-

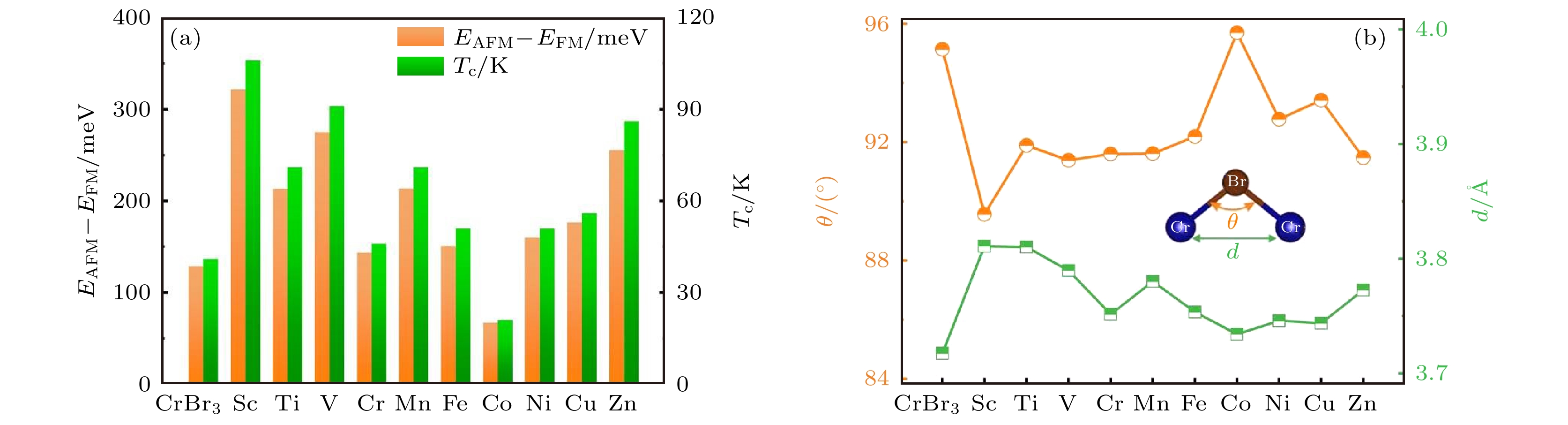

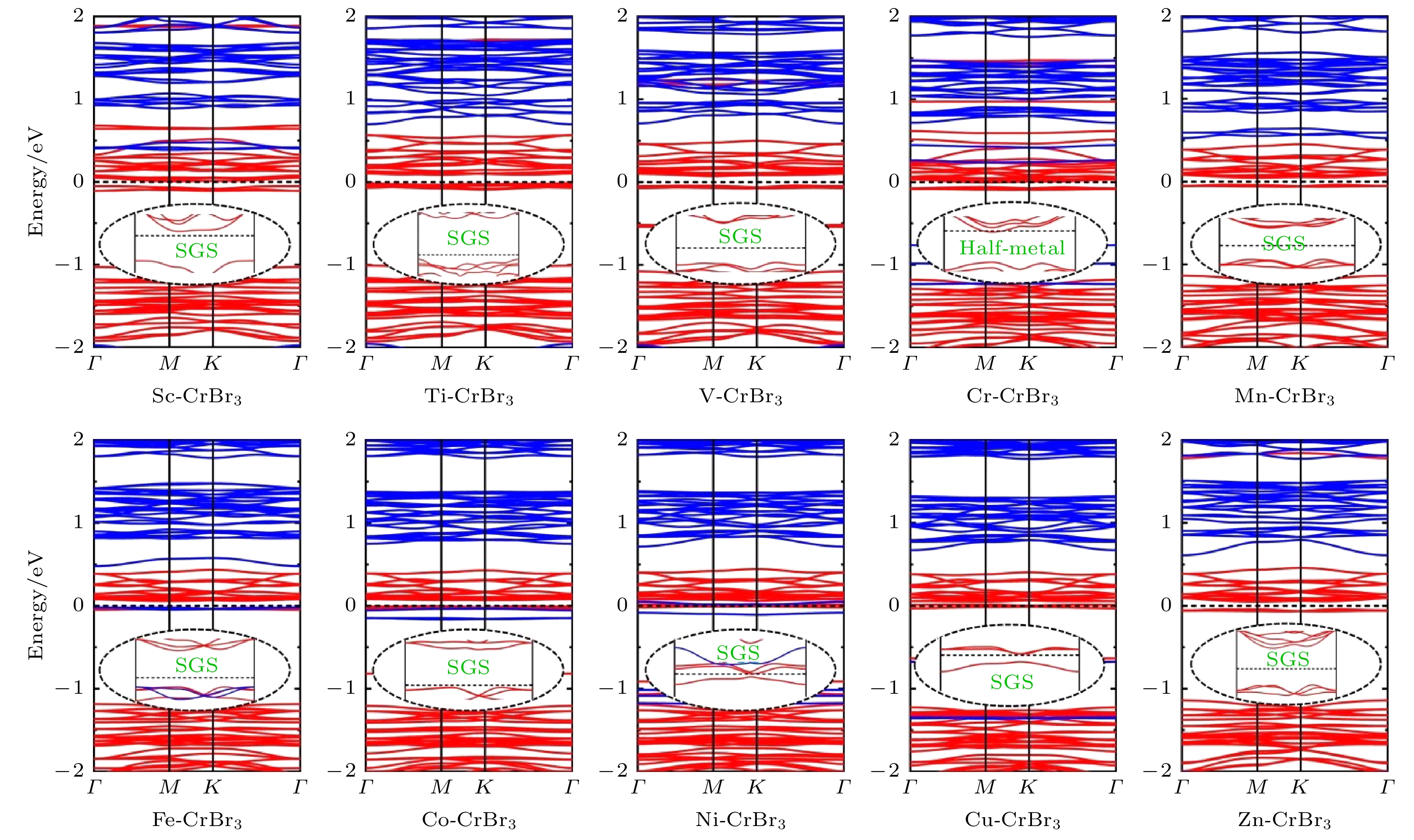

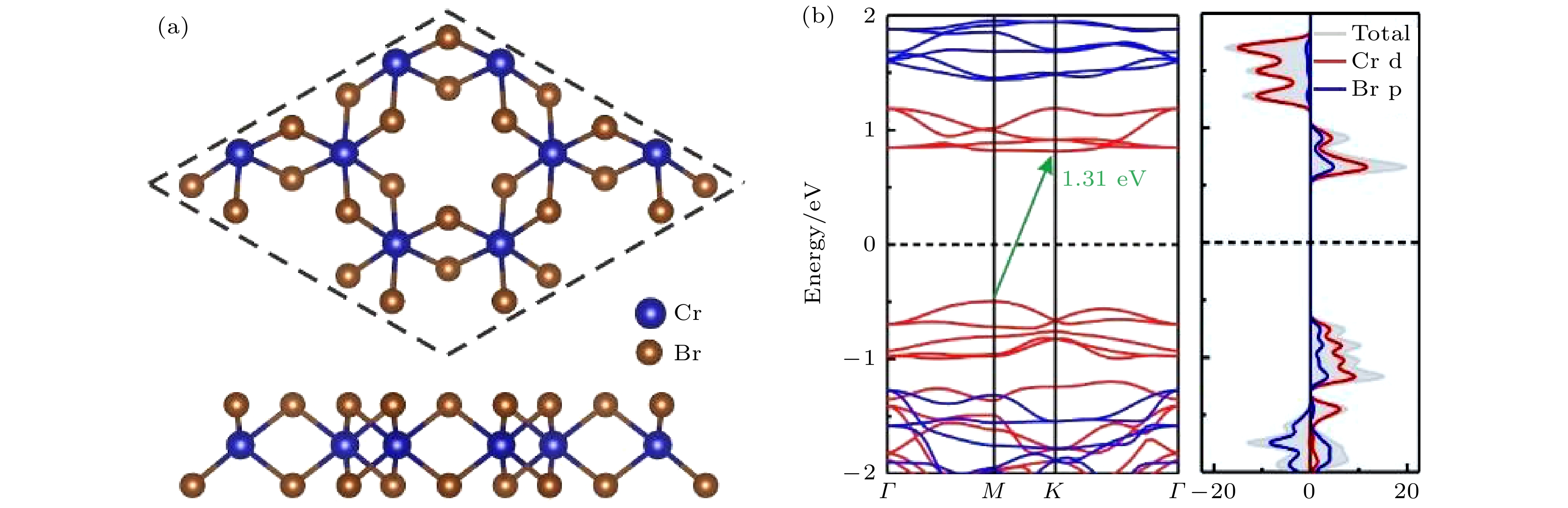

近年来, 二维铁磁材料由于其在自旋电子学领域中十分广阔的应用前景受到广泛关注. 单层CrBr3是具有本征铁磁性的半导体, 是自旋电子器件的潜在候选材料. 然而, 单层CrBr3的居里温度较低, 限制了其在自旋电子器件领域的应用. 本文基于密度泛函理论, 研究了3d过渡金属(TM)原子 (Sc, Ti, V, Cr, Mn, Fe, Co, Ni, Cu和Zn)掺杂单层CrBr3的磁学和电学性能. 计算结果表明, TM原子掺杂后, 体系总磁矩呈现先增加再减小的趋势. 并且TM原子掺杂能够显著提高单层CrBr3的居里温度(TC), 实现了铁磁稳定性的增强. 其中, Sc掺杂CrBr3体系的TC与本征CrBr3相比提高了159%. 铁磁稳定性的增强归因于掺杂体系 (TM-CrBr3) 中直接交换和超交换相互作用之间的竞争. 此外, 依赖于不同的TM原子掺杂, TM-CrBr3体系表现出半金属性和自旋零带隙半导体性质. 本文的研究结果为单层CrBr3在纳米电子和自旋电子器件中的应用开辟了新的前景.The CrBr3 monolayer is a two-dimensional semiconductor material with intrinsic ferromagnetism. However, the low Curie temperature of CrBr3 monolayer limits its practical development in innovative spintronic devices. The electronic and magnetic properties of transition-metal atoms doped CrBr3 monolayer have been systematically investigated by using the density functional theory calculations. The formation energy elucidates that all 3d transition metal (TM) atoms prefer to be doped in the middle of a hexagon (H) site of CrBr3 monolayer. And all the TM atoms, except the Zn atom, can bond strongly to the surrounding Cr atoms with sizable formation energy. The results also indicate that the magnetic moment of TM-CrBr3 system changes as a result of the charge transfer between TM atom and adjacent Cr atom. In addition, comparing with the intrinsic CrBr3, the TC of TM-CrBr3 system increases significantly, which means that the ferromagnetic stability of CrBr3 monolayer is enhanced. In particular, the TC of CrBr3 with Sc atom can be increased by 159%. The enhancement of ferromagnetism is mainly due to the competition between the direct exchange and the superexchange interaction. We also find that the electronic properties of the TM-CrBr3 systems are diverse. For example, Sc-, Ti-, V-, Mn-, Fe-, Co-, Ni-, Cu- and Zn-CrBr3 exhibit spin gapless semiconductor (SGS) properties with 100% spin polarization at Fermi level. The TM-CrBr3 system can be adjusted from semiconductor to half-metal when Cr atoms are doped into the CrBr3 monolayer. This work, together with recent achievements in the field of two-dimensional ferromagnetic materials, provides an experimentally achievable guide for realizing the preparation of TM-CrBr3 system with high Curie temperature. Moreover, the possibility of application of these systems in nanoelectronics and spintronics is increased.

-

Keywords:

- two-dimensional materials /

- transition-metal doping /

- electrical properties /

- magnetic properties

[1] Hu X H, Björkman T, Lipsanen H, Sun L T, Krasheninnikov A V 2015 J. Phys. Chem. Lett. 6 3263

Google Scholar

Google Scholar

[2] Hu X H, Wang Y F, Shen X D, Krasheninnikov A V, Sun L T, Chen Z F 2018 2D Mater. 5 031012

Google Scholar

Google Scholar

[3] Duan X D, Wang C, Pan A L, Yu R Q, Duan X F 2015 Chem. Soc. Rev. 44 8859

Google Scholar

Google Scholar

[4] Kou L Z, Ma Y D, Sun Z Q, Heine T, Chen C F 2017 J. Phys. Chem. Lett. 8 1905

Google Scholar

Google Scholar

[5] Hu X H, Zhao Y H, Shen X D, Krasheninnikov A V, Chen Z F, Sun L T 2020 ACS Appl. Mater. Interfaces 12 26367

Google Scholar

Google Scholar

[6] Ai W, Kou L Z, Hu X H, Wang Y F, Krasheninnikov A V, Sun L T, Shen X D 2019 J. Phys. Condens. Matter 31 445301

Google Scholar

Google Scholar

[7] Hu X H, Wan N, Sun L T, Krasheninnikov A V 2014 J. Phys. Chem. C 118 16133

Google Scholar

Google Scholar

[8] Hu X H, Zhang W, Sun L T, Krasheninnikov A V 2012 Phys. Rev. B 86 195418

Google Scholar

Google Scholar

[9] 艾雯, 胡小会, 潘林, 陈长春, 王一峰, 沈晓冬 2019 68 197101

Google Scholar

Google Scholar

Ai W, Hu X H, Pan L, Chen C C, Wang Y F, Shen X D 2019 Acta Phys. Sin. 68 197101

Google Scholar

Google Scholar

[10] Hu X H, Sun L T, Krasheninnikov A V 2012 Appl. Phys. Lett. 100 263115

Google Scholar

Google Scholar

[11] Zhang S L, Yan Z, Li Y F, Chen Z F, Zeng H B 2015 Angew. Chem. -Int. Ed. 54 3112

Google Scholar

Google Scholar

[12] Chen X P, Yang Q, Meng R S, Jiang J K, Liang Q H, Tan C J, Sun X 2016 J. Mater. Chem. C 4 5434

Google Scholar

Google Scholar

[13] Yang Q, Kou L Z, Hu X H, Wang Y F, Lu C H, Krasheninnikov A V, Sun L T 2020 J. Phys. Condens. Matter 32 365302

Google Scholar

Google Scholar

[14] Karthikeyan J, Komsa H P, Batzill M, Krasheninnikov A V 2019 Nano Lett. 19 4581

Google Scholar

Google Scholar

[15] Yang Q, Hu X H, Shen X D, Krasheninnikov A V, Chen Z F, Sun L T 2021 ACS Appl. Mater. Interfaces 13 21593

Google Scholar

Google Scholar

[16] Wang J X, Kou L Z, Ni Y R, Hu X H 2021 J. Phys. Condens. Matter 33 235502

Google Scholar

Google Scholar

[17] Kou L, Tang C, Guo W, Chen C 2011 ACS Nano 5 1012

Google Scholar

Google Scholar

[18] Liu L F, Kou L Z, Wang Y F, Lu C H, Hu X H 2020 Nanotechnology 31 455702

Google Scholar

Google Scholar

[19] Tao P, Guo H H, Zhang Z D, Yang T 2014 J. Appl. Phys. 115 054305

Google Scholar

Google Scholar

[20] Jiang C H, Zhou R Q, Peng Z H, Zhu J F, Chen Q 2016 Phys. Chem. Chem. Phys. 18 32528

Google Scholar

Google Scholar

[21] Huang B, Clark G, Navarro-Moratalla E, Klein D R, Cheng R, Seyler K L, Zhong D, Schmidgall E, McGuire M A, Cobden D H, Yao W, Xiao D, Jarillo-Herrero P, Xu X D 2017 Nature 546 270

Google Scholar

Google Scholar

[22] Gong C, Li L, Li Z L, Ji H W, Stern A, Xia Y, Cao T, Bao W, Wang C Z, Wang Y A, Qiu Z Q, Cava R J, Louie S G, Xia J, Zhang X 2017 Nature 546 265

Google Scholar

Google Scholar

[23] Zhang Z W, Shang J Z, Jiang C Y, Rasmita A, Gao W B, Yu T 2019 Nano Lett. 19 3138

Google Scholar

Google Scholar

[24] Chen W J, Sun Z Y, Wang Z J, Gu L H, Xu X D, Wu S W, Gao C L 2019 Science 366 983

Google Scholar

Google Scholar

[25] Tang C L, Zhang Z W, Lai S, Tan Q H, Gao W B 2020 Adv. Mater. 32 1908498

Google Scholar

Google Scholar

[26] Lyons T P, Gillard D, Molina-Sanchez A, Misra A, Withers F, Keatley P S, Kozikov A, Taniguchi T, Watanabe K, Novoselov K S, Fernandez-Rossier J, Tartakovskii A I 2020 Nat. Commun. 11 6021

Google Scholar

Google Scholar

[27] Webster L, Yan J A 2018 Phys. Rev. B 98 144411

Google Scholar

Google Scholar

[28] Cheng Y C, Zhu Z Y, Mi W B, Guo Z B, Schwingenschlogl U 2013 Phys. Rev. 87 100401

Google Scholar

Google Scholar

[29] Li B, Xing T, Zhong M Z, Huang L, Lei N, Zhang J, Li J B, Wei Z M 2017 Nat. Commun. 8 1958

Google Scholar

Google Scholar

[30] Peng Y T, Wei S Y, Xia C X, Jia Y 2013 Mod. Phys. Lett. B 27 1350204

Google Scholar

Google Scholar

[31] Song C S, Xiao W, Li L, Lu Y, Jiang P, Li C, Chen A X, Zhong Z C 2019 Phys. Rev. B 99 214435

Google Scholar

Google Scholar

[32] Guo Y L, Yuan S J, Wang B, Shi L, Wang J L 2018 J. Mater. Chem. C 6 5716

Google Scholar

Google Scholar

[33] Kresse G, Furthmuller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[34] Kresse G, Furthmuller J 1996 Comput. Mater. Sci. 6 15

Google Scholar

Google Scholar

[35] Blochl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[36] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[37] Chen S B, Huang C X, Sun H S, Ding J F, Jena P, Kan E 2019 J. Phys. Chem. C 123 17987

Google Scholar

Google Scholar

[38] Tang C, Zhang L, Du A J 2020 J. Mater. Chem. C 8 14948

Google Scholar

Google Scholar

[39] Bacaksiz C, Sabani D, Menezes R M, Milosevic M V 2021 Phys. Rev. B 103 125418

Google Scholar

Google Scholar

[40] Zhang H, Yang W, Ning Y, Xu X H 2020 Nanoscale 12 13964

Google Scholar

Google Scholar

[41] 隋雪蕾 2017 博士学位论文 (北京: 清华大学)

Sui X L 2017 Ph. D. Dissertation (Beijing: Tsinghua University) (in Chinese)

[42] Krasheninnikov A V, Lehtinen P O, Foster A S, Pyykko P, Nieminen R M 2009 Phys. Rev. Lett. 102 126807

Google Scholar

Google Scholar

[43] Sui X L, Si C, Shao B, Zou X L, Wu J, Gu B L, Duan W H 2015 J. Phys. Chem. C 119 10059

Google Scholar

Google Scholar

[44] Tiwari S, Van-de-Put M L, Soree B, Vandenberghe W G 2021 Phys. Rev. B 103 014432

Google Scholar

Google Scholar

[45] Goodenough J B 1955 Phys. Rev. 100 564

Google Scholar

Google Scholar

[46] Kanamori J 1960 J. Appl. Phys. 31 S14

Google Scholar

Google Scholar

[47] Anderson P W 1959 Phys. Rev. 115 2

Google Scholar

Google Scholar

[48] Wang X L 2008 Phys. Rev. Lett. 100 156404

Google Scholar

Google Scholar

-

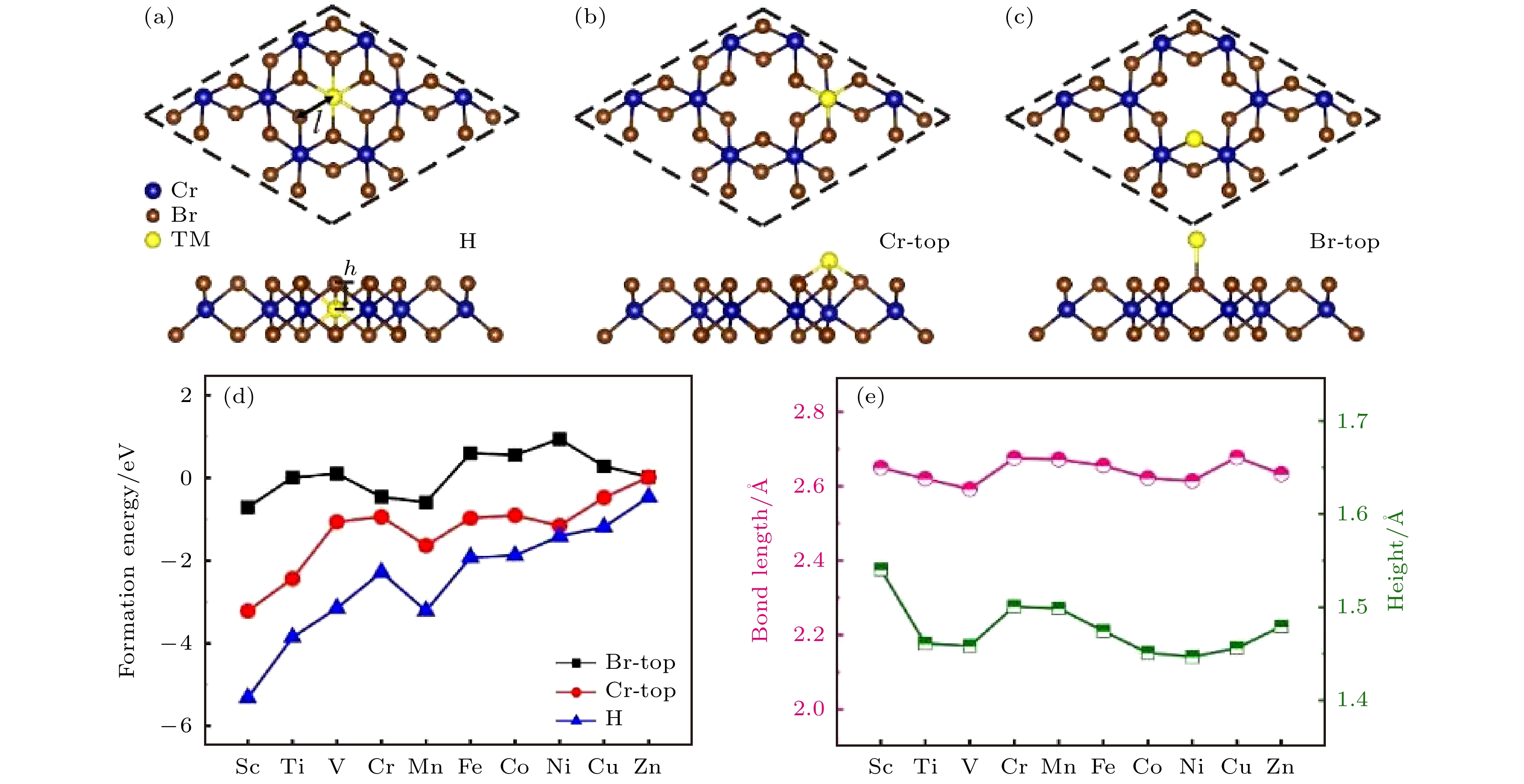

图 2 (a)−(c) TM原子分别掺杂在H, Cr-Top和Br-Top位点时TM-CrBr3晶体结构的俯视图和侧视图; (d) TM-CrBr3的形成能; (e) 在H构型中, TM原子到CrBr3表层Br原子的高度以及TM原子与最邻近Br原子共价键的键长

Fig. 2. Top and side views of the crystalline structure of three different doped positions of TM atoms labeled as (a) H, (b) Cr-Top and (c) Br-Top; (d) the formation energy of TM-CrBr3; (e) the height of the TM to Br on the surface of CrBr3 and the length of covalent bond between TM and nearest Br atom.

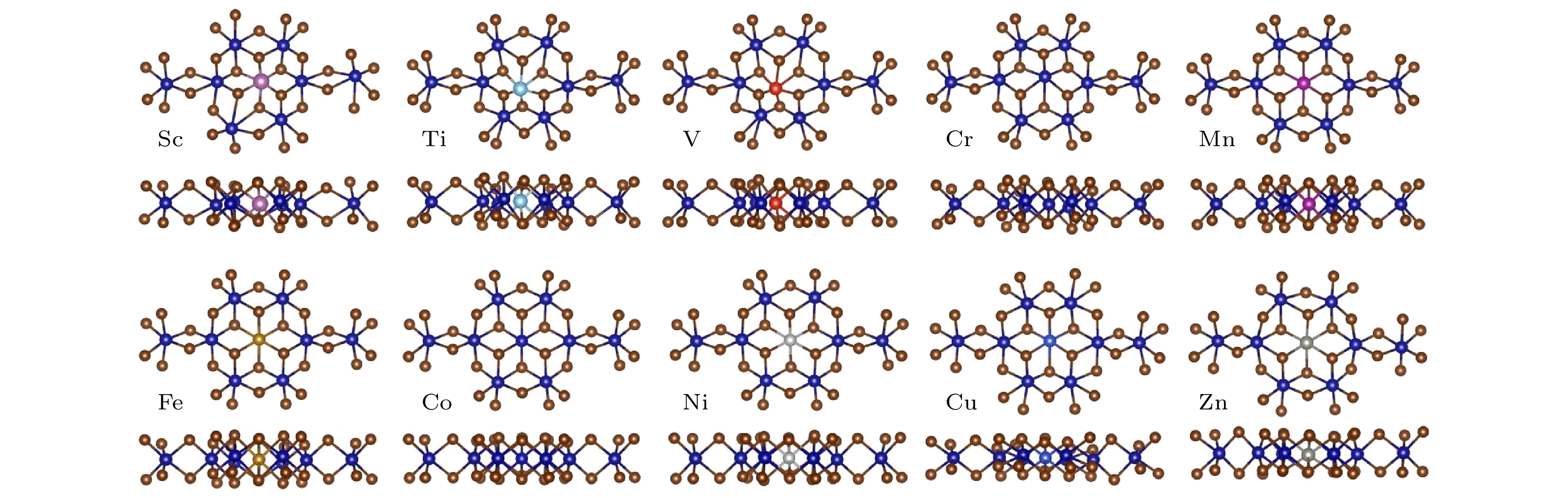

图 4 (a) H构型的TM-CrBr3中TM原子的磁矩以及与TM原子最近邻的Cr原子的磁矩; (b) TM-CrBr3中Cr和TM原子的电荷转移; (c) TM-CrBr3体系的总磁矩(Mtotal)

Fig. 4. (a) Magnetic moments of TM atom and Cr atom nearest to TM atom in TM-CrBr3 of H configuration; (b) charge transfer between Cr and TM atoms in TM-CrBr3; (c) the total magnetic moments (Mtotal) of TM-CrBr3.

图 6 3d TM原子掺杂单层CrBr3的自旋极化能带结构, 插图是费米能级附近能带结构的放大图. 自旋向上和自旋向下分别用红色实线和蓝色实线表示

Fig. 6. Spin-polarized band structures of 3d TM atoms doped CrBr3 monolayer. The illustration is an enlarged picture of the band structures near the Fermi level. The red and blue solid lines indicate spin-up and spin-down channels in the band structures, respectively.

表 1 本征CrBr3和TM-CrBr3体系中的交换耦合参数 (J )

Table 1. Exchange coupling parameter (J ) of pristine CrBr3 and TM-CrBr3.

CrBr3 Sc Ti V Cr Mn Fe Co Ni Cu Zn J/meV 2.39 5.95 3.95 5.10 2.66 3.96 2.80 1.25 2.97 3.27 4.73 -

[1] Hu X H, Björkman T, Lipsanen H, Sun L T, Krasheninnikov A V 2015 J. Phys. Chem. Lett. 6 3263

Google Scholar

Google Scholar

[2] Hu X H, Wang Y F, Shen X D, Krasheninnikov A V, Sun L T, Chen Z F 2018 2D Mater. 5 031012

Google Scholar

Google Scholar

[3] Duan X D, Wang C, Pan A L, Yu R Q, Duan X F 2015 Chem. Soc. Rev. 44 8859

Google Scholar

Google Scholar

[4] Kou L Z, Ma Y D, Sun Z Q, Heine T, Chen C F 2017 J. Phys. Chem. Lett. 8 1905

Google Scholar

Google Scholar

[5] Hu X H, Zhao Y H, Shen X D, Krasheninnikov A V, Chen Z F, Sun L T 2020 ACS Appl. Mater. Interfaces 12 26367

Google Scholar

Google Scholar

[6] Ai W, Kou L Z, Hu X H, Wang Y F, Krasheninnikov A V, Sun L T, Shen X D 2019 J. Phys. Condens. Matter 31 445301

Google Scholar

Google Scholar

[7] Hu X H, Wan N, Sun L T, Krasheninnikov A V 2014 J. Phys. Chem. C 118 16133

Google Scholar

Google Scholar

[8] Hu X H, Zhang W, Sun L T, Krasheninnikov A V 2012 Phys. Rev. B 86 195418

Google Scholar

Google Scholar

[9] 艾雯, 胡小会, 潘林, 陈长春, 王一峰, 沈晓冬 2019 68 197101

Google Scholar

Google Scholar

Ai W, Hu X H, Pan L, Chen C C, Wang Y F, Shen X D 2019 Acta Phys. Sin. 68 197101

Google Scholar

Google Scholar

[10] Hu X H, Sun L T, Krasheninnikov A V 2012 Appl. Phys. Lett. 100 263115

Google Scholar

Google Scholar

[11] Zhang S L, Yan Z, Li Y F, Chen Z F, Zeng H B 2015 Angew. Chem. -Int. Ed. 54 3112

Google Scholar

Google Scholar

[12] Chen X P, Yang Q, Meng R S, Jiang J K, Liang Q H, Tan C J, Sun X 2016 J. Mater. Chem. C 4 5434

Google Scholar

Google Scholar

[13] Yang Q, Kou L Z, Hu X H, Wang Y F, Lu C H, Krasheninnikov A V, Sun L T 2020 J. Phys. Condens. Matter 32 365302

Google Scholar

Google Scholar

[14] Karthikeyan J, Komsa H P, Batzill M, Krasheninnikov A V 2019 Nano Lett. 19 4581

Google Scholar

Google Scholar

[15] Yang Q, Hu X H, Shen X D, Krasheninnikov A V, Chen Z F, Sun L T 2021 ACS Appl. Mater. Interfaces 13 21593

Google Scholar

Google Scholar

[16] Wang J X, Kou L Z, Ni Y R, Hu X H 2021 J. Phys. Condens. Matter 33 235502

Google Scholar

Google Scholar

[17] Kou L, Tang C, Guo W, Chen C 2011 ACS Nano 5 1012

Google Scholar

Google Scholar

[18] Liu L F, Kou L Z, Wang Y F, Lu C H, Hu X H 2020 Nanotechnology 31 455702

Google Scholar

Google Scholar

[19] Tao P, Guo H H, Zhang Z D, Yang T 2014 J. Appl. Phys. 115 054305

Google Scholar

Google Scholar

[20] Jiang C H, Zhou R Q, Peng Z H, Zhu J F, Chen Q 2016 Phys. Chem. Chem. Phys. 18 32528

Google Scholar

Google Scholar

[21] Huang B, Clark G, Navarro-Moratalla E, Klein D R, Cheng R, Seyler K L, Zhong D, Schmidgall E, McGuire M A, Cobden D H, Yao W, Xiao D, Jarillo-Herrero P, Xu X D 2017 Nature 546 270

Google Scholar

Google Scholar

[22] Gong C, Li L, Li Z L, Ji H W, Stern A, Xia Y, Cao T, Bao W, Wang C Z, Wang Y A, Qiu Z Q, Cava R J, Louie S G, Xia J, Zhang X 2017 Nature 546 265

Google Scholar

Google Scholar

[23] Zhang Z W, Shang J Z, Jiang C Y, Rasmita A, Gao W B, Yu T 2019 Nano Lett. 19 3138

Google Scholar

Google Scholar

[24] Chen W J, Sun Z Y, Wang Z J, Gu L H, Xu X D, Wu S W, Gao C L 2019 Science 366 983

Google Scholar

Google Scholar

[25] Tang C L, Zhang Z W, Lai S, Tan Q H, Gao W B 2020 Adv. Mater. 32 1908498

Google Scholar

Google Scholar

[26] Lyons T P, Gillard D, Molina-Sanchez A, Misra A, Withers F, Keatley P S, Kozikov A, Taniguchi T, Watanabe K, Novoselov K S, Fernandez-Rossier J, Tartakovskii A I 2020 Nat. Commun. 11 6021

Google Scholar

Google Scholar

[27] Webster L, Yan J A 2018 Phys. Rev. B 98 144411

Google Scholar

Google Scholar

[28] Cheng Y C, Zhu Z Y, Mi W B, Guo Z B, Schwingenschlogl U 2013 Phys. Rev. 87 100401

Google Scholar

Google Scholar

[29] Li B, Xing T, Zhong M Z, Huang L, Lei N, Zhang J, Li J B, Wei Z M 2017 Nat. Commun. 8 1958

Google Scholar

Google Scholar

[30] Peng Y T, Wei S Y, Xia C X, Jia Y 2013 Mod. Phys. Lett. B 27 1350204

Google Scholar

Google Scholar

[31] Song C S, Xiao W, Li L, Lu Y, Jiang P, Li C, Chen A X, Zhong Z C 2019 Phys. Rev. B 99 214435

Google Scholar

Google Scholar

[32] Guo Y L, Yuan S J, Wang B, Shi L, Wang J L 2018 J. Mater. Chem. C 6 5716

Google Scholar

Google Scholar

[33] Kresse G, Furthmuller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[34] Kresse G, Furthmuller J 1996 Comput. Mater. Sci. 6 15

Google Scholar

Google Scholar

[35] Blochl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[36] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[37] Chen S B, Huang C X, Sun H S, Ding J F, Jena P, Kan E 2019 J. Phys. Chem. C 123 17987

Google Scholar

Google Scholar

[38] Tang C, Zhang L, Du A J 2020 J. Mater. Chem. C 8 14948

Google Scholar

Google Scholar

[39] Bacaksiz C, Sabani D, Menezes R M, Milosevic M V 2021 Phys. Rev. B 103 125418

Google Scholar

Google Scholar

[40] Zhang H, Yang W, Ning Y, Xu X H 2020 Nanoscale 12 13964

Google Scholar

Google Scholar

[41] 隋雪蕾 2017 博士学位论文 (北京: 清华大学)

Sui X L 2017 Ph. D. Dissertation (Beijing: Tsinghua University) (in Chinese)

[42] Krasheninnikov A V, Lehtinen P O, Foster A S, Pyykko P, Nieminen R M 2009 Phys. Rev. Lett. 102 126807

Google Scholar

Google Scholar

[43] Sui X L, Si C, Shao B, Zou X L, Wu J, Gu B L, Duan W H 2015 J. Phys. Chem. C 119 10059

Google Scholar

Google Scholar

[44] Tiwari S, Van-de-Put M L, Soree B, Vandenberghe W G 2021 Phys. Rev. B 103 014432

Google Scholar

Google Scholar

[45] Goodenough J B 1955 Phys. Rev. 100 564

Google Scholar

Google Scholar

[46] Kanamori J 1960 J. Appl. Phys. 31 S14

Google Scholar

Google Scholar

[47] Anderson P W 1959 Phys. Rev. 115 2

Google Scholar

Google Scholar

[48] Wang X L 2008 Phys. Rev. Lett. 100 156404

Google Scholar

Google Scholar

计量

- 文章访问数: 9030

- PDF下载量: 295

- 被引次数: 0

下载:

下载: