-

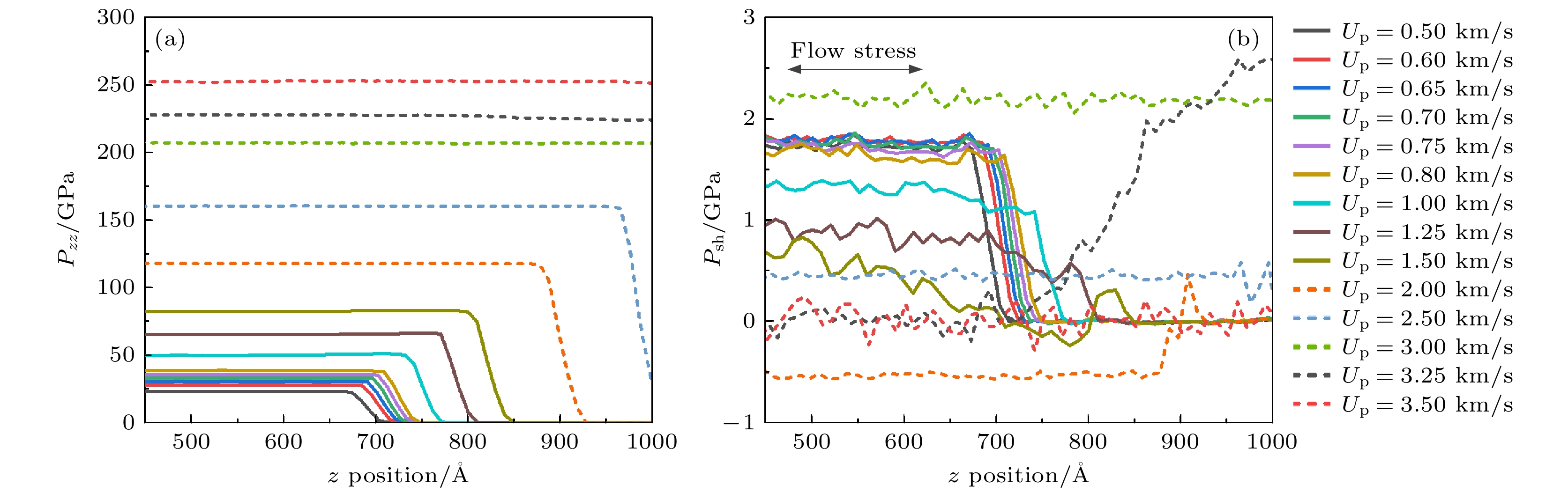

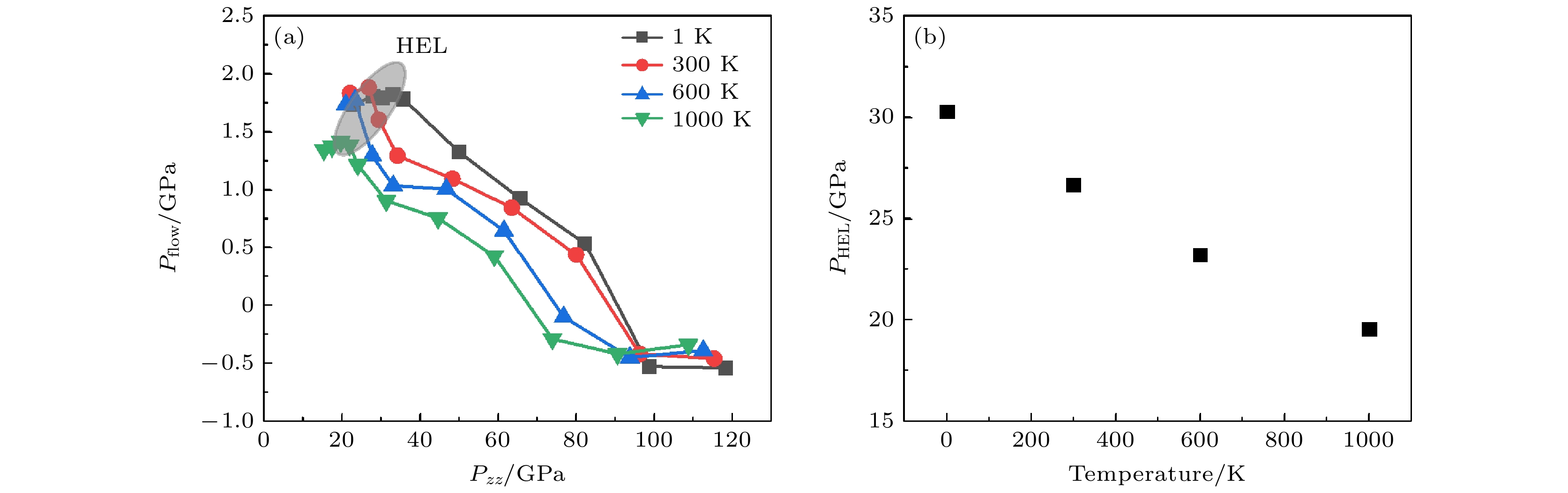

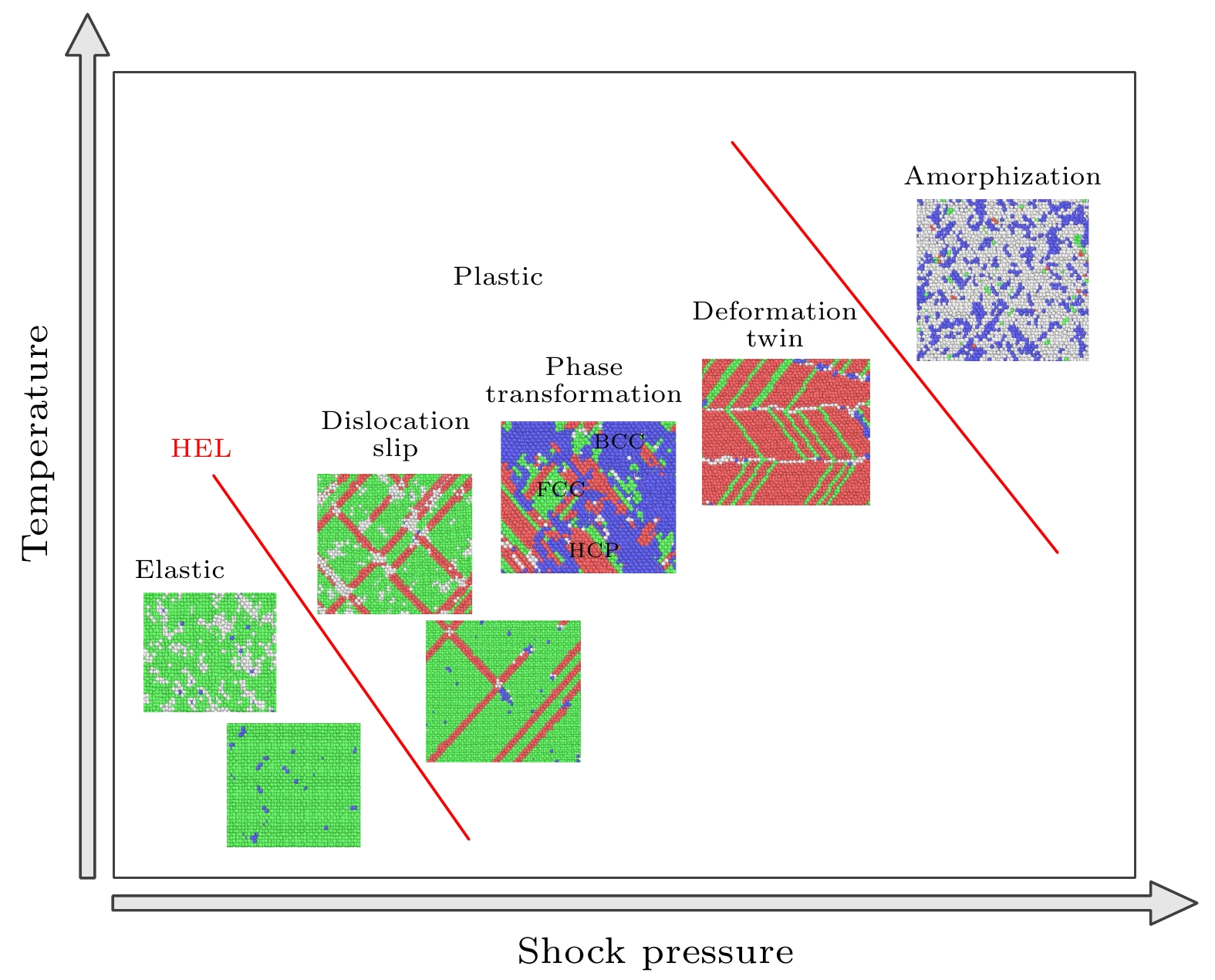

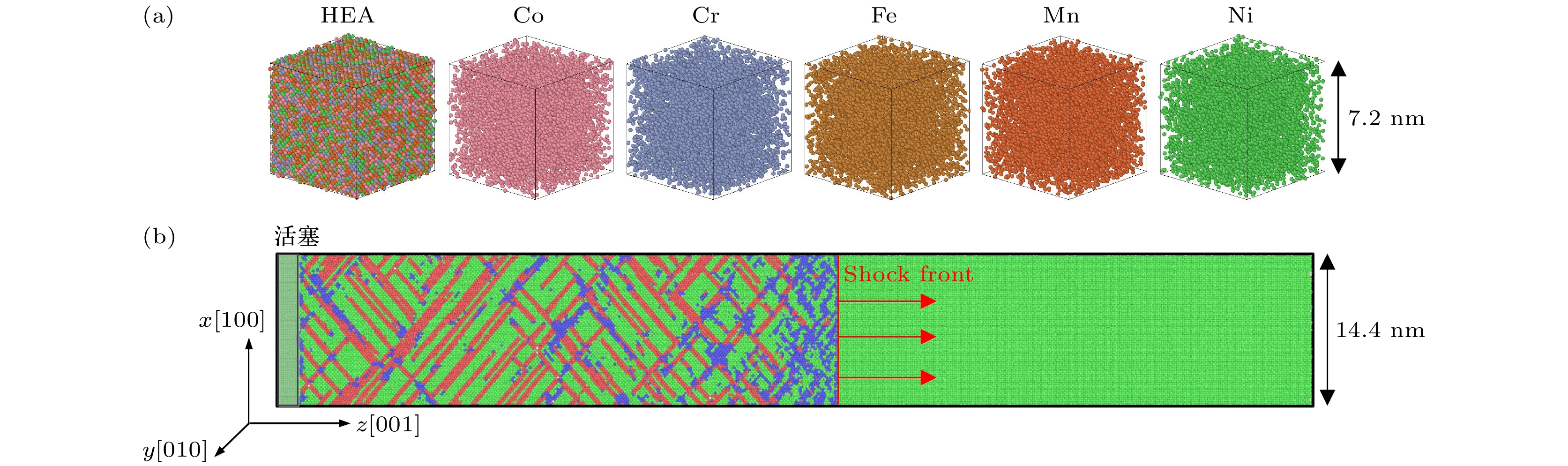

高熵合金作为一类新兴合金材料, 由于其优异的力学性能, 在航空、航天、军事等领域具有广阔的应用前景. 本文利用分子动力学方法, 探讨了温度对CoCrFeMnNi高熵合金冲击响应和塑性变形机制的影响. 研究发现, 初始温度的增加使得冲击压力、冲击波传播速度和冲击温升下降. 冲击Hugoniot弹性极限随着温度的上升线性下降. 随着冲击强度的增加, CoCrFeMnNi 高熵合金发生了复杂的塑性变形, 包括位错滑移、相变、变形孪晶和冲击诱导非晶化. 在较高的初始温度下, CoCrFeMnNi 高熵合金内部出现无序团簇, 其和由面心立方晶体结构转变而成的体心立方晶体结构以及无序结构是位错成核的重要来源. 由于Mn元素具有相对较大的原子体积和势能, 所以在Mn元素的周围会出现较大的晶格畸变和局部应力, 从而为冲击诱导塑性变形提供较大的贡献. 在温度较高时, Fe元素对塑性变形的贡献和Mn元素一样重要. 研究结果有助于深刻理解CoCrFeMnNi高熵合金的冲击诱导塑性和相关变形机制, 为CoCrFeMnNi高熵合金在不同温度下涉及高应变率冲击过程的应用提供理论支撑.High-entropy alloys have broad application prospects in aviation, aerospace, military and other fields due to their excellent mechanical properties. Temperature is an important external factor affecting the shock response of high-entropy alloys. In this paper, we investigate the effects of temperature on the shock response and plastic deformation mechanism of CoCrFeMnNi high-entropy alloys by using molecular dynamics method. The effects of temperature on the atomic volume and the radial distribution function of CoCrFeMnNi high-entropy alloy are studied. Then, the piston method is used to generate shock waves in the sample to study the shock response of CoCrFeMnNi high-entropy alloy. We observe the evolution of atomic-scale defects during the shock compression by the polyhedral template matching method. The results show that the shock pressure, the shock wave propagation velocity, and the rising of shock-induced temperature all decrease with the initial temperature increasing. For example, when piston velocity Up = 1.5 km/s, the shock pressure at an initial temperature of 1000 K decreases by 6.7% in comparison with that at 1 K. Moreover, the shock Hugoniot elastic limit decreases linearly with the increase of temperature. The Hugoniot Up-Us curve of CoCrFeMnNi HEA in the plastic stage can be linearly fitted by the formula Us = c0 + sUp, where c0 decreases with temperature increasing. As the shock intensity increases, the CoCrFeMnNi high-entropy alloy undergoes complex plastic deformation, including dislocation slip, phase transformation, deformation twinning, and shock-induced amorphization. At relatively high initial temperature, disordered clusters appear inside CoCrFeMnNi HEA, which together with the BCC (body-centered cubic) structure transformed from FCC (face-centered cubic) and disordered structure are significant dislocation nucleation sources. Compared with other elements, Mn element accounts for the largest proportion (25.4%) in disordered cluster. Owing to the large atomic volume and potential energy, large lattice distortion and local stress occur around the Mn-rich element, which makes a dominant contribution to shock-induced plastic deformation. At high temperatures, the contribution of Fe element to plastic deformation is as important as that of Mn element. The research results are conducive to understanding the shock-induced plasticity and deformation mechanisms of CoCrFeMnNi high-entropy alloys in depth.

-

Keywords:

- high-entropy alloys /

- shock response /

- molecular dynamics /

- temperature effects

[1] Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, Chang S Y 2004 Adv. Eng. Mater. 6 299

Google Scholar

Google Scholar

[2] Cantor B, Chang I T H, Knight P, Vincent A J B 2004 Mater. Sci. Eng. A 375–377 213

Google Scholar

Google Scholar

[3] Li Z, Zhao S, Ritchie R O, Meyers M A 2019 Prog. Mater. Sci. 102 296

Google Scholar

Google Scholar

[4] Miracle D B, Senkov O N 2017 Acta Mater. 122 448

Google Scholar

Google Scholar

[5] Zhang Y, Zuo T T, Tang Z, Gao M C, Dahmen K A, Liaw P K, Lu Z P 2014 Prog. Mater. Sci. 61 1

Google Scholar

Google Scholar

[6] Li W, Xie D, Li D, Zhang Y, Gao Y, Liaw P K 2021 Prog. Mater. Sci. 118 100777

Google Scholar

Google Scholar

[7] 王睿鑫, 唐宇, 李顺, 白书欣 2021 材料导报 35 17001

Google Scholar

Google Scholar

Wang R X, Tang Y, Li S, Bai S X 2021 Mater. Rep. 35 17001

Google Scholar

Google Scholar

[8] 李建国, 黄瑞瑞, 张倩, 李晓雁 2020 力学学报 52 333

Google Scholar

Google Scholar

Li J G, Huang R R, Zhang Q, Li X Y 2020 Chin. J. Theor. Appl. Mech. 52 333

Google Scholar

Google Scholar

[9] 陈海华, 张先锋, 刘闯, 林琨富, 熊玮, 谈梦婷 2021 爆炸与冲击 41 1

Google Scholar

Google Scholar

Chen H H, Zhang X F, Liu C, Lin K F, Xiong W 2021 Explo. Shock Waves 41 1

Google Scholar

Google Scholar

[10] Schuh C A, Hufnagel T C, Ramamurty U 2007 Acta Mater. 55 4067

Google Scholar

Google Scholar

[11] Jiao Z M, Ma S G, Chu M Y, Yang H J, Wang Z H, Zhang Y, Qiao J W 2016 J. Mater. Eng. Perform. 25 451

Google Scholar

Google Scholar

[12] Kumar N, Ying Q, Nie X, Mishra R S, Tang Z, Liaw P K, Brennan R E, Doherty K J, Cho K C 2015 Mater. Des. 86 598

Google Scholar

Google Scholar

[13] Qiao Y, Chen Y, Cao F H, Wang H Y, Dai L H 2021 Int. J. Impact Eng. 158 104008

Google Scholar

Google Scholar

[14] Jiang Z J, He J Y, Wang H Y, Zhang H S, Lu Z P, Dai L H 2016 Mater. Res. Lett. 4 226

Google Scholar

Google Scholar

[15] Liu X F, Tian Z L, Zhang X F, Chen H H, Liu T W, Chen Y, Wang Y J, Dai L H 2020 Acta Mater. 186 257

Google Scholar

Google Scholar

[16] Chen H, Zhang X, Xiong W, Liu C, Wei H, Wang H, Dai L 2020 Chin. J. Theor. Appl. Mech. 52 1443

Google Scholar

Google Scholar

[17] Zhang Z, Zhang H, Tang Y, Zhu L, Ye Y, Li S, Bai S 2017 Mater. Des. 133 435

Google Scholar

Google Scholar

[18] Zhang T W, Jiao Z M, Wang Z H, Qiao J W 2017 Scr. Mater. 136 15

Google Scholar

Google Scholar

[19] Wen P, Tao G, Spearot D E, Phillpot S R 2022 J. Appl. Phys. 131 051101

Google Scholar

Google Scholar

[20] Zhao L, Zong H, Ding X, Lookman T 2021 Acta Mater. 209 116801

Google Scholar

Google Scholar

[21] Xie Z, Jian W R, Xu S, Beyerlein I J, Zhang X, Wang Z, Yao X 2021 Acta Mater. 221 117380

Google Scholar

Google Scholar

[22] Jian W R, Xie Z, Xu S, Yao X, Beyerlein I J 2022 Scr. Mater. 209 114379

Google Scholar

Google Scholar

[23] Thürmer D, Gunkelmann N 2022 J. Appl. Phys. 131 065902

Google Scholar

Google Scholar

[24] Thürmer D, Zhao S, Deluigi O R, Stan C, Alhafez I A, Urbassek H M, Meyers M A, Bringa E M, Gunkelmann N 2022 J. Alloys Compd. 895 162567

Google Scholar

Google Scholar

[25] Liu B, Jian Z, Guo L, Li X, Wang K, Deng H, Hu W, Xiao S, Yuan D 2022 Int. J. Mech. Sci. 226 107373

Google Scholar

Google Scholar

[26] Singh S K, Parashar A 2022 Comput. Mater. Sci. 209 111402

Google Scholar

Google Scholar

[27] Huang S, Li W, Lu S, Tian F, Shen J, Holmström E, Vitos L 2015 Scr. Mater. 108 44

Google Scholar

Google Scholar

[28] Fu J X, Cao C M, Tong W, Hao Y X, Peng L M 2017 Mater. Sci. Eng. , A 690 418

Google Scholar

Google Scholar

[29] Kawamura M, Asakura M, Okamoto N L, Kishida K, Inui H, George E P 2021 Acta Mater. 203 116454

Google Scholar

Google Scholar

[30] Laplanche G, Gadaud P, Horst O, Otto F, Eggeler G, George E P 2015 J. Alloys Compd. 623 348

Google Scholar

Google Scholar

[31] Laplanche G, Gadaud P, Bärsch C, Demtröder K, Reinhart C, Schreuer J, George E P 2018 J. Alloys Compd. 746 244

Google Scholar

Google Scholar

[32] Haglund A, Koehler M, Catoor D, George E P, Keppens V 2015 Intermetallics 58 62

Google Scholar

Google Scholar

[33] Choi W M, Jo Y H, Sohn S S, Lee S, Lee B J 2018 npj Comput. Mater. 4 1

Google Scholar

Google Scholar

[34] Fang Q, Chen Y, Li J, Jiang C, Liu B, Liu Y, Liaw P K 2019 Int. J. Plast. 114 161

Google Scholar

Google Scholar

[35] Alabd Alhafez I, Ruestes C J, Bringa E M, Urbassek H M 2019 J. Alloys Compd. 803 618

Google Scholar

Google Scholar

[36] Goede A, Preissner R, Frömmel C 1997 J. Comput. Chem. 18 1113

Google Scholar

Google Scholar

[37] Holian B L, Lomdahl P S 1998 Science 280 2085

Google Scholar

Google Scholar

[38] Hahn E N, Germann T C, Ravelo R, Hammerberg J E, Meyers M A 2017 Acta Mater. 126 313

Google Scholar

Google Scholar

[39] Thompson A P, Aktulga H M, Berger R, Bolintineanu D S, Brown W M, Crozier P S, in 't Veld P J, Kohlmeyer A, Moore S G, Nguyen T D, Shan R, Stevens M J, Tranchida J, Trott C, Plimpton S J 2022 Comput. Phys. Commun. 271 108171

Google Scholar

Google Scholar

[40] Larsen P M, Schmidt S, Schiotz J 2016 Modell. Simul. Mater. Sci. Eng. 24 055007

Google Scholar

Google Scholar

[41] Stukowski A 2009 Modell. Simul. Mater. Sci. Eng. 18 15012

Google Scholar

Google Scholar

[42] Luo G, Huang S, Hu J, Zhu Y, Wang J, Yang G, Zhang R, Sun Y, Zhang J, Shen Q 2022 AIP Adv. 12 055123

Google Scholar

Google Scholar

[43] Tian X, Cui J, Ma K, Xiang M 2020 Int. J. Heat Mass Transfer 158 120013

Google Scholar

Google Scholar

[44] Wang Y, Zeng X, Yang X, Xu T 2022 Comput. Mater. Sci. 201 110870

Google Scholar

Google Scholar

[45] Wen P, Demaske B, Spearot D E, Phillpot S R, Tao G 2021 J. Appl. Phys. 129 165103

Google Scholar

Google Scholar

[46] Sharma S M, Turneaure S J, Winey J M, Gupta Y M 2020 Phys. Rev. B 102 020103

Google Scholar

Google Scholar

-

图 9 典型Up时不同初始温度下的结构含量随时间的变化 (a) Up = 0.65 km/s, T = 1 K; (b) Up = 1.0 km/s, T = 1 K; (c) Up = 1.5 km/s, T = 1 K; (d) Up = 0.65 km/s, T = 1000 K; (e) Up = 1.0 km/s, T = 1000 K; (f) Up = 1.5 km/s, T = 1000 K

Fig. 9. Atomic fraction of FCC, BCC, HCP and disordered structures as a function of the shocked time at different initial temperatures for typical Up: (a) Up = 0.65 km/s, T = 1 K; (b) Up = 1.0 km/s, T = 1 K; (c) Up = 1.5 km/s, T = 1 K; (d) Up = 0.65 km/s, T = 1000 K; (e) Up = 1.0 km/s, T = 1000 K; (f) Up = 1.5 km/s, T = 1000 K.

-

[1] Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, Chang S Y 2004 Adv. Eng. Mater. 6 299

Google Scholar

Google Scholar

[2] Cantor B, Chang I T H, Knight P, Vincent A J B 2004 Mater. Sci. Eng. A 375–377 213

Google Scholar

Google Scholar

[3] Li Z, Zhao S, Ritchie R O, Meyers M A 2019 Prog. Mater. Sci. 102 296

Google Scholar

Google Scholar

[4] Miracle D B, Senkov O N 2017 Acta Mater. 122 448

Google Scholar

Google Scholar

[5] Zhang Y, Zuo T T, Tang Z, Gao M C, Dahmen K A, Liaw P K, Lu Z P 2014 Prog. Mater. Sci. 61 1

Google Scholar

Google Scholar

[6] Li W, Xie D, Li D, Zhang Y, Gao Y, Liaw P K 2021 Prog. Mater. Sci. 118 100777

Google Scholar

Google Scholar

[7] 王睿鑫, 唐宇, 李顺, 白书欣 2021 材料导报 35 17001

Google Scholar

Google Scholar

Wang R X, Tang Y, Li S, Bai S X 2021 Mater. Rep. 35 17001

Google Scholar

Google Scholar

[8] 李建国, 黄瑞瑞, 张倩, 李晓雁 2020 力学学报 52 333

Google Scholar

Google Scholar

Li J G, Huang R R, Zhang Q, Li X Y 2020 Chin. J. Theor. Appl. Mech. 52 333

Google Scholar

Google Scholar

[9] 陈海华, 张先锋, 刘闯, 林琨富, 熊玮, 谈梦婷 2021 爆炸与冲击 41 1

Google Scholar

Google Scholar

Chen H H, Zhang X F, Liu C, Lin K F, Xiong W 2021 Explo. Shock Waves 41 1

Google Scholar

Google Scholar

[10] Schuh C A, Hufnagel T C, Ramamurty U 2007 Acta Mater. 55 4067

Google Scholar

Google Scholar

[11] Jiao Z M, Ma S G, Chu M Y, Yang H J, Wang Z H, Zhang Y, Qiao J W 2016 J. Mater. Eng. Perform. 25 451

Google Scholar

Google Scholar

[12] Kumar N, Ying Q, Nie X, Mishra R S, Tang Z, Liaw P K, Brennan R E, Doherty K J, Cho K C 2015 Mater. Des. 86 598

Google Scholar

Google Scholar

[13] Qiao Y, Chen Y, Cao F H, Wang H Y, Dai L H 2021 Int. J. Impact Eng. 158 104008

Google Scholar

Google Scholar

[14] Jiang Z J, He J Y, Wang H Y, Zhang H S, Lu Z P, Dai L H 2016 Mater. Res. Lett. 4 226

Google Scholar

Google Scholar

[15] Liu X F, Tian Z L, Zhang X F, Chen H H, Liu T W, Chen Y, Wang Y J, Dai L H 2020 Acta Mater. 186 257

Google Scholar

Google Scholar

[16] Chen H, Zhang X, Xiong W, Liu C, Wei H, Wang H, Dai L 2020 Chin. J. Theor. Appl. Mech. 52 1443

Google Scholar

Google Scholar

[17] Zhang Z, Zhang H, Tang Y, Zhu L, Ye Y, Li S, Bai S 2017 Mater. Des. 133 435

Google Scholar

Google Scholar

[18] Zhang T W, Jiao Z M, Wang Z H, Qiao J W 2017 Scr. Mater. 136 15

Google Scholar

Google Scholar

[19] Wen P, Tao G, Spearot D E, Phillpot S R 2022 J. Appl. Phys. 131 051101

Google Scholar

Google Scholar

[20] Zhao L, Zong H, Ding X, Lookman T 2021 Acta Mater. 209 116801

Google Scholar

Google Scholar

[21] Xie Z, Jian W R, Xu S, Beyerlein I J, Zhang X, Wang Z, Yao X 2021 Acta Mater. 221 117380

Google Scholar

Google Scholar

[22] Jian W R, Xie Z, Xu S, Yao X, Beyerlein I J 2022 Scr. Mater. 209 114379

Google Scholar

Google Scholar

[23] Thürmer D, Gunkelmann N 2022 J. Appl. Phys. 131 065902

Google Scholar

Google Scholar

[24] Thürmer D, Zhao S, Deluigi O R, Stan C, Alhafez I A, Urbassek H M, Meyers M A, Bringa E M, Gunkelmann N 2022 J. Alloys Compd. 895 162567

Google Scholar

Google Scholar

[25] Liu B, Jian Z, Guo L, Li X, Wang K, Deng H, Hu W, Xiao S, Yuan D 2022 Int. J. Mech. Sci. 226 107373

Google Scholar

Google Scholar

[26] Singh S K, Parashar A 2022 Comput. Mater. Sci. 209 111402

Google Scholar

Google Scholar

[27] Huang S, Li W, Lu S, Tian F, Shen J, Holmström E, Vitos L 2015 Scr. Mater. 108 44

Google Scholar

Google Scholar

[28] Fu J X, Cao C M, Tong W, Hao Y X, Peng L M 2017 Mater. Sci. Eng. , A 690 418

Google Scholar

Google Scholar

[29] Kawamura M, Asakura M, Okamoto N L, Kishida K, Inui H, George E P 2021 Acta Mater. 203 116454

Google Scholar

Google Scholar

[30] Laplanche G, Gadaud P, Horst O, Otto F, Eggeler G, George E P 2015 J. Alloys Compd. 623 348

Google Scholar

Google Scholar

[31] Laplanche G, Gadaud P, Bärsch C, Demtröder K, Reinhart C, Schreuer J, George E P 2018 J. Alloys Compd. 746 244

Google Scholar

Google Scholar

[32] Haglund A, Koehler M, Catoor D, George E P, Keppens V 2015 Intermetallics 58 62

Google Scholar

Google Scholar

[33] Choi W M, Jo Y H, Sohn S S, Lee S, Lee B J 2018 npj Comput. Mater. 4 1

Google Scholar

Google Scholar

[34] Fang Q, Chen Y, Li J, Jiang C, Liu B, Liu Y, Liaw P K 2019 Int. J. Plast. 114 161

Google Scholar

Google Scholar

[35] Alabd Alhafez I, Ruestes C J, Bringa E M, Urbassek H M 2019 J. Alloys Compd. 803 618

Google Scholar

Google Scholar

[36] Goede A, Preissner R, Frömmel C 1997 J. Comput. Chem. 18 1113

Google Scholar

Google Scholar

[37] Holian B L, Lomdahl P S 1998 Science 280 2085

Google Scholar

Google Scholar

[38] Hahn E N, Germann T C, Ravelo R, Hammerberg J E, Meyers M A 2017 Acta Mater. 126 313

Google Scholar

Google Scholar

[39] Thompson A P, Aktulga H M, Berger R, Bolintineanu D S, Brown W M, Crozier P S, in 't Veld P J, Kohlmeyer A, Moore S G, Nguyen T D, Shan R, Stevens M J, Tranchida J, Trott C, Plimpton S J 2022 Comput. Phys. Commun. 271 108171

Google Scholar

Google Scholar

[40] Larsen P M, Schmidt S, Schiotz J 2016 Modell. Simul. Mater. Sci. Eng. 24 055007

Google Scholar

Google Scholar

[41] Stukowski A 2009 Modell. Simul. Mater. Sci. Eng. 18 15012

Google Scholar

Google Scholar

[42] Luo G, Huang S, Hu J, Zhu Y, Wang J, Yang G, Zhang R, Sun Y, Zhang J, Shen Q 2022 AIP Adv. 12 055123

Google Scholar

Google Scholar

[43] Tian X, Cui J, Ma K, Xiang M 2020 Int. J. Heat Mass Transfer 158 120013

Google Scholar

Google Scholar

[44] Wang Y, Zeng X, Yang X, Xu T 2022 Comput. Mater. Sci. 201 110870

Google Scholar

Google Scholar

[45] Wen P, Demaske B, Spearot D E, Phillpot S R, Tao G 2021 J. Appl. Phys. 129 165103

Google Scholar

Google Scholar

[46] Sharma S M, Turneaure S J, Winey J M, Gupta Y M 2020 Phys. Rev. B 102 020103

Google Scholar

Google Scholar

计量

- 文章访问数: 7623

- PDF下载量: 154

- 被引次数: 0

下载:

下载: