-

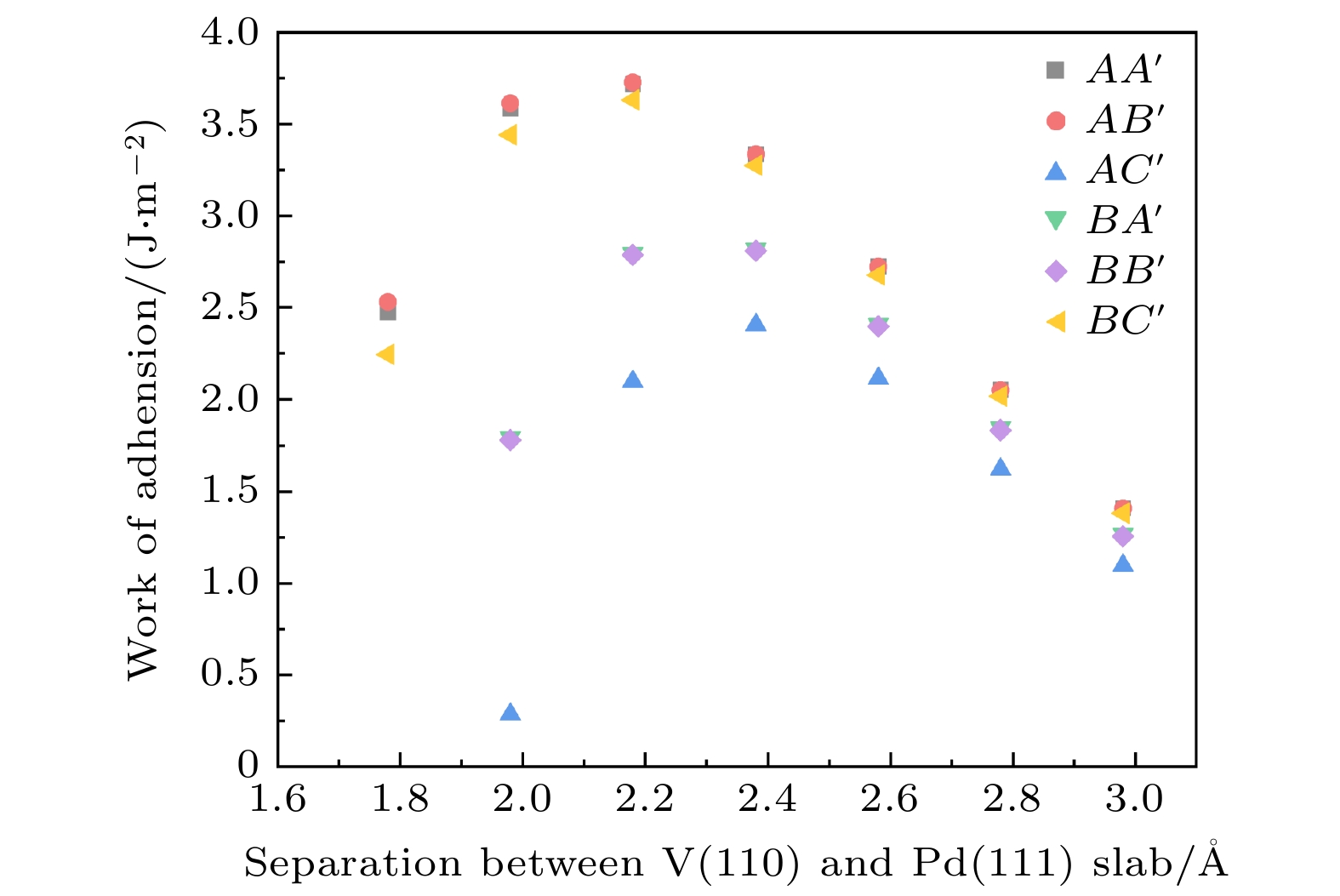

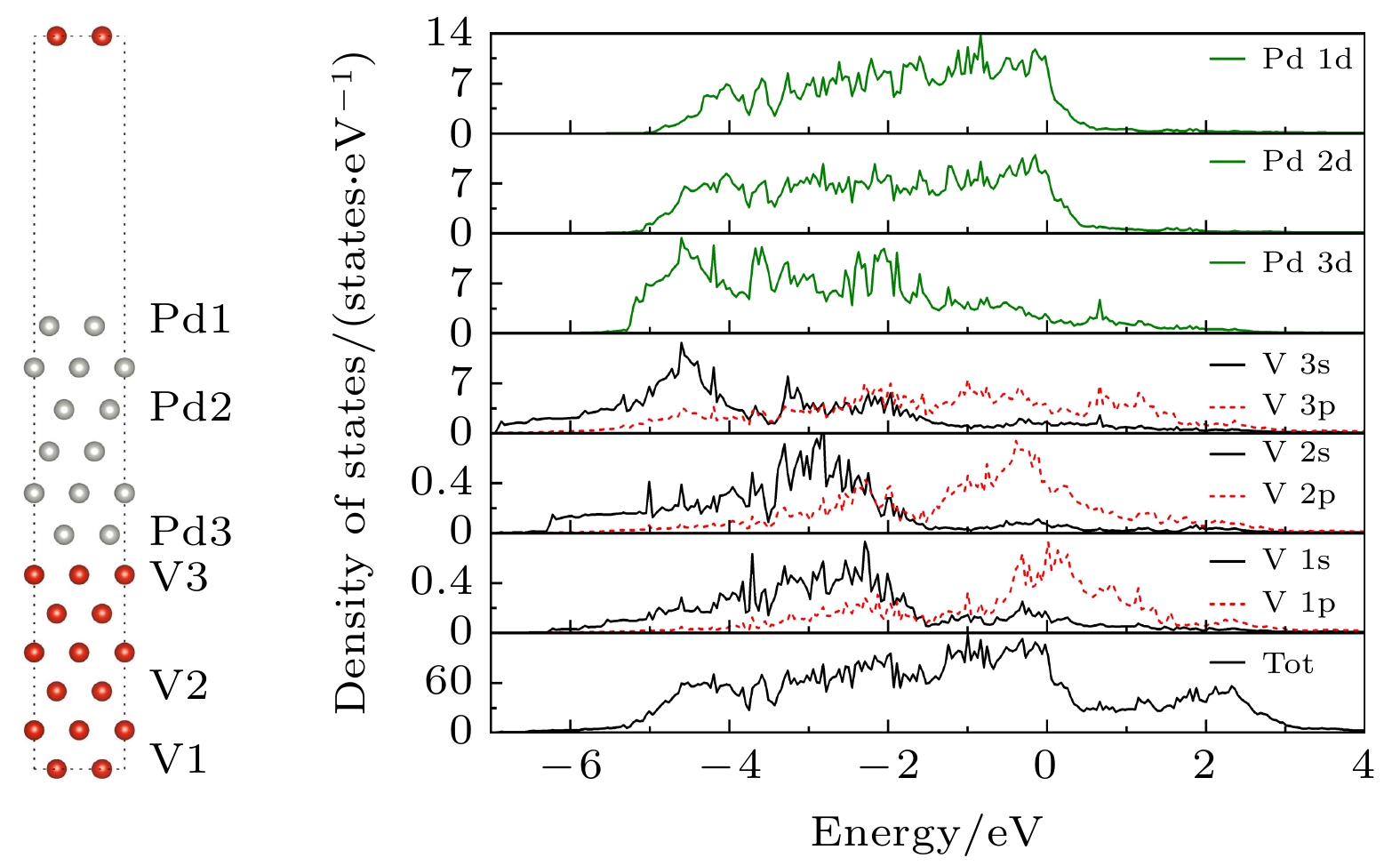

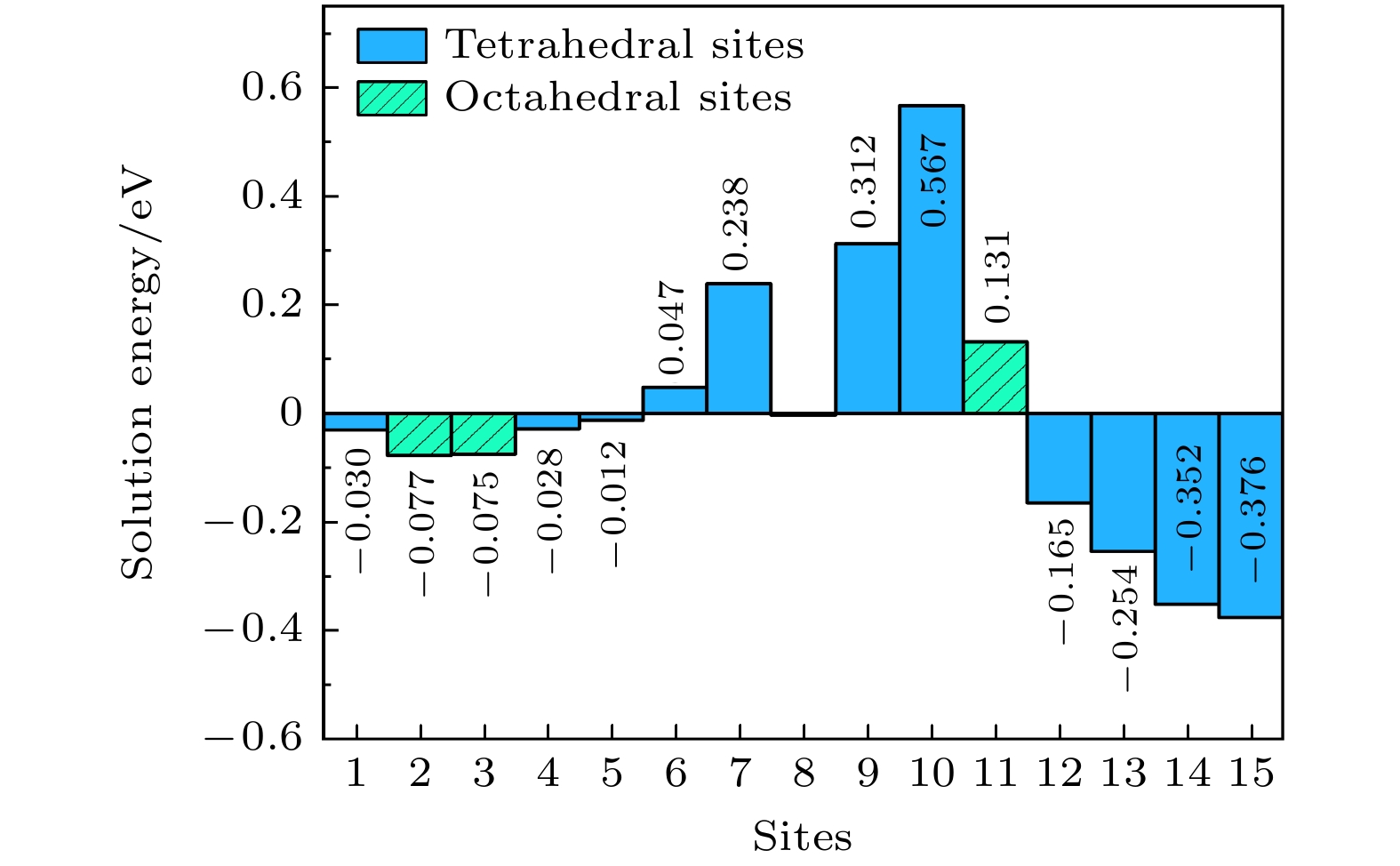

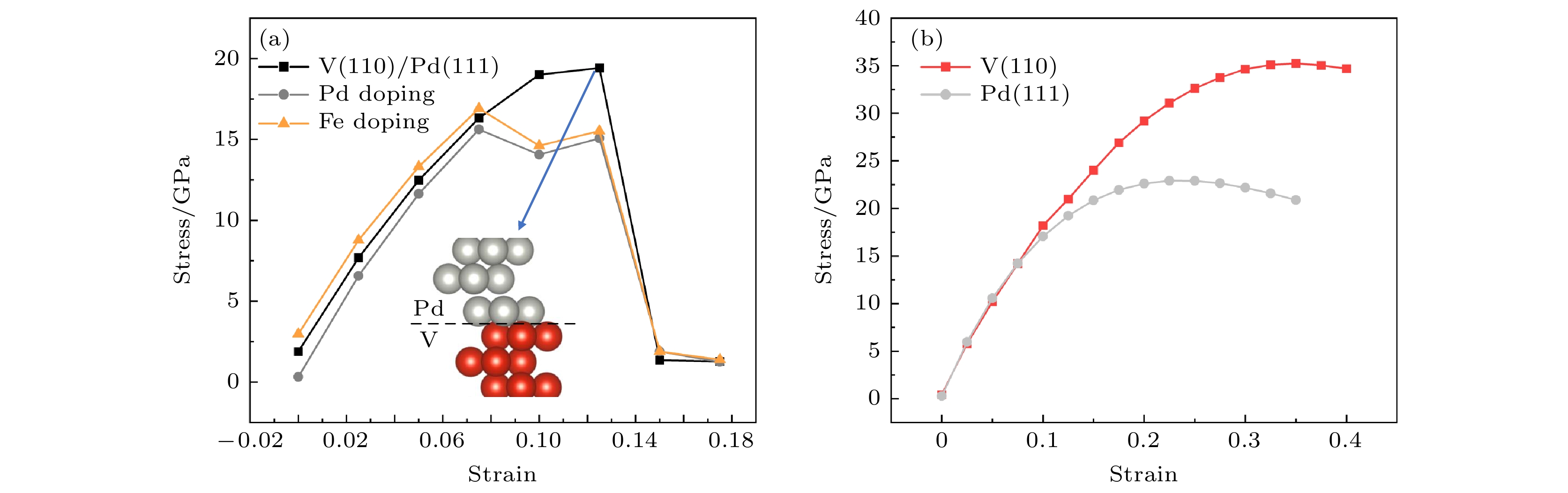

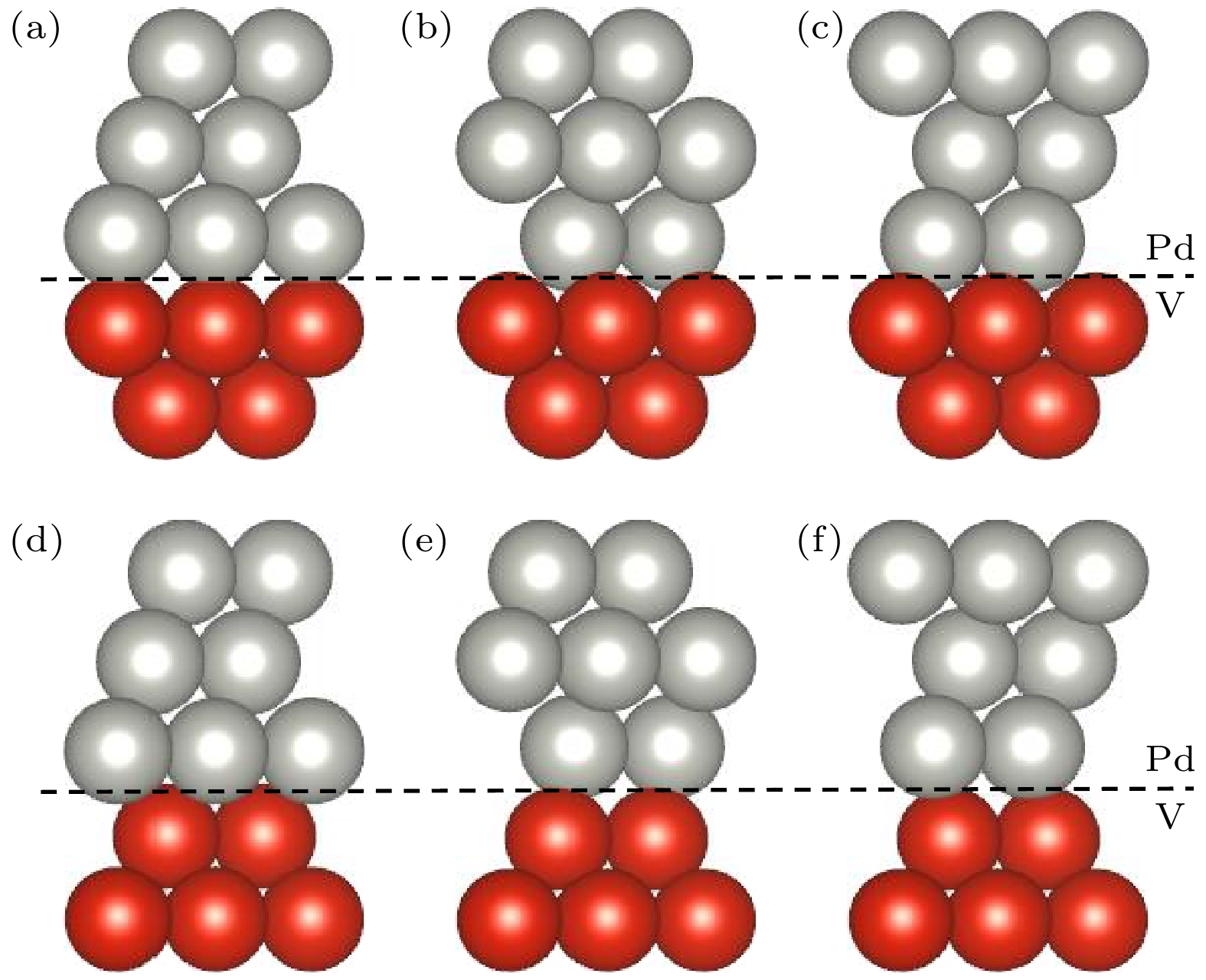

Hydrogen permeation through vanadium/palladium (V/Pd) metal composite membranes is an effective and practical method of separating hydrogen from gas mixtures. In order to gain an insight into the relation between the interfacial structure and hydrogen adsorption/diffusion properties of the catalytic Pd layer bonded to the metal membrane, and then improve the ability of the alloy membrane to purify hydrogen, the first principle based on the density functional theory is used to study the hydrogen adsorption/diffusion behavior at the V/Pd metal composite membrane interface. The results show that because the charge density at the V/Pd interface increases with the V/Pd bonding increasing, the dissolution energy of hydrogen atom (H) increases with it approaching to the interface, and it has the highest dissolution energy near the V/Pd interface (0.567 eV). Hydrogen migration energy barrier calculations show that compared with the maximum energy barrier for horizontal diffusion of H along the V/Pd interface (0.64 eV), the H vertical V/Pd interface energy barrier (0.56 eV) is small, thus H tends to migrate vertically V/Pd interface and diffuse from the Pd layer to the V substrate side. As the hydrogen solvation energy of the Pd layer at the V/Pd interface (0.238 eV) is higher than that on the V membrane side (–0.165 eV), H will gather on the V film side of the interface, which is easy to cause hydrogen to be embrittled. Calculations of Pd/Fe doping of the V matrix show that comparing with the undoped energy barrier (0.56 eV), Pd/Fe doping can significantly reduce the maximum energy barrier (0.45 eV/0.54 eV) in the diffusion path of the interface, which is favorable for hydrogen permeation and diffusion. And the doped interface can inhibit the interdiffusion of V layer and catalytic Pd layer to a certain extent, which improves the structural stability of the composite film.

-

Keywords:

- V/Pd interface /

- first principle /

- hydrogen permeation characteristics /

- mechanical property

[1] Li Q, Garcia-Muelas R, Lopez N 2018 Nat. Commun. 9 526

Google Scholar

Google Scholar

[2] Kim T, Song Y, Kang J, Kim S K, Kim S 2022 Int. J. Hydrogen Energy 47 24817

Google Scholar

Google Scholar

[3] Agnolin S, Melendez J, Di Felice L, Gallucci F 2022 Int. J. Hydrogen Energy 47 28505

Google Scholar

Google Scholar

[4] Park S B, Nam G H, Park Y I 2022 Thin Solid Films 757 139391

Google Scholar

Google Scholar

[5] Dolan M D 2010 J. Membr. Sci. 362 12

Google Scholar

Google Scholar

[6] Kozhakhmetov S, Sidorov N, Piven V, Sipatov I, Gabis I, Arinov B 2015 J. Alloys Compd. 645 S36

Google Scholar

Google Scholar

[7] Dolan M D, Viano D M, Langley M J, Lamb K E 2018 J. Membr. Sci. 549 306

Google Scholar

Google Scholar

[8] Zhang S, Zhang Z, Li J, Tu R, Shen Q, Wang C, Luo G, Zhang L 2020 J. Wuhan Univ. Technol. 35 879

Google Scholar

Google Scholar

[9] Ko W S, Jeon J B, Shim J H, Lee B J 2012 Int. J. Hydrogen Energy 37 13583

Google Scholar

Google Scholar

[10] Fasolin S, Barison S, Agresti F, Battiston S, Fiameni S, Isopi J, Armelao L 2022 Membranes (Basel, Switz.) 12 16

Google Scholar

Google Scholar

[11] Alimov V N, Busnyuk A O, Notkin M E, Livshits A I 2014 J. Membr. Sci. 457 103

Google Scholar

Google Scholar

[12] Dai J H, Xie R W, Chen Y Y, Song Y 2015 Phys. Chem. Chem. Phys. 17 16594

Google Scholar

Google Scholar

[13] Il Jeon S, Park J H, Magnone E, Lee Y T, Fleury E 2012 Curr. Appl. Phys. 12 394

Google Scholar

Google Scholar

[14] Ko W S, Oh J Y, Shim J H, Suh J Y, Yoon W Y, Lee B J 2014 Int. J. Hydrogen Energy 39 12031

Google Scholar

Google Scholar

[15] Qin J Y, Wang Z M, Wang D H, Wang F, Yan X F, Zhong Y, Hu C H, Zhou H Y 2019 J. Alloys Compd. 805 747

Google Scholar

Google Scholar

[16] Qin J Y, Hao C Y, Wang D H, Wang F, Yan X F, Zhong Y, Wang Z M, Hu C H, Wang X T 2020 J. Adv. Res. 21 25

Google Scholar

Google Scholar

[17] Mills G, Jonsson H, Schenter G K 1995 Surf. Sci. 324 305

Google Scholar

Google Scholar

[18] Henkelman G, Jonsson H 2000 J. Chem. Phys. 113 9978

Google Scholar

Google Scholar

[19] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[20] Blochl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[21] Qin J Y, Liu Z G, Zhao W, Wang D A H, Zhang Y L, Zhong Y, Zhang X H, Wang Z M, Hu C H, Liu J W 2021 Materials 14 12

Google Scholar

Google Scholar

[22] Mills G, Schenter G K, Makarov D E, Jonsson H 1997 Chem. Phys. Lett. 278 91

Google Scholar

Google Scholar

[23] Mills G, Jonsson H 1994 Phys. Rev. Lett. 72 1124

Google Scholar

Google Scholar

[24] Chen J F, Hu L, Tang T 2022 J. Phys. Chem. C 126 7468

Google Scholar

Google Scholar

[25] Castleton C W M, Hoglund A, Gothelid M, Qian M C, Mirbt S 2013 Phys. Rev. B 88 7

Google Scholar

Google Scholar

[26] Zhang H L, Wang J J, Huang W J, Wang L Q, Lu Z B 2022 Surf. Interfaces 30 10

Google Scholar

Google Scholar

[27] Rose J H, Ferrante J, Smith J R 1981 Phys. Rev. Lett. 47 675

Google Scholar

Google Scholar

[28] Jin N, Yang Y Q, Li J, Luo X, Huang B, Sun Q, Guo P F 2014 J. Appl. Phys. 115 11

Google Scholar

Google Scholar

[29] Lu T, Chen Q X 2018 Acta Phys. Chim. Sin. 34 503

Google Scholar

Google Scholar

[30] Wang J W, Song M, He Y H, Gong H R 2016 J. Membr. Sci. 503 124

Google Scholar

Google Scholar

[31] Kang S G, Coulter K E, Gade S K, Way J D, Sholl D S 2011 J. Phys. Chem. Lett. 2 3040

Google Scholar

Google Scholar

[32] Yang L, Wirth B D 2020 J. Appl. Phys. 127 12

Google Scholar

Google Scholar

[33] Puska M J, Nieminen R M, Manninen M 1981 Phys. Rev. B 24 3037

Google Scholar

Google Scholar

[34] Ko W S, Shim J H, Jung W S, Lee B J 2016 J. Membr. Sci. 497 270

Google Scholar

Google Scholar

-

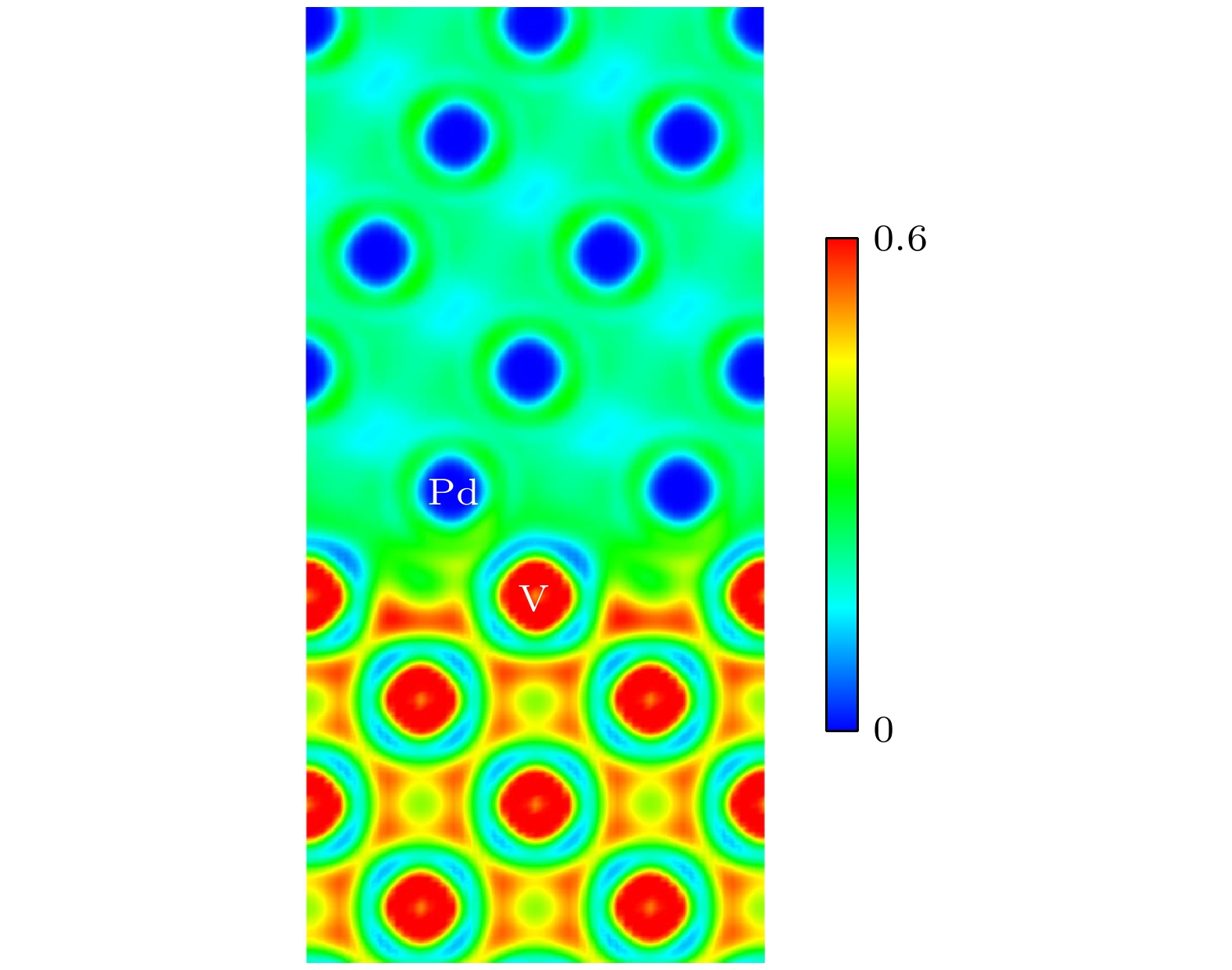

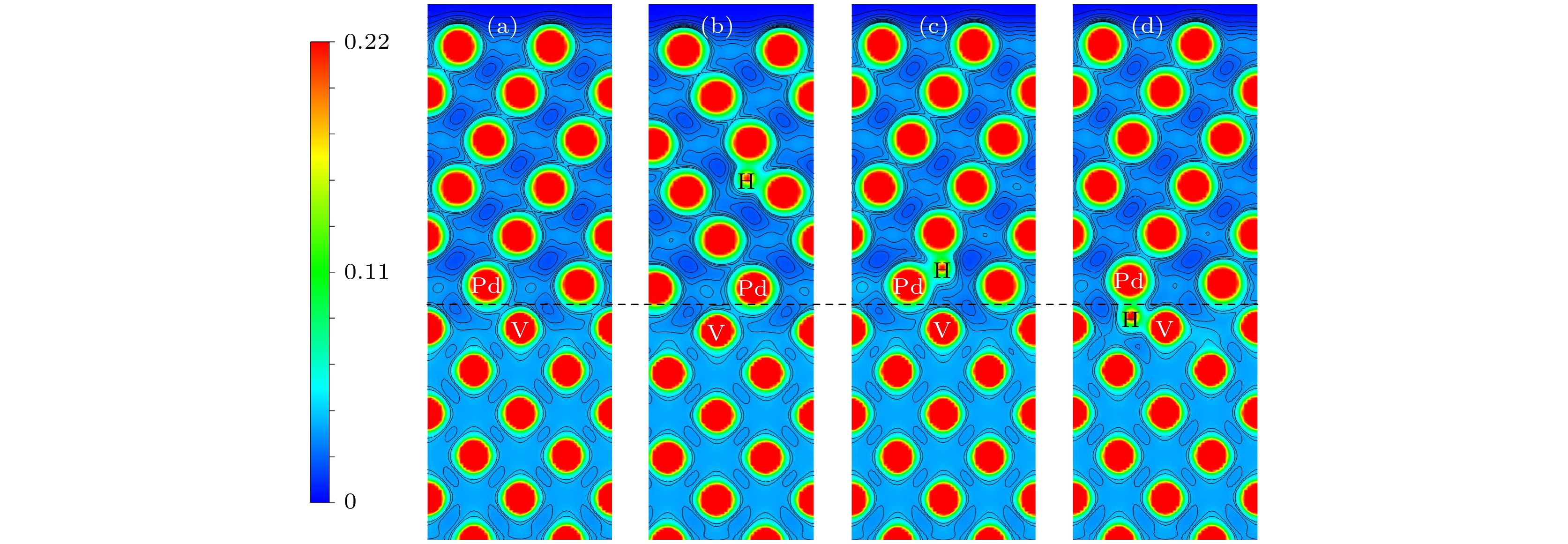

图 9 V/Pd界面的电荷密度 (a) 没有H原子的界面电荷密度图; (b)—(d) 分别为H原子在图5(a)中1, 7, 9位置的电荷密度图

Figure 9. Charge density at V/Pd interface: (a) Interface charge density map without H atom; (b)–(d) the charge density maps of H atoms at positions 1, 7, and 9 in Fig. 5 (a), respectively.

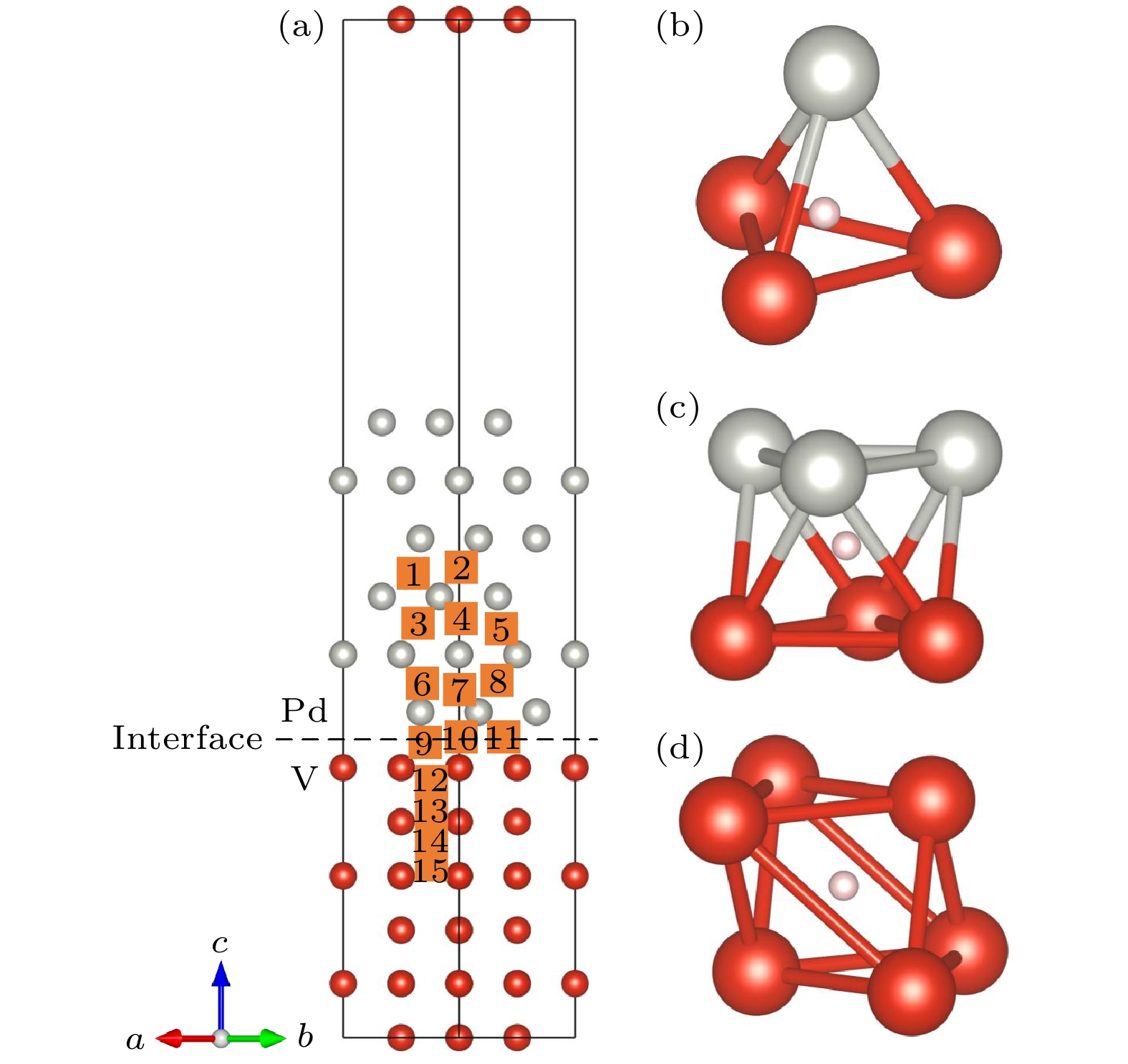

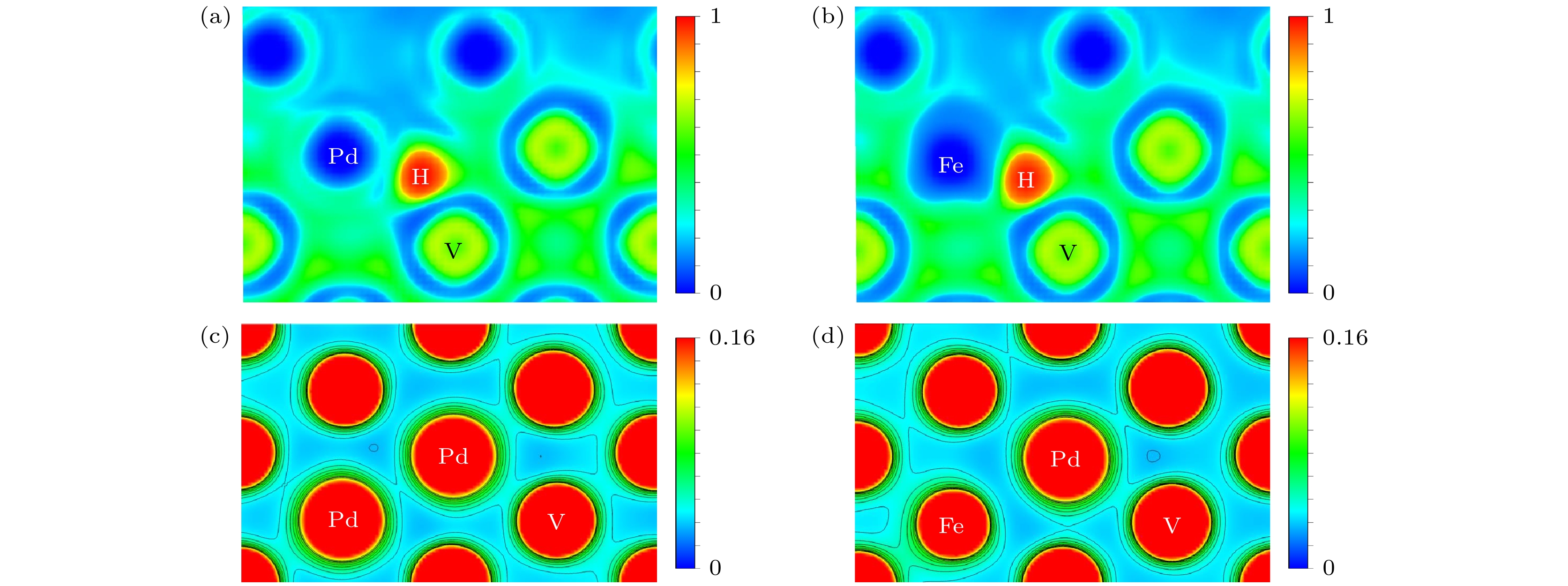

图 12 (a) H在Pd掺杂界面S4位置的电子局域函数图; (b) H在Fe掺杂界面S4位置的电子局域函数图; (c) Pd在Pd掺杂V基体空位的电荷密度图; (d) Pd在Fe掺杂V基体空位的电荷密度图

Figure 12. (a) Electronic local function diagram of H at S4 position of Pd doping interface; (b) electronic local function diagram of H at S4 position of Fe doping interface; (c) charge density diagram of Pd in Pd-doped V matrix vacancies; (d) charge density diagram of Pd in Fe-doped V matrix vacancies.

表 1 不同厚度的V(110)面表面能

Table 1. Surface energy of V(110) surface with different thickness.

Number of atomic

layers of V (Pd)Surface energy/(J·m–2) V(110) Pd(111) 2(3) 2.42 1.434 4(6) 2.36 1.363 6(9) 2.37 1.361 8(12) 2.35 1.362 10(15) 2.34 1.361 -

[1] Li Q, Garcia-Muelas R, Lopez N 2018 Nat. Commun. 9 526

Google Scholar

Google Scholar

[2] Kim T, Song Y, Kang J, Kim S K, Kim S 2022 Int. J. Hydrogen Energy 47 24817

Google Scholar

Google Scholar

[3] Agnolin S, Melendez J, Di Felice L, Gallucci F 2022 Int. J. Hydrogen Energy 47 28505

Google Scholar

Google Scholar

[4] Park S B, Nam G H, Park Y I 2022 Thin Solid Films 757 139391

Google Scholar

Google Scholar

[5] Dolan M D 2010 J. Membr. Sci. 362 12

Google Scholar

Google Scholar

[6] Kozhakhmetov S, Sidorov N, Piven V, Sipatov I, Gabis I, Arinov B 2015 J. Alloys Compd. 645 S36

Google Scholar

Google Scholar

[7] Dolan M D, Viano D M, Langley M J, Lamb K E 2018 J. Membr. Sci. 549 306

Google Scholar

Google Scholar

[8] Zhang S, Zhang Z, Li J, Tu R, Shen Q, Wang C, Luo G, Zhang L 2020 J. Wuhan Univ. Technol. 35 879

Google Scholar

Google Scholar

[9] Ko W S, Jeon J B, Shim J H, Lee B J 2012 Int. J. Hydrogen Energy 37 13583

Google Scholar

Google Scholar

[10] Fasolin S, Barison S, Agresti F, Battiston S, Fiameni S, Isopi J, Armelao L 2022 Membranes (Basel, Switz.) 12 16

Google Scholar

Google Scholar

[11] Alimov V N, Busnyuk A O, Notkin M E, Livshits A I 2014 J. Membr. Sci. 457 103

Google Scholar

Google Scholar

[12] Dai J H, Xie R W, Chen Y Y, Song Y 2015 Phys. Chem. Chem. Phys. 17 16594

Google Scholar

Google Scholar

[13] Il Jeon S, Park J H, Magnone E, Lee Y T, Fleury E 2012 Curr. Appl. Phys. 12 394

Google Scholar

Google Scholar

[14] Ko W S, Oh J Y, Shim J H, Suh J Y, Yoon W Y, Lee B J 2014 Int. J. Hydrogen Energy 39 12031

Google Scholar

Google Scholar

[15] Qin J Y, Wang Z M, Wang D H, Wang F, Yan X F, Zhong Y, Hu C H, Zhou H Y 2019 J. Alloys Compd. 805 747

Google Scholar

Google Scholar

[16] Qin J Y, Hao C Y, Wang D H, Wang F, Yan X F, Zhong Y, Wang Z M, Hu C H, Wang X T 2020 J. Adv. Res. 21 25

Google Scholar

Google Scholar

[17] Mills G, Jonsson H, Schenter G K 1995 Surf. Sci. 324 305

Google Scholar

Google Scholar

[18] Henkelman G, Jonsson H 2000 J. Chem. Phys. 113 9978

Google Scholar

Google Scholar

[19] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[20] Blochl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[21] Qin J Y, Liu Z G, Zhao W, Wang D A H, Zhang Y L, Zhong Y, Zhang X H, Wang Z M, Hu C H, Liu J W 2021 Materials 14 12

Google Scholar

Google Scholar

[22] Mills G, Schenter G K, Makarov D E, Jonsson H 1997 Chem. Phys. Lett. 278 91

Google Scholar

Google Scholar

[23] Mills G, Jonsson H 1994 Phys. Rev. Lett. 72 1124

Google Scholar

Google Scholar

[24] Chen J F, Hu L, Tang T 2022 J. Phys. Chem. C 126 7468

Google Scholar

Google Scholar

[25] Castleton C W M, Hoglund A, Gothelid M, Qian M C, Mirbt S 2013 Phys. Rev. B 88 7

Google Scholar

Google Scholar

[26] Zhang H L, Wang J J, Huang W J, Wang L Q, Lu Z B 2022 Surf. Interfaces 30 10

Google Scholar

Google Scholar

[27] Rose J H, Ferrante J, Smith J R 1981 Phys. Rev. Lett. 47 675

Google Scholar

Google Scholar

[28] Jin N, Yang Y Q, Li J, Luo X, Huang B, Sun Q, Guo P F 2014 J. Appl. Phys. 115 11

Google Scholar

Google Scholar

[29] Lu T, Chen Q X 2018 Acta Phys. Chim. Sin. 34 503

Google Scholar

Google Scholar

[30] Wang J W, Song M, He Y H, Gong H R 2016 J. Membr. Sci. 503 124

Google Scholar

Google Scholar

[31] Kang S G, Coulter K E, Gade S K, Way J D, Sholl D S 2011 J. Phys. Chem. Lett. 2 3040

Google Scholar

Google Scholar

[32] Yang L, Wirth B D 2020 J. Appl. Phys. 127 12

Google Scholar

Google Scholar

[33] Puska M J, Nieminen R M, Manninen M 1981 Phys. Rev. B 24 3037

Google Scholar

Google Scholar

[34] Ko W S, Shim J H, Jung W S, Lee B J 2016 J. Membr. Sci. 497 270

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 5698

- PDF Downloads: 104

- Cited By: 0

DownLoad:

DownLoad: