-

Localized surface plasmon resonance (LSPR) effect of metal nanoparticles (MNs) has been widely applied in organic light-emitting diodes (OLEDs) to improve the radiation of excitons. The LSPR wavelength and intensity of MNs and the coupling between MNs and excitons greatly affect the LSPR effect on exciton radiation. In this work, silica coated silver nanocubes (Ag@SiO2 NCs) were doped in the electron transport layer (ETL) of a solution-processed multilayered white OLED (WOLED). Due to the sharp edges and corners, Ag NCs have strong LSPR effect and can effectively enhance the radiation of nearby excitons. With an appropriate concentration of Ag@SiO2 NCs, the WOLED achieved two fold improvement in the current efficiency comparing with the control device without Ag@SiO2 NCs incorporated. The working mechanism of the Ag@SiO2 NCs based WOLED was investigated in detail. For the solution-processed OLED, excitons usually form and recombine near the interface of emission layer and electron transport layer (EML/ETL) because the commonly used host material (such as polyvinylcarbazole, PVK) has the unipolar hole transport property. So the Ag@SiO2 NCs in ETL greatly enhanced the radiation of the excitons located near the EML/ETL interface, which mostly contributed to the performance enhancement of the Ag@SiO2 NCs based WOLED. Study on a group of devices with Ag@SiO2 NCs doped in different locations indicated that Ag@SiO2 NCs in ETL showed more effective LSPR effect than those in hole injection layer. Electroluminescence and photoluminescence spectra of the WOLEDs declared that the Ag@SiO2 NCs simultaneously improved the radiation intensities of the blue and yellow excitons and helped the WOLED maintain the good chromaticity stability, which was mainly attributed to the wide LSPR wavelength range (450–650 nm) of the Ag@SiO2 NCs. The SiO2 coating layer of the Ag@SiO2 NCs played the important role in the LSPR enhanced emission. On the one hand, it formed an appropriated distance between the Ag NCs and the extions, helping to generate the strong coupling between them. On the other hand, it suppressed the effect of Ag NCs on charge trapping, keeping the stability of the carrier transport in the device. Our research demonstrate MNs can effectively improve the performance of OLEDs by carefully designing the device structure.

-

Keywords:

- white organic light-emitting diodes /

- Ag nanocubes /

- localized surface plasmon resonance /

- solution-processed electron transporting layer

[1] Kido J, Kimura M, Nagai K 1995 Science 267 1332

Google Scholar

Google Scholar

[2] Sasabe H, Takamatsu J, Motoyama T, Watanabe S, Wagenblast G, Langer N, Molt O, Fuchs E, Lennartz C, Kido J 2010 Adv. Mater. 22 5003

Google Scholar

Google Scholar

[3] Sun Y, Giebink N C, Kanno H, Ma B, Thompson M, Forrest S 2006 Nature 44090 8

[4] Sax S, Mauthner G, Piok T, Pradhan S, Scherf U, List E J W 2007 Org. Electron. 8 791

Google Scholar

Google Scholar

[5] Lee T, Noh T, Shin H, Kwon O, Park J, Choi B, Kim M, Shin D W, Kim Y 2009 Adv. Funct. Mater. 19 1625

Google Scholar

Google Scholar

[6] You J, Tseng S, Meng H, Yen F, Lin I, Horng S 2009 Org. Electron. 10 1610

Google Scholar

Google Scholar

[7] Kim K, Lee J, Park T, Jeon W, Kennedy G, Kwon J 2010 Synth. Met. 160 631

Google Scholar

Google Scholar

[8] Zhao Q, Zhang W, Fan Z, Li J, Chen X, Luo G, Zhang X 2015 Synth. Met. 204 70

Google Scholar

Google Scholar

[9] Ho S, Liu S, Chen Y, So F 2015 J. Photon. Energy 5 057611

Google Scholar

Google Scholar

[10] Yook K, Lee J 2014 Adv. Mater. 26 4218

Google Scholar

Google Scholar

[11] Noh Y, Lee C, Kim J, Yase K 2003 J. Chem. Phys. 118 2853

Google Scholar

Google Scholar

[12] Kim D H, Kim T W 2016 Org. Electron. 34 262

Google Scholar

Google Scholar

[13] Xu Y, Zhou H, Zhang R, Liu Y, Zhang Q, Zhang S, Zhang L, Chen S, Deng L, Qian Y, Wang L, Huang W 2015 AIP Adv. 5 067121

Google Scholar

Google Scholar

[14] Deng L, Zhou Z, Jia B, Zhou H, Peng L, Shang W, Feng J, Chen S 2018 Org. Electron. 53 346

Google Scholar

Google Scholar

[15] Kim T, Kang S, Heo J, Cho S, Kim J W, Choe A, Walker B, Shanker R, Ko H, Kim J Y 2019 Adv. Mater. 30 1800659

[16] Chen P, Xiong Z, Wu X, Shao M, Meng Y, Xiong Z H, Guo C 2017 J. Phys. Chem. Lett. 8 3961

Google Scholar

Google Scholar

[17] Shi Z, Li Y, Li S, Li X, Wu D, Xu T, Tian Y, Chen Y, Zhang Y, Zhang B, Shan C, Du G 2018 Adv. Funct. Mater. 28 1707031

Google Scholar

Google Scholar

[18] Cho C, Kang H, Baek S, Kim T, Lee C 2016 ACS Appl. Mater. Interfaces 8 911

[19] 贾博仑, 邓玲玲, 陈若曦, 张雅男, 房旭民 2017 66 237801

Google Scholar

Google Scholar

Jia B L, Deng L L, Chen R X, Zhang Y N, Fang X M 2017 Acta Phys. Sin. 66 237801

Google Scholar

Google Scholar

[20] Siekkinen A, Mclellan J, Chen J, Xia Y 2006 Chem. Phys. Lett. 432 491

Google Scholar

Google Scholar

[21] Deng L, Yang J, Zhan N, Yu T, Yu H, Chen S 2019 Opt. Lett. 44 983

Google Scholar

Google Scholar

[22] Kim T, Kang H, Jeong S, Kang D J, Lee C, Lee C H, Seo M K, Lee J Y, Kim B J 2014 ACS Appl. Mater. Interfaces 6 16956

Google Scholar

Google Scholar

-

图 2 (a)银纳米立方和(b) Ag@SiO2 NCs的TEM图像; (c) TPBi和掺有Ag@SiO2 NCs的TPBi的吸收光谱, 以及FIrpic和PO-01的PL光谱; (d)掺有Ag@SiO2 NCs的TPBi表面的SEM图像

Figure 2. TEM images of (a) Ag NCs and (b) Ag@SiO2 NCs; (c) Absorption spectra of TPBi and TPBi:Ag@SiO2 NCs, and PL spectra of FIrpic and PO-01; (d) SEM image of the surface of ETL doped with Ag@SiO2 NCs.

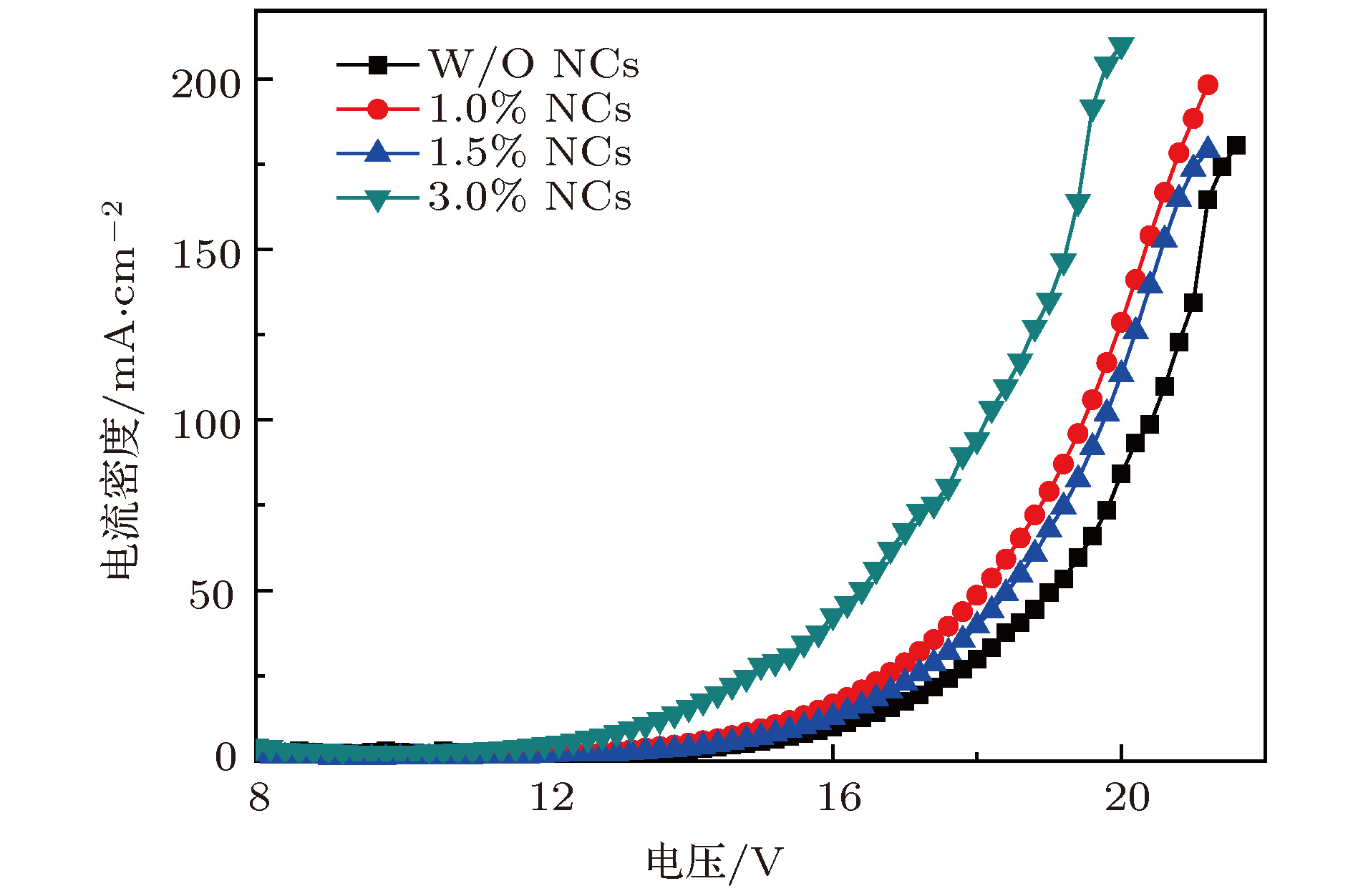

图 3 掺有1%, 1.5%, 2% Ag@SiO2 NCs 的WOLED以及基础器件的光电性能 (a)亮度-电压; (b)电流密度-电压; (c)电流效率-亮度; (d)归一化光谱. 图(d)中的插图为掺有1.5%Ag@SiO2 NCs 的WOLED在不同电压下的归一化光谱

Figure 3. (a) Luminance-voltage, (b) current density-voltage, (c) efficiency-luminance properties and (d) normalized electroluminescent spectra of the WOLEDs with 1%, 1.5%, 2% Ag@SiO2 NCs and the control device. The inset of Fig. (d) is the normalized electroluminescent spectra of the WOLED with 1.5% Ag@SiO2 NCs at different luminance.

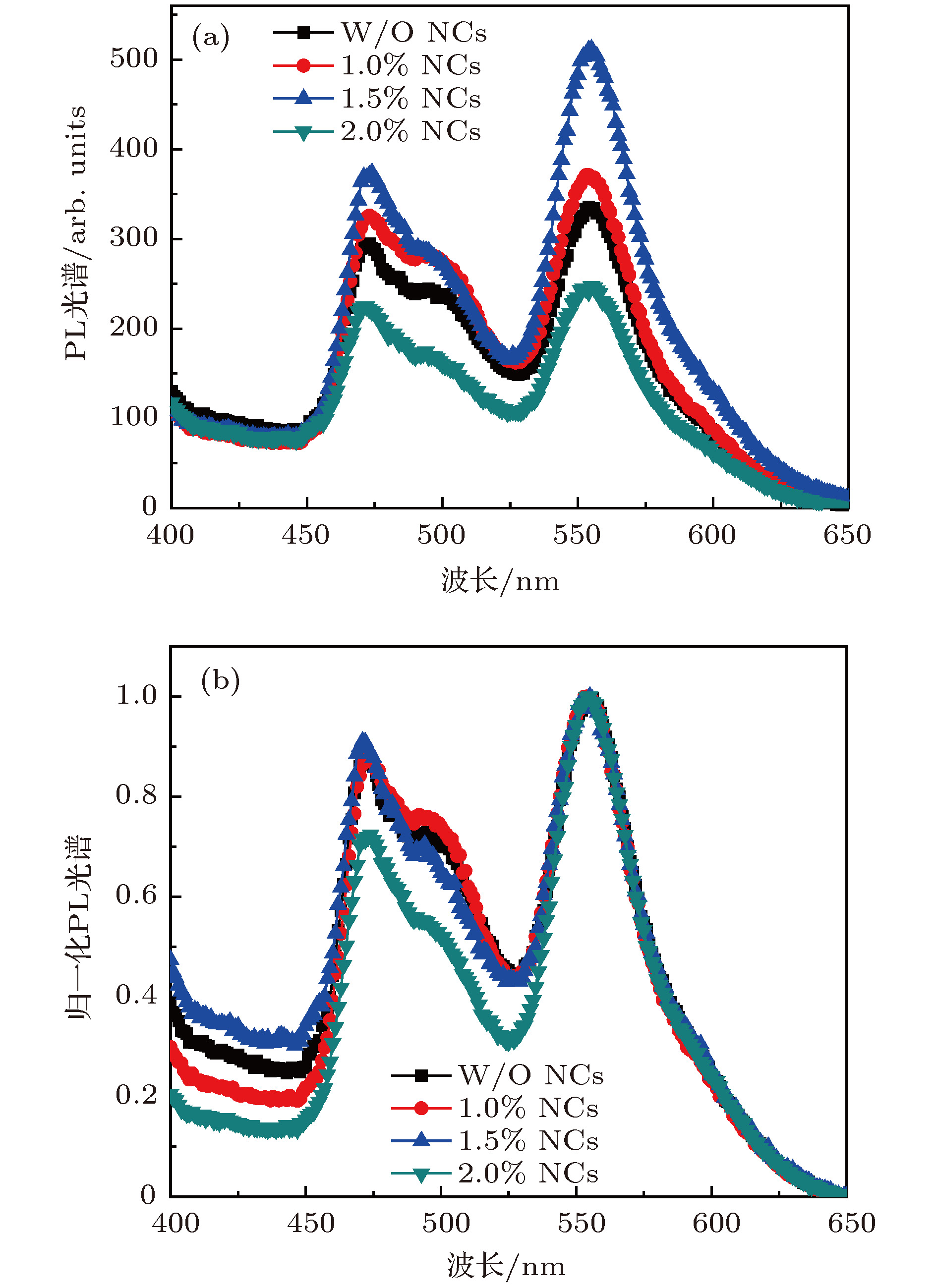

图 4 (a)未归一化和(b)归一化的PL光谱. 样品结构为: ITO/PEDOT:PSS (45 nm)/EML (50 nm)/ETL (45 nm): Ag@SiO2 NCs, 其中Ag@SiO2 NCs浓度为1%, 1.5% and 2%

Figure 4. (a) PL spectra and (b) normalized PL spectra of the samples of ITO/PEDOT:PSS (45 nm)/EML (50 nm)/ETL (45 nm) doped with 1%, 1.5% and 2% Ag@SiO2 NCs and the control sample without NCs.

表 1 WOLED器件的光电性能

Table 1. Summary of the optoelectrical performances of the WOLEDs.

WOLED Max Luminance/cd·m–2 Max Current Efficiency/cd·A–1 Max Power Efficiency/lm·W–1 Current Efficiency Enhancement/% Power Efficiency Enhancement/% W/O NCs 10091 14.7/14.1 a 8.5/7.7 a — — 1% NCs in ETL 15293 20.7 13.3 40.8 b 56.5 b 1.5% NCs in ETL 19427 30.0/26.3 a 18.3/16.5 a 104.1/86.5 a 115.3/114.3 a 2% NCs in ETL 12091 16.9 11.1 15.0 b 30.6 b 1.5% NCs in HIL 16545 17.6 11.5 24.8 c 49.4 c 1.5% NCs in HIL&ETL 11879 19.2 17.7 36.9 c 129.9 c a 图3中的器件效率或效率增强幅度/图6中的器件效率或效率增强幅度;

b 相对于图3中基础器件的效率增强幅度;

c 相对于图6中基础器件的效率增强幅度. -

[1] Kido J, Kimura M, Nagai K 1995 Science 267 1332

Google Scholar

Google Scholar

[2] Sasabe H, Takamatsu J, Motoyama T, Watanabe S, Wagenblast G, Langer N, Molt O, Fuchs E, Lennartz C, Kido J 2010 Adv. Mater. 22 5003

Google Scholar

Google Scholar

[3] Sun Y, Giebink N C, Kanno H, Ma B, Thompson M, Forrest S 2006 Nature 44090 8

[4] Sax S, Mauthner G, Piok T, Pradhan S, Scherf U, List E J W 2007 Org. Electron. 8 791

Google Scholar

Google Scholar

[5] Lee T, Noh T, Shin H, Kwon O, Park J, Choi B, Kim M, Shin D W, Kim Y 2009 Adv. Funct. Mater. 19 1625

Google Scholar

Google Scholar

[6] You J, Tseng S, Meng H, Yen F, Lin I, Horng S 2009 Org. Electron. 10 1610

Google Scholar

Google Scholar

[7] Kim K, Lee J, Park T, Jeon W, Kennedy G, Kwon J 2010 Synth. Met. 160 631

Google Scholar

Google Scholar

[8] Zhao Q, Zhang W, Fan Z, Li J, Chen X, Luo G, Zhang X 2015 Synth. Met. 204 70

Google Scholar

Google Scholar

[9] Ho S, Liu S, Chen Y, So F 2015 J. Photon. Energy 5 057611

Google Scholar

Google Scholar

[10] Yook K, Lee J 2014 Adv. Mater. 26 4218

Google Scholar

Google Scholar

[11] Noh Y, Lee C, Kim J, Yase K 2003 J. Chem. Phys. 118 2853

Google Scholar

Google Scholar

[12] Kim D H, Kim T W 2016 Org. Electron. 34 262

Google Scholar

Google Scholar

[13] Xu Y, Zhou H, Zhang R, Liu Y, Zhang Q, Zhang S, Zhang L, Chen S, Deng L, Qian Y, Wang L, Huang W 2015 AIP Adv. 5 067121

Google Scholar

Google Scholar

[14] Deng L, Zhou Z, Jia B, Zhou H, Peng L, Shang W, Feng J, Chen S 2018 Org. Electron. 53 346

Google Scholar

Google Scholar

[15] Kim T, Kang S, Heo J, Cho S, Kim J W, Choe A, Walker B, Shanker R, Ko H, Kim J Y 2019 Adv. Mater. 30 1800659

[16] Chen P, Xiong Z, Wu X, Shao M, Meng Y, Xiong Z H, Guo C 2017 J. Phys. Chem. Lett. 8 3961

Google Scholar

Google Scholar

[17] Shi Z, Li Y, Li S, Li X, Wu D, Xu T, Tian Y, Chen Y, Zhang Y, Zhang B, Shan C, Du G 2018 Adv. Funct. Mater. 28 1707031

Google Scholar

Google Scholar

[18] Cho C, Kang H, Baek S, Kim T, Lee C 2016 ACS Appl. Mater. Interfaces 8 911

[19] 贾博仑, 邓玲玲, 陈若曦, 张雅男, 房旭民 2017 66 237801

Google Scholar

Google Scholar

Jia B L, Deng L L, Chen R X, Zhang Y N, Fang X M 2017 Acta Phys. Sin. 66 237801

Google Scholar

Google Scholar

[20] Siekkinen A, Mclellan J, Chen J, Xia Y 2006 Chem. Phys. Lett. 432 491

Google Scholar

Google Scholar

[21] Deng L, Yang J, Zhan N, Yu T, Yu H, Chen S 2019 Opt. Lett. 44 983

Google Scholar

Google Scholar

[22] Kim T, Kang H, Jeong S, Kang D J, Lee C, Lee C H, Seo M K, Lee J Y, Kim B J 2014 ACS Appl. Mater. Interfaces 6 16956

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 9081

- PDF Downloads: 79

- Cited By: 0

DownLoad:

DownLoad: