-

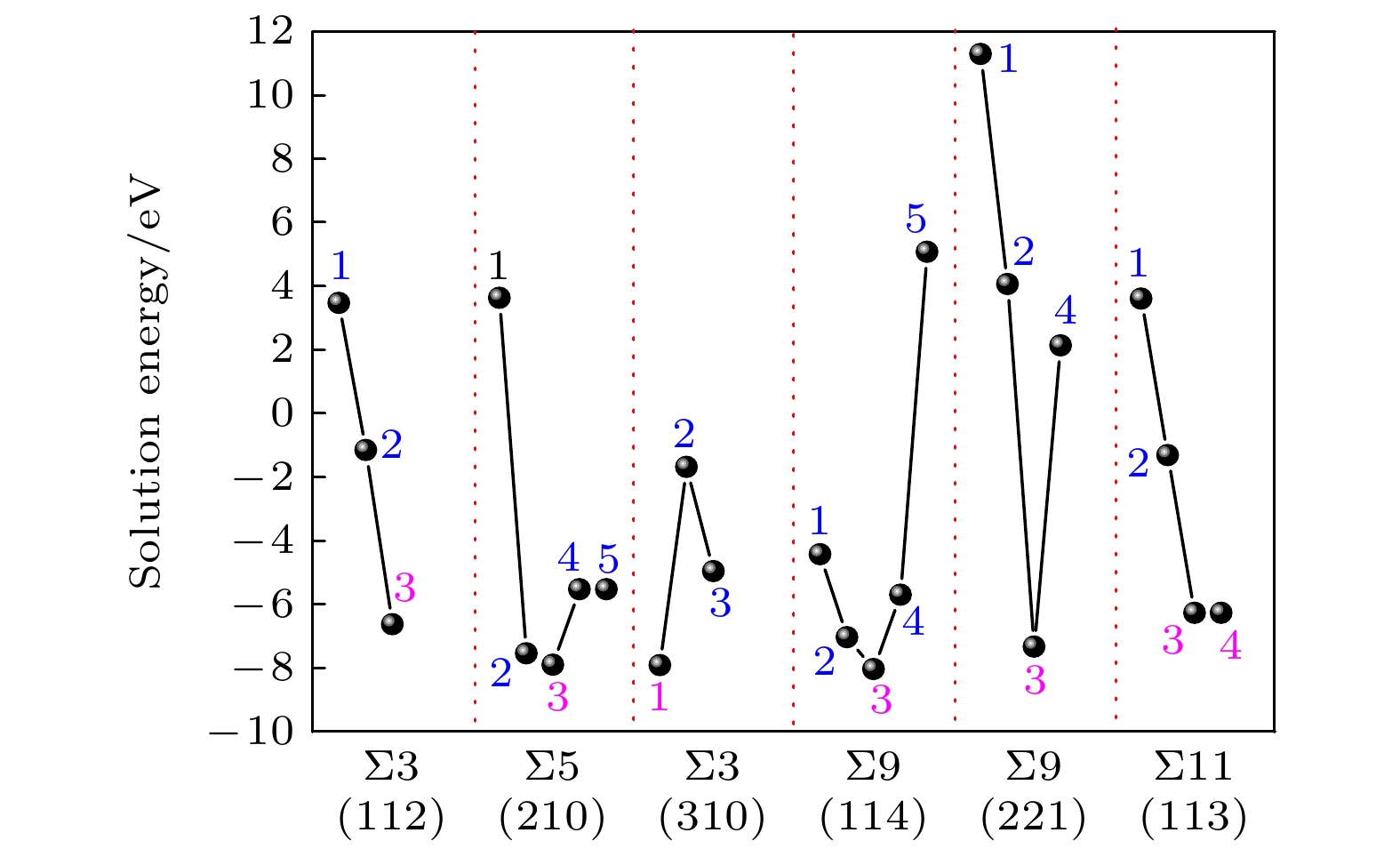

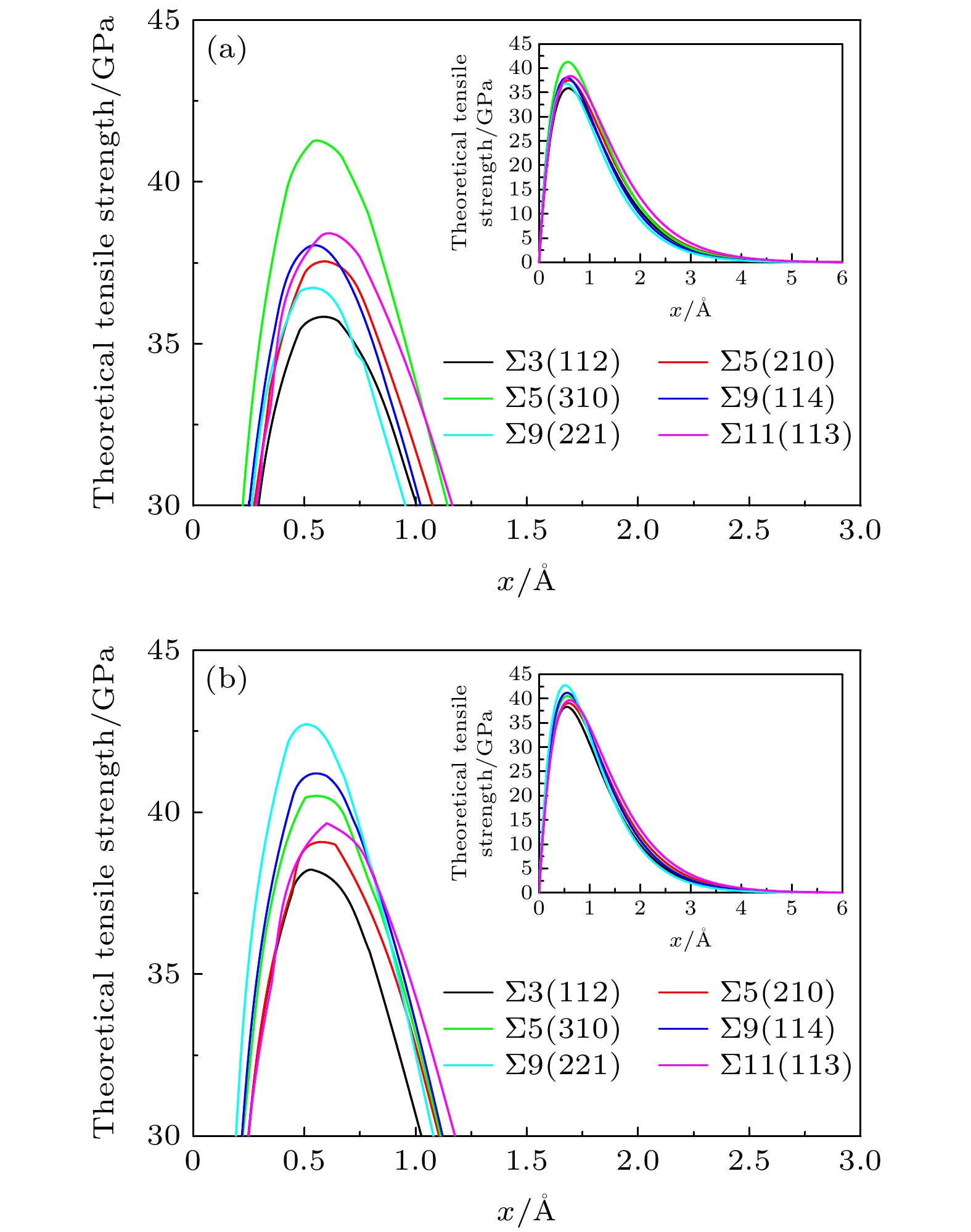

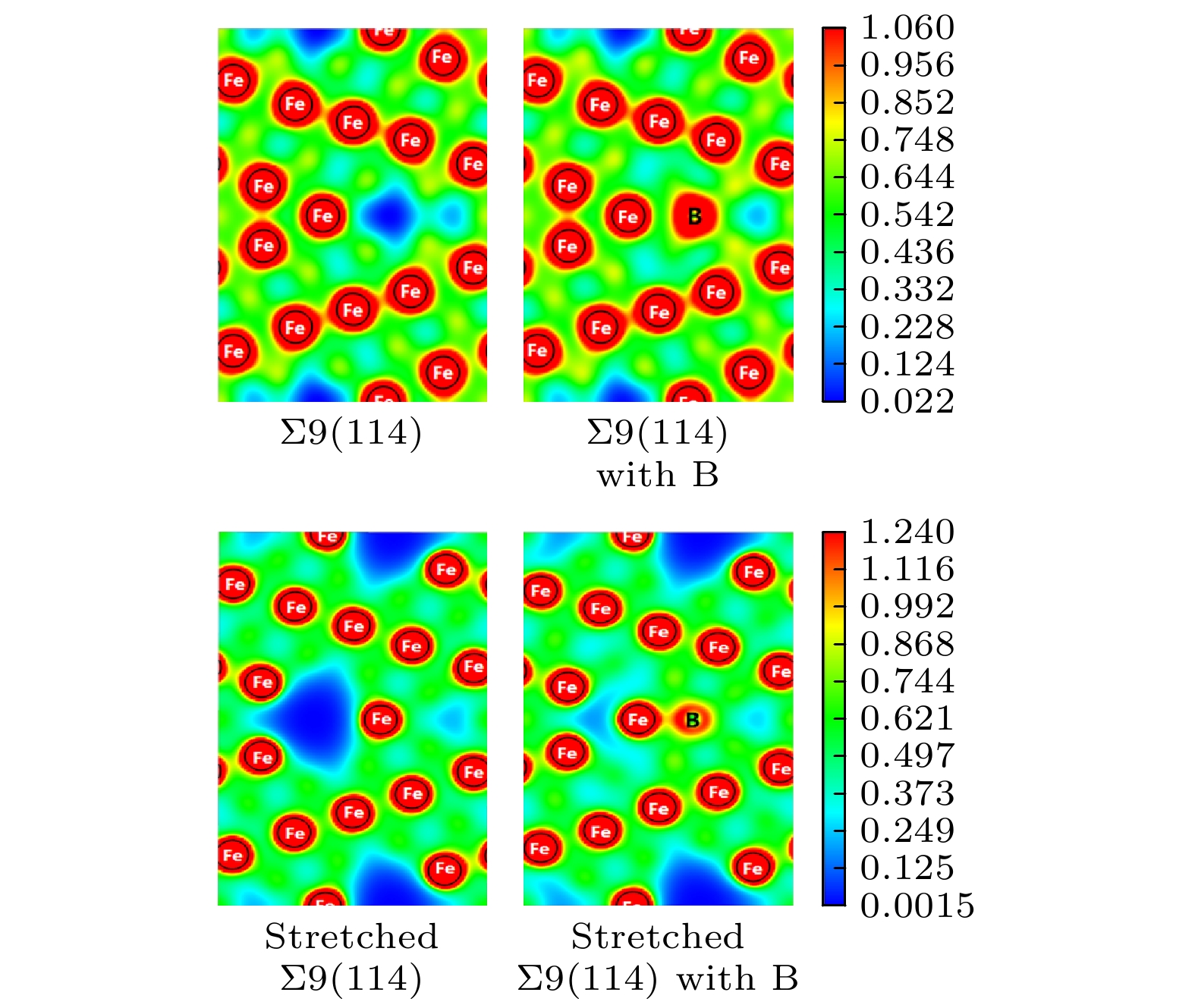

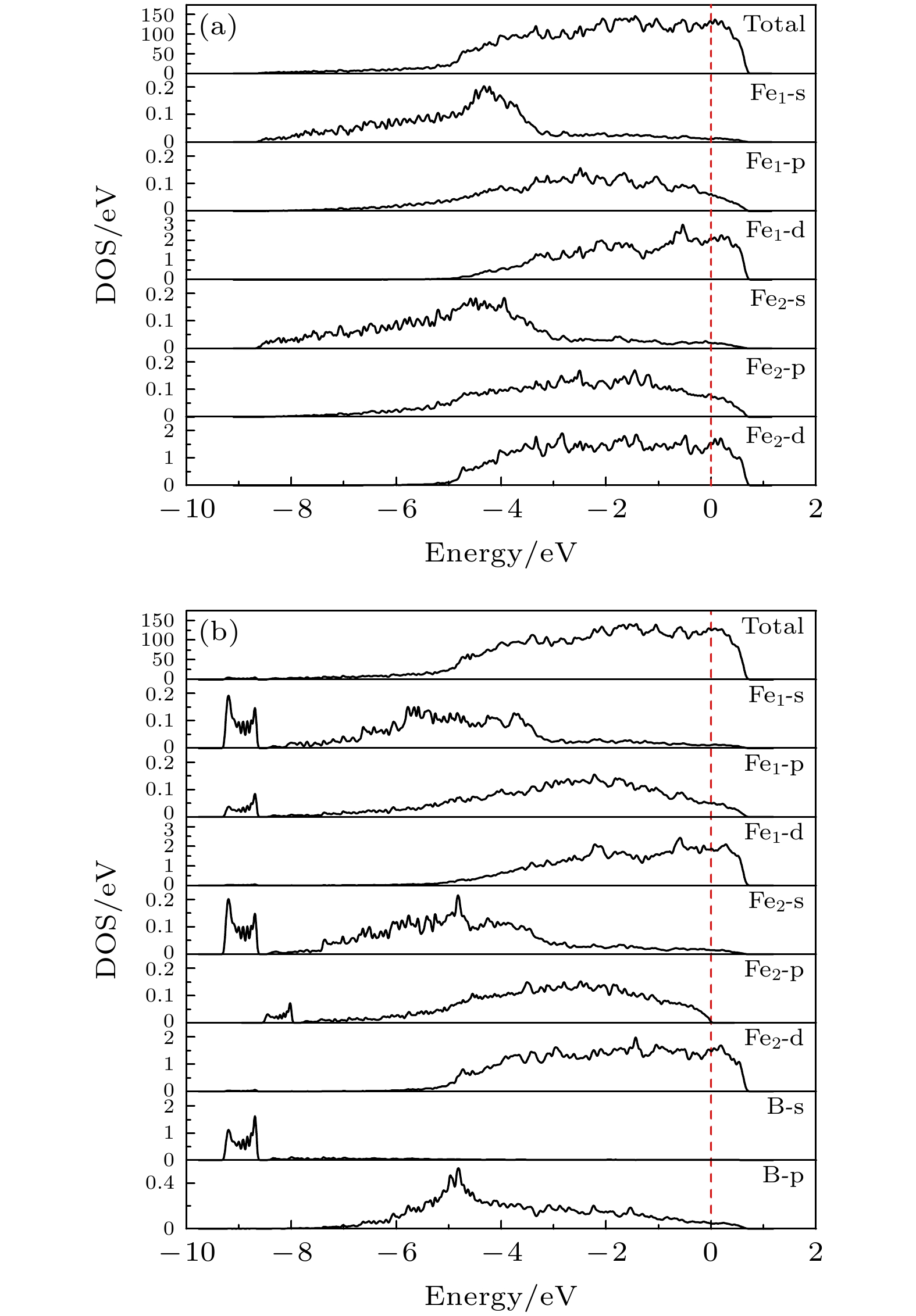

Boron, a commonly used microalloying element in steel, is distributed mainly at the grain boundary of stainless steel and plays an important role in regulating the mechanical, corrosion resistance and grain boundary structure of stainless steel. Owing to the small amount of boron added into the steel, it is difficult experimentally to detect the traces of boron segregation at the grain boundary, not to mention analyzing the structural characteristics of the boron segregation grain boundary. First-principles density functional theory (DFT) provides convenience in analyzing the existence mode and mechanism of boron in austenitic steel from the atomic level. Combining with the actual grain boundary structure types in austenitic stainless steel, Fcc-Fe Σ3(112), Σ5(210), Σ5(310), Σ9(114), Σ9(221) and Σ11(113) symmetric tilt grain boundaries are constructed based on DFT, and the segregation behaviors of boron atoms at the six grain boundaries are studied to reveal the segregation mechanism from the atomic and electronic level. The results show that boron segregation occurs mostly at Σ5(210), Σ5(310) and Σ9(114) grain boundaries, while a relatively weak segregation tendency is observed at Σ9(221), Σ3(112) and Σ11(113) grain boundaries; boron atom preferentially occupies the pentahedral or hexahedral segregation position with the largest coordination number; the interface adhesive strength at grain boundaries is improved by the segregation of boron according to the tensile test, which complies with the calculation results of Rice-Wang thermodynamic model; the chemical effect caused by the increase of local charge density after boron segregation at Σ9(114) grain boundary outstrips the adverse effect of structural changes, and the strong interaction between B-p electrons and Fe-s electrons improves the interface adhesive strength. The results provide a reference for using boron to optimize the interface structure of austenitic stainless-steel.

-

Keywords:

- austenite steel /

- boron /

- first-principles /

- segregation /

- interface adhesive strength

[1] Ma S, Pan W, Xing J, et al. 2017 Mater. Chem. Phys. 199 356

Google Scholar

Google Scholar

[2] Naderi M, Ketabchi M, Abbasi M, et al. 2010 Steel Res. Int. 81 216

Google Scholar

Google Scholar

[3] Ghali S N, El-Faramawy H S, Eissa M M 2012 J. Miner. Mater. Char. Eng. 11 995

[4] Jones R B, Younes C M, Heard P J, et al. 2002 Acta Mater. 50 4395

Google Scholar

Google Scholar

[5] Zarandi F, Yue S 2006 Metall. Mater. Trans. A 37 2316

Google Scholar

Google Scholar

[6] López-Chipres E, Mejía I, Maldonado C, et al. 2007 Mater. Sci. Eng. A-Struct 460/461 464

Google Scholar

Google Scholar

[7] Mejía I, Bedolla-Jacuinde A, Maldonado C, et al. 2011 Mater. Sci. Eng. A-Struct 528 4468

Google Scholar

Google Scholar

[8] Deva A, Jha B K, Mishra N S 2011 Mater. Sci. Eng. A-Struct 528 7375

Google Scholar

Google Scholar

[9] Takahashi J, Ishikawa K, Kawakami K, et al. 2017 Acta Mater. 133 41

Google Scholar

Google Scholar

[10] Li Y, Ponge D, Choi P, Raabe D 2015 Scripta Mater. 96 13

Google Scholar

Google Scholar

[11] 王博, 张建民, 路彦冬, 等 2011 60 016601

Google Scholar

Google Scholar

Wang B, Zhang J M, Lu Y D, et al. 2011 Acta Phys. Sin. 60 016601

Google Scholar

Google Scholar

[12] 孟凡顺, 李久会, 赵星 2014 63 237102

Google Scholar

Google Scholar

Meng F S, Li J H, Zhao X 2014 Acta Phys. Sin. 63 237102

Google Scholar

Google Scholar

[13] Li Y, Korzhavyi P A, Sandström R, et al. 2017 Phys. Rev. Mater. 1 070602

Google Scholar

Google Scholar

[14] Huang Z, Chen F, Shen Q, et al. 2018 Acta Mater. 148 110

Google Scholar

Google Scholar

[15] Huang Z, Chen F, Shen Q, et al. 2019 Acta Mater. 166 113

Google Scholar

Google Scholar

[16] Du Y A, Ismer L, Rogal J, et al. 2011 Phys. Rev. B 84 144121

Google Scholar

Google Scholar

[17] Wang J, Janisch R, Madsen G K H, et al. 2016 Acta Mater. 115 259

Google Scholar

Google Scholar

[18] Razumovskiy V I, Lozovoi A Y, Razumovskii I M 2015 Acta Mater. 82 369

Google Scholar

Google Scholar

[19] Bentria E L T, Lefkaier I K, Bentria B 2013 Mater. Sci. Eng. A-Struct 577 197

Google Scholar

Google Scholar

[20] Wu R, Freeman A J, Olson G B 1994 Science 265 376

Google Scholar

Google Scholar

[21] Shang J X, Wang C Y 2001 J. Phys.-Condens. Mat. 13 9635

Google Scholar

Google Scholar

[22] He B, Xiao W, Hao W, et al. 2013 J. Nucl. Mater. 441 301

Google Scholar

Google Scholar

[23] Li Y, Han C, Zhang C, et al. 2016 Comp. Mater. Sci. 115 170

Google Scholar

Google Scholar

[24] Rice J R, Wang J S 1989 Mater. Sci. Eng. A-Struct 107 23

Google Scholar

Google Scholar

[25] 张颖, 吕广宏, 邓胜华 2006 55 2901

Google Scholar

Google Scholar

Zhang Y, Lü G H, Deng S H 2006 Acta Phys. Sin. 55 2901

Google Scholar

Google Scholar

[26] 王晓中, 林理彬, 何捷, 等 2011 60 077104

Google Scholar

Google Scholar

Wang X Z, Lin L B, He J, et al. 2011 Acta Phys. Sin. 60 077104

Google Scholar

Google Scholar

[27] Zhou H, Jin S, Zhang Y, Lu G 2011 Prog. Nat. Sci. 21 240

Google Scholar

Google Scholar

[28] Shi F, Tian P C, Jia N, et al. 2016 Corros. Sci. 107 49

Google Scholar

Google Scholar

[29] Mahjoub R, Laws K J, Stanford N, Ferry M 2018 Acta Mater. 158 257

Google Scholar

Google Scholar

[30] Blöchl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[31] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[32] Häglund J, Guillermet A F, Grimvall G, et al. 1993 Phys. Rev. B 48 11685

Google Scholar

Google Scholar

[33] Jiang D E, Carter E A 2003 Phys. Rev. B 67 214103

Google Scholar

Google Scholar

[34] Basinski Z S, Hume-Rothery W, Sutton A L 1955 Proc. R. Soc. Lond. A 229 459

Google Scholar

Google Scholar

[35] Bean J J, McKenna K P 2016 Acta Mater. 110 246

Google Scholar

Google Scholar

[36] Tran R, Xu Z, Zhou N, et al. 2016 Acta Mater. 117 91

Google Scholar

Google Scholar

[37] Yang Y, Ding J, Zhang P, et al. 2019 Nucl. Instrum. Meth. B 456 7

Google Scholar

Google Scholar

[38] Lejcek P 2010 Grain Boundary Segregation in Metals (Berlin: Springer Science & Business Media) p51

[39] Zhang S, Kontsevoi O Y, Freeman A J, et al. 2011 Acta Mater. 59 6155

Google Scholar

Google Scholar

[40] Wu X, You Y W, Kong X S, et al. 2016 Acta Mater. 120 315

Google Scholar

Google Scholar

[41] Tian Z X, Yan J X, Xiao W, et al. 2009 Phys. Rev. B 79 144114

Google Scholar

Google Scholar

[42] Yamaguchi M, Shiga M, Kaburaki H 2005 Science 307 393

Google Scholar

Google Scholar

[43] Rose J H, Smith J R, Ferrante J 1983 Phys. Rev. B 28 1835

[44] Warrington D H 1975 J. Phys. Colloques 36 C4-87

[45] Brokman A, Balluffi R W 1981 Acta Metall. 29 1703

Google Scholar

Google Scholar

[46] Scholz F 1997 J Solid State Electrochem 1 117

Google Scholar

Google Scholar

[47] Zheng H, Li X, Tran R, et al. 2020 Acta Mater. 186 40

Google Scholar

Google Scholar

[48] Hatcher N, Madsen G K H, Drautz R 2014 J. Phys. Condens. Mat. 26 145502

Google Scholar

Google Scholar

[49] Rhodes N R, Tschopp M A, Solanki K N 2013 Model. Simul. Mater. Sc. 21 035009

Google Scholar

Google Scholar

[50] Bai J, Cui Y, Wang J, et al. 2018 Metals 8 497

Google Scholar

Google Scholar

-

图 7 (a)未添加B原子和(b)添加B原子Σ9(114)晶界的总态密度图, 以及B原子附近Fe1, Fe2和B原子的分波态密度图

Figure 7. The total density of states (TDOS) of Σ9(114) grain boundary without and with B atom, correspond to (a) and (b) respectively, and the projected density of states (PDOS) of Fe atoms in the vicinity of B atom (Fe1 and Fe2)and B atom.

表 1 fcc-Fe的CSL晶界的结构特性

Table 1. Structural characteristics of calculated grain boundaries

Grain boundaries γGB/(J·m–2) ΔV/(Å3·Å–2) Angle/(°) Numbers of atomes Supercell dimensions/(Å × Å × Å) S/Å2 ∑3(112)[110] 0.341 0.207 109.47 48 4.86 × 5.955 × 17.037 28.94 ∑5(210)[001] 1.661 0.762 53.13 76 6.873 × 7.685 × 15.37 52.82 ∑5(310)[001] 1.925 0.543 36.87 78 5.434 × 6.873 × 21.736 37.35 ∑9(114)[110] 1.546 0.771 141.06 68 4.86 × 10.31 × 14.58 52.54 ∑9(221)[110] 1.716 1.143 38.94 68 4.86 × 7.29 × 20.62 35.43 ∑11(113)[110] 0.559 0.499 129.52 88 4.86 × 8.06 × 23.296 39.17 表 2 B原子在各晶界最佳偏析位的多面体结构模型、添加B原子前后的多面体的体积和体积增量、B原子与近邻Fe原子的键长, 以及引起晶界能的变化量

Table 2. The local atomic configurations of the stable segregation sites, the volume and volume increment of the polyhedron without and with B, the bond length between B and neighboring Fe atoms, and the change of grain boundary energy caused by B segregation when B at the stable segregation sites.

Σ3(112) Σ5(210) Σ5(310) Σ9(221) Σ9(114) Σ11(113) Polyhedron of favorable interstitial sites

Volume of polyhedron/Å3 Vpure Fe 5.80 4.73 5.41 5.03 13.90 6.01 Vwith B 7.67 4.91 5.75 5.16 15.09 6.06 Vwith B-Vpure Fe 1.88 0.18 0.34 0.13 1.20 0.04 Bond length of

Fe-B/ÅFe1-B 2.04 2.17 2.15 2.13 2.09 1.98 Fe2-B 2.84 2.03 2.06 2.02 2.22 1.95 The change of grain boundary energy /(mJ·m–2) –14.90 –8.72 –11.50 –31.10 –25.00 –5.02 -

[1] Ma S, Pan W, Xing J, et al. 2017 Mater. Chem. Phys. 199 356

Google Scholar

Google Scholar

[2] Naderi M, Ketabchi M, Abbasi M, et al. 2010 Steel Res. Int. 81 216

Google Scholar

Google Scholar

[3] Ghali S N, El-Faramawy H S, Eissa M M 2012 J. Miner. Mater. Char. Eng. 11 995

[4] Jones R B, Younes C M, Heard P J, et al. 2002 Acta Mater. 50 4395

Google Scholar

Google Scholar

[5] Zarandi F, Yue S 2006 Metall. Mater. Trans. A 37 2316

Google Scholar

Google Scholar

[6] López-Chipres E, Mejía I, Maldonado C, et al. 2007 Mater. Sci. Eng. A-Struct 460/461 464

Google Scholar

Google Scholar

[7] Mejía I, Bedolla-Jacuinde A, Maldonado C, et al. 2011 Mater. Sci. Eng. A-Struct 528 4468

Google Scholar

Google Scholar

[8] Deva A, Jha B K, Mishra N S 2011 Mater. Sci. Eng. A-Struct 528 7375

Google Scholar

Google Scholar

[9] Takahashi J, Ishikawa K, Kawakami K, et al. 2017 Acta Mater. 133 41

Google Scholar

Google Scholar

[10] Li Y, Ponge D, Choi P, Raabe D 2015 Scripta Mater. 96 13

Google Scholar

Google Scholar

[11] 王博, 张建民, 路彦冬, 等 2011 60 016601

Google Scholar

Google Scholar

Wang B, Zhang J M, Lu Y D, et al. 2011 Acta Phys. Sin. 60 016601

Google Scholar

Google Scholar

[12] 孟凡顺, 李久会, 赵星 2014 63 237102

Google Scholar

Google Scholar

Meng F S, Li J H, Zhao X 2014 Acta Phys. Sin. 63 237102

Google Scholar

Google Scholar

[13] Li Y, Korzhavyi P A, Sandström R, et al. 2017 Phys. Rev. Mater. 1 070602

Google Scholar

Google Scholar

[14] Huang Z, Chen F, Shen Q, et al. 2018 Acta Mater. 148 110

Google Scholar

Google Scholar

[15] Huang Z, Chen F, Shen Q, et al. 2019 Acta Mater. 166 113

Google Scholar

Google Scholar

[16] Du Y A, Ismer L, Rogal J, et al. 2011 Phys. Rev. B 84 144121

Google Scholar

Google Scholar

[17] Wang J, Janisch R, Madsen G K H, et al. 2016 Acta Mater. 115 259

Google Scholar

Google Scholar

[18] Razumovskiy V I, Lozovoi A Y, Razumovskii I M 2015 Acta Mater. 82 369

Google Scholar

Google Scholar

[19] Bentria E L T, Lefkaier I K, Bentria B 2013 Mater. Sci. Eng. A-Struct 577 197

Google Scholar

Google Scholar

[20] Wu R, Freeman A J, Olson G B 1994 Science 265 376

Google Scholar

Google Scholar

[21] Shang J X, Wang C Y 2001 J. Phys.-Condens. Mat. 13 9635

Google Scholar

Google Scholar

[22] He B, Xiao W, Hao W, et al. 2013 J. Nucl. Mater. 441 301

Google Scholar

Google Scholar

[23] Li Y, Han C, Zhang C, et al. 2016 Comp. Mater. Sci. 115 170

Google Scholar

Google Scholar

[24] Rice J R, Wang J S 1989 Mater. Sci. Eng. A-Struct 107 23

Google Scholar

Google Scholar

[25] 张颖, 吕广宏, 邓胜华 2006 55 2901

Google Scholar

Google Scholar

Zhang Y, Lü G H, Deng S H 2006 Acta Phys. Sin. 55 2901

Google Scholar

Google Scholar

[26] 王晓中, 林理彬, 何捷, 等 2011 60 077104

Google Scholar

Google Scholar

Wang X Z, Lin L B, He J, et al. 2011 Acta Phys. Sin. 60 077104

Google Scholar

Google Scholar

[27] Zhou H, Jin S, Zhang Y, Lu G 2011 Prog. Nat. Sci. 21 240

Google Scholar

Google Scholar

[28] Shi F, Tian P C, Jia N, et al. 2016 Corros. Sci. 107 49

Google Scholar

Google Scholar

[29] Mahjoub R, Laws K J, Stanford N, Ferry M 2018 Acta Mater. 158 257

Google Scholar

Google Scholar

[30] Blöchl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[31] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[32] Häglund J, Guillermet A F, Grimvall G, et al. 1993 Phys. Rev. B 48 11685

Google Scholar

Google Scholar

[33] Jiang D E, Carter E A 2003 Phys. Rev. B 67 214103

Google Scholar

Google Scholar

[34] Basinski Z S, Hume-Rothery W, Sutton A L 1955 Proc. R. Soc. Lond. A 229 459

Google Scholar

Google Scholar

[35] Bean J J, McKenna K P 2016 Acta Mater. 110 246

Google Scholar

Google Scholar

[36] Tran R, Xu Z, Zhou N, et al. 2016 Acta Mater. 117 91

Google Scholar

Google Scholar

[37] Yang Y, Ding J, Zhang P, et al. 2019 Nucl. Instrum. Meth. B 456 7

Google Scholar

Google Scholar

[38] Lejcek P 2010 Grain Boundary Segregation in Metals (Berlin: Springer Science & Business Media) p51

[39] Zhang S, Kontsevoi O Y, Freeman A J, et al. 2011 Acta Mater. 59 6155

Google Scholar

Google Scholar

[40] Wu X, You Y W, Kong X S, et al. 2016 Acta Mater. 120 315

Google Scholar

Google Scholar

[41] Tian Z X, Yan J X, Xiao W, et al. 2009 Phys. Rev. B 79 144114

Google Scholar

Google Scholar

[42] Yamaguchi M, Shiga M, Kaburaki H 2005 Science 307 393

Google Scholar

Google Scholar

[43] Rose J H, Smith J R, Ferrante J 1983 Phys. Rev. B 28 1835

[44] Warrington D H 1975 J. Phys. Colloques 36 C4-87

[45] Brokman A, Balluffi R W 1981 Acta Metall. 29 1703

Google Scholar

Google Scholar

[46] Scholz F 1997 J Solid State Electrochem 1 117

Google Scholar

Google Scholar

[47] Zheng H, Li X, Tran R, et al. 2020 Acta Mater. 186 40

Google Scholar

Google Scholar

[48] Hatcher N, Madsen G K H, Drautz R 2014 J. Phys. Condens. Mat. 26 145502

Google Scholar

Google Scholar

[49] Rhodes N R, Tschopp M A, Solanki K N 2013 Model. Simul. Mater. Sc. 21 035009

Google Scholar

Google Scholar

[50] Bai J, Cui Y, Wang J, et al. 2018 Metals 8 497

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 11801

- PDF Downloads: 383

- Cited By: 0

DownLoad:

DownLoad: