-

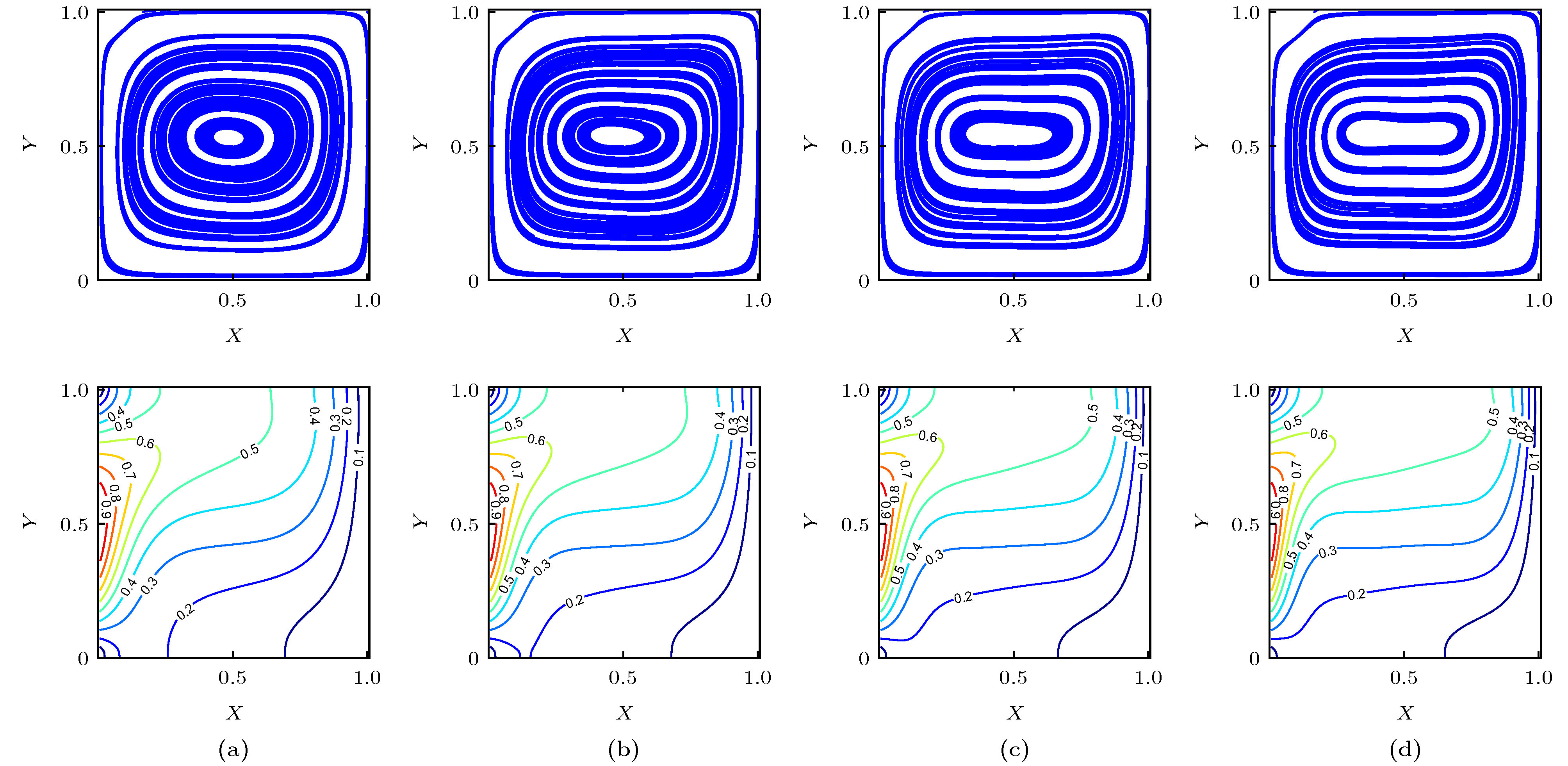

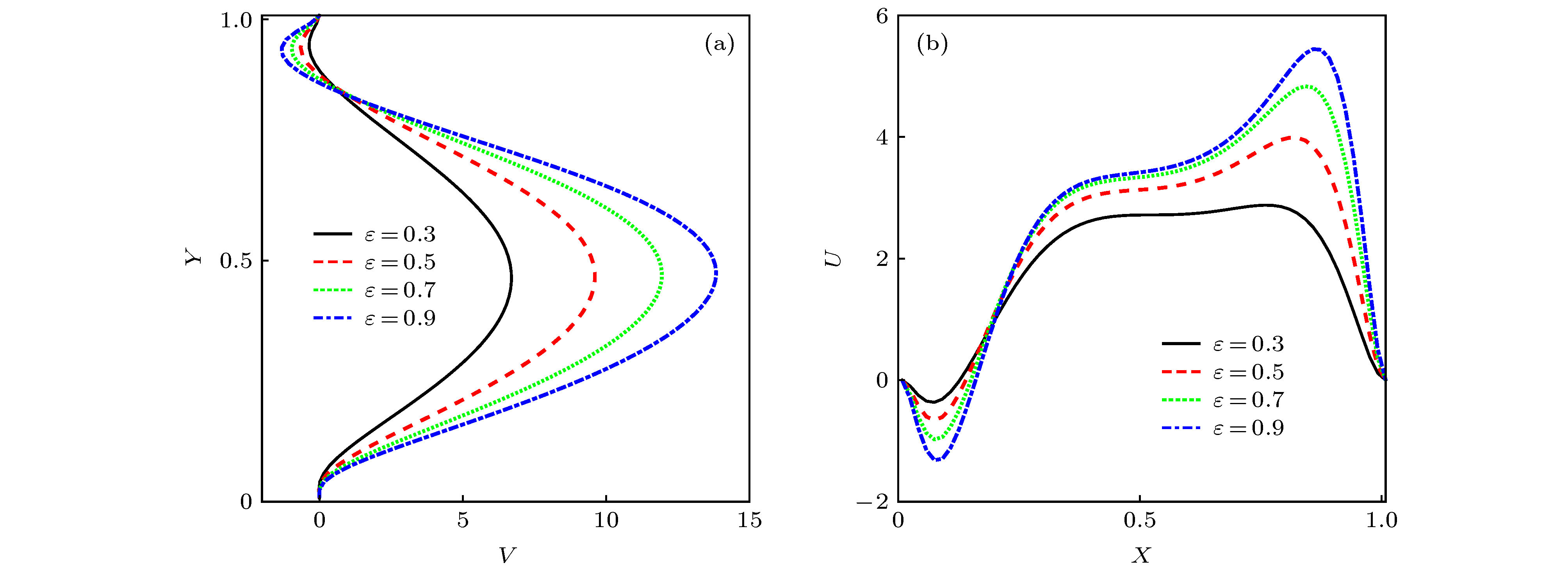

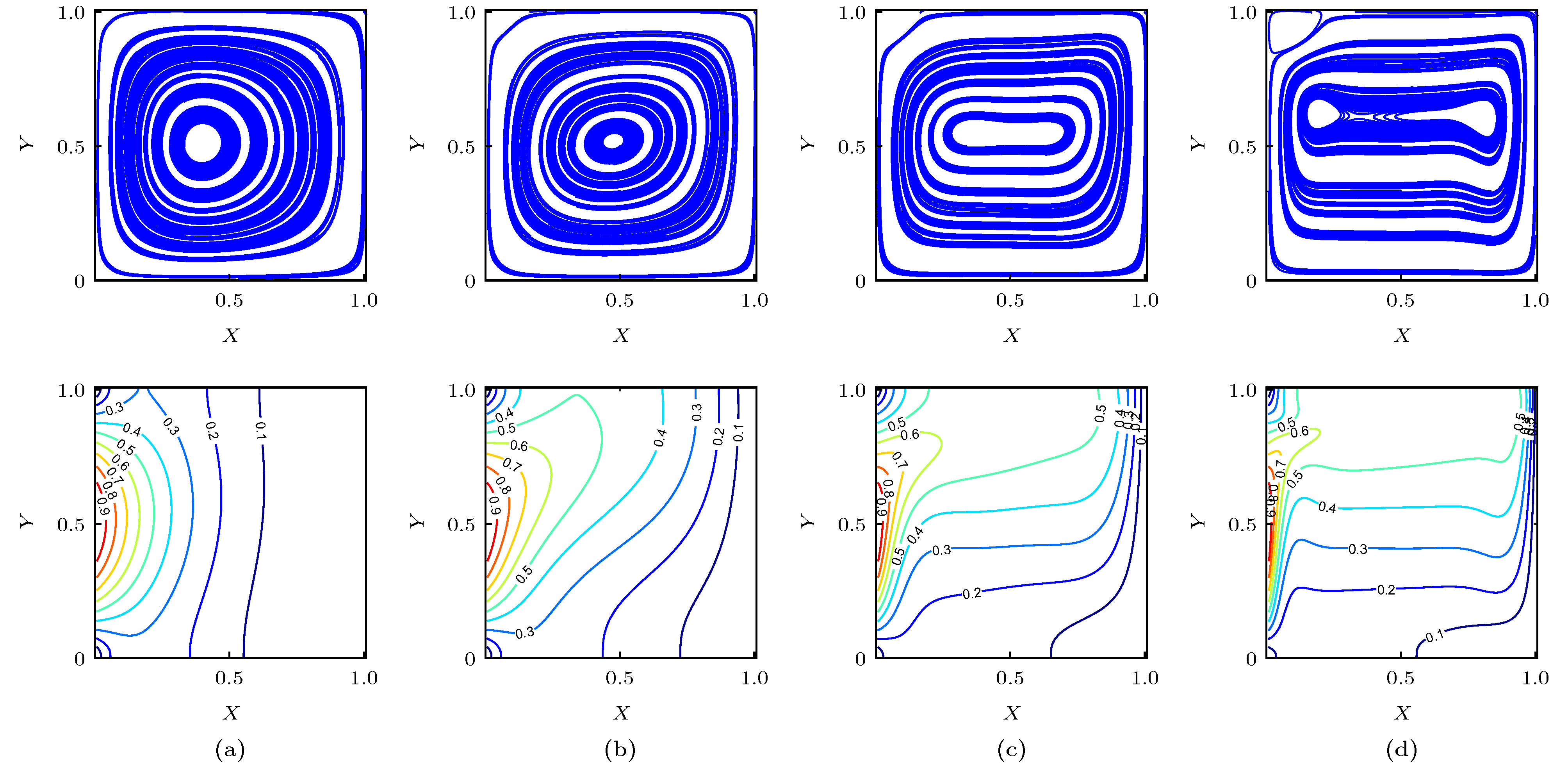

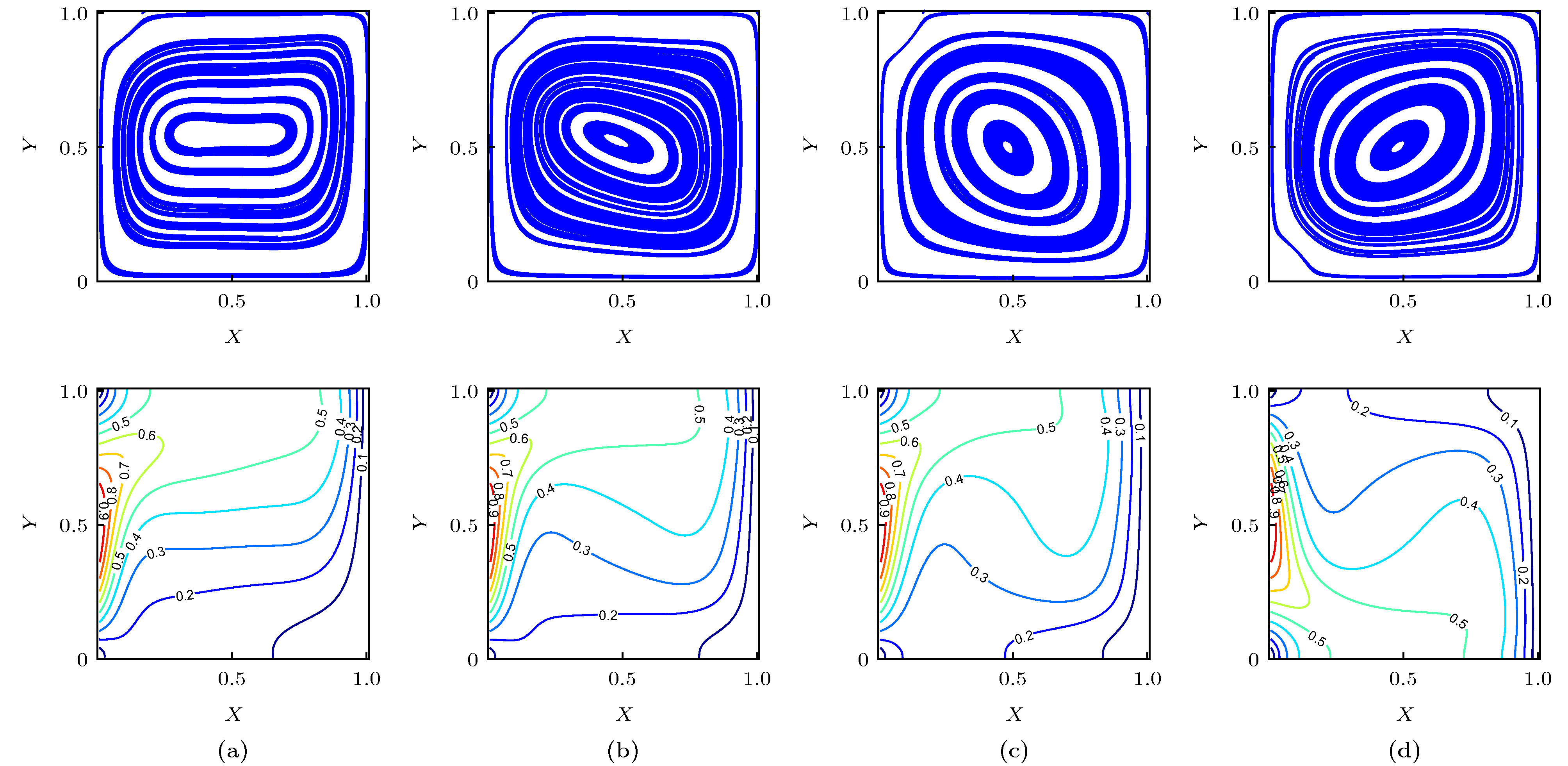

In this work, numerical simulation of nature convection of Al2O3-H2O nanofluid in an inclined square porous enclosure is investigated to analyze the influence of different physical parameters on fluid flow and heat transfer via the lattice Boltzmann method. Due to stable chemical properties and low price in the dispersion system, Al2O3-H2O nanofluid is widely used in the field of industrial heat transfer enhancement, which is the focus of present work. When the nanofluid is transport in a porous media, the Darcy-Brinkman-Forchheimer model is usually used to describe the porous media effects on nanofluid flow. Compared with uniform thermal boundary condition, the natural convection of nanofluids with non-uniform thermal boundary condition has not received much attention. In this paper, the sinusoidal boundary condition is applied to the left side wall to analyze the heat transfer mechanism of Al2O3-H2O nanofluid in the inclined square porous enclosure. The effect of porosity (0.3 ≤

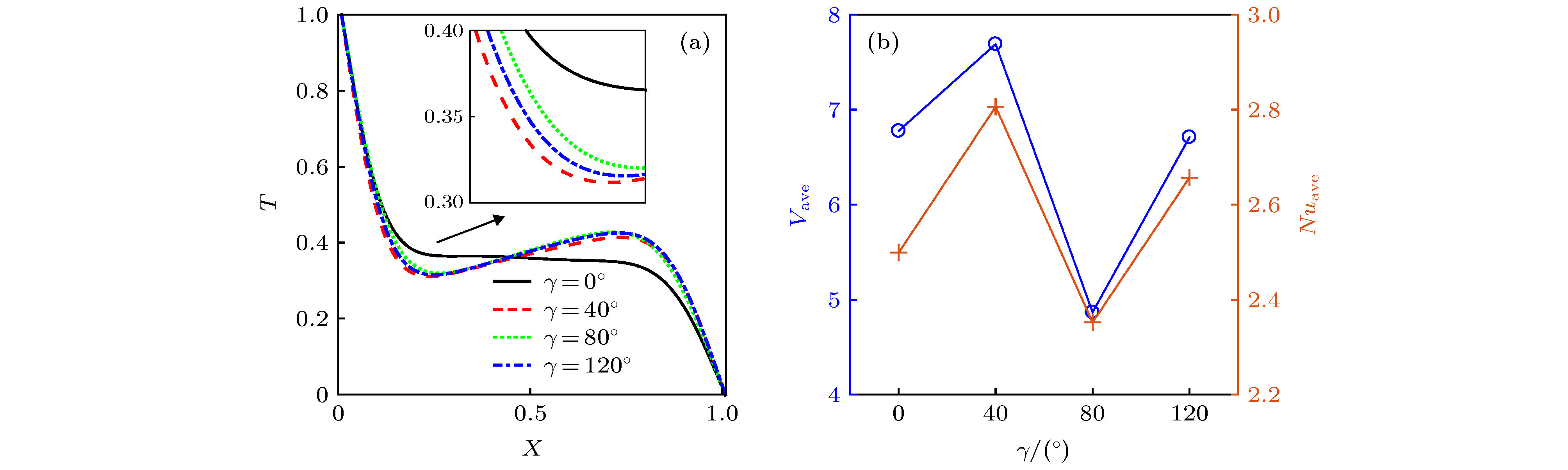

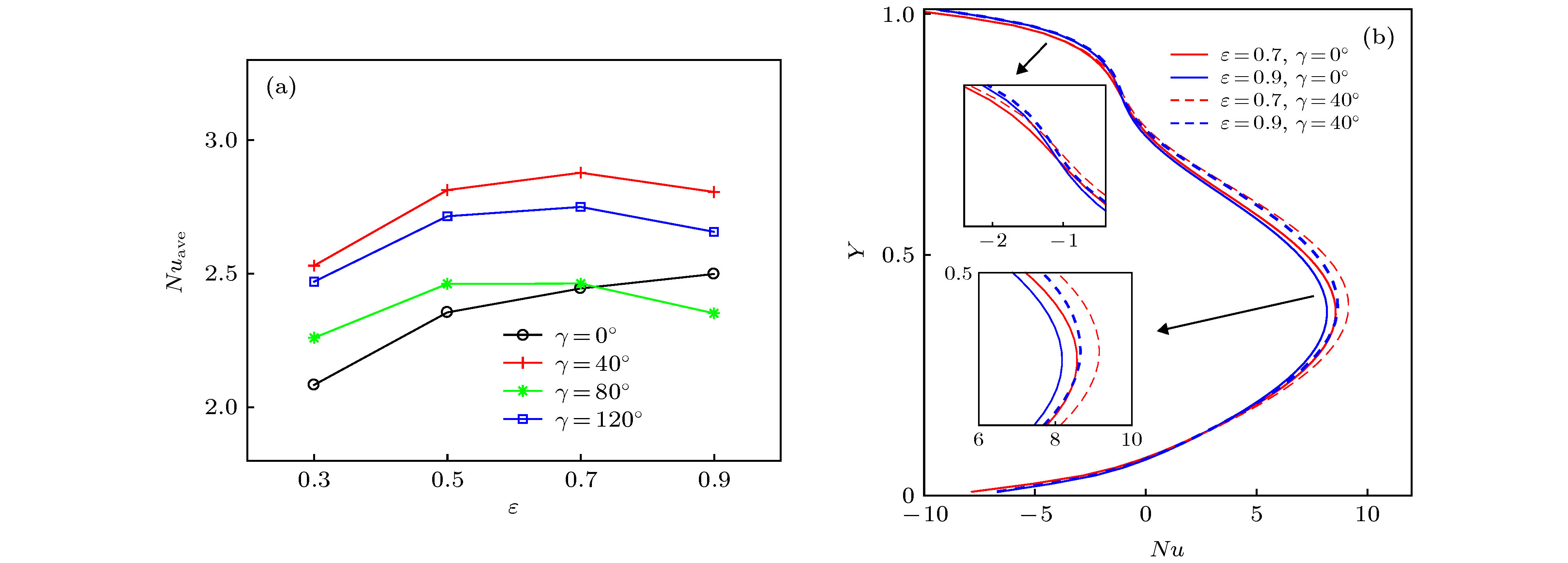

$\epsilon $ ≤ 0.9), Rayleigh number (103 ≤ Ra ≤ 106), volume fraction of nanoparticle (0 ≤ ϕ ≤ 0.04), tilt angle (0° ≤ γ ≤ 120°) on the heat transfer performance are systematically investigated. Numerical results show that the non-uniform boundary condition can affect the heat transfer performance on Al2O3-H2O nanofluid with different physical quantities, which is different from the uniform boundary condition. When γ = 0° and Ra is fixed, the Nuave number (average Nusselt number) at the heated wall increases with porosity. When γ = 40°, 80° or 120°, the Nuave reaches its maximum value at$\epsilon $ = 0.7. In addition, if$\epsilon $ and Ra are fixed, the results show that the heat transfer performance is most efficient at γ = 40° whereas it is weakened at γ = 80°. Moreover, when different inclination angles are applied to the square cavity, the Nuave increases slightly with an augmentation of ϕ. In all, compared with the uniform temperature boundary condition, the effect of volume fraction of nanoparticles on the enhanced heat transfer is not significant, therefore, to improve the heat transfer performance of nanofluids with given ϕ and Ra, it is necessary to take advantage of the improvement of effective thermal conductivity for the nanofluids in porous media and the perturbation influence of inclination angles on the system together with using appropriate porosity and square cavity tilt angle to intervene the flow.-

Keywords:

- nanofluids /

- nature convection /

- non-equilibrium temperature distribution /

- lattice Boltzmann method

[1] Kefayati G 2017 Int. J. Heat Mass Transfer 112 709

Google Scholar

Google Scholar

[2] 李新芳, 朱冬生 2009 低温与超导 37 67

Google Scholar

Google Scholar

Li X F, Zhu D S 2009 Cryogenics & Superconductivity 37 67

Google Scholar

Google Scholar

[3] 张晶, 白国君, 马文强, 王刚 2017 甘肃科学学报 29 110

Zhang J, Bai G J, Ma W Q, Wang G 2017 Journal of Gansu Sciences 29 110

[4] Khanafer K, Vafai K, Lightstone M 2003 Int. J. Heat Mass Transfer 46 3639

Google Scholar

Google Scholar

[5] Hatami M 2017 J. Mol. Liq. 233 1

Google Scholar

Google Scholar

[6] Chen S, Du R 2011 Energy 36 1721

Google Scholar

Google Scholar

[7] Selimefendigil F, Öztop H F 2016 J. Mol. Liq. 216 67

Google Scholar

Google Scholar

[8] Hatami M 2017 Journal of Molecular Liquids 233 1

[9] Jahanshahi M, Hosseinizadeh S F, Alipanah M, Dehghani A, Vakilinejad G R 2010 Int. Commun. Heat Mass Transfer 37 687

Google Scholar

Google Scholar

[10] Mackie C, Desai P, Meyers C 1999 Int. J. Heat Mass Transfer 42 3337

Google Scholar

Google Scholar

[11] Khair K 1985 Int. J. Heat Mass Transfer 28 909

Google Scholar

Google Scholar

[12] Lam P, Prakash K 2014 Int. J. Heat Mass Transfer 69 390

Google Scholar

Google Scholar

[13] Kaluri R, Basak T 2011 Energy 36 5065

Google Scholar

Google Scholar

[14] Alsabery A, Chamkha A, Saleh H, Hashim I 2017 Int. J. Heat Mass Transfer 7 2357

[15] Toosi M H, Siavashi M 2017 J. Mol. Liq. 238 553

Google Scholar

Google Scholar

[16] Wu F, Zhou W, Ma X 2015 Int. J. Heat Mass Transfer 85 756

Google Scholar

Google Scholar

[17] Basak T, Roy S, Paul T, Pop I 2006 Int. J. Heat Mass Transfer 49 1430

Google Scholar

Google Scholar

[18] Ghasemi K, Siavashi M 2017 J. Mol. Liq. 233 415

Google Scholar

Google Scholar

[19] Sivasankaran S, Alsabery A I, Hashim I 2018 Phys. A (Amsterdam, Neth.) 509 275

Google Scholar

Google Scholar

[20] Ho C J, Chen M W, Li Z W 2008 Int. J. Heat Mass Transfer 51 4506

Google Scholar

Google Scholar

[21] Ashorynejad H R, Hoseinpour B 2017 J. Theor. Appl. Mech. 62 86

[22] Nield D A, Bejan A 2006 Convection in Porous Media (Vol. 3) (New York: Springer) pp37–55

[23] Grott M, Knollenberg J, Krause C 2010 J. Geophys. Res.: Planets 115 E11005

Google Scholar

Google Scholar

[24] Reddy K S, Sreedhar D 2016 Int. J. Curr. Eng. Technol. 6 2277

[25] Sheikholeslami M, Gorji-Bandpy M, Domiri Ganji D 2013 Energy 60 501

Google Scholar

Google Scholar

[26] Selimefendigil F, Öztop H 2014 Int. J. Heat Mass Transfer 78 741

Google Scholar

Google Scholar

[27] Seta T, Takegoshi E, Okui K 2006 Math. Comput. Simul. 72 195

Google Scholar

Google Scholar

[28] Mohamad A, Kuzmin A 2010 Int. J. Heat Mass Transfer 53 990

Google Scholar

Google Scholar

[29] Sajjadi H, Delouei A A, Atashafrooz M, Sheikholeslami M 2018 Int. J. Heat Mass Transfer 126 489

Google Scholar

Google Scholar

[30] Sajjadi H, Kefayati G 2015 Heat Transf. Asian Res. 45 795

[31] Javadi K, Kazemi K 2018 Phys. Fluids 30 017104

Google Scholar

Google Scholar

[32] Sadr M, Gorji H 2017 Phys. Fluids 29 122007

Google Scholar

Google Scholar

[33] Davis G D V, Jones I P 1983 Int. J. Numer. Methods Fluids 3 227

Google Scholar

Google Scholar

[34] Nithiarasu P, Seetharamu K N, Sundararajan T 1997 Int. J. Heat Mass Transfer 40 3955

Google Scholar

Google Scholar

[35] Wang J, Lou Q, Xu H, Chen J, Yang M 2018 Int. Commun. Heat Mass Transf. 35 405

[36] Kefayati G H R 2018 Int. J. Heat Mass Transfer 116 762

Google Scholar

Google Scholar

-

表 1 H2O, Al2O3和玻璃纤维的热物理性质

Table 1. Thermophysical properties of water, Al2O3 and glass fibers.

表 2 纳米流体的热物性参数计算公式

Table 2. Calculation formula for thermodynamic properties of nanofluids.

热物性参数 计算表达式 纳米流体粘度 $\mu {}_{nf} = \dfrac{{{\mu _f}}}{{{{\left( {1 - \phi } \right)}^{2.5}}}}$ 纳米流体密度 ${\rho _{nf}} = \left( {1 - \phi } \right){\rho _f} + \phi {\rho _s}$ 纳米流体热容 ${\left( {\rho {C_p}} \right)_{nf}} = \left( {1 - \phi } \right){\left( {\rho {C_p}} \right)_f} + \phi {\left( {\rho {C_p}} \right)_s}$ 纳米流体热扩散系数 ${\alpha _{nf}} = \dfrac{{{k_{nf}}}}{{{{\left( {\rho {C_p}} \right)}_{nf}}}}$ 纳米流体热膨胀系数 ${\left( {\rho \beta } \right)_{nf}} = \left( {1 - \phi } \right){\left( {\rho \beta } \right)_f} + \phi {\left( {\rho \beta } \right)_s}$ 纳米流体导热系数 ${k_{nf}} = \dfrac{{{k_p} + 2{k_f} - 2\left( {{k_f} - {k_p}} \right)\phi }}{{{k_p} + 2{k_f} + 2\left( {{k_f} - {k_p}} \right)\phi }}{k_f}$ 多孔介质有效

导热系数${k_m} = \left( {1 - \epsilon} \right){k_p} + {\epsilon k_{nf}}$ 表 3 不同网格数与文献[33]的Nuave数比较

Table 3. Comparison of Nuave number with literature[33] in different grids number.

不同网格数下的Nuave数 80 × 80 100 × 100 120 × 120 140 × 140 Nuave数 8.528 8.670 8.744 8.785 误差/% 3.39% 1.70% 0.83% 0.36% Ra数 文献[27] 本文结果 误差/% 103 1.116 1.123 0.63 104 2.238 2.266 1.25 105 4.509 4.556 1.04 106 8.817 8.744 0.83 NO. Da数 Ra数 文献[34] 本文结果 误差/% 1 10–2 104 1.530 1.497 2.16 2 10–2 105 3.555 3.441 3.09 3 10–2 5 × 105 5.740 5.694 0.87 -

[1] Kefayati G 2017 Int. J. Heat Mass Transfer 112 709

Google Scholar

Google Scholar

[2] 李新芳, 朱冬生 2009 低温与超导 37 67

Google Scholar

Google Scholar

Li X F, Zhu D S 2009 Cryogenics & Superconductivity 37 67

Google Scholar

Google Scholar

[3] 张晶, 白国君, 马文强, 王刚 2017 甘肃科学学报 29 110

Zhang J, Bai G J, Ma W Q, Wang G 2017 Journal of Gansu Sciences 29 110

[4] Khanafer K, Vafai K, Lightstone M 2003 Int. J. Heat Mass Transfer 46 3639

Google Scholar

Google Scholar

[5] Hatami M 2017 J. Mol. Liq. 233 1

Google Scholar

Google Scholar

[6] Chen S, Du R 2011 Energy 36 1721

Google Scholar

Google Scholar

[7] Selimefendigil F, Öztop H F 2016 J. Mol. Liq. 216 67

Google Scholar

Google Scholar

[8] Hatami M 2017 Journal of Molecular Liquids 233 1

[9] Jahanshahi M, Hosseinizadeh S F, Alipanah M, Dehghani A, Vakilinejad G R 2010 Int. Commun. Heat Mass Transfer 37 687

Google Scholar

Google Scholar

[10] Mackie C, Desai P, Meyers C 1999 Int. J. Heat Mass Transfer 42 3337

Google Scholar

Google Scholar

[11] Khair K 1985 Int. J. Heat Mass Transfer 28 909

Google Scholar

Google Scholar

[12] Lam P, Prakash K 2014 Int. J. Heat Mass Transfer 69 390

Google Scholar

Google Scholar

[13] Kaluri R, Basak T 2011 Energy 36 5065

Google Scholar

Google Scholar

[14] Alsabery A, Chamkha A, Saleh H, Hashim I 2017 Int. J. Heat Mass Transfer 7 2357

[15] Toosi M H, Siavashi M 2017 J. Mol. Liq. 238 553

Google Scholar

Google Scholar

[16] Wu F, Zhou W, Ma X 2015 Int. J. Heat Mass Transfer 85 756

Google Scholar

Google Scholar

[17] Basak T, Roy S, Paul T, Pop I 2006 Int. J. Heat Mass Transfer 49 1430

Google Scholar

Google Scholar

[18] Ghasemi K, Siavashi M 2017 J. Mol. Liq. 233 415

Google Scholar

Google Scholar

[19] Sivasankaran S, Alsabery A I, Hashim I 2018 Phys. A (Amsterdam, Neth.) 509 275

Google Scholar

Google Scholar

[20] Ho C J, Chen M W, Li Z W 2008 Int. J. Heat Mass Transfer 51 4506

Google Scholar

Google Scholar

[21] Ashorynejad H R, Hoseinpour B 2017 J. Theor. Appl. Mech. 62 86

[22] Nield D A, Bejan A 2006 Convection in Porous Media (Vol. 3) (New York: Springer) pp37–55

[23] Grott M, Knollenberg J, Krause C 2010 J. Geophys. Res.: Planets 115 E11005

Google Scholar

Google Scholar

[24] Reddy K S, Sreedhar D 2016 Int. J. Curr. Eng. Technol. 6 2277

[25] Sheikholeslami M, Gorji-Bandpy M, Domiri Ganji D 2013 Energy 60 501

Google Scholar

Google Scholar

[26] Selimefendigil F, Öztop H 2014 Int. J. Heat Mass Transfer 78 741

Google Scholar

Google Scholar

[27] Seta T, Takegoshi E, Okui K 2006 Math. Comput. Simul. 72 195

Google Scholar

Google Scholar

[28] Mohamad A, Kuzmin A 2010 Int. J. Heat Mass Transfer 53 990

Google Scholar

Google Scholar

[29] Sajjadi H, Delouei A A, Atashafrooz M, Sheikholeslami M 2018 Int. J. Heat Mass Transfer 126 489

Google Scholar

Google Scholar

[30] Sajjadi H, Kefayati G 2015 Heat Transf. Asian Res. 45 795

[31] Javadi K, Kazemi K 2018 Phys. Fluids 30 017104

Google Scholar

Google Scholar

[32] Sadr M, Gorji H 2017 Phys. Fluids 29 122007

Google Scholar

Google Scholar

[33] Davis G D V, Jones I P 1983 Int. J. Numer. Methods Fluids 3 227

Google Scholar

Google Scholar

[34] Nithiarasu P, Seetharamu K N, Sundararajan T 1997 Int. J. Heat Mass Transfer 40 3955

Google Scholar

Google Scholar

[35] Wang J, Lou Q, Xu H, Chen J, Yang M 2018 Int. Commun. Heat Mass Transf. 35 405

[36] Kefayati G H R 2018 Int. J. Heat Mass Transfer 116 762

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 13003

- PDF Downloads: 153

- Cited By: 0

DownLoad:

DownLoad: