-

The sluggish diffusion and severe lattice distortion effects in high-entropy alloys (HEAs) theoretically impede the movement of radiation-induced point defects, thereby effectively suppressing the formation of larger defect clusters and ultimately enhancing the radiation resistance of materials. Current research on the radiation resistance of HEAs primarily concentrates on the qualitative analysis of the migration behaviors of radiation-induced defects, while the quantitative research on the energy barriers of the migration behavior of point defects is still limited. As a representative HEA system, FeCoCrNiAl-based alloy exhibits exceptional properties, including enhanced ductility, remarkable shear resistance, high tensile yield strength, and excellent oxidation resistance. In this study, FeCoCrNiAl0.3 alloy is selected as a model material and in-situ observations are conducted by using a 1.25-MV high-voltage electron microscope (HVEM) to systematically investigate the temporal evolution of irradiation-induced defects and precipitates at different temperatures. Based on the statistical data of saturated defect number density and defect growth rates under three irradiation temperatures, two intrinsic parameters of the alloy, i.e. interstitial atom migration energy and vacancy migration energy, are determined to be 1.09 eV and 1.47 eV, respectively. The higher interstitial atomic migration energy may be related to the incorporation of Al that has a smaller threshold energy and exhibits a larger atomic radius difference than the other elements in the alloy. In addition, the morphology and distribution of dislocation loops formed at 723 K and high-energy electron irradiation are characterized in detail, demonstrating the coexistence of perfect dislocation loops and Frank dislocation loops, both of which grow along different crystal planes. No systematic difference in growth process between the two types of loops is observed.

-

Keywords:

- FeCoCrNiAl0.3 high entropy alloy /

- high-energy electron irradiation /

- defect migration energy /

- irradiation induced the defects and precipitation

[1] Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, Chang S Y 2004 Adv. Eng. Mater. 6 299

Google Scholar

Google Scholar

[2] 张勇 2010非晶和高熵合金 (北京: 科学出版社)

Zhang Y 2010 Amorphous and High Entropy Alloys (Beijing: Science Press

[3] 田震, 李聪聪, 吴渊, 吕昭平 2024 材料工程 52 1

Google Scholar

Google Scholar

Tian Z, Li C C, Wu Y, Lü Z P 2024 J. Mater. Eng. 52 1

Google Scholar

Google Scholar

[4] Cheng Z Y, Sun J R, Gao X, Wang Y Y, Cui J H, Wang T, Chang H L 2023 J. Alloy. Compd. 930 166768

Google Scholar

Google Scholar

[5] Zhang Y W, Osetsky Y N, Weber W J 2021 Chem. Rev. 122 789

Google Scholar

Google Scholar

[6] Li D Y, Li C X, Feng T, Zhang Y D, Sha G, Lewandowski J J, Liaw P K, Zhang Y 2017 Acta Mater. 123 285

Google Scholar

Google Scholar

[7] Ma S G, Zhang S F, Qiao J W, Wang Z H, Gao M C, Jiao Z M, Yang H J, Zhang Y 2014 Intermetallics 54 104

Google Scholar

Google Scholar

[8] Li Z, Zhao S, Diao H, Liaw P K, Meyers M A 2017 Sci. Rep. 7 42742

Google Scholar

Google Scholar

[9] Gwalani B, Gorsse S, Choudhuri D, Zheng Y F, Mishra R S, Banerjee R 2019 Scr. Mater. 162 18

Google Scholar

Google Scholar

[10] Chen W Y, Liu X, Chen Y R, Yeh J W, Tseng K K, Natesan K 2018 J. Nucl. Mater. 510 421

Google Scholar

Google Scholar

[11] Chen W Y, Kirk M A, Hashimoti N, Yeh J W, Liu X, Chen Y R 2020 J. Nucl. Mater. 539 152324

Google Scholar

Google Scholar

[12] Diao S Z, Liu Q, Zhang Y, Wan F R, Zhan Q 2024 Mater. Charact. 212 113964.

Google Scholar

Google Scholar

[13] Yang T F, Guo W, Poplawsky J D, Li D Y, Wang L, Li Y, Hu W Y, Crespillo M L, Yan Z F, Zhang Y 2020 Acta Mater. 188 1

Google Scholar

Google Scholar

[14] Kiritani M 1994 J. Nucl. Mater. 216 220

Google Scholar

Google Scholar

[15] Bourret A 1971 Phys. Status Solidi A. 4 813

Google Scholar

Google Scholar

[16] Urban K, Wilkens M 1971 Phys. Status Solidi A. 6 173

Google Scholar

Google Scholar

[17] Liu P P, Jiang S N, Du Y F, Zhan Q, Zhao H F, Han W T, Yi X O, Ohnuki S, Wan F R 2021 Mater. Charact. 174 111014

Google Scholar

Google Scholar

[18] Schäublin R, Henry J, Dai Y 2008 C. R. Phys. 9 389

Google Scholar

Google Scholar

[19] Kiritani M, Yoshida N, Takata H, Maehara Y 1975 J. Phys. Soc. Jpn. 38 1677

Google Scholar

Google Scholar

[20] Kiritani M, Takata H, Moriyama K, Fujita F E 1979 Philos. Mag. A 40 779

Google Scholar

Google Scholar

[21] Kiritani M, Takata H 1978 J. Nucl. Mater. 69 277

Google Scholar

Google Scholar

[22] Liu P P, Bai J W, Ke D, Wan F R, Wang Y B, Wang Y M, Ohnuki S, Zhan Q 2012 J. Nucl. Mater. 423 47

Google Scholar

Google Scholar

[23] Kato T, Takahashi H, Izumiya M 1991 Mater. Trans. 32 921

Google Scholar

Google Scholar

[24] Hayashi T, Fukumoto K, Matsui H 2002 J. Nucl. Mater. 307 951

Google Scholar

Google Scholar

[25] Hashimoto N, Tanimoto J, Kubota T, Kinoshita H, Ohnuki S 2013 J. Nucl. Mater. 442 S796

Google Scholar

Google Scholar

[26] Takeuchi A, Inoue A 2005 Mater. Trans. 46 2817

Google Scholar

Google Scholar

[27] Zhang B Z, Zhang Z, Xun K H, Asta M, Ding J, Ma E 2024 Proc. Nati. Acad. Sci. 121 e2314248121

Google Scholar

Google Scholar

[28] Liu H C, Mitchell T 1982 J. Nucl. Mater. 107 318

Google Scholar

Google Scholar

[29] He M R, Wang S, Jin K, Bei H B, Yasuda K, Matsumura S, Higashida K, Robertson I M 2016 Scr. Mater. 125 5

Google Scholar

Google Scholar

[30] Wang X X, Niu L L, Wang S 2018 J. Nucl. Mater. 501 94

Google Scholar

Google Scholar

[31] Brown L, Spring M, Ipohorski M 1971 Philos. Mag. 24 1495

Google Scholar

Google Scholar

[32] Nakanishi D, Kawabata T, Doihara K, Okita T, Itakua M, Suziki K 2018 Philos. Mag. 98 3034

Google Scholar

Google Scholar

[33] Lu C Y, Niu L L, Chen N J, Jin K, Yang T N, Xiu P Y, Zhang Y W, Gao F, Bei H B, Shi S 2016 Nat. Commun. 7 13564

Google Scholar

Google Scholar

[34] He M R, Wang S, Shi S, Jin K, Bei H B, Yasuda K, Matsumura S, Higashida K, Robertson I M 2017 Acta Mater. 126 182

Google Scholar

Google Scholar

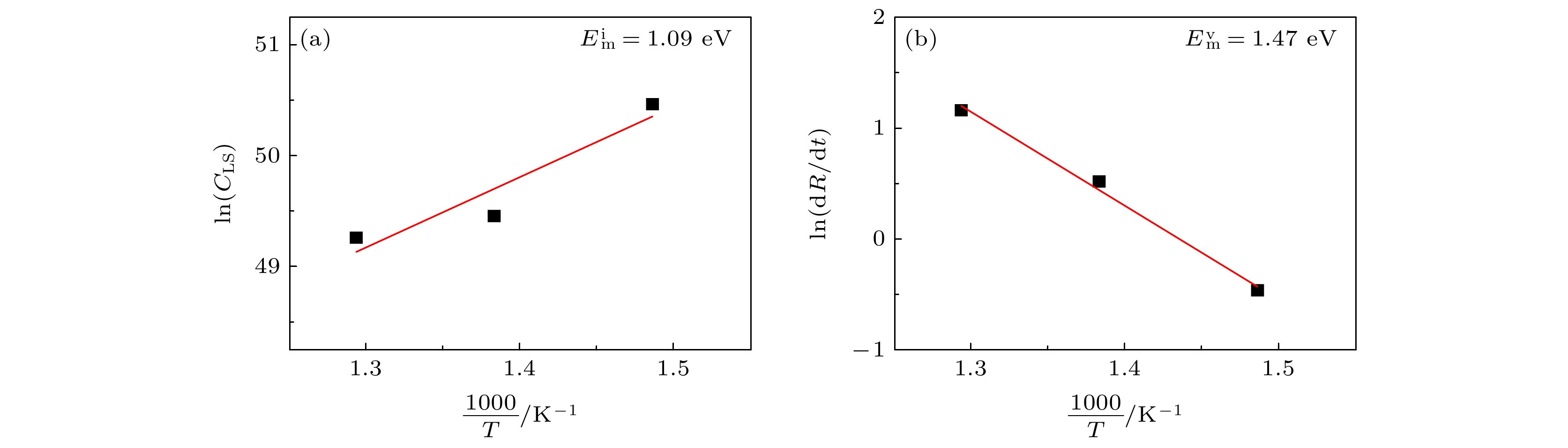

-

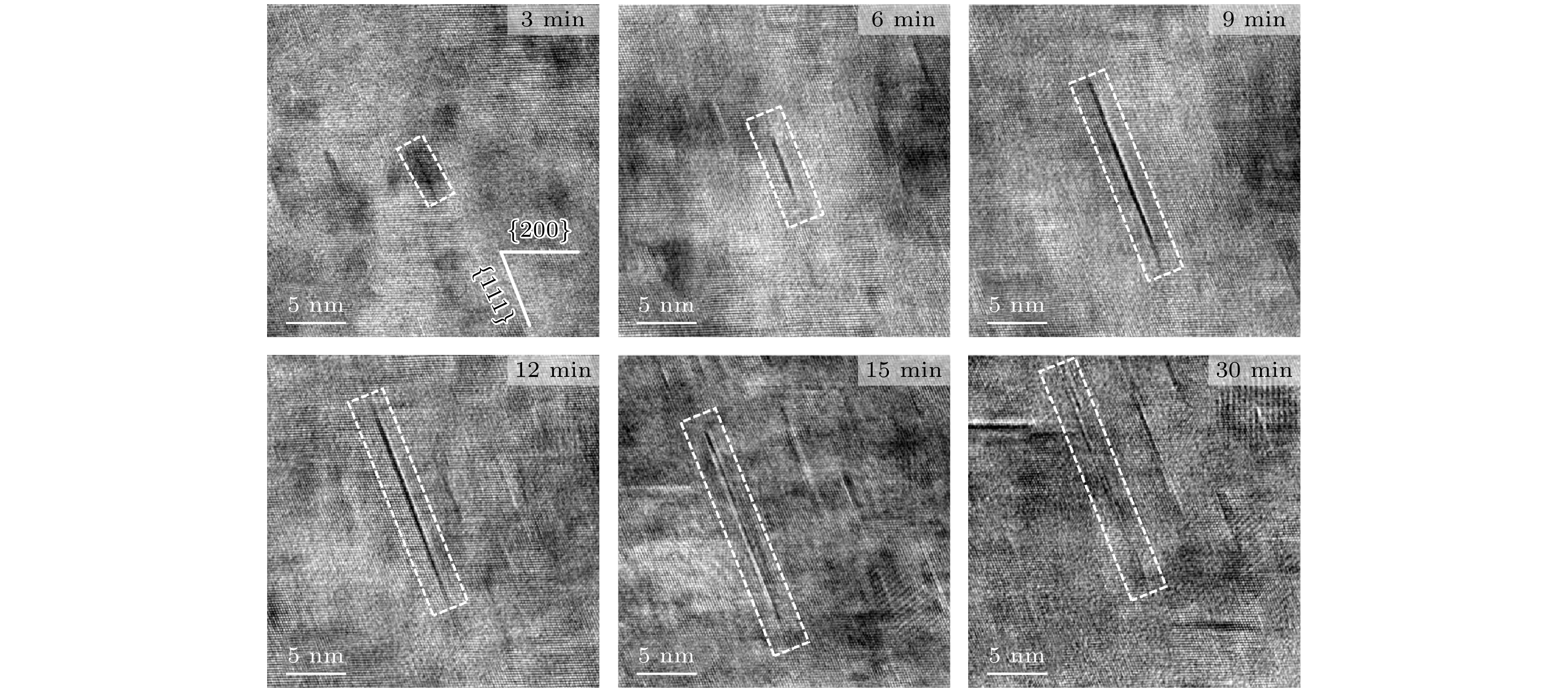

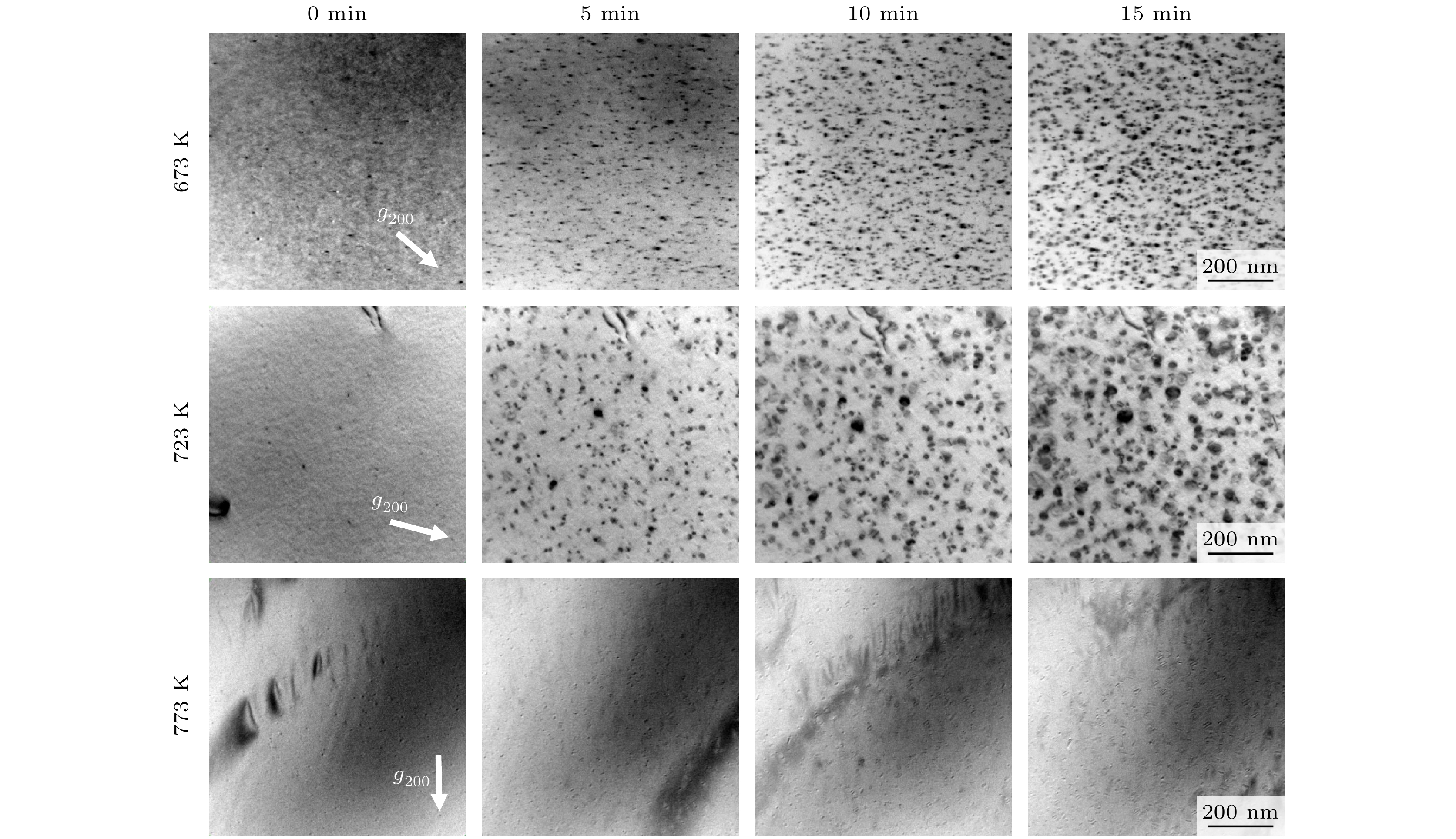

图 1 FeCoCrNiAl0.3高熵合金在不同辐照温度条件下原位电子辐照过程中缺陷的产生与生长, 电子束方向均平行于{011}晶带轴, 并使用g = (200)的“双束”衍射衬度条件进行记录

Figure 1. Production and growth of defects in FeCoCrNiAl0.3 high entropy alloy during in-situ electron irradiation at different irradiation temperature, the electron beam directions are parallel to the axis of the {011} with g = (200).

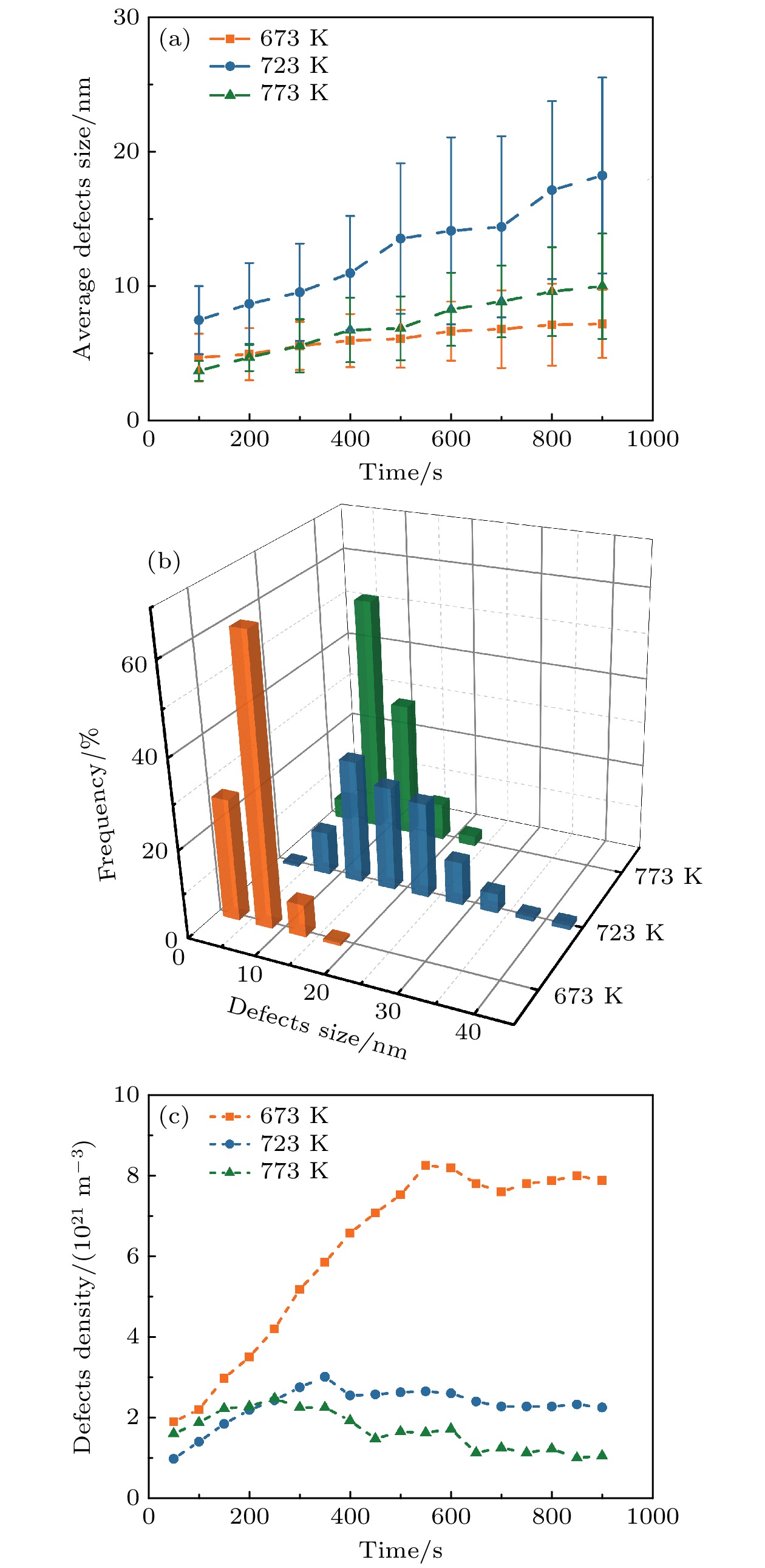

图 2 (a) 辐照诱导缺陷平均尺寸随辐照时间的变化; (b) 经15 min电子辐照后, 3种不同辐照温度下缺陷尺寸分布; (c) 辐照诱导缺陷密度随辐照时间的变化

Figure 2. (a) Variation of average size of irradiation induced defects with irradiation time; (b) the size distribution of defects at three different irradiation temperatures after 15 min electron irradiation; (c) variation of irradiation induced defect density with irradiation time.

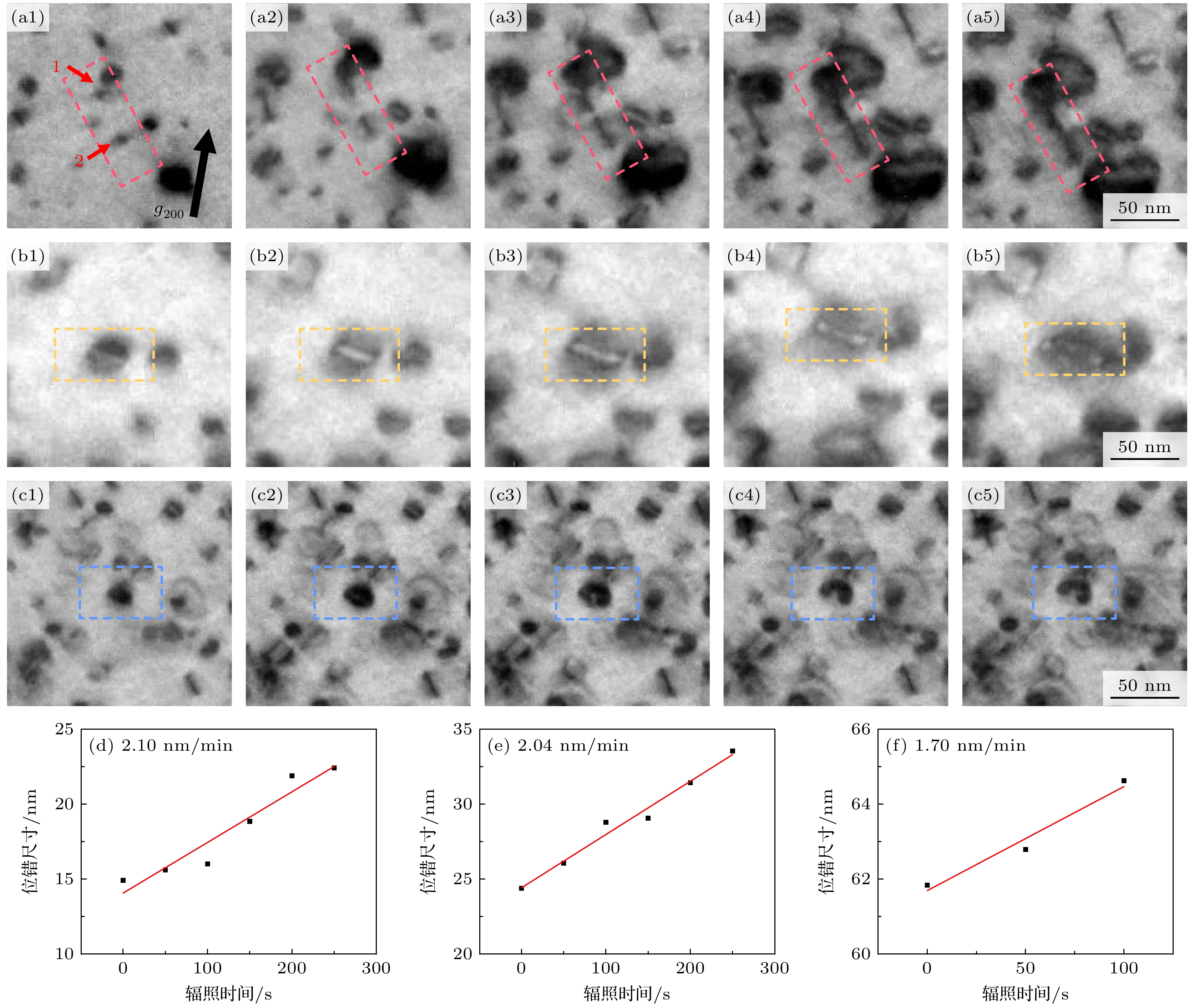

图 3 在723 K温度下, 原位电子辐照过程中具体的位错行为 (a1)—(a5)弗兰克位错环的合并过程; (b1)—(b5)长条状弗兰克位错环的湮灭过程; (c1)—(c5) “马蹄形”缺陷的形成过程; (d), (e)分别为图(a)中1, 2两个位错环在合并过程中尺寸随辐照时间的变化; (f)两位错合并后, 位错的生长行为与尺寸随辐照时间的变化

Figure 3. Specific dislocation behavior during in-situ electron irradiation at 723 K: (a1)–(a5) The merging process of Frank loops; (b1)–(b5) the annihilation process of long Frank loops, (c1)–(c5) the formation process of “horseshoe” defect; (d), (e) the size changes of the two dislocation loops 1 and 2 in panel (a) with irradiation time during the merging process, respectively; (f) the growth behavior and size of two dislocations combined with irradiation time.

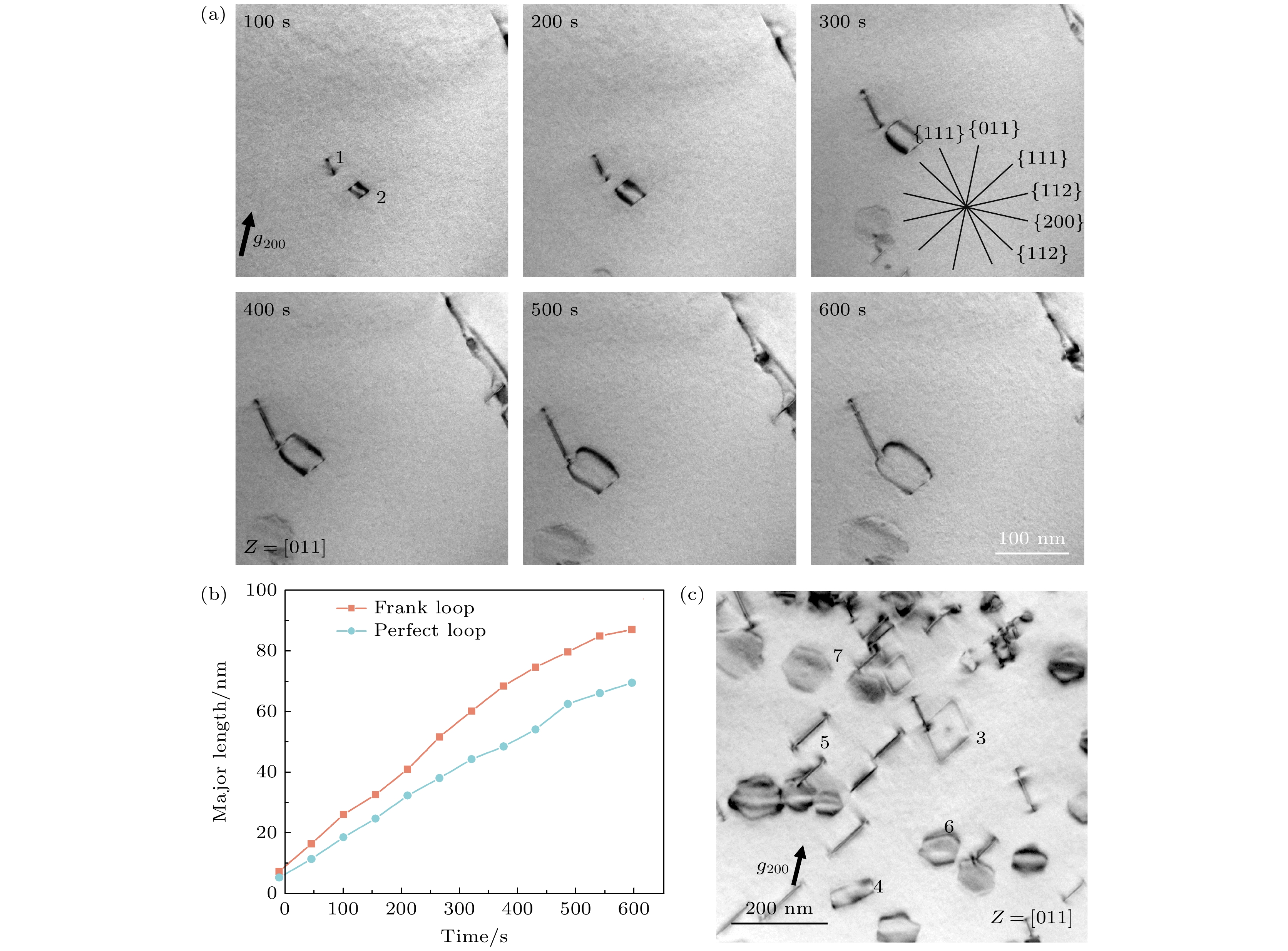

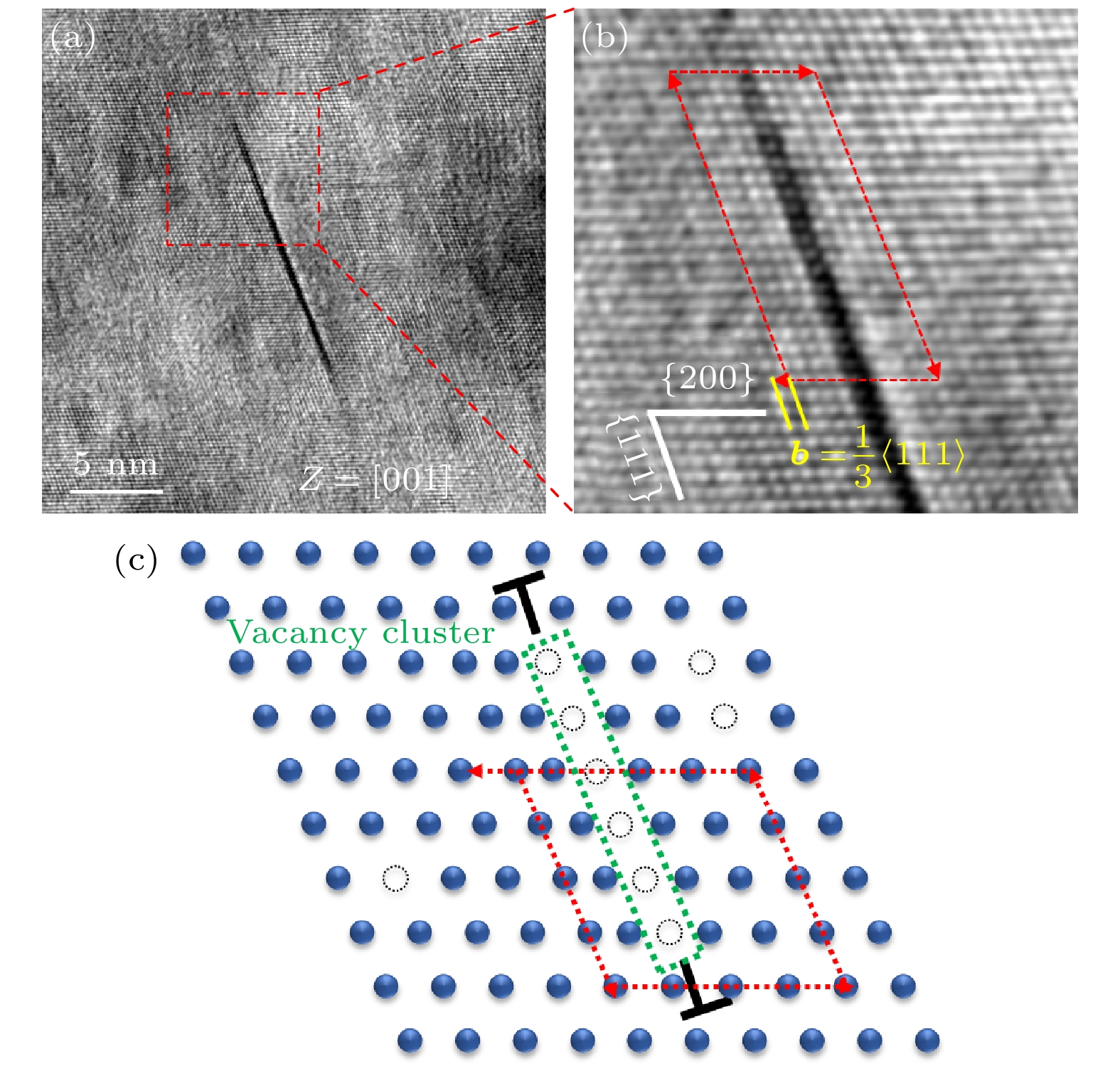

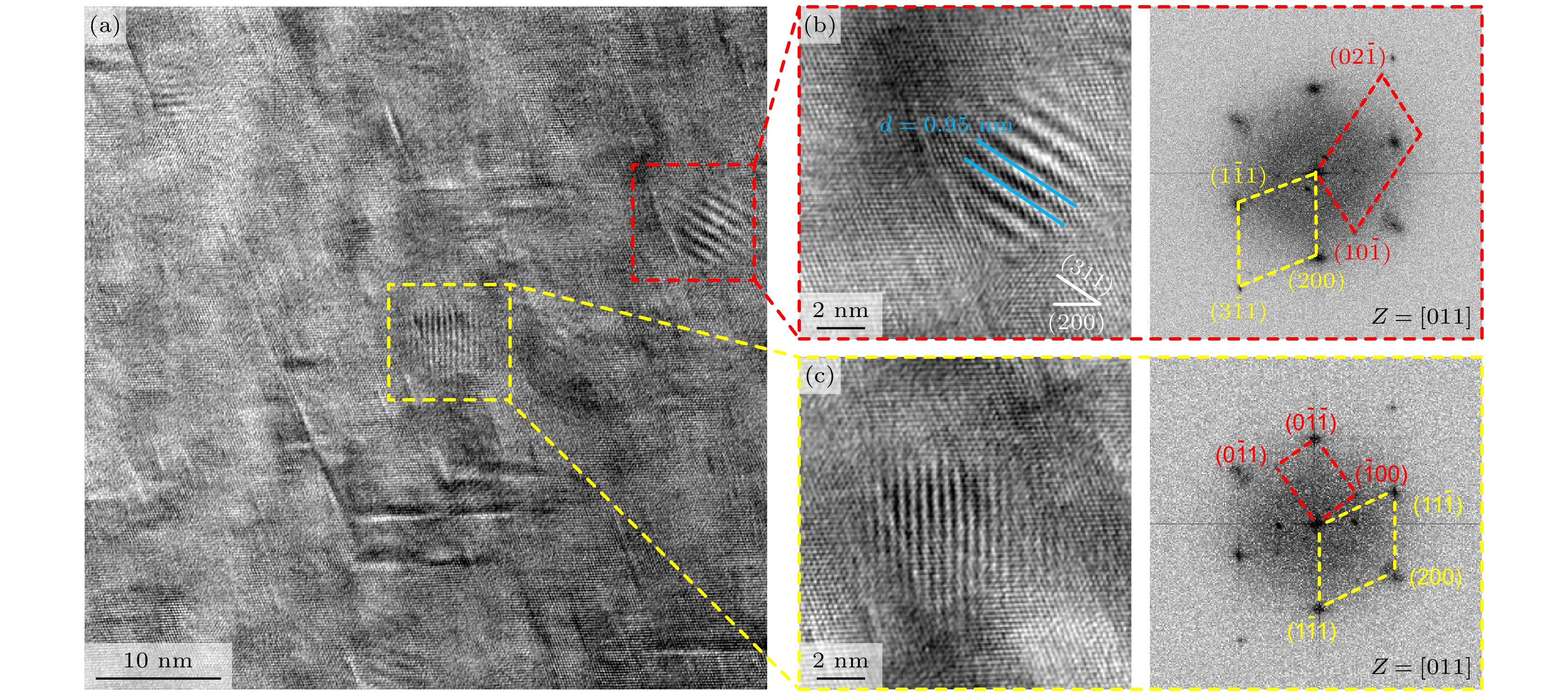

图 5 (a)弗兰克不全位错与全位错形成与生长的过程; (b)沿两个晶面生长的弗兰克位错环与全位错长轴方向的尺寸随辐照时间的变化; (c)不同类型的位错环在基体中的形貌与分布

Figure 5. (a) Production and growth of Frank loops and perfect loops; (b) variation of the size of Frank loop and perfect loop in the long axis with irradiation time; (c) the morphology and distribution of different types of dislocation rings in matrix.

表 1 三种不同温度下经电子辐照诱导缺陷的饱和密度与生长率

Table 1. Saturation density and growth rate of defects induced by electron irradiation at three different temperatures.

温度/K 饱和密度/(1021 m–3) 生长率(nm·min–1) 673 8.25 0.63 723 3.01 1.673 773 2.48 3.228 表 2 部分纯金属与核能系统候选材料的点缺陷迁移能数据

Table 2. Point defect migration energy data of some pure metals and candidate materials for nuclear power system.

材料 空位迁移能

$ {E}_{{\mathrm{m}}}^{{\mathrm{v}}} $/eV间隙原子

迁移能 $ {E}_{{\mathrm{m}}}^{{\mathrm{i}}} $/eVFe 0.7 0.26 Cu 0.3 0.12 Au 0.44 0.19 Al 0.29 0.08 Ni 0.6 0.18 Fe-10Cr 0.66 — F82H 1.2 0.3 V-4Cr-Ti 1.0 0.5 316L 1.07 — FeCoCrNiAl0.3* 1.47* 1.09* 注: *为本文工作 -

[1] Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, Chang S Y 2004 Adv. Eng. Mater. 6 299

Google Scholar

Google Scholar

[2] 张勇 2010非晶和高熵合金 (北京: 科学出版社)

Zhang Y 2010 Amorphous and High Entropy Alloys (Beijing: Science Press

[3] 田震, 李聪聪, 吴渊, 吕昭平 2024 材料工程 52 1

Google Scholar

Google Scholar

Tian Z, Li C C, Wu Y, Lü Z P 2024 J. Mater. Eng. 52 1

Google Scholar

Google Scholar

[4] Cheng Z Y, Sun J R, Gao X, Wang Y Y, Cui J H, Wang T, Chang H L 2023 J. Alloy. Compd. 930 166768

Google Scholar

Google Scholar

[5] Zhang Y W, Osetsky Y N, Weber W J 2021 Chem. Rev. 122 789

Google Scholar

Google Scholar

[6] Li D Y, Li C X, Feng T, Zhang Y D, Sha G, Lewandowski J J, Liaw P K, Zhang Y 2017 Acta Mater. 123 285

Google Scholar

Google Scholar

[7] Ma S G, Zhang S F, Qiao J W, Wang Z H, Gao M C, Jiao Z M, Yang H J, Zhang Y 2014 Intermetallics 54 104

Google Scholar

Google Scholar

[8] Li Z, Zhao S, Diao H, Liaw P K, Meyers M A 2017 Sci. Rep. 7 42742

Google Scholar

Google Scholar

[9] Gwalani B, Gorsse S, Choudhuri D, Zheng Y F, Mishra R S, Banerjee R 2019 Scr. Mater. 162 18

Google Scholar

Google Scholar

[10] Chen W Y, Liu X, Chen Y R, Yeh J W, Tseng K K, Natesan K 2018 J. Nucl. Mater. 510 421

Google Scholar

Google Scholar

[11] Chen W Y, Kirk M A, Hashimoti N, Yeh J W, Liu X, Chen Y R 2020 J. Nucl. Mater. 539 152324

Google Scholar

Google Scholar

[12] Diao S Z, Liu Q, Zhang Y, Wan F R, Zhan Q 2024 Mater. Charact. 212 113964.

Google Scholar

Google Scholar

[13] Yang T F, Guo W, Poplawsky J D, Li D Y, Wang L, Li Y, Hu W Y, Crespillo M L, Yan Z F, Zhang Y 2020 Acta Mater. 188 1

Google Scholar

Google Scholar

[14] Kiritani M 1994 J. Nucl. Mater. 216 220

Google Scholar

Google Scholar

[15] Bourret A 1971 Phys. Status Solidi A. 4 813

Google Scholar

Google Scholar

[16] Urban K, Wilkens M 1971 Phys. Status Solidi A. 6 173

Google Scholar

Google Scholar

[17] Liu P P, Jiang S N, Du Y F, Zhan Q, Zhao H F, Han W T, Yi X O, Ohnuki S, Wan F R 2021 Mater. Charact. 174 111014

Google Scholar

Google Scholar

[18] Schäublin R, Henry J, Dai Y 2008 C. R. Phys. 9 389

Google Scholar

Google Scholar

[19] Kiritani M, Yoshida N, Takata H, Maehara Y 1975 J. Phys. Soc. Jpn. 38 1677

Google Scholar

Google Scholar

[20] Kiritani M, Takata H, Moriyama K, Fujita F E 1979 Philos. Mag. A 40 779

Google Scholar

Google Scholar

[21] Kiritani M, Takata H 1978 J. Nucl. Mater. 69 277

Google Scholar

Google Scholar

[22] Liu P P, Bai J W, Ke D, Wan F R, Wang Y B, Wang Y M, Ohnuki S, Zhan Q 2012 J. Nucl. Mater. 423 47

Google Scholar

Google Scholar

[23] Kato T, Takahashi H, Izumiya M 1991 Mater. Trans. 32 921

Google Scholar

Google Scholar

[24] Hayashi T, Fukumoto K, Matsui H 2002 J. Nucl. Mater. 307 951

Google Scholar

Google Scholar

[25] Hashimoto N, Tanimoto J, Kubota T, Kinoshita H, Ohnuki S 2013 J. Nucl. Mater. 442 S796

Google Scholar

Google Scholar

[26] Takeuchi A, Inoue A 2005 Mater. Trans. 46 2817

Google Scholar

Google Scholar

[27] Zhang B Z, Zhang Z, Xun K H, Asta M, Ding J, Ma E 2024 Proc. Nati. Acad. Sci. 121 e2314248121

Google Scholar

Google Scholar

[28] Liu H C, Mitchell T 1982 J. Nucl. Mater. 107 318

Google Scholar

Google Scholar

[29] He M R, Wang S, Jin K, Bei H B, Yasuda K, Matsumura S, Higashida K, Robertson I M 2016 Scr. Mater. 125 5

Google Scholar

Google Scholar

[30] Wang X X, Niu L L, Wang S 2018 J. Nucl. Mater. 501 94

Google Scholar

Google Scholar

[31] Brown L, Spring M, Ipohorski M 1971 Philos. Mag. 24 1495

Google Scholar

Google Scholar

[32] Nakanishi D, Kawabata T, Doihara K, Okita T, Itakua M, Suziki K 2018 Philos. Mag. 98 3034

Google Scholar

Google Scholar

[33] Lu C Y, Niu L L, Chen N J, Jin K, Yang T N, Xiu P Y, Zhang Y W, Gao F, Bei H B, Shi S 2016 Nat. Commun. 7 13564

Google Scholar

Google Scholar

[34] He M R, Wang S, Shi S, Jin K, Bei H B, Yasuda K, Matsumura S, Higashida K, Robertson I M 2017 Acta Mater. 126 182

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 1218

- PDF Downloads: 46

- Cited By: 0

DownLoad:

DownLoad: