-

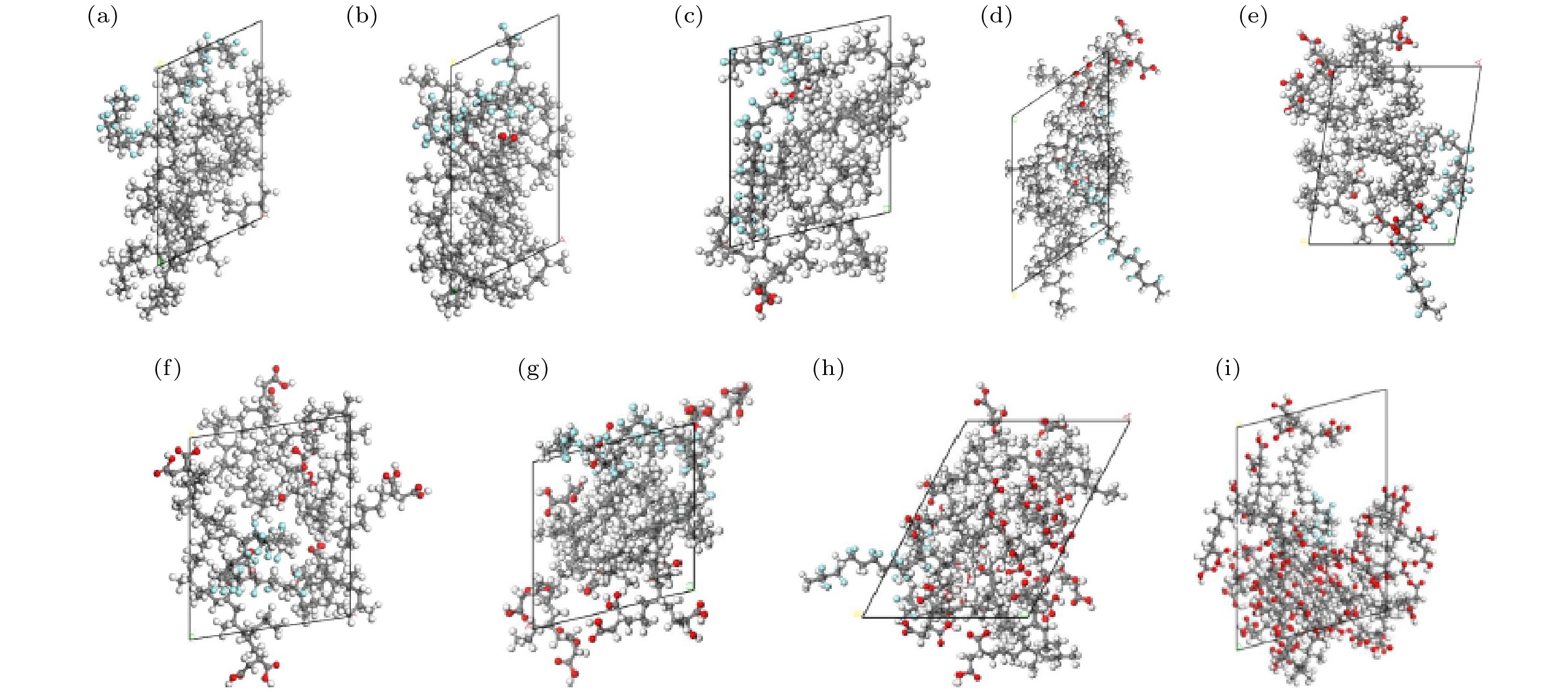

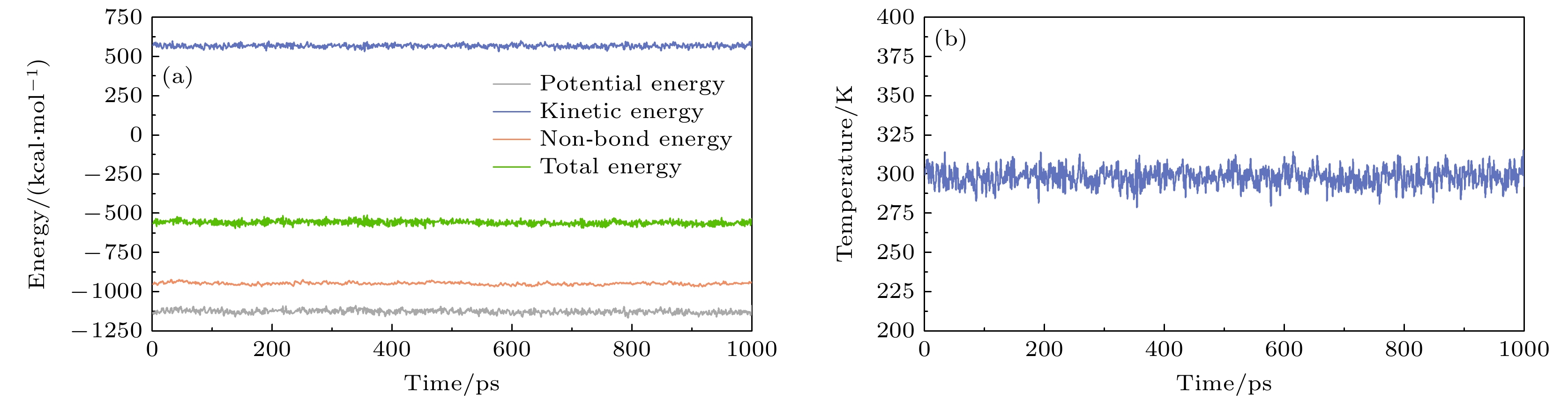

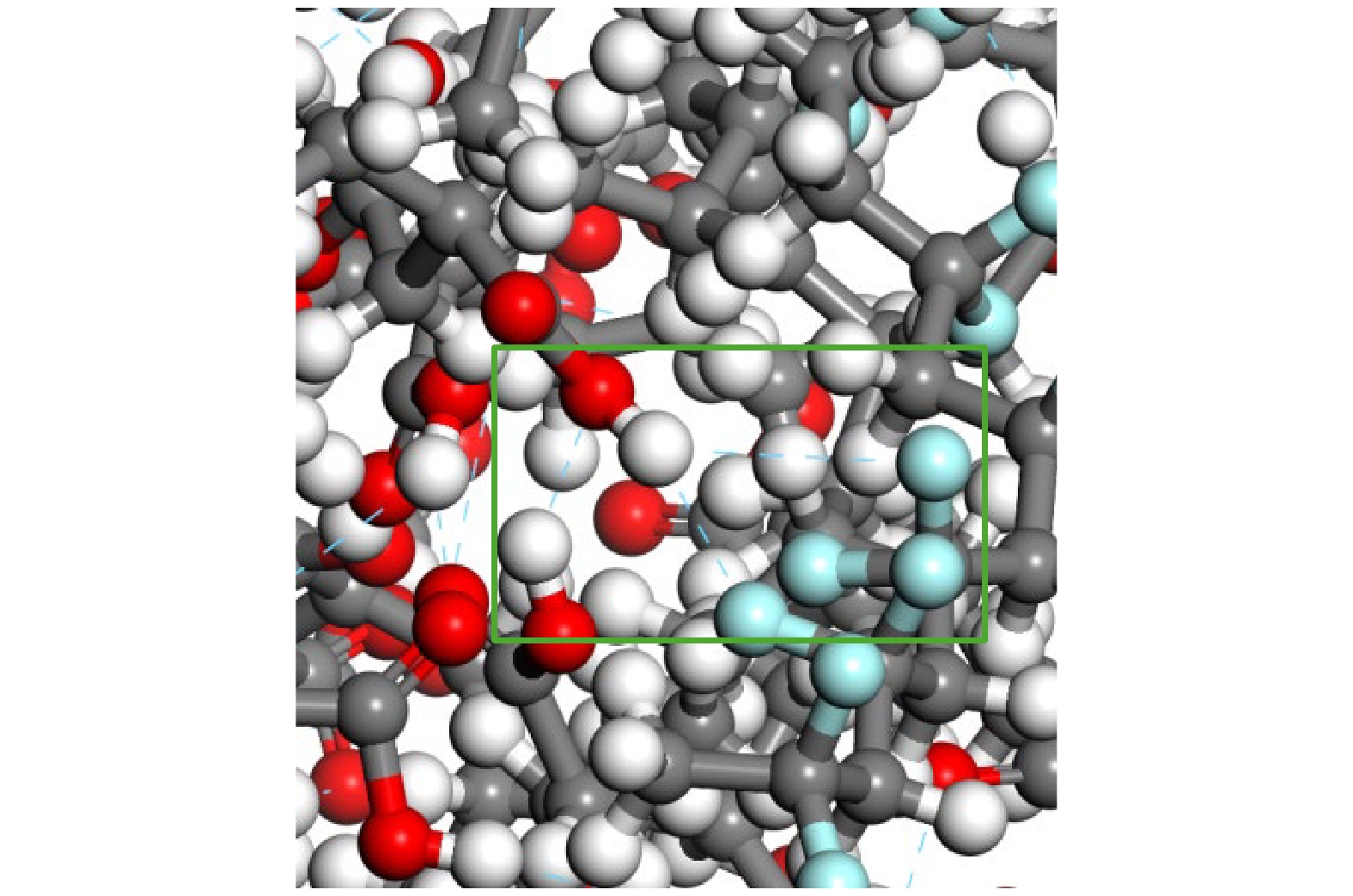

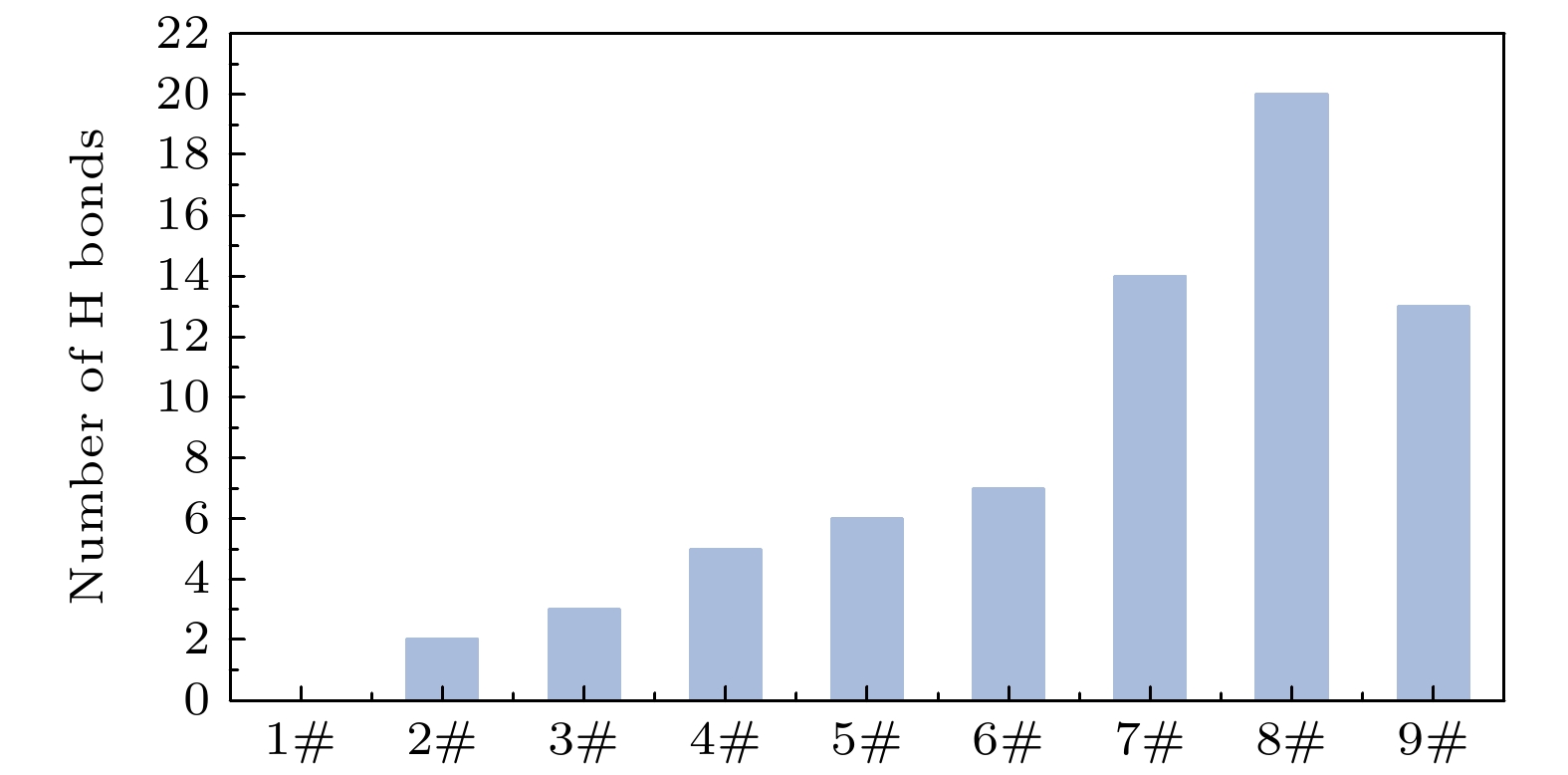

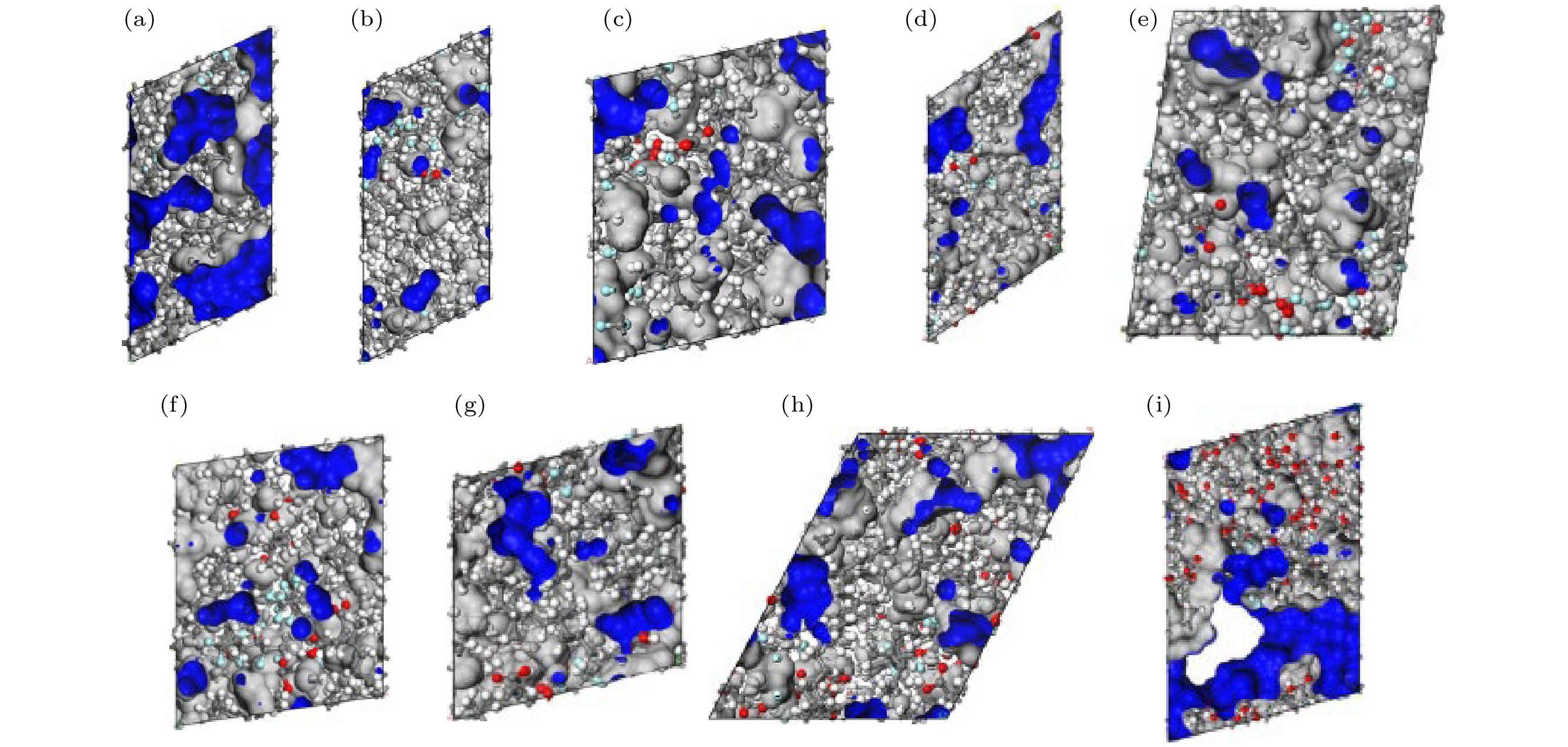

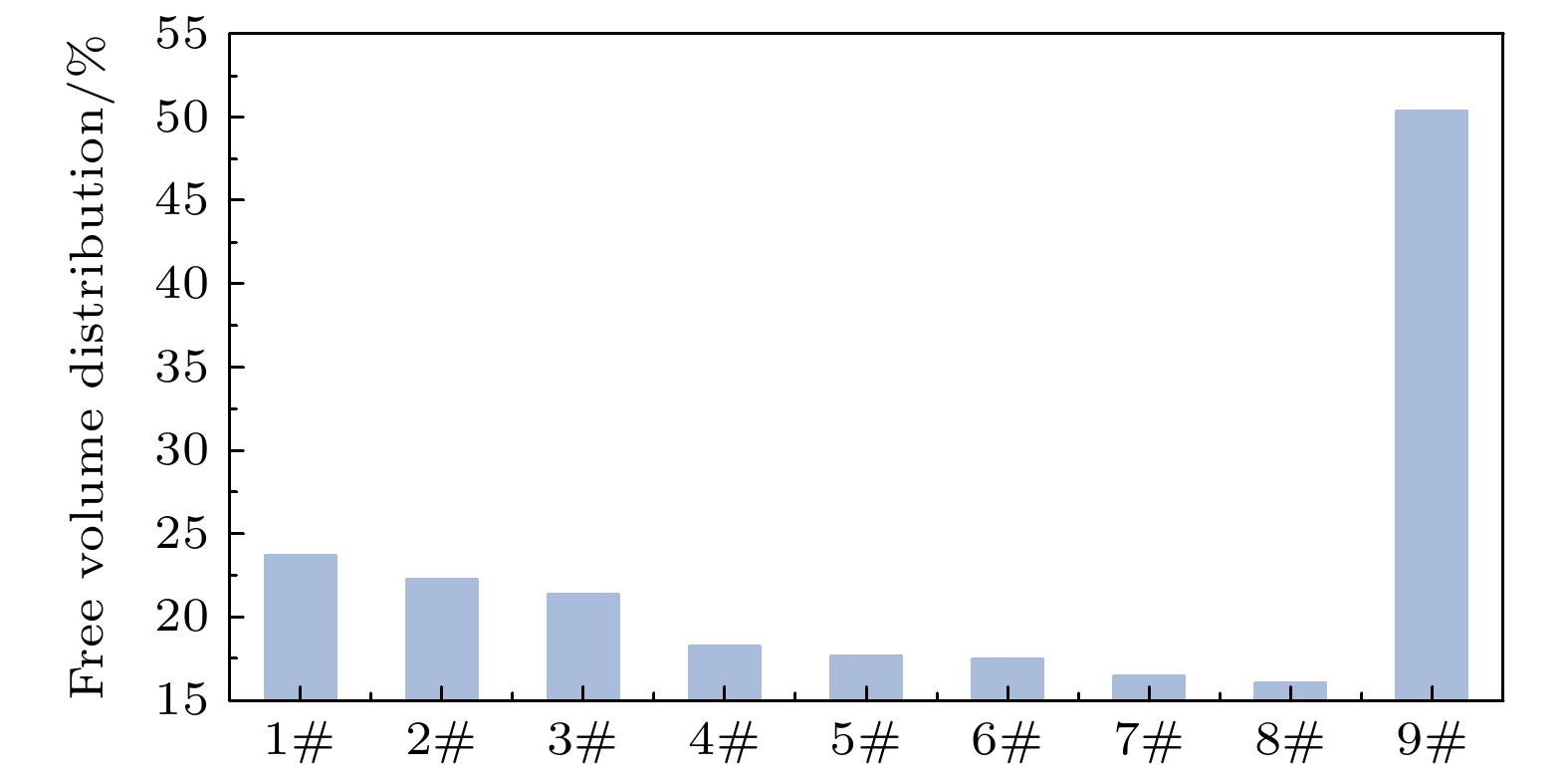

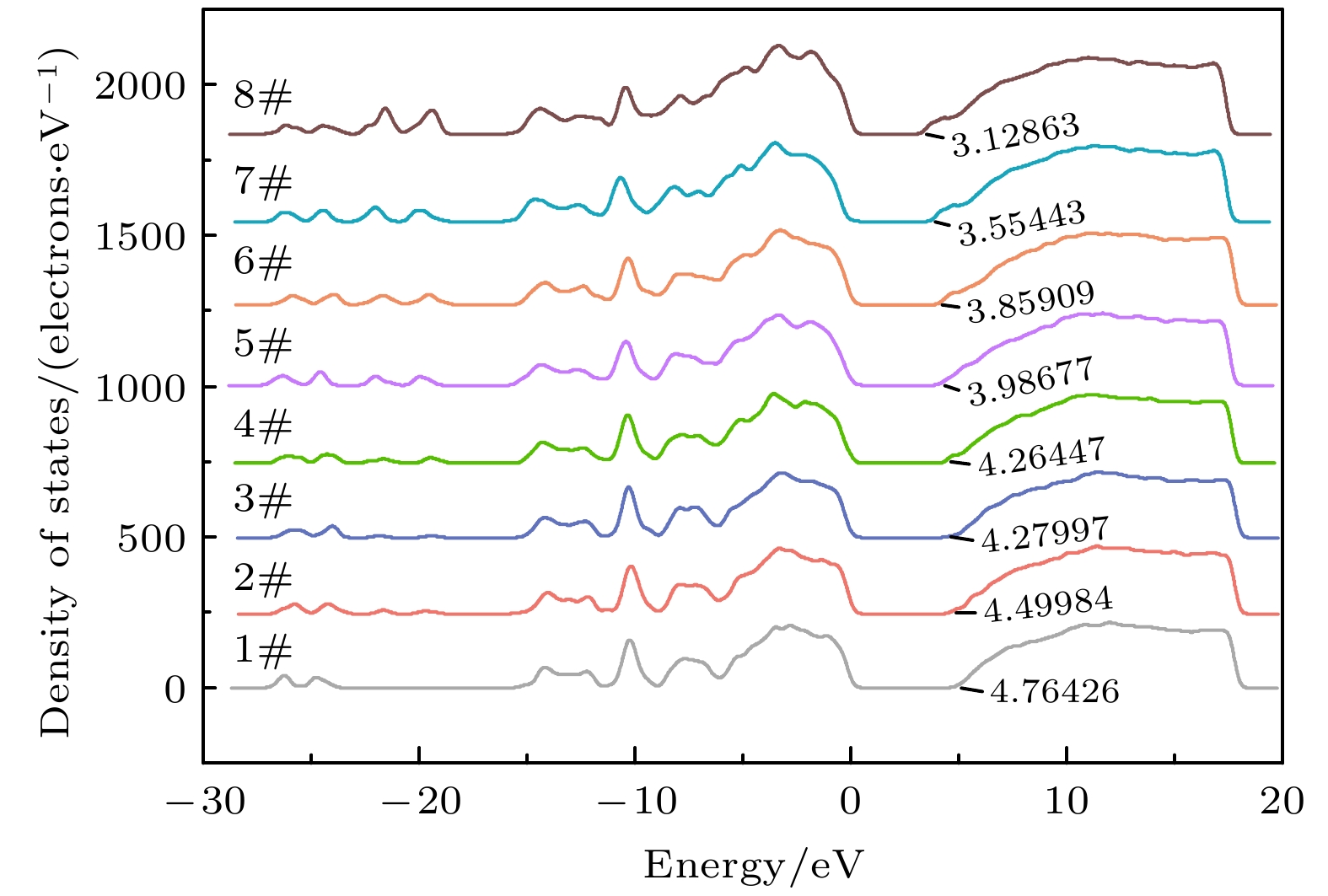

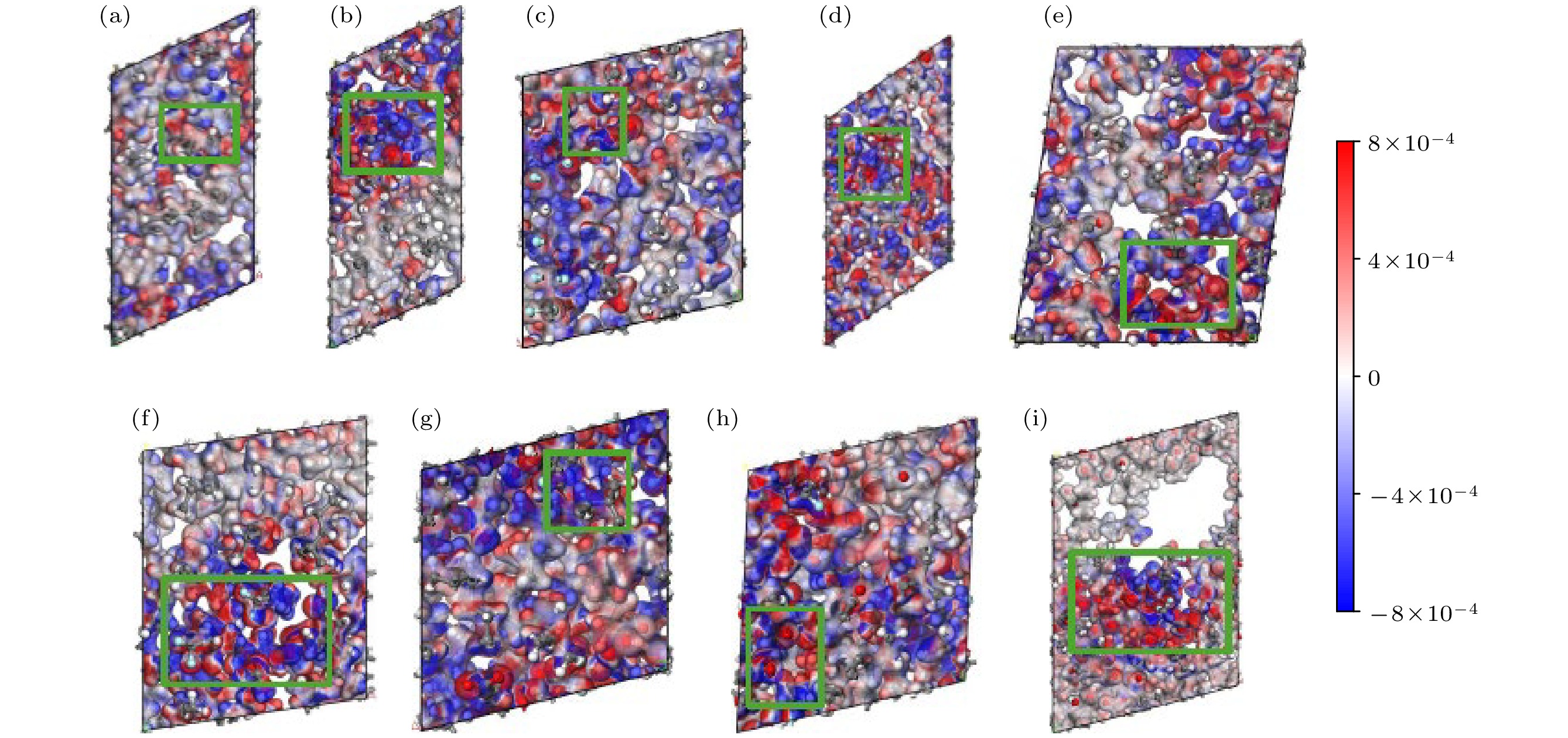

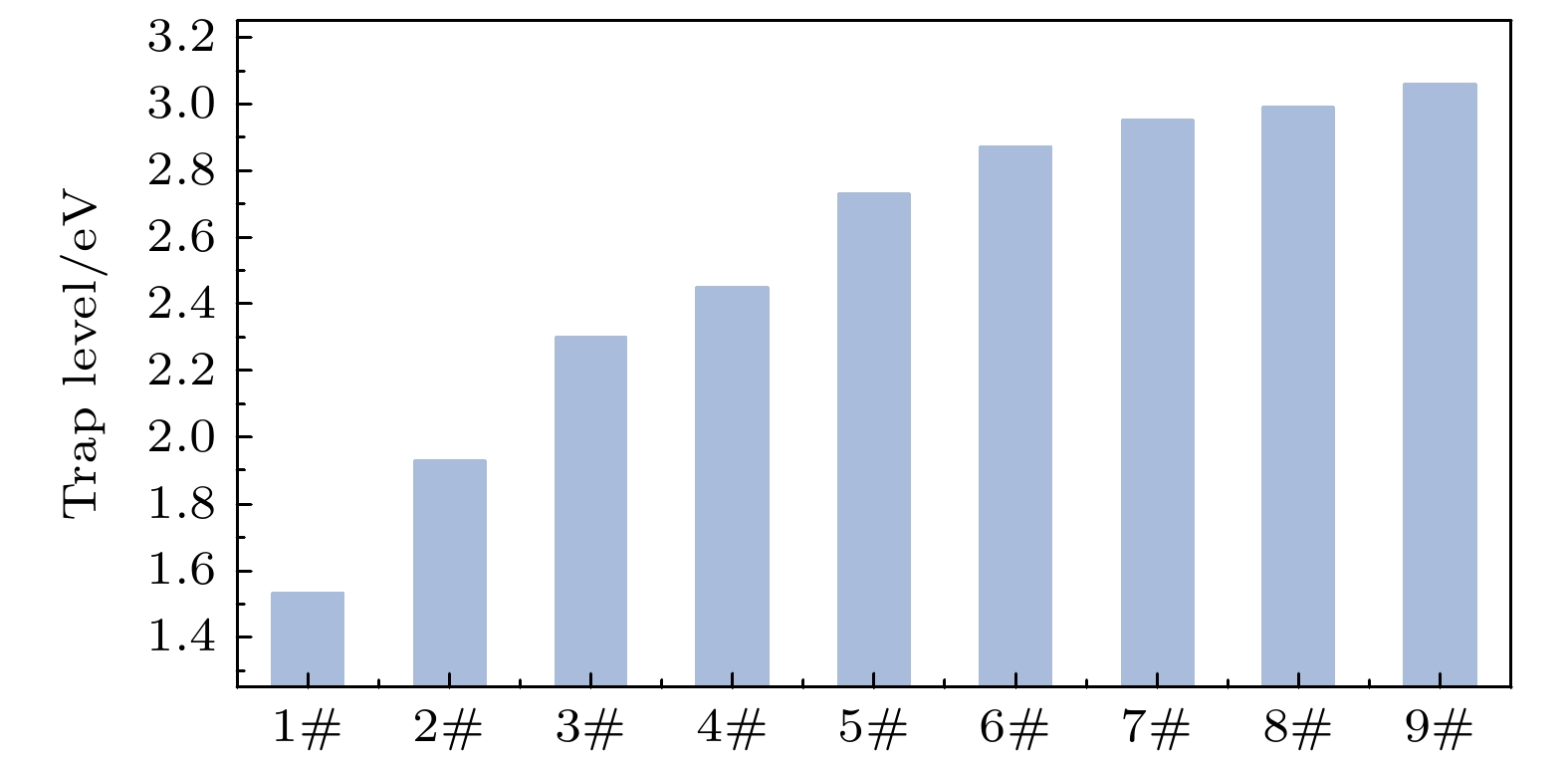

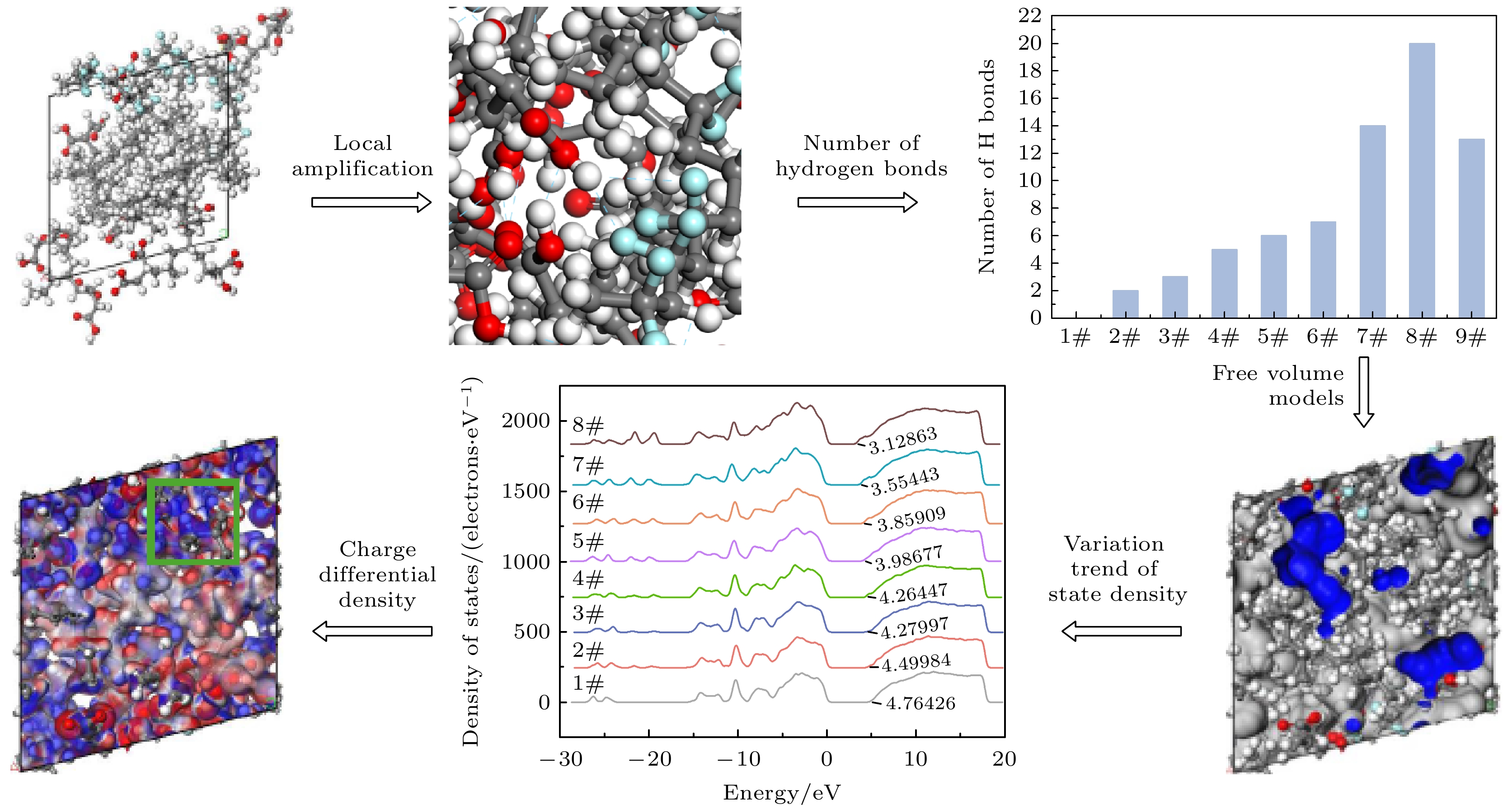

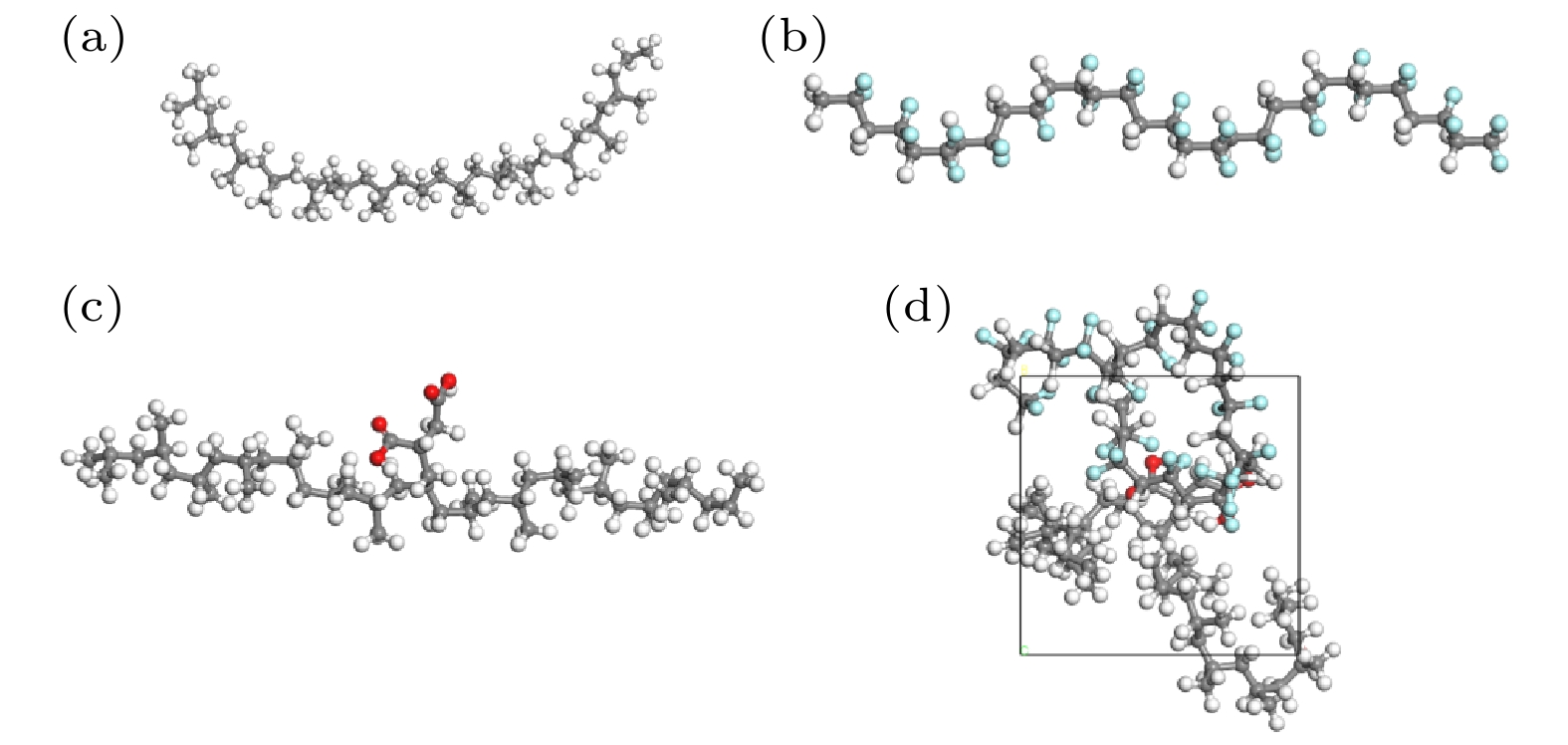

模拟分子的结构和行为有助于更深刻地分析电荷输运特性变化的微观机理. 本研究采用分子动力学模拟方法, 深入探究氢键对马来酸(MA)接枝聚丙烯(PP)/聚偏二氟乙烯(PVDF)复合体系分子结构演变与电荷输运特性的调控机制, 并对其分子间相互作用能、自由体积、电子态密度、电荷差分密度以及陷阱能级进行仿真分析. 研究结果表明: 随着MA接枝量的增加, 氢键数量显著增多. 当MA质量分数为36.22%时, 氢键数量达到20的峰值, 分子间相互作用能增至极大值2171.63 kcal·mol–1, 自由体积分布达到极小值16.03%, 此时分子内部结构最为紧密. 当MA质量分数为52.97%时, 复合材料的带隙达到极小值3.13 eV, 陷阱能级深度亦达到极大值3.06 eV, 此时PP/PVDF复合材料在氢键形成的区域显示出更高的电子密度积累, 电子逸出概率显著地降低. 至此, 模拟结果证实了氢键的作用不仅改变了材料的分子结构, 还通过改变局部电荷分布状态直接影响电荷输运特性, 为设计功能性高分子复合电介质材料提供了理论依据.Simulating molecular structures and dynamic behaviors presents critical insights into the microscopic mechanisms governing variations in charge transport properties. In this work, molecular dynamics (MD) simulations integrated with the Compass II force field and molecular modeling (including geometry optimization, annealing, and dynamic equilibration) are conducted to systematically analyze intermolecular interaction energy, free volume distribution, electronic density of states (DOS), charge differential density, and trap energy levels. aiming to unravel the regulatory role of hydrogen bonds in the structural evolution and charge transport dynamics of polypropylene (PP)/polyvinylidene fluoride (PVDF) composite systems. A quantitative framework is further established to correlate hydrogen bond density with key material performance metrics, such as free volume fraction, bandgap energy, and trap energy depth, thereby elucidating the hydrogen bond-mediated modulation of molecular architecture and charge transport behavior in PP/PVDF composites. Simulation results reveal a pronounced dependence of hydrogen bond formation on maleic acid (MA) grafting content. When the mass fraction of MA is 36.22%, the number of hydrogen bonds reaches a maximum value of 20, the intermolecular interaction energy increases to 2171.63 kcal·mol–1, and the free volume fraction reaches a minimum value of 16.03%. At this point, the internal structure of the molecule is most compact. When the mass fraction of MA increases to 52.97%, the band gap of the composite material reaches a minimum value of 3.13 eV, and the depth of the trap energy levels also reaches a maximum value of 3.06 eV. Spatial charge differential density analysis demonstrates that the enhanced electron density is localized near hydrogen-bonded region, thus suppressing electron escape probability by over 40% compared with the scenario in the non-bonded domains. All of the findings highlight a dual mechanism: hydrogen bonds not only reconfigure the molecular topology but also reshape the localized charge distribution, directly suppressing the carrier mobility and changing the charge transport pathways. These findings also establish a robust structure-property relationship, showing that hydrogen bond engineering serves as a pivotal strategy to tailor dielectric performance in polymer composites. By optimizing hydrogen bond density, the trade-off between structural compactness and electronic confinement can be strategically balanced, thus enabling the designing of PP-based dielectrics with low carbon footprints and superior insulating properties. This mechanistic understanding provides actionable guidelines for advancing high-performance insulating materials in energy storage systems, aerospace components, and next-generation electrical devices, where precise control over charge transport is paramount.

-

Keywords:

- polypropylene /

- hydrogen bond /

- molecular dynamics /

- charge transport

[1] Li H, Gadinski M R, Huang Y Q 2020 Energy Environ. Sci. 13 1279

Google Scholar

Google Scholar

[2] Tan D Q 2020 Adv. Funct. Mater. 30 1808567

Google Scholar

Google Scholar

[3] Pablo A R, Baltus C B, Sebastião V C, Sílvia H P 2024 Chem. Eng. Sci. 298 120319

Google Scholar

Google Scholar

[4] 殷嘉鑫, 王强华 2024 73 157401

Google Scholar

Google Scholar

Yin J X, Wang Q H 2024 Acta Phys. Sin. 73 157401

Google Scholar

Google Scholar

[5] 罗兵, 李君洛, 王少杰, 胡世勋, 徐永生, 肖微, 徐刚毅, 何金良, 李琦 2024 中国电机工程学报 44 3371

Google Scholar

Google Scholar

Luo B, Li J L, Wang S J, Hu S X, Xu Y S, Xiao W, Xu G Y, He J L, Li Q 2024 Proceedings of the CSEE 44 3371

Google Scholar

Google Scholar

[6] 樊林禛, 李琦, 袁浩, 黄上师, 何金良 2022 中国电机工程学报 45 4227

Google Scholar

Google Scholar

Fan L Z, Li Q, Yuan H, Huang S S, He J L 2022 Proceedings of the CSEE 45 4227

Google Scholar

Google Scholar

[7] Ohuk L, Kim D, Kim H, Seong H L, Taehoon K, Kwon I, Keisuke S, Masayuki H, Jin H L, Dae H L, Kim M H, Masahiro K, Yu S G 2025 Compos. Sci. Technol. 259 110939

Google Scholar

Google Scholar

[8] Hu S, Zhou Y, Yuan C, Wang W, Hu J 2020 High Voltage 5 249

Google Scholar

Google Scholar

[9] 樊林禛, 郝国辉, 张雯嘉, 董新华, 屠幼萍, 胡世勋, 邵清, 郑重, 王伟, 袁浩, 李琦, 何金良 2023 中国电机工程学报 45 5251

Google Scholar

Google Scholar

Fan L Z, Hao G H, Zhang W J, Dong X H, Tu Y P, Hu S X, Shao Q, Zheng Z, Wang W, Yuan H, Li Q, He J L 2023 Proceedings of the CSEE 45 5251

Google Scholar

Google Scholar

[10] 李琳, 王暄, 孙伟峰, 雷清泉 2013 62 106201

Google Scholar

Google Scholar

Li L, Wang X, Sun W F, Lei Q Q 2013 Acta Phys. Sin. 62 106201

Google Scholar

Google Scholar

[11] 李丽丽, 张晓虹, 王玉龙, 国家辉 2017 66 087201

Google Scholar

Google Scholar

Li L L, Zhang X H, Wang Y L, Guo J H 2017 Acta Phys. Sin. 66 087201

Google Scholar

Google Scholar

[12] Ulian G, Moro D, Valdrè G 2018 Micro Nano Lett. 13 4

Google Scholar

Google Scholar

[13] Duan X H, Wah H S, Martin G, John L, He J L 2020 High Voltage 5 397

Google Scholar

Google Scholar

[14] Etcheverry M, Barbosa S E 2012 Materials 5 1084

Google Scholar

Google Scholar

[15] Kang J W, Choi K, John W H, Hu S L 1998 Polymer 39 7079

Google Scholar

Google Scholar

[16] 庞曦, 许天蕾, 刘鹏, 魏鼎欣, 谢宗良, 彭宗仁 2024 高电压技术 50 3

Google Scholar

Google Scholar

Pang X, Xu T L, Liu P, Wei D X, Xie Z L, Peng Z R 2024 High Voltage Engineering 50 3

Google Scholar

Google Scholar

[17] 马超, 闵道敏, 李盛涛, 郑旭, 李西育, 闵超, 湛海涯 2017 66 067701

Google Scholar

Google Scholar

Ma C, Min D M, Li S T, Zheng X, Li X Y, Min C, Zhan H Y 2017 Acta Phys. Sin. 66 067701

Google Scholar

Google Scholar

[18] Boek E S, Coveney P V, Skipper N T 1995 Langmuir 11 46295

Google Scholar

Google Scholar

[19] Martínez, Mario J, Martínez L 2003 J. Comput. Chem. 24 819

Google Scholar

Google Scholar

[20] 彭向阳, 姚驰, 余欣, 胡世勋, 范亚洲, 何金良 2023 高电压技术 49 4480

Google Scholar

Google Scholar

Peng X Y, Yao C, Yu X, Hu S X, Fan Y Z, He J L 2023 High Voltage Engineering 49 4480

Google Scholar

Google Scholar

[21] 贾海鹏, 苏勋家, 侯根良, 曹小平, 毕松, 刘朝辉 2013 化工学报 64 1862

Google Scholar

Google Scholar

Jia H P, Su X J, Hou G L, Cao X P, Bi S, Liu Z H 2013 J. Chem. Ind. Eng. 64 1862

Google Scholar

Google Scholar

[22] Ferraris G, Ivaldi G 1988 Acta Cryst 44 341

Google Scholar

Google Scholar

[23] 冯阳, 渠广昊, 李盛涛 2024 高电压技术 50 2363

Google Scholar

Google Scholar

Feng Y, Qu G H, Li S T 2024 High Voltage Engineering 50 2363

Google Scholar

Google Scholar

[24] Ran Z Y, Luo Z, Li J L, Meng L, Liu Y H, Hu J, He J L, Li Q 2024 IEEE 5th International Conference on Dielectrics France, August 2–6, 2024, p1241

[25] 樊金泽, 方展伯, 罗超杰, 张汇 2022 71 127103

Google Scholar

Google Scholar

Fan J Z, Fang Z B, Luo C J, Zhang H 2022 Acta Phys. Sin. 71 127103

Google Scholar

Google Scholar

[26] Li G C, Liu T Z, Gu Z L, Chen X L, Sun B B, Zhu Y W, Li S T, Wei Y H 2024 High Voltage 85 2397

Google Scholar

Google Scholar

[27] 洪迪昆, 刘亮, 郭欣 2015 中国电机工程学报 35 6099

Google Scholar

Google Scholar

Hong D K, Liu L, Guo X 2015 Proceedings of the CSEE 35 6099

Google Scholar

Google Scholar

[28] Li Q, Yao F Z, Liu Yang 2018 Annu. Rev. Mater. Res. 48 219

Google Scholar

Google Scholar

[29] Gabriel P, Jacob P T, Mikhail I, Wu Z G, John W L 2025 J. Chem. Phys. 162 054709

Google Scholar

Google Scholar

[30] 王进, 王军霞, 曾凡桂, 吴秀玲 2010 化学学报 68 1653

Wang J, Wang J X, Zeng F G, Wu X L 2010 Acta Chim Sinica 68 1653

[31] 肖萌, 陈毓妍, 赵亦烁, 杜伯学 2024 高电压技术 50 2319

Google Scholar

Google Scholar

Xiao M, Chen Y Y, Zhao Y S, Du B X 2024 High Voltage Engineering 50 2319

Google Scholar

Google Scholar

[32] Blaise P G, Le G C 2018 AIP Adv. 8 095228

Google Scholar

Google Scholar

[33] Li H, Ai D, Ren L, L 2019 Adv. Mater. 31 1900875

Google Scholar

Google Scholar

[34] Zhou Y, Li Q, Dang B 2018 Adv. Mater. 30 1805672

Google Scholar

Google Scholar

[35] 李盛涛, 谢东日, 闵道敏 2019 中国电机工程学报 39 6122

Google Scholar

Google Scholar

Li S T, Xie D R, Min D M 2019 Proceedings of the CSEE 39 6122

Google Scholar

Google Scholar

[36] Wang J, David B A, Carlos A F, De L, Zhang D X, Alexander B, Aart W V, David S 2022 Composites Part A 159 16993

Google Scholar

Google Scholar

[37] 国家辉 2014 硕士学位论文 (哈尔滨: 哈尔滨理工大学)

Guo J H 2014 M. S. Thesis (Harbin: Harbin University of Science and Technology

-

表 1 Compass II力场势能和参数及单位

Table 1. Force field potential energy and parameters in COMPASS II.

Epotential Function form Parameters and units Ebond $ {E_{{\text{bond}}}} = \displaystyle\sum\limits_{{\text{bonds}}} {{k_b}{{(r - {r_0})}^2} + k_b^{(3)}{{(r - {r_0})}^3} + k_b^{(4)}{{(r - {r_0})}^4}} $ kb/(kcal·mol–1·Å–2); r, r0/Å Eangle $ {E_{{\text{angle}}}} = \displaystyle\sum\limits_{{\text{angles}}} {{k_\theta }{{(\theta - {\theta _0})}^2} + k_\theta ^{(3)}{{(\theta - {\theta _0})}^3} + k_\theta ^{(4)}{{(\theta - {\theta _0})}^4}} $ kθ/(kcal·mol–1); θ, θ0/(°) Etorsion $ {E_{{\text{torsion}}}} = \displaystyle\sum\limits_{{\text{torsions}}} {{k_\varphi }(1 + \cos (n} \varphi - {\varphi _0})) $ kφ/(kcal·mol–1); φ, φ0/(°) Eout-of-plane $ {E_{{\text{out-of-plane}}}} = \displaystyle\sum\limits_{{\text{out-of-plane}}} {{k_\omega }{\omega ^2}} $ kω/(kcal·mol–1); ω/(°) Evdw $ {E_{{\text{vdW}}}} = \displaystyle\sum\limits_{i, j} {4\varepsilon \left[ {{{\left( {\frac{\sigma }{{{r_{ij}}}}} \right)}^{12}} - {{\left( {\frac{\sigma }{{{r_{ij}}}}} \right)}^6}} \right]} $ Ε/eV; σ/Å; rij/Å Eelectrostatic $ {E_{{\text{electrostatic}}}} = \displaystyle\sum\limits_{i, j} {\frac{{{q_i}{q_j}}}{{4\pi {\varepsilon _0}{r_{ij}}}}} $ qi, qj/e; rij/Å 表 2 不同PP/PVDF复合材料体系模型的编号及其质量分数

Table 2. Designation and mass fraction of different PP/PVDF composites models.

试样编号

PP-g-MA/%PVDF/% MA PP 1# 0 77.94 22.26 2# 2.74 75.52 21.74 3# 5.33 73.41 21.26 4# 10.13 69.57 20.30 5# 14.50 65.94 19.56 6# 18.47 62.83 18.70 7# 22.05 59.84 18.11 8# 36.22 48.51 15.27 9# 52.97 35.34 11.69 表 3 NPT平衡后不同PP/PVDF复合材料能量和温度的波动范围

Table 3. Fluctuation range of energy and temperature of different PP/PVDF composites after NPT equilibrium.

试样

编号平衡

时间/ps波动/% 温度 Epotential Ekinetic Enon-bond Etotal 1# 58.93 3.25 1.56 3.85 4.52 4.11 2# 74.68 2.89 2.56 4.26 1.57 2.10 3# 25.95 4.56 4.56 3.73 2.94 1.61 4# 78.59 1.12 2.76 1.52 4.51 1.52 5# 85.45 2.59 3.81 1.14 1.52 3.20 6# 36.58 3.58 4.19 2.81 2.73 2.17 7# 57.58 1.56 1.25 4.20 2.85 3.96 8# 85.42 3.20 2.48 1.52 4.22 2.57 9# 54.20 2.74 4.21 1.23 2.52 1.85 表 4 不同PP/PVDF复合材料的能量变化

Table 4. Energy evolution in different PP/PVDF composites.

Enon-bond/(kcal·mol–1)

Ediagonal/(kcal·mol–1)Einteraction

/(kcal·mol–1)Etotal

/(kcal·mol–1)Evdw Eelectrostatic Ebond Eangle Etorsion 1# 84.65 853.99 214.04 371.93 –721.02 53.49 552.18 2# 85.17 906.80 215.48 398.77 –728.18 63.88 601.15 3# 86.71 977.26 217.09 412.65 –751.63 75.86 654.46 4# 97.89 1083.01 218.45 448.12 –753.56 85.58 723.28 5# 110.28 1205.79 242.31 453.70 –770.93 88.09 828.37 6# 110.97 1332.96 264.16 536.79 –787.47 89.02 898.72 7# 122.93 1462.88 268.80 547.69 –792.07 108.50 1002.49 8# 132.42 2094.95 309.91 689.15 –858.76 127.05 1413.73 9# 55.29 3377.36 402.88 1026.23 –1028.7 74.86 2171.63 -

[1] Li H, Gadinski M R, Huang Y Q 2020 Energy Environ. Sci. 13 1279

Google Scholar

Google Scholar

[2] Tan D Q 2020 Adv. Funct. Mater. 30 1808567

Google Scholar

Google Scholar

[3] Pablo A R, Baltus C B, Sebastião V C, Sílvia H P 2024 Chem. Eng. Sci. 298 120319

Google Scholar

Google Scholar

[4] 殷嘉鑫, 王强华 2024 73 157401

Google Scholar

Google Scholar

Yin J X, Wang Q H 2024 Acta Phys. Sin. 73 157401

Google Scholar

Google Scholar

[5] 罗兵, 李君洛, 王少杰, 胡世勋, 徐永生, 肖微, 徐刚毅, 何金良, 李琦 2024 中国电机工程学报 44 3371

Google Scholar

Google Scholar

Luo B, Li J L, Wang S J, Hu S X, Xu Y S, Xiao W, Xu G Y, He J L, Li Q 2024 Proceedings of the CSEE 44 3371

Google Scholar

Google Scholar

[6] 樊林禛, 李琦, 袁浩, 黄上师, 何金良 2022 中国电机工程学报 45 4227

Google Scholar

Google Scholar

Fan L Z, Li Q, Yuan H, Huang S S, He J L 2022 Proceedings of the CSEE 45 4227

Google Scholar

Google Scholar

[7] Ohuk L, Kim D, Kim H, Seong H L, Taehoon K, Kwon I, Keisuke S, Masayuki H, Jin H L, Dae H L, Kim M H, Masahiro K, Yu S G 2025 Compos. Sci. Technol. 259 110939

Google Scholar

Google Scholar

[8] Hu S, Zhou Y, Yuan C, Wang W, Hu J 2020 High Voltage 5 249

Google Scholar

Google Scholar

[9] 樊林禛, 郝国辉, 张雯嘉, 董新华, 屠幼萍, 胡世勋, 邵清, 郑重, 王伟, 袁浩, 李琦, 何金良 2023 中国电机工程学报 45 5251

Google Scholar

Google Scholar

Fan L Z, Hao G H, Zhang W J, Dong X H, Tu Y P, Hu S X, Shao Q, Zheng Z, Wang W, Yuan H, Li Q, He J L 2023 Proceedings of the CSEE 45 5251

Google Scholar

Google Scholar

[10] 李琳, 王暄, 孙伟峰, 雷清泉 2013 62 106201

Google Scholar

Google Scholar

Li L, Wang X, Sun W F, Lei Q Q 2013 Acta Phys. Sin. 62 106201

Google Scholar

Google Scholar

[11] 李丽丽, 张晓虹, 王玉龙, 国家辉 2017 66 087201

Google Scholar

Google Scholar

Li L L, Zhang X H, Wang Y L, Guo J H 2017 Acta Phys. Sin. 66 087201

Google Scholar

Google Scholar

[12] Ulian G, Moro D, Valdrè G 2018 Micro Nano Lett. 13 4

Google Scholar

Google Scholar

[13] Duan X H, Wah H S, Martin G, John L, He J L 2020 High Voltage 5 397

Google Scholar

Google Scholar

[14] Etcheverry M, Barbosa S E 2012 Materials 5 1084

Google Scholar

Google Scholar

[15] Kang J W, Choi K, John W H, Hu S L 1998 Polymer 39 7079

Google Scholar

Google Scholar

[16] 庞曦, 许天蕾, 刘鹏, 魏鼎欣, 谢宗良, 彭宗仁 2024 高电压技术 50 3

Google Scholar

Google Scholar

Pang X, Xu T L, Liu P, Wei D X, Xie Z L, Peng Z R 2024 High Voltage Engineering 50 3

Google Scholar

Google Scholar

[17] 马超, 闵道敏, 李盛涛, 郑旭, 李西育, 闵超, 湛海涯 2017 66 067701

Google Scholar

Google Scholar

Ma C, Min D M, Li S T, Zheng X, Li X Y, Min C, Zhan H Y 2017 Acta Phys. Sin. 66 067701

Google Scholar

Google Scholar

[18] Boek E S, Coveney P V, Skipper N T 1995 Langmuir 11 46295

Google Scholar

Google Scholar

[19] Martínez, Mario J, Martínez L 2003 J. Comput. Chem. 24 819

Google Scholar

Google Scholar

[20] 彭向阳, 姚驰, 余欣, 胡世勋, 范亚洲, 何金良 2023 高电压技术 49 4480

Google Scholar

Google Scholar

Peng X Y, Yao C, Yu X, Hu S X, Fan Y Z, He J L 2023 High Voltage Engineering 49 4480

Google Scholar

Google Scholar

[21] 贾海鹏, 苏勋家, 侯根良, 曹小平, 毕松, 刘朝辉 2013 化工学报 64 1862

Google Scholar

Google Scholar

Jia H P, Su X J, Hou G L, Cao X P, Bi S, Liu Z H 2013 J. Chem. Ind. Eng. 64 1862

Google Scholar

Google Scholar

[22] Ferraris G, Ivaldi G 1988 Acta Cryst 44 341

Google Scholar

Google Scholar

[23] 冯阳, 渠广昊, 李盛涛 2024 高电压技术 50 2363

Google Scholar

Google Scholar

Feng Y, Qu G H, Li S T 2024 High Voltage Engineering 50 2363

Google Scholar

Google Scholar

[24] Ran Z Y, Luo Z, Li J L, Meng L, Liu Y H, Hu J, He J L, Li Q 2024 IEEE 5th International Conference on Dielectrics France, August 2–6, 2024, p1241

[25] 樊金泽, 方展伯, 罗超杰, 张汇 2022 71 127103

Google Scholar

Google Scholar

Fan J Z, Fang Z B, Luo C J, Zhang H 2022 Acta Phys. Sin. 71 127103

Google Scholar

Google Scholar

[26] Li G C, Liu T Z, Gu Z L, Chen X L, Sun B B, Zhu Y W, Li S T, Wei Y H 2024 High Voltage 85 2397

Google Scholar

Google Scholar

[27] 洪迪昆, 刘亮, 郭欣 2015 中国电机工程学报 35 6099

Google Scholar

Google Scholar

Hong D K, Liu L, Guo X 2015 Proceedings of the CSEE 35 6099

Google Scholar

Google Scholar

[28] Li Q, Yao F Z, Liu Yang 2018 Annu. Rev. Mater. Res. 48 219

Google Scholar

Google Scholar

[29] Gabriel P, Jacob P T, Mikhail I, Wu Z G, John W L 2025 J. Chem. Phys. 162 054709

Google Scholar

Google Scholar

[30] 王进, 王军霞, 曾凡桂, 吴秀玲 2010 化学学报 68 1653

Wang J, Wang J X, Zeng F G, Wu X L 2010 Acta Chim Sinica 68 1653

[31] 肖萌, 陈毓妍, 赵亦烁, 杜伯学 2024 高电压技术 50 2319

Google Scholar

Google Scholar

Xiao M, Chen Y Y, Zhao Y S, Du B X 2024 High Voltage Engineering 50 2319

Google Scholar

Google Scholar

[32] Blaise P G, Le G C 2018 AIP Adv. 8 095228

Google Scholar

Google Scholar

[33] Li H, Ai D, Ren L, L 2019 Adv. Mater. 31 1900875

Google Scholar

Google Scholar

[34] Zhou Y, Li Q, Dang B 2018 Adv. Mater. 30 1805672

Google Scholar

Google Scholar

[35] 李盛涛, 谢东日, 闵道敏 2019 中国电机工程学报 39 6122

Google Scholar

Google Scholar

Li S T, Xie D R, Min D M 2019 Proceedings of the CSEE 39 6122

Google Scholar

Google Scholar

[36] Wang J, David B A, Carlos A F, De L, Zhang D X, Alexander B, Aart W V, David S 2022 Composites Part A 159 16993

Google Scholar

Google Scholar

[37] 国家辉 2014 硕士学位论文 (哈尔滨: 哈尔滨理工大学)

Guo J H 2014 M. S. Thesis (Harbin: Harbin University of Science and Technology

计量

- 文章访问数: 568

- PDF下载量: 17

- 被引次数: 0

下载:

下载: