-

近年来, 二维层状材料由于其丰富的材料体系和独特的物理化学性质而受到人们的广泛关注. 后摩尔时代要求器件高度集成化, 大面积、高质量的二维材料可以保证器件中结构和电子性能的连续性. 要实现二维材料工业级别的规模化生产, 样品的可控制备是其前提. 化学气相沉积是满足上述要求的一种强有力的方法, 已广泛应用于二维材料及其复合结构的生长制备. 但是要实现多种二维材料大尺寸以至晶圆级的批量制备仍然是很困难的, 因此, 需要进一步建立对各种二维材料生长控制的系统认识. 本文基于材料生长机理分析了化学气相沉积反应中的物质运输、成核、产物生长过程对二维材料尺寸的影响, 以及如何通过调控这些过程实现二维材料大面积薄膜的可控制备. 通过对目前研究成果的总结分析, 讨论了如何进一步实现二维材料的高质量大面积制备.Two-dimensional (2D) layered materials have attracted increasing attention in recent years because of their abundant material categories and superior physical/chemical properties. In order to satisfy the requirements for highly integrated devices in the post-Moore era, substantial efforts have been devoted to producing atomically thin 2D materials with large lateral dimensions and high crystalline quality. The controllable synthesis is the precondition of the implementation of large mass producing 2D material in industry. Chemical vapor deposition (CVD) is a powerful method widely used in the synthesis of 2D materials and their hybrid structures. However, it is still challengeable to flexibly and easily grow any 2D materials into large area. Therefore, a systematic understanding of the requirements for controllable growth of different 2D materials are desired. In this review article, we provide a comprehensive discussion on the influencing factors, material transport, nucleation and growth rate in the CVD growth process. Finally, the strategies to further improve the size and quality of 2D materials are prospected.

[1] Buscema M, Groenendijk D J, Blanter S I, Steele G A, Van Der Zant H S, Castellanos-Gomez A 2014 Nano Lett. 14 3347

Google Scholar

Google Scholar

[2] Geim A K, Novoselov K S 2007 Nat. Mater. 6 183

Google Scholar

Google Scholar

[3] Mak K F, Shan J 2016 Nat. Photonics 10 216

Google Scholar

Google Scholar

[4] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[5] Wang H, Yu L, Lee Y H, Shi Y, Hsu A, Chin M L, Li L J, Dubey M, Kong J, Palacios T 2012 Nano Lett. 12 4674

Google Scholar

Google Scholar

[6] Wang Q H, Kalantar Zadeh K, Kis A, Coleman J N, Strano M S 2012 Nat. Nanotechnol. 7 699

Google Scholar

Google Scholar

[7] Novoselov K S, Fal V, Colombo L, Gellert P, Schwab M, Kim K 2012 Nature 490 192

Google Scholar

Google Scholar

[8] Desai S B, Madhvapathy S R, Sachid A B, Linas J P, Wang Q, Ahn G H, Pitner G, Kim M J, Bokor J, Hu C 2016 Science 354 99

Google Scholar

Google Scholar

[9] Li M Y, Su S K, Wong H S P, Li L J 2019 Nature 567 169

Google Scholar

Google Scholar

[10] Wang F, Zhang Y, Tian C, Girit C, Zettl A, Crommie M, Shen Y R 2008 Science 320 206

Google Scholar

Google Scholar

[11] Carvalho A, Wang M, Zhu X, Rodin A S, Su H, Neto A H C 2016 Nat. Rev. Mater. 1 1

Google Scholar

Google Scholar

[12] Manzeli S, Ovchinnikov D, Pasquier D, Yazyev O V, Kis A 2017 Nat. Rev. Mater. 2 17033

Google Scholar

Google Scholar

[13] Chen X, Qiu Y, Liu G, Zheng W, Feng W, Gao F, Cao W, Fu Y, Hu W, Hu P 2017 J. Mater. Chem. A 5 11357

Google Scholar

Google Scholar

[14] Watanabe K, Taniguchi T, Kanda H 2004 Nat. Mater. 3 404

Google Scholar

Google Scholar

[15] Xu M, Liang T, Shi M, Chen H 2013 Chem. Rev. 113 3766

Google Scholar

Google Scholar

[16] Yang H, Heo J, Park S, Song H J, Seo D H, Byun K E, Kim P, Yoo I, Chung H J, Kim K 2012 Science 336 1140

Google Scholar

Google Scholar

[17] Goossens S, Navickaite G, Monasterio C, Gupta S, Piqueras J, Pérez R, Burwell G, Nikitskiy I, Lasanta T, Galán T 2017 Nat. Photonics 11 366

Google Scholar

Google Scholar

[18] Sun L, Zhang Y, Han G, Hwang G, Jiang J, Joo B, Watanabe K, Taniguchi T, Kim Y M, Yu W J 2019 Nat. Commun. 10 1

Google Scholar

Google Scholar

[19] Zhang Y, Yao Y, Sendeku M G, Yin L, Zhan X, Wang F, Wang Z, He J 2019 Adv. Mater. 31 1901694

Google Scholar

Google Scholar

[20] Huo C, Yan Z, Song X, Zeng H 2015 Sci. Bull. 60 1994

Google Scholar

Google Scholar

[21] Cai Z, Liu B, Zou X, Cheng H M 2018 Chem. Rev. 118 6091

Google Scholar

Google Scholar

[22] Kang K, Xie S, Huang L, Han Y, Huang P Y, Mak K F, Kim C J, Muller D, Park J 2015 Nature 520 656

Google Scholar

Google Scholar

[23] Kalanyan B, Kimes W A, Beams R, Stranick S J, Garratt E, Kalish I, Davydov A V, Kanjolia R K, Maslar J E 2017 Chem. Mater. 29 6279

Google Scholar

Google Scholar

[24] Choi S H, Stephen B, Park J H, Lee J S, Kim S M, Yang W, Kim K K 2017 Sci. Rep. 7 1

Google Scholar

Google Scholar

[25] Cwik S, Mitoraj D, Mendoza Reyes O, Rogalla D, Peeters D, Kim J, Schütz H M, Bock C, Beranek R, Devi A 2018 Adv. Mater. Interfaces 5 1800140

Google Scholar

Google Scholar

[26] Ma L, Nath D N, Lee E W, Lee C H, Yu M, Arehart A, Rajan S, Wu Y 2014 Appl. Phys. Lett. 105 072105

Google Scholar

Google Scholar

[27] Tao L, Chen K, Chen Z, Chen W, Gui X, Chen H, Li X, Xu J B 2017 ACS Appl. Mater. Interfaces 9 12073

Google Scholar

Google Scholar

[28] Qian S, Yang R, Lan F, Xu Y, Sun K, Zhang S, Zhang Y, Dong Z 2019 Mater. Sci. Semicond. Process 93 317

Google Scholar

Google Scholar

[29] Gong Y, Ye G, Lei S, Shi G, He Y, Lin J, Zhang X, Vajtai R, Pantelides S T, Zhou W 2016 Adv. Funct. Mater. 26 2009

Google Scholar

Google Scholar

[30] 李娜, 张儒静, 甄真, 许振华, 何利民 2020 材料工程 48 36

Google Scholar

Google Scholar

Li N, Zhang R J, Zhen Z, Xu Z H, He L M 2020 J. Mater. Eng. 48 36

Google Scholar

Google Scholar

[31] Zhang L, Shi Z, Wang Y, Yang R, Shi D, Zhang G 2011 Nano Res. 4 315

Google Scholar

Google Scholar

[32] Wei D, Lu Y, Han C, Niu T, Chen W, Wee A T S 2013 Angew. Chem. Int. Ed. 125 14371

Google Scholar

Google Scholar

[33] Kim H, Ahn C, Arabale G, Lee C, Kim T 2013 ECS Trans. 58 47

[34] Lu A Y, Zhu H, Xiao J, Chuu C P, Han Y, Chiu M H, Cheng C C, Yang C W, Wei K H, Yang Y 2017 Nat. Nanotechnol. 12 744

Google Scholar

Google Scholar

[35] Lin L, Deng B, Sun J, Peng H, Liu Z 2018 Chem. Rev. 118 9281

Google Scholar

Google Scholar

[36] 尤佳毅, 沈鸿烈, 吴天如, 谢晓明 2015 真空科学与技术学报 35 109

Google Scholar

Google Scholar

You J Y, Sheng H L, Wu T R, Xie X M 2015 Chin. J. Vac. Sci. Technol. 35 109

Google Scholar

Google Scholar

[37] Rao R, Weaver K, Maruyama B 2015 Mater. Express 5 541

Google Scholar

Google Scholar

[38] 任文杰, 朱永, 龚天诚, 王宁, 张洁 2015 功能材料 46 16115

Ren W J, Zhu Y, Gong T C, Wang N, Zhang J 2015 J. Funct. Mater. 46 16115

[39] Shi R, He P, Cai X, Zhang Z, Wang W, Wang J, Feng X, Wu Z, Amini A, Wang N 2020 ACS Nano 14 7593

Google Scholar

Google Scholar

[40] Yu H, Liao M, Zhao W, Liu G, Zhou X, Wei Z, Xu X, Liu K, Hu Z, Deng K 2017 ACS Nano 11 12001

Google Scholar

Google Scholar

[41] Regmi M, Chisholm M F, Eres G 2012 Carbon 50 134

Google Scholar

Google Scholar

[42] Li J, Cheng S, Liu Z, Zhang W, Chang H 2018 J. Phys. Chem. C 122 7005

Google Scholar

Google Scholar

[43] Yu Y, Li C, Liu Y, Su L, Zhang Y, Cao L 2013 Sci. Rep. 3 1866

Google Scholar

Google Scholar

[44] Elías A L, Perea-López N, Castro-Beltrán A, Berkdemir A, Lü R, Feng S, Long A D, Hayashi T, Kim Y A, Endo M 2013 ACS Nano 7 5235

Google Scholar

Google Scholar

[45] 葛雯, 吕斌 2013 材料科学与工程学报 31 489

Google Scholar

Google Scholar

Ge Wd, Lv B 2013 Mater. Sci. Eng. 31 489

Google Scholar

Google Scholar

[46] Hammer B, Norskov J K 1995 Nature 376 238

Google Scholar

Google Scholar

[47] Chen H, Zhu W, Zhang Z 2010 Phys. Rev. Lett. 104 186101

Google Scholar

Google Scholar

[48] Gao J, Yip J, Zhao J, Yakobson B I, Ding F 2011 J. Am. Chem. Soc. 133 5009

Google Scholar

Google Scholar

[49] Abraham F F 1974 Homogeneous Nucleation Theory (Vol. 263) (New York: Academic Press) pp1−8

[50] Schmelzer J, Röpke G, Priezzhev V B 2005 Nucleation Theory and Applications (Vol. 76) (Hoboken: Wiley-VCH Weinheim) pp39−54

[51] Pruppacher H R, Klett J D 1980 Nature 284 88

[52] [53] 杨雅萍 2016 硕士学位论文 (长沙: 国防科学技术大学)

Yang Y P 2016 M. S. Thesis (Changsha: National University of Defense Technology) (in Chinese)

[54] Geng D, Wu B, Guo Y, Huang L, Xue Y, Chen J, Yu G, Jiang L, Hu W, Liu Y 2012 Proc. Natl. Acad. Sci. U.S.A. 109 7992

Google Scholar

Google Scholar

[55] Chen J Y, Zhao X X, Tan S J R, Xu H, Wu B, Liu B, Fu D Y, Fu W, Geng D C, Liu Y P, Liu W, Tang W, Li L J, Zhou W, Sum T C, Loh K P 2017 J. Am. Chem. Soc. 139 1073

Google Scholar

Google Scholar

[56] [57] 王璐, 高峻峰, 丁峰 2014 化学学报 72 345

Google Scholar

Google Scholar

Wang L, Gao J F, Ding F 2014 Acta Chim. Sin. 72 345

Google Scholar

Google Scholar

[58] Jia C, Jiang J, Gan L, Guo X 2012 Sci. Rep. 2 707

Google Scholar

Google Scholar

[59] 程想 2016 硕士学位论文 (武汉: 华中科技大学)

Cheng X 2016 M. S. Thesis (WuHan: Huazhong University of Science and Technology) (in Chinese)

[60] Zafar A, Zafar Z, Zhao W, Jiang J, Zhang Y, Chen Y, Lu J, Ni Z 2019 Adv. Funct. Mater. 29 1809261

[61] Patera L L, Bianchini F, Africh C, Dri C, Soldano G, Mariscal M M, Peressi M, Comelli G 2018 Science 359 1243

Google Scholar

Google Scholar

[62] Hao Y, Bharathi M, Wang L, Liu Y, Chen H, Nie S, Wang X, Chou H, Tan C, Fallahazad B 2013 Science 342 720

Google Scholar

Google Scholar

[63] Xu X, Zhang Z, Qiu L, Zhuang J, Zhang L, Wang H, Liao C, Song H, Qiao R, Gao P 2016 Nat. Nanotechnol. 11 930

Google Scholar

Google Scholar

[64] Yang P, Zou X, Zhang Z, Hong M, Shi J, Chen S, Shu J, Zhao L, Jiang S, Zhou X 2018 Nat. Commun. 9 979

Google Scholar

Google Scholar

[65] Zhou J, Lin J, Huang X, Zhou Y, Chen Y, Xia J, Wang H, Xie Y, Yu H, Lei J 2018 Nature 556 355

Google Scholar

Google Scholar

[66] Tan C, Tang M, Wu J, Liu Y, Li T, Liang Y, Deng B, Tan Z, Tu T, Zhang Y 2019 Nano Lett. 19 2148

Google Scholar

Google Scholar

-

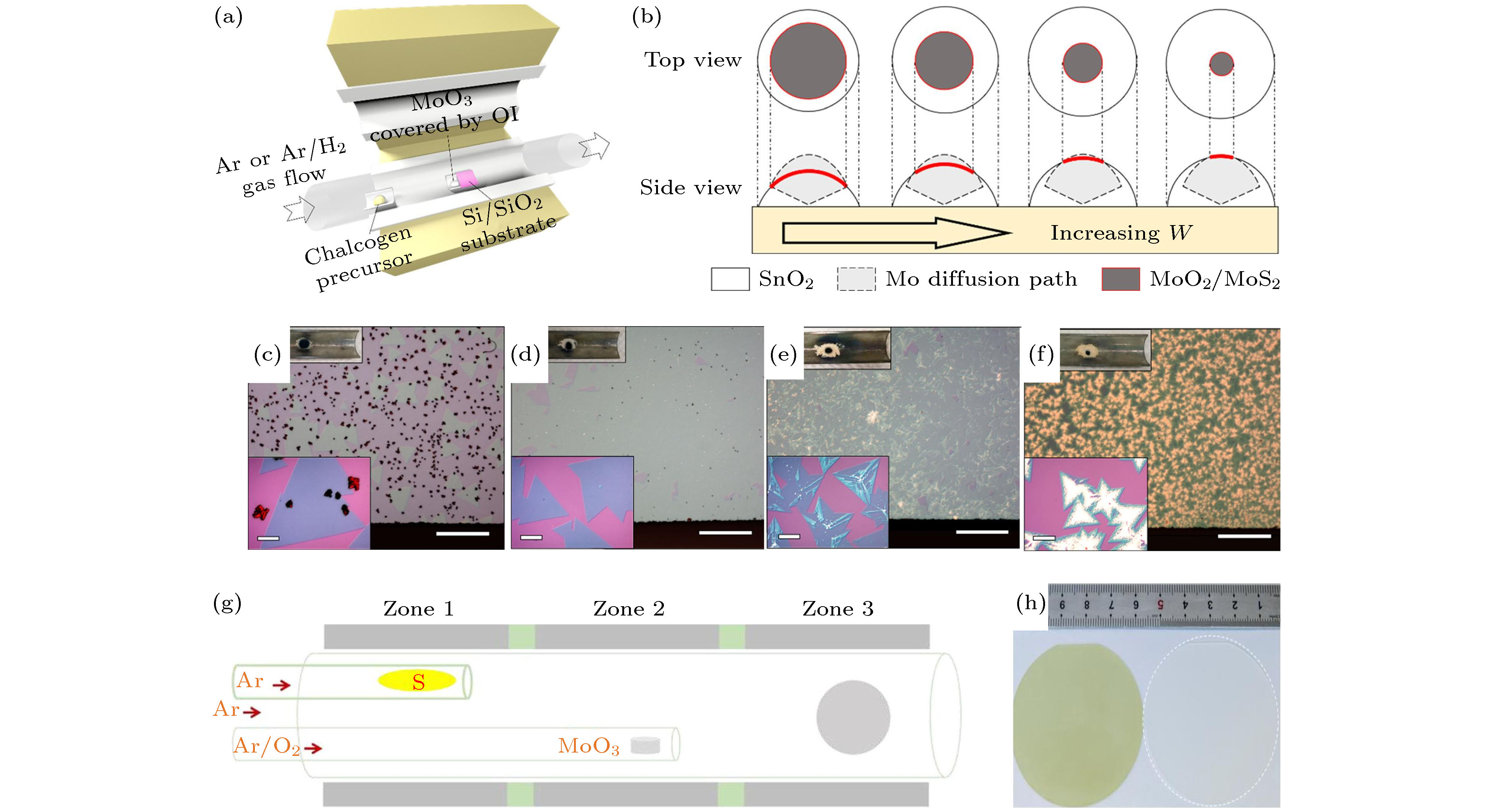

图 3 (a) OIAG法生长MoX2的方案示意图; (b) OIAG中OI的工作机制示意图; (c)−(f)不同OI剂量(c) 4 mg, (d) 5 mg, (e) 6 mg, (f) 7 mg 下MoS2的光镜图像[39]; (g) 使用多条路径制备MoS2薄膜的方案示意图; (h) 蓝宝石衬底上生长的晶圆级MoS2图像[40]

Fig. 3. Schematic illustration of (a) the growth of MoX2 by OIAG and (b) the working mechanism of OI in the progress of OIAG; (c)−(f) optical images of MoS2 with different concentrations: (c) 4 mg, (d) 5 mg, (e) 6 mg, (f) 7 mg[39]; (g) schematic illustration of the modified CVD system for MoS2 growth; (h) photograph of MoS2 film grown on sapphire substrates[40].

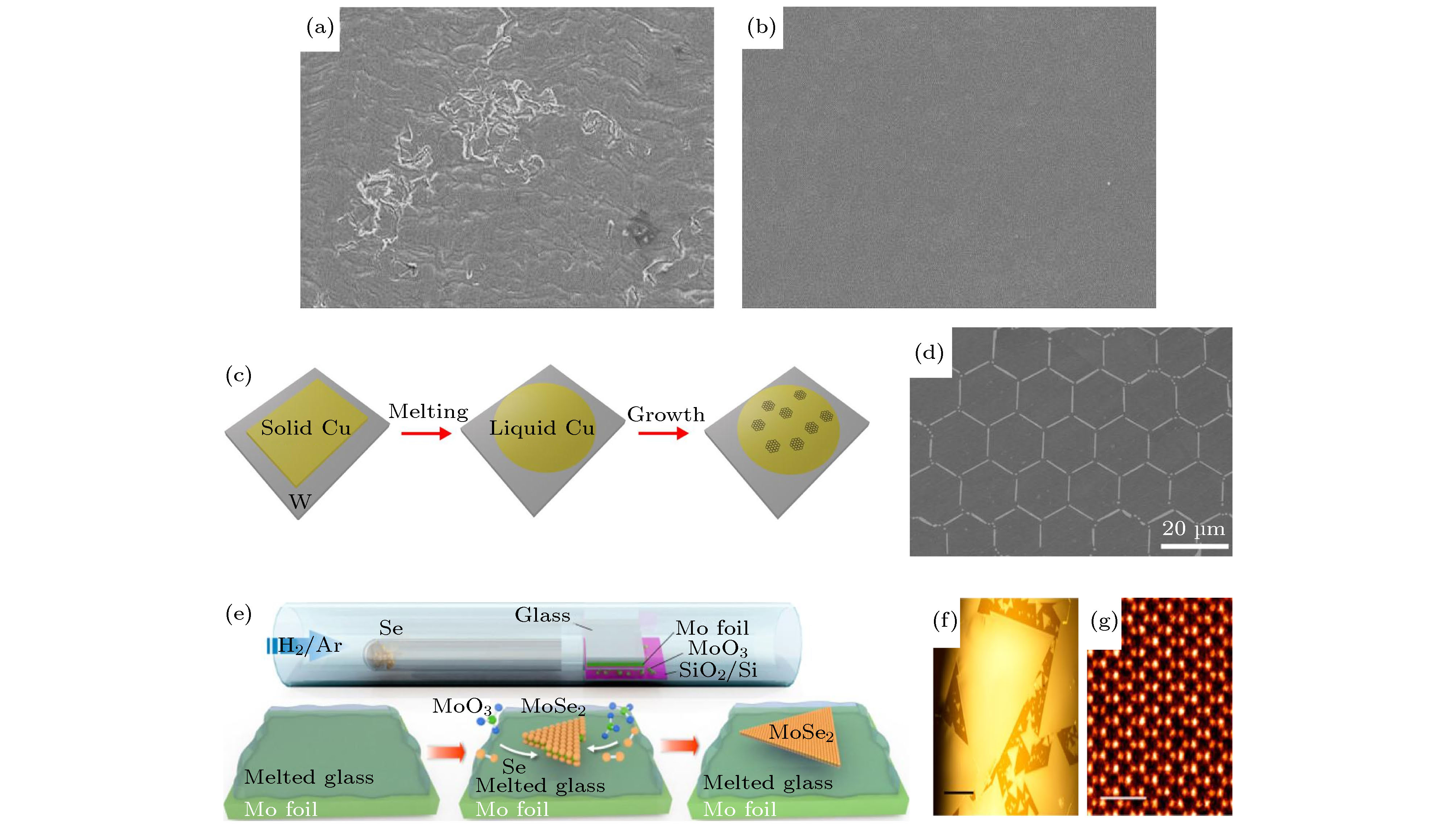

图 5 (a), (b) 抛光前后的铜箔的扫描电子显微镜(scanning electron microscope, SEM)图像[53]; (c) 在钨衬底上平坦液体Cu表面制备石墨烯的示意图; (d) SEM下六方石墨烯畴在液体Cu表面的“自组装样”行为[54]; (e) 合成MoSe2薄膜的CVD装置图示; (f) 光镜下MoSe2薄膜的图像; (g) MoSe2薄膜的扫描隧道显微镜(scanning tunneling microscope, STM)图像[55]

Fig. 5. SEM images of Cu foil (a) before- and (b) after-polishing[53]; (c) schematic illustration of the synthesis of graphene on the liquid Cu surface; (d) SEM image of “self-assembling sample behavior” of hexagonal graphene domains on liquid Cu surface[54]; (e) schematic demonstration of the growth of the WTe2 film by CVD; (f) optical image of MoSe2 film; (g) STM image of MoSe2 film[55].

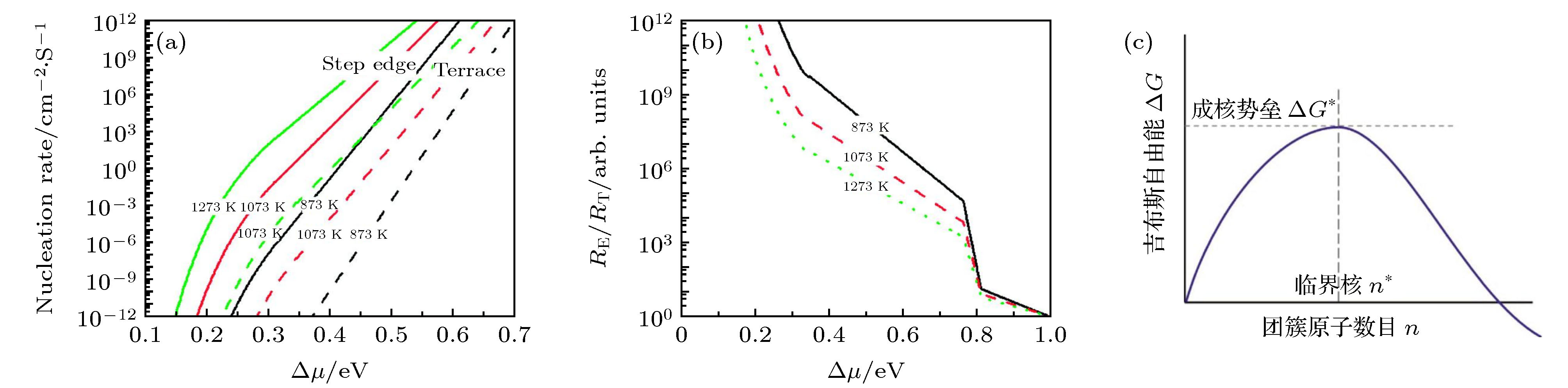

图 6 (a) 石墨烯在不同温度下在Ni(111)表面和台阶处的成核率与

$ \Delta \mu $ 的函数关系; (b) 不同温度下RE/RT比率与$ \Delta \mu $ 的函数关系[48] (RT, 平台上石墨烯的成核率; RE, 台阶表面的成核率); (c) 晶体生长曲线, 吉布斯自由能变化和团簇所含原子数n的关系[57]Fig. 6. (a) Nucleation rates of graphene growth on a Ni(111) terrace and near a step edge as a function of

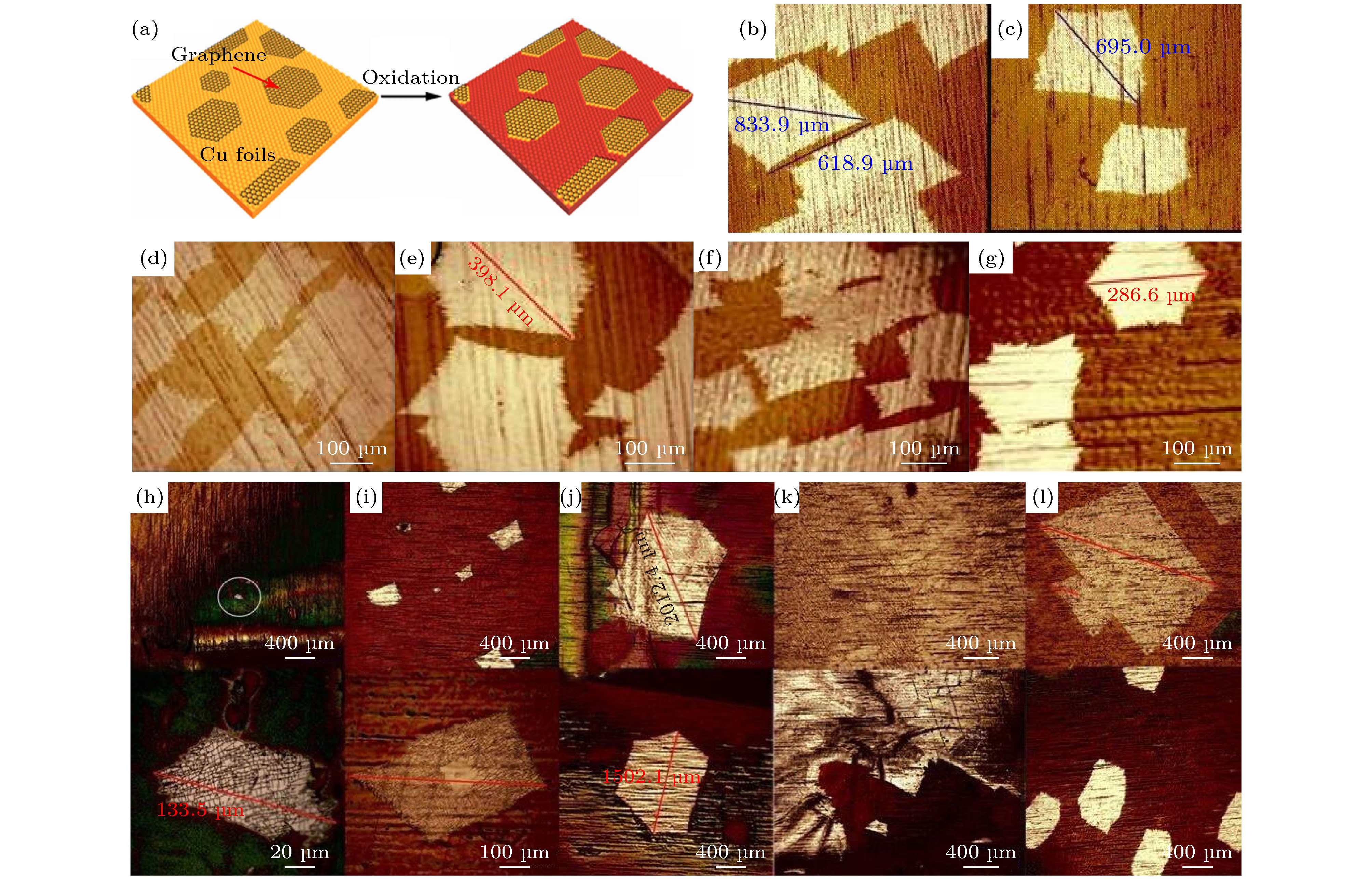

$ \Delta \mu $ ; (b) RE/RT ratio as the function of$ \Delta \mu $ [48] (RT, nucleation rate of graphene on the terrace; RE, nucleation rate of graphene on the step edge); (c) crystal growth curve: Gibbs free energy as a function of the cluster size, n[57].图 7 (a)铜片氧化前后对比图[58]; 不同退火时间下的石墨烯光学图片 (b) 50 min; (c) 90 min; 不同CH4和H2比例下长出的石墨烯光学图片 (d) 2 sccm: 60 sccm; (e) 1 sccm: 80 sccm; (f) 1 sccm: 100 sccm; (g) 0.5 sccm: 80 sccm; 不同生长时间下石墨烯的形貌图 (h) 100 min; (i) 200 min; (j) 420 min; (k) 500 min; (l) 660 min[59]

Fig. 7. (a) Comparison diagram of Cu foil with/without oxidation[58]; optical images of graphene for different annealing time: (b) 50 min; (c) 90 min; optical images of graphene for different proportion of CH4 and H2: (d) 2 sccm:60 sccm; (e) 1 sccm:80 sccm; (f) 1 sccm∶100 sccm; (g) 0.5 sccm∶80.0 sccm; optical images of graphene for different growth time: (h) 100 min; (i) 200 min; (j) 420 min; (k) 500 min; (l) 660 min[59].

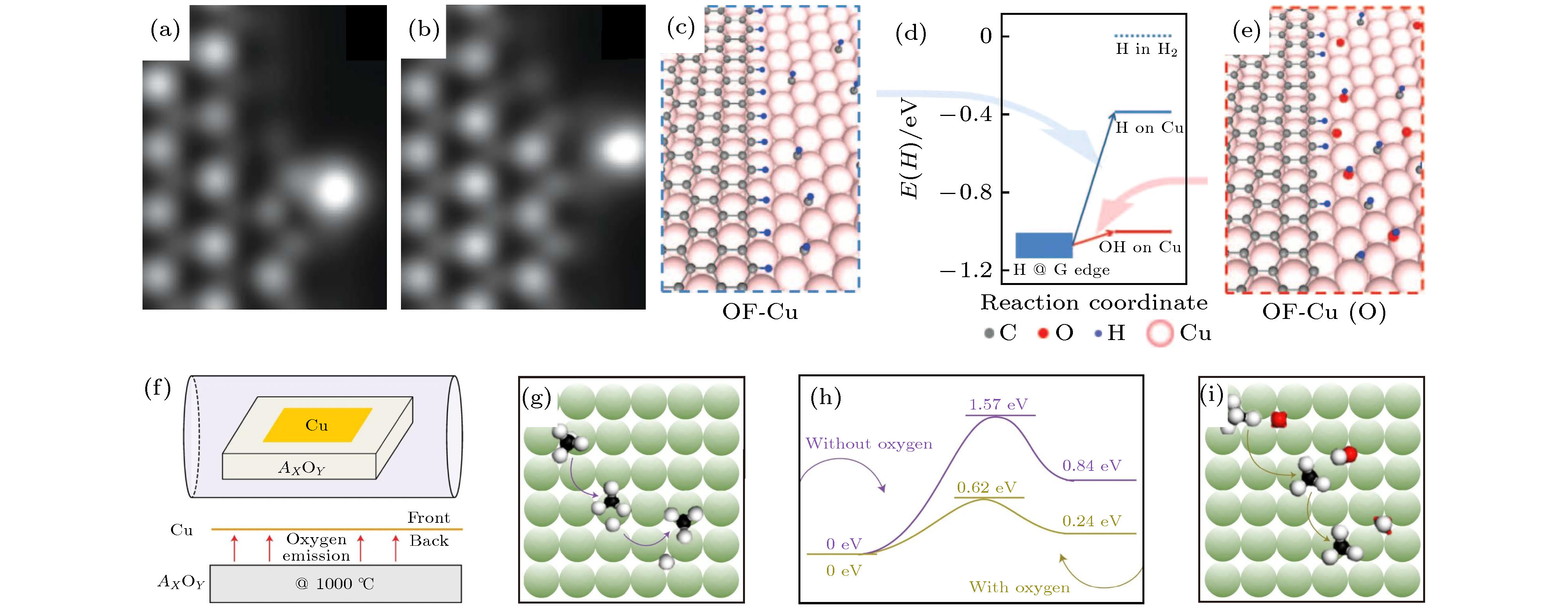

图 9 (a), (b) 位于石墨烯边缘的Ni原子的STM图像[61]; (c) 未经氧处理的石墨烯边缘示意图; (d) 对H附着的能量进行的密度泛函理论计算(density functional theory, DFT)[62]; (e) 氧处理的石墨烯边缘示意图; (f) 局部供氧法示意图; (g) 氧未参与反应的CH4分解过程; (h) 反应能量分布示意图; (i) 氧参与反应的CH4分解过程[63]

Fig. 9. (a), (b) STM images of the Ni adatoms at the graphene edges[61]; (c)−(e) schematic illustration of graphene edges (e) with and (c) without oxygen and (d) the corresponding DFT calculations of the energies for H attachment[62]; (f) schematic illustration of the growth of WTe2 film by local-oxygen-feeding method; (g)−(i) the energy profiles of the reaction of CH4 decomposition (i) with and (g) without oxygen supply on Cu surface and (h) the corresponding DFT calculations of the energy dispersion[63].

图 10 (a) 单层MoS2的光学图像; (b), (c) 引入Na元素和未引入Na元素的DFT对比实验[64]; (d) 使用盐辅助法合成的几种TMDs薄膜的光学图像[65]

Fig. 10. (a) Optical image of monolayer MoS2 film; (b), (c) DFT calculations for the growth of MoS2 (b) without and (c) with Na[64]; (d) schematic illustration of the salt-assisted reaction process and optical images of TMDs films[65].

-

[1] Buscema M, Groenendijk D J, Blanter S I, Steele G A, Van Der Zant H S, Castellanos-Gomez A 2014 Nano Lett. 14 3347

Google Scholar

Google Scholar

[2] Geim A K, Novoselov K S 2007 Nat. Mater. 6 183

Google Scholar

Google Scholar

[3] Mak K F, Shan J 2016 Nat. Photonics 10 216

Google Scholar

Google Scholar

[4] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[5] Wang H, Yu L, Lee Y H, Shi Y, Hsu A, Chin M L, Li L J, Dubey M, Kong J, Palacios T 2012 Nano Lett. 12 4674

Google Scholar

Google Scholar

[6] Wang Q H, Kalantar Zadeh K, Kis A, Coleman J N, Strano M S 2012 Nat. Nanotechnol. 7 699

Google Scholar

Google Scholar

[7] Novoselov K S, Fal V, Colombo L, Gellert P, Schwab M, Kim K 2012 Nature 490 192

Google Scholar

Google Scholar

[8] Desai S B, Madhvapathy S R, Sachid A B, Linas J P, Wang Q, Ahn G H, Pitner G, Kim M J, Bokor J, Hu C 2016 Science 354 99

Google Scholar

Google Scholar

[9] Li M Y, Su S K, Wong H S P, Li L J 2019 Nature 567 169

Google Scholar

Google Scholar

[10] Wang F, Zhang Y, Tian C, Girit C, Zettl A, Crommie M, Shen Y R 2008 Science 320 206

Google Scholar

Google Scholar

[11] Carvalho A, Wang M, Zhu X, Rodin A S, Su H, Neto A H C 2016 Nat. Rev. Mater. 1 1

Google Scholar

Google Scholar

[12] Manzeli S, Ovchinnikov D, Pasquier D, Yazyev O V, Kis A 2017 Nat. Rev. Mater. 2 17033

Google Scholar

Google Scholar

[13] Chen X, Qiu Y, Liu G, Zheng W, Feng W, Gao F, Cao W, Fu Y, Hu W, Hu P 2017 J. Mater. Chem. A 5 11357

Google Scholar

Google Scholar

[14] Watanabe K, Taniguchi T, Kanda H 2004 Nat. Mater. 3 404

Google Scholar

Google Scholar

[15] Xu M, Liang T, Shi M, Chen H 2013 Chem. Rev. 113 3766

Google Scholar

Google Scholar

[16] Yang H, Heo J, Park S, Song H J, Seo D H, Byun K E, Kim P, Yoo I, Chung H J, Kim K 2012 Science 336 1140

Google Scholar

Google Scholar

[17] Goossens S, Navickaite G, Monasterio C, Gupta S, Piqueras J, Pérez R, Burwell G, Nikitskiy I, Lasanta T, Galán T 2017 Nat. Photonics 11 366

Google Scholar

Google Scholar

[18] Sun L, Zhang Y, Han G, Hwang G, Jiang J, Joo B, Watanabe K, Taniguchi T, Kim Y M, Yu W J 2019 Nat. Commun. 10 1

Google Scholar

Google Scholar

[19] Zhang Y, Yao Y, Sendeku M G, Yin L, Zhan X, Wang F, Wang Z, He J 2019 Adv. Mater. 31 1901694

Google Scholar

Google Scholar

[20] Huo C, Yan Z, Song X, Zeng H 2015 Sci. Bull. 60 1994

Google Scholar

Google Scholar

[21] Cai Z, Liu B, Zou X, Cheng H M 2018 Chem. Rev. 118 6091

Google Scholar

Google Scholar

[22] Kang K, Xie S, Huang L, Han Y, Huang P Y, Mak K F, Kim C J, Muller D, Park J 2015 Nature 520 656

Google Scholar

Google Scholar

[23] Kalanyan B, Kimes W A, Beams R, Stranick S J, Garratt E, Kalish I, Davydov A V, Kanjolia R K, Maslar J E 2017 Chem. Mater. 29 6279

Google Scholar

Google Scholar

[24] Choi S H, Stephen B, Park J H, Lee J S, Kim S M, Yang W, Kim K K 2017 Sci. Rep. 7 1

Google Scholar

Google Scholar

[25] Cwik S, Mitoraj D, Mendoza Reyes O, Rogalla D, Peeters D, Kim J, Schütz H M, Bock C, Beranek R, Devi A 2018 Adv. Mater. Interfaces 5 1800140

Google Scholar

Google Scholar

[26] Ma L, Nath D N, Lee E W, Lee C H, Yu M, Arehart A, Rajan S, Wu Y 2014 Appl. Phys. Lett. 105 072105

Google Scholar

Google Scholar

[27] Tao L, Chen K, Chen Z, Chen W, Gui X, Chen H, Li X, Xu J B 2017 ACS Appl. Mater. Interfaces 9 12073

Google Scholar

Google Scholar

[28] Qian S, Yang R, Lan F, Xu Y, Sun K, Zhang S, Zhang Y, Dong Z 2019 Mater. Sci. Semicond. Process 93 317

Google Scholar

Google Scholar

[29] Gong Y, Ye G, Lei S, Shi G, He Y, Lin J, Zhang X, Vajtai R, Pantelides S T, Zhou W 2016 Adv. Funct. Mater. 26 2009

Google Scholar

Google Scholar

[30] 李娜, 张儒静, 甄真, 许振华, 何利民 2020 材料工程 48 36

Google Scholar

Google Scholar

Li N, Zhang R J, Zhen Z, Xu Z H, He L M 2020 J. Mater. Eng. 48 36

Google Scholar

Google Scholar

[31] Zhang L, Shi Z, Wang Y, Yang R, Shi D, Zhang G 2011 Nano Res. 4 315

Google Scholar

Google Scholar

[32] Wei D, Lu Y, Han C, Niu T, Chen W, Wee A T S 2013 Angew. Chem. Int. Ed. 125 14371

Google Scholar

Google Scholar

[33] Kim H, Ahn C, Arabale G, Lee C, Kim T 2013 ECS Trans. 58 47

[34] Lu A Y, Zhu H, Xiao J, Chuu C P, Han Y, Chiu M H, Cheng C C, Yang C W, Wei K H, Yang Y 2017 Nat. Nanotechnol. 12 744

Google Scholar

Google Scholar

[35] Lin L, Deng B, Sun J, Peng H, Liu Z 2018 Chem. Rev. 118 9281

Google Scholar

Google Scholar

[36] 尤佳毅, 沈鸿烈, 吴天如, 谢晓明 2015 真空科学与技术学报 35 109

Google Scholar

Google Scholar

You J Y, Sheng H L, Wu T R, Xie X M 2015 Chin. J. Vac. Sci. Technol. 35 109

Google Scholar

Google Scholar

[37] Rao R, Weaver K, Maruyama B 2015 Mater. Express 5 541

Google Scholar

Google Scholar

[38] 任文杰, 朱永, 龚天诚, 王宁, 张洁 2015 功能材料 46 16115

Ren W J, Zhu Y, Gong T C, Wang N, Zhang J 2015 J. Funct. Mater. 46 16115

[39] Shi R, He P, Cai X, Zhang Z, Wang W, Wang J, Feng X, Wu Z, Amini A, Wang N 2020 ACS Nano 14 7593

Google Scholar

Google Scholar

[40] Yu H, Liao M, Zhao W, Liu G, Zhou X, Wei Z, Xu X, Liu K, Hu Z, Deng K 2017 ACS Nano 11 12001

Google Scholar

Google Scholar

[41] Regmi M, Chisholm M F, Eres G 2012 Carbon 50 134

Google Scholar

Google Scholar

[42] Li J, Cheng S, Liu Z, Zhang W, Chang H 2018 J. Phys. Chem. C 122 7005

Google Scholar

Google Scholar

[43] Yu Y, Li C, Liu Y, Su L, Zhang Y, Cao L 2013 Sci. Rep. 3 1866

Google Scholar

Google Scholar

[44] Elías A L, Perea-López N, Castro-Beltrán A, Berkdemir A, Lü R, Feng S, Long A D, Hayashi T, Kim Y A, Endo M 2013 ACS Nano 7 5235

Google Scholar

Google Scholar

[45] 葛雯, 吕斌 2013 材料科学与工程学报 31 489

Google Scholar

Google Scholar

Ge Wd, Lv B 2013 Mater. Sci. Eng. 31 489

Google Scholar

Google Scholar

[46] Hammer B, Norskov J K 1995 Nature 376 238

Google Scholar

Google Scholar

[47] Chen H, Zhu W, Zhang Z 2010 Phys. Rev. Lett. 104 186101

Google Scholar

Google Scholar

[48] Gao J, Yip J, Zhao J, Yakobson B I, Ding F 2011 J. Am. Chem. Soc. 133 5009

Google Scholar

Google Scholar

[49] Abraham F F 1974 Homogeneous Nucleation Theory (Vol. 263) (New York: Academic Press) pp1−8

[50] Schmelzer J, Röpke G, Priezzhev V B 2005 Nucleation Theory and Applications (Vol. 76) (Hoboken: Wiley-VCH Weinheim) pp39−54

[51] Pruppacher H R, Klett J D 1980 Nature 284 88

[52] [53] 杨雅萍 2016 硕士学位论文 (长沙: 国防科学技术大学)

Yang Y P 2016 M. S. Thesis (Changsha: National University of Defense Technology) (in Chinese)

[54] Geng D, Wu B, Guo Y, Huang L, Xue Y, Chen J, Yu G, Jiang L, Hu W, Liu Y 2012 Proc. Natl. Acad. Sci. U.S.A. 109 7992

Google Scholar

Google Scholar

[55] Chen J Y, Zhao X X, Tan S J R, Xu H, Wu B, Liu B, Fu D Y, Fu W, Geng D C, Liu Y P, Liu W, Tang W, Li L J, Zhou W, Sum T C, Loh K P 2017 J. Am. Chem. Soc. 139 1073

Google Scholar

Google Scholar

[56] [57] 王璐, 高峻峰, 丁峰 2014 化学学报 72 345

Google Scholar

Google Scholar

Wang L, Gao J F, Ding F 2014 Acta Chim. Sin. 72 345

Google Scholar

Google Scholar

[58] Jia C, Jiang J, Gan L, Guo X 2012 Sci. Rep. 2 707

Google Scholar

Google Scholar

[59] 程想 2016 硕士学位论文 (武汉: 华中科技大学)

Cheng X 2016 M. S. Thesis (WuHan: Huazhong University of Science and Technology) (in Chinese)

[60] Zafar A, Zafar Z, Zhao W, Jiang J, Zhang Y, Chen Y, Lu J, Ni Z 2019 Adv. Funct. Mater. 29 1809261

[61] Patera L L, Bianchini F, Africh C, Dri C, Soldano G, Mariscal M M, Peressi M, Comelli G 2018 Science 359 1243

Google Scholar

Google Scholar

[62] Hao Y, Bharathi M, Wang L, Liu Y, Chen H, Nie S, Wang X, Chou H, Tan C, Fallahazad B 2013 Science 342 720

Google Scholar

Google Scholar

[63] Xu X, Zhang Z, Qiu L, Zhuang J, Zhang L, Wang H, Liao C, Song H, Qiao R, Gao P 2016 Nat. Nanotechnol. 11 930

Google Scholar

Google Scholar

[64] Yang P, Zou X, Zhang Z, Hong M, Shi J, Chen S, Shu J, Zhao L, Jiang S, Zhou X 2018 Nat. Commun. 9 979

Google Scholar

Google Scholar

[65] Zhou J, Lin J, Huang X, Zhou Y, Chen Y, Xia J, Wang H, Xie Y, Yu H, Lei J 2018 Nature 556 355

Google Scholar

Google Scholar

[66] Tan C, Tang M, Wu J, Liu Y, Li T, Liang Y, Deng B, Tan Z, Tu T, Zhang Y 2019 Nano Lett. 19 2148

Google Scholar

Google Scholar

计量

- 文章访问数: 37346

- PDF下载量: 1325

- 被引次数: 0

下载:

下载: