-

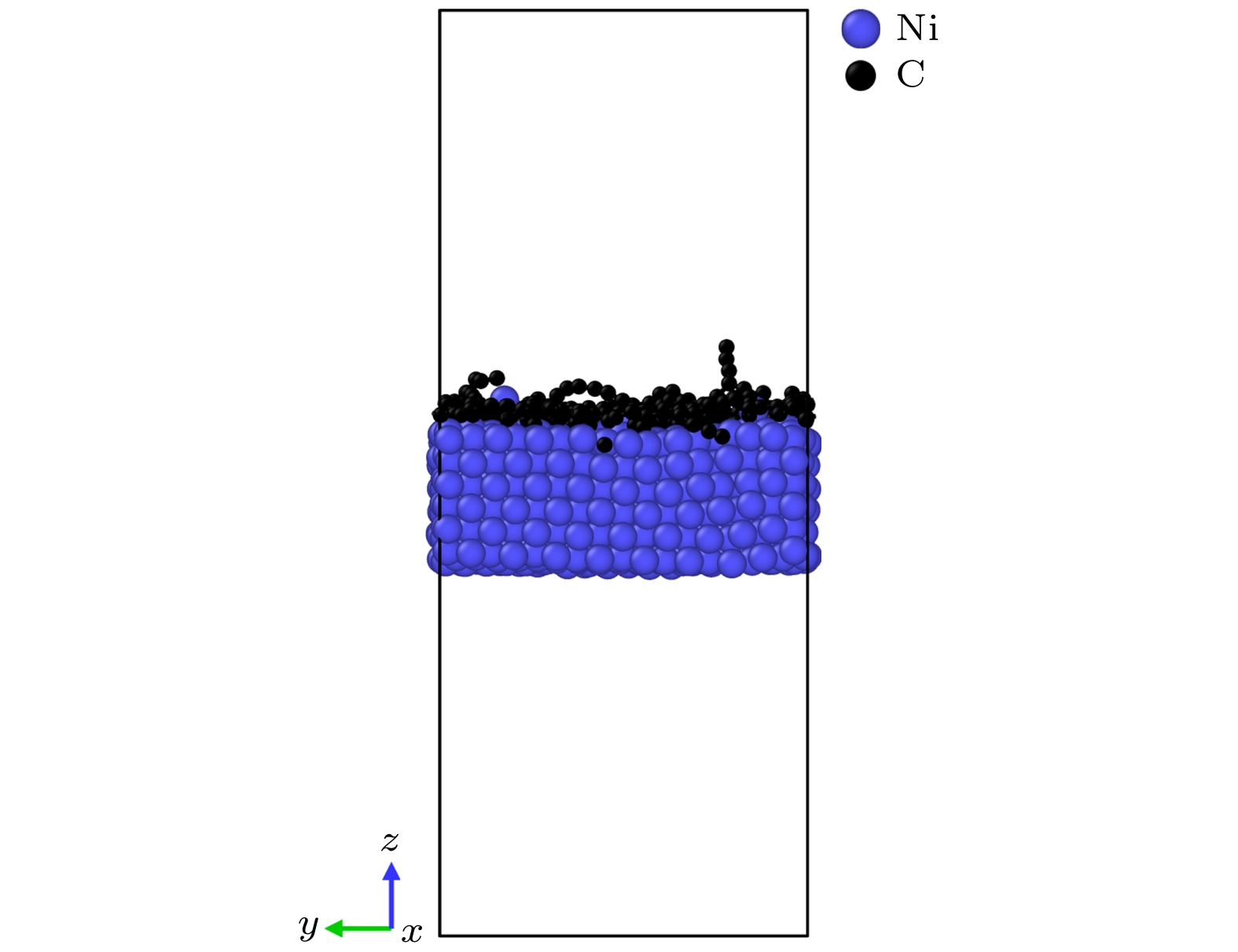

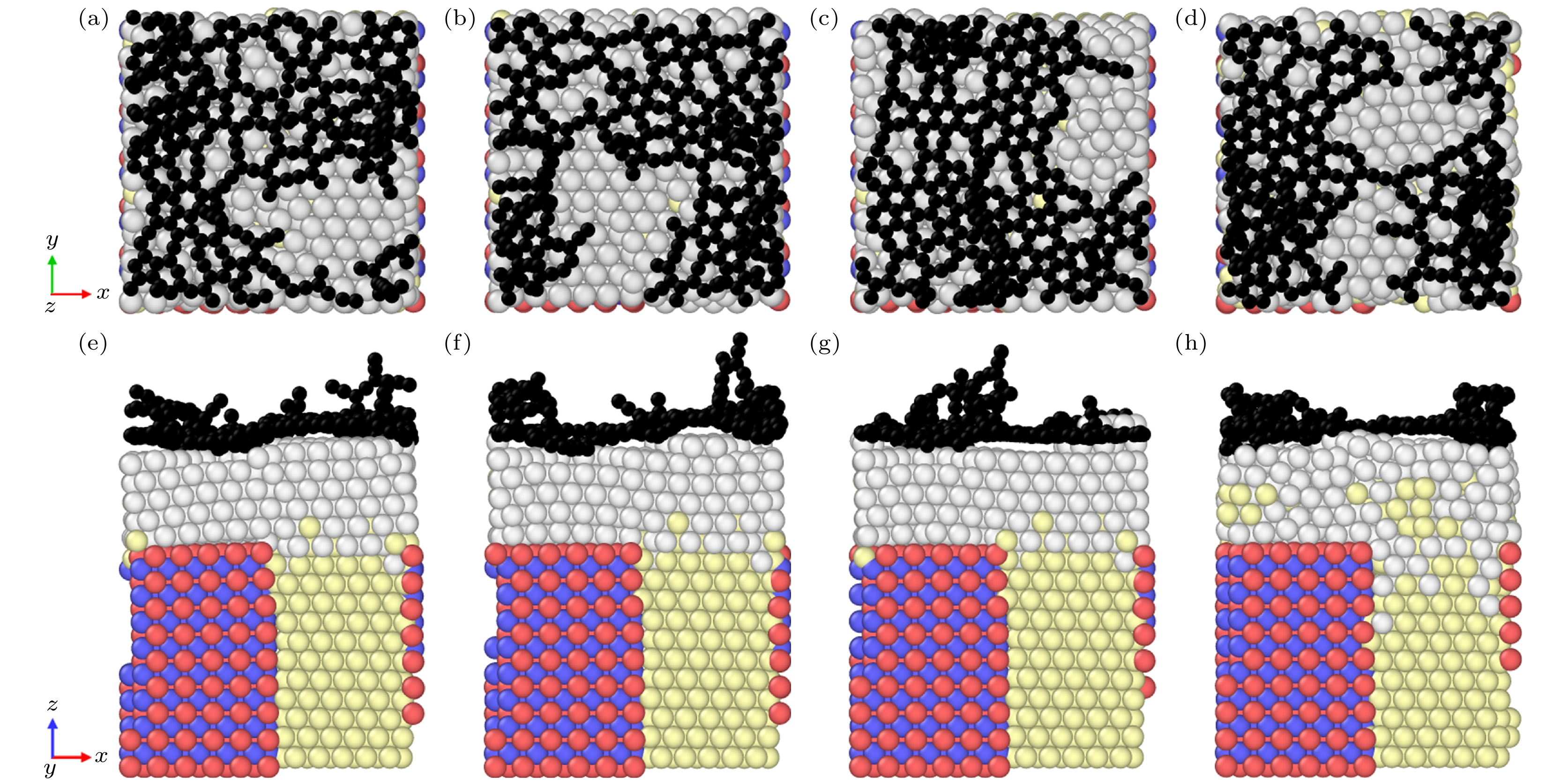

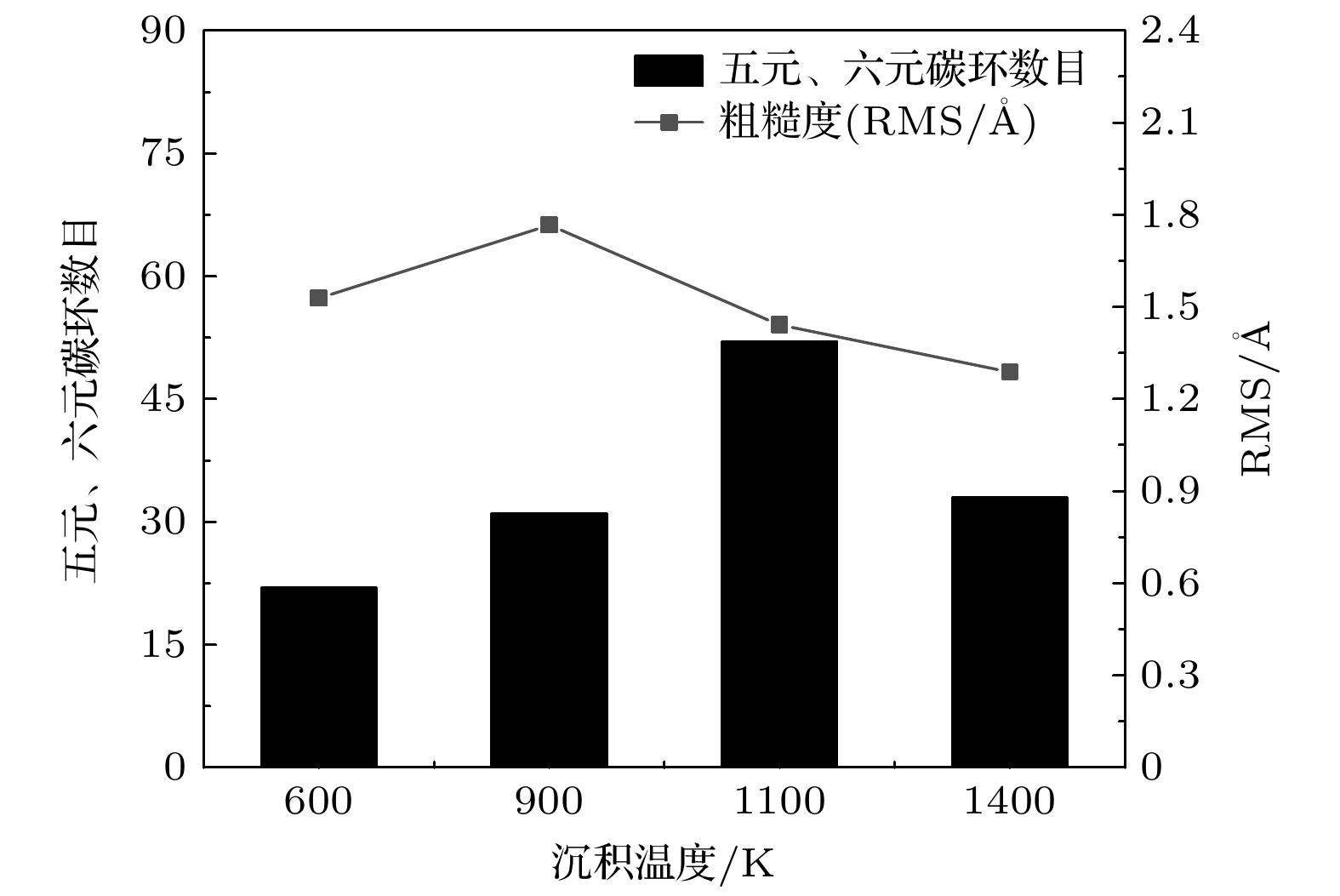

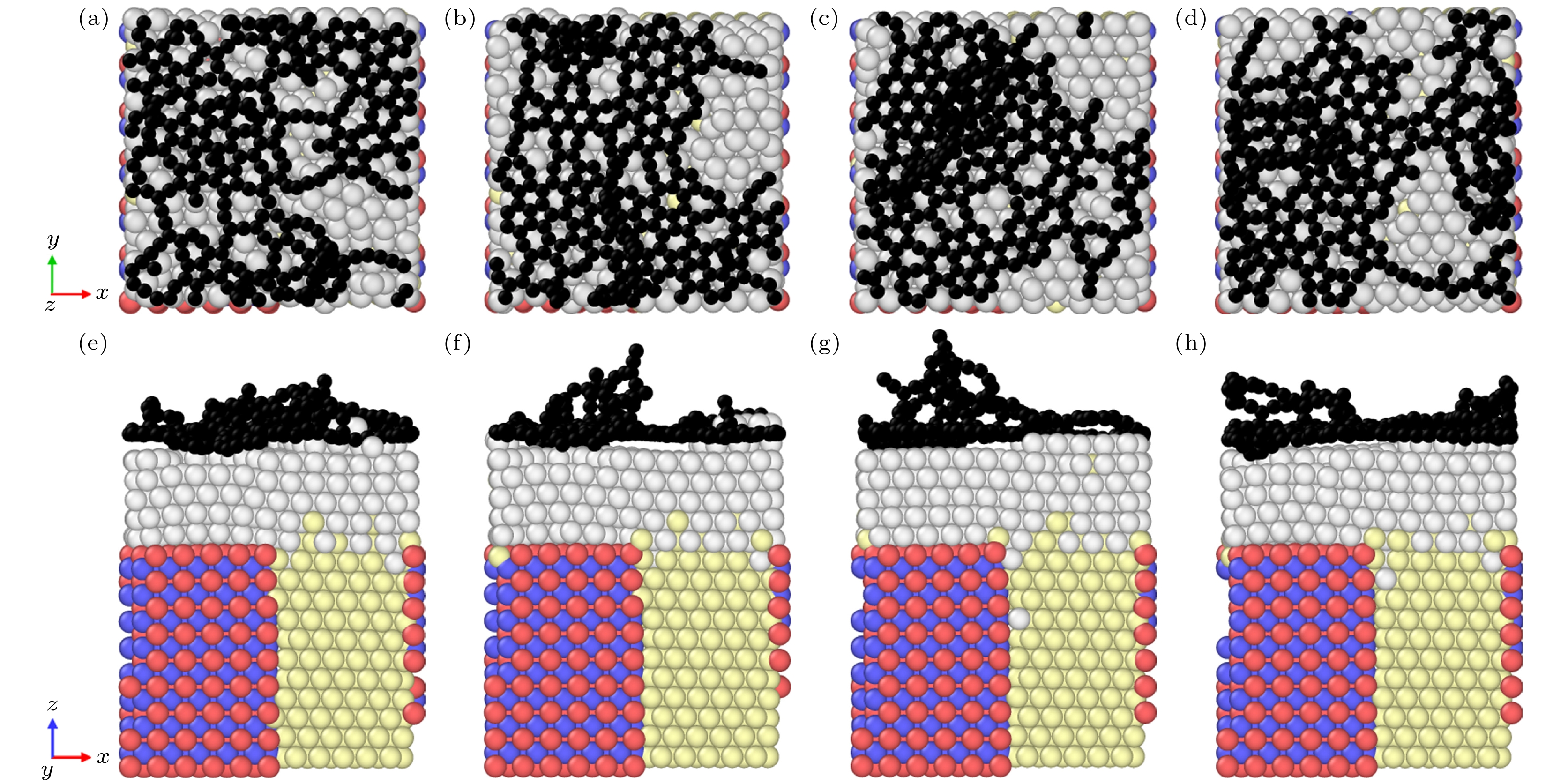

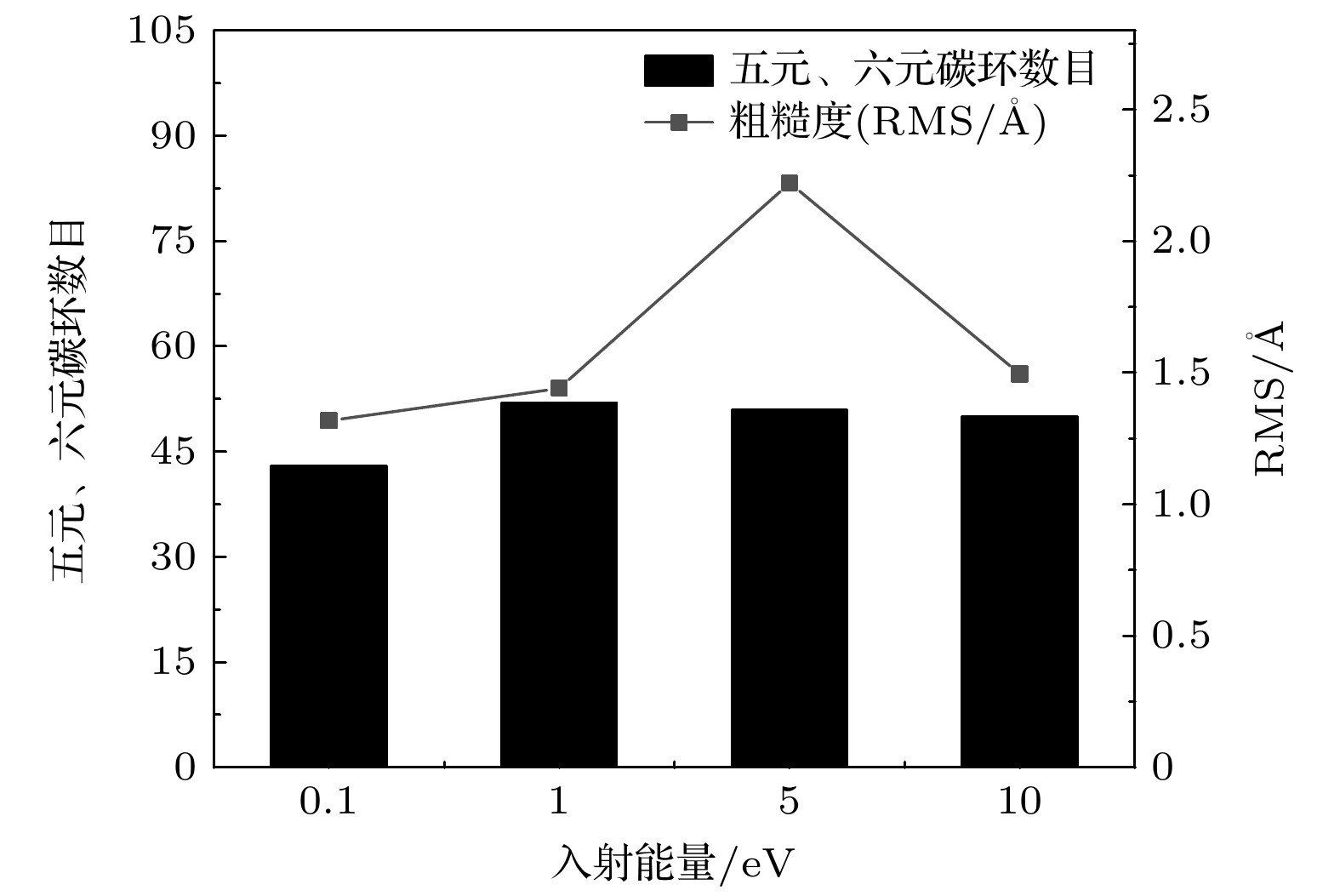

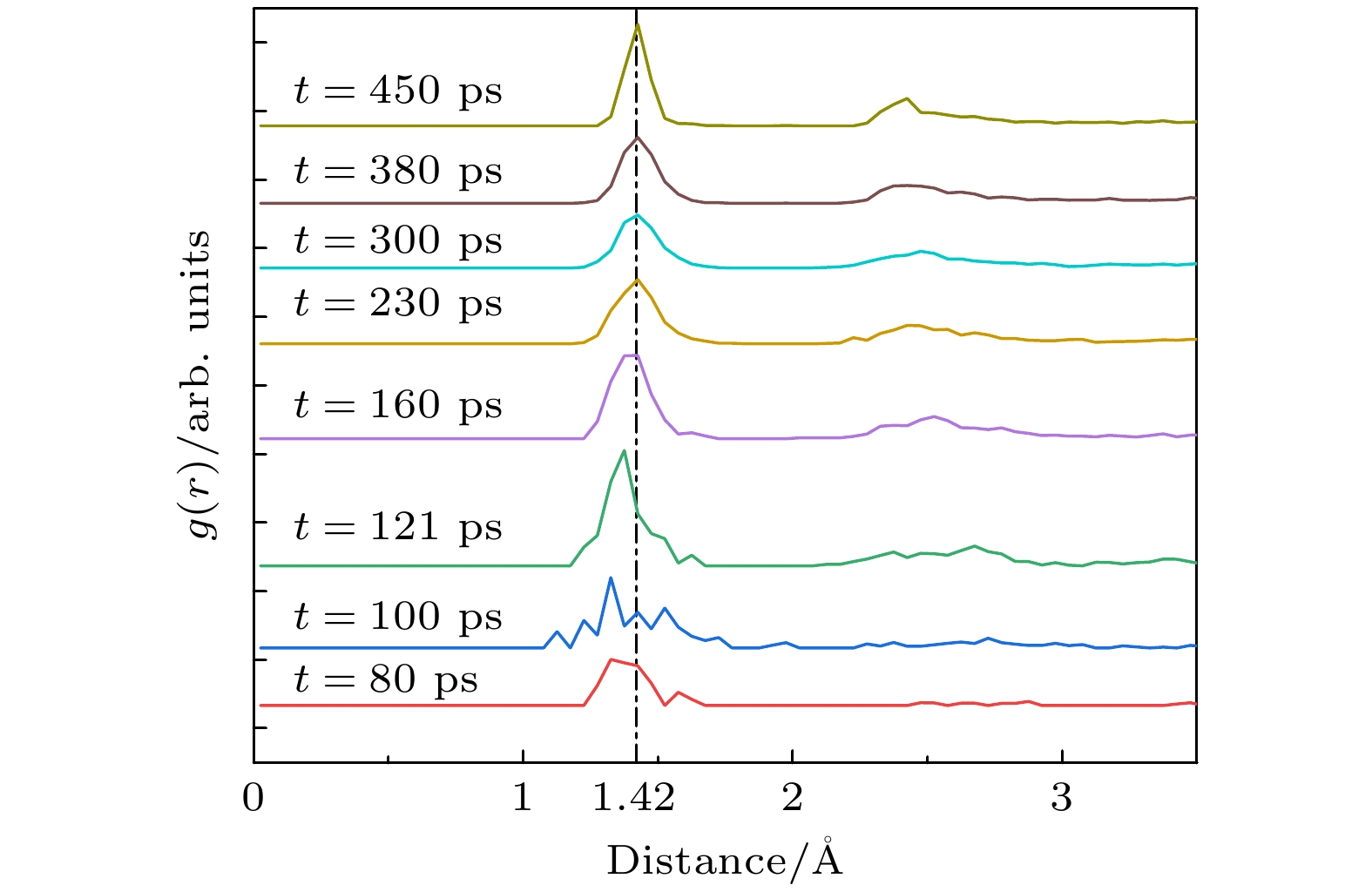

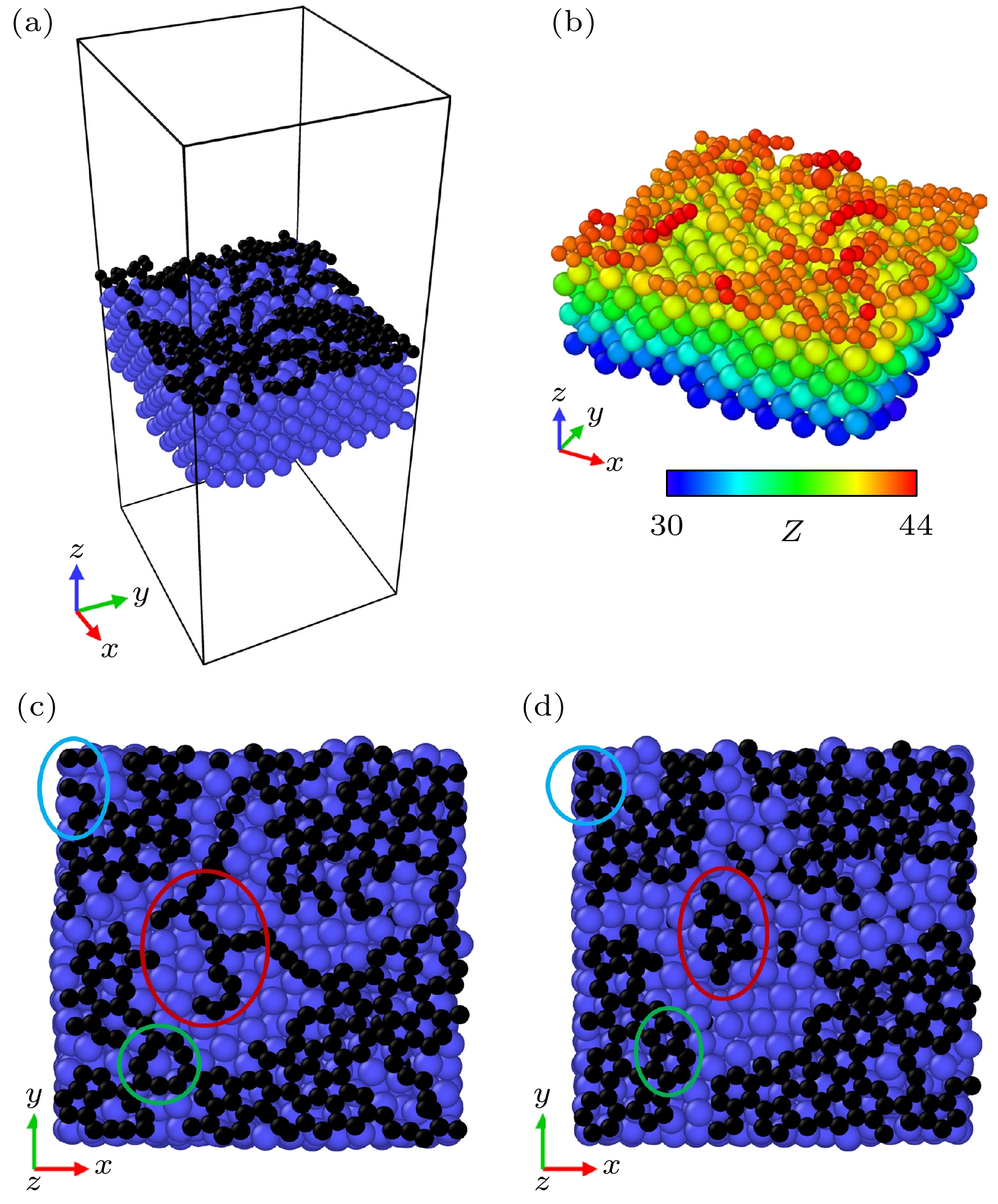

石墨烯具有优异的力学性能, 是一种较佳的硬质合金刀具涂层材料. 本文采用分子动力学, 以硬质合金(WC-Co)为基底, 并以Ni为过渡层, 建立沉积石墨烯涂层模型, 模拟Ni, C原子连续沉积和高温退火过程, 研究沉积温度和入射能量对石墨烯涂层生长的影响, 探究石墨烯沉积过程. 模拟结果发现, 当沉积温度为1100 K时, 石墨烯的覆盖率较高, 结构平整. 较高的沉积温度有助于提供足够的动能使碳原子来克服成核的势能障碍, 减少石墨烯生长缺陷. 温度过高导致碳原子不断在优先沉积的碳环处堆积形成多层网状结构和无序结构, 形成的石墨烯涂层覆盖率低. 入射能量的增大有助于减少石墨烯中的空位缺陷; 但入射能量过高, C-C的吸附作用较之C-Ni的吸附作用更强, 导致涂层连续性较差. 入射能量为1 eV时, 涂层表面粗糙度较低, 生长出较多的单层状石墨烯. 1100 K退火时, 碳膜在Ni过渡层同时存在溶解-成核过程, Ni过渡层催化消除了部分石墨烯缺陷, 六元碳环数量增多, 适宜的高温退火有利于缺陷碳环的修复重构和碳链的重排成环, 提高了石墨烯质量. 因此, 当沉积温度1100 K、入射能量1 eV时, 石墨烯沉积完后并退火, 可生长出较高质量的石墨烯涂层.

WC-Co cemented carbide has excellent cutting performance, which is a potential tool material. But when it is used as cutting ultra-high strength and high hardness materials, the machining accuracy and service life of the tool are significantly reduced. Graphene is a potential coating material for cemented carbide cutting tools due to its excellent mechanical properties. In this work, molecular dynamics (MD) is used to simulate the deposition of nickel transition layer and high-temperature catalytic growth of graphene in cemented carbide. The Ni and C atomic deposition process and the high temperature annealing process are simulated, and a combination of potential functions is adopted to continuously simulate these two deposition processes. The effect of deposition temperature and the effect of incident energy on the growth of graphene are analyzed. The healing mechanism of nickel-based catalytic defective graphene under high-temperature annealing is explored in detail. The simulation results show that at the deposition temperature of 1100 K, the coverage of graphene is higher and the microstructure is flat. The higher temperature helps to provide enough kinetic energy for carbon atoms to overcome the potential energy barrier of nucleation, thereby promoting the migration and rearrangement of carbon atoms and reducing graphene growth defects. Too high a temperature will lead to continuous accumulation of carbon atoms on the deposited carbon rings, forming a multilayered reticulation and disordered structure, which will cause a low coverage rate of graphene. The increase of incident energy helps to reduce the vacancy defects in the film, but excessive energy leads to poor continuity of the film, agglomeration, the more obvious stacking effect of carbon atoms and the tendency of epitaxial growth. When the incident energy is 1 eV, the surface roughness of the film is lower, and more monolayer graphene can be grown. During annealing at 1100 K, the carbon film dissolves and nucleates simultaneously in the Ni transition layer, and the nickel transition layer catalyzes the repair of defective graphene. The graphene film becomes more uniform, and the number of hexagonal carbon rings increases. Appropriate high-temperature annealing can help to repair and reconstruct defective carbon rings and rearrange carbon chains into rings. Therefore, when the deposition temperature is 1100 K and the incident energy is 1 eV, graphene can be deposited and annealed to grow a high-quality graphene coatings. The simulation results provide the reference for preparing the cemented carbide graphene coated tools. -

Keywords:

- molecular dynamics /

- graphene /

- physical vapour deposition /

- nickel transition layer /

- high temperature annealing

[1] 储开宇 2011 机床与液压 39 117

Google Scholar

Google Scholar

Chu K Y 2011 Machine Tools Hydraul. 39 117

Google Scholar

Google Scholar

[2] Tian Q Q, Huang N, Yang B, Zhuang H, Wang C, Zhai Z F, Li J H, Jia X Y, Liu L S, Jiang X 2017 J. Mater. Sci. Technol. 33 1097

Google Scholar

Google Scholar

[3] Bouzakis K D, Michailidis N, Skordaris G, Bouzakis E, Biermann D, M'Saoubi R 2012 CIRP Ann. 61 703

Google Scholar

Google Scholar

[4] Bobzin K, Brögelmann T, Kalscheuer C, Naderi M 2016 Surf. Coat. Technol. 308 349

Google Scholar

Google Scholar

[5] Konstantiniuk F, Tkadletz M, Kainz C, Czettl C, Schalk N 2021 Surf. Coat. Technol. 410 126959

Google Scholar

Google Scholar

[6] Wei Q P, Yu Z M, Ashfold M N, Chen Z, Wang L, Ma L 2010 Surf. Coat. Technol. 205 158

Google Scholar

Google Scholar

[7] 吴张欣 2023 硕士学位论文 (上海: 华东理工大学)

Wu Z X 2023 M.S. Thesis (Shanghai: East China University of Science and Technology

[8] Kabir M S, Munroe P, Zhou Z, Xie Z 2017 Surf. Coat. Technol. 309 779

Google Scholar

Google Scholar

[9] Contreras E, Galindez Y, Rodas M A, Bejarano G, Gómez M A 2017 Surf. Coat. Technol. 332 214

Google Scholar

Google Scholar

[10] Suresh S 2001 Science 292 2447

Google Scholar

Google Scholar

[11] Lu K 2014 Science 345 1455

Google Scholar

Google Scholar

[12] Geim A K, Novoselov K S 2007 Nat. Mater. 6 183

Google Scholar

Google Scholar

[13] 林奎鑫, 李多生, 叶寅, 江五贵, 叶志国, Qinghua Qin, 邹伟 2018 67 246802

Google Scholar

Google Scholar

Lin K X, Li D S, Ye Y, Jiang W G, Ye Z G 2018 Acta Phys. Sin. 67 246802

Google Scholar

Google Scholar

[14] Balandin A A, Ghosh S, Bao W, Calizo I, Teweldebrhan D, Miao F, Lau C N 2008 Nano Lett. 8 90

Google Scholar

Google Scholar

[15] Lee C, Wei X, Kysar J W, Hone J 2008 Science 321 385

Google Scholar

Google Scholar

[16] Bolotin K I, Sikes K J, Jiang Z, Klima M, Fudenberg G, Hone J, Stormer H L 2008 Solid State Commun. 146 351

Google Scholar

Google Scholar

[17] Zhang Z, Du Y, Huang S, Meng F, Chen L, Xie W, Chang K, Zhang C, Lu Y, Lin C, Li S, Parkin I P, Guo D 2020 Adv. Sci. 7 1903239

Google Scholar

Google Scholar

[18] Li S Z, Li Q Y, Carpick R W, Gumbsch P, Liu X Z, Ding X D, Li J 2016 Nature 539 541

Google Scholar

Google Scholar

[19] Fan S Y, Chen Y N, Xiao S, Shi K J, Meng X Y, Lin S S, Su F H, Su Y F, Chu P K 2024 Carbon 216 118561

Google Scholar

Google Scholar

[20] Min F L, Yu S B, Sheng W A N G, Yao Z H, Noudem J G, Liu S J, Zhang J F 2022 Trans. Nonferrous Met. Soc. China 32 1935

Google Scholar

Google Scholar

[21] Garlow J A, Barrett L K, Wu L, Kisslinger K, Zhu Y, Pulecio J F 2016 Sci. Rep. 6 19804

Google Scholar

Google Scholar

[22] Orofeo C M, Ago H, Hu B, Tsuji M 2011 Nano Res. 4 531

Google Scholar

Google Scholar

[23] Reina A, Thiele S, Jia X, Bhaviripudi S, Dresselhaus M S, Schaefer J A, Kong J 2009 Nano Res. 2 509

Google Scholar

Google Scholar

[24] Seo J H, Lee H W, Kim J K, Kim D G, Kang J W, Kang M S, Kim C S 2012 Curr. Appl. Phys. 12 S131

Google Scholar

Google Scholar

[25] Li X S, Cai W W, Colombo L, Ruoff R S 2009 Nano Lett. 9 4268

Google Scholar

Google Scholar

[26] Li X, Li H, Lee K R, Wang A 2020 Appl. Surf. Sci. 529 147042

Google Scholar

Google Scholar

[27] 王泽, 李国禄, 王海斗, 徐滨士, 康嘉杰 材料导报 28 91

Wang Z, Li G L, Wang H D, Xu B S, Kang J J 2014 Mater. Rev. 28 91

[28] Kato T, Nagai T, Sasajima Y, Onuki J 2010 Mater. Trans. 51 664

Google Scholar

Google Scholar

[29] 丁业章, 叶寅, 李多生, 徐锋, 朗文昌, 刘俊红, 温鑫 2023 72 068703

Google Scholar

Google Scholar

Ding Y Z, Ye Y, Li D S, Xu F, Lang W C, Liu J H, Wen X 2023 Acta Phys. Sin. 72 068703

Google Scholar

Google Scholar

[30] Backholm M, Foss M, Nordlund K 2013 Appl. Surf. Sci. 268 270

Google Scholar

Google Scholar

[31] Shibuta Y, Elliott J A 2009 Chem. Phys. Lett. 472 200

Google Scholar

Google Scholar

[32] Juslin N, Erhart P, Träskelin P, Nord J, Henriksson K O E, Nordlund K, Salonen E, Albe K 2005 J. Appl. Phys. 98 123520

Google Scholar

Google Scholar

[33] Béland L K, Lu C, Osetskiy Y N, Samolyuk G D, Caro A, Wang L, Stoller R E 2016 J. Appl. Phys. 119 085901

Google Scholar

Google Scholar

[34] Morse P M 1929 Phys. Rev. 34 57

Google Scholar

Google Scholar

[35] 冯艳, 段海明 2011 原子与分子 28 251

Google Scholar

Google Scholar

Feng Y, Duan H M 2011 J. At. Mol. Phys. 28 251

Google Scholar

Google Scholar

[36] Stuart S J, Tutein A B, Harrison J A 2000 J. Chem. Phys. 112 6472

Google Scholar

Google Scholar

[37] Jones J E 1924 Proc. Roy. Soc. A 106 463

[38] Cao Q, Chen Y J, Shao W, Ma X T, Zheng C, Cui Z, Liu Y, Yu B 2020 J. Mol. Liq. 319 114218

Google Scholar

Google Scholar

[39] 王涛 2010 硕士学位论文 (湘潭: 湘潭大学)

Wang T 2010 M. S. Thesis ( Xiangtan: Xiangtan University

[40] Mueller J E, Van Duin A C, Goddard III W A 2010 J. Phys. Chem. C 114 4939

Google Scholar

Google Scholar

[41] Loginova E, Bartelt N C, Feibelman P J, McCarty K F 2008 New J. Phys. 10 093026

Google Scholar

Google Scholar

[42] Pagon A M, Partridge J G, Hubbard P, Taylor M B, McCulloch D G, Doyle E D, Li G 2010 Surf. Coat. Technol. 204 3552

Google Scholar

Google Scholar

[43] 王璐, 高峻峰, 丁峰 2014 化学学报 72 345

Google Scholar

Google Scholar

Wang L, Gao J F, Ding F 2014 Acta Chim. Sin. 72 345

Google Scholar

Google Scholar

[44] 戴达煌 2008 薄膜与涂层现代表面技术(长沙: 中南大学出版社) 第411页

Dai D H 2008 Thin Films and Coatings Modern Surface Technology (Changsha: Central South University Press) p411

[45] Chen S D, Bai Q S, Wang H F, Dou Y H, Guo W 2022 Physics E 144 115465

Google Scholar

Google Scholar

[46] Chen S, Xiong W, Zhou Y S, Lu Y F, Zeng X C 2016 Nanoscale 8 9746

Google Scholar

Google Scholar

[47] Rut’kov E V, Gall N R 2011 Equilibrium Nucleation, Growth, and Thermal Stability of Graphene on Solids (Russia St. Petersburg: inTech) pp209–292

-

图 3 不同温度下石墨烯生长的俯视图和主视图 (a) 600 K时的俯视图; (b) 900 K时的俯视图; (c) 1100 K时的俯视图; (d) 1400 K时的俯视图; (e) 600 K时的主视图; (f) 900 K时的主视图; (g) 1100 K时的主视图; (i) 1400 K时的主视图

Fig. 3. Top and main views of graphene growth at different temperatures: (a) Top view at 600 K; (b) top view at 900 K; (c) top view at 1100 K; (d) top view at 1400 K; (e) main view at 600 K; (f) main view at 900 K; (g) main view at 1100 K; (i) main view at 1400 K.

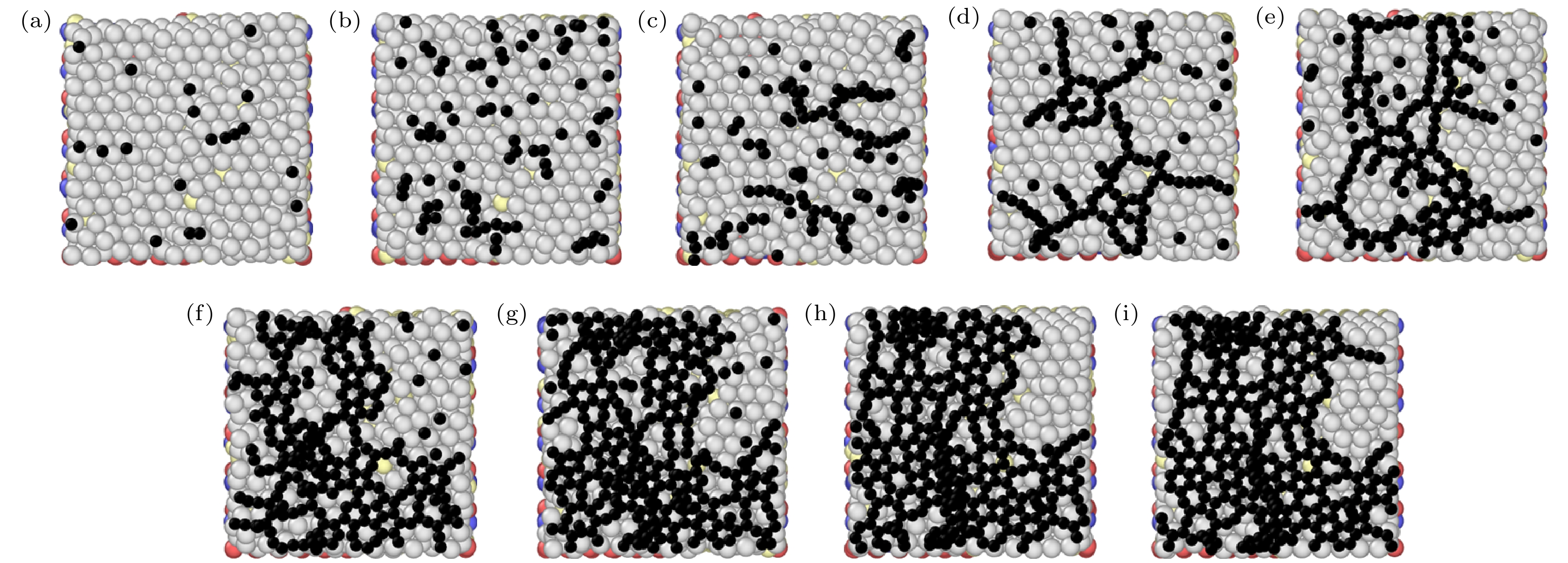

图 5 不同入射能量下石墨烯生长的俯视图和主视图 (a) 0.1 eV时的俯视图; (b) 1 eV时的俯视图; (c) 5 eV时的俯视图; (d) 10 eV时的俯视图; (e) 0.1 eV时的主视图; (f) 1 eV时的主视图; (g) 5 eV时的主视图; (h) 10 eV时的主视图

Fig. 5. Top and main views of graphene growth at different incident energies: (a) Top view at 0.1 eV; (b) top view at 1 eV; (c) top view at 5 eV; (d) top view at 10 eV; (e) main view at 0.1 eV; (f) main view at 1 eV; (g) main view at 5 eV; (h) main view at 10 eV.

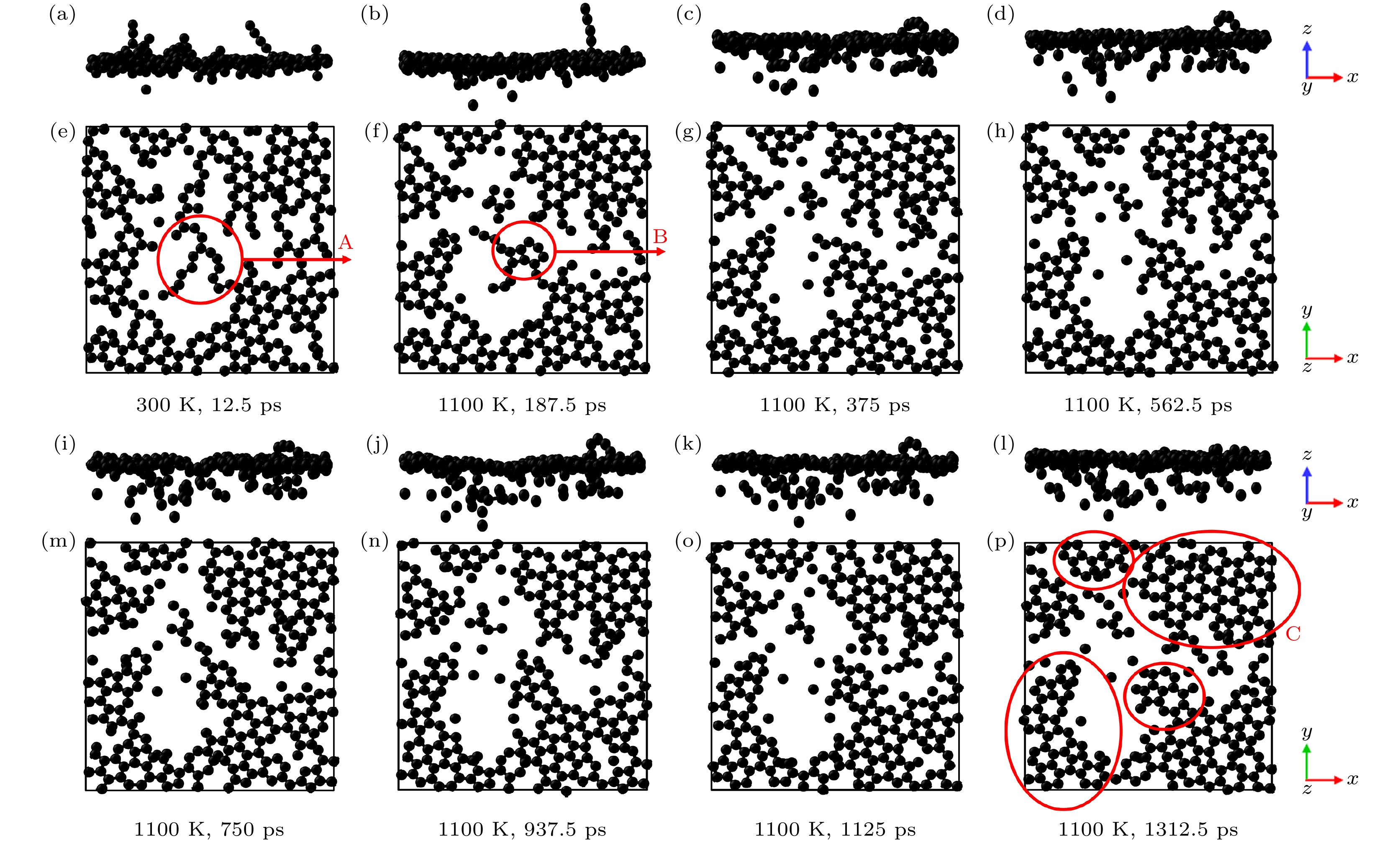

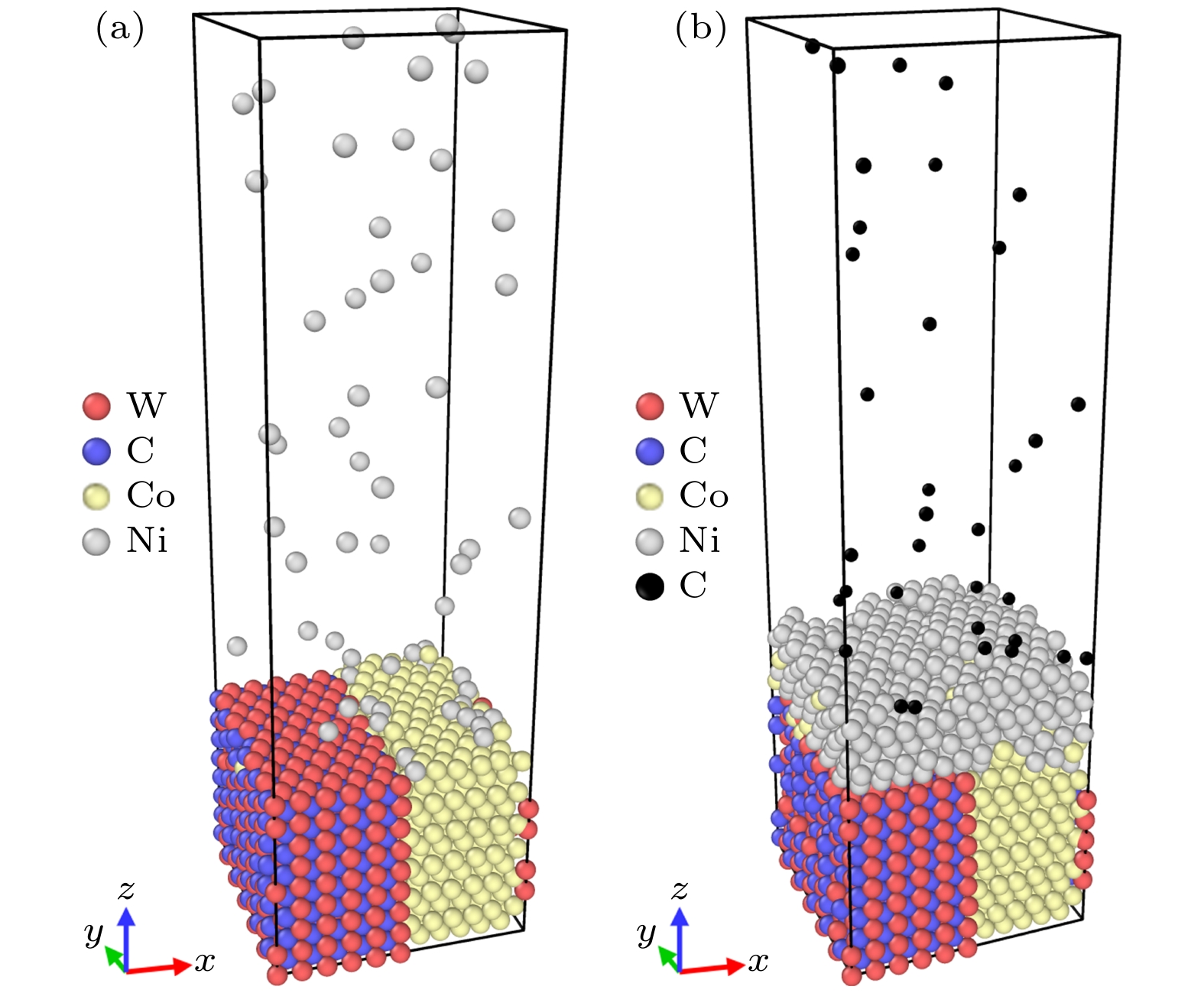

图 10 不同时间的石墨烯涂层高温退火模拟的主视图和俯视图 (a), (b), (c), (d), (i), (j), (k), (l) 主视图; (e), (f), (g), (h), (m), (n), (o), (p) 俯视图

Fig. 10. Main and top views of high-temperature annealing simulations of graphene coatings at different times: (a), (b), (c), (d), (i), (j), (k), (l) Main view; (e), (f), (g), (h), (m), (n), (o), (p) top view.

表 1 WC与Co原子之间的Morse势函数参数[35]

Table 1. Parameters of Morse potential function between WC and Co atoms[35].

Atom pair $ {D}_{{\mathrm{e}}} $/eV $ \alpha $/Å–1 $ {r}_{0} $/Å W-Co 0.098 25.14 0.0872 C-Co 0.1114 19.725 0.1743 表 2 WC与过渡层Ni、过渡层Ni和基底硬质合金各元素及沉积碳原子之间的L-J参数

Table 2. L-J parameters between WC and transition layer Ni, transition layer Ni and base carbide and each element of deposited carbon atoms.

Atom pair $ \varepsilon $/eV $ \sigma $/Å W-Ni 0.07449 2.4180 C-Ni 0.0487 2.9645 W-C 0.0073 3.1411 C-C 0.0050 3.8510 Co-C 0.0017 3.3257 Ni-C 0.0487 2.9645 -

[1] 储开宇 2011 机床与液压 39 117

Google Scholar

Google Scholar

Chu K Y 2011 Machine Tools Hydraul. 39 117

Google Scholar

Google Scholar

[2] Tian Q Q, Huang N, Yang B, Zhuang H, Wang C, Zhai Z F, Li J H, Jia X Y, Liu L S, Jiang X 2017 J. Mater. Sci. Technol. 33 1097

Google Scholar

Google Scholar

[3] Bouzakis K D, Michailidis N, Skordaris G, Bouzakis E, Biermann D, M'Saoubi R 2012 CIRP Ann. 61 703

Google Scholar

Google Scholar

[4] Bobzin K, Brögelmann T, Kalscheuer C, Naderi M 2016 Surf. Coat. Technol. 308 349

Google Scholar

Google Scholar

[5] Konstantiniuk F, Tkadletz M, Kainz C, Czettl C, Schalk N 2021 Surf. Coat. Technol. 410 126959

Google Scholar

Google Scholar

[6] Wei Q P, Yu Z M, Ashfold M N, Chen Z, Wang L, Ma L 2010 Surf. Coat. Technol. 205 158

Google Scholar

Google Scholar

[7] 吴张欣 2023 硕士学位论文 (上海: 华东理工大学)

Wu Z X 2023 M.S. Thesis (Shanghai: East China University of Science and Technology

[8] Kabir M S, Munroe P, Zhou Z, Xie Z 2017 Surf. Coat. Technol. 309 779

Google Scholar

Google Scholar

[9] Contreras E, Galindez Y, Rodas M A, Bejarano G, Gómez M A 2017 Surf. Coat. Technol. 332 214

Google Scholar

Google Scholar

[10] Suresh S 2001 Science 292 2447

Google Scholar

Google Scholar

[11] Lu K 2014 Science 345 1455

Google Scholar

Google Scholar

[12] Geim A K, Novoselov K S 2007 Nat. Mater. 6 183

Google Scholar

Google Scholar

[13] 林奎鑫, 李多生, 叶寅, 江五贵, 叶志国, Qinghua Qin, 邹伟 2018 67 246802

Google Scholar

Google Scholar

Lin K X, Li D S, Ye Y, Jiang W G, Ye Z G 2018 Acta Phys. Sin. 67 246802

Google Scholar

Google Scholar

[14] Balandin A A, Ghosh S, Bao W, Calizo I, Teweldebrhan D, Miao F, Lau C N 2008 Nano Lett. 8 90

Google Scholar

Google Scholar

[15] Lee C, Wei X, Kysar J W, Hone J 2008 Science 321 385

Google Scholar

Google Scholar

[16] Bolotin K I, Sikes K J, Jiang Z, Klima M, Fudenberg G, Hone J, Stormer H L 2008 Solid State Commun. 146 351

Google Scholar

Google Scholar

[17] Zhang Z, Du Y, Huang S, Meng F, Chen L, Xie W, Chang K, Zhang C, Lu Y, Lin C, Li S, Parkin I P, Guo D 2020 Adv. Sci. 7 1903239

Google Scholar

Google Scholar

[18] Li S Z, Li Q Y, Carpick R W, Gumbsch P, Liu X Z, Ding X D, Li J 2016 Nature 539 541

Google Scholar

Google Scholar

[19] Fan S Y, Chen Y N, Xiao S, Shi K J, Meng X Y, Lin S S, Su F H, Su Y F, Chu P K 2024 Carbon 216 118561

Google Scholar

Google Scholar

[20] Min F L, Yu S B, Sheng W A N G, Yao Z H, Noudem J G, Liu S J, Zhang J F 2022 Trans. Nonferrous Met. Soc. China 32 1935

Google Scholar

Google Scholar

[21] Garlow J A, Barrett L K, Wu L, Kisslinger K, Zhu Y, Pulecio J F 2016 Sci. Rep. 6 19804

Google Scholar

Google Scholar

[22] Orofeo C M, Ago H, Hu B, Tsuji M 2011 Nano Res. 4 531

Google Scholar

Google Scholar

[23] Reina A, Thiele S, Jia X, Bhaviripudi S, Dresselhaus M S, Schaefer J A, Kong J 2009 Nano Res. 2 509

Google Scholar

Google Scholar

[24] Seo J H, Lee H W, Kim J K, Kim D G, Kang J W, Kang M S, Kim C S 2012 Curr. Appl. Phys. 12 S131

Google Scholar

Google Scholar

[25] Li X S, Cai W W, Colombo L, Ruoff R S 2009 Nano Lett. 9 4268

Google Scholar

Google Scholar

[26] Li X, Li H, Lee K R, Wang A 2020 Appl. Surf. Sci. 529 147042

Google Scholar

Google Scholar

[27] 王泽, 李国禄, 王海斗, 徐滨士, 康嘉杰 材料导报 28 91

Wang Z, Li G L, Wang H D, Xu B S, Kang J J 2014 Mater. Rev. 28 91

[28] Kato T, Nagai T, Sasajima Y, Onuki J 2010 Mater. Trans. 51 664

Google Scholar

Google Scholar

[29] 丁业章, 叶寅, 李多生, 徐锋, 朗文昌, 刘俊红, 温鑫 2023 72 068703

Google Scholar

Google Scholar

Ding Y Z, Ye Y, Li D S, Xu F, Lang W C, Liu J H, Wen X 2023 Acta Phys. Sin. 72 068703

Google Scholar

Google Scholar

[30] Backholm M, Foss M, Nordlund K 2013 Appl. Surf. Sci. 268 270

Google Scholar

Google Scholar

[31] Shibuta Y, Elliott J A 2009 Chem. Phys. Lett. 472 200

Google Scholar

Google Scholar

[32] Juslin N, Erhart P, Träskelin P, Nord J, Henriksson K O E, Nordlund K, Salonen E, Albe K 2005 J. Appl. Phys. 98 123520

Google Scholar

Google Scholar

[33] Béland L K, Lu C, Osetskiy Y N, Samolyuk G D, Caro A, Wang L, Stoller R E 2016 J. Appl. Phys. 119 085901

Google Scholar

Google Scholar

[34] Morse P M 1929 Phys. Rev. 34 57

Google Scholar

Google Scholar

[35] 冯艳, 段海明 2011 原子与分子 28 251

Google Scholar

Google Scholar

Feng Y, Duan H M 2011 J. At. Mol. Phys. 28 251

Google Scholar

Google Scholar

[36] Stuart S J, Tutein A B, Harrison J A 2000 J. Chem. Phys. 112 6472

Google Scholar

Google Scholar

[37] Jones J E 1924 Proc. Roy. Soc. A 106 463

[38] Cao Q, Chen Y J, Shao W, Ma X T, Zheng C, Cui Z, Liu Y, Yu B 2020 J. Mol. Liq. 319 114218

Google Scholar

Google Scholar

[39] 王涛 2010 硕士学位论文 (湘潭: 湘潭大学)

Wang T 2010 M. S. Thesis ( Xiangtan: Xiangtan University

[40] Mueller J E, Van Duin A C, Goddard III W A 2010 J. Phys. Chem. C 114 4939

Google Scholar

Google Scholar

[41] Loginova E, Bartelt N C, Feibelman P J, McCarty K F 2008 New J. Phys. 10 093026

Google Scholar

Google Scholar

[42] Pagon A M, Partridge J G, Hubbard P, Taylor M B, McCulloch D G, Doyle E D, Li G 2010 Surf. Coat. Technol. 204 3552

Google Scholar

Google Scholar

[43] 王璐, 高峻峰, 丁峰 2014 化学学报 72 345

Google Scholar

Google Scholar

Wang L, Gao J F, Ding F 2014 Acta Chim. Sin. 72 345

Google Scholar

Google Scholar

[44] 戴达煌 2008 薄膜与涂层现代表面技术(长沙: 中南大学出版社) 第411页

Dai D H 2008 Thin Films and Coatings Modern Surface Technology (Changsha: Central South University Press) p411

[45] Chen S D, Bai Q S, Wang H F, Dou Y H, Guo W 2022 Physics E 144 115465

Google Scholar

Google Scholar

[46] Chen S, Xiong W, Zhou Y S, Lu Y F, Zeng X C 2016 Nanoscale 8 9746

Google Scholar

Google Scholar

[47] Rut’kov E V, Gall N R 2011 Equilibrium Nucleation, Growth, and Thermal Stability of Graphene on Solids (Russia St. Petersburg: inTech) pp209–292

计量

- 文章访问数: 1868

- PDF下载量: 172

- 被引次数: 0

下载:

下载: