-

MoS2是一种具有优异光电性能和奇特物理性质的二维材料,在电子器件领域具有巨大的应用潜力. 高效可控生长出大尺寸单晶MoS2是该材料进入产业应用所必须克服的重大难关, 而化学气相沉积技术被认为是工业化生产二维材料的最有效手段. 本文介绍了一种利用磁控溅射预沉积钼源至熔融玻璃上,通过快速升温的化学气相沉积技术生长出尺寸达1 mm的单晶MoS2的方法, 并通过引入WO3粉末生长出了二硫化钼与二硫化钨的横向异质结(WS2-MoS2). 拉曼和荧光光谱仪测试表明所生长的样品具有较好的晶体质量. 利用转移电极技术制备出了背栅器件样品并对其进行了电学测试, 在室温常压下开关比可达105, 迁移率可达4.53 cm2/(V·s). 这种低成本高质量的大尺寸材料生长方法为二维材料电子器件的大规模应用找到了出路.Molybdenum disulfide (MoS2), as a kind of two-dimensional(2D) material with novel physical properties and excellent electrical performances, has great potential applications in electronic devices. Efficient and controllable growth of large-size single crystal MoS2 is a major difficulty that must be overcome towards scalable production. Chemical vapor deposition (CVD) is considered as the most promising means for industrial production of 2D materials. Here in this work, the high-quality and millimeter-level single crystal MoS2monolayer grows on molten glass by the pre-chemical vapor deposition, in which MoO3 film deposited on the molten glass is used as Mo precursor instead of MoO3 powder. In addition, by introducing WO3 powder into such a CVD system, MoS2-WS2 lateral heterojunctions can also be obtained. Raman and PL measurements indicate that the as-grown MoS2 monolayer samples possess high quality. The Back-gate FETs are fabricated on SiO2/Si substrates by using transferring elelctrode methods to investigate the electrical properties of the as-grown MoS2 crystals. At room temperature and atmosphere pressure, the on-off ratio can reach 105 and the carrier mobility can arrive at 4.53 cm2/(V·s). The low-cost and high-quality large-size material growth method pave the way for the scalable production of such a 2D material based electronic devices.

-

Keywords:

- MoS2 /

- molten glass /

- CVD /

- heterojunction

[1] Hynek D J, Singhania R M, Xu S, Davis B, Wang L, Yarali M, Pondick J V, Woods J M, Strandwitz N C, Cha J J 2021 ACS Nano 15 410

Google Scholar

Google Scholar

[2] Susarla S, Kutana A, Hachtel J A, Kochat V, Apte A, Vajtai R, Idrobo J C, Yakobson B I, Tiwary C S, Ajayan P M 2017 Advan. Mater. 29 1702457

Google Scholar

Google Scholar

[3] Huo N, Yang Y, Li J 2017 J. Semicond. 38 031002

Google Scholar

Google Scholar

[4] Cheng P, Tang C, Ahmed S, Qiao J, Zeng L, Tsang Y 2020 Nanotechnology 32 055201

[5] Wu Y, Lin Y M, Bol A A, Jenkins K A, Xia F, Farmer D B, Zhu Y, Avouris P 2011 Nature 472 74

Google Scholar

Google Scholar

[6] Sarkar D, Xie X, Liu W, Cao W, Kang J, Gong Y, Kraemer S, Ajayan P M, Banerjee K 2015 Nature 526 91

Google Scholar

Google Scholar

[7] Jia S, Jin Z, Zhang J, Yuan J, Chen W, Feng W, Hu P, Ajayan P M, Lou J 2020 Small 16 2002263

Google Scholar

Google Scholar

[8] Akinwande D, Petrone N, Hone J 2014 Nat. Commun. 5 5678

Google Scholar

Google Scholar

[9] Chang H Y, Yang S, Lee J, Tao L, Hwang W S, Jena D, Lu N, Akinwande D 2013 ACS Nano 7 5446

Google Scholar

Google Scholar

[10] Lee G H, Yu Y J, Cui X, Petrone N, Lee C H, Choi M S, Lee D Y, Lee C, Yoo W J, Watanabe K, Taniguchi T, Nuckolls C, Kim P, Hone J 2013 ACS Nano 7 7931

Google Scholar

Google Scholar

[11] Das S, Gulotty R, Sumant A V, Roelofs A 2014 Nano Lett. 14 2861

Google Scholar

Google Scholar

[12] Xiao X, Chen M, Zhang J, Zhang T, Zhang L, Jin Y, Wang J, Jiang K, Fan S, Li Q 2019 ACS Appl. Mater. Inter. 11 11612

Google Scholar

Google Scholar

[13] 董艳芳, 何大伟, 王永生, 许海腾, 巩哲 2016 65 128101

Google Scholar

Google Scholar

Dong Y F, He D W, Wang Y S, Xu H T, Gong Z 2016 Acta Phys. Sin. 65 128101

Google Scholar

Google Scholar

[14] 王铄, 王文辉, 吕俊鹏, 倪振华 2021 70 026802

Wang S, Wang W H, Lv J P, Ni Z H 2021 Acta Phys. Sin. 70 026802

[15] Yang P, Zou X, Zhang Z, Hong M, Shi J, Chen S, Shu J, Zhao L, Jiang S, Zhou X, Huan Y, Xie C, Gao P, Chen Q, Zhang Q, Liu Z, Zhang Y 2018 Nat. Commun. 9 979

Google Scholar

Google Scholar

[16] Zhang Z, Xu X, Song J, Gao Q, Li S, Hu Q, Li X, Wu Y 2018 Appl. Phys. Lett. 113 202103

Google Scholar

Google Scholar

[17] Chen J, Zhao X, Tan S J R, Xu H, Wu B, Liu B, Fu D, Fu W, Geng D, Liu Y, Liu W, Tang W, Li L, Zhou W, Sum T C, Loh K P 2017 J. Am. Chem. Soc. 139 1073

Google Scholar

Google Scholar

[18] Tang L, Tan J, Nong H, Liu B, Cheng H M 2021 Acc. Mater. Res. 2 36

Google Scholar

Google Scholar

[19] Wan X, Miao X, Yao J, Wang S, Shao F, Xiao S, Zhan R, Chen K, Zeng X, Gu X, Xu J 2021 Advan. Mater. 33 2100260

Google Scholar

Google Scholar

[20] Zhang X, Nan H, Xiao S, Wan X, Gu X, Du A, Ni Z, Ostrikov K 2019 Nat. Commun. 10 598

Google Scholar

Google Scholar

[21] Wang Z, Xie Y, Wang H, Wu R, Nan T, Zhan Y, Sun J, Jiang T, Zhao Y, Lei Y, Yang M, Wang W, Zhu Q, Ma X, Hao Y 2017 Nanotechnology 28 325602

Google Scholar

Google Scholar

[22] Park J H, Lu A Y, Shen P C, Shin B G, Wang H, Mao N, Xu R, Jung S J, Ham D, Kern K, Han Y, Kong J 2021 Small Methods 5 2000720

Google Scholar

Google Scholar

[23] 王璐, 高俊峰, 丁峰 2014 化学学报 72 345

Google Scholar

Google Scholar

Wang L, Gao J F, Ding F 2014 Acta Chim. Sin. 72 345

Google Scholar

Google Scholar

[24] Wang J, Cai X, Shi R, Wu Z, Wang W, Long G, Tang Y, Cai N, Ouyang W, Geng P, Chandrashekar B N, Amini A, Wang N, Cheng C 2018 ACS Nano 12 635

Google Scholar

Google Scholar

[25] Yang P, Zhang S, Pan S, Tang B, Liang Y, Zhao X, Zhang Z, Shi J, Huan Y, Shi Y, Pennycook S J, Ren Z, Zhang G, Chen Q, Zou X, Liu Z, Zhang Y 2020 ACS Nano 14 5036

Google Scholar

Google Scholar

[26] Withanage S S, Khondaker S I 2019 MRS Advan. 4 587

Google Scholar

Google Scholar

-

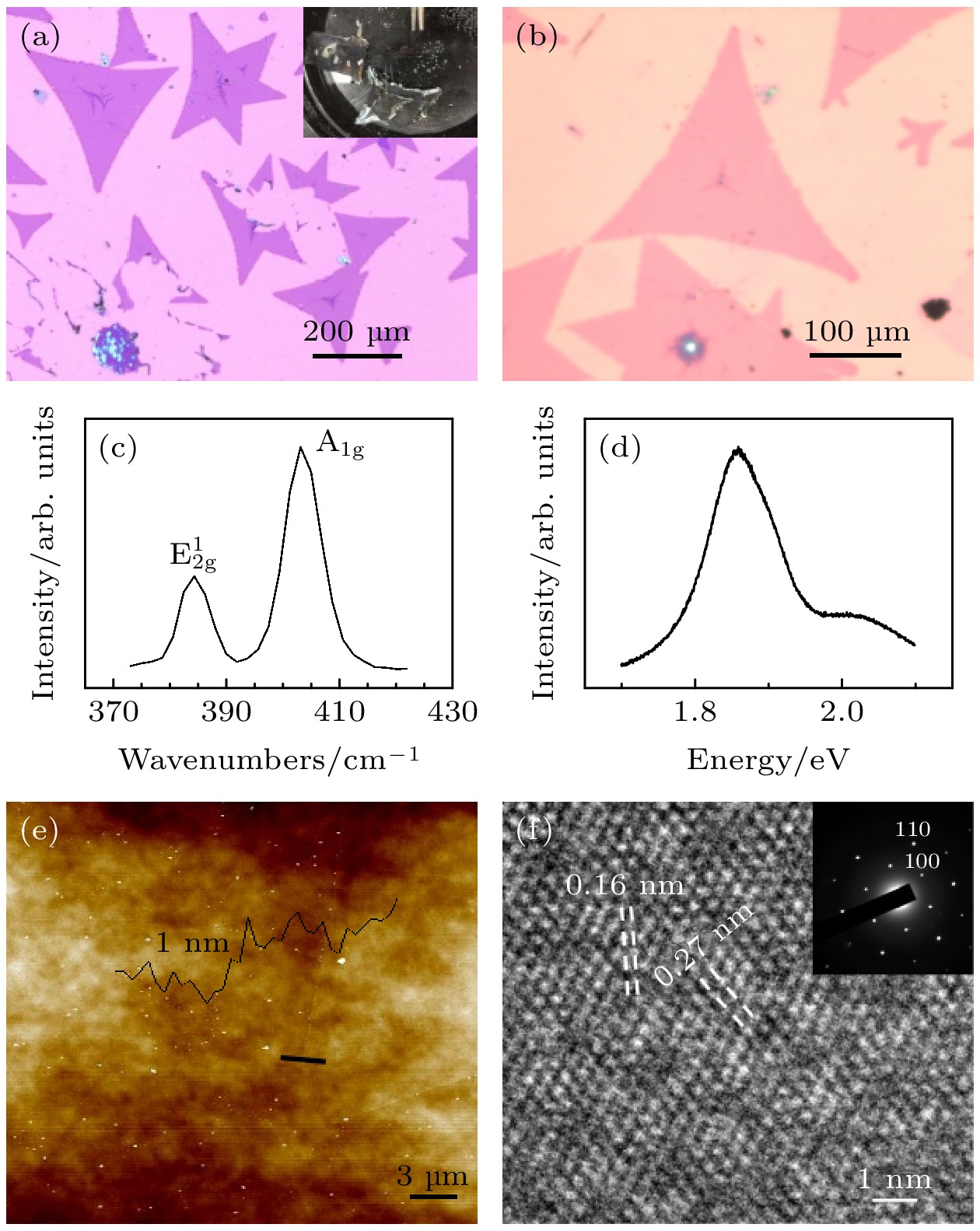

图 3 转移至硅衬底上的MoS2及相应的拉曼荧光表征 (a)(b)转移后的MoS2光镜图; (c)(d)为(b)中样品的拉曼与荧光表征; (e)所生长MoS2的AFM图像; (f)生长MoS2的HRTEM, 内插图为相应的SAED

Fig. 3. MoS2 films transfered onto the Si/SiO2 substrates and its Raman spectrum: (a) (b) Optical images of transfered MoS2; (c) (d)single-point Raman and PL spectrum of the as-grown MoS2films in (b); (e) AFM image of as-grown MoS2; (f) HRTEM of as-grown MoS2, the inset image is the SAED pattern of as-grown MoS2.

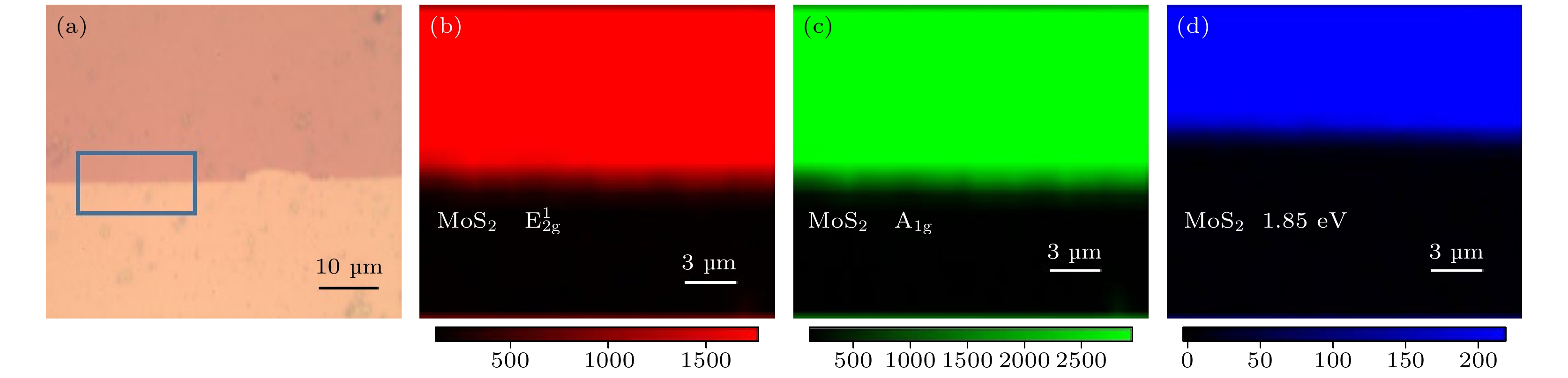

图 4 所生长MoS2薄膜的拉曼与荧光 mapping测试(a) MoS2薄膜光镜图; (b)图(a)中蓝框区域拉曼峰

$ \rm E^1_{\rm 2g} $ 的mapping图像; (c)拉曼峰A1g的mapping图像; (d)荧光峰1.85 eV处的mapping图像Fig. 4. Raman mapping test of as-grown MoS2 film: (a) Optical image of a selected MoS2 films; (b) Raman intensity mapping of

$ \rm E^1_{\rm 2g} $ peak (blue area in Fig. (a)); (c) Raman intensity mapping of A1g (blue area in Fig. (a)) ; (d) PL intensity mapping of PL peak at 1.85 eV (blue area in Fig. (a)).图 5 (a) MoS2场效应管的3D模型以及真实器件的光镜图; (b) MoS2场效应管的输出曲线; (c) MoS2场效应管的线性转移曲线; (d) MoS2场效应管的指数转移曲线

Fig. 5. (a) Schematic of MoS2 FET and a typical optical image of the devices; (b) output curves (Ids-Vds) of a typical MoS2 FET device; (c) liner transfer curves of a typical MoS2 FET device; (d) semilog transfer curves of a typical MoS2 FET device.

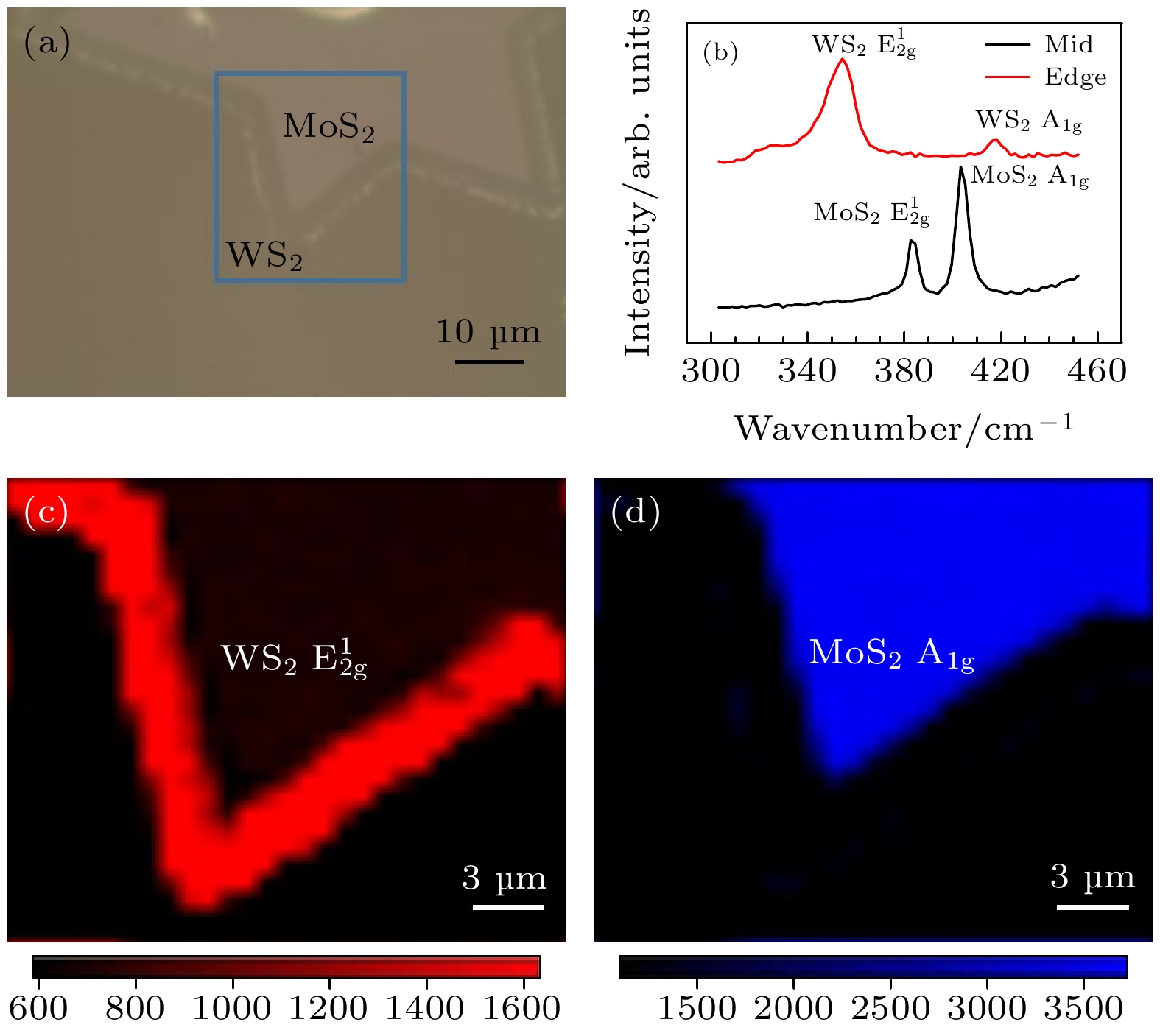

图 6 (a)熔融玻璃上生长的WS2-MoS2异质结的光镜图; (b) WS2-MoS2相应区域的拉曼表征; (c)异质结对应于350 cm–1处的拉曼强度mapping; (d)异质结对应于403 cm–1处的拉曼强度mapping

Fig. 6. (a) Optical image of the as-grown WS2-MoS2 heterostructures on soda-lime glass; (b) single-point Raman spectra of the as-grown WS2-MoS2 heterostructures, (c) Raman intensity mapping of the heterostructure region at 350 cm–1; (d) Raman intensity mapping of the heterostructure region at 403 cm–1.

表 1 不同CVD法生长的MoS2的各项性能对比

Table 1. MoS2 FET performance of different kinds of CVD.

-

[1] Hynek D J, Singhania R M, Xu S, Davis B, Wang L, Yarali M, Pondick J V, Woods J M, Strandwitz N C, Cha J J 2021 ACS Nano 15 410

Google Scholar

Google Scholar

[2] Susarla S, Kutana A, Hachtel J A, Kochat V, Apte A, Vajtai R, Idrobo J C, Yakobson B I, Tiwary C S, Ajayan P M 2017 Advan. Mater. 29 1702457

Google Scholar

Google Scholar

[3] Huo N, Yang Y, Li J 2017 J. Semicond. 38 031002

Google Scholar

Google Scholar

[4] Cheng P, Tang C, Ahmed S, Qiao J, Zeng L, Tsang Y 2020 Nanotechnology 32 055201

[5] Wu Y, Lin Y M, Bol A A, Jenkins K A, Xia F, Farmer D B, Zhu Y, Avouris P 2011 Nature 472 74

Google Scholar

Google Scholar

[6] Sarkar D, Xie X, Liu W, Cao W, Kang J, Gong Y, Kraemer S, Ajayan P M, Banerjee K 2015 Nature 526 91

Google Scholar

Google Scholar

[7] Jia S, Jin Z, Zhang J, Yuan J, Chen W, Feng W, Hu P, Ajayan P M, Lou J 2020 Small 16 2002263

Google Scholar

Google Scholar

[8] Akinwande D, Petrone N, Hone J 2014 Nat. Commun. 5 5678

Google Scholar

Google Scholar

[9] Chang H Y, Yang S, Lee J, Tao L, Hwang W S, Jena D, Lu N, Akinwande D 2013 ACS Nano 7 5446

Google Scholar

Google Scholar

[10] Lee G H, Yu Y J, Cui X, Petrone N, Lee C H, Choi M S, Lee D Y, Lee C, Yoo W J, Watanabe K, Taniguchi T, Nuckolls C, Kim P, Hone J 2013 ACS Nano 7 7931

Google Scholar

Google Scholar

[11] Das S, Gulotty R, Sumant A V, Roelofs A 2014 Nano Lett. 14 2861

Google Scholar

Google Scholar

[12] Xiao X, Chen M, Zhang J, Zhang T, Zhang L, Jin Y, Wang J, Jiang K, Fan S, Li Q 2019 ACS Appl. Mater. Inter. 11 11612

Google Scholar

Google Scholar

[13] 董艳芳, 何大伟, 王永生, 许海腾, 巩哲 2016 65 128101

Google Scholar

Google Scholar

Dong Y F, He D W, Wang Y S, Xu H T, Gong Z 2016 Acta Phys. Sin. 65 128101

Google Scholar

Google Scholar

[14] 王铄, 王文辉, 吕俊鹏, 倪振华 2021 70 026802

Wang S, Wang W H, Lv J P, Ni Z H 2021 Acta Phys. Sin. 70 026802

[15] Yang P, Zou X, Zhang Z, Hong M, Shi J, Chen S, Shu J, Zhao L, Jiang S, Zhou X, Huan Y, Xie C, Gao P, Chen Q, Zhang Q, Liu Z, Zhang Y 2018 Nat. Commun. 9 979

Google Scholar

Google Scholar

[16] Zhang Z, Xu X, Song J, Gao Q, Li S, Hu Q, Li X, Wu Y 2018 Appl. Phys. Lett. 113 202103

Google Scholar

Google Scholar

[17] Chen J, Zhao X, Tan S J R, Xu H, Wu B, Liu B, Fu D, Fu W, Geng D, Liu Y, Liu W, Tang W, Li L, Zhou W, Sum T C, Loh K P 2017 J. Am. Chem. Soc. 139 1073

Google Scholar

Google Scholar

[18] Tang L, Tan J, Nong H, Liu B, Cheng H M 2021 Acc. Mater. Res. 2 36

Google Scholar

Google Scholar

[19] Wan X, Miao X, Yao J, Wang S, Shao F, Xiao S, Zhan R, Chen K, Zeng X, Gu X, Xu J 2021 Advan. Mater. 33 2100260

Google Scholar

Google Scholar

[20] Zhang X, Nan H, Xiao S, Wan X, Gu X, Du A, Ni Z, Ostrikov K 2019 Nat. Commun. 10 598

Google Scholar

Google Scholar

[21] Wang Z, Xie Y, Wang H, Wu R, Nan T, Zhan Y, Sun J, Jiang T, Zhao Y, Lei Y, Yang M, Wang W, Zhu Q, Ma X, Hao Y 2017 Nanotechnology 28 325602

Google Scholar

Google Scholar

[22] Park J H, Lu A Y, Shen P C, Shin B G, Wang H, Mao N, Xu R, Jung S J, Ham D, Kern K, Han Y, Kong J 2021 Small Methods 5 2000720

Google Scholar

Google Scholar

[23] 王璐, 高俊峰, 丁峰 2014 化学学报 72 345

Google Scholar

Google Scholar

Wang L, Gao J F, Ding F 2014 Acta Chim. Sin. 72 345

Google Scholar

Google Scholar

[24] Wang J, Cai X, Shi R, Wu Z, Wang W, Long G, Tang Y, Cai N, Ouyang W, Geng P, Chandrashekar B N, Amini A, Wang N, Cheng C 2018 ACS Nano 12 635

Google Scholar

Google Scholar

[25] Yang P, Zhang S, Pan S, Tang B, Liang Y, Zhao X, Zhang Z, Shi J, Huan Y, Shi Y, Pennycook S J, Ren Z, Zhang G, Chen Q, Zou X, Liu Z, Zhang Y 2020 ACS Nano 14 5036

Google Scholar

Google Scholar

[26] Withanage S S, Khondaker S I 2019 MRS Advan. 4 587

Google Scholar

Google Scholar

计量

- 文章访问数: 8746

- PDF下载量: 179

- 被引次数: 0

下载:

下载: