-

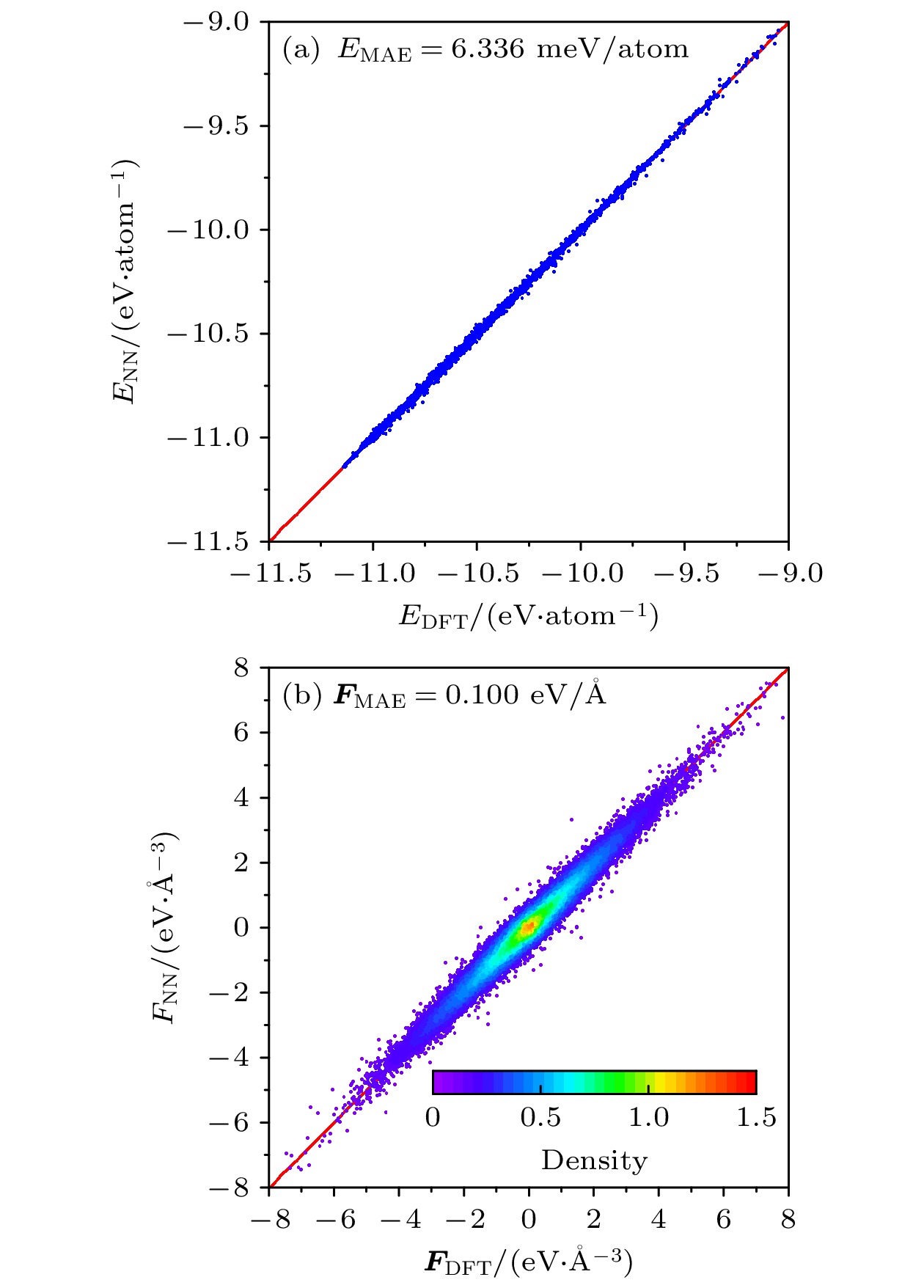

Uranium-niobium alloys exhibit complex crystal phases and unique mechanical behaviors under various thermodynamic states and external loads. However, due to the lack of accurate interatomic potentials, the atomic-scale phase behaviors and dynamical processes in this important alloy are still unclear. In recent years, the development of machine-learning-based force fields has provided a systematic way to generate accurate interatomic potentials on large and complex first-principle-based datasets. However, this crucial nuclear material has received limited attention from researchers in the field of machine-learning potentials. In this work, based on our previous researches on the neural-network potential training and evaluation framework, which we called NNAP (neural-network atomic potential), a new neural network potential is constructed for the uranium-niobium alloy system. A combination of random structure search and active learning algorithms is utilized to enhance coverage of the chemical and structural space of the alloy system. Testing of the generated potential demonstrates high generalization performance and accuracy. On the testing set, the mean absolute error of the energy and the force are 5.6 meV/atom and 0.095 eV/Å, respectively. Further calculation results of crystal structure parameters, equation of state, and phonon dispersions coincide well with the results from the first-principle or experimental references. The atomic-scale evolution of the spinodal decomposition process in the U-Nb alloys is investigated based on the newly trained potential. It is shown that the atom-swapping hybrid Monte Carlo can be a powerful tool to understand the thermodynamic evolution of the systems. By using the atom-swapping hybrid Monte Carlo method, the decrease of potential energy due to phase segregation is observed within 5000 steps, while no significant energy reduction is found after 3-ns MD simulation. Finally, the stress-strain curves under shear load for different initial states are obtained. It is found that the Nb precipitation generates strengthened phases in the alloy and the deformation behavior of U-Nb alloys is significantly changed, where a disorder shear band emerges in the deformation path of the $ {\mathrm{\gamma }} $-phase alloys. Our work lays a foundation for understanding the mechanical processes in this important alloy system. -

Keywords:

- uranium-niobium alloys /

- neural network potential /

- molecular dynamics /

- mechanical properties

[1] Vandermeer R A 1980 Acta Metall. 28 383

Google Scholar

Google Scholar

[2] Clarke A J, Field R D, Hackenberg R E, et al. 2009 J. Nucl. Mater. 393 282

Google Scholar

Google Scholar

[3] Vandermeer R A, Ogle J C, Snyder W B 1978 Scr. Metall. 12 243

Google Scholar

Google Scholar

[4] Field R D, Brown D W, Thoma D J 2005 Philos. Mag. 85 2593

Google Scholar

Google Scholar

[5] Zhang C, Wang H, Li J, et al. 2019 Mater. Des. 162 94

Google Scholar

Google Scholar

[6] Choung S, Park W, Moon J, Han J W 2024 Chem. Eng. J. 494 152757

Google Scholar

Google Scholar

[7] Ma S, Liu Z P 2020 ACS Catal. 10 13213

Google Scholar

Google Scholar

[8] Su R, Yu J, Guan P, Wang W 2024 Sci. Chin. Mater. 67 3298

Google Scholar

Google Scholar

[9] Shapeev A V 2016 Multiscale Model. Simul. 14 1153

Google Scholar

Google Scholar

[10] Artrith N, Urban A, Ceder G 2018 J. Chem. Phys. 148 241711

Google Scholar

Google Scholar

[11] Behler J, Parrinello M 2007 Phys. Rev. Lett. 98 146401

Google Scholar

Google Scholar

[12] Chiriki S, Jindal S, Bulusu S S 2017 J. Chem. Phys. 146 084314

Google Scholar

Google Scholar

[13] Zhao R, Wang S, Kong Z, et al. 2023 Mater. Des. 231 112012

Google Scholar

Google Scholar

[14] Young T A, Johnston-Wood T, Deringer V L, Duarte F 2021 Chem. Sci. 12 10944

Google Scholar

Google Scholar

[15] Smith J S, Nebgen B, Lubbers N, Isayev O, Roitberg A E 2018 J. Chem. Phys. 148 241733

Google Scholar

Google Scholar

[16] van der Oord C, Sachs M, Kovács D P, Ortner C, Csányi G 2023 npj Comput. Mater. 9 1

Google Scholar

Google Scholar

[17] Kulichenko M, Barros K, Lubbers N, Li Y W, Messerly R, Tretiak S, Smith J S, Nebgen B 2023 Nat. Comput. Sci. 3 230

Google Scholar

Google Scholar

[18] Deringer V L, Pickard C J, Csányi G 2018 Phys. Rev. Lett. 120 156001

Google Scholar

Google Scholar

[19] Hao M S, Guan P F 2023 Chin. Phys. B 32 098401

Google Scholar

Google Scholar

[20] Li F, Zhang Z, Liu H, et al. 2024 Nat. Mater. 23 52

Google Scholar

Google Scholar

[21] Zhang Z, Zhang S, Wang Q, et al. 2024 Proc. Natl. Acad. Sci. U. S. A. 121 e2400200121

Google Scholar

Google Scholar

[22] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

[23] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[24] Adak S, Nakotte H, de Châtel P F, Kiefer B 2011 Phys. B: Condens. Matter. 406 3342

Google Scholar

Google Scholar

[25] Bartók A P, Kondor R, Csányi G 2013 Phys. Rev. B 87 184115

Google Scholar

Google Scholar

[26] Jindal S, Chiriki S, Bulusu S S 2017 J. Chem. Phys. 146 204301

Google Scholar

Google Scholar

[27] Gasteiger J, Groß J, Günnemann S 2022 arXiv: 2003.03123 [cs. LG]

[28] Artrith N, Urban A, Ceder G 2017 Phys. Rev. B 96 014112

Google Scholar

Google Scholar

[29] Loshchilov I, Hutter F 2019 arXiv: 1711.05101 [cs. LG]

[30] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[31] Thompson A P, Aktulga H M, Berger R, et al. 2022 Comput. Phys. Commun. 271 108171

Google Scholar

Google Scholar

[32] Nosé S 1984 J. Chem. Phys. 81 511

Google Scholar

Google Scholar

[33] Parrinello M, Rahman A 1980 Phys. Rev. Lett. 45 1196

Google Scholar

Google Scholar

[34] Zhang L, Han J, Wang H, Car R, E W 2018 Phys. Rev. Lett. 120 143001

Google Scholar

Google Scholar

[35] Wen T, Wang C Z, Kramer M J, et al. 2019 Phys. Rev. B 100 174101

Google Scholar

Google Scholar

[36] Pickard C J, Needs R J 2011 J. Phys. Condens. Matter 23 053201

Google Scholar

Google Scholar

[37] Imbalzano G, Anelli A, Giofré D, Klees S, Behler J, Ceriotti M 2018 J. Chem. Phys. 148 241730

Google Scholar

Google Scholar

[38] Mahoney M W, Drineas P 2009 Proc. Natl. Acad. Sci. U. S. A. 106 697

Google Scholar

Google Scholar

[39] Pan X L, Wang H, Zhang L L, Wang Y F, Chen X R, Geng H Y, Chen Y 2023 J. Nucl. Mater. 579 154394

Google Scholar

Google Scholar

[40] Barrett C S, Mueller M H, Hitterman R L 1963 Phys. Rev. 129 625

Google Scholar

Google Scholar

[41] Wilson A S, Rundle R E 1949 Acta Cryst. 2 126

Google Scholar

Google Scholar

[42] Roberge R 1975 J. Less-Common Met. 40 161

Google Scholar

Google Scholar

[43] Koike J, Kassner M E, Tate R E, Rosen R S 1998 J. Phase Equilib. 19 253

Google Scholar

Google Scholar

[44] Shimizu F, Ogata S, Li J 2007 Mater. Trans. 48 2923

Google Scholar

Google Scholar

-

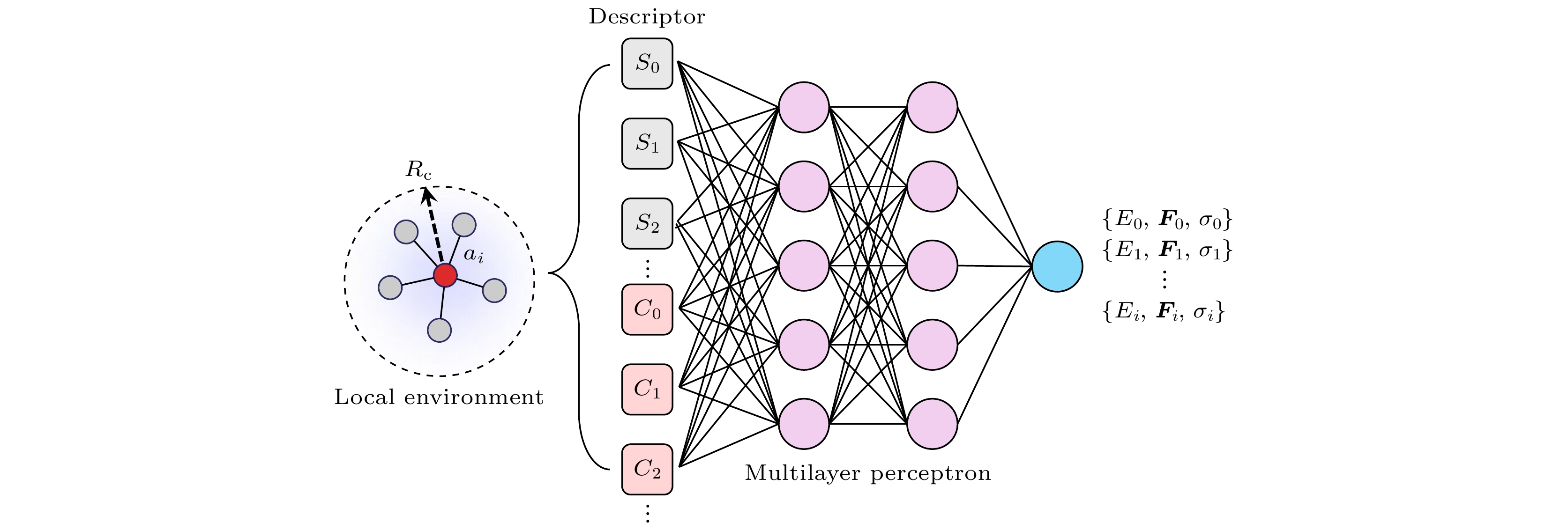

图 1 神经网络势能函数基本架构. $ {S}_{i} $和$ {C}_{i} $分别为未考虑和考虑化学权重后的局域原子描述符. 训练集中结构的原子局域环境描述符是包含多个隐藏层的多层感知机模型的输入参量, 在输出端可获得原子势能、力以及原子应力

Figure 1. The basic architecture of the neural network potential function. $ {S}_{i} $ and $ {C}_{i} $ represent the local atomic descriptors before and after considering chemical weights, respectively. The atomic local environment descriptors of structures in the training set serve as input parameters to a multi-layer perceptron model with multiple hidden layers. The output provides the atomic potential energy, forces, and atomic stress.

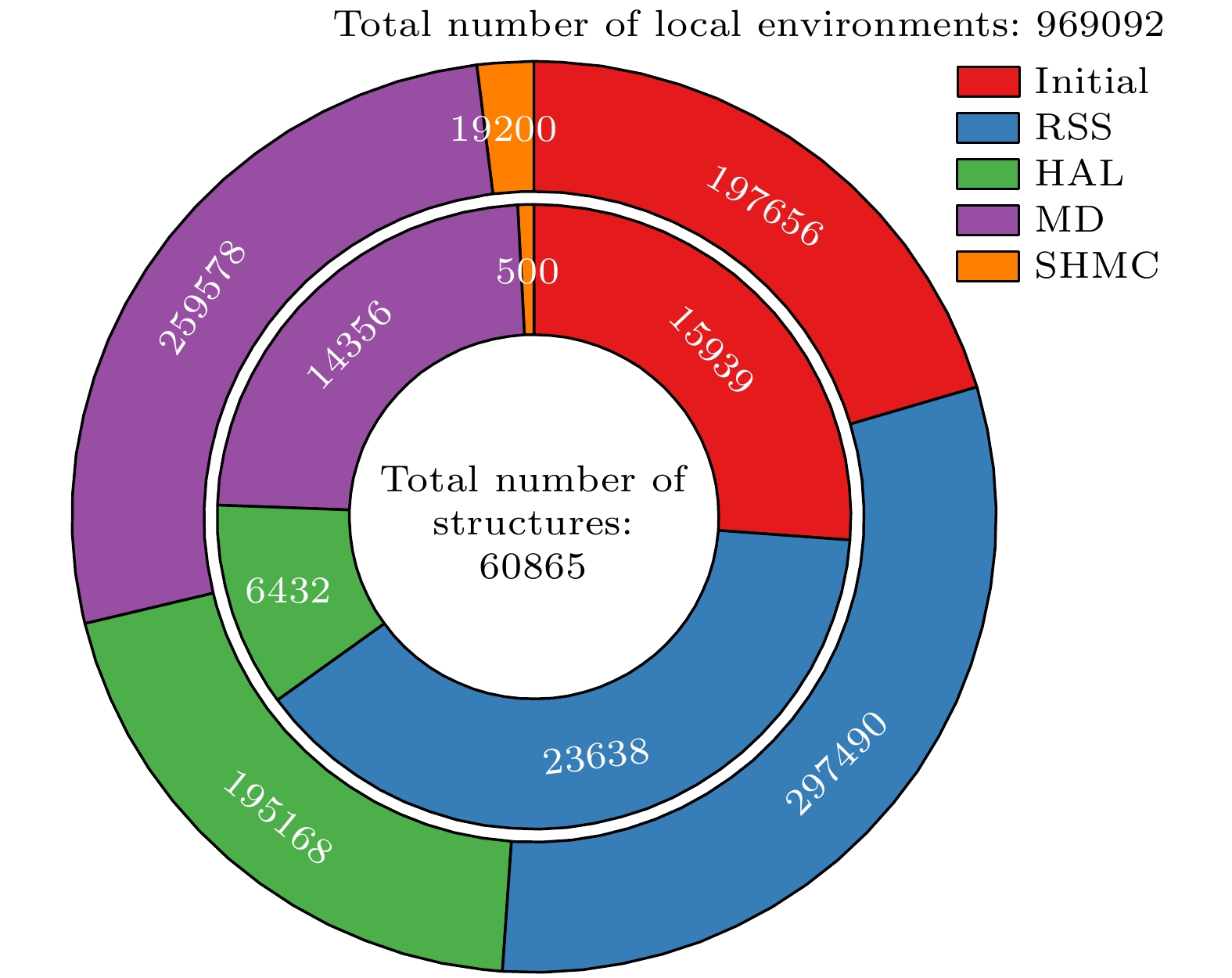

图 2 训练集中不同来源数据的占比及分布. 内圈为结构数目, 外圈为局域环境数目(原子数). Initial为初始数据集, RSS为随机结构搜索数据集, HAL为主动学习数据集, MD为分子动力学数据集, SHMC为原子交换蒙特卡罗数据集

Figure 2. The proportion and distribution of data from different sources in the whole training set. The inner circle represents the number of structures, while the outer circle represents the number of local environments (atoms). Initial refers to the initial dataset, RSS to the random structure search dataset, HAL to the active learning dataset, MD to the molecular dynamics simulation dataset, and SHMC to the atomic swap Monte Carlo dataset.

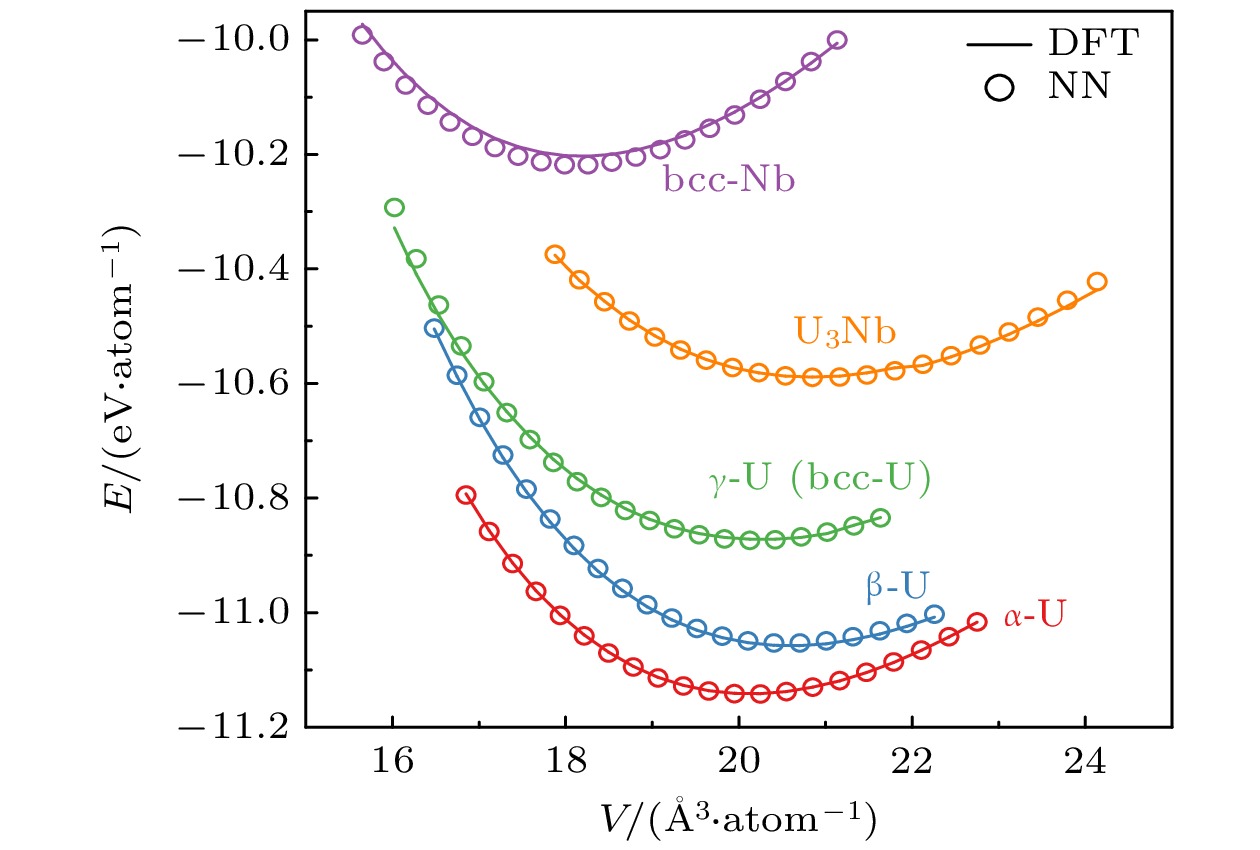

图 4 铀铌合金体系状态方程. 实线和空心圆圈分别代表DFT和NNP计算结果. $ {{\mathrm{U}}}_{3}{\mathrm{N}}{\mathrm{b}} $的结构取自Materials project网站, 结构编号为mp-972551

Figure 4. Equation of states of U-Nb alloy. Solid and empty circles represent the DFT and NNP results, respectively. The U3Nb structure is obtained from the Materials project website with an id of mp-972551.

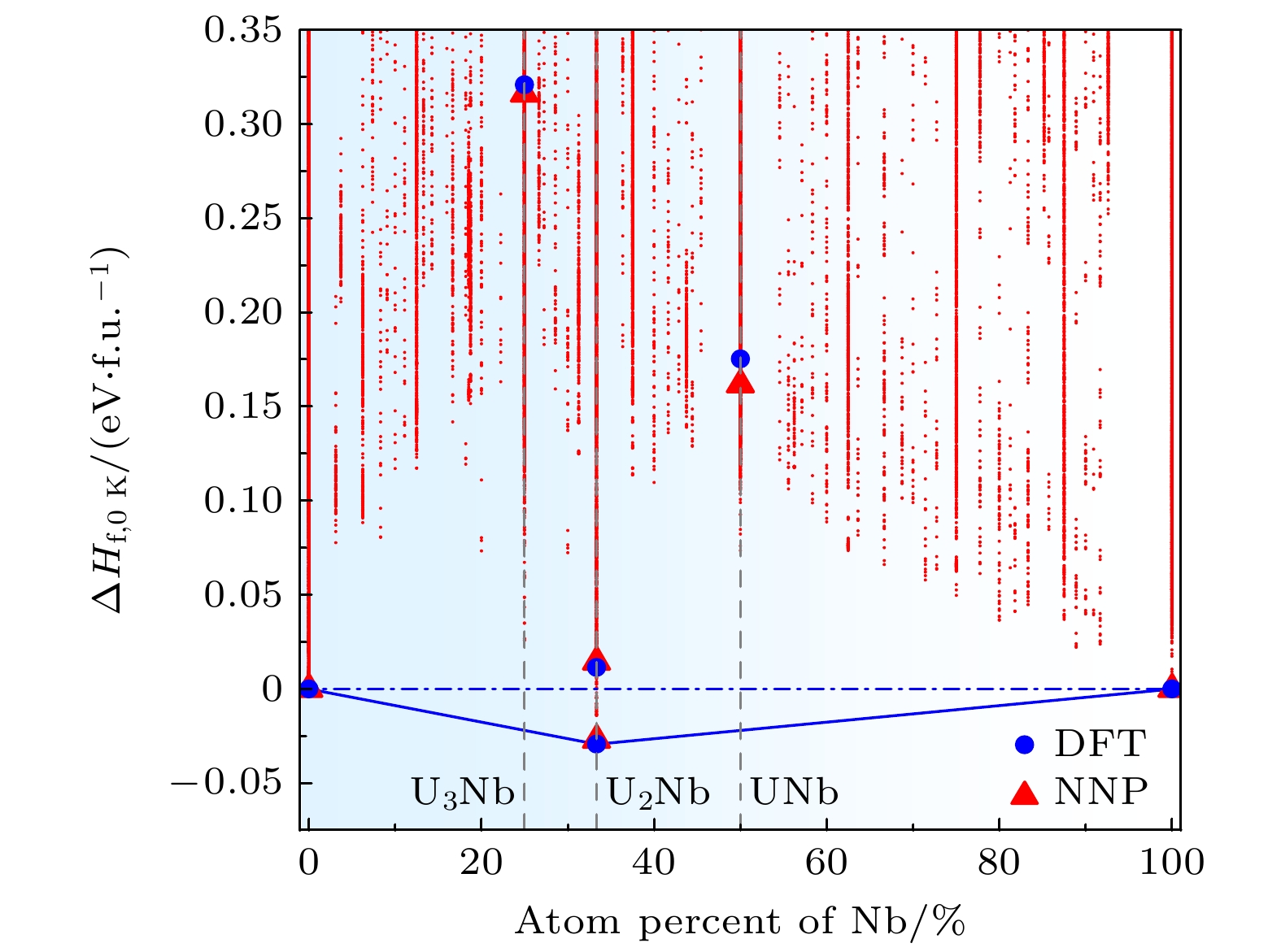

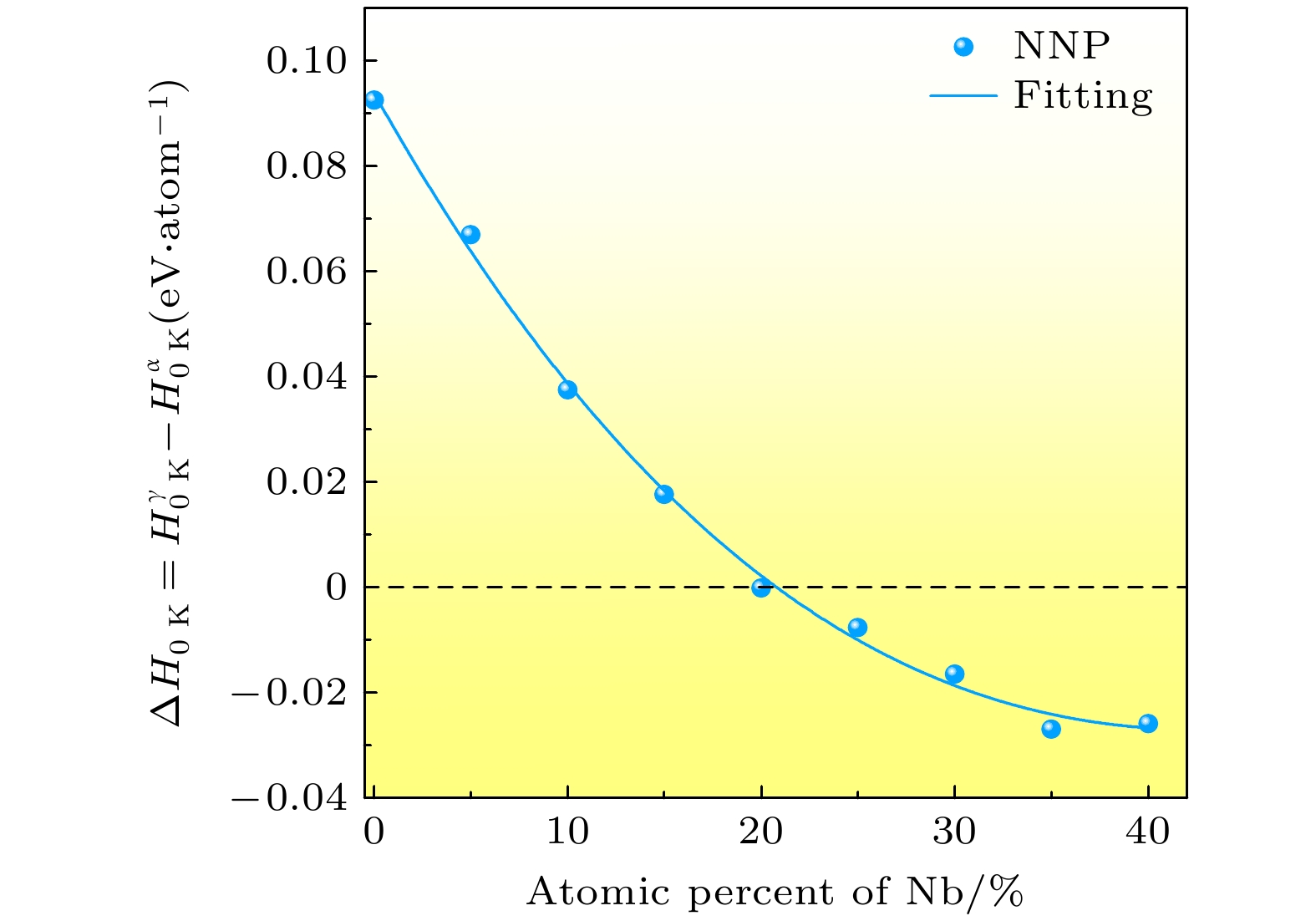

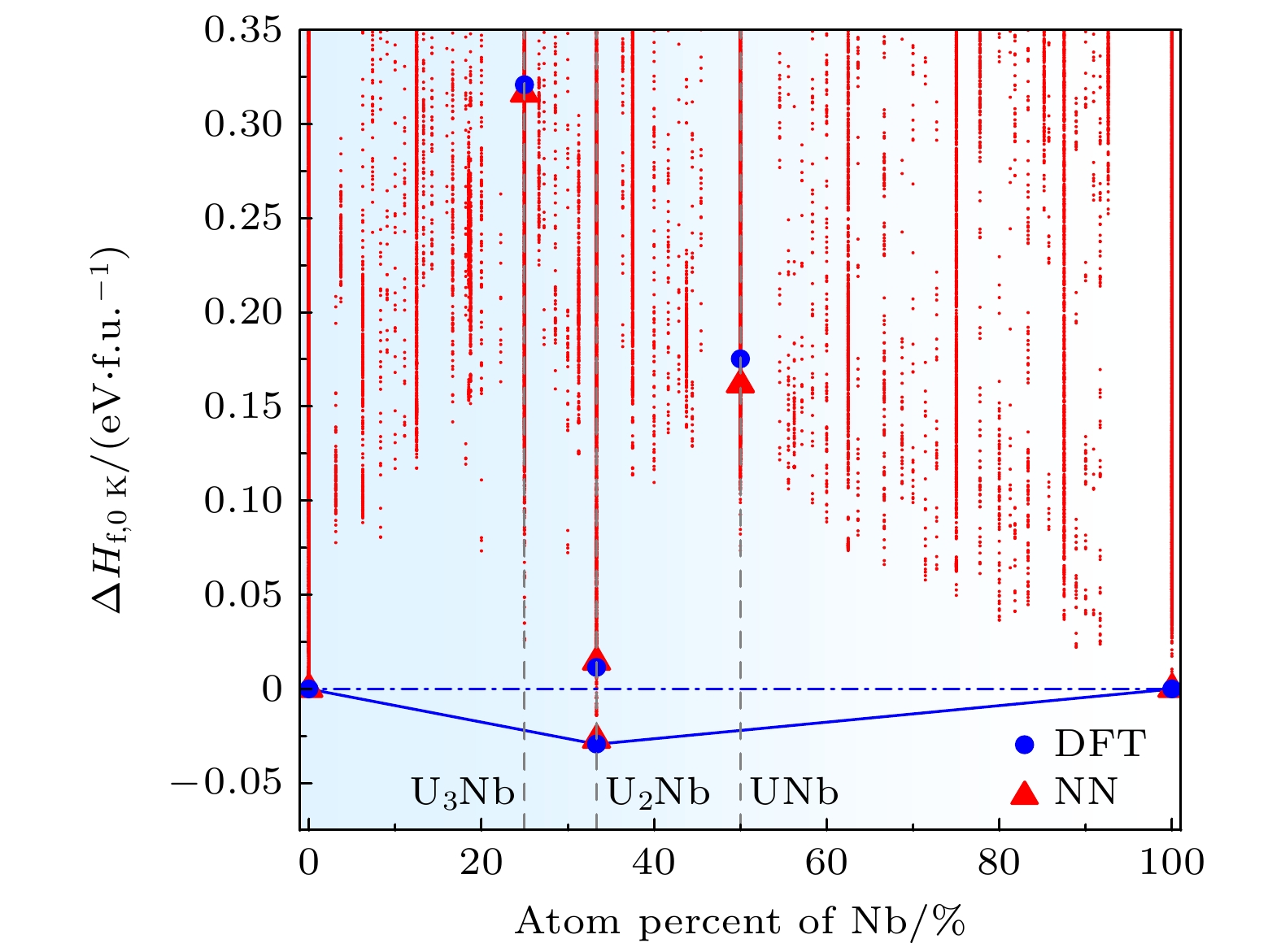

图 5 0 K下铀铌二元合金成分相图. 蓝色圆点为第一性原理计算结果, 红色三角形为NNP计算结果, 红色点为数据集中的结构能量

Figure 5. Composition phase diagram of U-Nb phase diagram at 0 K. The blue filled circles and red filled triangles show the DFT and NNP results, respectively. The red points correspond to training structure energies in the training set.

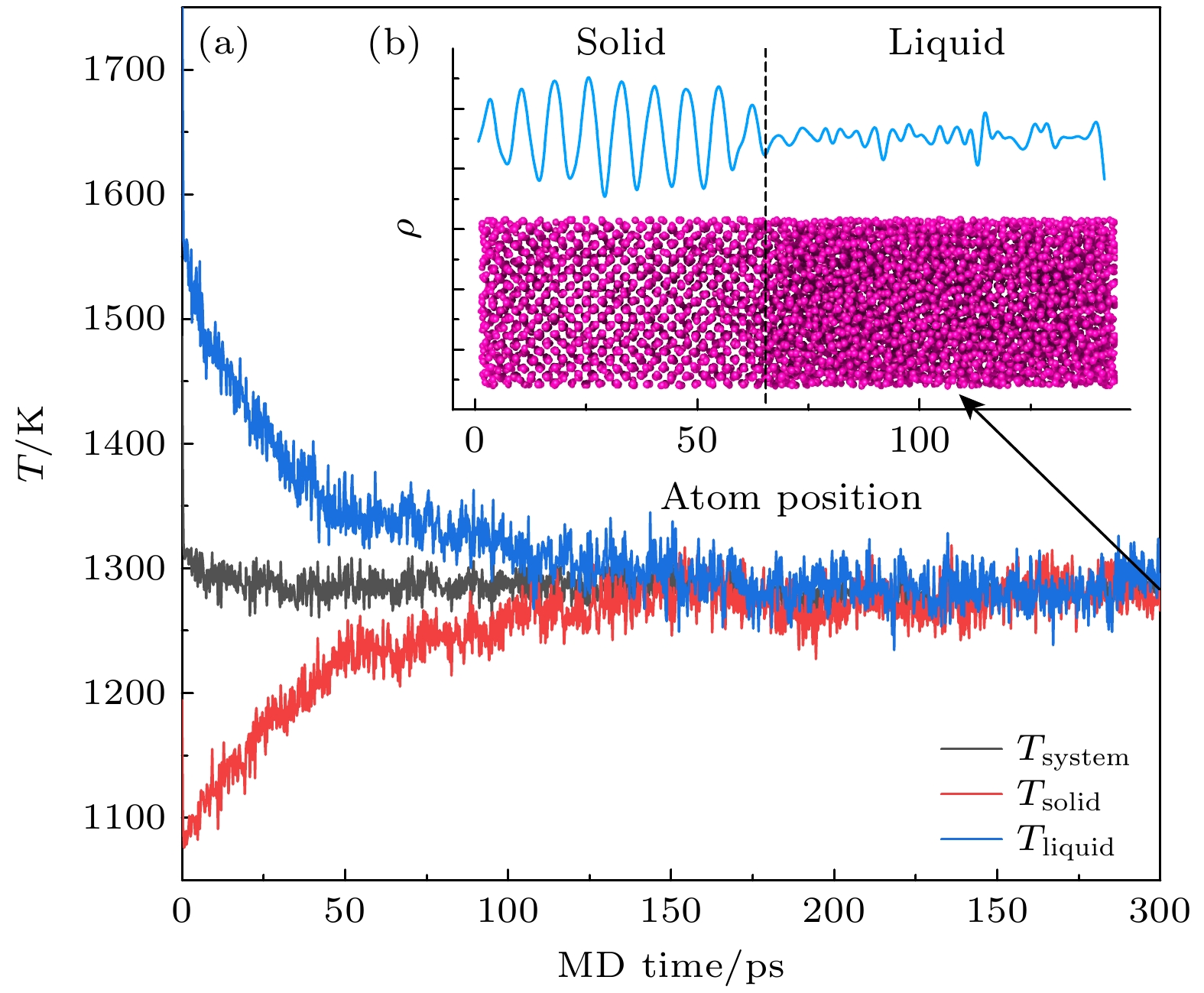

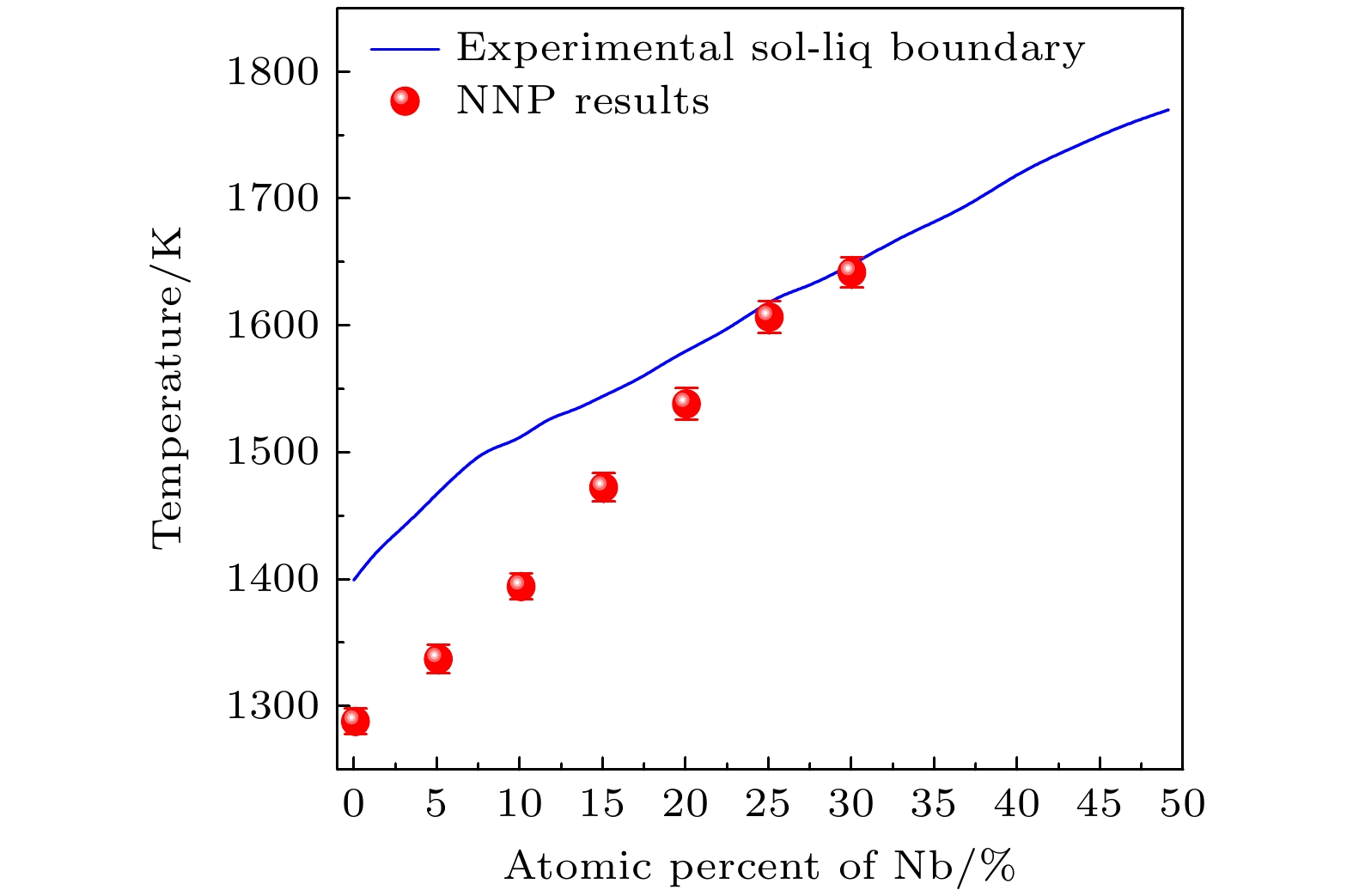

图 7 $ \gamma {\mathrm{铀}} $的相固-液相平衡模拟 (a)体系平均温度及固体和液体部分的温度; (b)平衡构型中x方向原子数密度的空间变化以及固-液界面原子结构. 计算得到的熔点(固-液平衡点)为(1286±9) K

Figure 7. Calculated melting point of $ {\mathrm{\gamma }} $-U: (a) Temperature evolution of whole, liquid and solid part of system; (b) number density evolution along the x direction, showing a sharp solid-liquid interface in coordinate to the MD snapshot. The calculated melting point is (1286±9) K.

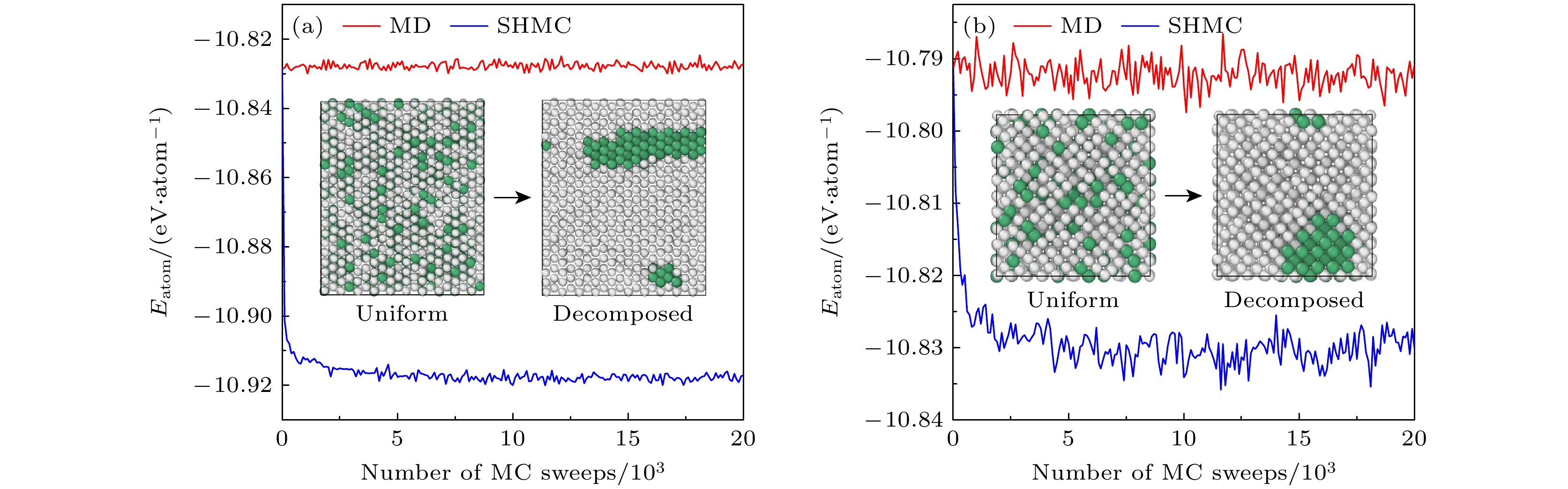

图 10 600 K模拟时效下Nb原子百分数为13%的铀铌合金的相失稳分离现象 (a) $ \alpha $-U相势能和结构的演化; (b) $ \gamma $-U相势能和结构的演化. 白色小球和绿色小球分别代表铀原子和铌原子

Figure 10. Spinodal decomposition of U-Nb alloy with an atomic percentage content of 13% aged at $ T=600~{\mathrm{K}} $ (a) Potential energy and structure evolutions of $ \alpha $-U phase; (b) potential energy and structure evolutions in $ \gamma $-U phase. The uranium and niobium atoms are shown as white and green balls, respectively.

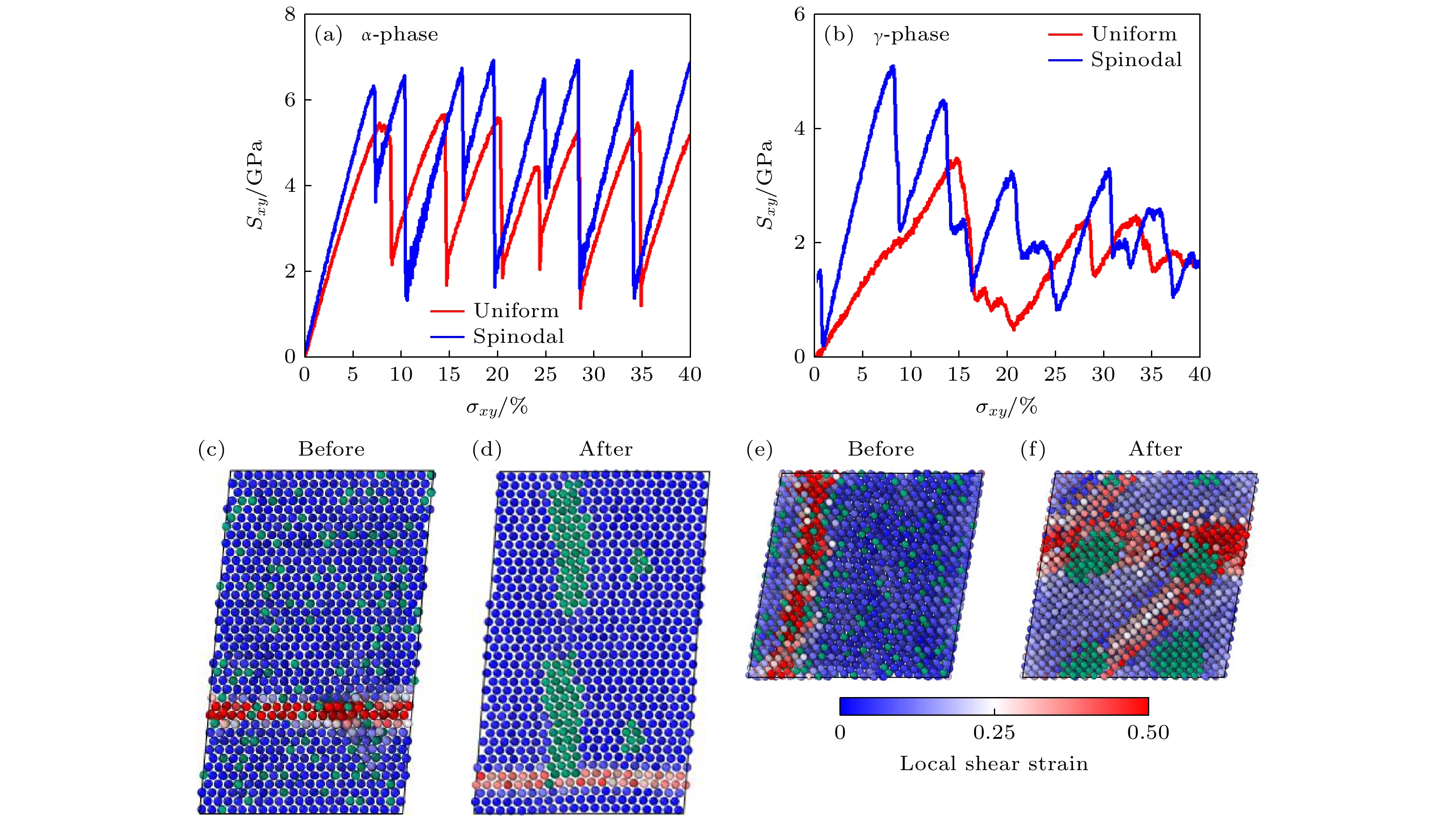

图 11 室温(300 K)下不同初始结构Nb原子百分数为13%的铀铌合金剪切应变下的变形损伤 (a), (b)均匀与相分离后$ \alpha $和$ \gamma $铀铌合金的应力应变关系; (c) $ \alpha $铀铌合金相分离前后塑性变形的原子机制; (d) $ \gamma $铀铌合金相分离前后塑性变形的原子响应机制. 其中Nb原子由绿色圆球表示, U原子的颜色代表局域剪切应变

Figure 11. Deformation and damage of U-Nb alloys with a Nb atomic percentage content of 13% under shear strain at room temperature (300 K) with different initial structures: (a), (b) Stress-strain relationships of uniform and phase-separated α and γ uranium-niobium alloys; (c) atomic mechanisms of plastic deformation in α uranium-niobium alloy before and after phase decomposition; (d) atomic response mechanisms of plastic deformation in γ uranium-niobium alloy before and after phase decomposition. Niobium atoms are represented by green balls, and the color of uranium atoms indicates local shear strain[44].

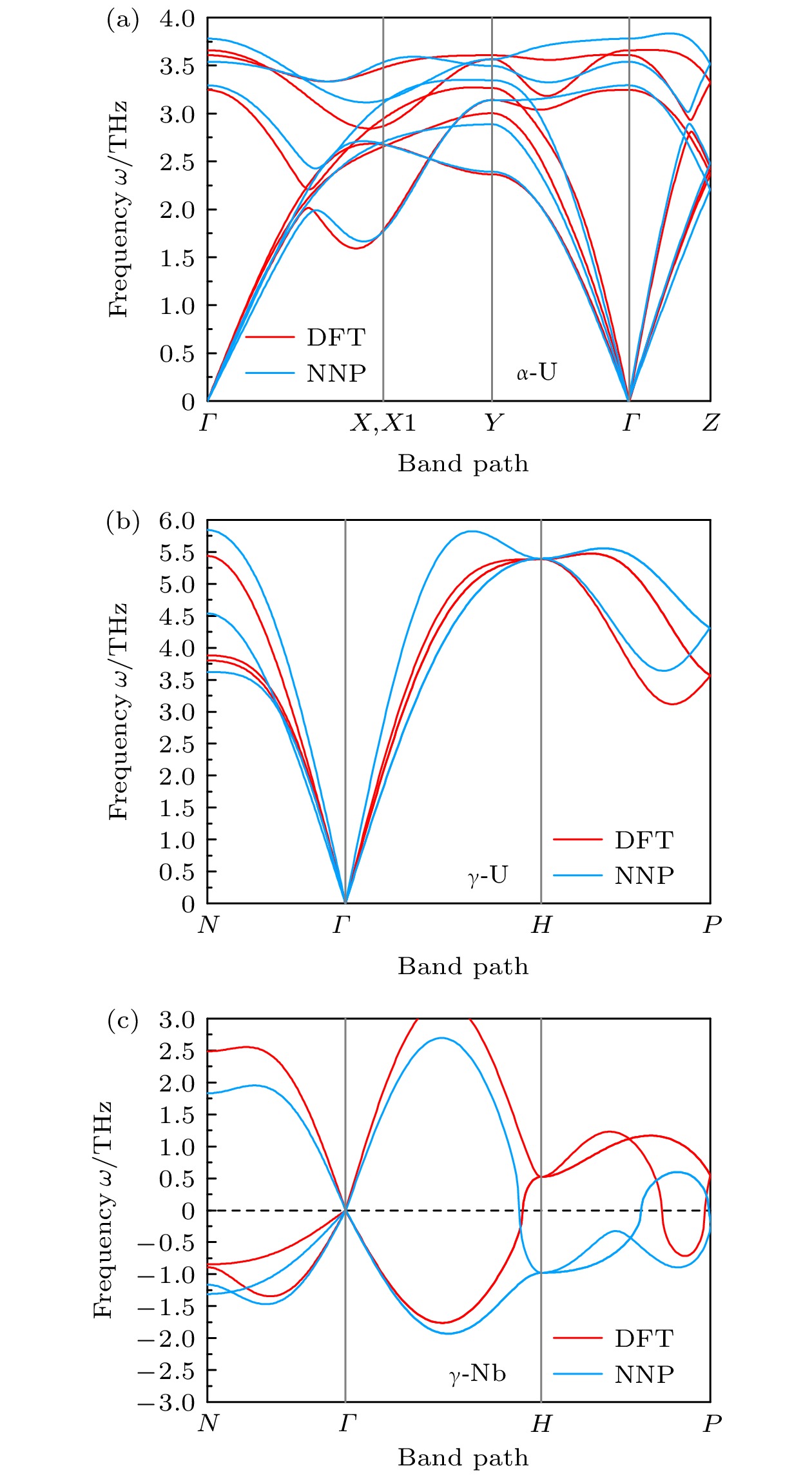

表 1 NNP计算得到的晶格参数与第一性原理计算及实验测量结果的比较

Table 1. Computed lattice constants for various crystalline phases, compared with experimental results

晶体相 晶格参数/Å DFT NNP Exp. $ \alpha \text{-}{\mathrm{U}} $ $ a $ 2.806 2.809 (+0.10%) 2.836[40] $ b $ 5.836 5.854 (+0.32%) 5.867[40] $ c $ 4.908 4.893 (–0.31%) 4.935[40] $ \gamma \text{-}{\mathrm{U}} $ $ a $ 3.435 3.431 (–0.12%) 3.47[41] $ \gamma \text{-}{\mathrm{N}}{\mathrm{b}} $ $ a $ 3.308 3.309 (+0.03%) 3.3063[42] $ {{\mathrm{U}}}_{2}{\mathrm{N}}{\mathrm{b}} $ $ a $ 4.806 4.799 (–0.15%) — $ c $ 5.903 5.914 (0.18%) — -

[1] Vandermeer R A 1980 Acta Metall. 28 383

Google Scholar

Google Scholar

[2] Clarke A J, Field R D, Hackenberg R E, et al. 2009 J. Nucl. Mater. 393 282

Google Scholar

Google Scholar

[3] Vandermeer R A, Ogle J C, Snyder W B 1978 Scr. Metall. 12 243

Google Scholar

Google Scholar

[4] Field R D, Brown D W, Thoma D J 2005 Philos. Mag. 85 2593

Google Scholar

Google Scholar

[5] Zhang C, Wang H, Li J, et al. 2019 Mater. Des. 162 94

Google Scholar

Google Scholar

[6] Choung S, Park W, Moon J, Han J W 2024 Chem. Eng. J. 494 152757

Google Scholar

Google Scholar

[7] Ma S, Liu Z P 2020 ACS Catal. 10 13213

Google Scholar

Google Scholar

[8] Su R, Yu J, Guan P, Wang W 2024 Sci. Chin. Mater. 67 3298

Google Scholar

Google Scholar

[9] Shapeev A V 2016 Multiscale Model. Simul. 14 1153

Google Scholar

Google Scholar

[10] Artrith N, Urban A, Ceder G 2018 J. Chem. Phys. 148 241711

Google Scholar

Google Scholar

[11] Behler J, Parrinello M 2007 Phys. Rev. Lett. 98 146401

Google Scholar

Google Scholar

[12] Chiriki S, Jindal S, Bulusu S S 2017 J. Chem. Phys. 146 084314

Google Scholar

Google Scholar

[13] Zhao R, Wang S, Kong Z, et al. 2023 Mater. Des. 231 112012

Google Scholar

Google Scholar

[14] Young T A, Johnston-Wood T, Deringer V L, Duarte F 2021 Chem. Sci. 12 10944

Google Scholar

Google Scholar

[15] Smith J S, Nebgen B, Lubbers N, Isayev O, Roitberg A E 2018 J. Chem. Phys. 148 241733

Google Scholar

Google Scholar

[16] van der Oord C, Sachs M, Kovács D P, Ortner C, Csányi G 2023 npj Comput. Mater. 9 1

Google Scholar

Google Scholar

[17] Kulichenko M, Barros K, Lubbers N, Li Y W, Messerly R, Tretiak S, Smith J S, Nebgen B 2023 Nat. Comput. Sci. 3 230

Google Scholar

Google Scholar

[18] Deringer V L, Pickard C J, Csányi G 2018 Phys. Rev. Lett. 120 156001

Google Scholar

Google Scholar

[19] Hao M S, Guan P F 2023 Chin. Phys. B 32 098401

Google Scholar

Google Scholar

[20] Li F, Zhang Z, Liu H, et al. 2024 Nat. Mater. 23 52

Google Scholar

Google Scholar

[21] Zhang Z, Zhang S, Wang Q, et al. 2024 Proc. Natl. Acad. Sci. U. S. A. 121 e2400200121

Google Scholar

Google Scholar

[22] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

[23] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[24] Adak S, Nakotte H, de Châtel P F, Kiefer B 2011 Phys. B: Condens. Matter. 406 3342

Google Scholar

Google Scholar

[25] Bartók A P, Kondor R, Csányi G 2013 Phys. Rev. B 87 184115

Google Scholar

Google Scholar

[26] Jindal S, Chiriki S, Bulusu S S 2017 J. Chem. Phys. 146 204301

Google Scholar

Google Scholar

[27] Gasteiger J, Groß J, Günnemann S 2022 arXiv: 2003.03123 [cs. LG]

[28] Artrith N, Urban A, Ceder G 2017 Phys. Rev. B 96 014112

Google Scholar

Google Scholar

[29] Loshchilov I, Hutter F 2019 arXiv: 1711.05101 [cs. LG]

[30] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[31] Thompson A P, Aktulga H M, Berger R, et al. 2022 Comput. Phys. Commun. 271 108171

Google Scholar

Google Scholar

[32] Nosé S 1984 J. Chem. Phys. 81 511

Google Scholar

Google Scholar

[33] Parrinello M, Rahman A 1980 Phys. Rev. Lett. 45 1196

Google Scholar

Google Scholar

[34] Zhang L, Han J, Wang H, Car R, E W 2018 Phys. Rev. Lett. 120 143001

Google Scholar

Google Scholar

[35] Wen T, Wang C Z, Kramer M J, et al. 2019 Phys. Rev. B 100 174101

Google Scholar

Google Scholar

[36] Pickard C J, Needs R J 2011 J. Phys. Condens. Matter 23 053201

Google Scholar

Google Scholar

[37] Imbalzano G, Anelli A, Giofré D, Klees S, Behler J, Ceriotti M 2018 J. Chem. Phys. 148 241730

Google Scholar

Google Scholar

[38] Mahoney M W, Drineas P 2009 Proc. Natl. Acad. Sci. U. S. A. 106 697

Google Scholar

Google Scholar

[39] Pan X L, Wang H, Zhang L L, Wang Y F, Chen X R, Geng H Y, Chen Y 2023 J. Nucl. Mater. 579 154394

Google Scholar

Google Scholar

[40] Barrett C S, Mueller M H, Hitterman R L 1963 Phys. Rev. 129 625

Google Scholar

Google Scholar

[41] Wilson A S, Rundle R E 1949 Acta Cryst. 2 126

Google Scholar

Google Scholar

[42] Roberge R 1975 J. Less-Common Met. 40 161

Google Scholar

Google Scholar

[43] Koike J, Kassner M E, Tate R E, Rosen R S 1998 J. Phase Equilib. 19 253

Google Scholar

Google Scholar

[44] Shimizu F, Ogata S, Li J 2007 Mater. Trans. 48 2923

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 2364

- PDF Downloads: 73

- Cited By: 0

DownLoad:

DownLoad: