-

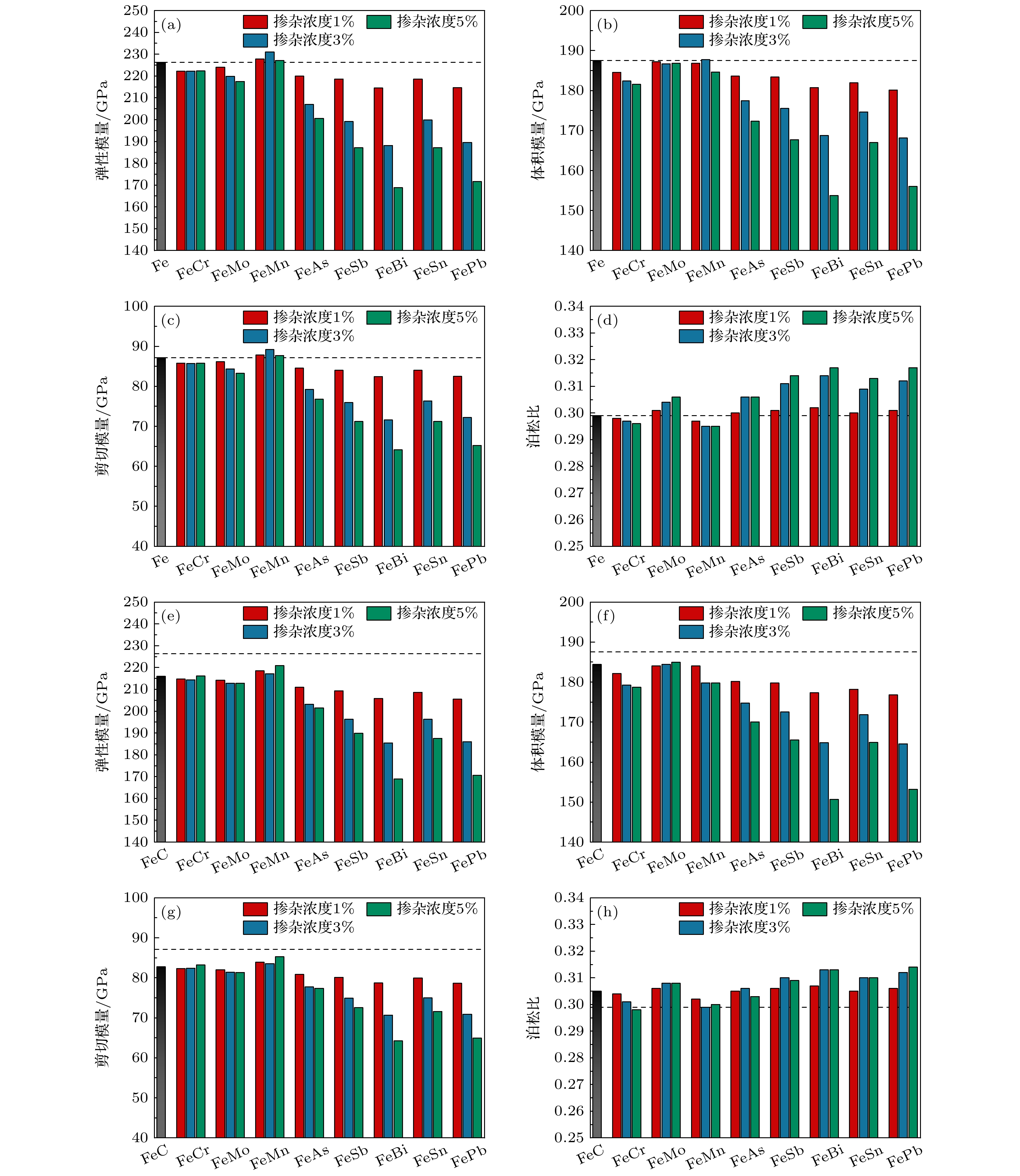

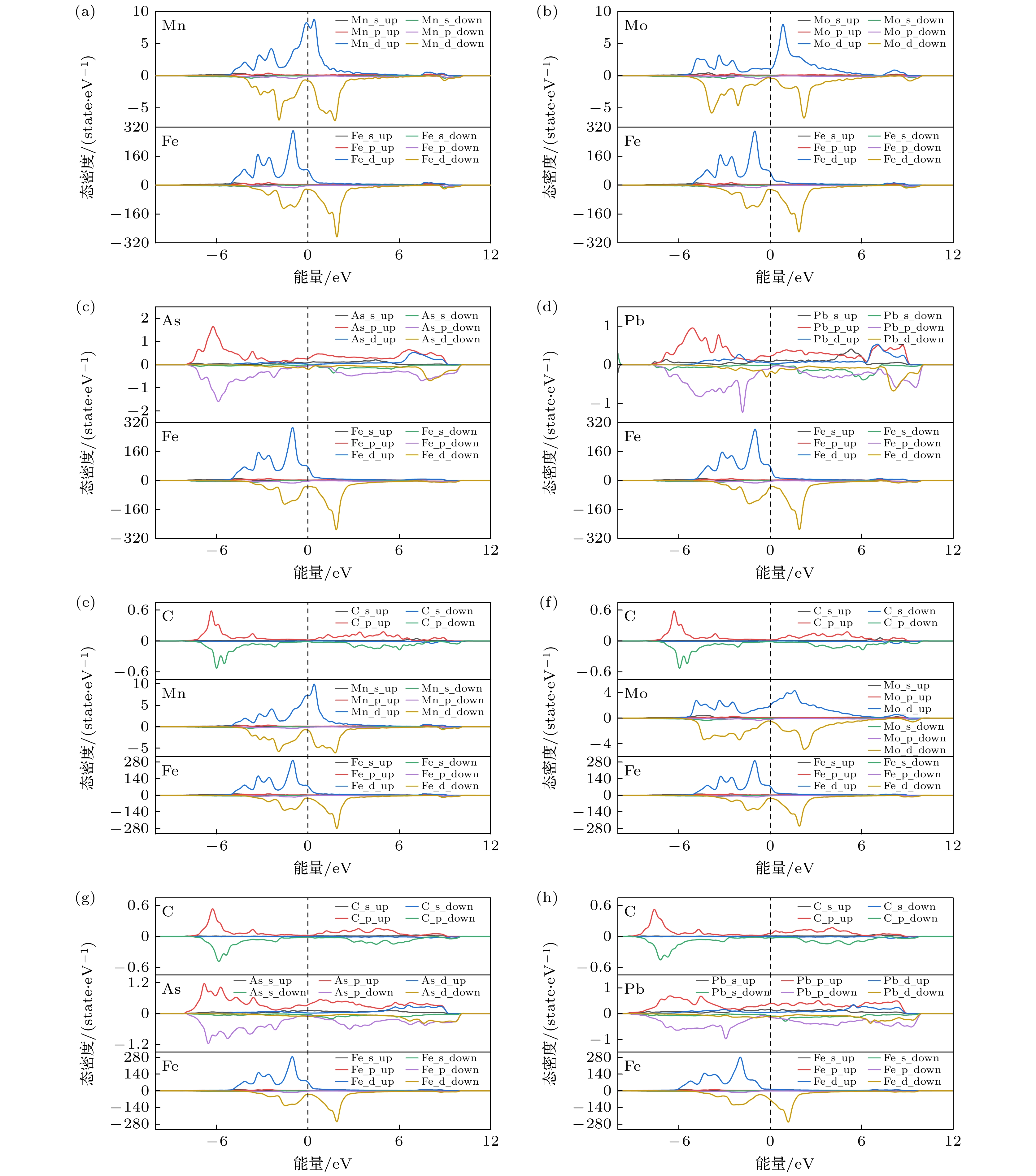

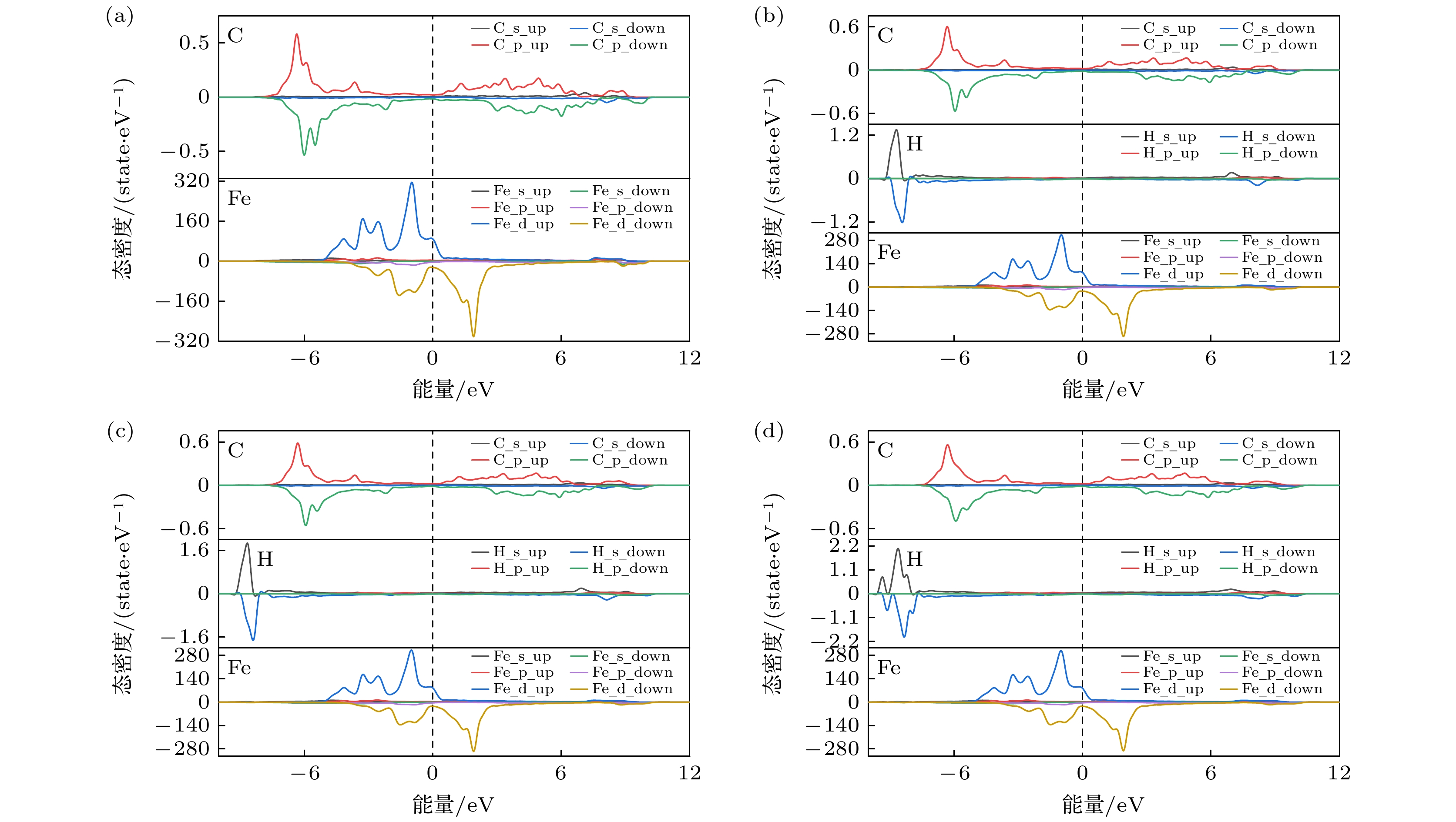

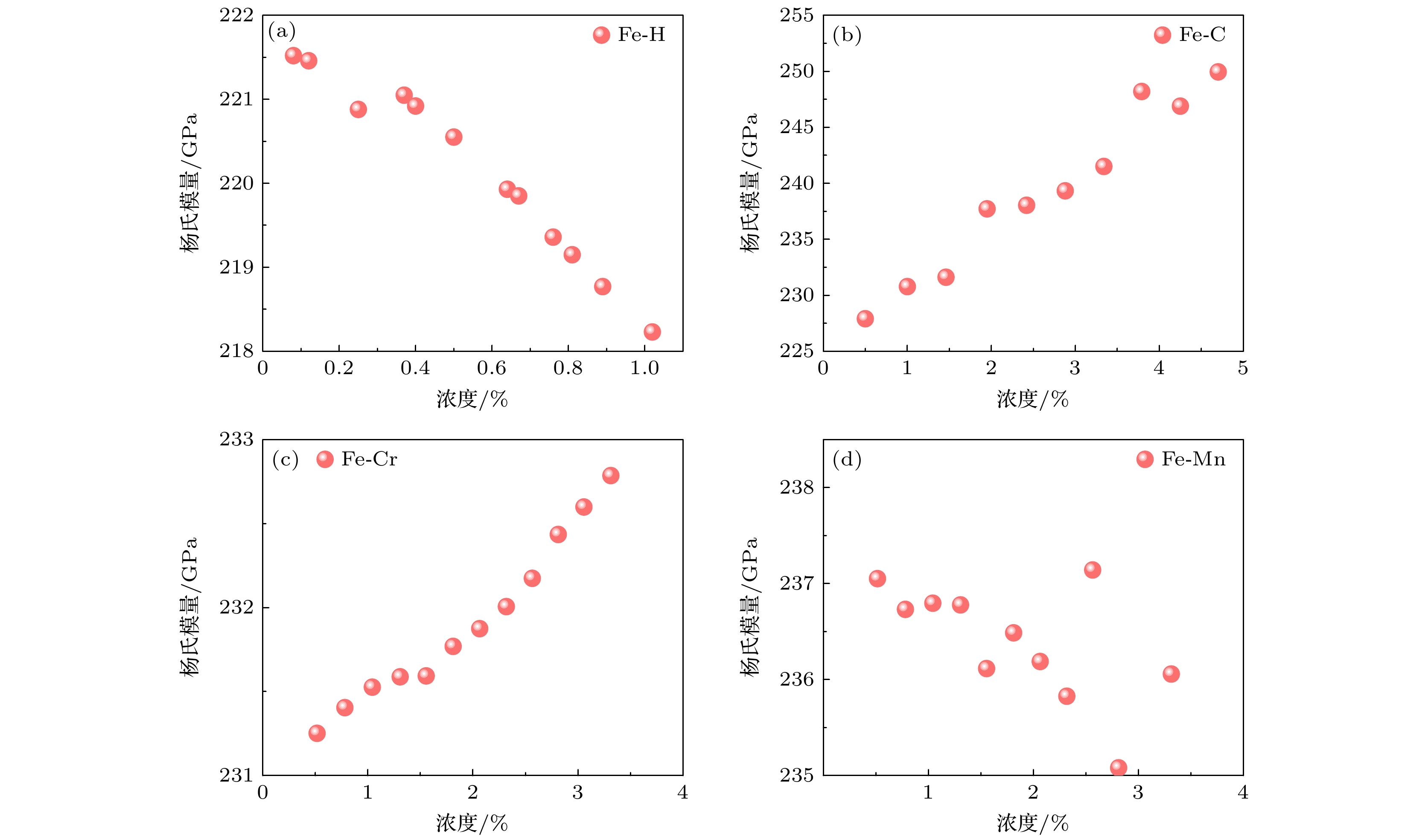

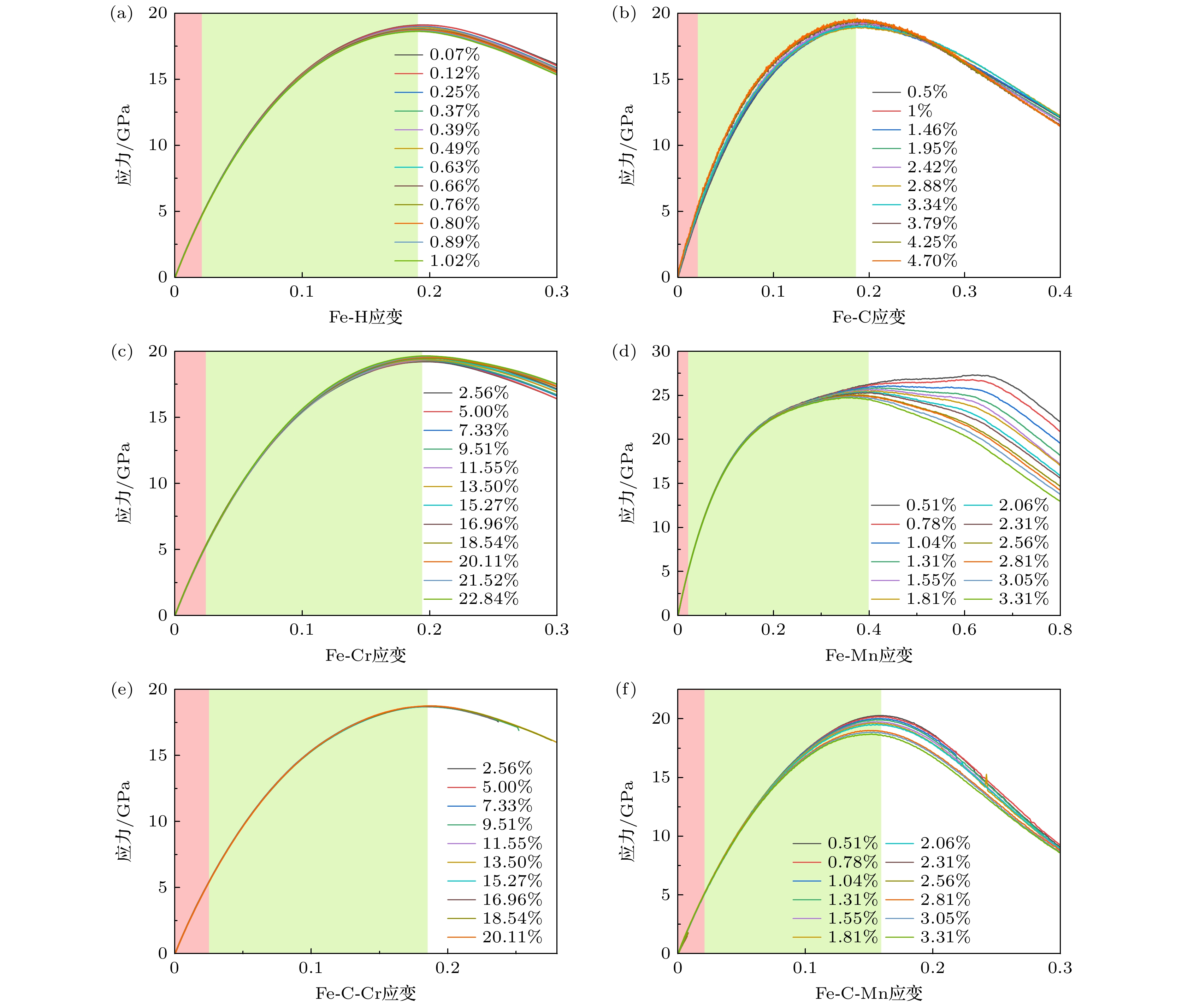

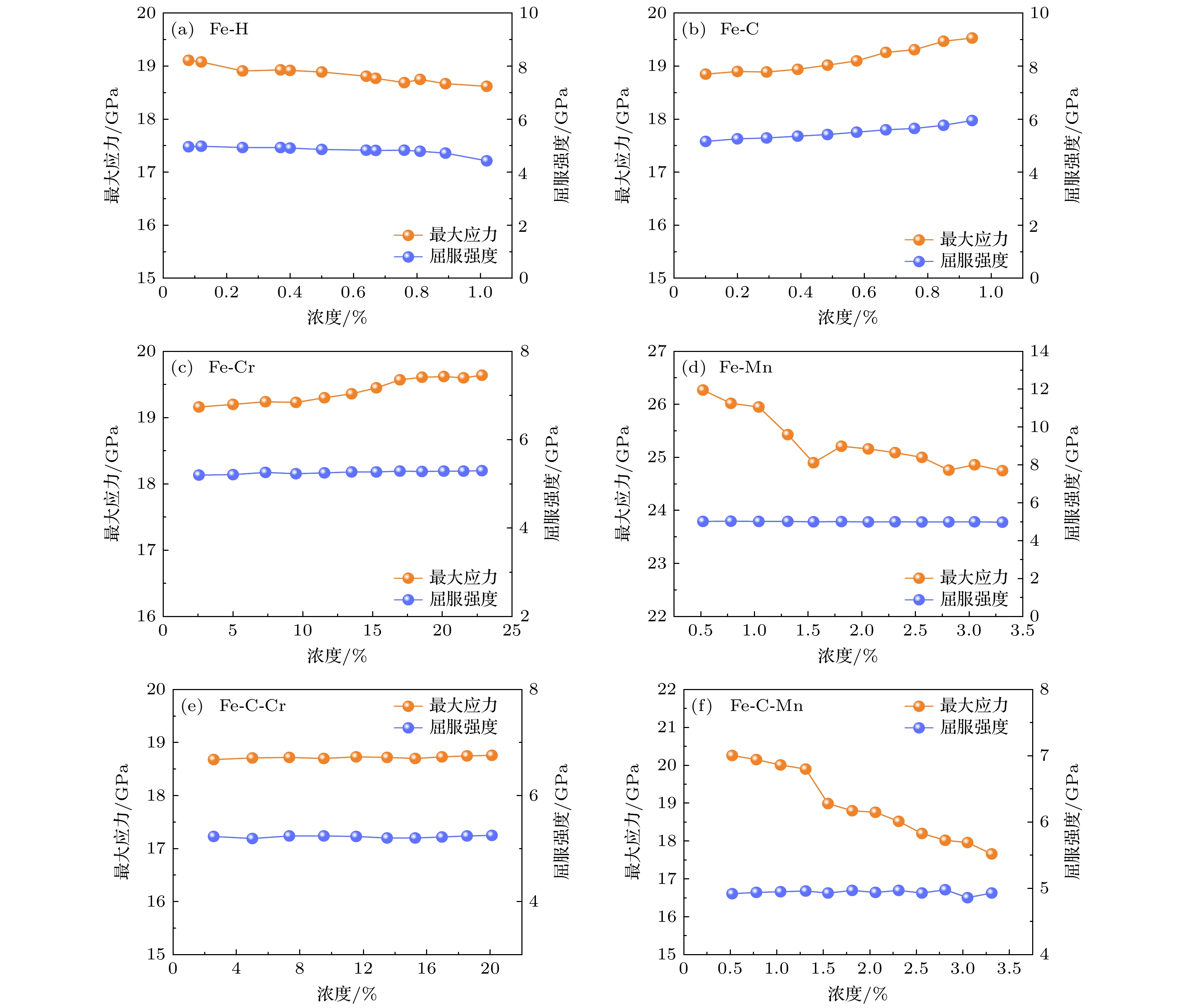

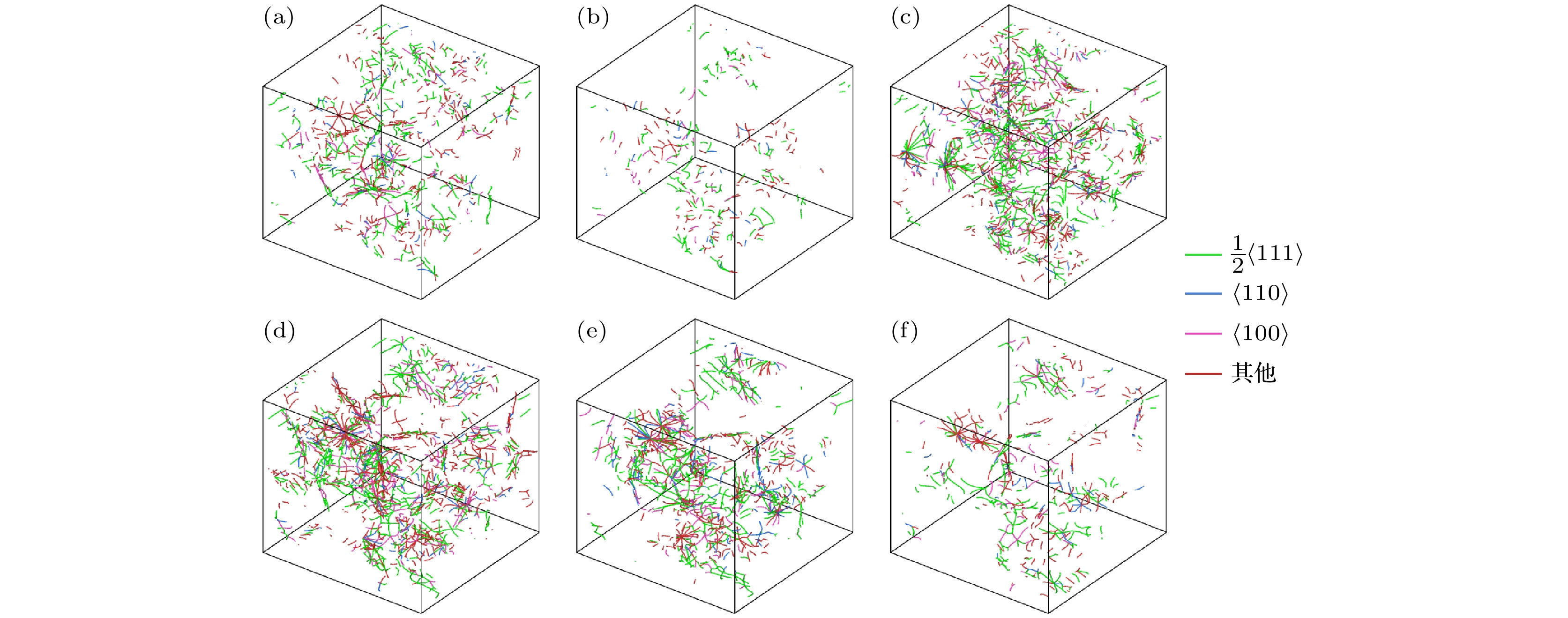

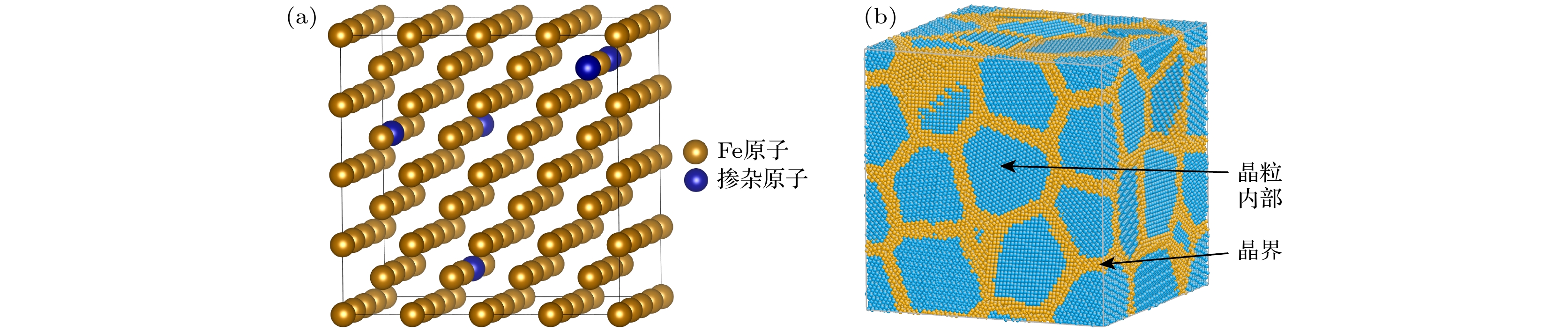

高压气态储氢是当前氢能储运的重要方式, 而高强钢材料则是储氢容器主要采用的材料之一. 然而, 其内部杂质元素和固有缺陷常导致其力学性能下降, 从而降低了容器的承压能力和存储寿命. 目前元素掺杂对于高强度钢力学性能的影响机制尚不完全明确, 基于此, 本文应用第一性原理计算模拟方法研究了Fe-M及Fe-C-M (M = Cr, Mn, Mo, As, Sb, Bi, Sn, Pb)体系中元素掺杂对其机械性能的影响. 结果表明, Mn掺杂使得高强钢的弹性模量、体模量和剪切模量等增强, 而其余元素的引入均使得高强钢的3种模量减弱, 其中非过渡金属元素对3种模量的影响大于过渡金属元素. 电子结构分析表明, 过渡金属元素与Fe晶格有着更好的相容性. 分子动力学模拟结果进一步显示H原子的注入显著地破坏了Fe多晶掺杂C, Cr, Mn元素体系的晶格有序性, 而Cr元素的掺入则可以显著提升体系的位错密度. 综上, 本文探究了掺杂元素对单晶和多晶Fe力学性能的影响, 对Fe基材料掺杂及缺陷对强度影响的机理研究具有较强的指导意义.High-pressure gaseous hydrogen storage is an important way of hydrogen energy storage and transport at present, while high-strength steel material is one of the main materials used for hydrogen storage vessels. However, their internal doping elements and inherent defects often lead their mechanical properties to decrease, thus reducing the pressure-bearing capability and storage life of the vessel. At present, the mechanism of doping elements influencing the mechanical properties of high-strength steels is still unclear. In this work, a first-principles approach is used to study the influence of elemental doping (Cr, Mn, Mo, As, Sb, Bi, Sn, Pb) on the mechanical properties of Fe single crystals and Fe-C systems. The results show that among the above elements, Mn doping can increase the elastic modulus, bulk modulus, and shear modulus compared with those of pure Fe, while the doping by remaining elements will reduce the three moduli above, with the non-transition metal elements having a greater effect on the three moduli than the transition metal elements. Electronic structure analysis shows that the transition metal elements have better compatibility with the Fe lattice. Molecular dynamics results further show that the injection of H atoms significantly disrupts the lattice ordering of the Fe polycrystalline doped by C, Cr, and Mn elements, while the doping of Cr elements can significantly enhance the dislocation density of the system. The effects of doping elements on the mechanical properties of single-crystal and polycrystalline Fe, which are studied in this work, are of great significance in guiding the mechanistic study of the effects of doping and defects on the strength of Fe-based materials.

-

Keywords:

- first-principles /

- molecular dynamics /

- mechanical properties /

- crystal defects

[1] Zhou X Y, Yang X S, Zhu J H, Xing F 2020 Int. J. Hydrog. Energy 45 3294

Google Scholar

Google Scholar

[2] Xing X, Chen W X, Zhang H 2017 Int. J. Hydrog. Energy 42 4571

Google Scholar

Google Scholar

[3] Zafra A, Peral L B, Belzunce J, Rodríguez C 2018 Int. J. Hydrog. Energy 43 9068

Google Scholar

Google Scholar

[4] Bechtle S, Kumar M, Somerday B P, Launey M E, Ritchie R O 2009 Acta Mater. 57 4148

Google Scholar

Google Scholar

[5] Ye T Z, Wang Z T, Wu Y W, Zhang J, Chen P, Wang M J, Tian W X, Su G H, Qiu S Z 2023 J. Mater. Res. 38 828

Google Scholar

Google Scholar

[6] Chen K, Xu Y W, Song S H 2019 Results Phys. 13 102208

Google Scholar

Google Scholar

[7] 周华生, 曹燕, 章小峰, 吴迪, 赵鑫磊, 邢梅, 林方敏, 江雅 2024 材料导报 38 22110194

Zhou H S, Cao Y, Zhang X F, Wu D, Zhao X L, Xing M, Lin F M, Jiang Y 2024 Mater. Rep. 38 22110194

[8] Chatterjee S, Ghosh S, Saha-Dasgupta T 2021 Minerals 11 258

Google Scholar

Google Scholar

[9] Xiong X L, Ma H X, Zhang L N, Song K K, Yan Y, Qian P, Su Y J 2023 Comput. Mater. Sci. 216 111854

Google Scholar

Google Scholar

[10] 文平, 李春福, 赵毅, 张凤春, 童丽华 2014 63 197101

Google Scholar

Google Scholar

Wen P, Li C F, Zhao Y, Zhang F C, Tong L H 2014 Acta Phys. Sin. 63 197101

Google Scholar

Google Scholar

[11] 王明军, 李春福, 文平, 张凤春, 王垚, 刘恩佐 2016 65 037101

Google Scholar

Google Scholar

Wang M J, Li C F, Wen P, Zhang F C, Wang Y, Liu E Z 2016 Acta Phys. Sin. 65 037101

Google Scholar

Google Scholar

[12] Zhou X Y, Zhu J H, Wu H H 2021 Int. J. Hydrog. Energy 46 5842

Google Scholar

Google Scholar

[13] Hafner J, Kresse G 1997 Properties of Complex Inorganic Solids (Boston: Springer) pp69–82

[14] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[15] Thompson A P, Aktulga H M, Berger R, et al. 2022 Comput. Phys. Commun. 271 108171

Google Scholar

Google Scholar

[16] Liu Z R, Yao B N, Zhang R F 2022 Comput. Mater. Sci. 210 111027

Google Scholar

Google Scholar

[17] Starikov S, Smirnova D, Pradhan T, Gordeev I, Drautz R, Mrovec M 2022 Phys. Rev. Mater. 6 043604

Google Scholar

Google Scholar

[18] Hepburn D J, Ackland G J 2008 Phys. Rev. B 78 165115

Google Scholar

Google Scholar

[19] Kim Y M, Shin Y H, Lee B J 2009 Acta Mater. 57 474

Google Scholar

Google Scholar

[20] Evans D J, Holian B L 1985 J. Chem. Phys. 83 4069

Google Scholar

Google Scholar

[21] Stukowski A 2010 Modell. Simul. Mater. Sci. Eng. 18 015012

Google Scholar

Google Scholar

[22] Zhao Y J, Zunger A 2004 Phys. Rev. B 69 075208

Google Scholar

Google Scholar

[23] 刘柏年, 马颖, 周益春 2010 59 3377

Google Scholar

Google Scholar

Liu B N, Ma Y, Zhou Y C 2010 Acta Phys. Sin. 59 3377

Google Scholar

Google Scholar

[24] Lee H S, Mizoguchi T, Yamamoto T, Kang S J L, Ikuhara Y 2007 Acta Mater. 55 6535

Google Scholar

Google Scholar

-

图 2 (a)—(d) Fe-M体系、(e)—(h) Fe-C-M体系不同M种类及浓度下的弹性模量、体模量、剪切模量和泊松比, 虚线表示纯铁体系对应的数值

Fig. 2. Young’s moduli, bulk moduli, shear moduli and Poisson’s ratio for (a)–(d) Fe-M systems and (e)–(h) Fe-C-M systems with different M species and concentrations. Dotted line represents moduli and Poisson’s ratio of pure Fe systems.

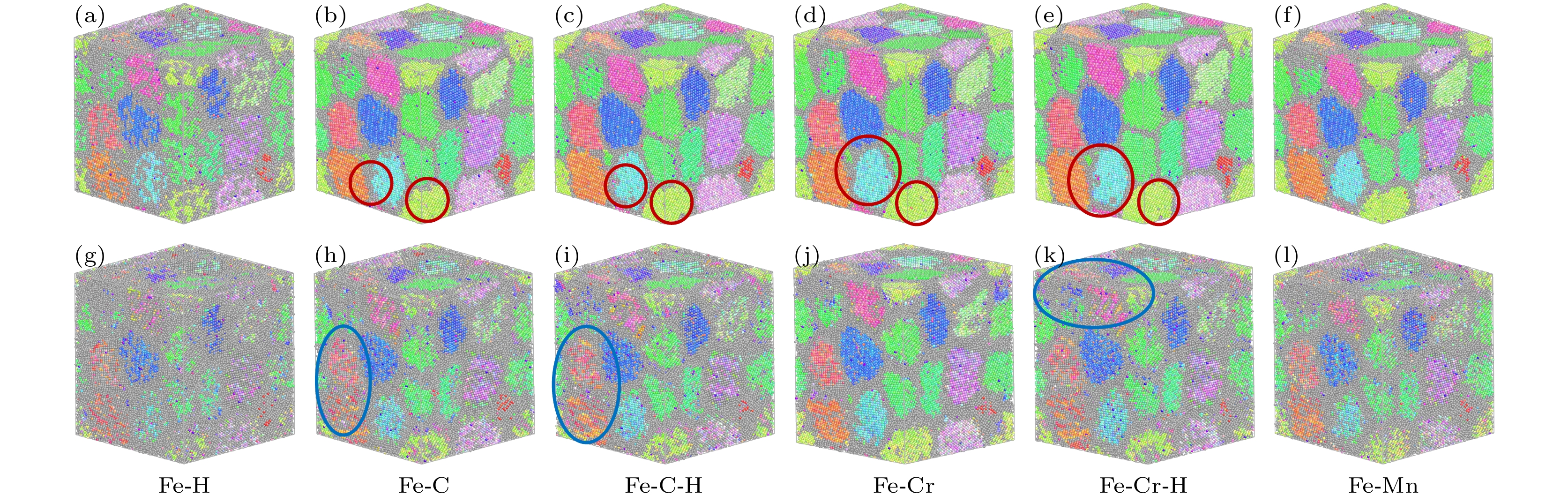

图 8 (a)—(f) Fe-H体系、Fe-C体系、Fe-C-H体系、Fe-Cr体系、Fe-Cr-H体系及Fe-Mn体系在拉伸初始条件下的晶格取向模型; (g)—(l) Fe-H体系、Fe-C体系、Fe-C-H体系、Fe-Cr体系、Fe-Cr-H体系及Fe-Mn体系在拉伸过程4 ps到达最大应变时的晶体取向模型, 不同颜色代表晶体的不同取向

Fig. 8. (a)–(f) Lattice orientation models of Fe-H, Fe-C, Fe-C-H, Fe-Cr, Fe-Cr-H and Fe-Mn systems under fully relaxed conditions; (g)–(l) crystal orientation models of Fe-H, Fe-C, Fe-C-H, Fe-Cr, Fe-Cr-H and Fe-Mn systems at maximum strain during stretching. Different colours indicate different orientations of crystals.

表 1 Fe-M体系的晶格参数a, b和c, 以及Fe-M体系和Fe-C-M掺杂体系的形成能$ \Delta {H_{{\text{D,q}}}} $和$ \Delta {H_{{\text{C,D,q}}}} $

Table 1. Lattice parameters of Fe-M systems, and formation energy of Fe-M and Fe-C-M systems.

掺杂/% a/Å b/Å c/Å ΔHD,q

/eVΔHC,D,q

/eVCr 1 2.831 2.831 2.831 –0.168 0.565 3 2.834 2.835 2.835 –0.456 0.690 5 2.838 2.837 2.838 –0.721 0.863 Mo 1 2.834 2.834 2.834 0.001 0.738 3 2.841 2.842 2.841 0.009 1.174 5 2.849 2.848 2.850 –0.003 1.603 Mn 1 2.830 2.830 2.830 0.232 0.964 3 2.829 2.830 2.829 0.756 1.307 5 2.829 2.829 2.828 0.993 1.711 As 1 2.832 2.832 2.832 –0.387 0.335 3 2.837 2.837 2.836 –1.173 0.023 5 2.842 2.843 2.842 –1.983 –0.269 Sb 1 2.836 2.836 2.836 0.433 1.169 3 2.851 2.850 2.849 1.233 3.165 5 2.864 2.868 2.863 1.807 4.969 Bi 1 2.839 2.839 2.839 2.125 2.864 3 2.862 2.859 2.858 6.156 7.641 5 2.878 2.885 2.878 9.758 11.807 Sn 1 2.836 2.836 2.836 0.613 1.357 3 2.851 2.850 2.850 1.663 3.181 5 2.864 2.868 2.864 2.452 4.797 Pb 1 2.839 2.839 2.839 2.233 2.976 3 2.860 2.857 2.858 6.412 7.613 5 2.875 2.880 2.877 10.206 11.695 -

[1] Zhou X Y, Yang X S, Zhu J H, Xing F 2020 Int. J. Hydrog. Energy 45 3294

Google Scholar

Google Scholar

[2] Xing X, Chen W X, Zhang H 2017 Int. J. Hydrog. Energy 42 4571

Google Scholar

Google Scholar

[3] Zafra A, Peral L B, Belzunce J, Rodríguez C 2018 Int. J. Hydrog. Energy 43 9068

Google Scholar

Google Scholar

[4] Bechtle S, Kumar M, Somerday B P, Launey M E, Ritchie R O 2009 Acta Mater. 57 4148

Google Scholar

Google Scholar

[5] Ye T Z, Wang Z T, Wu Y W, Zhang J, Chen P, Wang M J, Tian W X, Su G H, Qiu S Z 2023 J. Mater. Res. 38 828

Google Scholar

Google Scholar

[6] Chen K, Xu Y W, Song S H 2019 Results Phys. 13 102208

Google Scholar

Google Scholar

[7] 周华生, 曹燕, 章小峰, 吴迪, 赵鑫磊, 邢梅, 林方敏, 江雅 2024 材料导报 38 22110194

Zhou H S, Cao Y, Zhang X F, Wu D, Zhao X L, Xing M, Lin F M, Jiang Y 2024 Mater. Rep. 38 22110194

[8] Chatterjee S, Ghosh S, Saha-Dasgupta T 2021 Minerals 11 258

Google Scholar

Google Scholar

[9] Xiong X L, Ma H X, Zhang L N, Song K K, Yan Y, Qian P, Su Y J 2023 Comput. Mater. Sci. 216 111854

Google Scholar

Google Scholar

[10] 文平, 李春福, 赵毅, 张凤春, 童丽华 2014 63 197101

Google Scholar

Google Scholar

Wen P, Li C F, Zhao Y, Zhang F C, Tong L H 2014 Acta Phys. Sin. 63 197101

Google Scholar

Google Scholar

[11] 王明军, 李春福, 文平, 张凤春, 王垚, 刘恩佐 2016 65 037101

Google Scholar

Google Scholar

Wang M J, Li C F, Wen P, Zhang F C, Wang Y, Liu E Z 2016 Acta Phys. Sin. 65 037101

Google Scholar

Google Scholar

[12] Zhou X Y, Zhu J H, Wu H H 2021 Int. J. Hydrog. Energy 46 5842

Google Scholar

Google Scholar

[13] Hafner J, Kresse G 1997 Properties of Complex Inorganic Solids (Boston: Springer) pp69–82

[14] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[15] Thompson A P, Aktulga H M, Berger R, et al. 2022 Comput. Phys. Commun. 271 108171

Google Scholar

Google Scholar

[16] Liu Z R, Yao B N, Zhang R F 2022 Comput. Mater. Sci. 210 111027

Google Scholar

Google Scholar

[17] Starikov S, Smirnova D, Pradhan T, Gordeev I, Drautz R, Mrovec M 2022 Phys. Rev. Mater. 6 043604

Google Scholar

Google Scholar

[18] Hepburn D J, Ackland G J 2008 Phys. Rev. B 78 165115

Google Scholar

Google Scholar

[19] Kim Y M, Shin Y H, Lee B J 2009 Acta Mater. 57 474

Google Scholar

Google Scholar

[20] Evans D J, Holian B L 1985 J. Chem. Phys. 83 4069

Google Scholar

Google Scholar

[21] Stukowski A 2010 Modell. Simul. Mater. Sci. Eng. 18 015012

Google Scholar

Google Scholar

[22] Zhao Y J, Zunger A 2004 Phys. Rev. B 69 075208

Google Scholar

Google Scholar

[23] 刘柏年, 马颖, 周益春 2010 59 3377

Google Scholar

Google Scholar

Liu B N, Ma Y, Zhou Y C 2010 Acta Phys. Sin. 59 3377

Google Scholar

Google Scholar

[24] Lee H S, Mizoguchi T, Yamamoto T, Kang S J L, Ikuhara Y 2007 Acta Mater. 55 6535

Google Scholar

Google Scholar

计量

- 文章访问数: 3739

- PDF下载量: 92

- 被引次数: 0

下载:

下载: