-

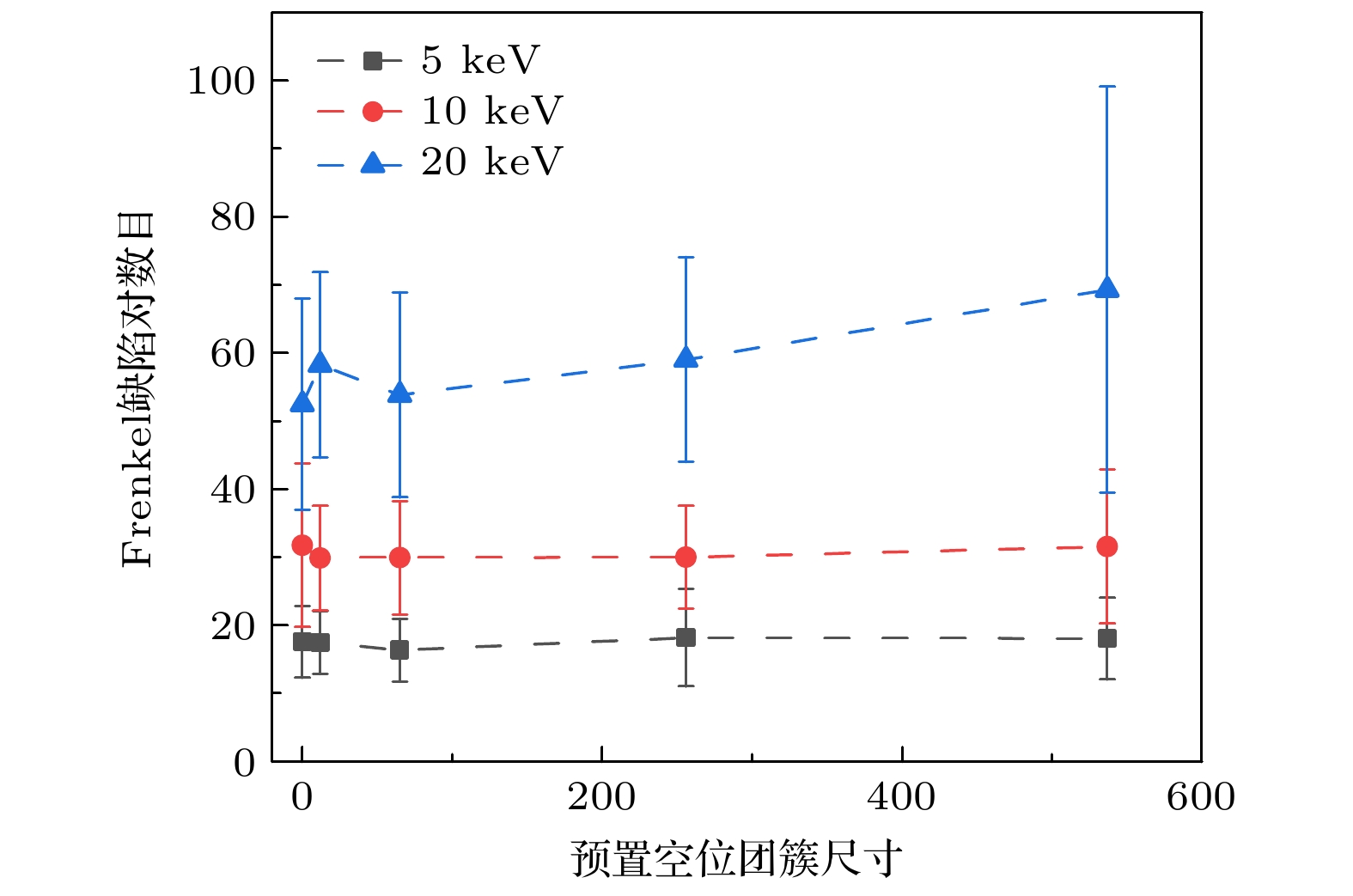

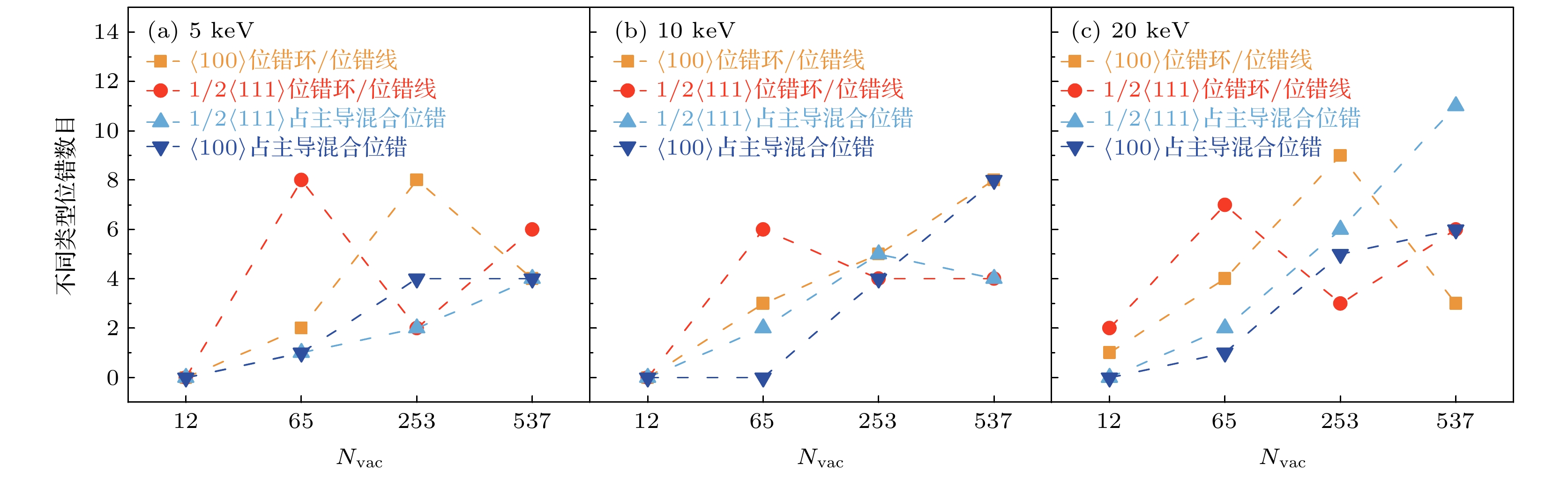

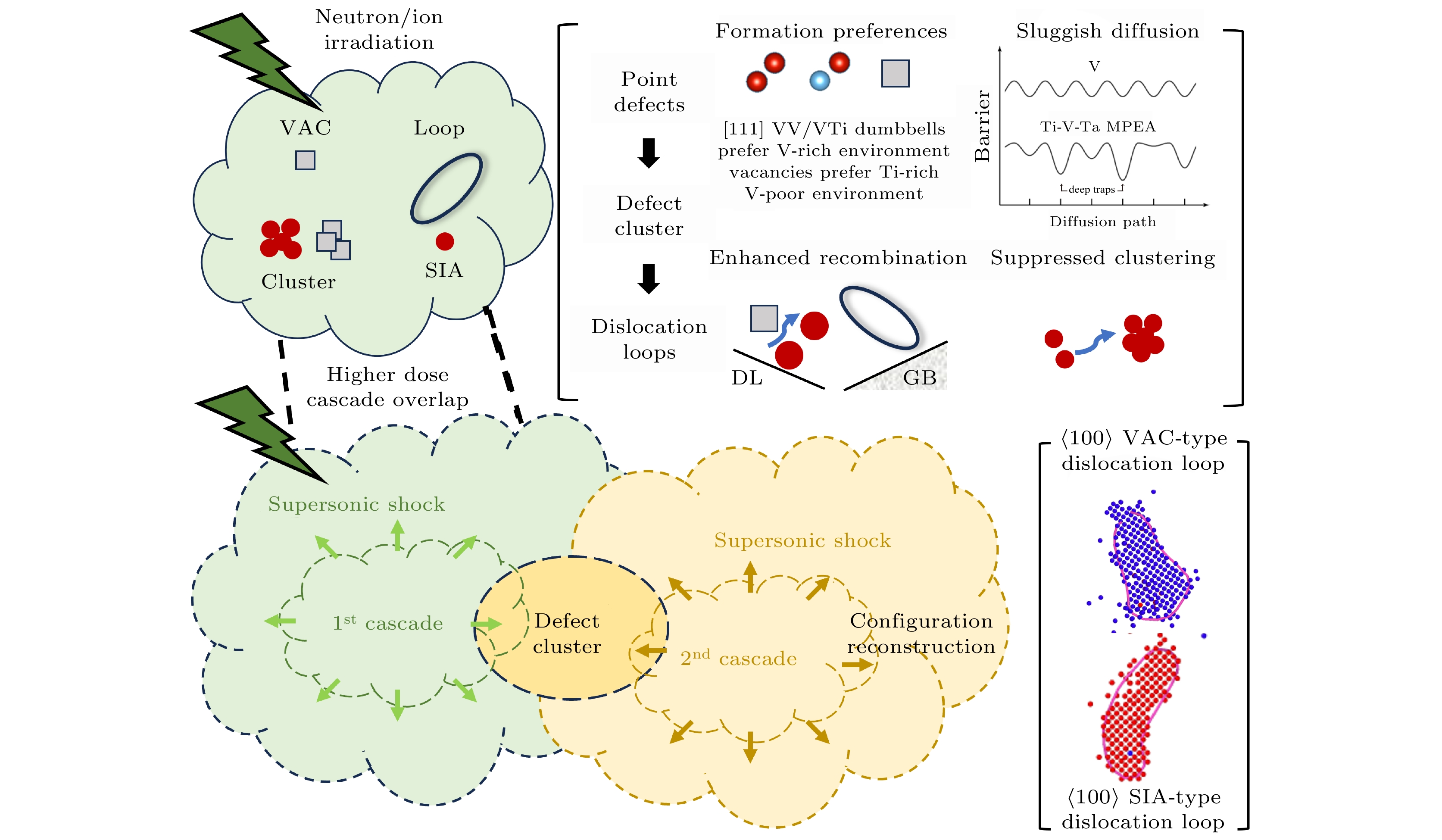

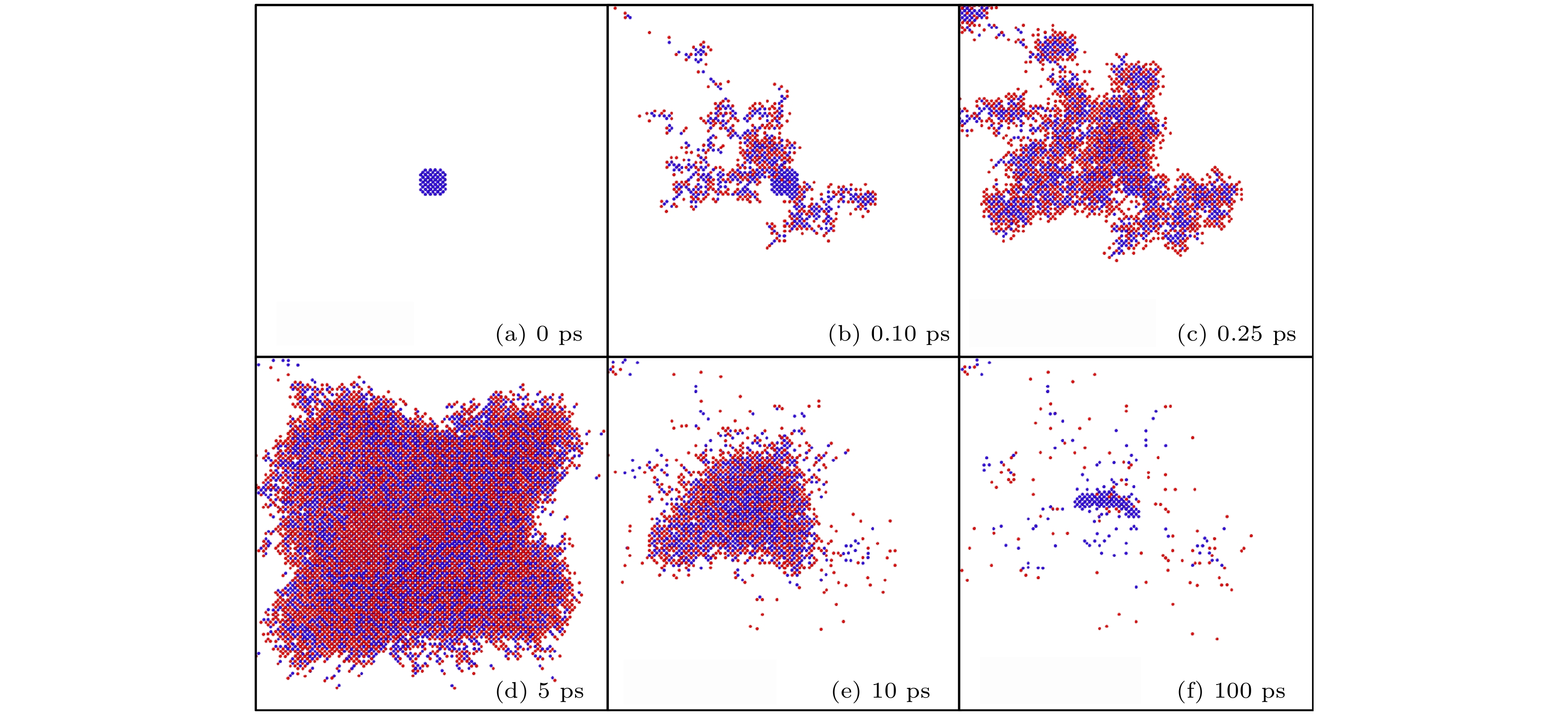

Among the currently developed multi-principal element alloys (MPEAs), Ti-V-Ta MPEA stands out because of its good high-temperature strength, good room-temperature plasticity, stable organizational structure, and low neutron activation, and becomes a first option for cladding material of special power reactors. The radiation resistance of Ti-V-Ta MPEA is the focus of current research. Dislocation loops are the main irradiation defects in Ti-V-Ta MPEA, which can significantly affect the mechanical properties. Therefore, clarifying the formation mechanism of dislocation loops in Ti-V-Ta HEA can help to understand its radiation resistance. The formation behavior of dislocation loops in Ti-V-Ta MPEA is studied based on molecular dynamics method in this work. Cascade overlap simulations with vacancy clusters and interstitial clusters are carried out. The cascade overlap formation mechanism of dislocation loops is analyzed and discussed. In Ti-V-Ta MPEA, the cascade overlap with defect clusters can directly produce different types of dislocation structures. The defect configuration after cascade overlap is determined by the primary knock-on atom (PKA) energy and the type and size of the preset defect clusters. Cascade overlap can improve the formation probability of $ \left\langle {100} \right\rangle $ dislocation loops in Ti-V-Ta MPEA. Cascade overlap with vacancy clusters is an important mechanism for the formation of $ \left\langle {100} \right\rangle $ vacancy dislocation loops, and the size of vacancy clusters is the dominant factor for the formation of $ \left\langle {100} \right\rangle $ vacancy dislocation loops. When the PKA energy is enough to dissolve the defect clusters, $ \left\langle {100} \right\rangle $ vacancy dislocation loops are more likely to form. Furthermore, cascade overlap with interstitial clusters in Ti-V-Ta MPEA is a possible mechanism for the formation of $ \left\langle {100} \right\rangle $ interstitial dislocation loops. This study can contribute to understanding the evolution behavior of irradiation defects in Ti-V-Ta MPEA, and provide theoretical support for designing the composition and optimizing the high-entropy alloys.

-

Keywords:

- Ti-V-Ta multi-principal element alloy /

- dislocation loop /

- cascade overlap /

- molecular dynamics

[1] El-Genk M S, Tournier J M 2005 J. Nucl. Mater. 340 93

Google Scholar

Google Scholar

[2] Busby J T, Leonard K J 2007 JOM 59 20

[3] Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, Chang S Y 2004 Adv. Eng. Mater. 6 299

Google Scholar

Google Scholar

[4] Tsai M H, Yeh J W 2014 Mater. Res. Lett. 2 107

Google Scholar

Google Scholar

[5] Ye Y F, Wang Q, Lu J, Liu C T, Yang Y 2016 Mater. Today 19 349

Google Scholar

Google Scholar

[6] Miracle D B, Senkov O N 2017 Acta Mater. 122 448

Google Scholar

Google Scholar

[7] George E P, Raabe D, Ritchie R O 2019 Nat. Rev. Mater. 4 515

Google Scholar

Google Scholar

[8] Pickering E J, Carruthers A W, Barron P J, Middleburgh S C, Armstrong D E J, Gandy A S 2021 Entropy 23 98

Google Scholar

Google Scholar

[9] Jia N N, Li Y K, Liu X, Zheng Y, Wang B P, Wang J S, Xue Y F, Jin K 2019 JOM. 71 3490

Google Scholar

Google Scholar

[10] Hu B, Yao B, Wang J, Liu Y, Wang C J, Du Y, Yin H Q 2020 Intermetallics 118 106701

Google Scholar

Google Scholar

[11] Yin X, Dou Y K, He X F, Jin K, Wang C L, Dong Y G, Wang H R, Zhong W H, Xue Y F, Yang W 2022 JOM 74 4326

Google Scholar

Google Scholar

[12] Jia N N, Li Y, Huang H F, Chen S, Li D, Dou Y K, He X F, Yang W, Yin X, Jin K 2021 J. Nucl. Mater. 550 152937

Google Scholar

Google Scholar

[13] Mei L, Zhang Q H, Dou Y K, Fu E G, Li L, Chen S, Dong Y G, Guo X, He X F, Yang W, Yin X, Jin K 2023 Scr. Mater. 223 115070

Google Scholar

Google Scholar

[14] Dou Y K, Zhao Y P, He X F, Gao J, Cao J L, Yang W 2023 J. Nucl. Mater. 573 154096

Google Scholar

Google Scholar

[15] Zhao Y P, Dou Y K, He X F, Deng H Q, Wang L F, Yang W 2023 Comput. Mater. Sci. 218 111943

Google Scholar

Google Scholar

[16] Zhao Y P, Dou Y K, He X F, Cao H, Wang L F, Deng H Q, Yang W 2024 Chin. Phys. B 33 036104

Google Scholar

Google Scholar

[17] Peng Q, Meng F J, Yang Y Z, Lu C Y, Deng H Q, Wang L M, De S, Gao F 2018 Nat. Commun. 9 4880

Google Scholar

Google Scholar

[18] Granberg F, Byggmästar J, Sand A E, Nordlund K 2017 Europhys. Lett. 119 56003

Google Scholar

Google Scholar

[19] Byggmästar J, Granberg F, Sand A E, Pirttikoski A, Alexander R, Marinica M C, Nordlund K 2019 J. Phys. Condens. Matter. 31 245402

Google Scholar

Google Scholar

[20] Wang X Y, Gao N, Wang Y N, Liu H L, Shu G G, Li C L, Xu B, Liu W 2019 J. Nucl. Mater. 519 322

Google Scholar

Google Scholar

[21] Marinica M C, Willaime F, Crocombette J P 2012 Phys. Rev. Lett. 108 025501

Google Scholar

Google Scholar

[22] Gao J, Gaganidze E, Kaiser B, Aktaa J 2021 J. Nucl. Mater. 557 153212

Google Scholar

Google Scholar

[23] Esfandiarpour A, Byggmästar J, Balbuena J P, Caturla M J, Nordlund K, Granberg F 2022 Materialia. 21 101344

Google Scholar

Google Scholar

[24] Arakawa K, Hatanaka M, Kuramoto E, Ono K, Mori H 2006 Phys. Rev. Lett. 96 125506

Google Scholar

Google Scholar

[25] Chen J, Gao N, Jung P, Sauvage T 2013 J. Nucl. Mater. 441 216

Google Scholar

Google Scholar

[26] Gao N, Chen J, Kurtz R J, Wang Z G, Zhang R F, Gao F 2017 J. Phys. Condens. Matter. 29 455301

Google Scholar

Google Scholar

[27] Xu H, Stoller R E, Osetsky Y N, Terentyev D 2013 Phys. Rev. Lett. 110 265503

Google Scholar

Google Scholar

[28] Wang X Y, Gao N, Wang Y N, Wu X Y, Shu G G, Li C L, Li Q L, Xu B, Liu W 2019 Scr. Mater. 162 204

Google Scholar

Google Scholar

[29] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[30] Qiu R Y, Chen Y C, Liao X C, He X F, Yang W, Hu W Y, Deng H Q 2021 J. Nucl. Mater. 557 153231

Google Scholar

Google Scholar

[31] Stukowski A 2010 Model. Simul. Mater. Sc. 18 015012

Google Scholar

Google Scholar

[32] Fellman A, Sand A E 2022 J. Nucl. Mater. 572 154020

Google Scholar

Google Scholar

[33] Fellman A, Sand A E, Byggmästar J, Nordlund K 2019 J. Phys. Condens. Matter. 31 405402

Google Scholar

Google Scholar

[34] Qiu R Y, Chen Y C, Gao N, He X F, Dou Y K, Yang W, Hu W Y, Deng H Q 2023 Nucl. Mater. Energy 34 101394

Google Scholar

Google Scholar

-

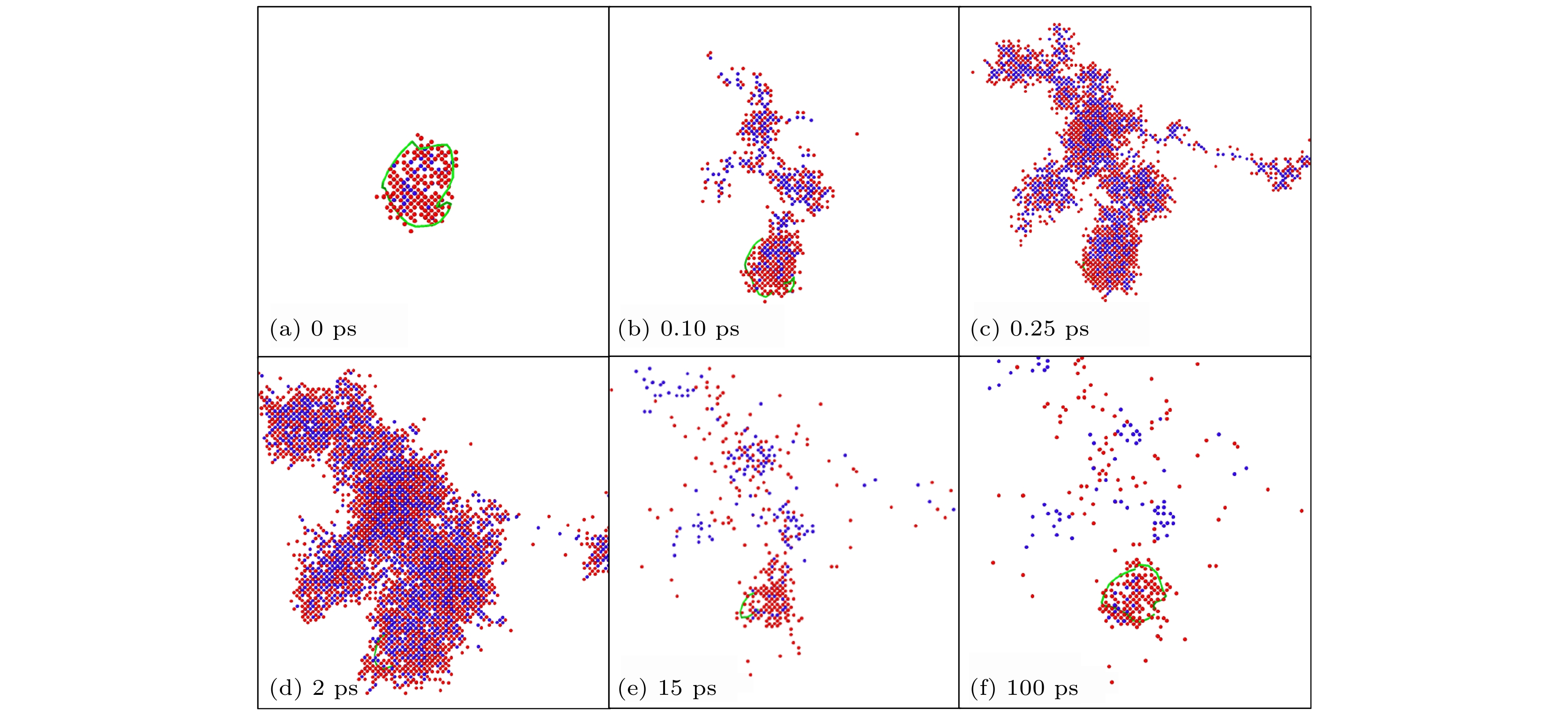

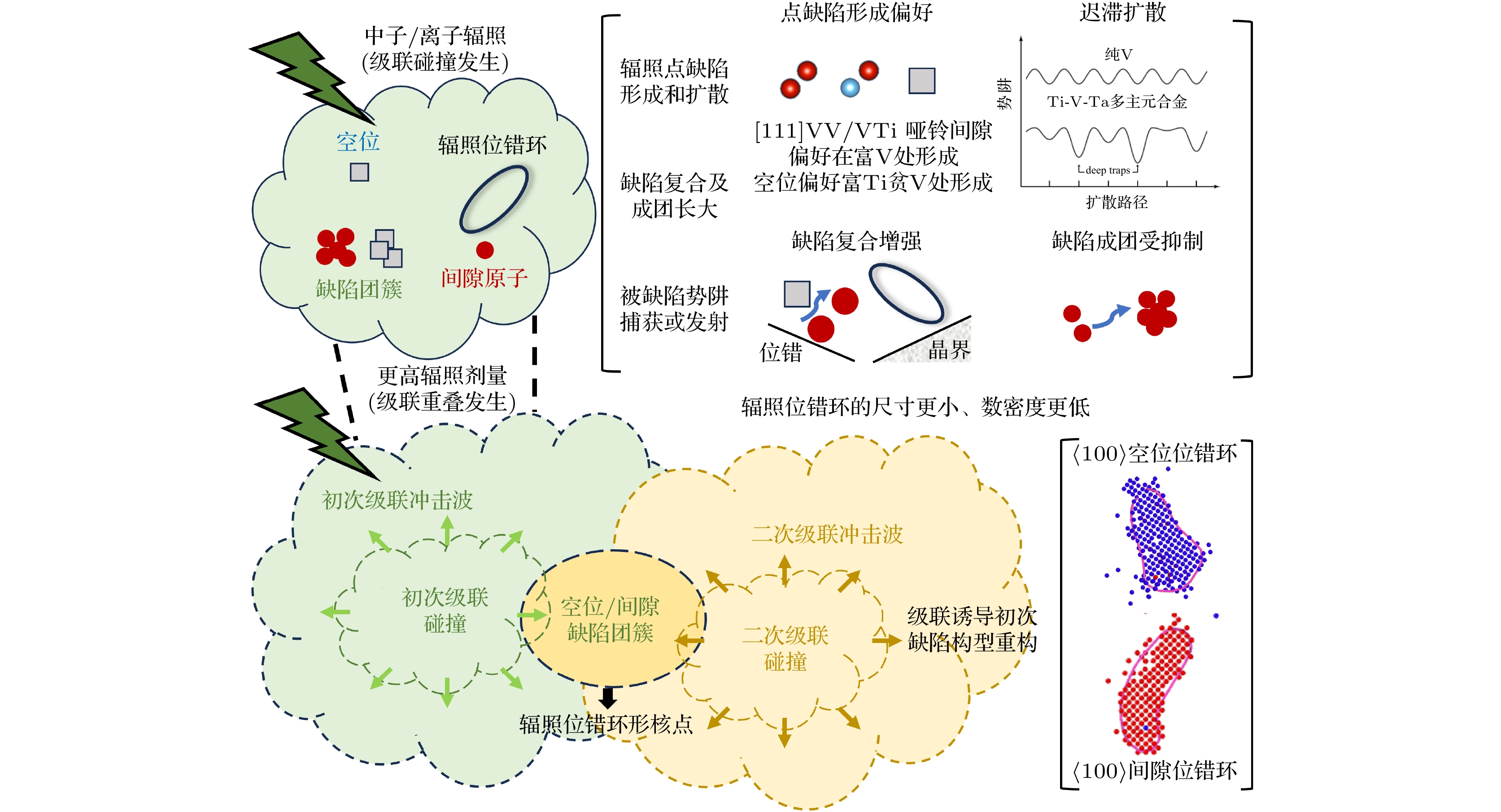

图 1 Ti-V-Ta多主元合金与空位团簇级联重叠模拟的缺陷演化过程(40 keV, $ {N}_{{\mathrm{V}}{\mathrm{A}}{\mathrm{C}}} = 253$), 红色和蓝色为间隙原子和空位

Figure 1. Defect evolution process during the cascade overlap simulation with vacancy cluster (40 keV, $ {N}_{{\mathrm{V}}{\mathrm{A}}{\mathrm{C}}}= 253 $) in Ti-V-Ta multi-principal element alloy, red and blue are interstitials and vacancies.

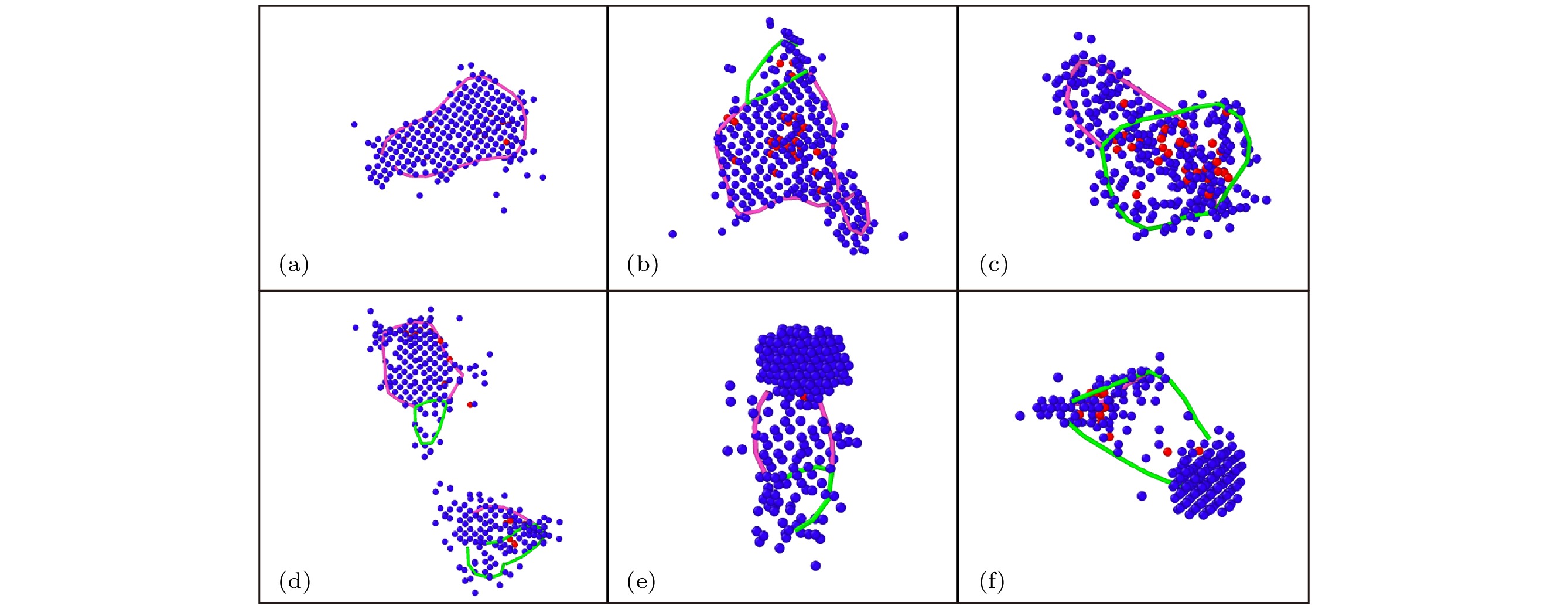

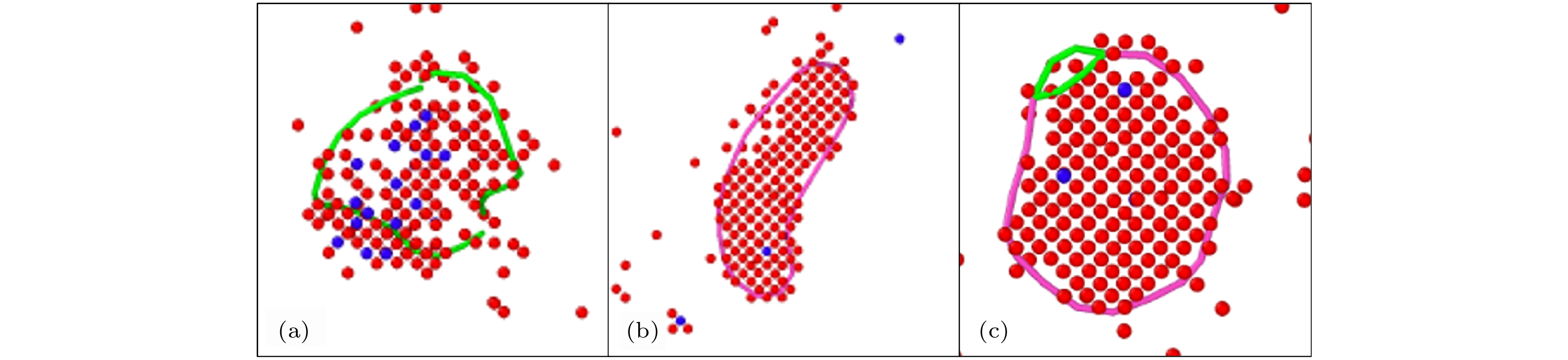

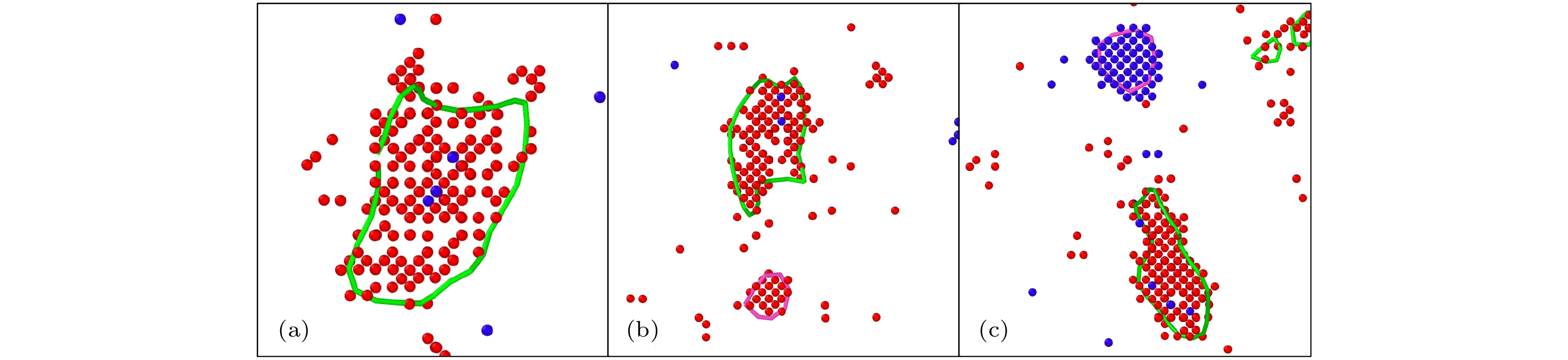

图 2 Ti-V-Ta多主元合金与空位团簇级联重叠形成的典型缺陷构型(40 keV, $ {N}_{{\mathrm{V}}{\mathrm{A}}{\mathrm{C}}} $= 253), 红色和蓝色为间隙原子和空位, 粉线和绿线为$ \left\langle {100} \right\rangle $和1/2$ \left\langle {111} \right\rangle $位错线

Figure 2. Typical defect configuration during the cascade overlap simulation with vacancy cluster (40 keV, $ {N}_{{\mathrm{V}}{\mathrm{A}}{\mathrm{C}}} $= 253) in Ti-V-Ta multi-principal element alloy, red and blue are interstitials and vacancies, pink and green lines are $ \left\langle {100} \right\rangle $ and 1/2$ \left\langle {111} \right\rangle $ dislocation lines.

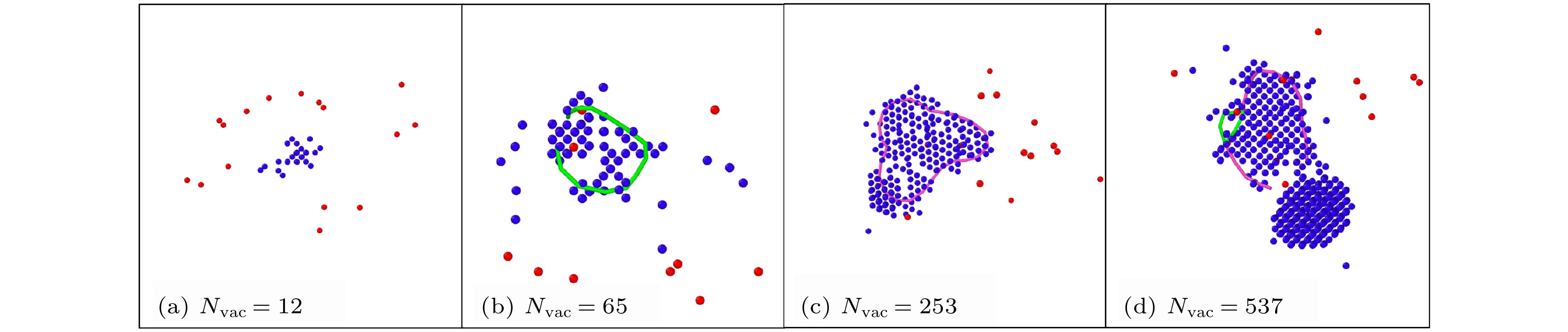

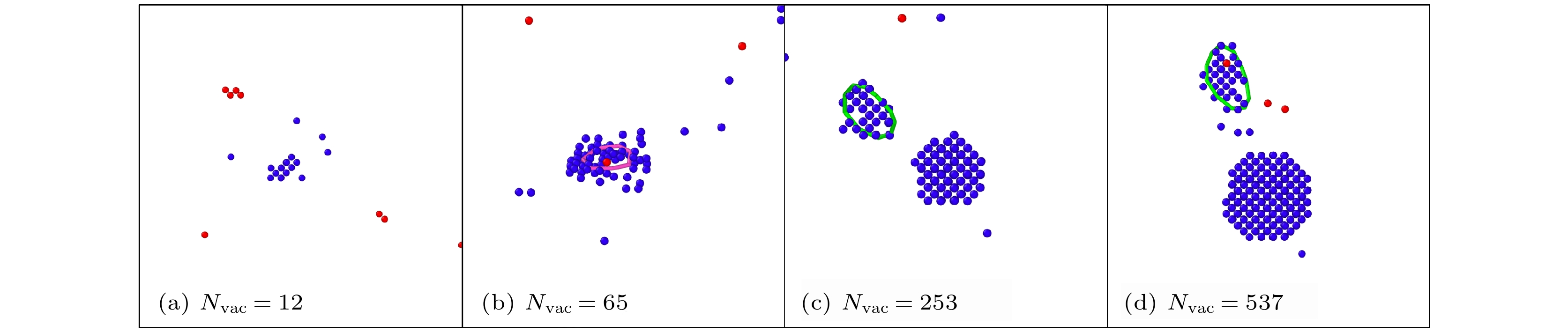

图 4 Ti-V-Ta多主元合金与不同尺寸空位团簇级联重叠形成的典型缺陷构型(5 keV), 红色和蓝色为间隙原子和空位, 粉线和绿线为$ \left\langle {100} \right\rangle $和1/2$ \left\langle {111} \right\rangle $位错线

Figure 4. Typical defect configuration formed during the cascade overlap simulations with different size vacancy clusters in Ti-V-Ta multi-principal element alloy (5 keV), red and blue interstitials and vacancies, and pink and green lines are $ \left\langle {100} \right\rangle $ and 1/2$ \left\langle {111} \right\rangle $ dislocation lines.

图 6 纯V与不同尺寸空位团簇级联重叠形成的典型缺陷构型(5 keV), 红色和蓝色为间隙原子和空位, 粉线和绿线为$ \left\langle {100} \right\rangle $和1/2$ \left\langle {111} \right\rangle $位错线

Figure 6. Typical defect configuration formed during the cascade overlap simulations with different size vacancy clusters in pure V (5 keV), red and blue interstitials and vacancies, and pink and green lines are $ \left\langle {100} \right\rangle $ and 1/2$ \left\langle {111} \right\rangle $ dislocation lines.

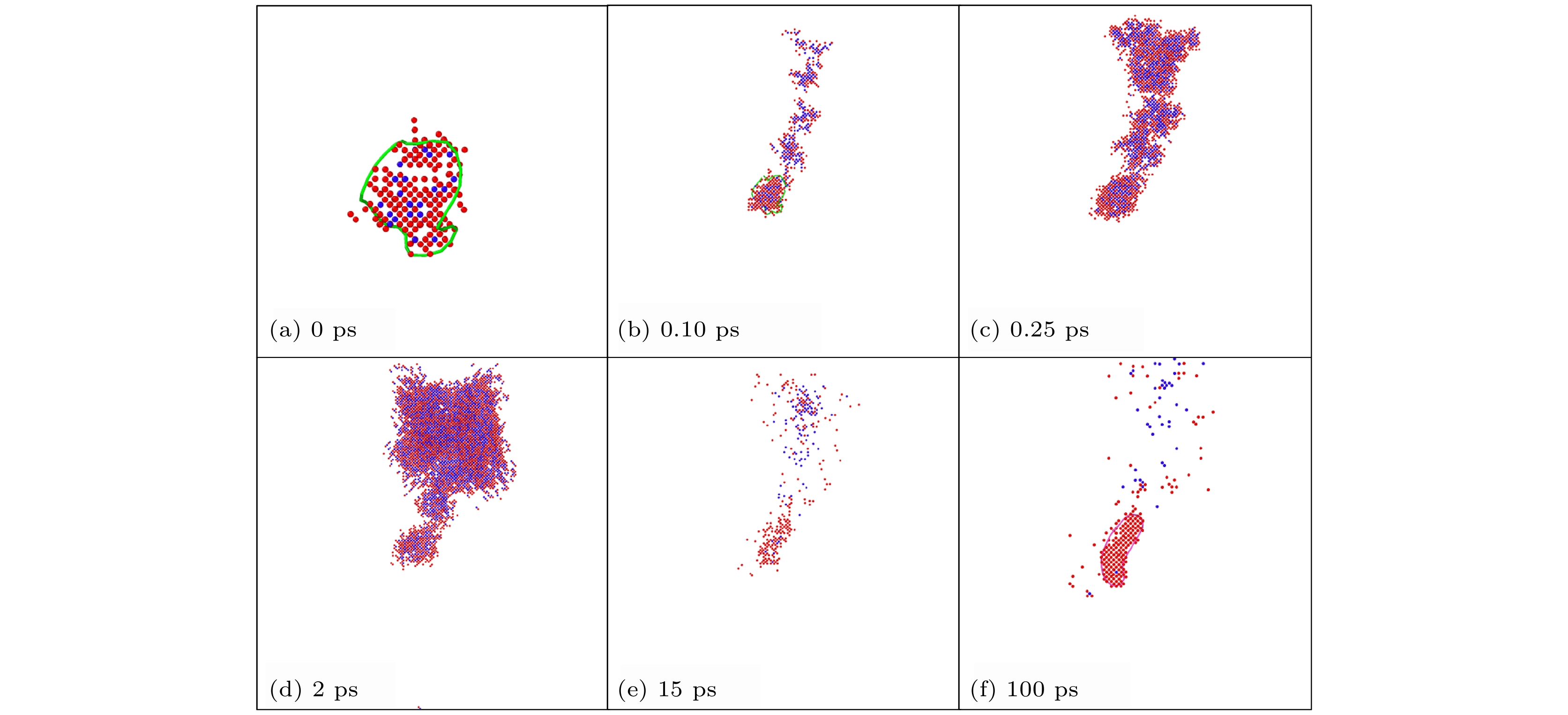

图 7 Ti-V-Ta多主元合金与间隙团簇级联重叠形成1/2$ \left\langle {111} \right\rangle $位错环的缺陷演化过程(40 keV, $ {N}_{{\mathrm{S}}{\mathrm{I}}{\mathrm{A}}} $= 183), 红色和蓝色为间隙原子和空位, 绿线为1/2$ \left\langle {111} \right\rangle $位错线

Figure 7. Defect evolution process during the cascade overlap simulation with interstitial cluster (40 keV, $ {N}_{{\mathrm{S}}{\mathrm{I}}{\mathrm{A}}} $= 183) in Ti-V-Ta multi-principal element alloy, red and blue are interstitials and vacancies, green lines are 1/2$ \left\langle {111} \right\rangle $ dislocation lines.

图 8 Ti-V-Ta多主元合金与间隙团簇级联重叠形成$ \left\langle {100} \right\rangle $间隙位错环的缺陷演化过程(40 keV, $ {N}_{{\mathrm{S}}{\mathrm{I}}{\mathrm{A}}} $= 183), 红色和蓝色为间隙原子和空位, 粉线为$ \left\langle {100} \right\rangle $位错线

Figure 8. Defect evolution process during the cascade overlap simulation with interstitial cluster (40 keV, $ {N}_{{\mathrm{S}}{\mathrm{I}}{\mathrm{A}}} $= 183) in Ti-V-Ta multi-principal element alloy, red and blue are interstitials and vacancies, pink lines are $ \left\langle {100} \right\rangle $ dislocation lines.

图 9 Ti-V-Ta多主元合金与间隙团簇级联重叠形成的典型缺陷构型(40 keV, $ {N}_{{\mathrm{S}}{\mathrm{I}}{\mathrm{A}}} $=183), 红色和蓝色为间隙原子和空位, 粉线和绿线为$ \left\langle {100} \right\rangle $和1/2$ \left\langle {111} \right\rangle $位错线

Figure 9. Typical defect configuration during the cascade overlap simulation with interstitial cluster (40 keV, $ {N}_{{\mathrm{S}}{\mathrm{I}}{\mathrm{A}}} $=183) in Ti-V-Ta multi-principal element alloy, red and blue are interstitials and vacancies, pink and green lines are $ \left\langle {100} \right\rangle $ and 1/2$ \left\langle {111} \right\rangle $ dislocation lines.

图 10 纯V与间隙团簇级联重叠形成的典型缺陷构型(40 keV, $ {N}_{{\mathrm{S}}{\mathrm{I}}{\mathrm{A}}} $=183), 红色和蓝色为间隙原子和空位, 粉线和绿线为$ \left\langle {100} \right\rangle $和1/2$ \left\langle {111} \right\rangle $位错线

Figure 10. Typical defect configuration during the cascade overlap simulation with interstitial cluster (40 keV, $ {N}_{{\mathrm{S}}{\mathrm{I}}{\mathrm{A}}} $=183) in pure V, red and blue are interstitials and vacancies, pink and green lines are $ \left\langle {100} \right\rangle $ and 1/2$ \left\langle {111} \right\rangle $ dislocation lines.

-

[1] El-Genk M S, Tournier J M 2005 J. Nucl. Mater. 340 93

Google Scholar

Google Scholar

[2] Busby J T, Leonard K J 2007 JOM 59 20

[3] Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, Chang S Y 2004 Adv. Eng. Mater. 6 299

Google Scholar

Google Scholar

[4] Tsai M H, Yeh J W 2014 Mater. Res. Lett. 2 107

Google Scholar

Google Scholar

[5] Ye Y F, Wang Q, Lu J, Liu C T, Yang Y 2016 Mater. Today 19 349

Google Scholar

Google Scholar

[6] Miracle D B, Senkov O N 2017 Acta Mater. 122 448

Google Scholar

Google Scholar

[7] George E P, Raabe D, Ritchie R O 2019 Nat. Rev. Mater. 4 515

Google Scholar

Google Scholar

[8] Pickering E J, Carruthers A W, Barron P J, Middleburgh S C, Armstrong D E J, Gandy A S 2021 Entropy 23 98

Google Scholar

Google Scholar

[9] Jia N N, Li Y K, Liu X, Zheng Y, Wang B P, Wang J S, Xue Y F, Jin K 2019 JOM. 71 3490

Google Scholar

Google Scholar

[10] Hu B, Yao B, Wang J, Liu Y, Wang C J, Du Y, Yin H Q 2020 Intermetallics 118 106701

Google Scholar

Google Scholar

[11] Yin X, Dou Y K, He X F, Jin K, Wang C L, Dong Y G, Wang H R, Zhong W H, Xue Y F, Yang W 2022 JOM 74 4326

Google Scholar

Google Scholar

[12] Jia N N, Li Y, Huang H F, Chen S, Li D, Dou Y K, He X F, Yang W, Yin X, Jin K 2021 J. Nucl. Mater. 550 152937

Google Scholar

Google Scholar

[13] Mei L, Zhang Q H, Dou Y K, Fu E G, Li L, Chen S, Dong Y G, Guo X, He X F, Yang W, Yin X, Jin K 2023 Scr. Mater. 223 115070

Google Scholar

Google Scholar

[14] Dou Y K, Zhao Y P, He X F, Gao J, Cao J L, Yang W 2023 J. Nucl. Mater. 573 154096

Google Scholar

Google Scholar

[15] Zhao Y P, Dou Y K, He X F, Deng H Q, Wang L F, Yang W 2023 Comput. Mater. Sci. 218 111943

Google Scholar

Google Scholar

[16] Zhao Y P, Dou Y K, He X F, Cao H, Wang L F, Deng H Q, Yang W 2024 Chin. Phys. B 33 036104

Google Scholar

Google Scholar

[17] Peng Q, Meng F J, Yang Y Z, Lu C Y, Deng H Q, Wang L M, De S, Gao F 2018 Nat. Commun. 9 4880

Google Scholar

Google Scholar

[18] Granberg F, Byggmästar J, Sand A E, Nordlund K 2017 Europhys. Lett. 119 56003

Google Scholar

Google Scholar

[19] Byggmästar J, Granberg F, Sand A E, Pirttikoski A, Alexander R, Marinica M C, Nordlund K 2019 J. Phys. Condens. Matter. 31 245402

Google Scholar

Google Scholar

[20] Wang X Y, Gao N, Wang Y N, Liu H L, Shu G G, Li C L, Xu B, Liu W 2019 J. Nucl. Mater. 519 322

Google Scholar

Google Scholar

[21] Marinica M C, Willaime F, Crocombette J P 2012 Phys. Rev. Lett. 108 025501

Google Scholar

Google Scholar

[22] Gao J, Gaganidze E, Kaiser B, Aktaa J 2021 J. Nucl. Mater. 557 153212

Google Scholar

Google Scholar

[23] Esfandiarpour A, Byggmästar J, Balbuena J P, Caturla M J, Nordlund K, Granberg F 2022 Materialia. 21 101344

Google Scholar

Google Scholar

[24] Arakawa K, Hatanaka M, Kuramoto E, Ono K, Mori H 2006 Phys. Rev. Lett. 96 125506

Google Scholar

Google Scholar

[25] Chen J, Gao N, Jung P, Sauvage T 2013 J. Nucl. Mater. 441 216

Google Scholar

Google Scholar

[26] Gao N, Chen J, Kurtz R J, Wang Z G, Zhang R F, Gao F 2017 J. Phys. Condens. Matter. 29 455301

Google Scholar

Google Scholar

[27] Xu H, Stoller R E, Osetsky Y N, Terentyev D 2013 Phys. Rev. Lett. 110 265503

Google Scholar

Google Scholar

[28] Wang X Y, Gao N, Wang Y N, Wu X Y, Shu G G, Li C L, Li Q L, Xu B, Liu W 2019 Scr. Mater. 162 204

Google Scholar

Google Scholar

[29] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[30] Qiu R Y, Chen Y C, Liao X C, He X F, Yang W, Hu W Y, Deng H Q 2021 J. Nucl. Mater. 557 153231

Google Scholar

Google Scholar

[31] Stukowski A 2010 Model. Simul. Mater. Sc. 18 015012

Google Scholar

Google Scholar

[32] Fellman A, Sand A E 2022 J. Nucl. Mater. 572 154020

Google Scholar

Google Scholar

[33] Fellman A, Sand A E, Byggmästar J, Nordlund K 2019 J. Phys. Condens. Matter. 31 405402

Google Scholar

Google Scholar

[34] Qiu R Y, Chen Y C, Gao N, He X F, Dou Y K, Yang W, Hu W Y, Deng H Q 2023 Nucl. Mater. Energy 34 101394

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 3627

- PDF Downloads: 84

- Cited By: 0

DownLoad:

DownLoad: