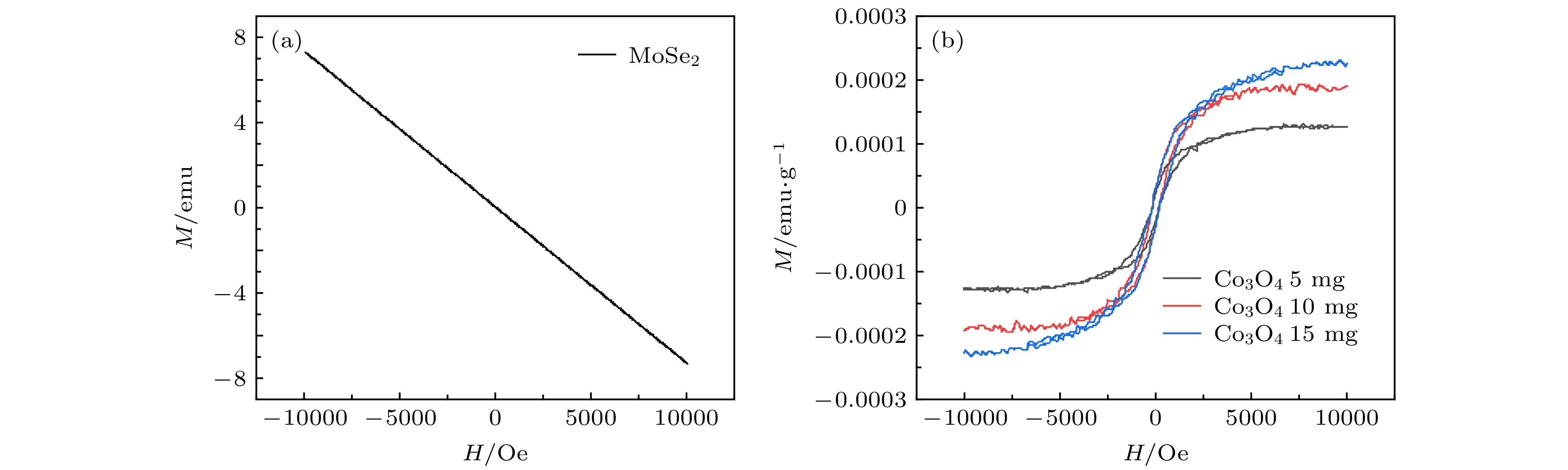

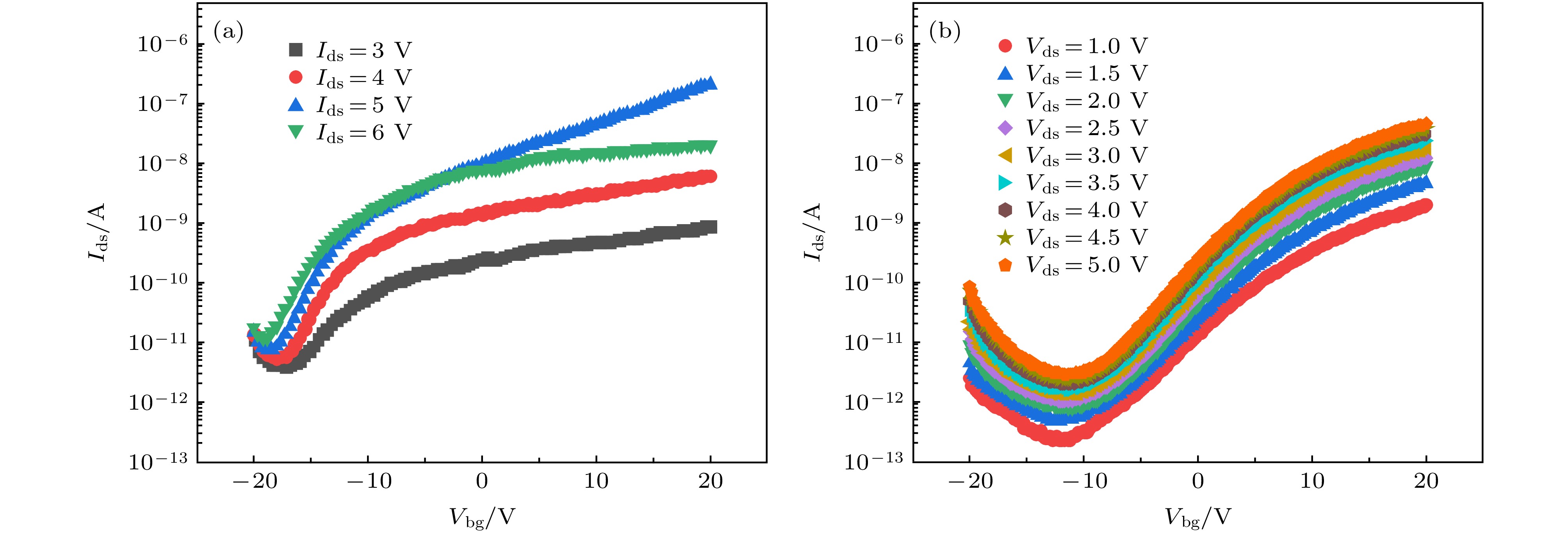

In this paper, Co3O4、MoO3 and Se powders were used as precursors in in-situ co-growth chemical vapor deposition method. Cobalt-doped MoSe2 nanosheets were grown on SiO2 substrate at 710 ℃. The influence of hydrogen content on its growth and regulation mechanism was discussed. Surface morphology analysis showed that the introduction of hydrogen promoted the formation of oxy-selenium metal compounds required for nucleation and the CoMoSe compound molecules required for lateral growth. AFM(atomic force microscope) results show that hydrogen is beneficial to the growth of single-layer two-dimensional cobalt-doped MoSe2. With the increase of the amount of Co3O4 precursor, the Raman and PL(photoluminescence) spectra of the sample showed red shift and blue shift, respectively, and the bandgap was modulated from 1.52 eV to 1.57 eV. The XPS(X-ray photoelectron spectroscopy) results analysis showed that the elemental composition ratio of Co was 4.4%. The magneto and electric properties of the samples were analyzed by SQUID-VSM(superconducting quantum interference device) and semiconductor parameter analyzer for electrical testing. The results show that MoSe2 changes from diamagnetic to soft magnetic after Co incorporation; the threshold voltage of back gate FETs is shifted by 5 V from pure MoSe2, and the off-state current is lower. This research provides a basis for the research and application development of ultra-thin two-dimensional materials.

-

Keywords:

- two-dimensional materials /

- MoSe2 /

- Colbat-doping /

- chemistry phase deposition(CVD)

[1] Larentis S, Fallahazad B, Tutuc E 2012 Appl. Phys. Lett. 101 223104

Google Scholar

Google Scholar

[2] Wang Q H, Kalantar-Zadeh K, Kis A, Coleman J N, Strano M S 2012 Nat. Nanotechnol. 7 699

Google Scholar

Google Scholar

[3] Li Y, Zhang K, Wang F, Feng Y, Li Y, Han Y, Tang D, Zhang B 2017 ACS Appl. Mater. Interfaces. 9 36009

Google Scholar

Google Scholar

[4] Li X, Puretzky A A, Sang X, KC S, Tian M, Ceballos F, Mahjouri‐Samani M, Wang K, Unocic R R, Zhao H 2017 Adv. Funct. Mater. 27 1603850

Google Scholar

Google Scholar

[5] Huang B, Yoon M, Sumpter B G, Wei S-H, Liu F 2015 Appl. Phys. Lett. 115 126806

Google Scholar

Google Scholar

[6] Fan S, Shen W, An C, Sun Z, Wu S, Xu L, Sun D, Hu X, Zhang D, Liu J 2018 ACS Appl. Mater. Interfaces. 10 26533

Google Scholar

Google Scholar

[7] Feng Q, Mao N, Wu J, Xu H, Wang C, Zhang J, Xie L 2015 ACS Nano. 9 7450

Google Scholar

Google Scholar

[8] Feng Q, Zhu Y, Hong J, Zhang M, Duan W, Mao N, Wu J, Xu H, Dong F, Lin F, Jin C, Wang C, Zhang J, Xie L 2014 Adv. Mater. 26 2648

Google Scholar

Google Scholar

[9] Tang D, Wang F, Zhang B, Li Y, Li Y, Feng Y, Han Y, Ma J, Ren T, and Zhang K 2018 J. Mater. Sci. 53 14447

Google Scholar

Google Scholar

[10] Li X, Lin M W, Basile L, Hus S M, Puretzky A A, Lee J, Kuo Y C, Chang L Y, Wang K, Idrobo J C, Li A P, Chen C-H, Rouleau C M, Geohegan D B, Xiao K 2016 Adv. Mater. 28 8240

Google Scholar

Google Scholar

[11] Cheng Y C, Zhu Z, Mi W B, Guo Z B, Schwingenschlögl U 2013 Phys. Rev. B. 87 100401

Google Scholar

Google Scholar

[12] Xie L Y, Zhang J M 2016 Superlattices Microstruct. 98 148

[13] Xu R, Liu B, Zou X, Cheng H M 2017 ACS Appl. Mater. Interfaces. 9 38796

Google Scholar

Google Scholar

[14] Li B, Huang L, Zhong M, Huo N, Li Y, Yang S, Fan C, Yang J, Hu W, Wei Z, Li J 2015 ACS Nano. 9 1257

Google Scholar

Google Scholar

[15] Chen X, Qiu Y, Liu G, Zheng W, Feng W, Gao F, Cao W, Fu Y, Hu W, Hu P 2017 J. Mater. Chem. A. 5 11357

Google Scholar

Google Scholar

[16] 黄静雯, 罗利琼, 金波, 楚士晋, 彭汝芳 2017 66 137801

Google Scholar

Google Scholar

Huang J W, Luo L Q, Jin B, Chu S J, Peng R F 2017 Acta Phys. Sin. 66 137801

Google Scholar

Google Scholar

[17] Zhang J, Yu H, Chen W, Tian X, Liu D, Cheng M, Xie G, Yang W, Yang R, Bai X, Shi D, Zhang G 2014 ACS nano. 8 6024

Google Scholar

Google Scholar

[18] Tu Z, Li G, Ni X, Meng L, Bai S, Chen X, Lou J, Qin Y 2016 Appl. Phys. Lett. 109 223101

Google Scholar

Google Scholar

[19] Rong Y, Fan Y, Koh A L, Robertson A W, He K, Wang S, Tan H, Sinclair R, Warner J H 2014 Nanoscale. 6 12096

Google Scholar

Google Scholar

[20] Chen J, Liu B, Liu Y, Tang W, Nai C T, Li L, Zheng J, Gao L, Zheng Y, Shin H. S, Jeong H Y, Loh K P 2015 Adv. Mater. 27 6722

Google Scholar

Google Scholar

[21] Zhan L, Wan W, Zhu Z, Xu Y, Shih T-M, Zhang C, Lin W, Li X, Zhao Z, Ying H, Yao Q, Zheng Y, Zhu Z, Cai W 2017 J. Phys. Chem. C 121 4703

Google Scholar

Google Scholar

[22] Chen J, Zhao X, Tan S J, Xu H, Wu B, Liu B, Fu D, Fu W, Geng D, Liu Y, Liu W, Li L, Zhou W, Sum T C, Loh K P 2017 J. Am. Chem. Soc. 139 1073

Google Scholar

Google Scholar

[23] Cheng J, Jiang T, Ji Q, Zhang Y, Li Z, Shan Y, Zhang Y, Gong X, Liu W, Wu S 2015 Adv. Mater. 27 4069

Google Scholar

Google Scholar

[24] Gao Y, Hong Y L, Yin L C, Wu Z, Yang Z, Chen M L, Liu Z, Ma T, Sun D M, Ni Z, Ma X-L, Cheng H-M, Ren W 2017 Adv. Mater. 29 1700990

Google Scholar

Google Scholar

-

图 4 (a)掺Co MoSe2的EDS谱图; (b)掺Co MoSe2样品EDS mapping图; (c)−(e)为未掺钴与掺钴的二硒化钼样品的XPS: (c) Co2p谱, (d) Mo3d谱和(e) Se3d谱

Figure 4. (a) EDS spectrum of doped Co MoSe2; (b) EDS mapping of Co doped MoSe2; (c−e) XPS contrast spectra of MoSe2 and cobalt-doped MoSe2: (c) Co2p core level region, (d) Mo3d core level region and (e) Se3d core level region, respectively.

-

[1] Larentis S, Fallahazad B, Tutuc E 2012 Appl. Phys. Lett. 101 223104

Google Scholar

Google Scholar

[2] Wang Q H, Kalantar-Zadeh K, Kis A, Coleman J N, Strano M S 2012 Nat. Nanotechnol. 7 699

Google Scholar

Google Scholar

[3] Li Y, Zhang K, Wang F, Feng Y, Li Y, Han Y, Tang D, Zhang B 2017 ACS Appl. Mater. Interfaces. 9 36009

Google Scholar

Google Scholar

[4] Li X, Puretzky A A, Sang X, KC S, Tian M, Ceballos F, Mahjouri‐Samani M, Wang K, Unocic R R, Zhao H 2017 Adv. Funct. Mater. 27 1603850

Google Scholar

Google Scholar

[5] Huang B, Yoon M, Sumpter B G, Wei S-H, Liu F 2015 Appl. Phys. Lett. 115 126806

Google Scholar

Google Scholar

[6] Fan S, Shen W, An C, Sun Z, Wu S, Xu L, Sun D, Hu X, Zhang D, Liu J 2018 ACS Appl. Mater. Interfaces. 10 26533

Google Scholar

Google Scholar

[7] Feng Q, Mao N, Wu J, Xu H, Wang C, Zhang J, Xie L 2015 ACS Nano. 9 7450

Google Scholar

Google Scholar

[8] Feng Q, Zhu Y, Hong J, Zhang M, Duan W, Mao N, Wu J, Xu H, Dong F, Lin F, Jin C, Wang C, Zhang J, Xie L 2014 Adv. Mater. 26 2648

Google Scholar

Google Scholar

[9] Tang D, Wang F, Zhang B, Li Y, Li Y, Feng Y, Han Y, Ma J, Ren T, and Zhang K 2018 J. Mater. Sci. 53 14447

Google Scholar

Google Scholar

[10] Li X, Lin M W, Basile L, Hus S M, Puretzky A A, Lee J, Kuo Y C, Chang L Y, Wang K, Idrobo J C, Li A P, Chen C-H, Rouleau C M, Geohegan D B, Xiao K 2016 Adv. Mater. 28 8240

Google Scholar

Google Scholar

[11] Cheng Y C, Zhu Z, Mi W B, Guo Z B, Schwingenschlögl U 2013 Phys. Rev. B. 87 100401

Google Scholar

Google Scholar

[12] Xie L Y, Zhang J M 2016 Superlattices Microstruct. 98 148

[13] Xu R, Liu B, Zou X, Cheng H M 2017 ACS Appl. Mater. Interfaces. 9 38796

Google Scholar

Google Scholar

[14] Li B, Huang L, Zhong M, Huo N, Li Y, Yang S, Fan C, Yang J, Hu W, Wei Z, Li J 2015 ACS Nano. 9 1257

Google Scholar

Google Scholar

[15] Chen X, Qiu Y, Liu G, Zheng W, Feng W, Gao F, Cao W, Fu Y, Hu W, Hu P 2017 J. Mater. Chem. A. 5 11357

Google Scholar

Google Scholar

[16] 黄静雯, 罗利琼, 金波, 楚士晋, 彭汝芳 2017 66 137801

Google Scholar

Google Scholar

Huang J W, Luo L Q, Jin B, Chu S J, Peng R F 2017 Acta Phys. Sin. 66 137801

Google Scholar

Google Scholar

[17] Zhang J, Yu H, Chen W, Tian X, Liu D, Cheng M, Xie G, Yang W, Yang R, Bai X, Shi D, Zhang G 2014 ACS nano. 8 6024

Google Scholar

Google Scholar

[18] Tu Z, Li G, Ni X, Meng L, Bai S, Chen X, Lou J, Qin Y 2016 Appl. Phys. Lett. 109 223101

Google Scholar

Google Scholar

[19] Rong Y, Fan Y, Koh A L, Robertson A W, He K, Wang S, Tan H, Sinclair R, Warner J H 2014 Nanoscale. 6 12096

Google Scholar

Google Scholar

[20] Chen J, Liu B, Liu Y, Tang W, Nai C T, Li L, Zheng J, Gao L, Zheng Y, Shin H. S, Jeong H Y, Loh K P 2015 Adv. Mater. 27 6722

Google Scholar

Google Scholar

[21] Zhan L, Wan W, Zhu Z, Xu Y, Shih T-M, Zhang C, Lin W, Li X, Zhao Z, Ying H, Yao Q, Zheng Y, Zhu Z, Cai W 2017 J. Phys. Chem. C 121 4703

Google Scholar

Google Scholar

[22] Chen J, Zhao X, Tan S J, Xu H, Wu B, Liu B, Fu D, Fu W, Geng D, Liu Y, Liu W, Li L, Zhou W, Sum T C, Loh K P 2017 J. Am. Chem. Soc. 139 1073

Google Scholar

Google Scholar

[23] Cheng J, Jiang T, Ji Q, Zhang Y, Li Z, Shan Y, Zhang Y, Gong X, Liu W, Wu S 2015 Adv. Mater. 27 4069

Google Scholar

Google Scholar

[24] Gao Y, Hong Y L, Yin L C, Wu Z, Yang Z, Chen M L, Liu Z, Ma T, Sun D M, Ni Z, Ma X-L, Cheng H-M, Ren W 2017 Adv. Mater. 29 1700990

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 11476

- PDF Downloads: 140

- Cited By: 0

DownLoad:

DownLoad: