-

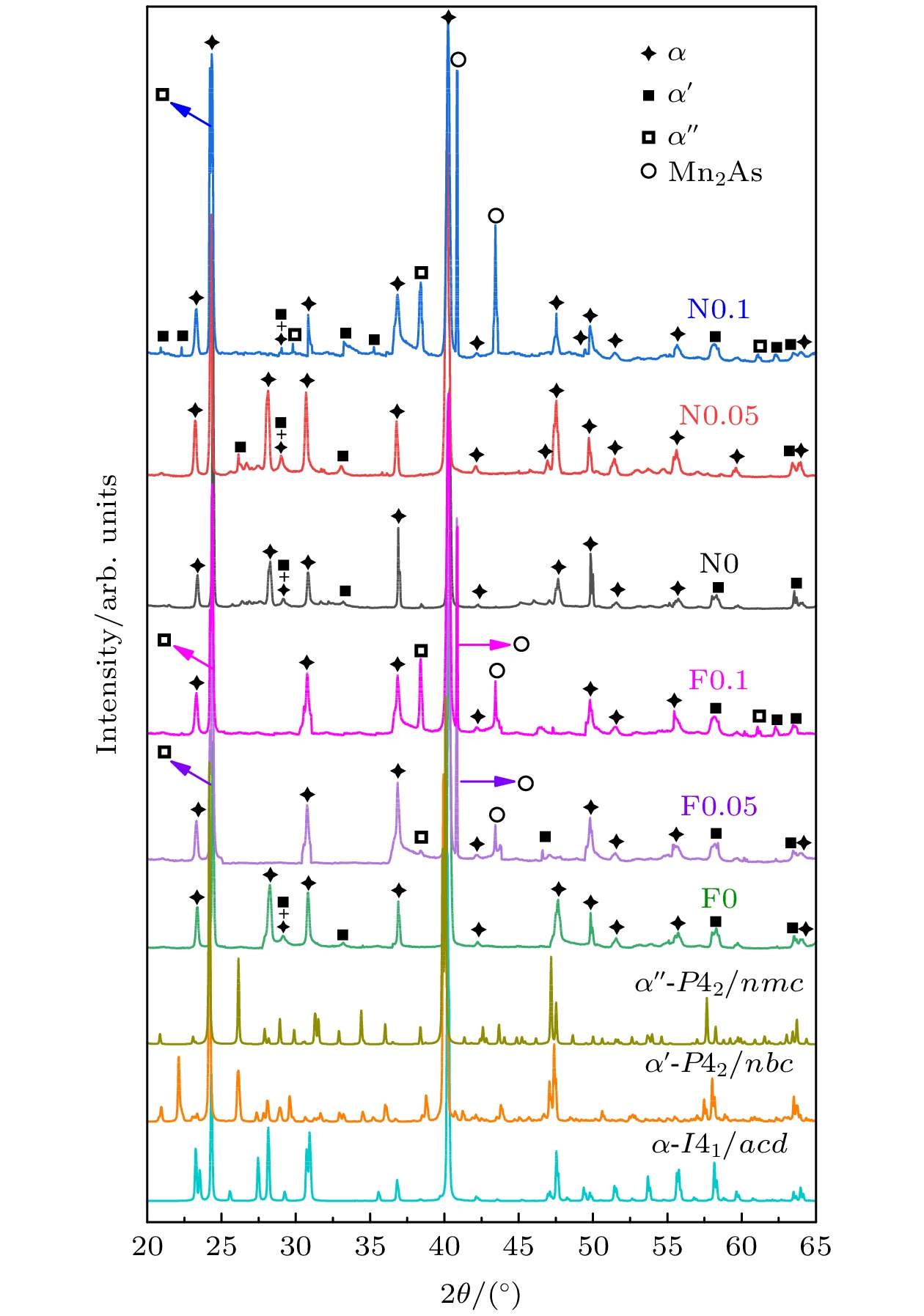

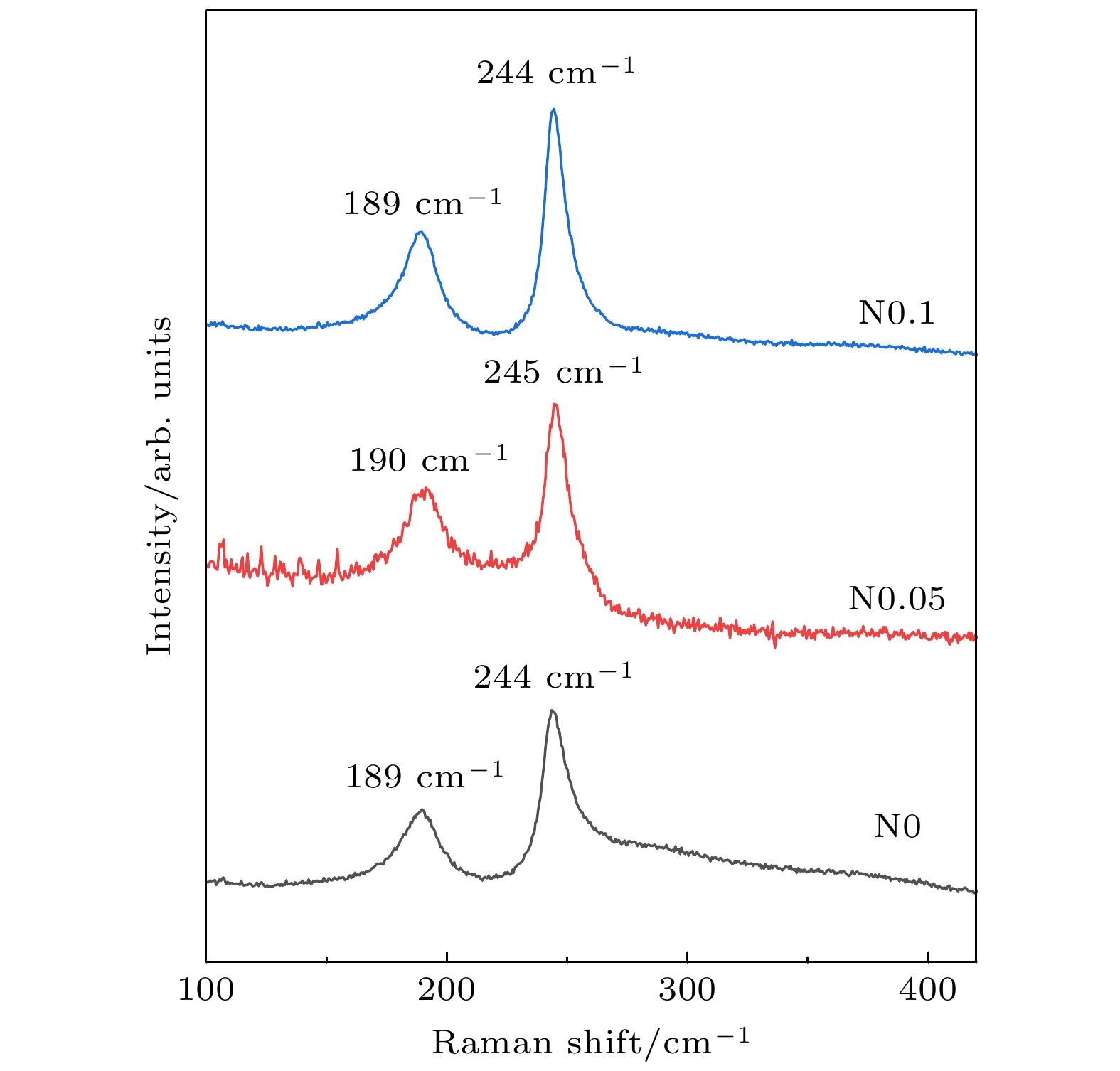

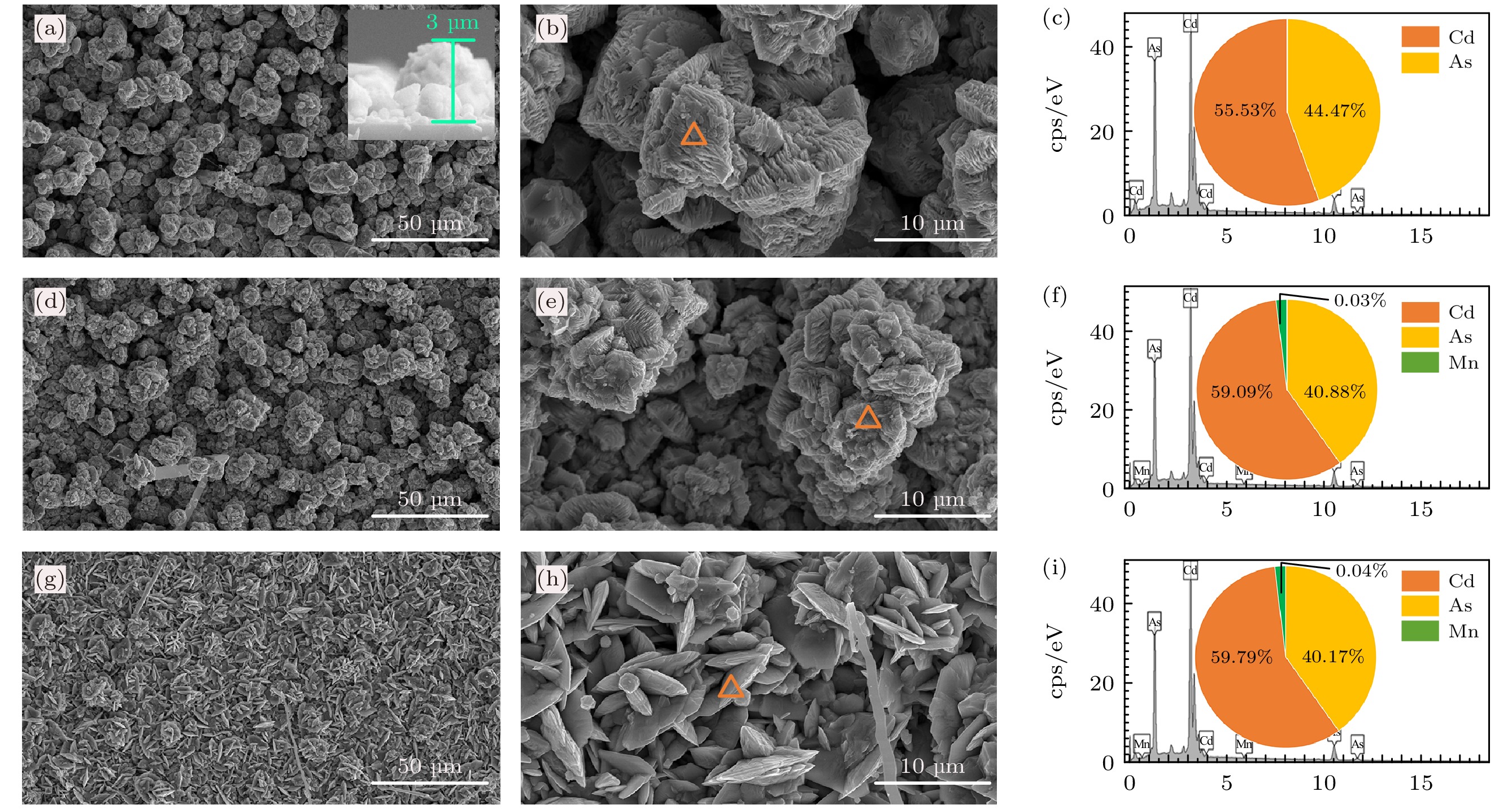

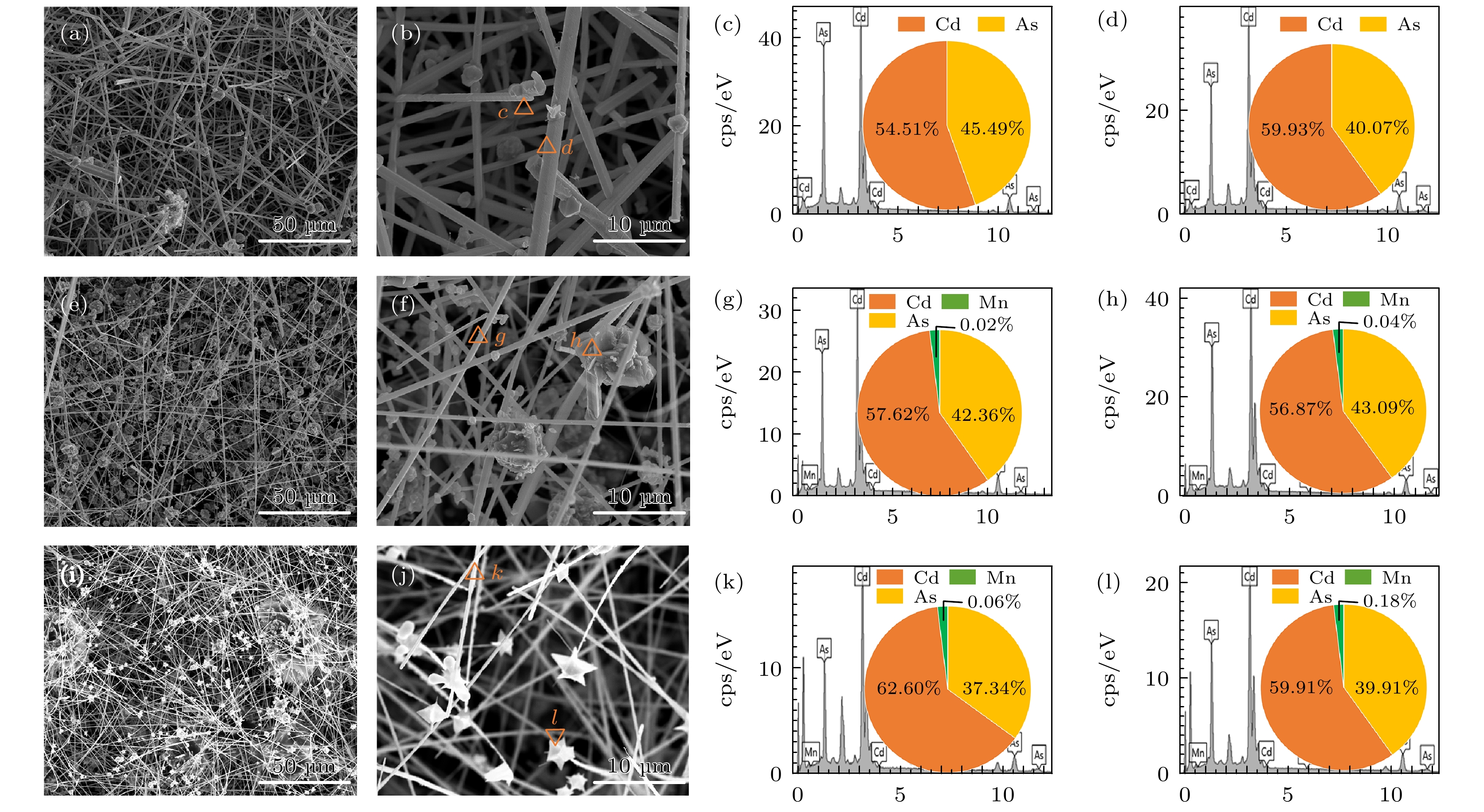

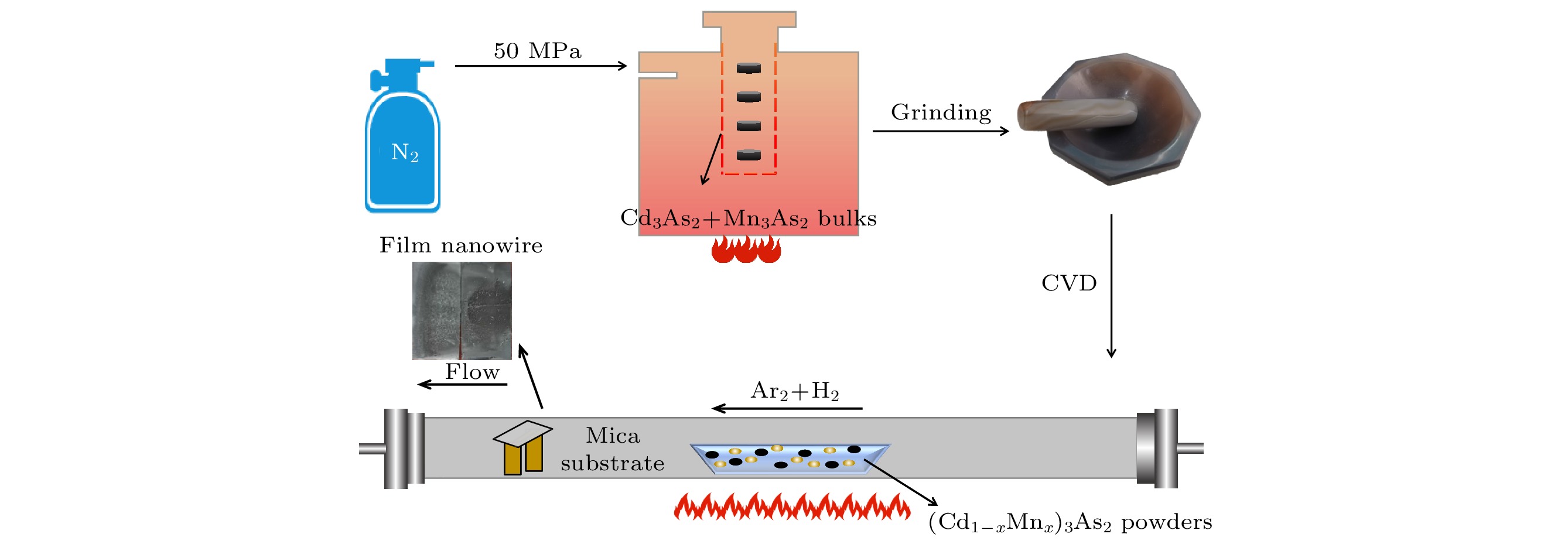

Cd3As2具有高电子迁移率、相对较低的热导率及良好的空气稳定性, 有望应用于热电领域. 本文首先采用高气压烧结技术抑制As元素挥发, 合成了(Cd1–xMnx)3As2 (x = 0, 0.05, 0.1)母合金, 然后通过化学气相沉积蒸发母合金粉末在云母基底上制备了Mn3As2掺杂的多种Cd3As2纳米结构(高温区形成竹笋纳米线结构, 低温区形成薄膜). 系统研究了掺杂对相组成、元素含量、微结构及热电性能的影响. 所有纳米结构的主相均为α相, 并伴有少量α'相, Mn3As2掺杂导致样品中出现α''相和Mn2As杂相. 电子能谱分析表明这些纳米结构中Mn的实际原子百分比约为0.02%—0.18%. 掺杂使薄膜的微观形貌从自组装菜花结构转变为贝壳结构, 并使纳米线直径显著减小. 与薄膜相比, 竹笋纳米线结构的室温电导率提高一个数量级, 达到247—320 S/cm, 这归因于更好的结晶质量和竹笋之间的纳米线相互连接形成了高导电网络, 导致更高的载流子浓度和迁移率. 竹笋纳米线结构的最大室温功率因子为0.144 mW/(m·K2), 是薄膜样品的14倍.Cd3As2, especially its various nanostructures, has been considered as an excellent candidate for application in novel optoelectronic devices due to its ultrahigh mobility and good air-stability. Recent researches exhibited Cd3As2 as a candidate of thermoelectric materials by virtue of its ultralow thermal conductivity in comparison with other semimetals or metals. In this work, at first ( Cd1–xMnx)3As2 (x = 0, 0.05, 0.1) bulk alloys are prepared by high-pressure sintering to suppress the volatilization of As element, and then several kinds of Mn3As2-doped Cd3As2 nanostructures are obtained on mica substrates by chemical vapor deposition (CVD), with bamboo-shoot-nanowire structure forming in a high-temperature region and films in a low-temperature region. Effects of Mn3As2 doping on the crystalline structure, phase compositions, microstructures and thermoelectric properties of the Cd3As2 nanostructures are systematically studied. Energy-dispersive spectrometer (EDS) analysis at various typical positions of the Mn3As2-doped Cd3As2 nanostructures shows that the Mn content in these nanostructures is in a range of 0.02%–0.18% (atomic percent), which is much lower than the Mn content in ( Cd1–xMnx)3As2 (x = 0, 0.05, 0.1) parent alloys. The main phases of these nanostructures are all body centered tetragonal α phase with a small amount of primitive tetragonal α′ phase. Doping results in the α″ phase and Mn2As impurity phase occurring. The Cd3As2 film presents a self-assembled cauliflower microstructure. Upon Mn3As2 doping, this morphology finally transforms into a vertical-growth seashell structure. In a high temperature region of the mica substrate, a unique bamboo-shoot-nanowire structure is formed, with vertical-growth bamboo shoots connected by nanowires, and at the end of these nanowires grows a white pentagonal flower structure with the highest Mn content of 0.18% (atomic percent) for all the nanostructures. Conductivity of the Cd3As2 film and the bamboo-shoot-nanowire structure are ~20 and 320 S/cm, respectively. The remarkable conductivity enhancement can be attributed to higher crystallinity and the formation of nanowire conductive network, which significantly increase carrier concentration and Hall mobility. The Hall mobility values of the nanowire structures range from 2271 to 3048 cm2/(V·s) much higher than the values of 378–450 cm2/(V·s) for the films. The Seebeck coefficient for the bamboo-shoot-nanowire structure is in a range of 59–68 µV/K, which is about 15% higher than those for the films (50–61 µV/K). Although maximal power factor of the bamboo-shoot-nanowire structure is 14 times as high as that of the thin film, reaching 0.144 mW/(m·K2) at room temperature, this value is still one order of magnitude lower than the previously reported value of 1.58 mW/(m·K2) for Cd3As2 single crystal.

-

Keywords:

- thermoelectric properties /

- Cd3As2 /

- chemical vapor deposition /

- nanostructure

[1] Kaleem U, Meng Y F, Sun Y, et al. 2020 Appl. Phys. Lett. 117 011102

Google Scholar

Google Scholar

[2] Wang H L, Ma J L, Wei Q Q, Zhao J H 2020 J. Semicond. 41 072903

Google Scholar

Google Scholar

[3] Zhang Y X, Nappini S, Sankar R, Bondino F, Gao J F, Politano A 2021 J. Mater. Chem. C 9 1235

Google Scholar

Google Scholar

[4] Liang T, Gibson Q, Ali M N, Liu M H, Cava R J, Ong N P 2015 Nat. Mater. 14 280

Google Scholar

Google Scholar

[5] Cheng P H, Zhang C, Liu Y W, et al. 2016 New J. Phys. 18 083003

Google Scholar

Google Scholar

[6] Park K, Jung M, Kim D, Bayogan J R, Lee J H, An S J, Seo J, Seo J, Ahn J P, Park J 2020 Nano Lett. 20 4939

Google Scholar

Google Scholar

[7] Suslov A V, Davydov A B, Oveshnikov L N, et al. 2019 Phys. Rev. B 99 094512

Google Scholar

Google Scholar

[8] Zhou T, Zhang C, Zhang H S, Xiu F X, Yang Z Q 2016 Inorg. Chem. Front. 3 1637

Google Scholar

Google Scholar

[9] Zhang C, Zhou T, Liang S H, et al. 2016 Chin. Phys. B 25 017202

Google Scholar

Google Scholar

[10] Wang H H, Luo X G, Peng K L, et al. 2019 Adv. Funct. Mater. 29 1902437

Google Scholar

Google Scholar

[11] Pariari A, Khan N, Singha R, Satpati B, Mandal P 2016 Phys. Rev. B 94 165139

Google Scholar

Google Scholar

[12] 杨亮亮, 勤源浩, 魏江涛, 宋培帅, 张明亮, 杨富华, 王晓东 2021 70 076802

Google Scholar

Google Scholar

Yang L L, Qin Y H, Wei J T, Song P S, Zhang M L, Yang F H, Wang X D 2021 Acta Phys. Sin. 70 076802

Google Scholar

Google Scholar

[13] 李彩云, 何文科, 王东洋, 张潇, 赵立东 2021 70 208401

Google Scholar

Google Scholar

Li C Y, He W K, Wang D Y, Zhang X, Zhao L D 2021 Acta Phys. Sin. 70 208401

Google Scholar

Google Scholar

[14] Sun N K, Li W, Pang C, Zhong D H, Li M L 2021 Solid State Commun. 339 114505

Google Scholar

Google Scholar

[15] Liao W W, Yang L, Chen J, et al. 2019 Chem. Eng. J. 371 593

Google Scholar

Google Scholar

[16] Yue Z M, Zhao K P, Chen H Y, Qiu P F, Zhao L D, Shi X 2021 Chin. Phys. Lett. 38 117201

Google Scholar

Google Scholar

[17] 胡威威, 孙进昌, 张玗, 龚悦, 范玉婷, 唐新峰, 谭刚健 2022 71 047101

Google Scholar

Google Scholar

Hu W W, Sun J C, Zhang Y, Guo Y, Fan Y T, Tang X F, Tan G J 2022 Acta Phys. Sin. 71 047101

Google Scholar

Google Scholar

[18] Chen R K, Lee J, Lee W, Li D Y 2019 Chem. Rev. 119 9260

Google Scholar

Google Scholar

[19] Zhu G P, Zhao C W, Wang X W, Wang J 2021 Chin. Phys. Lett. 38 024401

Google Scholar

Google Scholar

[20] Guo J, Zhao X G, Sun N K, Xiao X F, Liu W, Zhang Z D 2021 J. Mater. Sci. Technol. 76 247

Google Scholar

Google Scholar

[21] Celinski Z, Burian A, Rzepa B, Zdanowicz W 1987 Mat. Res. Bull. 22 419

Google Scholar

Google Scholar

[22] Ril A I, Marenkin S F, Volkov V V, Oveshnikov L N, Kozlov V V 2021 J. Alloys Compd. 892 162082

[23] Oveshnikov L N, Davydov A B, Suslov A V, Ril A I, Marenkin S F, Vasiliev A L, Aronzon B A 2020 Sci. Rep. 10 4601

Google Scholar

Google Scholar

[24] Wei S, Lu J, Yu W C, Zhang H B, Qian Y T 2006 Cryst. Growth Des. 6 849

Google Scholar

Google Scholar

[25] Weszka J 1999 Phys. Stat. Sol. (b) 211 605

Google Scholar

Google Scholar

[26] Davydov A B, Oveshnikov L N, SuSlov A V, Ril A I, Marenkin S F, Aronzon B A 2020 Phys. Solid State 62 419

Google Scholar

Google Scholar

[27] Marenkin S F, Trukhan V M, Fedorchenko I V, TruKhanov S V, Shoukavaya T V 2014 Russ. J. Inorg. Chem. 59 355

Google Scholar

Google Scholar

[28] Li C Z, Zhu R, Ke X X, Zhang J M, Wang L X, Zhang L, Liao Z M, Yu D P 2015 Cryst. Growth Des. 15 3264

Google Scholar

Google Scholar

[29] Rice A D, Park K, Hughes E T, Mukherjee K, Alberi K 2019 Phys. Rev. Mater. 3 121201

Google Scholar

Google Scholar

[30] Li C Z, Wang L X, Liu H W, Wang J, Liao Z M, Yu D P 2015 Nat. Commun. 6 10137

Google Scholar

Google Scholar

[31] Schonherr P, Hesjedal T 2015 Appl. Phys. Lett. 106 013115

Google Scholar

Google Scholar

[32] Hwang Y, Choi J, Dung D D, Shin Y, Cho S 2011 J. Appl. Phys. 109 063914

Google Scholar

Google Scholar

[33] Dai Z J, Manjappa M, Yang Y K, Tan T C W, Qiang B, Han S, Wong L J, Xiu F X, Liu W W, Singh R 2021 Adv. Funct. Mater. 31 2011011

Google Scholar

Google Scholar

[34] Nishihaya S, Uchida M, Nakazawa Y, Akiba K, Kriener M, Kozuka Y, Miyake A, Taguchi Y, Tokunaga M, Kawasaki M 2018 Phys. Rev. B 97 245103

Google Scholar

Google Scholar

[35] Jia Z Z, Li C Z, Li X Q, Shi J R, Liao Z M, Yu D P, Wu X S 2016 Nat. Commun. 7 13013

Google Scholar

Google Scholar

-

图 4 Mn3As2掺杂Cd3As2薄膜的SEM图(第1和第2列)及EDS分析结果(第3列) (a)—(c) F0样品 ((a)插图为薄膜横截面图); (d)—(f) F0.05样品; (g)—(i) F0.1样品

Fig. 4. SEM images (the first and second column) and EDS analysis results (the third column) of Mn3As2-doped Cd3As2 films: (a)–(c) F0 sample (the inset of (a) shows the fracture morphology); (d)–(f) F0.05 sample; (g)–(i) F0.1 sample.

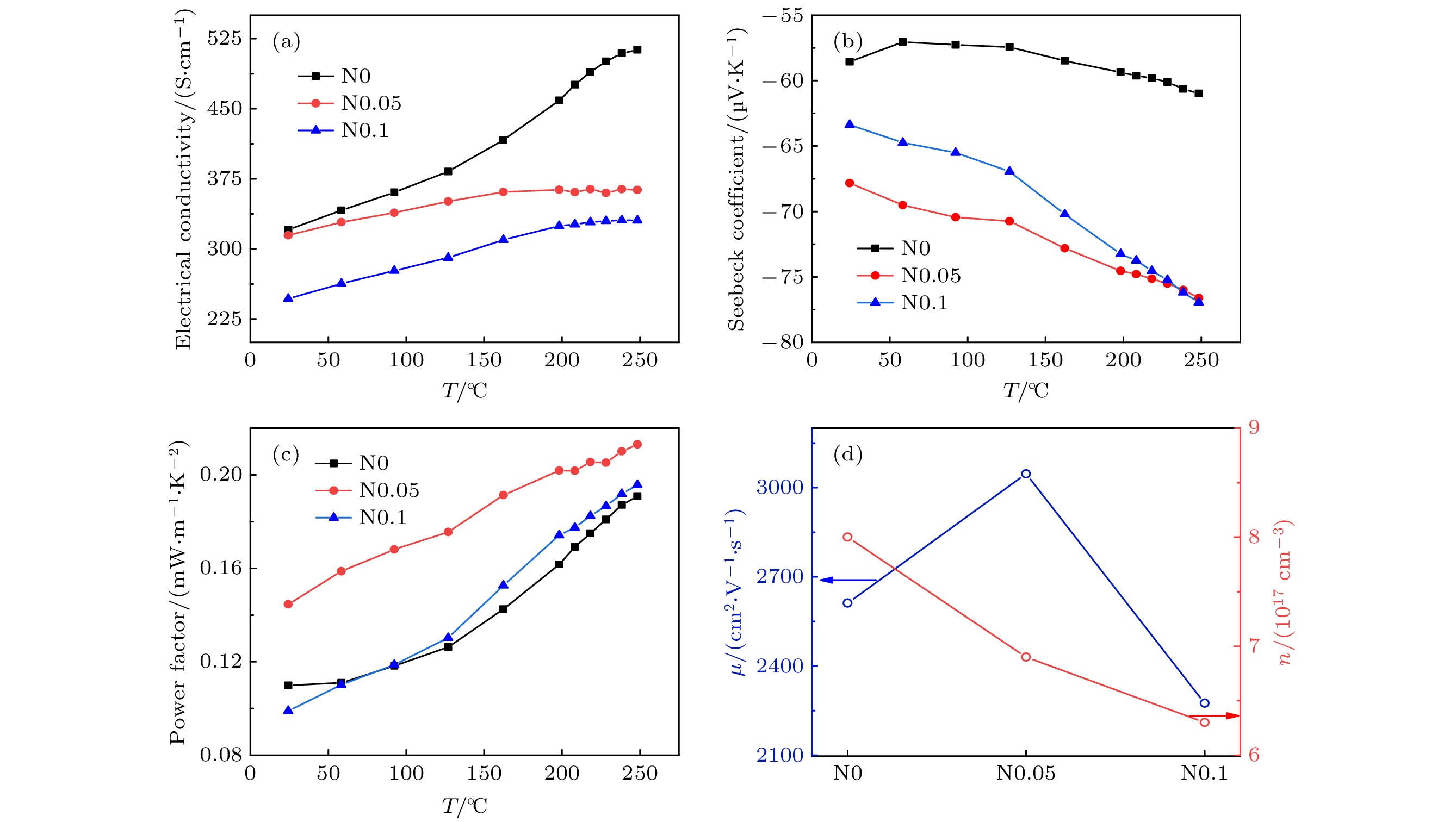

图 8 (a)—(c) Mn3As2掺杂Cd3As2薄膜的电导率 (a)、塞贝克系数(b)、功率因子(c)随温度的变化曲线; (d) Mn3As2掺杂Cd3As2薄膜的室温载流子浓度和霍尔迁移率

Fig. 8. (a)–(c) Temperature dependence of electrical conductivity (a), Seebeck coefficient (b), and power factor (c) of Mn3As2-doped Cd3As2 films; (d) room-temperature carrier concentration and Hall mobility (d) of Mn3As2-doped Cd3As2 films.

图 9 (a)—(c) Mn3As2掺杂Cd3As2竹笋纳米线结构的电导率 (a)、塞贝克系数 (b)、功率因子(c)随温度的变化曲线; (d) Mn3As2掺杂Cd3As2竹笋纳米线结构的室温载流子浓度和霍尔迁移率

Fig. 9. (a)–(c) Temperature dependence of electrical conductivity (a), Seebeck coefficient (b), and power factor (c) of Mn3As2-doped Cd3As2 bamboo-shoot-nanowire structure; (d) room-temperature carrier concentration and Hall mobility of Mn3As2-doped Cd3As2 bamboo-shoot-nanowire structure.

-

[1] Kaleem U, Meng Y F, Sun Y, et al. 2020 Appl. Phys. Lett. 117 011102

Google Scholar

Google Scholar

[2] Wang H L, Ma J L, Wei Q Q, Zhao J H 2020 J. Semicond. 41 072903

Google Scholar

Google Scholar

[3] Zhang Y X, Nappini S, Sankar R, Bondino F, Gao J F, Politano A 2021 J. Mater. Chem. C 9 1235

Google Scholar

Google Scholar

[4] Liang T, Gibson Q, Ali M N, Liu M H, Cava R J, Ong N P 2015 Nat. Mater. 14 280

Google Scholar

Google Scholar

[5] Cheng P H, Zhang C, Liu Y W, et al. 2016 New J. Phys. 18 083003

Google Scholar

Google Scholar

[6] Park K, Jung M, Kim D, Bayogan J R, Lee J H, An S J, Seo J, Seo J, Ahn J P, Park J 2020 Nano Lett. 20 4939

Google Scholar

Google Scholar

[7] Suslov A V, Davydov A B, Oveshnikov L N, et al. 2019 Phys. Rev. B 99 094512

Google Scholar

Google Scholar

[8] Zhou T, Zhang C, Zhang H S, Xiu F X, Yang Z Q 2016 Inorg. Chem. Front. 3 1637

Google Scholar

Google Scholar

[9] Zhang C, Zhou T, Liang S H, et al. 2016 Chin. Phys. B 25 017202

Google Scholar

Google Scholar

[10] Wang H H, Luo X G, Peng K L, et al. 2019 Adv. Funct. Mater. 29 1902437

Google Scholar

Google Scholar

[11] Pariari A, Khan N, Singha R, Satpati B, Mandal P 2016 Phys. Rev. B 94 165139

Google Scholar

Google Scholar

[12] 杨亮亮, 勤源浩, 魏江涛, 宋培帅, 张明亮, 杨富华, 王晓东 2021 70 076802

Google Scholar

Google Scholar

Yang L L, Qin Y H, Wei J T, Song P S, Zhang M L, Yang F H, Wang X D 2021 Acta Phys. Sin. 70 076802

Google Scholar

Google Scholar

[13] 李彩云, 何文科, 王东洋, 张潇, 赵立东 2021 70 208401

Google Scholar

Google Scholar

Li C Y, He W K, Wang D Y, Zhang X, Zhao L D 2021 Acta Phys. Sin. 70 208401

Google Scholar

Google Scholar

[14] Sun N K, Li W, Pang C, Zhong D H, Li M L 2021 Solid State Commun. 339 114505

Google Scholar

Google Scholar

[15] Liao W W, Yang L, Chen J, et al. 2019 Chem. Eng. J. 371 593

Google Scholar

Google Scholar

[16] Yue Z M, Zhao K P, Chen H Y, Qiu P F, Zhao L D, Shi X 2021 Chin. Phys. Lett. 38 117201

Google Scholar

Google Scholar

[17] 胡威威, 孙进昌, 张玗, 龚悦, 范玉婷, 唐新峰, 谭刚健 2022 71 047101

Google Scholar

Google Scholar

Hu W W, Sun J C, Zhang Y, Guo Y, Fan Y T, Tang X F, Tan G J 2022 Acta Phys. Sin. 71 047101

Google Scholar

Google Scholar

[18] Chen R K, Lee J, Lee W, Li D Y 2019 Chem. Rev. 119 9260

Google Scholar

Google Scholar

[19] Zhu G P, Zhao C W, Wang X W, Wang J 2021 Chin. Phys. Lett. 38 024401

Google Scholar

Google Scholar

[20] Guo J, Zhao X G, Sun N K, Xiao X F, Liu W, Zhang Z D 2021 J. Mater. Sci. Technol. 76 247

Google Scholar

Google Scholar

[21] Celinski Z, Burian A, Rzepa B, Zdanowicz W 1987 Mat. Res. Bull. 22 419

Google Scholar

Google Scholar

[22] Ril A I, Marenkin S F, Volkov V V, Oveshnikov L N, Kozlov V V 2021 J. Alloys Compd. 892 162082

[23] Oveshnikov L N, Davydov A B, Suslov A V, Ril A I, Marenkin S F, Vasiliev A L, Aronzon B A 2020 Sci. Rep. 10 4601

Google Scholar

Google Scholar

[24] Wei S, Lu J, Yu W C, Zhang H B, Qian Y T 2006 Cryst. Growth Des. 6 849

Google Scholar

Google Scholar

[25] Weszka J 1999 Phys. Stat. Sol. (b) 211 605

Google Scholar

Google Scholar

[26] Davydov A B, Oveshnikov L N, SuSlov A V, Ril A I, Marenkin S F, Aronzon B A 2020 Phys. Solid State 62 419

Google Scholar

Google Scholar

[27] Marenkin S F, Trukhan V M, Fedorchenko I V, TruKhanov S V, Shoukavaya T V 2014 Russ. J. Inorg. Chem. 59 355

Google Scholar

Google Scholar

[28] Li C Z, Zhu R, Ke X X, Zhang J M, Wang L X, Zhang L, Liao Z M, Yu D P 2015 Cryst. Growth Des. 15 3264

Google Scholar

Google Scholar

[29] Rice A D, Park K, Hughes E T, Mukherjee K, Alberi K 2019 Phys. Rev. Mater. 3 121201

Google Scholar

Google Scholar

[30] Li C Z, Wang L X, Liu H W, Wang J, Liao Z M, Yu D P 2015 Nat. Commun. 6 10137

Google Scholar

Google Scholar

[31] Schonherr P, Hesjedal T 2015 Appl. Phys. Lett. 106 013115

Google Scholar

Google Scholar

[32] Hwang Y, Choi J, Dung D D, Shin Y, Cho S 2011 J. Appl. Phys. 109 063914

Google Scholar

Google Scholar

[33] Dai Z J, Manjappa M, Yang Y K, Tan T C W, Qiang B, Han S, Wong L J, Xiu F X, Liu W W, Singh R 2021 Adv. Funct. Mater. 31 2011011

Google Scholar

Google Scholar

[34] Nishihaya S, Uchida M, Nakazawa Y, Akiba K, Kriener M, Kozuka Y, Miyake A, Taguchi Y, Tokunaga M, Kawasaki M 2018 Phys. Rev. B 97 245103

Google Scholar

Google Scholar

[35] Jia Z Z, Li C Z, Li X Q, Shi J R, Liao Z M, Yu D P, Wu X S 2016 Nat. Commun. 7 13013

Google Scholar

Google Scholar

计量

- 文章访问数: 6894

- PDF下载量: 67

- 被引次数: 0

下载:

下载: