-

Reduced activation ferritic/martensitic (RAFM) steel, as a typical body centered cubic (bcc) iron based structure material, has become a candidate material for future fusion reactor. Nano-scale prismatic interstitial dislocation loops formed in irradiated RAFM have been studied for many years because of their significant influences on the mechanical properties (e.g. irradiation embrittlement, hardening, creep, etc.). Compared with edge dislocation, screw dislocation has very important influence on plastic deformation behavior because of its low mobility. Thus, the mechanism of interaction between screw dislocation and interstitial dislocation loops has become an intense research topic of interest. In this study, the slip behavior of screw dislocation and the mechanisms of interaction between screw dislocation and ½[

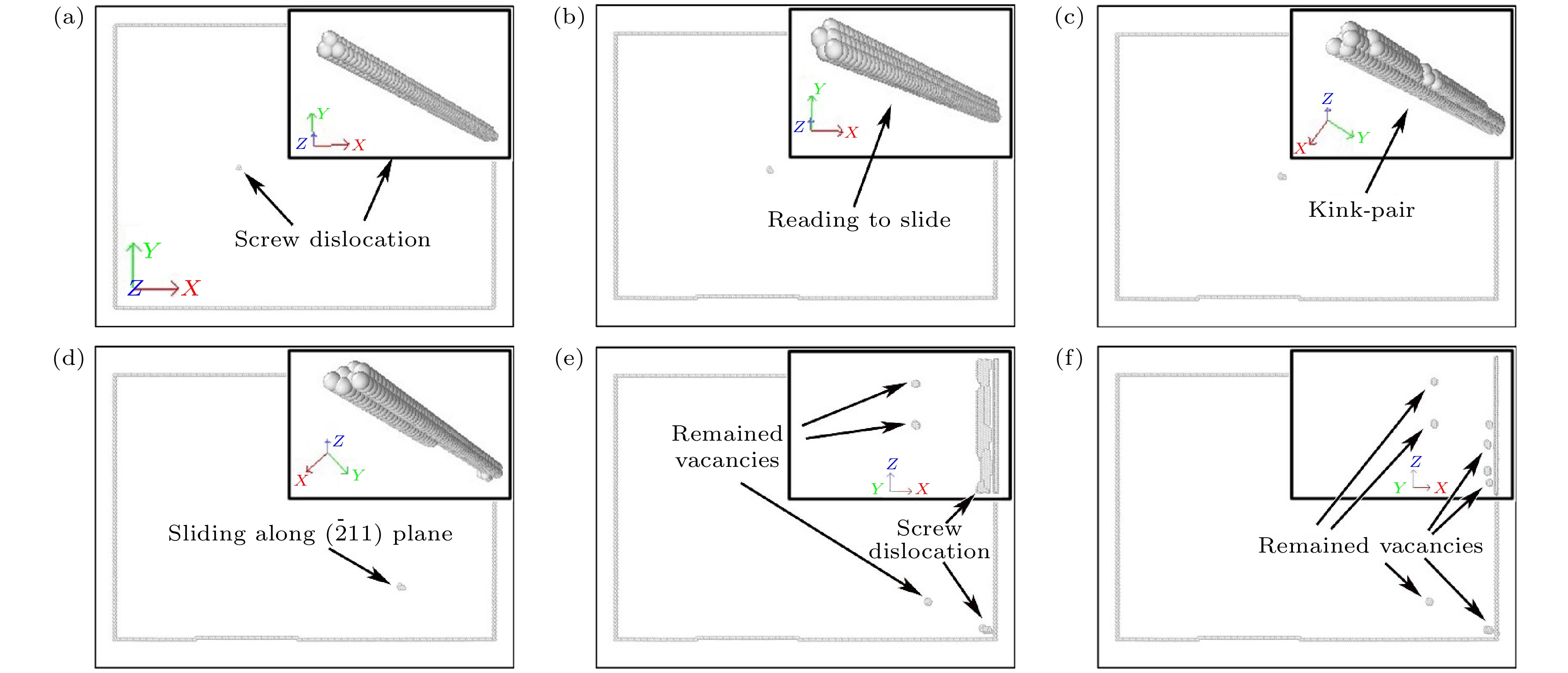

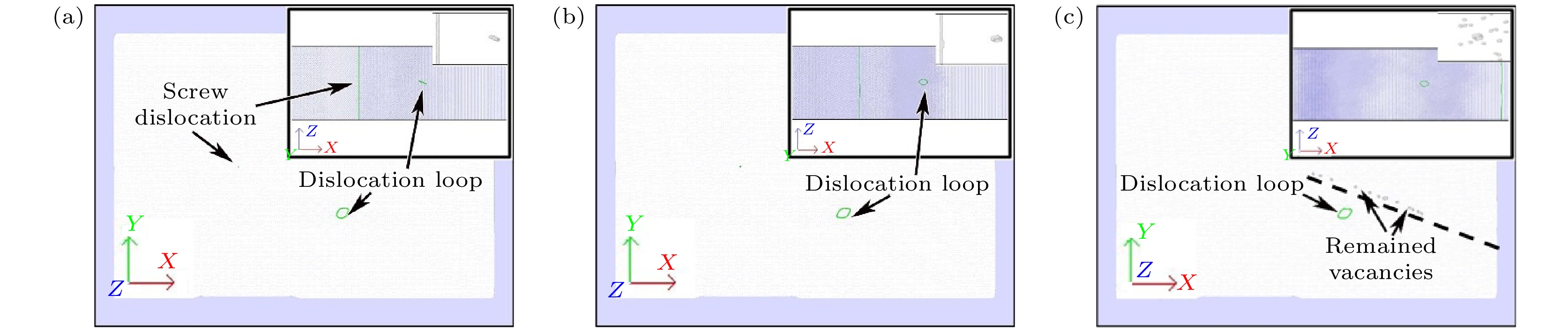

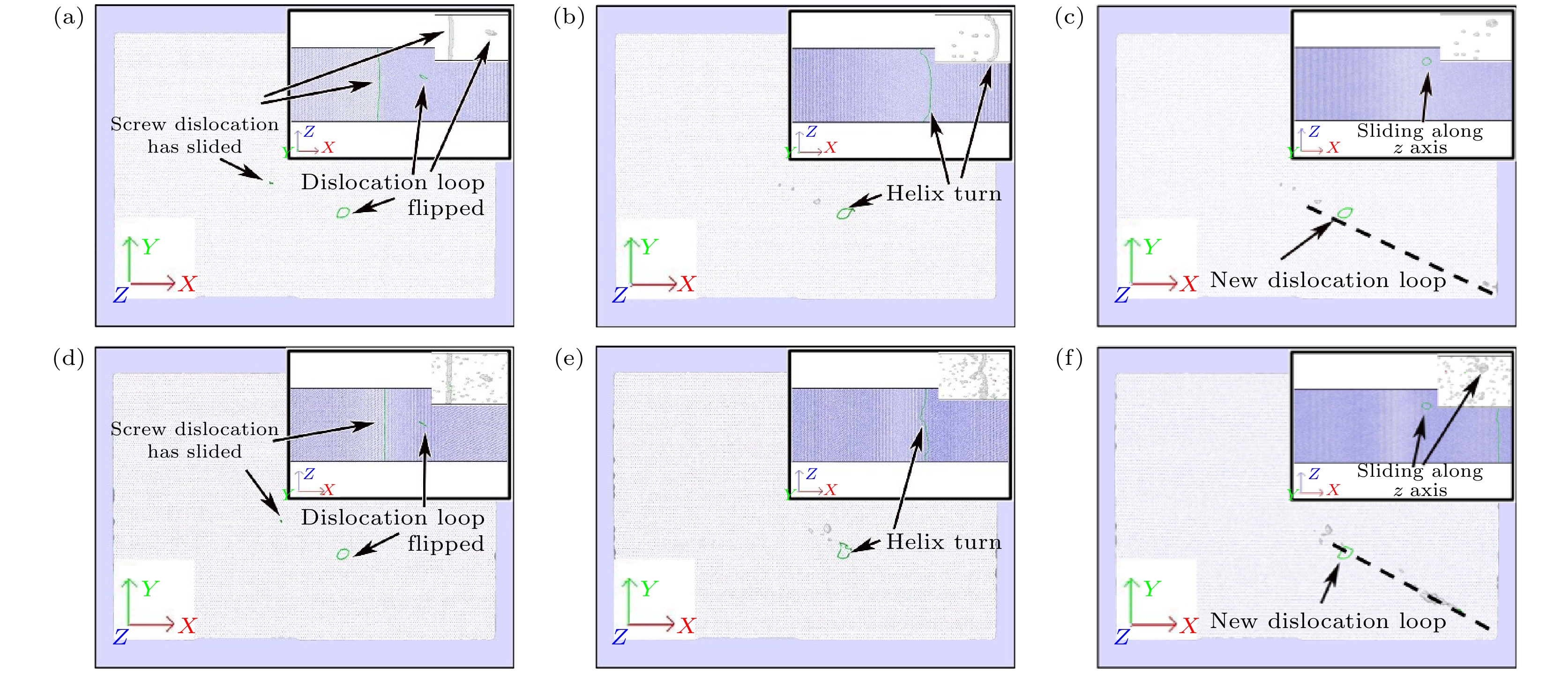

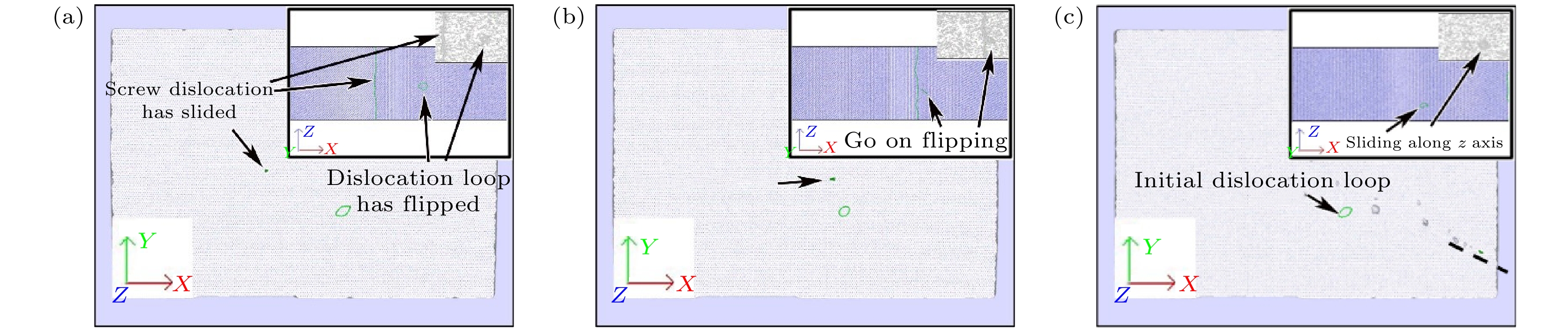

$11\bar 1$ ] dislocation loop in bcc-Fe at different temperatures are investigated by molecular dynamics simulation. The results show that the screw dislocation mainly slides along the ($\bar 2 11$ ) plane at a low temperature of 2 K under the increase of shear stress. With the temperature increasing to 823 K, it is prone to cross slip, and then the cross slip occurs alternately in the ($\bar 1 10$ ) plane and the ($\bar 2 11$ ) plane. Therefore, with the increase of temperature, the critical shear stress decreases gradually. When the screw dislocation slips close to the dislocation loop, the mechanism of interaction between screw dislocation and dislocation loop is different at different temperature: at low temperature of 2 K, there is repulsive force between screw dislocation and dislocation loop, when screw dislocation slip approaches to the dislocation loop, the cross slip of screw dislocation can occur, and shear stress is lower than that from the model without dislocation loop; at medium temperatures of 300 K and 600 K, the influence of repulsive force on the cross slip of screw dislocation can be weakened, and screw dislocation will slip through the dislocation loop then form the new structure named helix turn, which further hinders screw dislocation slipping and results in the increase of shear stress; at a high temperature of 823 K, the screw dislocation is more likely to cross slip due to the thermal activation, and the slip of dislocation loop is also easier to occur, but the screw dislocation and the dislocation loop do not contact each other in the whole shearing process, therefore the shear stress is lowest.-

Keywords:

- bcc-Fe /

- screw dislocation /

- dislocation loop /

- molecular dynamics

[1] Ullmaier H 1984 Nucl. Fusion 24 1039

Google Scholar

Google Scholar

[2] Sokolov M A, Tanigawa H, Odette G R, Shiba K, Klueh R L 2007 J. Nucl. Mater. 367 68

Google Scholar

Google Scholar

[3] Dai Y, Long B, Tong Z F 2008 J. Nucl. Mater. 377 115

Google Scholar

Google Scholar

[4] Hardie C D, Williams C A, Xu S, Roberts S G 2013 J. Nucl. Mater. 439 33

Google Scholar

Google Scholar

[5] Suganuma K, Kayano H 1983 J. Nucl. Mater. 118 234

Google Scholar

Google Scholar

[6] Terentyev D, Haghighat S M H, Schaublin R 2010 J. Appl. Phys. 107 55

Google Scholar

Google Scholar

[7] 贾丽霞, 贺新福, 豆艳坤, 吴石, 王东杰, 杨文 2017 核动力工程 38 115

Google Scholar

Google Scholar

Jia L X, He X F, Dou Y K, Wu S, Wang D J, Yang Wen 2017 Nuclear Power Engineering 38 115

Google Scholar

Google Scholar

[8] Wang Y X, Xu Q, Yoshiie T, Pan Z Y 2008 J. Nucl. Mater. 376 133

Google Scholar

Google Scholar

[9] Osetsky Y N, Stoller R E 2015 J. Nucl. Mater. 465 448

Google Scholar

Google Scholar

[10] Yang L, Zhu Z Q, Peng S M, Long X G, Zhou X S, Zu X T, Heinisch H L, Kurtz R J, Gao F 2013 J. Nucl. Mater. 441 6

Google Scholar

Google Scholar

[11] Terentyev D, Bergner F, Osetsky Y 2013 Acta Mater. 61 1444

Google Scholar

Google Scholar

[12] Rong Z, Osetsky Y N, Bacon D J 2005 Philos. Mag. 85 1473

Google Scholar

Google Scholar

[13] Jia L X, He X F, Dou Y K, Wang D J, Wu S, Cao H, Yang W 2019 Nucl. Instrum. Methods Phys. Res. 456 103

Google Scholar

Google Scholar

[14] Liu X Y, Biner S B 2008 Scripta Mater. 59 51

Google Scholar

Google Scholar

[15] Hale L M, Zimmerman J A, Weinberger C R 2014 Comput. Mater. Sci. 90 106

Google Scholar

Google Scholar

[16] Yang L, Gao F, Kurtz R J, Zu X T 2015 Acta Mater. 82 275

Google Scholar

Google Scholar

[17] Zhang L, Fu C C, Hayward E, Lu G H 2015 J. Nucl. Mater. 459 247

Google Scholar

Google Scholar

[18] Martinez E, Schwen D, Caro A 2015 Acta Mater. 84 208

Google Scholar

Google Scholar

[19] Zhurkin E E, Terentyev D, Hou M, Malerba L, Bonny G 2011 J. Nucl. Mater. 417 1082

Google Scholar

Google Scholar

[20] Wakai E, Hishinuma A, Kato Y, Yano H, Takaki S, Abiko K 1995 J. Phys. IV France 5 C7-277

Google Scholar

Google Scholar

[21] Xu H X, Stoller R E, Osetsky Y N, Terentyev D 2013 Phys. Rev. Lett. 110 265503

Google Scholar

Google Scholar

[22] Terentyev D, Bacon D J, Osetsky Y N 2010 Philos. Mag. 90 1019

Google Scholar

Google Scholar

[23] Pascale E T, Shehadeh M A 2018 Int. J. Plasticity 9 2

Google Scholar

Google Scholar

[24] Song G, Lee S W 2019 Comput. Mater. Sci. 168 172

Google Scholar

Google Scholar

[25] Xia Z Y, Zhang Z J, Yan J X, Yang J B, Zhang Z F 2020 Comput. Mater. Sci. 174 109503

Google Scholar

Google Scholar

[26] LAMMPS Molecular Dynamics Simulator http://lammps. sandia.gov/ [2020-10-7]

[27] Caro A, Hetherly J, Stukowski A, Caro M, Martinez E, Srivilliputhur S, Zepeda-Ruiz L, Nastasi M 2011 J. Nucl. Mater. 418 261

Google Scholar

Google Scholar

[28] Stukowski A 2010 Modell. Simul. Mater. Sci. Eng. 18 015012

Google Scholar

Google Scholar

[29] Gordon P A, Neeraj T, Li Y, Li J 2010 Modell. Simul. Mater. Sci. Eng. 18 085008

Google Scholar

Google Scholar

[30] Jaime M, Wei C, Vasily V B 2004 Nature Mater. 3 158

Google Scholar

Google Scholar

[31] Bacon D J, Osetsky Y N, Rong Z 2006 Philos. Mag. 86 3921

Google Scholar

Google Scholar

-

图 6 不同温度下含位错环的螺位错模型在 ε = 0.015 (a), (d), 0.03 (b), (e)和0.045 (c), (f)时构型图 (a), (b), (c) 300 K; (d), (e), (f) 600 K

Figure 6. Configurations of screw dislocation model with dislocation loop when ε = 0.015 (a), (d), 0.03 (b), (e), and 0.045 (c), (f) under different temperatures: (a), (b), (c) 300 K; (d), (e), (f) 600 K.

-

[1] Ullmaier H 1984 Nucl. Fusion 24 1039

Google Scholar

Google Scholar

[2] Sokolov M A, Tanigawa H, Odette G R, Shiba K, Klueh R L 2007 J. Nucl. Mater. 367 68

Google Scholar

Google Scholar

[3] Dai Y, Long B, Tong Z F 2008 J. Nucl. Mater. 377 115

Google Scholar

Google Scholar

[4] Hardie C D, Williams C A, Xu S, Roberts S G 2013 J. Nucl. Mater. 439 33

Google Scholar

Google Scholar

[5] Suganuma K, Kayano H 1983 J. Nucl. Mater. 118 234

Google Scholar

Google Scholar

[6] Terentyev D, Haghighat S M H, Schaublin R 2010 J. Appl. Phys. 107 55

Google Scholar

Google Scholar

[7] 贾丽霞, 贺新福, 豆艳坤, 吴石, 王东杰, 杨文 2017 核动力工程 38 115

Google Scholar

Google Scholar

Jia L X, He X F, Dou Y K, Wu S, Wang D J, Yang Wen 2017 Nuclear Power Engineering 38 115

Google Scholar

Google Scholar

[8] Wang Y X, Xu Q, Yoshiie T, Pan Z Y 2008 J. Nucl. Mater. 376 133

Google Scholar

Google Scholar

[9] Osetsky Y N, Stoller R E 2015 J. Nucl. Mater. 465 448

Google Scholar

Google Scholar

[10] Yang L, Zhu Z Q, Peng S M, Long X G, Zhou X S, Zu X T, Heinisch H L, Kurtz R J, Gao F 2013 J. Nucl. Mater. 441 6

Google Scholar

Google Scholar

[11] Terentyev D, Bergner F, Osetsky Y 2013 Acta Mater. 61 1444

Google Scholar

Google Scholar

[12] Rong Z, Osetsky Y N, Bacon D J 2005 Philos. Mag. 85 1473

Google Scholar

Google Scholar

[13] Jia L X, He X F, Dou Y K, Wang D J, Wu S, Cao H, Yang W 2019 Nucl. Instrum. Methods Phys. Res. 456 103

Google Scholar

Google Scholar

[14] Liu X Y, Biner S B 2008 Scripta Mater. 59 51

Google Scholar

Google Scholar

[15] Hale L M, Zimmerman J A, Weinberger C R 2014 Comput. Mater. Sci. 90 106

Google Scholar

Google Scholar

[16] Yang L, Gao F, Kurtz R J, Zu X T 2015 Acta Mater. 82 275

Google Scholar

Google Scholar

[17] Zhang L, Fu C C, Hayward E, Lu G H 2015 J. Nucl. Mater. 459 247

Google Scholar

Google Scholar

[18] Martinez E, Schwen D, Caro A 2015 Acta Mater. 84 208

Google Scholar

Google Scholar

[19] Zhurkin E E, Terentyev D, Hou M, Malerba L, Bonny G 2011 J. Nucl. Mater. 417 1082

Google Scholar

Google Scholar

[20] Wakai E, Hishinuma A, Kato Y, Yano H, Takaki S, Abiko K 1995 J. Phys. IV France 5 C7-277

Google Scholar

Google Scholar

[21] Xu H X, Stoller R E, Osetsky Y N, Terentyev D 2013 Phys. Rev. Lett. 110 265503

Google Scholar

Google Scholar

[22] Terentyev D, Bacon D J, Osetsky Y N 2010 Philos. Mag. 90 1019

Google Scholar

Google Scholar

[23] Pascale E T, Shehadeh M A 2018 Int. J. Plasticity 9 2

Google Scholar

Google Scholar

[24] Song G, Lee S W 2019 Comput. Mater. Sci. 168 172

Google Scholar

Google Scholar

[25] Xia Z Y, Zhang Z J, Yan J X, Yang J B, Zhang Z F 2020 Comput. Mater. Sci. 174 109503

Google Scholar

Google Scholar

[26] LAMMPS Molecular Dynamics Simulator http://lammps. sandia.gov/ [2020-10-7]

[27] Caro A, Hetherly J, Stukowski A, Caro M, Martinez E, Srivilliputhur S, Zepeda-Ruiz L, Nastasi M 2011 J. Nucl. Mater. 418 261

Google Scholar

Google Scholar

[28] Stukowski A 2010 Modell. Simul. Mater. Sci. Eng. 18 015012

Google Scholar

Google Scholar

[29] Gordon P A, Neeraj T, Li Y, Li J 2010 Modell. Simul. Mater. Sci. Eng. 18 085008

Google Scholar

Google Scholar

[30] Jaime M, Wei C, Vasily V B 2004 Nature Mater. 3 158

Google Scholar

Google Scholar

[31] Bacon D J, Osetsky Y N, Rong Z 2006 Philos. Mag. 86 3921

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 10771

- PDF Downloads: 227

- Cited By: 0

DownLoad:

DownLoad: