-

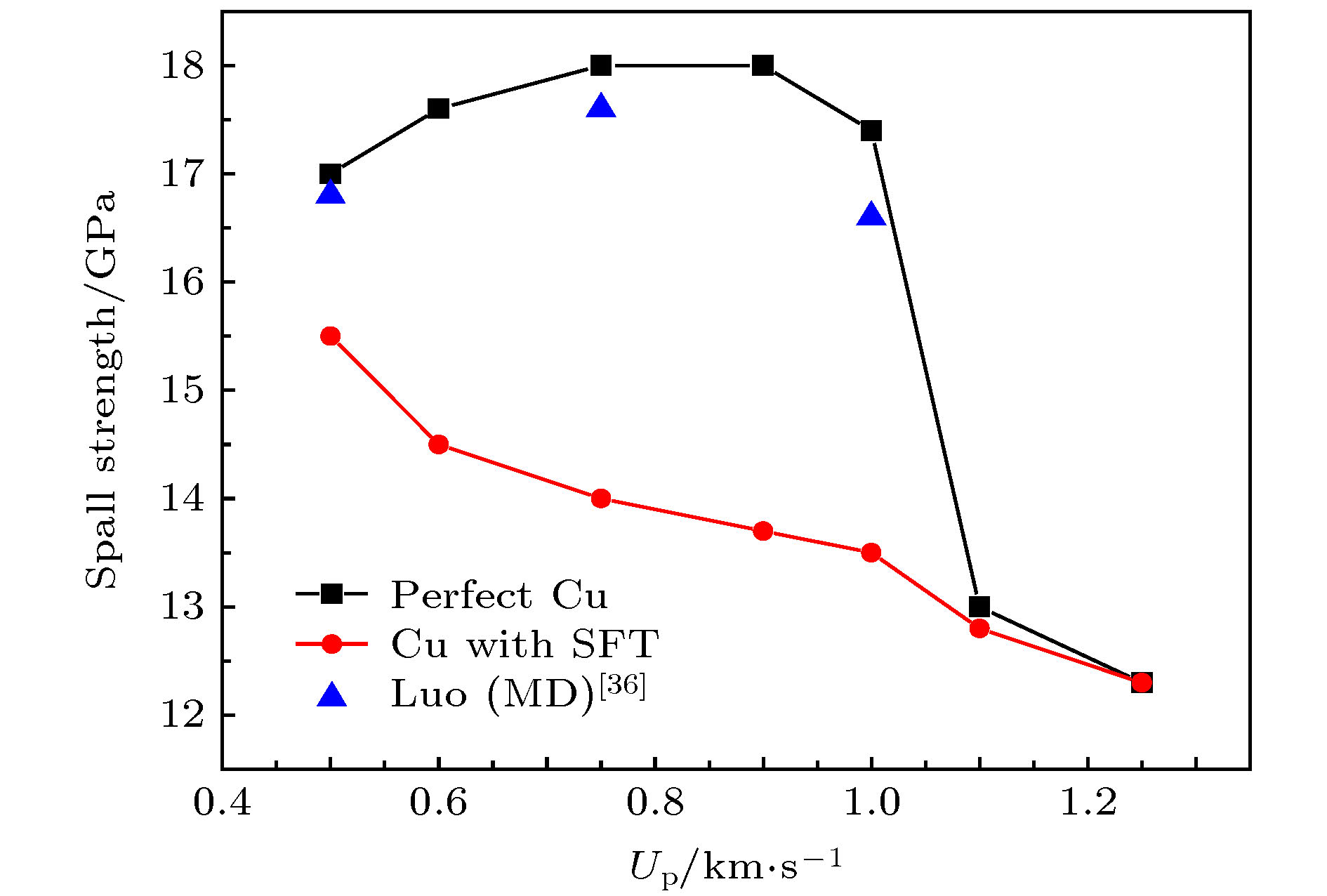

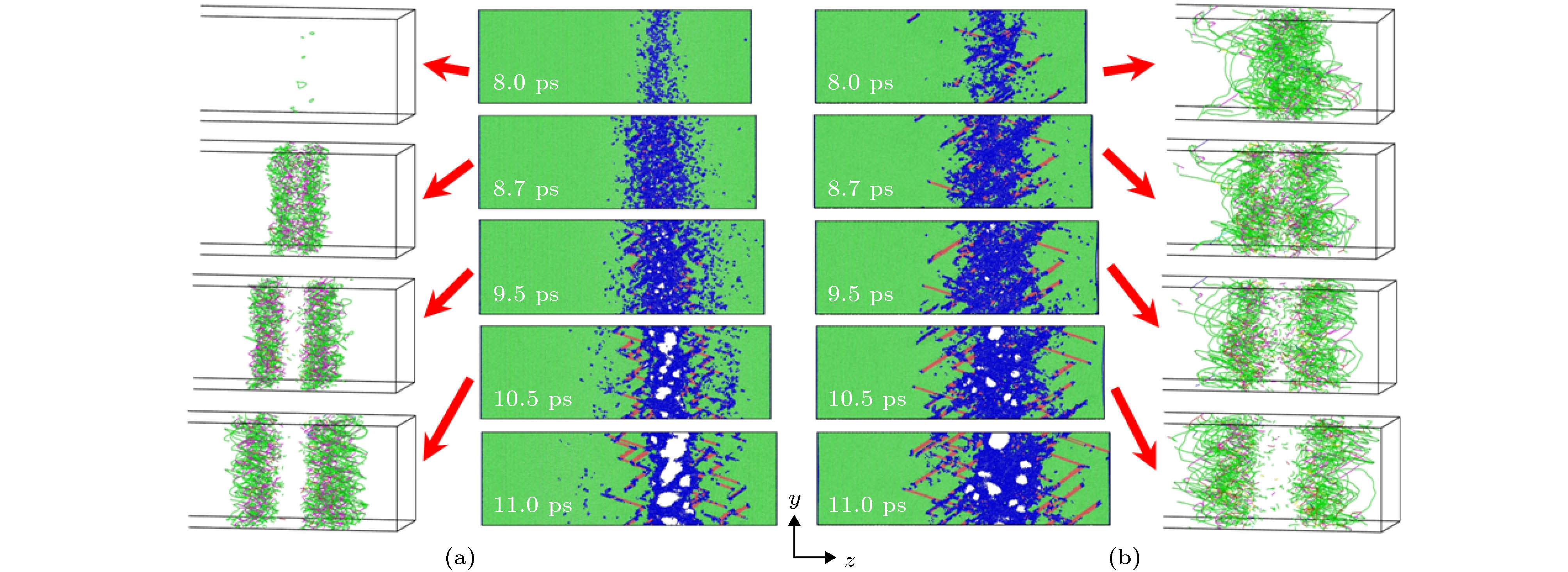

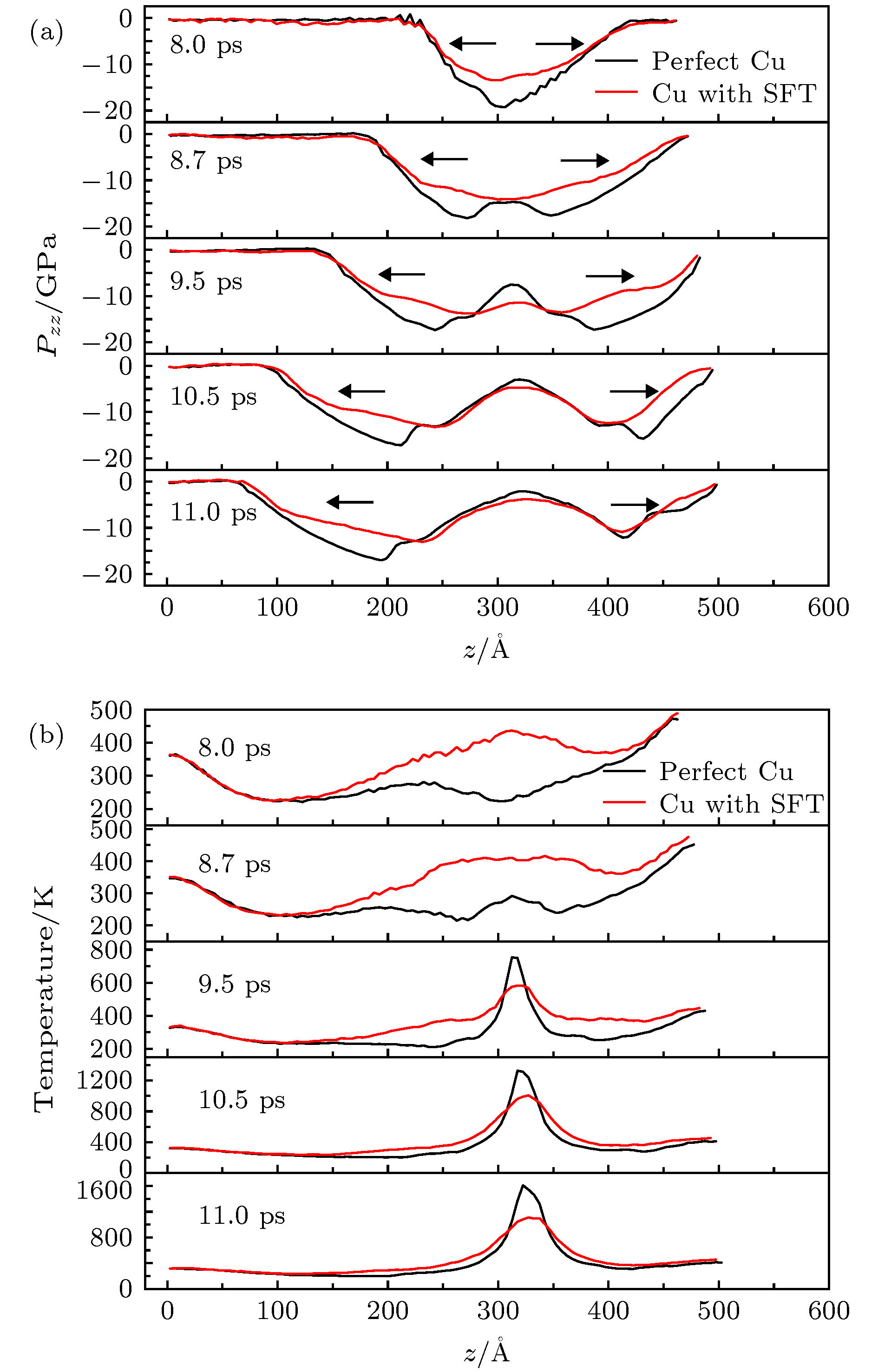

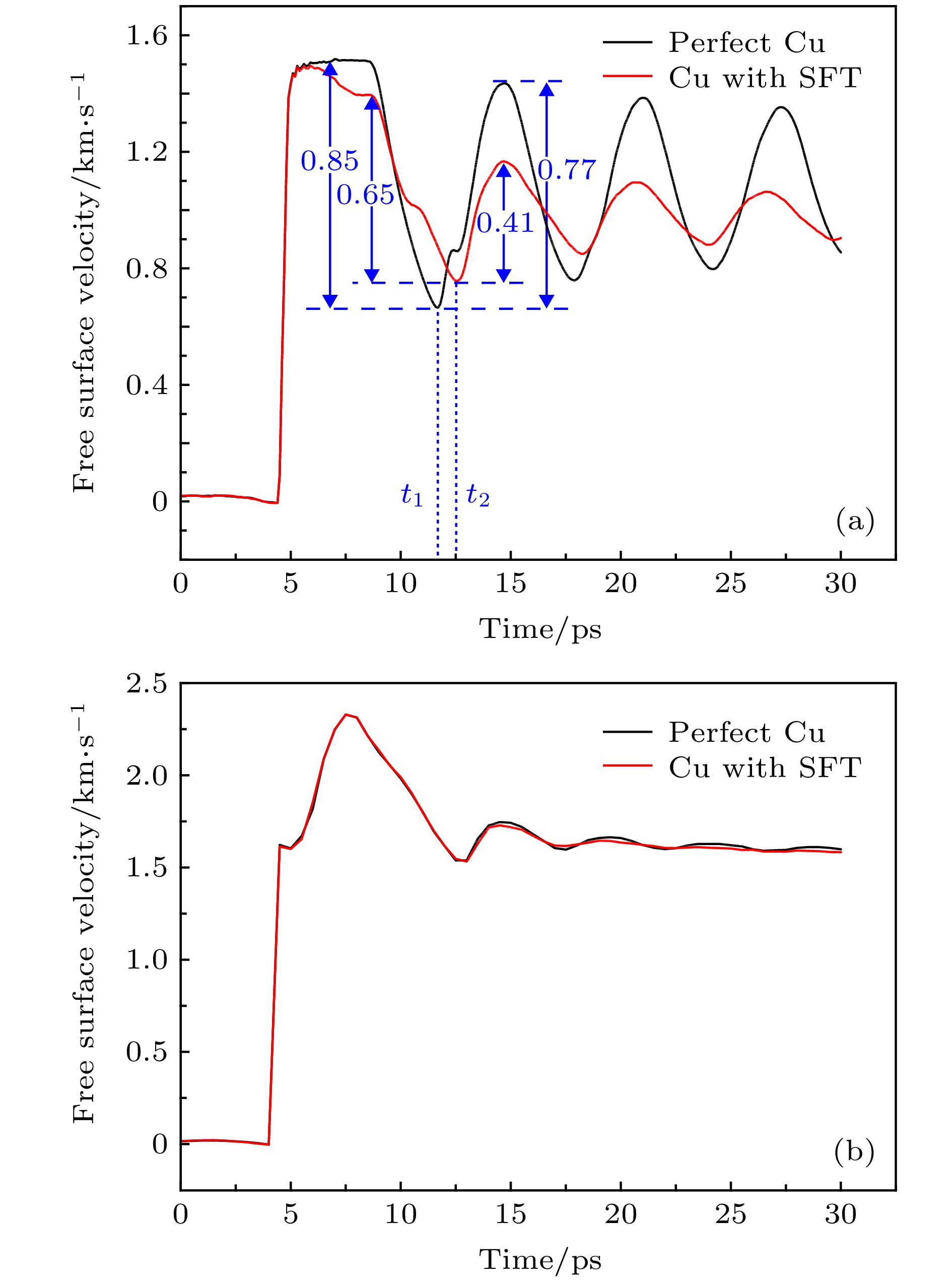

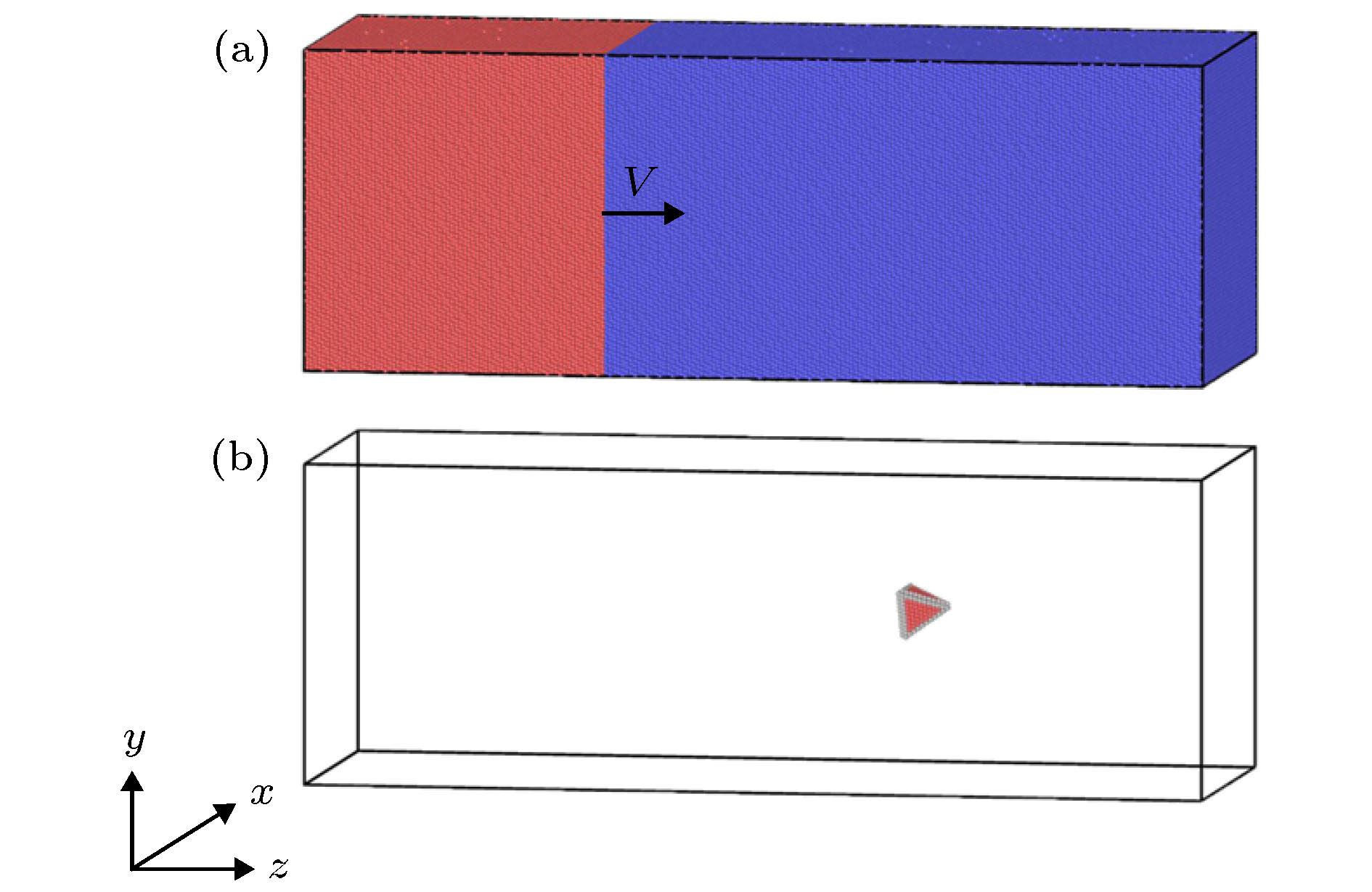

层错四面体是一种典型的三维空位型缺陷, 广泛存在于受辐照后的面心立方金属材料中, 对材料的力学性能有显著的影响. 目前, 关于层错四面体对辐照材料层裂行为的影响还缺乏深入系统的研究. 本文使用分子动力学方法模拟了含有层错四面体的单晶铜在不同冲击速度下的层裂行为, 对整个冲击过程中的自由表面速度及微结构演化等进行了深入的分析. 研究发现, 层错四面体在冲击波作用下会发生坍塌, 并进一步诱导材料产生位错、层错等缺陷. 在中低速度加载下, 层错四面体坍塌引起的缺陷快速向周围扩展, 为孔洞提供了更宽的形核区域, 促进了孔洞的异质成核, 造成材料层裂强度大幅度减小. 当冲击速度较高时, 层错四面体坍塌导致的局部缺陷对材料的层裂强度不再有明显影响.Stacking fault tetrahedron (SFT) is a common type of three-dimensional vacancy clustered defect in irradiated FCC metals and alloys, which has a great influence on the mechanical properties of the materials. Previous researches mostly concentrated on the effect of SFT on the mechanical response of material under quasi-static or constant strain rate loading condition, while very few studies focused on its influence on mechanical properties under the shock loading condition. Spallation is a typical failure mode of ductile metal material under shock loading, and the initial defects in the material have a great influence on the spallation behavior. In this study, molecular dynamics simulation is carried out to investigate the influence of SFT on spallation behavior of irradiated copper single crystal under different shock intensities. Copper single crystal with a perfect structural model is also investigated under the same simulation condition for comparison. The model is divided into two parts: the flyer and the target. The shock wave is generated by moving the flyer at a velocity in a range of 1.0–2.5 km/s along the [111] crystallographic orientation to achieve the desired shock-state particle velocity Up in a range of 0.5–1.25 km/s. The time evolution of pressure, free surface velocity and corresponding microstructure, are analyzed in detail to illuminate the spallation behavior of the Cu with SFT. It is revealed that the SFT collapses during shock compression and induces the generation of dislocations and stacking faults in the material. Subsequently, spallation happens when the voids nucleate and grow in the region of dislocations and stacking faults. Moreover, the materials show different spallation behaviors at different shock intensities. When Up ≤ 1.0 km/s, only elastic deformation occurs in perfect single crystal copper under shock compression, but in the copper with SFT, local defects appear and plastic deformation occurs due to the collapse of SFT under shock compression. The influence of SFT on spallation is most pronounced at a medium shock intensity. When Up = 0.75 km/s, the local defects caused by the collapse of SFT provide a wider nucleation area for the voids and promote the heterogeneous nucleation of the voids, resulting in the decreasing of the spall strength. The void nucleation of single crystal copper with SFT is found to be much later than the perfect one and the rate of spall damage evolution also decreases due to energy dissipation during SFT’s collapse and plastic deformation. When Up increases to 1.25 km/s, shock compression induces many defected atoms in both samples, so the SFT has little influence on the spall strength and spall damage of the materials.

-

Keywords:

- spallation /

- stacking fault tetrahedron /

- shock /

- molecular dynamics

[1] Zinkle S J, Busby J T 2009 Mater. Today 12 12

[2] Yoshida N, Akashi Y, Kitajima K, Kiritani M 1985 J. Nucl. Mater. 133 405

[3] Zinkle S J, Farrell K 1989 J. Nucl. Mater. 168 262

Google Scholar

Google Scholar

[4] Hashimoto N, Byun T S, Farrell K 2006 J. Nucl. Mater. 351 295

Google Scholar

Google Scholar

[5] Schäublin R, Yao Z, Baluc N, Victoria M 2005 Philos. Mag. 85 769

Google Scholar

Google Scholar

[6] Fabritsiev S A, Pokrovsky A S 2007 J. Nucl. Mater. 367 977

[7] Shao J L, Wang P, He A M, Duan S Q, Qin C S 2014 Modell. Simul. Mater. Sci. Eng. 22 025012

Google Scholar

Google Scholar

[8] Zhou T T, He A M, Wang P, Shao J L 2019 Comput. Mater. Sci. 162 255

Google Scholar

Google Scholar

[9] Lin E Q, Shi H, Niu L 2014 Modell. Simul. Mater. Sci. Eng. 22 035012

Google Scholar

Google Scholar

[10] Qiu T, Xiong Y N, Xiao S F, Li X F, Hu W Y, Deng H Q 2017 Comput. Mater. Sci. 137 273

Google Scholar

Google Scholar

[11] Dai Y, Victoria M 1996 MRS. Symp. Proc. 439 319

[12] Edwards D J, Singh B N, Bilde-Sørensen J B 2005 J. Nucl. Mater. 342 164

Google Scholar

Google Scholar

[13] Lee H J, Wirth B D 2009 Philos. Mag. 89 821

Google Scholar

Google Scholar

[14] Osetsky Y N, Stoller R E, Rodney D, Bacon D J 2005 Mater. Sci. Eng., A 400 370

[15] Osetsky Y N, Rodney D, Bacon D J 2006 Philos. Mag. 86 2295

Google Scholar

Google Scholar

[16] Fan H, El-Awady J A, Wang Q 2015 J. Nucl. Mater. 458 176

Google Scholar

Google Scholar

[17] Fan H, Wang Q, Ouyang C 2015 J. Nucl. Mater. 465 245

Google Scholar

Google Scholar

[18] Martínez E, Uberuaga B P, Beyerlein I J 2016 Phys. Rev. B 93 054105

Google Scholar

Google Scholar

[19] Arsenlis A, Wirth B D, Rhee M 2004 Philos. Mag. 84 3617

Google Scholar

Google Scholar

[20] Krishna S, Zamiri A, De S 2010 Philos. Mag. 90 4013

Google Scholar

Google Scholar

[21] Xiao X Z, Song D K, Xue J M, Chu H J, Duan H L 2015 Int. J. Plast. 65 152

Google Scholar

Google Scholar

[22] Zhang L, Lu C, Tieu K, Shibuta Y 2018 Scr. Mater. 144 78

Google Scholar

Google Scholar

[23] Wu L P, Yu W S, Hu S L, Shen S P 2017 Int. J. Plast. 97 246

Google Scholar

Google Scholar

[24] Wu L P, Yu W S, Hu S L, Shen S P 2018 Comput. Mater. Sci. 155 256

Google Scholar

Google Scholar

[25] Xiao X Z, Song D K, Chu H J, Xue J M, Duan H L 2015 Int. J. Plast. 74 110

Google Scholar

Google Scholar

[26] Salehinia I, Bahr D F 2012 Scr. Mater. 66 339

Google Scholar

Google Scholar

[27] Figueroa E, Tramontina D, Gutierrez G, Bringa E 2015 J. Nucl. Mater. 467 677

Google Scholar

Google Scholar

[28] Salehinia I, Lawrence S K, Bahr D F 2013 Acta Mater. 61 1421

Google Scholar

Google Scholar

[29] Zhang L, Lu C, Tieu K, Su L, Zhao X, Pei L 2017 Mater. Sci. Eng., A 680 27

Google Scholar

Google Scholar

[30] Mishin Y, Mehl M J, Papaconstantopoulos D A, Voter A F, Kress J D 2001 Phys. Rev. B 63 224106

Google Scholar

Google Scholar

[31] Silcox J, Hirsch P B 1959 Philos. Mag. 4 1356

Google Scholar

Google Scholar

[32] Thompson A P, Plimpton S J, Mattson W 2009 J. Chem. Phys. 131 154107

Google Scholar

Google Scholar

[33] Stukowski A 2010 Modell. Simul. Mater. Sci. Eng. 18 015012

[34] Stukowski A 2012 Modell. Simul. Mater. Sci. Eng. 20 045021

Google Scholar

Google Scholar

[35] Stukowski A, Albe K 2010 Modell. Simul. Mater. Sci. Eng. 18 085001

Google Scholar

Google Scholar

[36] Luo S N, Qi A, Germann T C, Han L B 2009 J. Appl. Phys. 106 013502

Google Scholar

Google Scholar

[37] 裴晓阳, 彭辉, 贺红亮, 李平 2015 64 034601

Google Scholar

Google Scholar

Pei X Y, Peng H, He H L, Li P 2015 Acta Phys. Sin. 64 034601

Google Scholar

Google Scholar

-

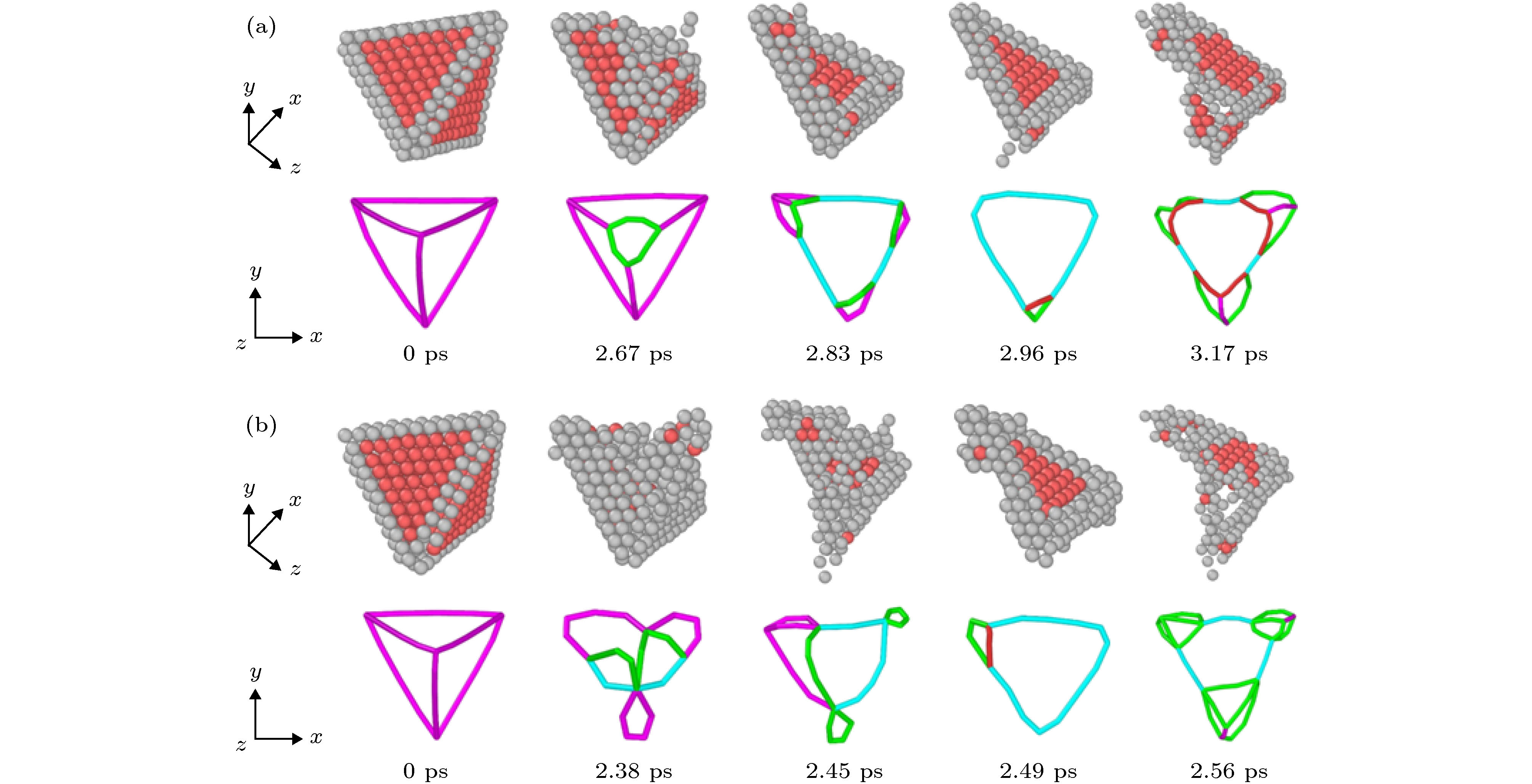

图 4 压缩过程中SFT的演化形态图及对应的位错演化图(其中, 玫红色线是压杆位错, 绿色线是Shockley不完全位错, 浅蓝色线是Frank不完全位错, 红色线是其他位错) (a) Up = 0.5 km/s; (b) Up = 0.75 km/s

Fig. 4. Snapshots of SFT configuration and dislocation evolution at different deformation stages during shock compression: (a) Up = 0.5 km/s; (b) Up = 0.75 km/s. The rose red line represents the stair-rod dislocation, the green line represents the Shockley partial dislocation, the light blue line represents the Frank partial dislocation, and the red line is the undefined dislocation.

-

[1] Zinkle S J, Busby J T 2009 Mater. Today 12 12

[2] Yoshida N, Akashi Y, Kitajima K, Kiritani M 1985 J. Nucl. Mater. 133 405

[3] Zinkle S J, Farrell K 1989 J. Nucl. Mater. 168 262

Google Scholar

Google Scholar

[4] Hashimoto N, Byun T S, Farrell K 2006 J. Nucl. Mater. 351 295

Google Scholar

Google Scholar

[5] Schäublin R, Yao Z, Baluc N, Victoria M 2005 Philos. Mag. 85 769

Google Scholar

Google Scholar

[6] Fabritsiev S A, Pokrovsky A S 2007 J. Nucl. Mater. 367 977

[7] Shao J L, Wang P, He A M, Duan S Q, Qin C S 2014 Modell. Simul. Mater. Sci. Eng. 22 025012

Google Scholar

Google Scholar

[8] Zhou T T, He A M, Wang P, Shao J L 2019 Comput. Mater. Sci. 162 255

Google Scholar

Google Scholar

[9] Lin E Q, Shi H, Niu L 2014 Modell. Simul. Mater. Sci. Eng. 22 035012

Google Scholar

Google Scholar

[10] Qiu T, Xiong Y N, Xiao S F, Li X F, Hu W Y, Deng H Q 2017 Comput. Mater. Sci. 137 273

Google Scholar

Google Scholar

[11] Dai Y, Victoria M 1996 MRS. Symp. Proc. 439 319

[12] Edwards D J, Singh B N, Bilde-Sørensen J B 2005 J. Nucl. Mater. 342 164

Google Scholar

Google Scholar

[13] Lee H J, Wirth B D 2009 Philos. Mag. 89 821

Google Scholar

Google Scholar

[14] Osetsky Y N, Stoller R E, Rodney D, Bacon D J 2005 Mater. Sci. Eng., A 400 370

[15] Osetsky Y N, Rodney D, Bacon D J 2006 Philos. Mag. 86 2295

Google Scholar

Google Scholar

[16] Fan H, El-Awady J A, Wang Q 2015 J. Nucl. Mater. 458 176

Google Scholar

Google Scholar

[17] Fan H, Wang Q, Ouyang C 2015 J. Nucl. Mater. 465 245

Google Scholar

Google Scholar

[18] Martínez E, Uberuaga B P, Beyerlein I J 2016 Phys. Rev. B 93 054105

Google Scholar

Google Scholar

[19] Arsenlis A, Wirth B D, Rhee M 2004 Philos. Mag. 84 3617

Google Scholar

Google Scholar

[20] Krishna S, Zamiri A, De S 2010 Philos. Mag. 90 4013

Google Scholar

Google Scholar

[21] Xiao X Z, Song D K, Xue J M, Chu H J, Duan H L 2015 Int. J. Plast. 65 152

Google Scholar

Google Scholar

[22] Zhang L, Lu C, Tieu K, Shibuta Y 2018 Scr. Mater. 144 78

Google Scholar

Google Scholar

[23] Wu L P, Yu W S, Hu S L, Shen S P 2017 Int. J. Plast. 97 246

Google Scholar

Google Scholar

[24] Wu L P, Yu W S, Hu S L, Shen S P 2018 Comput. Mater. Sci. 155 256

Google Scholar

Google Scholar

[25] Xiao X Z, Song D K, Chu H J, Xue J M, Duan H L 2015 Int. J. Plast. 74 110

Google Scholar

Google Scholar

[26] Salehinia I, Bahr D F 2012 Scr. Mater. 66 339

Google Scholar

Google Scholar

[27] Figueroa E, Tramontina D, Gutierrez G, Bringa E 2015 J. Nucl. Mater. 467 677

Google Scholar

Google Scholar

[28] Salehinia I, Lawrence S K, Bahr D F 2013 Acta Mater. 61 1421

Google Scholar

Google Scholar

[29] Zhang L, Lu C, Tieu K, Su L, Zhao X, Pei L 2017 Mater. Sci. Eng., A 680 27

Google Scholar

Google Scholar

[30] Mishin Y, Mehl M J, Papaconstantopoulos D A, Voter A F, Kress J D 2001 Phys. Rev. B 63 224106

Google Scholar

Google Scholar

[31] Silcox J, Hirsch P B 1959 Philos. Mag. 4 1356

Google Scholar

Google Scholar

[32] Thompson A P, Plimpton S J, Mattson W 2009 J. Chem. Phys. 131 154107

Google Scholar

Google Scholar

[33] Stukowski A 2010 Modell. Simul. Mater. Sci. Eng. 18 015012

[34] Stukowski A 2012 Modell. Simul. Mater. Sci. Eng. 20 045021

Google Scholar

Google Scholar

[35] Stukowski A, Albe K 2010 Modell. Simul. Mater. Sci. Eng. 18 085001

Google Scholar

Google Scholar

[36] Luo S N, Qi A, Germann T C, Han L B 2009 J. Appl. Phys. 106 013502

Google Scholar

Google Scholar

[37] 裴晓阳, 彭辉, 贺红亮, 李平 2015 64 034601

Google Scholar

Google Scholar

Pei X Y, Peng H, He H L, Li P 2015 Acta Phys. Sin. 64 034601

Google Scholar

Google Scholar

计量

- 文章访问数: 16973

- PDF下载量: 225

- 被引次数: 0

下载:

下载: