-

刮膜蒸发器是通过旋转刮板强制成膜, 可实现高黏度非牛顿流体类物料平稳蒸发的新型高效蒸发器. 蒸发器内流体的流动、分布与传输机制直接决定了蒸发器的蒸发效率与功耗. 不同于现有研究主要基于牛顿流体开展, 本文针对不同黏度的非牛顿流体, 建立蒸发器三维计算流体动力学模型, 系统研究了蒸发器内的流场分布特性和成膜机理. 结果表明: 低黏非牛顿流体的流场分布特性和牛顿流体类似, 物料可在壁面形成均匀且连续的液膜; 随着黏度的增加, 液膜的均匀性和连续性逐渐变差. 通过对流场分布与传输形式的研究, 结合液膜分布、速度分布、剪应变率分布, 以及黏度分布进行对比分析发现, 蒸发器内部结构与运行状态形成的剪切场与黏度分布是蒸发器良好成膜的关键. 此外, 提出对刮板前缘进行弯折可辅助高黏流体液膜铺展, 并对最佳弯折角度进行探索. 本研究为刮膜蒸发器的设计和应用提供了理论指导与依据.Agitated thin film evaporator (ATFE) is a new type of high-efficiency evaporator where a film is forced to form through a rotating scraper and the high-viscosity non-Newtonian flow materials can be evaporated smoothly. The flow distribution and transmission mechanism of the material in the evaporator directly determine the evaporation efficiency and power consumption of the evaporator. Unlike previous study that was based mainly on Newtonian flow, this paper establishes a three-dimensional computational fluid dynamics model of ATFE for non-Newtonian flow with different viscosities, and systematically probes the flow field distribution characteristics and film forming mechanism in the evaporator. The results show that the flow field distribution characteristics of low-viscosity non-Newtonian flow are similar to those of Newtonian flow, the material can form a uniform and continuous liquid film on the wall; as the viscosity increases, the uniformity and continuity of the liquid film gradually deteriorate. Through studying the flow field distribution and transmission form of the materials, and combining the liquid film distribution, velocity distribution, shear strain rate distribution, and viscosity distribution, it is found that the shear field and viscosity distribution formed by the internal structure and operating state of the evaporator are the key to the good film formation. In addition, it is proposed that the bending of the leading edge of the scraper can assist the spreading of high viscous fluid liquid film, and the best bending angle is explored. This research provides theoretical guidance and basis for the design and application of ATFE.

-

Keywords:

- non-Newtonian flow /

- shear strain rate /

- viscosity /

- flow characteristics

[1] Jasch K, Grutzner T, Rosenthal G, Scholl S 2021 Chem. Eng. Res. Des. 165 162

Google Scholar

Google Scholar

[2] Appelhaus D, Jasch K, Jahnke S, Bin K H, Tegethoff W, Kohler J, Scholl S 2020 Chem. Eng. Res. Des. 161 115

Google Scholar

Google Scholar

[3] Hozan J S, Abdulsalam R K 2020 Pet. Sci. Technol. 38 323

Google Scholar

Google Scholar

[4] Mutzenburg A B 1965 Chem. Eng. 72 175

[5] Mckelvey J M, Sharps G V 1979 Polym Eng. Sci. 19 651

Google Scholar

Google Scholar

[6] Komori S, Takata K, Murakami Y 1988 J. Chem. Eng. Jpn. 21 639

Google Scholar

Google Scholar

[7] Komori S, Takata K, Murakami Y 1989 J. Chem. Eng. Jpn. 22 346

Google Scholar

Google Scholar

[8] Komori S, Takata K, Nagaosa R, Murakami Y 1990 J. Chem. Eng. Jpn. 23 550

Google Scholar

Google Scholar

[9] 张彬, 成鹏, 李清廉, 陈慧源, 李晨阳 2021 70 054702

Google Scholar

Google Scholar

Zhang B, Cheng P, Li L Q, Chen H Y, Li C Y 2021 Acta Phys. Sin. 70 054702

Google Scholar

Google Scholar

[10] 卢长兰, 李庆生, 于建华 2008 食品工业科技 29 209

Google Scholar

Google Scholar

Lu C L, Li Q S, Yu J H, Zhang Y 2008 Sci. Technol. Food Ind. 29 209

Google Scholar

Google Scholar

[11] 汪蕊, 贺小华 2004 南京工业大学学报(自然科学版) 26 72

Wang L, He X H 2004 Nan Tech Univ. Sci. 26 72

[12] 贺小华, 唐平, 李佳, 陆小华 2005 过程工程学报 5 357

Google Scholar

Google Scholar

He X H, Tang P, Li J, Lu X H 2005 Chin. J. Process Eng. 5 357

Google Scholar

Google Scholar

[13] Pawar S B, Mujumdar A S, Thorat B N 2012 Chem. Eng. Res. Des. 90 757

Google Scholar

Google Scholar

[14] 江体乾, 余永彬 1984 华东化工学院学报 3 395

Google Scholar

Google Scholar

Jiang T K, Yu Y B 1984 J. East China Univ. Sci. Technol. 3 395

Google Scholar

Google Scholar

[15] 左娟莉, 杨泓, 魏炳乾, 侯精明, 张凯 2020 69 064705

Google Scholar

Google Scholar

Zuo J L, Yang H, Wei B Q, Hou J M, Zhang K 2020 Acta Phys. Sin. 69 064705

Google Scholar

Google Scholar

[16] Chen S Y, Li C, Ren H J 2021 Int J Hydrogen Energ. 46 25252

Google Scholar

Google Scholar

[17] Menter, F R 1993 24th Fluid Dynamics Conference Orlando, Florida, July 6–9, 1993 p2906

[18] Mourad Y, Jeremy P, Francine F, Jack L 2007 Chem. Eng. Process. 47 1550

[19] Chen B, Fu C F, Gu L X 2011 Seminar on Development and Application of Super Soft and Easy-Dyeing Polyester Fiber Shanghai, China, October 24, 2011 p18

[20] 于浩淼, 陈延明, 王立岩, 吴全才 2019 中国塑料 33 28

Google Scholar

Google Scholar

Yu H M, Chen Y M, Wang Y Y, Wu Q C 2019 China Plast. 33 28

Google Scholar

Google Scholar

[21] 高殿才, 路喜英, 王华平, 张玉梅, 魏广信 2019 人造纤维 49 13

Google Scholar

Google Scholar

Gao D C, Lu X Y, Wang H P, Zhang Y M, Wei G X 2019 Artificial Fibre 49 13

Google Scholar

Google Scholar

[22] Mourad Y, Francine F, Jack L 2009 Chem. Eng. Process. 48 1445

[23] Jerome M, Francine F, Jack L 2003 Chem. Eng. Sci. 58 4667

Google Scholar

Google Scholar

[24] 经昊达, 张向军, 田煜, 孟永钢 2015 64 168101

Google Scholar

Google Scholar

Jing H D, Zhang X J, Tian Y, Meng Y G 2015 Acta Phys. Sin. 64 168101

Google Scholar

Google Scholar

[25] Buss-SMS-Canzler Gmb H https://www.sms-vt.com/[2021-10-01]

[26] McKenna T F 1995 Chem. Eng. Sci. 50 453

Google Scholar

Google Scholar

-

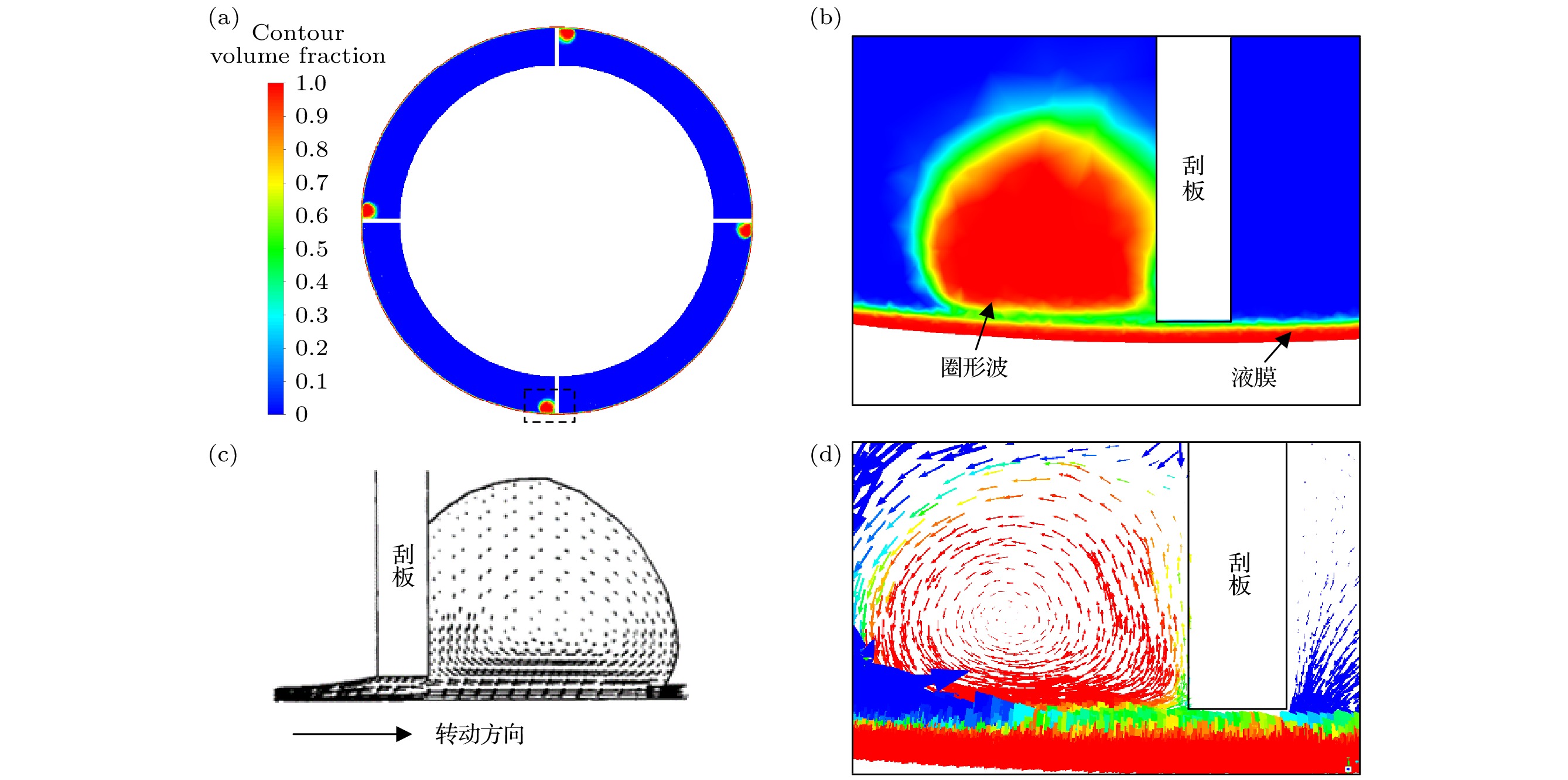

图 3 (a)薄膜蒸发器内流场截面图; (b)液膜和圈形波局部显示图; (c) Komori模型圈形波流体速度矢量图[6] ; (d)仿真圈形波流体速度矢量图

Fig. 3. (a) Flow distribution in ATFE (cross section); (b) film and fillet distribution in ATFE (cross section); (c) velocity vectors in the fillet (Komori model) [6]; (d) velocity vectors in the fillet(simulation result)

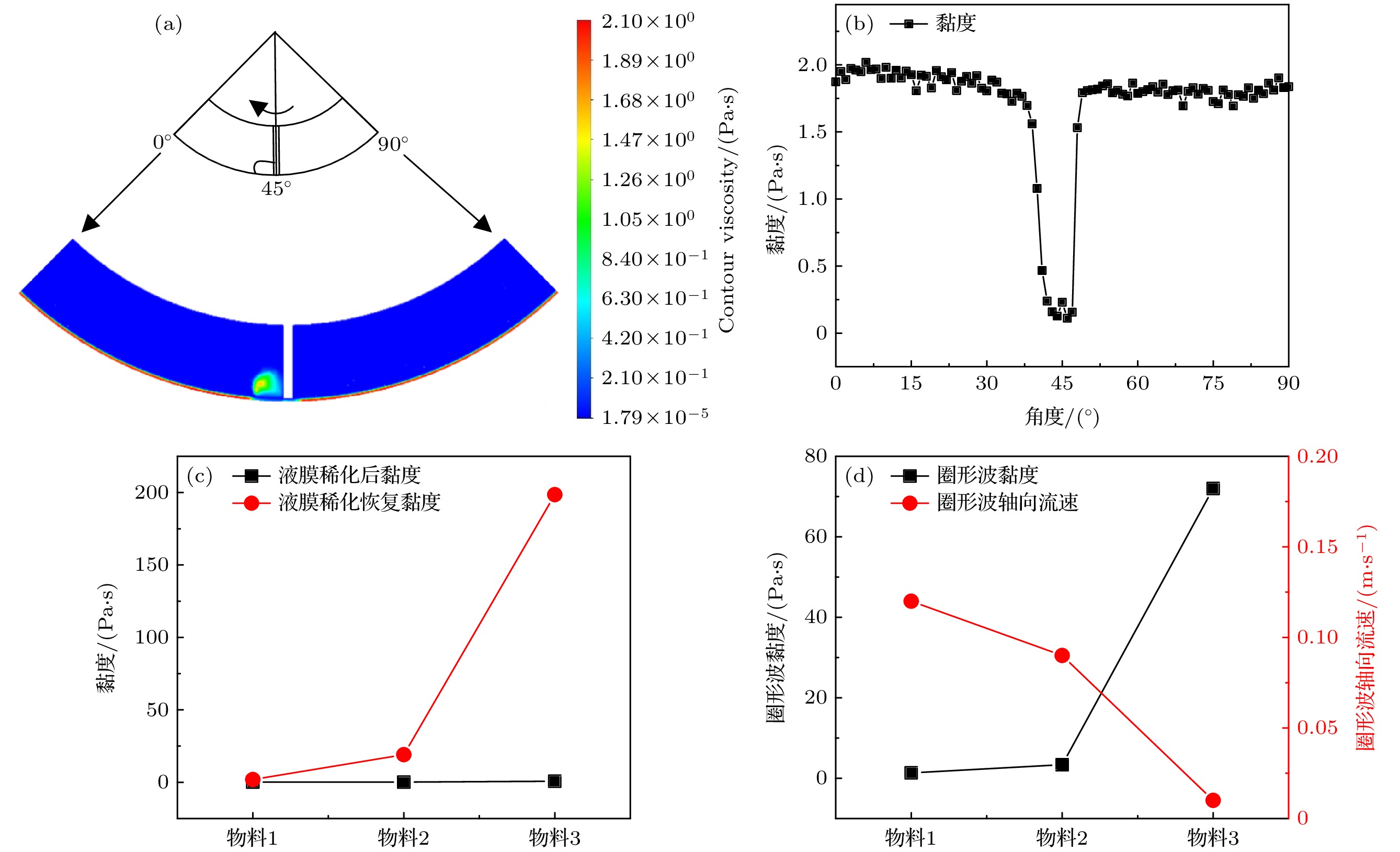

图 7 (a)蒸发器内物料1表观黏度截面分布图; (b)蒸发器内物料1液膜流体表观黏度统计图; (c)不同物料下液膜黏度统计图; (d)不同物料下圈形波流体黏度和轴向平均速度统计图

Fig. 7. (a) Distribution filed of apparent viscosity in ATFE (cross section) (feed material one); (b) apparent viscosity of film (feed material one); (c) apparent viscosity of film for different feed materials; (d) apparent viscosity and axial velocity of film for different feed materials

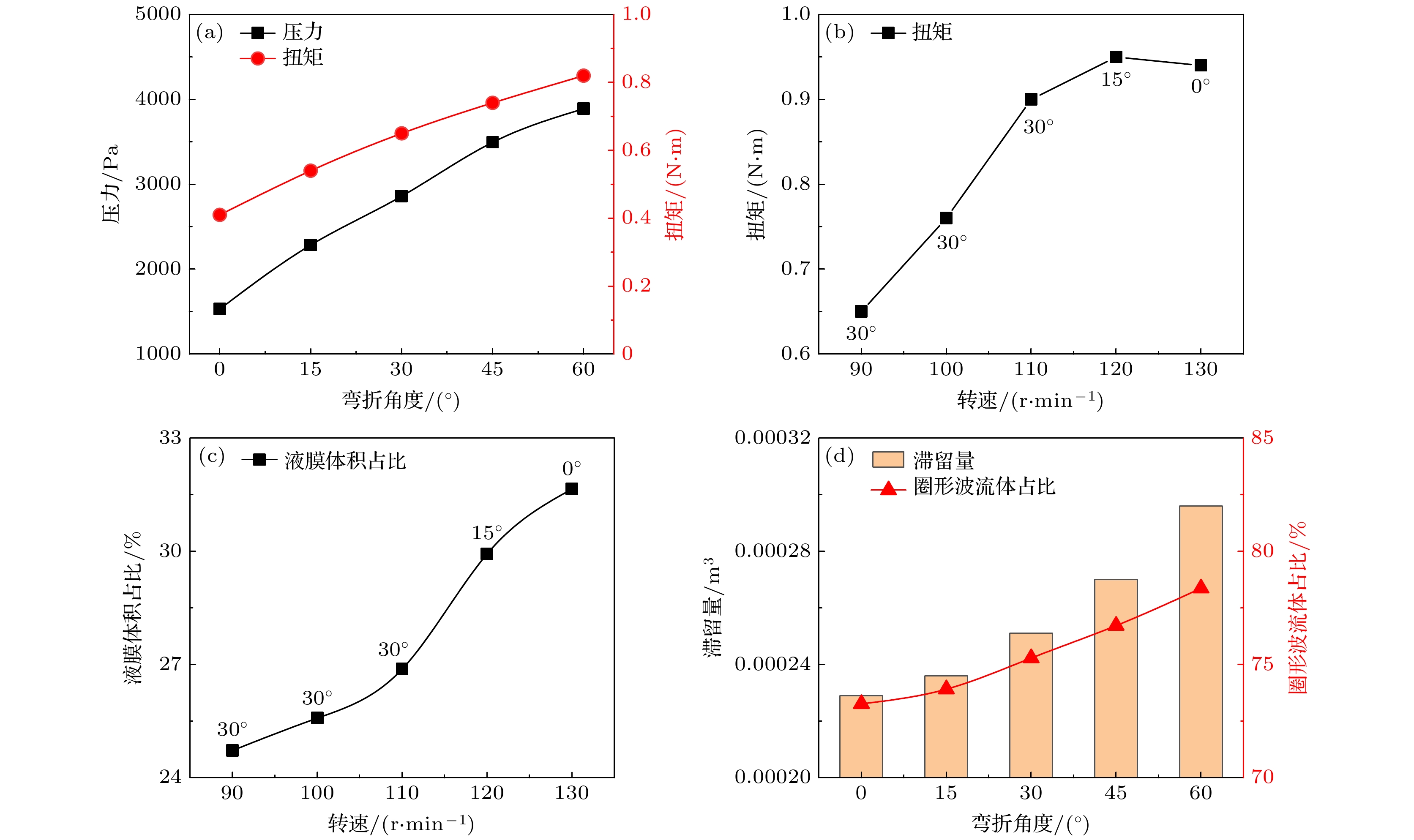

图 11 (a)物料3下物料所受压力及转子扭矩随刮板弯折角度变化统计图; (b)物料3下转子扭矩随转速和最佳弯折角度变化统计图; (c)物料3下液膜体积占比随转速和最佳弯折角度变化统计图; (d)物料3下蒸发器内液体滞留量及圈形波流体占比随刮板弯折角度变化统计图

Fig. 11. For feed material three: (a) Pressure and torque for different scraper angle; (b) the torque with different rotation speed and optimal scraper angle; (c) film volume of the solution in the evaporator with different rotation speed and optimal scraper angle; (d) occupied volume and fillet volume of the solution in the evaporator for different scraper angle

表 1 模拟介质参数表

Table 1. Physical properties of materials used for simulation

物料 本构模型 kμ/(Pa·sn) Γ n $ {\mu }_{\mathrm{o}} $/(Pa·s) $ {\mu }_{\mathrm{\infty }} $/(Pa·s) 物料1: CMC溶液 幂律模型 4.44 — 0.48 4.5 0.01 物料2: 聚酯溶液 幂律模型 9.10 — 0.38 100 0.08 物料3: 纤维素浆粕 Carreau模型 — 4.13 0.10 1100 0.12 -

[1] Jasch K, Grutzner T, Rosenthal G, Scholl S 2021 Chem. Eng. Res. Des. 165 162

Google Scholar

Google Scholar

[2] Appelhaus D, Jasch K, Jahnke S, Bin K H, Tegethoff W, Kohler J, Scholl S 2020 Chem. Eng. Res. Des. 161 115

Google Scholar

Google Scholar

[3] Hozan J S, Abdulsalam R K 2020 Pet. Sci. Technol. 38 323

Google Scholar

Google Scholar

[4] Mutzenburg A B 1965 Chem. Eng. 72 175

[5] Mckelvey J M, Sharps G V 1979 Polym Eng. Sci. 19 651

Google Scholar

Google Scholar

[6] Komori S, Takata K, Murakami Y 1988 J. Chem. Eng. Jpn. 21 639

Google Scholar

Google Scholar

[7] Komori S, Takata K, Murakami Y 1989 J. Chem. Eng. Jpn. 22 346

Google Scholar

Google Scholar

[8] Komori S, Takata K, Nagaosa R, Murakami Y 1990 J. Chem. Eng. Jpn. 23 550

Google Scholar

Google Scholar

[9] 张彬, 成鹏, 李清廉, 陈慧源, 李晨阳 2021 70 054702

Google Scholar

Google Scholar

Zhang B, Cheng P, Li L Q, Chen H Y, Li C Y 2021 Acta Phys. Sin. 70 054702

Google Scholar

Google Scholar

[10] 卢长兰, 李庆生, 于建华 2008 食品工业科技 29 209

Google Scholar

Google Scholar

Lu C L, Li Q S, Yu J H, Zhang Y 2008 Sci. Technol. Food Ind. 29 209

Google Scholar

Google Scholar

[11] 汪蕊, 贺小华 2004 南京工业大学学报(自然科学版) 26 72

Wang L, He X H 2004 Nan Tech Univ. Sci. 26 72

[12] 贺小华, 唐平, 李佳, 陆小华 2005 过程工程学报 5 357

Google Scholar

Google Scholar

He X H, Tang P, Li J, Lu X H 2005 Chin. J. Process Eng. 5 357

Google Scholar

Google Scholar

[13] Pawar S B, Mujumdar A S, Thorat B N 2012 Chem. Eng. Res. Des. 90 757

Google Scholar

Google Scholar

[14] 江体乾, 余永彬 1984 华东化工学院学报 3 395

Google Scholar

Google Scholar

Jiang T K, Yu Y B 1984 J. East China Univ. Sci. Technol. 3 395

Google Scholar

Google Scholar

[15] 左娟莉, 杨泓, 魏炳乾, 侯精明, 张凯 2020 69 064705

Google Scholar

Google Scholar

Zuo J L, Yang H, Wei B Q, Hou J M, Zhang K 2020 Acta Phys. Sin. 69 064705

Google Scholar

Google Scholar

[16] Chen S Y, Li C, Ren H J 2021 Int J Hydrogen Energ. 46 25252

Google Scholar

Google Scholar

[17] Menter, F R 1993 24th Fluid Dynamics Conference Orlando, Florida, July 6–9, 1993 p2906

[18] Mourad Y, Jeremy P, Francine F, Jack L 2007 Chem. Eng. Process. 47 1550

[19] Chen B, Fu C F, Gu L X 2011 Seminar on Development and Application of Super Soft and Easy-Dyeing Polyester Fiber Shanghai, China, October 24, 2011 p18

[20] 于浩淼, 陈延明, 王立岩, 吴全才 2019 中国塑料 33 28

Google Scholar

Google Scholar

Yu H M, Chen Y M, Wang Y Y, Wu Q C 2019 China Plast. 33 28

Google Scholar

Google Scholar

[21] 高殿才, 路喜英, 王华平, 张玉梅, 魏广信 2019 人造纤维 49 13

Google Scholar

Google Scholar

Gao D C, Lu X Y, Wang H P, Zhang Y M, Wei G X 2019 Artificial Fibre 49 13

Google Scholar

Google Scholar

[22] Mourad Y, Francine F, Jack L 2009 Chem. Eng. Process. 48 1445

[23] Jerome M, Francine F, Jack L 2003 Chem. Eng. Sci. 58 4667

Google Scholar

Google Scholar

[24] 经昊达, 张向军, 田煜, 孟永钢 2015 64 168101

Google Scholar

Google Scholar

Jing H D, Zhang X J, Tian Y, Meng Y G 2015 Acta Phys. Sin. 64 168101

Google Scholar

Google Scholar

[25] Buss-SMS-Canzler Gmb H https://www.sms-vt.com/[2021-10-01]

[26] McKenna T F 1995 Chem. Eng. Sci. 50 453

Google Scholar

Google Scholar

计量

- 文章访问数: 8142

- PDF下载量: 91

- 被引次数: 0

下载:

下载: