-

High-energy particles’ radiation produces a large number of radiation defects in material, such as interstitial atoms, vacancies, dislocation loops, voids and helium bubbles. The formation and evolution of massive radiation defects cause the instability of microstructure in metal, which further degrades its mechanical performance. Interface engineering is an effective method to tune the radiation resistance of metal and alloy. By introducing a large number of grain boundaries, phase interfaces, free surfaces, etc., the recombination probability of radiation-induced vacancies and interstitial atoms increases, thereby reducing the accumulation of radiation defects, improving the structural stability of the metal and eliminating the harmful effects of radiation. In this paper, we briefly review the recent progress of the mechanisms of interactions between several typical interfaces and various types of irradiation defects. The influence of interface structure, irradiation condition and defect character on their interaction behavior are reviewed and discussed. We also propose some critical questions about the radiation damage to material which remain to be understood. It is necessary to combine multidisciplinary techniques, knowledge and theories in order to fully understand the mechanism of radiation damage and design the advanced radiation-tolerant materials.

-

Keywords:

- interface /

- point defect /

- dislocation /

- helium bubble

[1] Zinkle S J, Was G S 2013 Acta Mater. 61 735

Google Scholar

Google Scholar

[2] Zinkle S, Sindelar R 1988 J. Nucl. Mater. 155 1196

[3] Kiritani M 2000 J. Nucl. Mater. 276 41

Google Scholar

Google Scholar

[4] Griffiths M 1988 J. Nucl. Mater. 159 190

Google Scholar

Google Scholar

[5] Silcox J, Hirsch P B 1959 Philos. Mag. 4 72

Google Scholar

Google Scholar

[6] Kadoyoshi T, Kaburaki H, Shimizu F, Kimizuka H, Jitsukawa S, Li J 2007 Acta Mater. 55 3073

Google Scholar

Google Scholar

[7] Wirth B D, Bulatov V, Diaz de la Rubia T 2000 J. Nucl. Mater. 283 773

[8] Mansur L K 1978 Nucl. Technol. 40 5

Google Scholar

Google Scholar

[9] Stubbins J, Garner F 1992 J. Nucl. Mater. 191 1295

[10] Han W Z, Fu E, Demkowicz M J, Wang Y, Misra A 2013 J. Mater. Res. 28 2763

Google Scholar

Google Scholar

[11] Yu K Y, Liu Y, Sun C, Wang H, Shao L, Fu E G, Zhang X 2012 J. Nucl. Mater. 425 140

Google Scholar

Google Scholar

[12] Mazey D J, Evans J H 1986 J. Nucl. Mater. 138 16

Google Scholar

Google Scholar

[13] Holt R A, Ibtahim E F 1979 Acta Metall. 27 1319

Google Scholar

Google Scholar

[14] Fidleris V 1978 Atom. Energy Rev. 13 51

[15] Carpenter G J C, Zee R H, Rogerson A 1988 J. Nucl. Mater. 159 86

Google Scholar

Google Scholar

[16] Hu X X, Koyanagi T, Fukuda M, Kumar N A P K, Snead L L, Wirth B D, Katoh Y 2016 J. Nucl. Mater. 480 235

Google Scholar

Google Scholar

[17] Pokor C, Brechet Y, Dubuisson P, Massoud J P, Avertye X 2004 J. Nucl. Mater. 326 30

[18] Odette G R, Lucas G E 1998 Radiat. Eff. Defects Solids 44 189

[19] Odette G R, Lucas G E 2001 JOM 53 18

[20] Zinkle S J, Busby J T 2009 Mater. Today 12 12

[21] Lu L, Shen Y F, Chen X H, Qian L H, Lu K 2004 Science 304 422

Google Scholar

Google Scholar

[22] Han W Z, Demkowicz M J, Mara N A, Fu E, Sinha S, Rollett A D, Wang Y Q, Carpenter J S, Beyerlein I J, Misra A 2013 Adv. Mater. 25 6975

Google Scholar

Google Scholar

[23] Han W Z, Demkowicz M J, Fu E G, Wang Y Q, Misra A 2012 Acta Mater. 60 6341

Google Scholar

Google Scholar

[24] Hsiung L L, Fluss M J, Tumey S J, Choi B W, Serruys Y, Willaime F, Kimura A 2010 Phys. Rev. B 82 184103

Google Scholar

Google Scholar

[25] Hsiung L, Fluss M, Tumey S, Kuntz J, El-Dasher B, Wall M, Choi B, Kimura A, Willaime F, Serruys Y 2011 J. Nucl. Mater. 409 72

Google Scholar

Google Scholar

[26] Han W Z, Mara N A, Wang Y Q, Misra A, Demkowicz M J 2014 J. Nucl. Mater. 452 57

Google Scholar

Google Scholar

[27] Fu E G, Caro M, Zepeda-Ruiz L A, Wang Y Q, Baldwin K, Bringa E, Nastasi M, Caro A 2012 Appl. Phys. Lett. 101 191607

Google Scholar

Google Scholar

[28] Bringa E M, Monk J D, Caro A, Misra A, Zepeda-Ruiz L, Duchaineau M, Abraham F, Nastasi M, Picraux S T, Wang Y Q, Farkas D 2012 Nano Lett. 7 3351

[29] Bai X M, Voter A F, Hoagland R G, Nastasi M, Uberuaga B P 2010 Science 327 1631

Google Scholar

Google Scholar

[30] Chen D, Wang J, Chen T, Shao L 2013 Sci. Rep. 3 1450

Google Scholar

Google Scholar

[31] Sun C, Zheng S, Wei C C, Wu Y, Shao L, Yang Y, Hartwig K T, Maloy S A, Zinkle S J, Allen T R, Wang H, Zhang X 2015 Sci. Rep. 5 7801

Google Scholar

Google Scholar

[32] Zinkle S J, Farrell K 1989 J. Nucl. Mater. 168 262

Google Scholar

Google Scholar

[33] Siegel R W, Chang S M, Balluffi R W 1980 Acta Metall. 28 249

Google Scholar

Google Scholar

[34] Klueh R L, Nelson A T 2007 J. Nucl. Mater. 371 37

Google Scholar

Google Scholar

[35] Demkowicz M J, Misra A, Caro A 2012 Curr. Opin. Solid State Mater. Sci. 16 101

Google Scholar

Google Scholar

[36] Zhang X, Fu E G, Li N, Misra A, Wang Y Q, Shao L, Wang H 2012 J. Eng. Mater. Technol. 134 041010

Google Scholar

Google Scholar

[37] Lu C Y, Zheng Lyu, Li Y P, Liu C M 2014 J. Notheastern U. (Nat. Sci. Ed)

35 1133 [38] Beyerlein I J, Demkowicz M J, Misra A, Uberuaga B P 2015 Prog. Mater. Sci. 74 125

Google Scholar

Google Scholar

[39] Demkowicz M J, Hoagland R G, Hirth J P 2008 Phys. Rev. Lett. 100 136102

Google Scholar

Google Scholar

[40] Tschopp M A, Mcdowell D L 2007 Philos. Mag. 87 3147

Google Scholar

Google Scholar

[41] Wang J, Beyerlein I J, Mara N A, Bhattacharyya D 2011 Scr. Mater. 64 1083

Google Scholar

Google Scholar

[42] Wang M, Beyerlein I J, Zhang J, Han W Z 2018 Acta Mater. 160 211

Google Scholar

Google Scholar

[43] Han W Z, Carpenter J S, Wang J, Beyerlein I J, Mara N A 2012 Appl. Phys. Lett. 100 011911

Google Scholar

Google Scholar

[44] Demkowicz M J, Anderoglu O, Zhang X, Misra A 2011 J. Mater. Res. 26 1666

Google Scholar

Google Scholar

[45] Barnes R S, Redding G B, Cottrell A H 1958 Philos. Mag. 3 97

Google Scholar

Google Scholar

[46] Uberuaga B P, Choudhury S, Caro A 2015 J. Nucl. Mater. 462 402

Google Scholar

Google Scholar

[47] Embury J D, Nicholson R B 1965 Acta Metall. 13 403

Google Scholar

Google Scholar

[48] Mao S, Shu S, Zhou J, Averback R S, Dillon S J 2015 Acta Mater. 82 328

Google Scholar

Google Scholar

[49] Mitchell T E, Lu Y C, Griffin A J, Nastasi M, Kung H 1997 J. Am. Ceram. Soc. 80 1673

[50] Fu E G, Li N, Misra A, Hoagland R G, Wang H, Zhang X 2008 Mater. Sci. Eng. A 493 283

Google Scholar

Google Scholar

[51] Misra A, Verdier M, Lu Y C, Kung H, Mitchell T E, Nastasi M 1998 Scr. Mater. 39 555

Google Scholar

Google Scholar

[52] Gao F, Chen D, Hu W, Weber W J 2010 Phys. Rev. B 81 184101

Google Scholar

Google Scholar

[53] Balluffi R W 1978 J. Nucl. Mater. 69-70 9

[54] Bai X M, Uberuaga B P 2013 JOM 65 360

Google Scholar

Google Scholar

[55] Bai X M, Vernon L J, Hoagland R G, Voter A F, Nastasi M, Uberuaga B P 2012 Phys. Rev. B 85 214103

Google Scholar

Google Scholar

[56] Borovikov V, Tang X Z, Perez D, Bai X M, Uberuaga B P, Voter A F 2013 Nucl. Fusion 53 063001

Google Scholar

Google Scholar

[57] Singh B N, Leffers T 1974 Scr. Metall. Mater. 8 1974

[58] Liu X Y, Uberuaga B P, Demkowicz M J, Germann T C, Misra A, Nastasi M 2012 Phys. Rev. B 85 012103

[59] Zhang L, Lu C, Tieu K, Shibuta Y 2018 Scripta Mater. 144 78

Google Scholar

Google Scholar

[60] Xu J, Liu J B, Li S N, Liu B X, Jiang Y 2016 Phys. Chem. Phys. 18 17930

Google Scholar

Google Scholar

[61] Demkowicz M J, Thilly L 2011 Acta Mater. 59 7744

Google Scholar

Google Scholar

[62] Uberuaga B P, Bai X M, Dholabhai P P, Moore N, Duffy D M 2013 J. Phys. Condens. Matter 25 355001

Google Scholar

Google Scholar

[63] Uberuaga B P, Vernon L J, Martinez E, Voter A F 2015 Sci. Rep. 5 09095

Google Scholar

Google Scholar

[64] Demkowicz M J, Hoagland R G 2009 Intern. J. Appl. Mechan. 1 421

Google Scholar

Google Scholar

[65] Nomura M, Adams J B 1995 J. Mater. Res. 10 2916

Google Scholar

Google Scholar

[66] Zheng S, Shao S, Zhang J, Wang Y Q, Demkowicz M J, Beyerlein I J, Mara N A 2015 Sci. Rep. 5 15428

Google Scholar

Google Scholar

[67] Lao Y X, Hu S L, Deng Y, Wang F, Du H, Zhang H B, Wang Y 2016 Sci. Rep. 7 40044

[68] Zinkle S J, Seitzman L E, Wolfer W G I 1987 Philos. Mag. A 55 111

Google Scholar

Google Scholar

[69] Kiener D, Hosemann P, Maloy S A, Minor A M 2011 Nat. Mater. 10 608

Google Scholar

Google Scholar

[70] Niewczas M, Hoagland R G 2009 Philos. Mag. 89 727

Google Scholar

Google Scholar

[71] Yu K Y, Bufford D, Sun C, Liu Y, Wang H, Kirk M A, Li M, Zhang X 2013 Nat. Commun. 4 1377

Google Scholar

Google Scholar

[72] Chen Y, Li J, Yu K Y, Wang H, Kirk M A, Li M, Zhang X 2016 Acta Mater. 111 148

Google Scholar

Google Scholar

[73] Wang J, Li N, Anderoglu O, Zhang X, Misra A, Huang J Y, Hirth J P 2010 Acta Mater. 58 2262

Google Scholar

Google Scholar

[74] Wang J, Li N, Misra A 2013 Philos. Mag. 93 315

Google Scholar

Google Scholar

[75] Wang J, Anderoglu O, Hirth J P 2009 Appl. Phys. Lett. 95 021908

Google Scholar

Google Scholar

[76] Li J, Yu K Y, Chen Y, Song M, Wang H, Kirk M A, Li M, Zhang X 2015 Nano Lett. 15 2922

Google Scholar

Google Scholar

[77] Sun C, Song M, Yu K Y, Kirk M, Li M, Wang H, Zhang X 2013 Metall. Mater. Trans. A 44 1966

Google Scholar

Google Scholar

[78] Chen Y, Zhang X, Wang J 2016 JOM 68 235

Google Scholar

Google Scholar

[79] Sun C, Bufford D, Chen Y, Kirk M A, Wang Y Q, Li M, Wang H, Maloy S A, Zhang X 2014 Sci. Rep. 4 3737

[80] Thorsen P A, Bilde-Sørensen J B, Singh B N 2004 Scr. Mater. 51 557

Google Scholar

Google Scholar

[81] Zhang L, Fu C C, Lu G H 2013 Phys. Rev. B 87 134107

Google Scholar

Google Scholar

[82] Ding M S, Du J P, Wan L, Ogata S, Tian L, Ma E, Han W Z, Li J, Shan Z W 2016 Nano Lett. 16 4118

Google Scholar

Google Scholar

[83] Ding M S, Tian L, Han W Z, Li J, Ma E, Shan Z W 2016 Phys. Rev. Lett. 117 215501

Google Scholar

Google Scholar

[84] Han W Z, Ding M S, Shan Z W 2018 Scr. Mater. 147 1

Google Scholar

Google Scholar

[85] Grimes R W, Kinungs R J M, Edwards L 2008 Nat. Mater. 7 683

Google Scholar

Google Scholar

[86] Hochbauer T, Misra A, Hattar K, Hoagland R G 2005 J. Appl. Phys. 98 123516

Google Scholar

Google Scholar

[87] Zhang X, Li N, Anderoglu O, Wang H, Swadener J G, Hochbauer T 2007 Nucl. Instrum. Methods Phys. Res. Sect. B 261 1129

Google Scholar

Google Scholar

[88] Kashinath A, Misra A, Demkowicz M J 2013 Phys. Rev. Lett. 110 086101

Google Scholar

Google Scholar

[89] Demkowicz M J, Bhattacharyya D, Usov I, Wang Y Q, Nastasi M, Misra A 2010 Appl. Phys. Lett. 97 161903

Google Scholar

Google Scholar

[90] Di Z F, Bai X M, Wei Q M, Won J, Hoagland R G, Wang Y Q, Misra A, Uberuaga B P, Nastasi M 2011 Phys. Rev. B 84 052101

[91] Lane P L, Goodhew P J 1983 Philos. Mag. A 48 965

Google Scholar

Google Scholar

[92] Kashinath A, Demkowicz M J 2011 Model Simul. Mater. Sci. Eng. 19 035007

Google Scholar

Google Scholar

[93] Singh B N, Leffers T, Green W V, Victoria M 1984 J. Nucl. Mater. 125 287

Google Scholar

Google Scholar

[94] Bollmann W 1974 Phys. Status Solidi A 21 543

Google Scholar

Google Scholar

[95] Bollmann W 1970 The Meaning of Dislocations in Crystalline Interfaces Washington, DC, USA, April 21-25, 1971 p465.

[96] Chen D, Li N, Yuryev D, Baldwin J K, Wang Y Q, Demkowicz M J 2017 Sci. Adv. 3 eaao2710

Google Scholar

Google Scholar

-

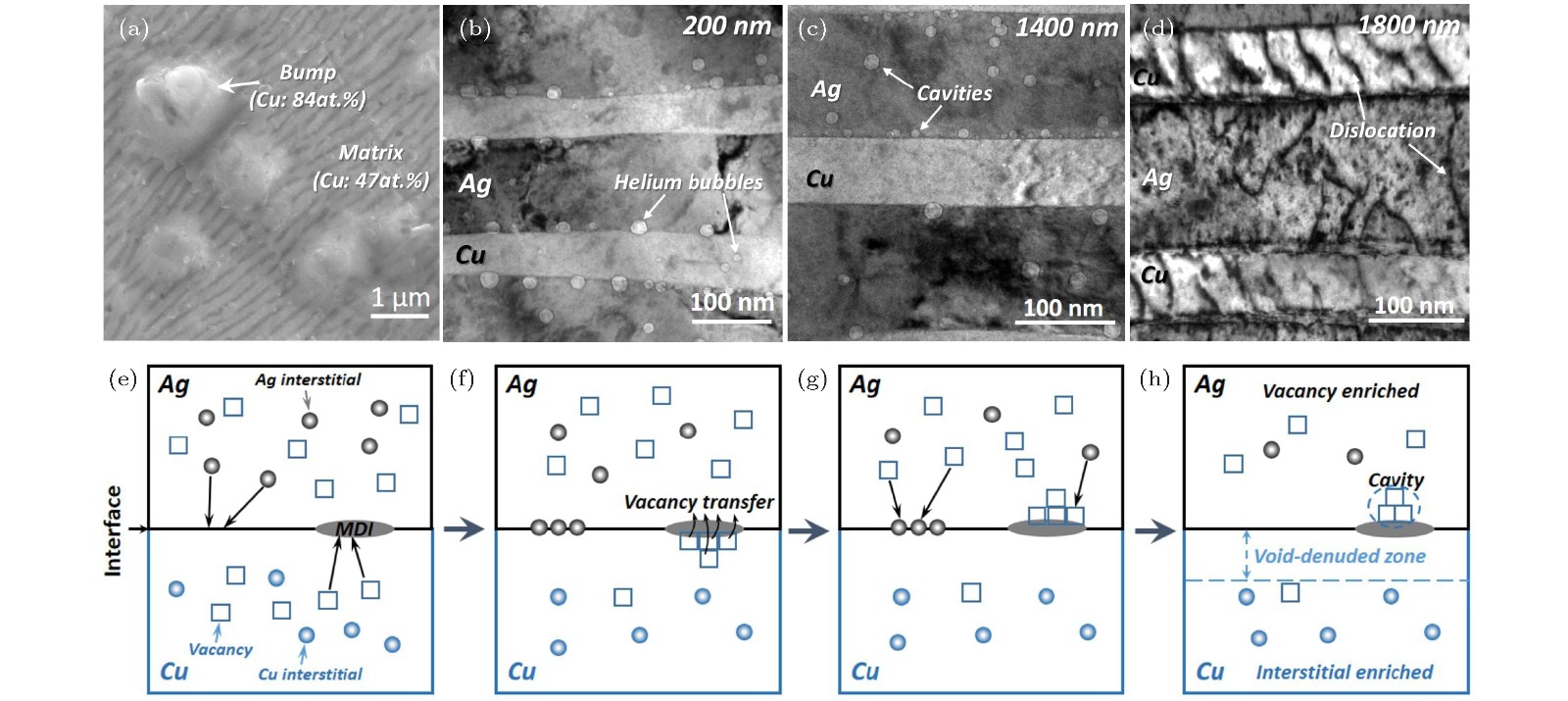

图 1 金属材料中的几种典型的界面结构 (a)经过200 keV, 剂量为2 × 1017 ions cm–2的氦离子在450 ℃辐照后的铜中的晶界; (b)经24.18 MeV 8价铁离子和1.7 MeV氦离子在430 ℃辐照后的ODS钢中高密度第二相和基体之间的界面; (c)经过200keV, 剂量为2 × 1021 ions cm–2的氦离子在450 ℃辐照后的铜-铌异质金属间的相界面; (d)经过400 keV, 剂量为8.64 × 1014 ions cm–2的氖离子在室温下辐照后的纳米多孔金中的自由表面(数据来源于文献[23,24,26,27],有改动)

Figure 1. Typical interfaces in metals[23,24,26,27]: (a) Grain boundary in Cu which irradiated at 450 ℃ by 200 keV He ions with a fluence of 2 × 1017 ions cm–2; (b) interfaces between oxides and matrix in ODS steel which irradiated with 24.18 MeV Fe8+ ions and 1.7 MeV He+ ions at nearly 430 ℃; (c) Cu-Nb interface which irradiated at 450 ℃ by 200 keV He ions with a fluence of 2 × 1021 ions cm–2; (d) free surface in nanoporous gold (NPG) which irradiated at room temperature by 400 keV Ne++ ions with a fluence of 8.64 × 1014 ions/cm–2.

图 2 (a)不同界面在相同的辐照条件下形成的无缺陷区的宽度随界面类型的变化; (b)经过200 keV, 剂量为2 × 1017 ions cm–2的氦离子在450 ℃辐照后的铜中大角晶界的无缺陷区域; (c)相同辐照条件下的K-S铜-铌相界面的无缺陷区域 (数据来源于文献[22,23],有改动)

Figure 2. (a) Variation of the width of the void-denuded zone (VDZ) with the character of interfaces. The large angle grain boundary in (b) Cu which irradiated at 450 ℃ by 200 keV He ions with a fluence of 2 × 1017 ions cm–2. and in (c) Cu-Nb interface in the same irradiation condition[22,23].

图 3 分子动力学模拟铜中Σ11对称倾斜晶界在吸收间隙原子前后对空位和间隙原子的形成能和迁移能的影响 (a)原始晶界的空位形成能; (b)级联碰撞发生后, 晶界吸收10个间隙原子的空位形成能, 虚线框代表容易被无障碍间隙原子发射复合掉的不稳定空位位点; (c)缺陷扩散能垒随着晶界距离的变化. 1代表原始晶界附近空位扩散的能垒; 2代表块体中空位扩散的能垒; 3代表原始晶界附近间隙原子扩散的能垒; 4代表块体中间隙原子扩散的能垒; 5代表吸收间隙原子的晶界附近空位扩散的能垒; 6代表吸收间隙原子的晶界附近间隙原子释放的能垒. 显而易见, 与原始晶界相比, 吸收间隙原子的晶界附近空位扩散和间隙原子释放的能垒都明显降低(数据来源于文献[29])

Figure 3. The influence of grain boundaries loading with interstitials on the defect properties in Σ11 GB of copper: (a) Vacancy formation energy profile of a pristine GB; (b)vacancy formation energy profile of a GB loaded with 10 interstitials after a collision cascade. Vacancy sites denoted by dashed box are unstable sites that are annihilated via barrier-free interstitial emission; (c) defect diffusion barriers as a function of distance from a pristine and an interstitial-loaded GB. Line 1 represents vacancy diffusion barriers near the pristine GB. Line 2 represents vacancy diffusion barriers in the bulk. Line 3 represents interstitial diffusion barriers near the pristine GB. Line 4 represents interstitial diffusion barriers in the bulk. Line 5 represents vacancy diffusion barriers near the interstitial loaded GB. Line 6 represents interstitial emission near the interstitial loaded GB. Clearly, barriers for vacancy diffusion and interstitial emission near the interstitial-loaded GB are greatly reduced compared with the vacancy diffusion barriers near the pristine GB.

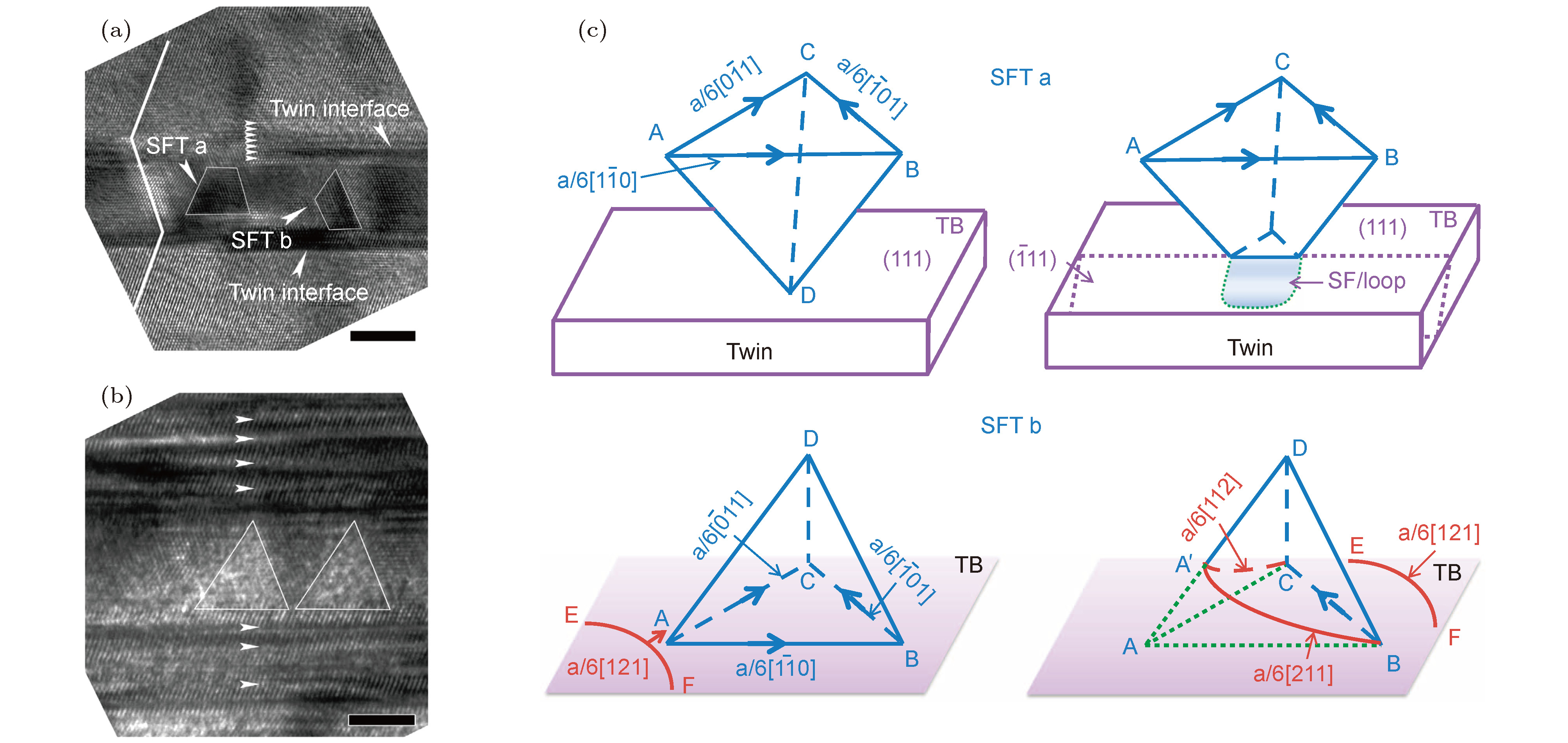

图 4 铜–银界面“空位泵”的工作机理 (a) 400 keV, 2 × 1017 ion/cm2氦离子400 ℃辐照后的纳米层状共晶铜–银复合材料表面形成了富铜的凸起物; (b)距表面约200 nm深度形成大量纳米氦泡, 且银层氦泡密度和尺寸显著高于铜层中的氦泡; (c)距表面约1400 nm深度形成大量的空洞; (d)距表面约1800 nm深度形成位错结构; (e)铜–银界面上界面位错由于在铜侧产生压应力捕获铜空位到界面偏聚; (f)铜侧的空位自发转移至银层中; (g)银间隙原子由于界面拉应力偏聚到界面处, 并在铜–银界面处与部分界面空位复合; (h)铜层中的间隙原子浓度越来越高, 而银层中的空位浓度越来越高, 最终在表面形成富铜的凸起物(数据来源于文献[42], 有改动)

Figure 4. Mechanism of vacancy pump in Cu/Ag interface: (a) A surface bump enriched copper formed on surface of the Cu/Ag nanocomposites after 400 keV, 2 × 1017 ion/cm2 helium ions implantation at 400 ℃; (b) high density of helium bubbles formed at the depth of 200 nm. The density and diameter of helium bubbles in Ag are larger than that in Cu; (c) high density of voids formed at the depth of 1400 nm; (d) high density of dislocation lines formed at the depth of 1800 nm; (e) Cu vacancies segregate to the MDI due to compressive stress field; (f) Cu vacancies at MDI transfer into Ag layer and attach to interface; (g) Ag interstitials migrate to non-MDI area because of tensile stress; (h) a state of interstitials enriched in Cu and vacancies enriched in Ag is achieved due to the vacancy pump effect of Cu/Ag interface.

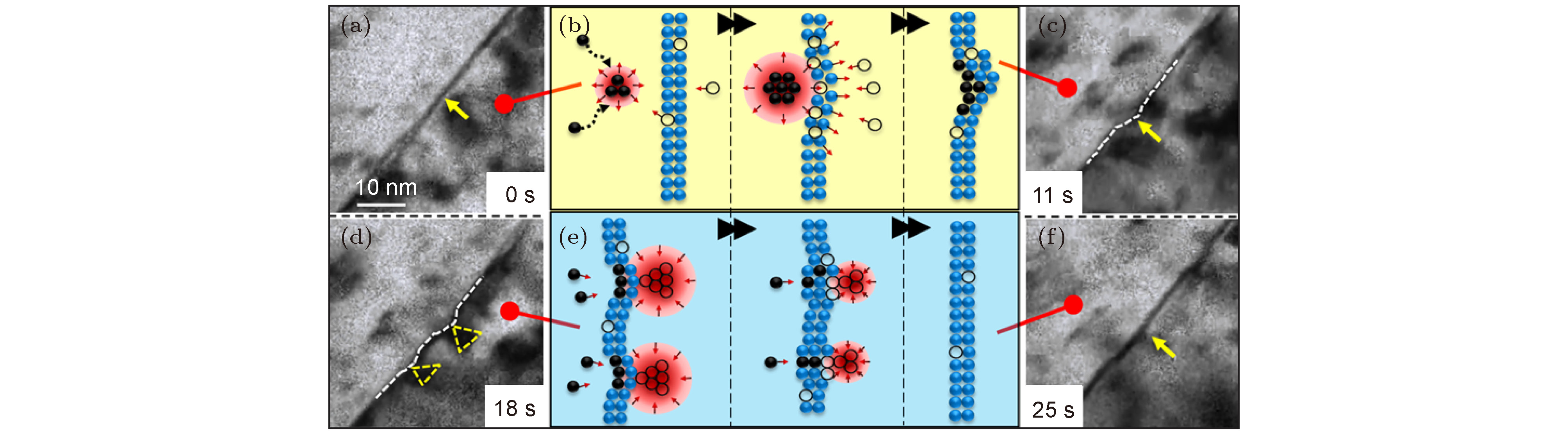

图 5 层错四面体与共格孪晶界的交互作用 (a)两种典型的四边形层错四面体, 层错四面体a从顶点削去一角, 层错四面体b从底角削去一角; (b)层错四面体和孪晶界交互作用沿着孪晶界形成大量层错; (c)对应(a)中共格孪晶界和层错四面体发交互作用的两种情况. 第一种, 由于层错四面体顶点先接触孪晶界而被削去一角, 在{111}面形成位错环; 另一种情况, 可动位错和压杆位错发生位错反应(如AB和AC), 在层错面形成两个新的可动位错, 分位错的进一步扩展消除整个层错四面体(数据来源于文献[71], 有改动)

Figure 5. The mechanism of the interaction between the SFTs and the coherent twin boundaries: (a) The two truncated SFTs during their interactions with CTBs. SFT-a was truncated from its apex, whereas SFT-b was destructed from its base; (b) HRTEM micrograph showing the formation of groups of stacking faults during SFTs interactions with CTBs; (c) schematics of two types of interactions between SFTs and twin boundaries corresponding to the two cases in (a). The removal of SFT initiated from its apex (in contact with a twin boundary) results in the formation of dislocation loops on {111} plane in the twin lattices. In the lower case, the interaction of a mobile partial with stair-rod dislocations, AB and AC, results in two new mobile partials that can migrate on the surface of SFT and lead to its decomposition.

图 6 银中的共格孪晶界在原位辐照过程与间隙型位错环的交互作用机制 (a)初始平直的共格孪晶界; (b)分子动力学模拟辐照产生了间隙型位错环, 在原位辐照下移动, 撞到共格孪晶界, 形成凸起; (c)共格孪晶界由于吸收间隙原子形成小凸起; (d)凸起的共格孪晶界遇到两个层错四面体; (e)分子动力学模拟拱起的共格孪晶界吸收邻近辐照产生的空位, 而后空位和孪晶界上的间隙原子复合, 使共格孪晶界恢复平直状态, 实现自愈合; (f)凸起的共格孪晶界恢复成平直状态(数据来源于文献[76], 有改动)

Figure 6. The mechanism of interaction between CTBs and interstitial dislocation loops in Ag under in situ radiation: (a) An initially straight CTB; (b) the monocular dynamic simulation for the formation, movement and diffusion of an interstitial loop near a CTB; (c) the formation of puddle at the CTB; (d) Two SFTs adjacent to the puddle were gradually absorbed by the CTB; (e) the annihilation of interstitials with SFTs leads to the self-healing of the CTB; (f) the CTB was nearly recovered to a straight line.

图 7 镍中Kr离子辐照产生的位错环向晶界运动、缩小并被最终被界面复合的机理. 在远离晶界的区域2中, 空位浓度达到饱和, 位错环持续吸收空位导致半径收缩; 在接近晶界的区域1中, 空位浓度梯度使位错环的一侧吸收空位, 另一侧释放空位, 使位错环向晶界迁移得以进行(数据来源于文献[77])

Figure 7. Illustration of the shrinkage and migration of dislocation loops toward GBs in Ni irradiated by Kr ions. In region 2, further away from the GB, the concentration of vacancy induced by radiation approaches a plateau and the continuous absorption of vacancy leads to the gradual reduction of interstitial loop diameter. In region 1, adjacent to the GB, there is a concentration gradient of vacancies. The absorption of vacancy by one side of dislocation loop and the corresponding emission of vacancy from the other side (facing GB) lead to rapid migration (climb) of the loop toward the GB.

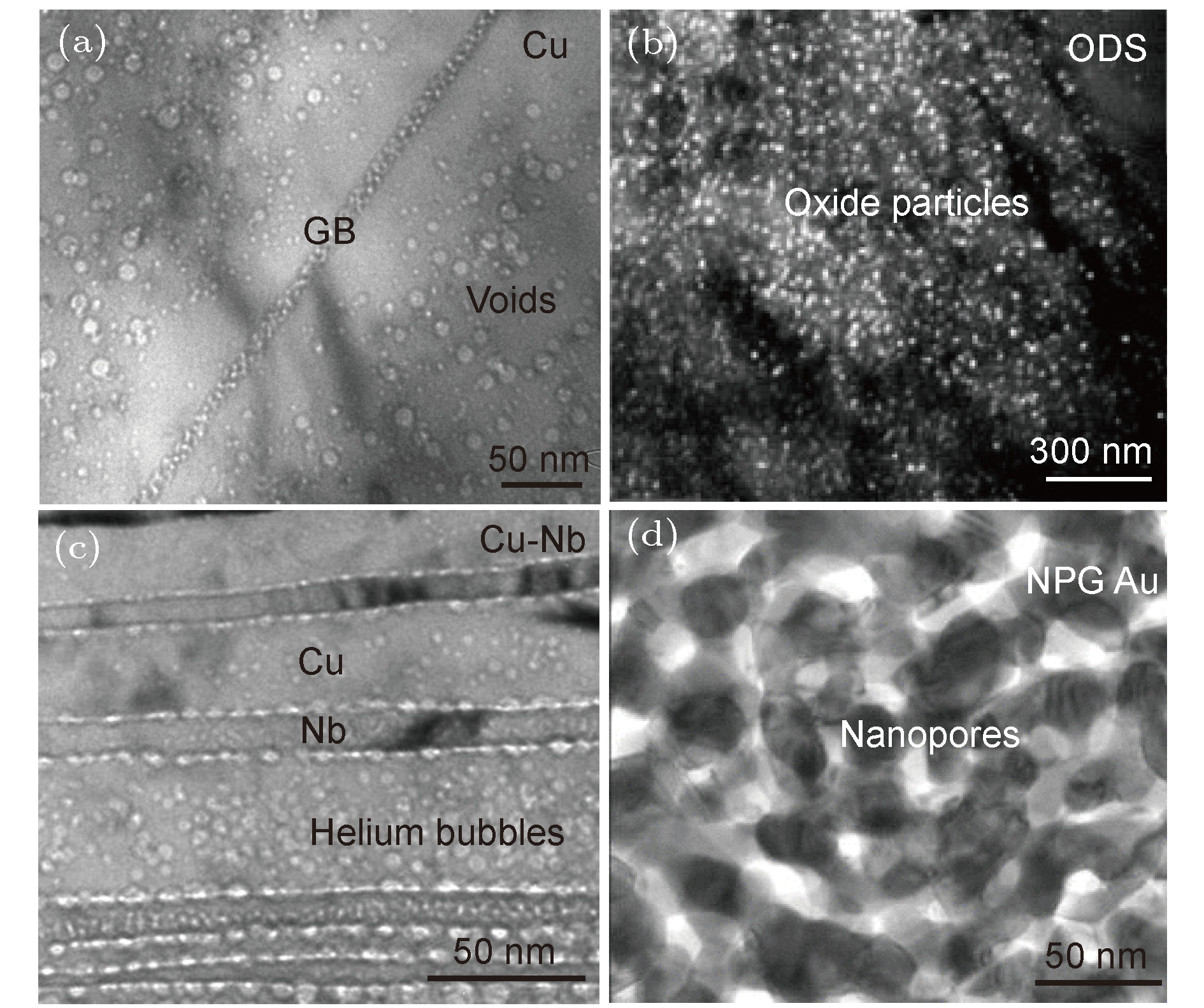

图 8 铜铌界面既可作为障碍物阻碍位错滑移, 也作为缺陷陷阱愈合辐照缺陷. 在相同的辐照条件下, 纯铜晶粒内部形成了大量的氦泡, 而铜-铌纳米层状材料内观察不到任何的辐照缺陷. 说明纳米层状复合物比块体材料的强度更高, 抗辐照损伤能力更强(数据来源于文献[85])

Figure 8. Cu-Nb interfaces act as obstacles to slip and sinks for radiation-induced defects. Under the same radiation condition, helium bubbles form in bulk Copper but not in Cu/Nb heterostructures. Hence, nanolayered composites not only increase strength but enhance radiation-damaged tolerance as well, compared with bulk materials.

图 9 金中的辐照氦泡 (a)辐照后金薄膜中形成了大量纳米氦泡; (b)纳米氦泡分布在金的小角度扭转晶界的螺位错节点处; (c)分子动力学模拟沿着(001)小角度扭转晶界上不同原子位置的空位形成能和固溶能(数据来源于文献[90], 有改动)

Figure 9. Helium bubbles in irradiated Au: (a) Nanoscale helium bubbles in Au film; (b) nanoscale helium bubbles are formed in the point of misfit dislocations in twist boundary of Au; (c) formation and solution energies of vacancy for different atom sites along (001) twist boundary.

图 10 临界储氦量与界面失配位错密度与K-S界面取向的关系. 图中呈现了三种典型的FCC/BCC界面(K-S铜-铌界面, K-S铜-钒界面, K-S铜-钼界面)(数据来源于文献[35])

Figure 10. The relationship of critical He concentration and MIDs densities for interfaces with Kurdjumov-Sachs interface orientation. As plotted are three typical FCC/BCC interface such as Cu-Nb, Cu-V, Cu-Mo.

-

[1] Zinkle S J, Was G S 2013 Acta Mater. 61 735

Google Scholar

Google Scholar

[2] Zinkle S, Sindelar R 1988 J. Nucl. Mater. 155 1196

[3] Kiritani M 2000 J. Nucl. Mater. 276 41

Google Scholar

Google Scholar

[4] Griffiths M 1988 J. Nucl. Mater. 159 190

Google Scholar

Google Scholar

[5] Silcox J, Hirsch P B 1959 Philos. Mag. 4 72

Google Scholar

Google Scholar

[6] Kadoyoshi T, Kaburaki H, Shimizu F, Kimizuka H, Jitsukawa S, Li J 2007 Acta Mater. 55 3073

Google Scholar

Google Scholar

[7] Wirth B D, Bulatov V, Diaz de la Rubia T 2000 J. Nucl. Mater. 283 773

[8] Mansur L K 1978 Nucl. Technol. 40 5

Google Scholar

Google Scholar

[9] Stubbins J, Garner F 1992 J. Nucl. Mater. 191 1295

[10] Han W Z, Fu E, Demkowicz M J, Wang Y, Misra A 2013 J. Mater. Res. 28 2763

Google Scholar

Google Scholar

[11] Yu K Y, Liu Y, Sun C, Wang H, Shao L, Fu E G, Zhang X 2012 J. Nucl. Mater. 425 140

Google Scholar

Google Scholar

[12] Mazey D J, Evans J H 1986 J. Nucl. Mater. 138 16

Google Scholar

Google Scholar

[13] Holt R A, Ibtahim E F 1979 Acta Metall. 27 1319

Google Scholar

Google Scholar

[14] Fidleris V 1978 Atom. Energy Rev. 13 51

[15] Carpenter G J C, Zee R H, Rogerson A 1988 J. Nucl. Mater. 159 86

Google Scholar

Google Scholar

[16] Hu X X, Koyanagi T, Fukuda M, Kumar N A P K, Snead L L, Wirth B D, Katoh Y 2016 J. Nucl. Mater. 480 235

Google Scholar

Google Scholar

[17] Pokor C, Brechet Y, Dubuisson P, Massoud J P, Avertye X 2004 J. Nucl. Mater. 326 30

[18] Odette G R, Lucas G E 1998 Radiat. Eff. Defects Solids 44 189

[19] Odette G R, Lucas G E 2001 JOM 53 18

[20] Zinkle S J, Busby J T 2009 Mater. Today 12 12

[21] Lu L, Shen Y F, Chen X H, Qian L H, Lu K 2004 Science 304 422

Google Scholar

Google Scholar

[22] Han W Z, Demkowicz M J, Mara N A, Fu E, Sinha S, Rollett A D, Wang Y Q, Carpenter J S, Beyerlein I J, Misra A 2013 Adv. Mater. 25 6975

Google Scholar

Google Scholar

[23] Han W Z, Demkowicz M J, Fu E G, Wang Y Q, Misra A 2012 Acta Mater. 60 6341

Google Scholar

Google Scholar

[24] Hsiung L L, Fluss M J, Tumey S J, Choi B W, Serruys Y, Willaime F, Kimura A 2010 Phys. Rev. B 82 184103

Google Scholar

Google Scholar

[25] Hsiung L, Fluss M, Tumey S, Kuntz J, El-Dasher B, Wall M, Choi B, Kimura A, Willaime F, Serruys Y 2011 J. Nucl. Mater. 409 72

Google Scholar

Google Scholar

[26] Han W Z, Mara N A, Wang Y Q, Misra A, Demkowicz M J 2014 J. Nucl. Mater. 452 57

Google Scholar

Google Scholar

[27] Fu E G, Caro M, Zepeda-Ruiz L A, Wang Y Q, Baldwin K, Bringa E, Nastasi M, Caro A 2012 Appl. Phys. Lett. 101 191607

Google Scholar

Google Scholar

[28] Bringa E M, Monk J D, Caro A, Misra A, Zepeda-Ruiz L, Duchaineau M, Abraham F, Nastasi M, Picraux S T, Wang Y Q, Farkas D 2012 Nano Lett. 7 3351

[29] Bai X M, Voter A F, Hoagland R G, Nastasi M, Uberuaga B P 2010 Science 327 1631

Google Scholar

Google Scholar

[30] Chen D, Wang J, Chen T, Shao L 2013 Sci. Rep. 3 1450

Google Scholar

Google Scholar

[31] Sun C, Zheng S, Wei C C, Wu Y, Shao L, Yang Y, Hartwig K T, Maloy S A, Zinkle S J, Allen T R, Wang H, Zhang X 2015 Sci. Rep. 5 7801

Google Scholar

Google Scholar

[32] Zinkle S J, Farrell K 1989 J. Nucl. Mater. 168 262

Google Scholar

Google Scholar

[33] Siegel R W, Chang S M, Balluffi R W 1980 Acta Metall. 28 249

Google Scholar

Google Scholar

[34] Klueh R L, Nelson A T 2007 J. Nucl. Mater. 371 37

Google Scholar

Google Scholar

[35] Demkowicz M J, Misra A, Caro A 2012 Curr. Opin. Solid State Mater. Sci. 16 101

Google Scholar

Google Scholar

[36] Zhang X, Fu E G, Li N, Misra A, Wang Y Q, Shao L, Wang H 2012 J. Eng. Mater. Technol. 134 041010

Google Scholar

Google Scholar

[37] Lu C Y, Zheng Lyu, Li Y P, Liu C M 2014 J. Notheastern U. (Nat. Sci. Ed)

35 1133 [38] Beyerlein I J, Demkowicz M J, Misra A, Uberuaga B P 2015 Prog. Mater. Sci. 74 125

Google Scholar

Google Scholar

[39] Demkowicz M J, Hoagland R G, Hirth J P 2008 Phys. Rev. Lett. 100 136102

Google Scholar

Google Scholar

[40] Tschopp M A, Mcdowell D L 2007 Philos. Mag. 87 3147

Google Scholar

Google Scholar

[41] Wang J, Beyerlein I J, Mara N A, Bhattacharyya D 2011 Scr. Mater. 64 1083

Google Scholar

Google Scholar

[42] Wang M, Beyerlein I J, Zhang J, Han W Z 2018 Acta Mater. 160 211

Google Scholar

Google Scholar

[43] Han W Z, Carpenter J S, Wang J, Beyerlein I J, Mara N A 2012 Appl. Phys. Lett. 100 011911

Google Scholar

Google Scholar

[44] Demkowicz M J, Anderoglu O, Zhang X, Misra A 2011 J. Mater. Res. 26 1666

Google Scholar

Google Scholar

[45] Barnes R S, Redding G B, Cottrell A H 1958 Philos. Mag. 3 97

Google Scholar

Google Scholar

[46] Uberuaga B P, Choudhury S, Caro A 2015 J. Nucl. Mater. 462 402

Google Scholar

Google Scholar

[47] Embury J D, Nicholson R B 1965 Acta Metall. 13 403

Google Scholar

Google Scholar

[48] Mao S, Shu S, Zhou J, Averback R S, Dillon S J 2015 Acta Mater. 82 328

Google Scholar

Google Scholar

[49] Mitchell T E, Lu Y C, Griffin A J, Nastasi M, Kung H 1997 J. Am. Ceram. Soc. 80 1673

[50] Fu E G, Li N, Misra A, Hoagland R G, Wang H, Zhang X 2008 Mater. Sci. Eng. A 493 283

Google Scholar

Google Scholar

[51] Misra A, Verdier M, Lu Y C, Kung H, Mitchell T E, Nastasi M 1998 Scr. Mater. 39 555

Google Scholar

Google Scholar

[52] Gao F, Chen D, Hu W, Weber W J 2010 Phys. Rev. B 81 184101

Google Scholar

Google Scholar

[53] Balluffi R W 1978 J. Nucl. Mater. 69-70 9

[54] Bai X M, Uberuaga B P 2013 JOM 65 360

Google Scholar

Google Scholar

[55] Bai X M, Vernon L J, Hoagland R G, Voter A F, Nastasi M, Uberuaga B P 2012 Phys. Rev. B 85 214103

Google Scholar

Google Scholar

[56] Borovikov V, Tang X Z, Perez D, Bai X M, Uberuaga B P, Voter A F 2013 Nucl. Fusion 53 063001

Google Scholar

Google Scholar

[57] Singh B N, Leffers T 1974 Scr. Metall. Mater. 8 1974

[58] Liu X Y, Uberuaga B P, Demkowicz M J, Germann T C, Misra A, Nastasi M 2012 Phys. Rev. B 85 012103

[59] Zhang L, Lu C, Tieu K, Shibuta Y 2018 Scripta Mater. 144 78

Google Scholar

Google Scholar

[60] Xu J, Liu J B, Li S N, Liu B X, Jiang Y 2016 Phys. Chem. Phys. 18 17930

Google Scholar

Google Scholar

[61] Demkowicz M J, Thilly L 2011 Acta Mater. 59 7744

Google Scholar

Google Scholar

[62] Uberuaga B P, Bai X M, Dholabhai P P, Moore N, Duffy D M 2013 J. Phys. Condens. Matter 25 355001

Google Scholar

Google Scholar

[63] Uberuaga B P, Vernon L J, Martinez E, Voter A F 2015 Sci. Rep. 5 09095

Google Scholar

Google Scholar

[64] Demkowicz M J, Hoagland R G 2009 Intern. J. Appl. Mechan. 1 421

Google Scholar

Google Scholar

[65] Nomura M, Adams J B 1995 J. Mater. Res. 10 2916

Google Scholar

Google Scholar

[66] Zheng S, Shao S, Zhang J, Wang Y Q, Demkowicz M J, Beyerlein I J, Mara N A 2015 Sci. Rep. 5 15428

Google Scholar

Google Scholar

[67] Lao Y X, Hu S L, Deng Y, Wang F, Du H, Zhang H B, Wang Y 2016 Sci. Rep. 7 40044

[68] Zinkle S J, Seitzman L E, Wolfer W G I 1987 Philos. Mag. A 55 111

Google Scholar

Google Scholar

[69] Kiener D, Hosemann P, Maloy S A, Minor A M 2011 Nat. Mater. 10 608

Google Scholar

Google Scholar

[70] Niewczas M, Hoagland R G 2009 Philos. Mag. 89 727

Google Scholar

Google Scholar

[71] Yu K Y, Bufford D, Sun C, Liu Y, Wang H, Kirk M A, Li M, Zhang X 2013 Nat. Commun. 4 1377

Google Scholar

Google Scholar

[72] Chen Y, Li J, Yu K Y, Wang H, Kirk M A, Li M, Zhang X 2016 Acta Mater. 111 148

Google Scholar

Google Scholar

[73] Wang J, Li N, Anderoglu O, Zhang X, Misra A, Huang J Y, Hirth J P 2010 Acta Mater. 58 2262

Google Scholar

Google Scholar

[74] Wang J, Li N, Misra A 2013 Philos. Mag. 93 315

Google Scholar

Google Scholar

[75] Wang J, Anderoglu O, Hirth J P 2009 Appl. Phys. Lett. 95 021908

Google Scholar

Google Scholar

[76] Li J, Yu K Y, Chen Y, Song M, Wang H, Kirk M A, Li M, Zhang X 2015 Nano Lett. 15 2922

Google Scholar

Google Scholar

[77] Sun C, Song M, Yu K Y, Kirk M, Li M, Wang H, Zhang X 2013 Metall. Mater. Trans. A 44 1966

Google Scholar

Google Scholar

[78] Chen Y, Zhang X, Wang J 2016 JOM 68 235

Google Scholar

Google Scholar

[79] Sun C, Bufford D, Chen Y, Kirk M A, Wang Y Q, Li M, Wang H, Maloy S A, Zhang X 2014 Sci. Rep. 4 3737

[80] Thorsen P A, Bilde-Sørensen J B, Singh B N 2004 Scr. Mater. 51 557

Google Scholar

Google Scholar

[81] Zhang L, Fu C C, Lu G H 2013 Phys. Rev. B 87 134107

Google Scholar

Google Scholar

[82] Ding M S, Du J P, Wan L, Ogata S, Tian L, Ma E, Han W Z, Li J, Shan Z W 2016 Nano Lett. 16 4118

Google Scholar

Google Scholar

[83] Ding M S, Tian L, Han W Z, Li J, Ma E, Shan Z W 2016 Phys. Rev. Lett. 117 215501

Google Scholar

Google Scholar

[84] Han W Z, Ding M S, Shan Z W 2018 Scr. Mater. 147 1

Google Scholar

Google Scholar

[85] Grimes R W, Kinungs R J M, Edwards L 2008 Nat. Mater. 7 683

Google Scholar

Google Scholar

[86] Hochbauer T, Misra A, Hattar K, Hoagland R G 2005 J. Appl. Phys. 98 123516

Google Scholar

Google Scholar

[87] Zhang X, Li N, Anderoglu O, Wang H, Swadener J G, Hochbauer T 2007 Nucl. Instrum. Methods Phys. Res. Sect. B 261 1129

Google Scholar

Google Scholar

[88] Kashinath A, Misra A, Demkowicz M J 2013 Phys. Rev. Lett. 110 086101

Google Scholar

Google Scholar

[89] Demkowicz M J, Bhattacharyya D, Usov I, Wang Y Q, Nastasi M, Misra A 2010 Appl. Phys. Lett. 97 161903

Google Scholar

Google Scholar

[90] Di Z F, Bai X M, Wei Q M, Won J, Hoagland R G, Wang Y Q, Misra A, Uberuaga B P, Nastasi M 2011 Phys. Rev. B 84 052101

[91] Lane P L, Goodhew P J 1983 Philos. Mag. A 48 965

Google Scholar

Google Scholar

[92] Kashinath A, Demkowicz M J 2011 Model Simul. Mater. Sci. Eng. 19 035007

Google Scholar

Google Scholar

[93] Singh B N, Leffers T, Green W V, Victoria M 1984 J. Nucl. Mater. 125 287

Google Scholar

Google Scholar

[94] Bollmann W 1974 Phys. Status Solidi A 21 543

Google Scholar

Google Scholar

[95] Bollmann W 1970 The Meaning of Dislocations in Crystalline Interfaces Washington, DC, USA, April 21-25, 1971 p465.

[96] Chen D, Li N, Yuryev D, Baldwin J K, Wang Y Q, Demkowicz M J 2017 Sci. Adv. 3 eaao2710

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 44781

- PDF Downloads: 599

- Cited By: 0

DownLoad:

DownLoad: