-

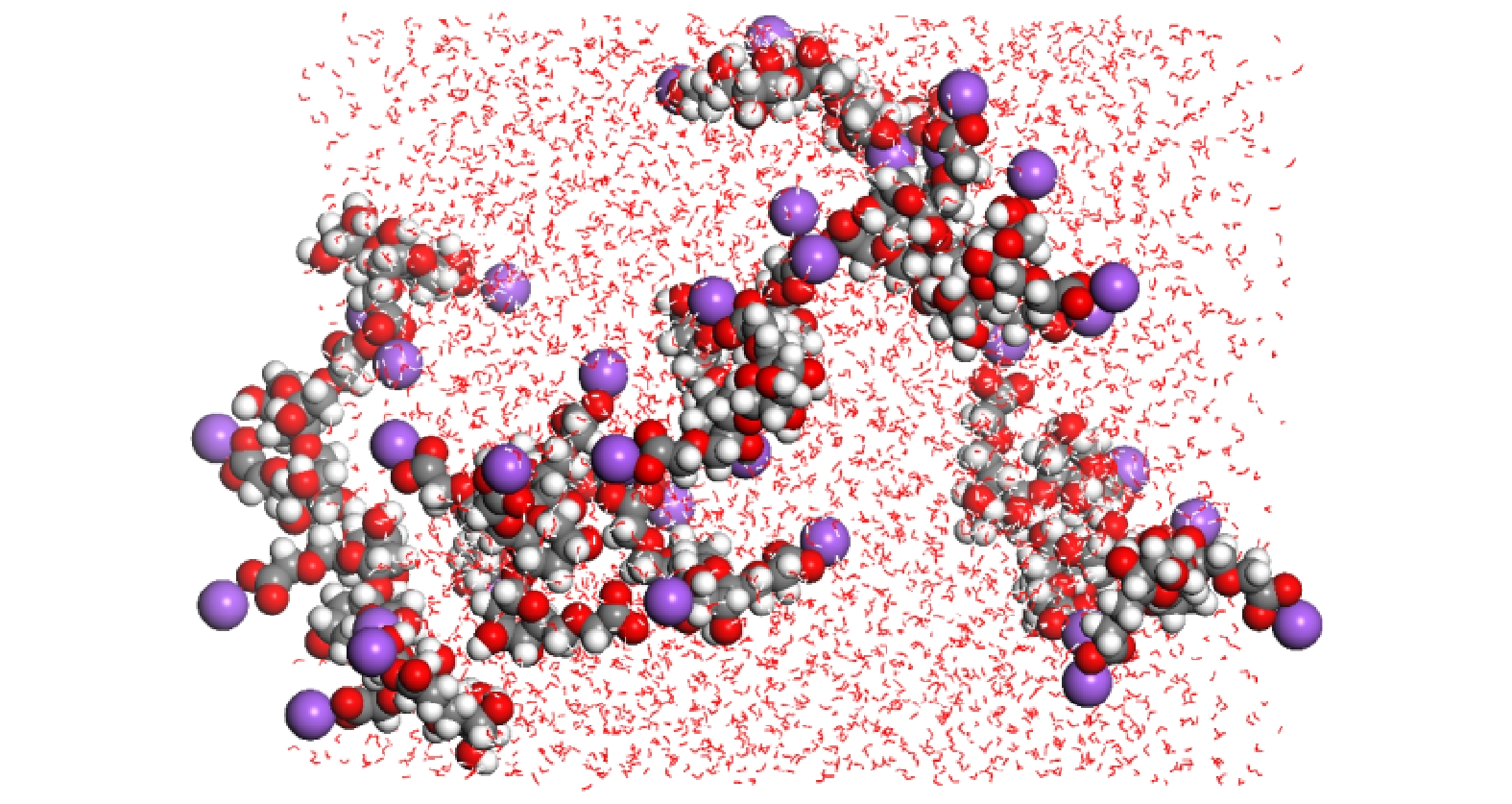

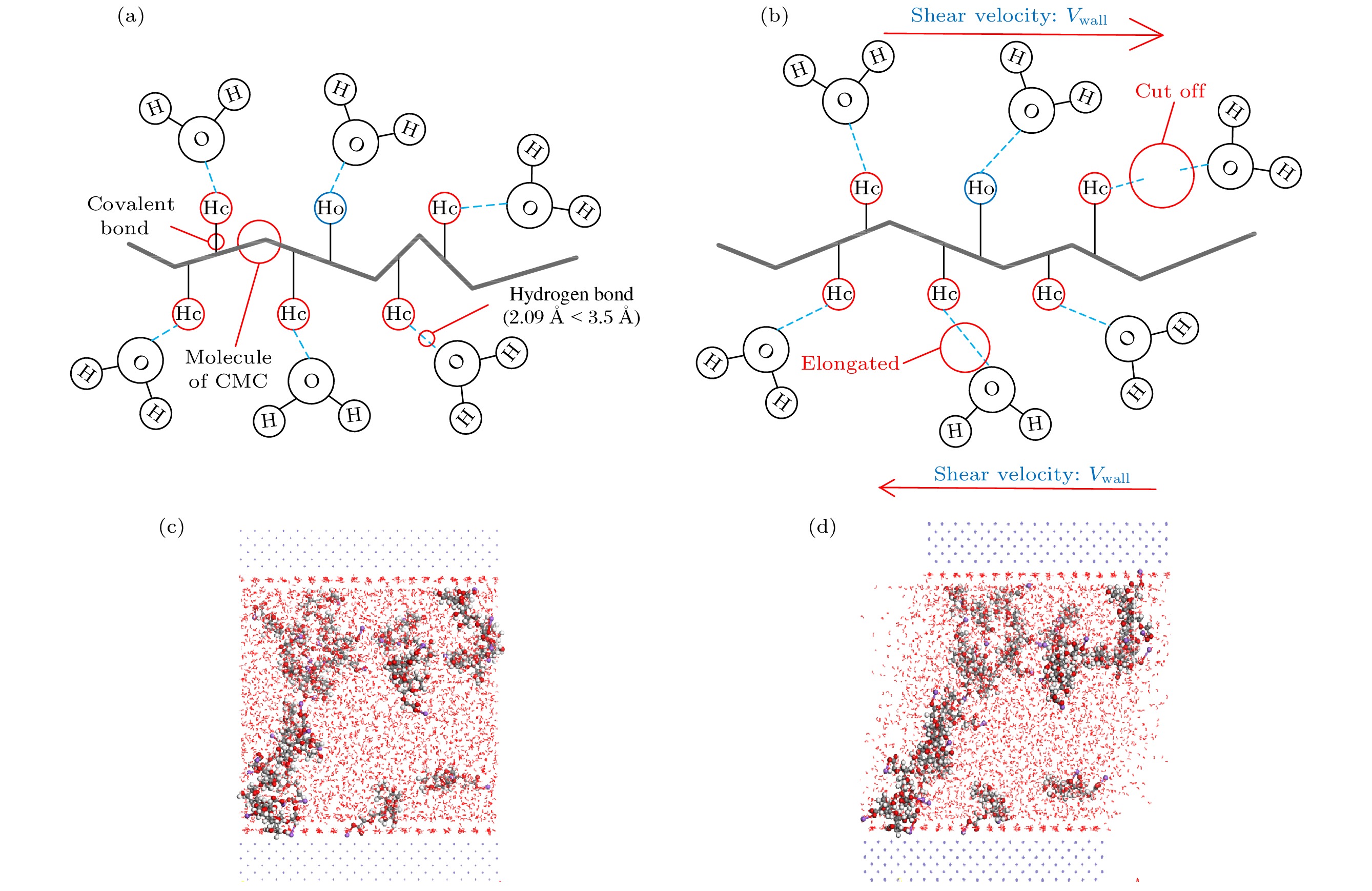

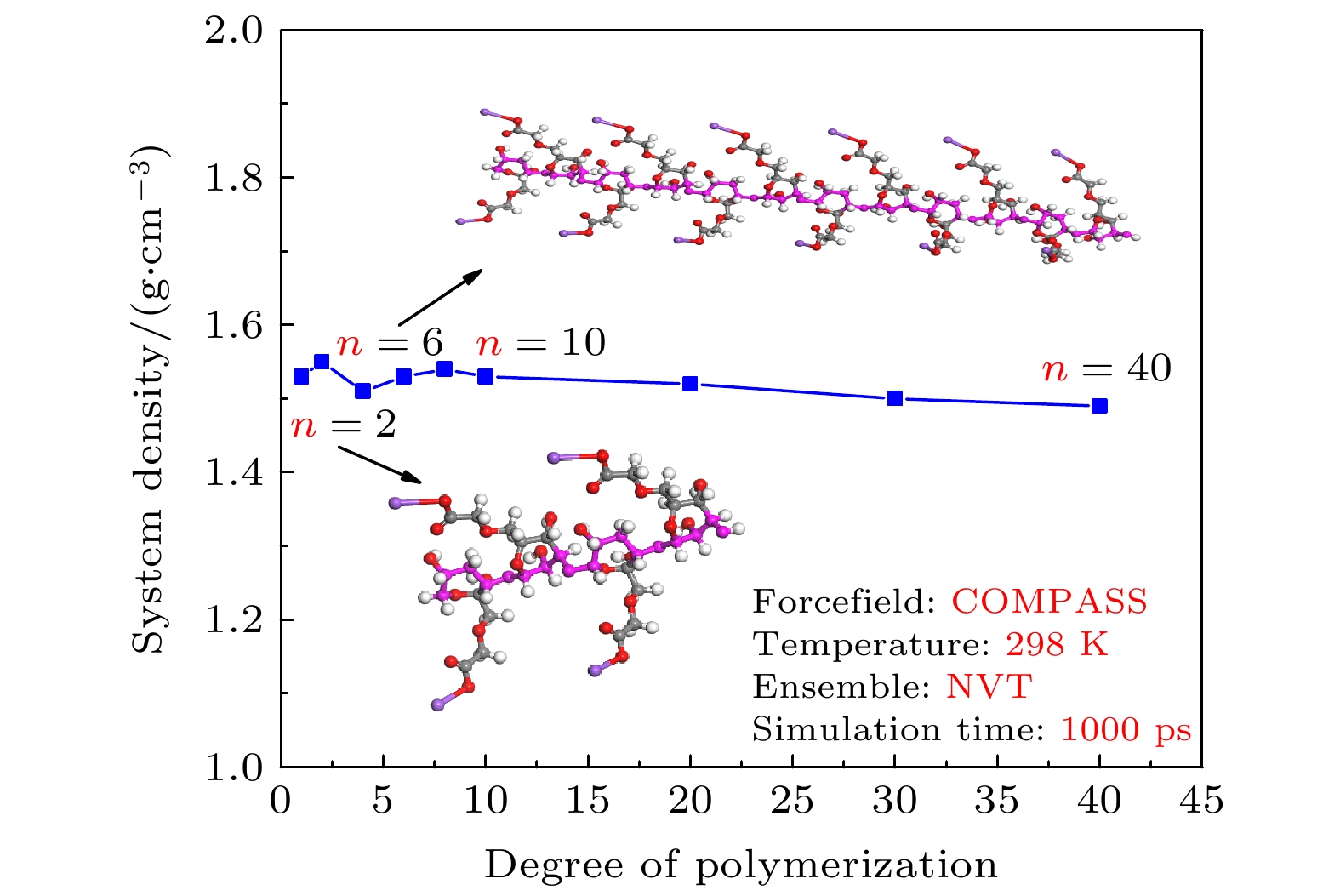

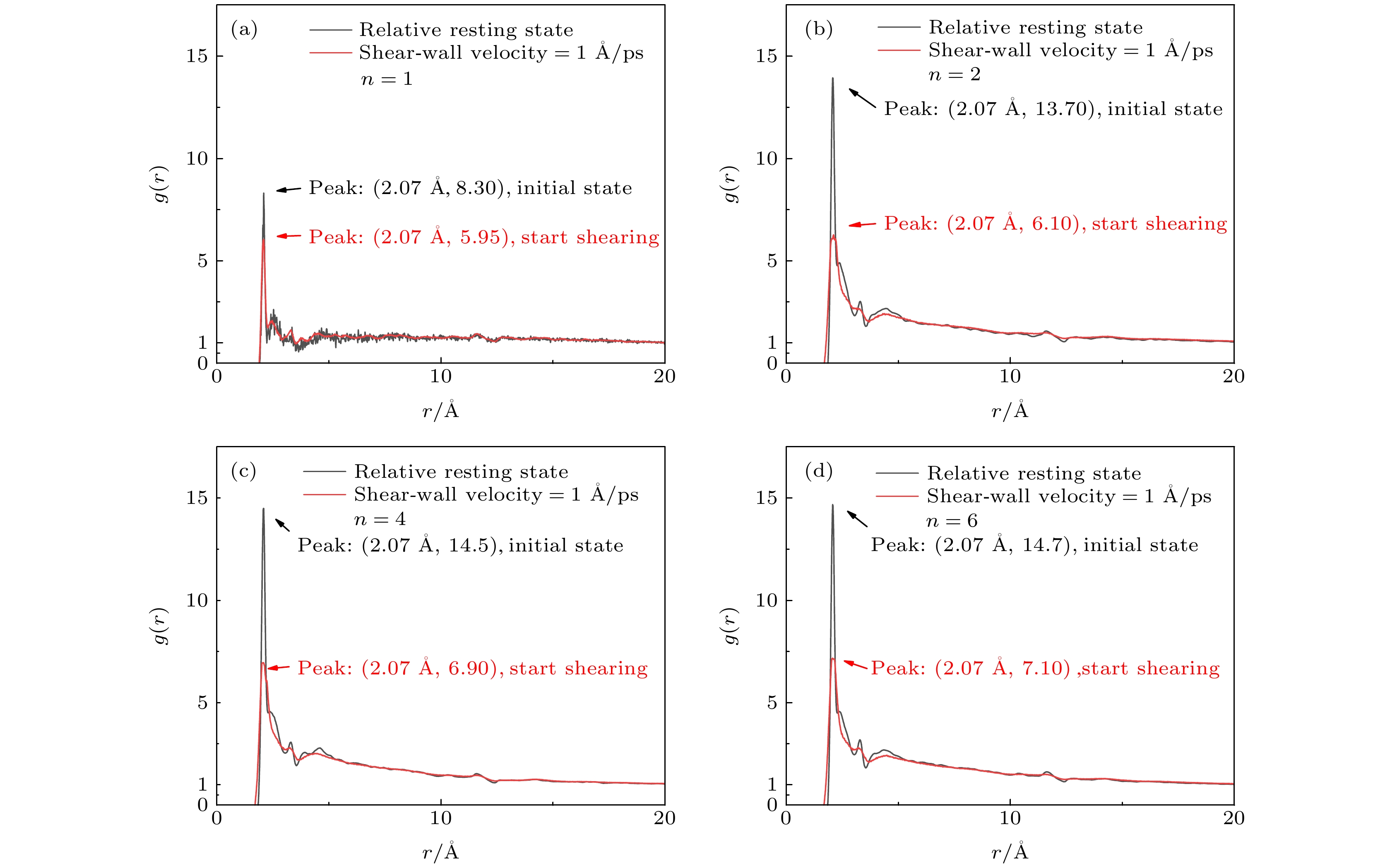

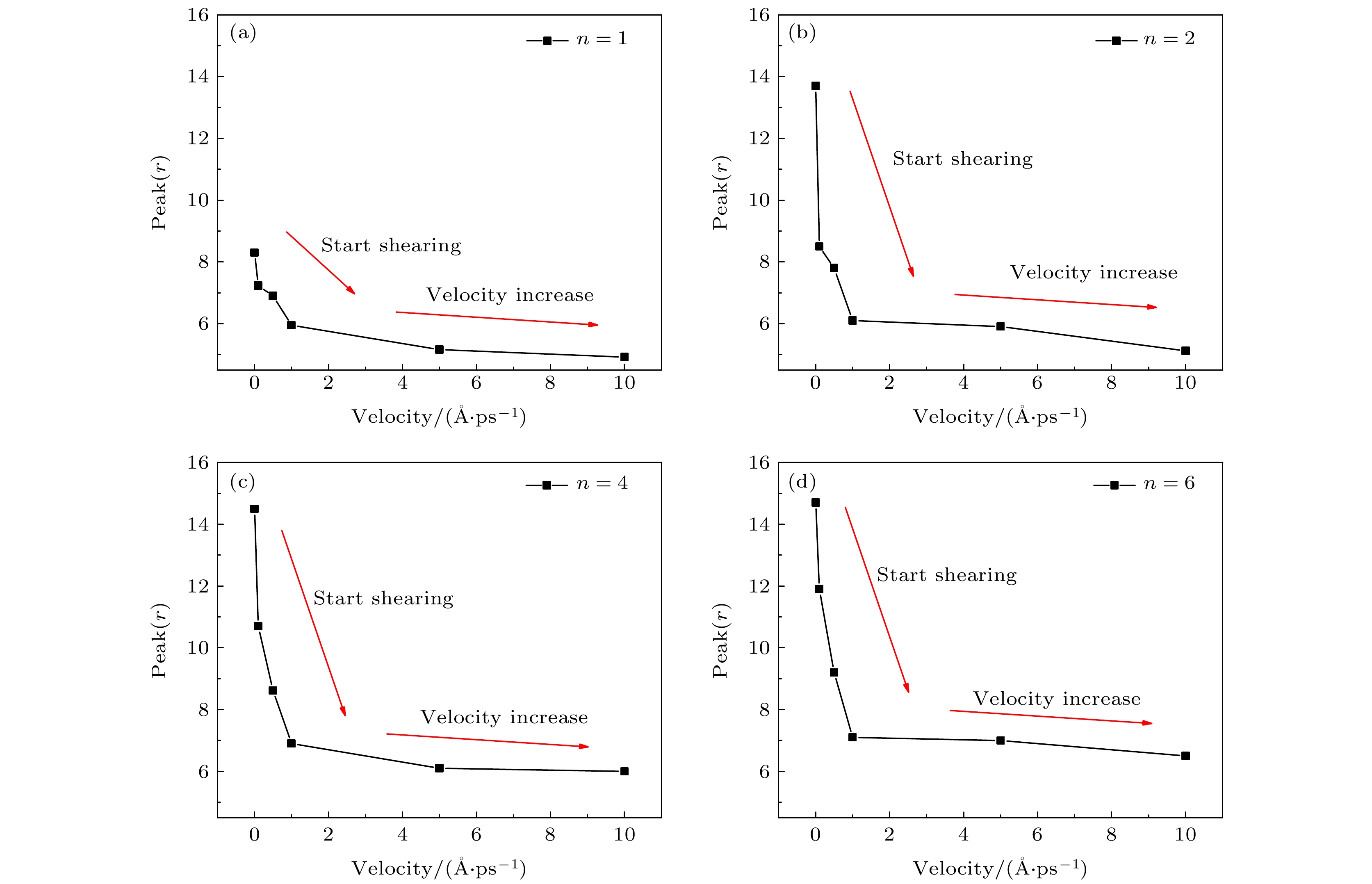

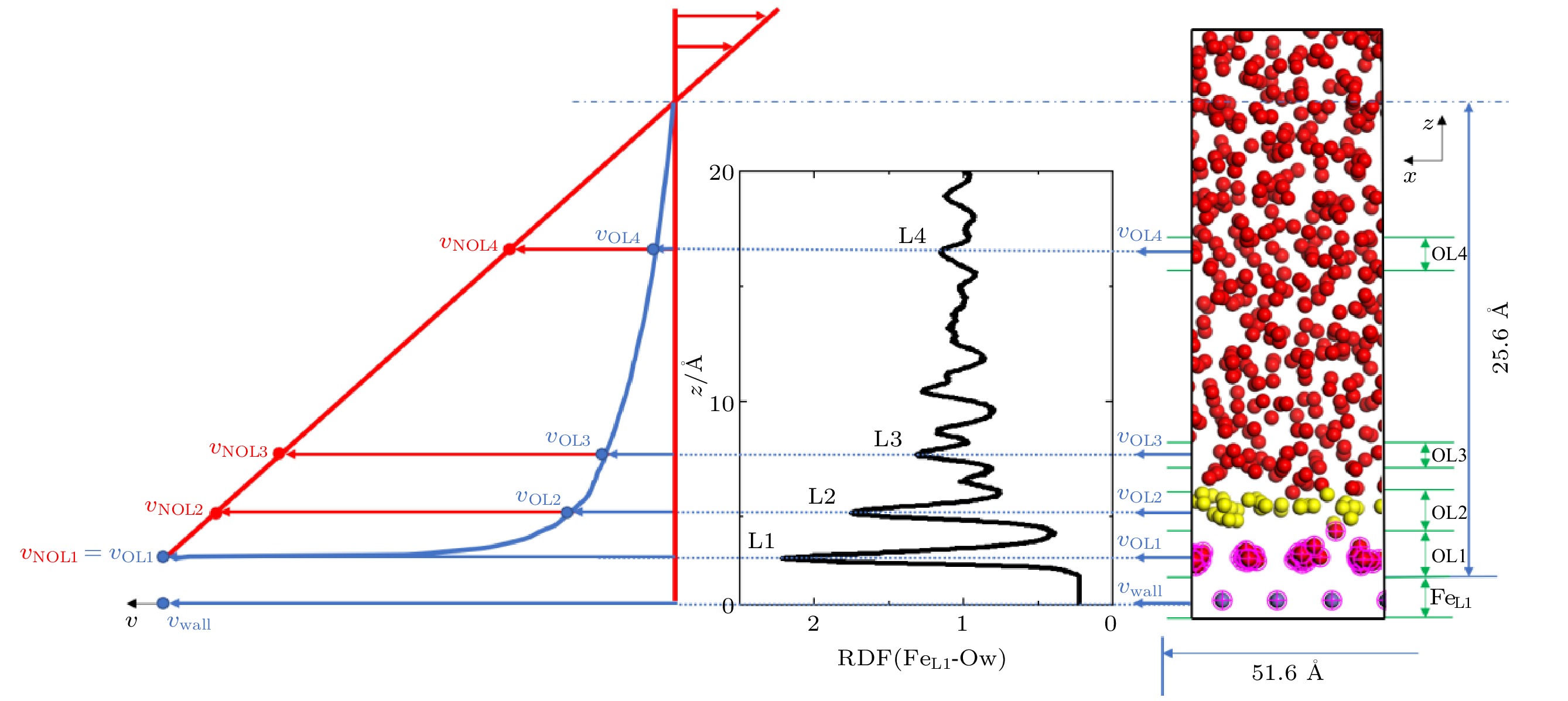

Non-Newtonian fluids are widely used in microfluidic systems and biomedical fields. In this paper, based on molecular dynamics simulation, taking the system composed of sodium carboxymethyl cellulose molecules and water molecules as the research object, the configuration evolutions of sodium carboxymethyl cellulose solution are simulated under different shear rates. Change of the solution viscosity is characterized by mean square displacement of sodium carboxymethyl cellulose molecules and the relative velocity between water layer and shear boundary. The effect of hydrogen bonding on the viscosity of the solution is analyzed emphatically. The results show that water molecules and solute molecules attract each other to form a more compact hydrogen bond network, which increases the viscosity of the solution; the peak value of the radial distribution function between the hydrogen atoms attached to carbon and the water oxygen atoms decreases when shear action is applied to the solution, and the hydrogen bond between the two atoms is weakened; the mobility of solute molecules increases and the blocking effect of water molecules on the movement of solute molecules weakens under the shear action; at the same time, the shorter the distance to the shear boundary, the closer to the shear velocity the velocity of water molecules is, and with the increase of distance, the velocity of water molecular layer decreases greatly. These results are macroscopically understood as the viscosity of the system decreasing. As the shear rate increases, the shear thinning of the sodium carboxymethyl cellulose solution becomes more significant.

-

Keywords:

- non-Newtonian fluids /

- molecular dynamics /

- shear thinning /

- hydrogen bonding

[1] Nair R, Choudhury A R 2020 Int. J. Biol. Macromol. 159 922

Google Scholar

Google Scholar

[2] Ponalagusamy R 2018 Appl. Math. Comput. 337 545

Google Scholar

Google Scholar

[3] 杨金姝 2014 农产品加工(学刊) 22 76

Google Scholar

Google Scholar

Yang J S 2014 J. Process. Agric. Prod. 22 76

Google Scholar

Google Scholar

[4] 吴淑茗, 柯萍萍, 黄俊祥, 陈梦霞, 许心怡, 王玮靖 2018 化学工程与装备 10 246

Google Scholar

Google Scholar

Wu S M, Ke P P, Huang J X, Chen M X, Xu X Y, Wang W J 2018 J. Chem. Eng. Equip. 10 246

Google Scholar

Google Scholar

[5] Jordi L, Josep S, Joan L 2007 Colloids Surf. A 301 8

Google Scholar

Google Scholar

[6] Laporte M, Montillet A, Belkadi A, et al. 2020 Chem. Eng. Process. 148 107787

Google Scholar

Google Scholar

[7] Khan M, Salahuddin T, Malik M Y, Khan F 2020 Physica A 547 123440

Google Scholar

Google Scholar

[8] Roberts T G, Cox S J 2020 J. Non-Newton. Fluids Mech. 280 104278

Google Scholar

Google Scholar

[9] Wu W W, Sun S L, Wang Z Z, Ding S 2019 Mech. Mater. 139 103187

Google Scholar

Google Scholar

[10] Dong B, Zhang Y, Zhou X, Chen C, Li W 2019 Ther. Sci. Eng. Progr. 10 309

Google Scholar

Google Scholar

[11] Afrouzi H, Ahmadian M, Moshfegh A, Toghraie D, Javadzadegan 2019 Physica A 535 122486

Google Scholar

Google Scholar

[12] Blanco-Díaz E G, Castrejón-González E O, Alvarado J F, et al. 2017 J. Mol. Liq. 242 265

Google Scholar

Google Scholar

[13] Esmaeili A, Haseli M 2017 Carbohydr. Polym. 173 645

Google Scholar

Google Scholar

[14] Zhao Y, Xu Z M, Wang B B, He J J 2019 Int. J. Heat Mass Transfer 141 457

Google Scholar

Google Scholar

[15] Reshma G, Reshmi C R, Shantikumar V N, Deepthy M 2020 Carbohydr. Polym. 248 116763

Google Scholar

Google Scholar

[16] Sridevi S, Sutha S, Kavitha L, Gopi D 2020 Mater. Chem. Phys. 254 123455

Google Scholar

Google Scholar

[17] Wang B, Cavallo D, Chen J B 2020 Polym. J. 210 123000

Google Scholar

Google Scholar

[18] Castillo-Tejas J, Castrejón-González O, Carro S, et al. 2016 Colloids Surf. A 491 37

Google Scholar

Google Scholar

[19] 张烨, 张冉, 常青, 李桦 2019 68 124702

Google Scholar

Google Scholar

Zhang Y, Zhang R, Chang Q, Li H 2019 Acta Phys. Sin. 68 124702

Google Scholar

Google Scholar

[20] Graham R S 2019 J. Rheol. 63 203

Google Scholar

Google Scholar

[21] 洪迪昆, 刘亮, 郭欣 2015 中国电机工程学报 35 6099

Google Scholar

Google Scholar

Hong D K, Liu L, Guo X 2015 Proc. CSEE 35 6099

Google Scholar

Google Scholar

[22] 张跃 2007 计算材料学基础 (北京: 北京航空航天大学出版社) 第121页

Zhang Y 2007 Foundations of Computational Materials Science (Beijing: Beihang University Press) p121 (in Chinese)

[23] Kumar R, Schmidt J R, Skinner J L 2007 Chem. Phys. 126 204107

Google Scholar

Google Scholar

-

-

[1] Nair R, Choudhury A R 2020 Int. J. Biol. Macromol. 159 922

Google Scholar

Google Scholar

[2] Ponalagusamy R 2018 Appl. Math. Comput. 337 545

Google Scholar

Google Scholar

[3] 杨金姝 2014 农产品加工(学刊) 22 76

Google Scholar

Google Scholar

Yang J S 2014 J. Process. Agric. Prod. 22 76

Google Scholar

Google Scholar

[4] 吴淑茗, 柯萍萍, 黄俊祥, 陈梦霞, 许心怡, 王玮靖 2018 化学工程与装备 10 246

Google Scholar

Google Scholar

Wu S M, Ke P P, Huang J X, Chen M X, Xu X Y, Wang W J 2018 J. Chem. Eng. Equip. 10 246

Google Scholar

Google Scholar

[5] Jordi L, Josep S, Joan L 2007 Colloids Surf. A 301 8

Google Scholar

Google Scholar

[6] Laporte M, Montillet A, Belkadi A, et al. 2020 Chem. Eng. Process. 148 107787

Google Scholar

Google Scholar

[7] Khan M, Salahuddin T, Malik M Y, Khan F 2020 Physica A 547 123440

Google Scholar

Google Scholar

[8] Roberts T G, Cox S J 2020 J. Non-Newton. Fluids Mech. 280 104278

Google Scholar

Google Scholar

[9] Wu W W, Sun S L, Wang Z Z, Ding S 2019 Mech. Mater. 139 103187

Google Scholar

Google Scholar

[10] Dong B, Zhang Y, Zhou X, Chen C, Li W 2019 Ther. Sci. Eng. Progr. 10 309

Google Scholar

Google Scholar

[11] Afrouzi H, Ahmadian M, Moshfegh A, Toghraie D, Javadzadegan 2019 Physica A 535 122486

Google Scholar

Google Scholar

[12] Blanco-Díaz E G, Castrejón-González E O, Alvarado J F, et al. 2017 J. Mol. Liq. 242 265

Google Scholar

Google Scholar

[13] Esmaeili A, Haseli M 2017 Carbohydr. Polym. 173 645

Google Scholar

Google Scholar

[14] Zhao Y, Xu Z M, Wang B B, He J J 2019 Int. J. Heat Mass Transfer 141 457

Google Scholar

Google Scholar

[15] Reshma G, Reshmi C R, Shantikumar V N, Deepthy M 2020 Carbohydr. Polym. 248 116763

Google Scholar

Google Scholar

[16] Sridevi S, Sutha S, Kavitha L, Gopi D 2020 Mater. Chem. Phys. 254 123455

Google Scholar

Google Scholar

[17] Wang B, Cavallo D, Chen J B 2020 Polym. J. 210 123000

Google Scholar

Google Scholar

[18] Castillo-Tejas J, Castrejón-González O, Carro S, et al. 2016 Colloids Surf. A 491 37

Google Scholar

Google Scholar

[19] 张烨, 张冉, 常青, 李桦 2019 68 124702

Google Scholar

Google Scholar

Zhang Y, Zhang R, Chang Q, Li H 2019 Acta Phys. Sin. 68 124702

Google Scholar

Google Scholar

[20] Graham R S 2019 J. Rheol. 63 203

Google Scholar

Google Scholar

[21] 洪迪昆, 刘亮, 郭欣 2015 中国电机工程学报 35 6099

Google Scholar

Google Scholar

Hong D K, Liu L, Guo X 2015 Proc. CSEE 35 6099

Google Scholar

Google Scholar

[22] 张跃 2007 计算材料学基础 (北京: 北京航空航天大学出版社) 第121页

Zhang Y 2007 Foundations of Computational Materials Science (Beijing: Beihang University Press) p121 (in Chinese)

[23] Kumar R, Schmidt J R, Skinner J L 2007 Chem. Phys. 126 204107

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 14467

- PDF Downloads: 216

- Cited By: 0

DownLoad:

DownLoad: