-

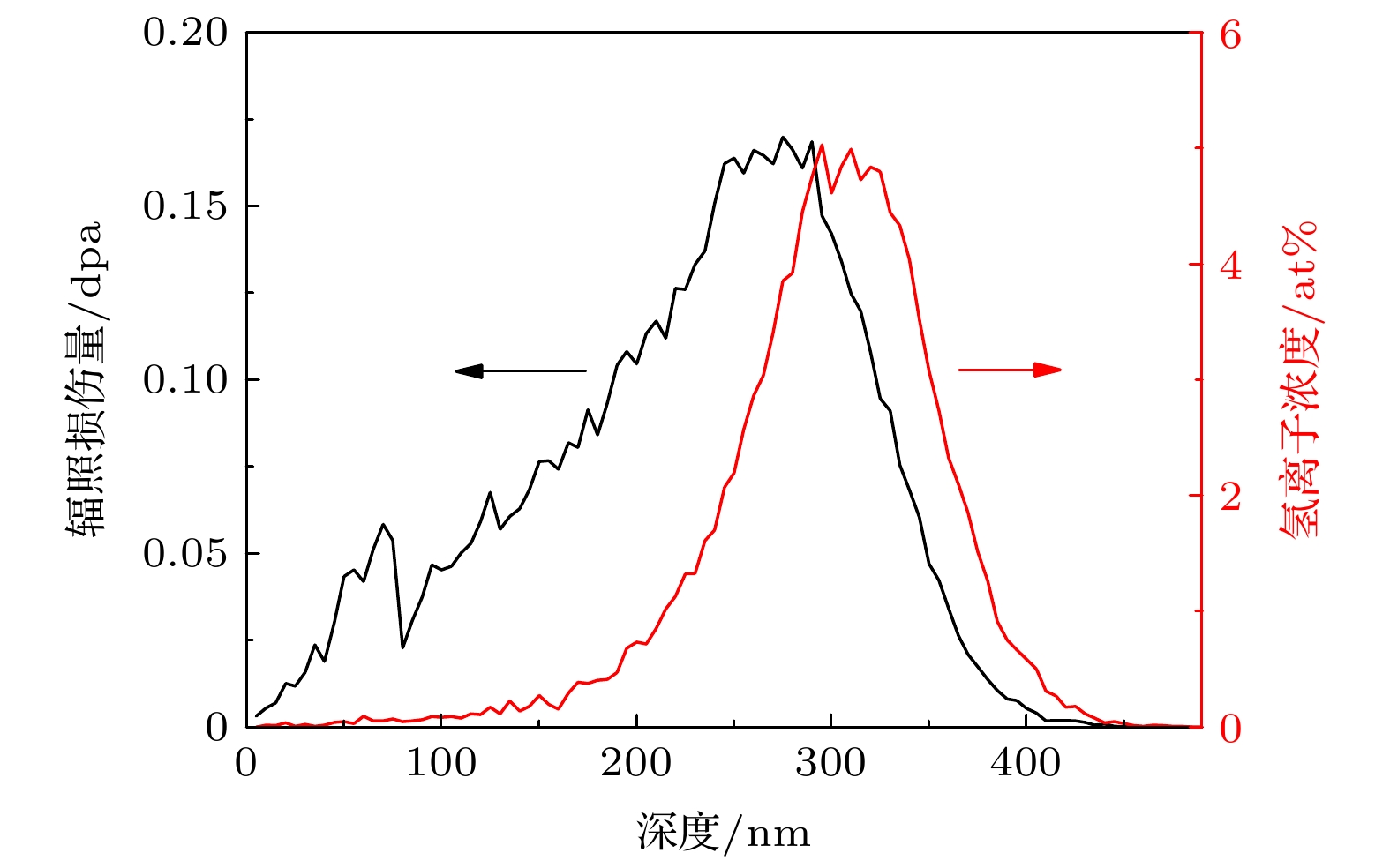

核聚变堆材料在高能粒子辐照过程中会产生大量点缺陷, 导致辐照脆性和辐照肿胀等现象. 因而, 研究点缺陷在辐照过程中的演变过程至关重要. 点缺陷团簇的一维迁移现象是这种演变过程的主要研究内容之一. 本文采用普通低压(200 kV)透射电镜, 在室温条件下对注氢纯铝中的间隙型位错环在电子辐照下的一维迁移现象进行了观察和分析. 在200 keV电子辐照下, 注氢纯铝中的位错环可多个、同时发生一维迁移运动, 也可单个、独立进行一维迁移运动. 位错环沿柏氏矢量1/3

$\left\langle {111} \right\rangle$ 的方向可进行微米尺度的一维长程迁移, 沿柏氏矢量1/2$\left\langle {110} \right\rangle $ 的方向一维迁移也可达数百纳米. 电子束辐照时产生的间隙原子浓度梯度是引起位错环一维迁移并决定其迁移方向的原因. 位错环发生快速一维迁移时, 其后会留下一条运动轨迹; 位错环一维迁移的速率越快, 运动的轨迹则越长, 在完成迁移过后的几十秒内这些运动轨迹会逐渐消失.The one-dimensional (1D) glide motion of dislocation loops along the direction of Burgers vector in various metallic materials has attracted considerable attention in recent years. During the operation of nuclear fusion reactor, component materials will be bombarded by high energy neutrons, resulting in production of radiation defects such as self-interstitial-atoms (SIAs), vacancies and their clusters. These defects feature large difference in migration energy, which may lead to concentration imbalance between SIAs and vacancies, and eventually irradiation damages such as swelling and embrittlement. Generally speaking, the mobility of a defect cluster is lower than that of a point defect. However, fast 1D motion may also take place among SIA clusters in the form of prismatic dislocation loops. This increases the transport efficiency of SIAs towards grain boundaries, surface and interface sites in the material, in favour of defect concentration imbalance and damage accumulation. To date, most literature works have found that the 1D motion of dislocation loops exhibited short-range (nanometer-scale) character. In addition, such experimental studies were generally conducted in pure metals using high voltage electron microscopes (HVEM) operated at acceleration voltages ≥1000 kV. However, for pure aluminum (Al), the maximum transferable kinetic energy from 200 keV electrons is 19.5 eV, while the displacement threshold energy is only 16 eV. Therefore, the observation and mechanistic investigation of 1D motion of dislocation loops in Al should also be possible with conventional transmission electron microscopes (C-TEM), as it may also exhibit the effects of beam heating and point defect production in HVEM. In view of the shortage of HVEM, this work reports the 1D motion of dislocation loops in pure Al implanted with hydrogen ions using C-TEM. Simultaneous dislocation loop motion in opposite directions of Burgers vector 1/2$\left\langle {110} \right\rangle $ has been captured, as well as the collective 1D motion of an array of dislocation loops in the direction of Burgers vector 1/3$\left\langle {111} \right\rangle $ under 200 keV electron irradiation. In addition, 1D motion of dislocation loops up to micron-scale range along the direction of Burgers vector 1/3$\left\langle {111} \right\rangle $ , and up to a few hundred nanometers range along the direction of Burgers vector 1/2$\left\langle {110} \right\rangle $ have been found, which is different from previous literature works. A characteristic migration track would form behind the moving dislocation loop, lasting for about tens of seconds. The more rapid the dislocation loop motion, the longer the migration track length is. The concentration gradient of SIAs by electron irradiation and the redistribution of hydrogen atoms caused by the moving dislocation loops may account for the observed micron-scale 1D motion of dislocation loops and the migration tracks.-

Keywords:

- one-dimensional motion /

- electron irradiation /

- dislocation loops /

- aluminum

[1] 万发荣 1993 金属材料的辐照损伤 (北京: 科学出版社) 第7页

Wan F R 1993 Irradiation Damage of Metal Materials (Beijing: Science Press) p7 (in Chinese)

[2] 郭立平, 罗凤凤, 于雁霞 2016 核材料辐照位错环 (北京: 国防工业出版社) 第37页

Guo L P, Luo F F, Yu Y X 2016 Dislocation loops in irradiated nuclear materials (Beijing: National Defense Industry Press) p37 (in Chinese)

[3] Du Y F, Cui L J, Han W T, Wan F R 2019 Acta Metall. Sin. 32 566

Google Scholar

Google Scholar

[4] Terentyev D, He X, Bonny G, Bakaev A, Zhurkin E, Malerba L 2015 J. Nucl. Mater. 457 173

Google Scholar

Google Scholar

[5] 万发荣 2020 工程科学学报 42 1535

Google Scholar

Google Scholar

Wan F R 2020 Chin. J. Eng. 42 1535

Google Scholar

Google Scholar

[6] Hwang T, Hasegawa A, Tomura K, Ebisawa N, Toyama T, Nagai Y, Fukuda M, Miyazawa T, Tanaka T, Nogami S 2018 J. Nucl. Mater. 507 78

Google Scholar

Google Scholar

[7] Ipatova I, Wady P T, Shubeita S M, Barcellini C, Impagnatiello A, Jimenez-Melero E 2018 J. Microsc. 270 110

Google Scholar

Google Scholar

[8] Satoh Y, Abe H, Matsukawa Y, Matsunaga T, Kano S, Arai S, Yamamoto Y, Tanaka N 2015 Philos. Mag. 95 1587

Google Scholar

Google Scholar

[9] Wang J, Hou Q, Zhang B L 2021 Solid State Commun. 325 114158

Google Scholar

Google Scholar

[10] Chen D, Murakami K, Abe H, Li Z, Sekimura N 2019 Acta Mater. 163 78

Google Scholar

Google Scholar

[11] Marian J, Wirth B D, Caro A, Sadigh B, Odette G R, Perlado J M, de la Rubia T D 2002 Phys. Rev. B 65 144102

Google Scholar

Google Scholar

[12] Arakawa K, Ono K, Isshiki M, Mimura K, Uchikoshi M, Mori H 2007 Science 318 956

Google Scholar

Google Scholar

[13] Osetsky Y N, Bacon D J, Serra A 1999 Philos. Mag. Lett. 79 273

Google Scholar

Google Scholar

[14] Abe Y, Satoh Y, Hashimoto N, Ohnuki S 2020 Philos. Mag. 100 110

Google Scholar

Google Scholar

[15] Nandipati G, Setyawan W, Roche K J, Kurtz R J, Wirth B D 2020 J. Nucl. Mater. 542 152402

Google Scholar

Google Scholar

[16] Satoh Y, Matsui H, Hamaoka T 2008 Phys. Rev. B 77 094135

Google Scholar

Google Scholar

[17] Satoh Y, Matsui H 2009 Philos. Mag. 89 1489

Google Scholar

Google Scholar

[18] Osetsky Y N, Bacon D J, Serra A, Singh B N, Golubov S I 2000 J. Nucl. Mater. 276 65

Google Scholar

Google Scholar

[19] Matsukawa Y, Zinkle S J 2007 Science 318 959

Google Scholar

Google Scholar

[20] Derlet P M, Gilbert M R, Dudarev S L 2011 Phys. Rev. B 84 134109

Google Scholar

Google Scholar

[21] Wirth B D, Odette G R, Maroudas D, Lucas G E 2000 J. Nucl. Mater. 276 33

Google Scholar

Google Scholar

[22] Wirth B D 2000 Ph D Dissertation (Santa Barbara: University of California)

[23] Arakawa K, Hatanaka M, Mori H, Ono K 2004 J. Nucl. Mater. 329 1194

Google Scholar

Google Scholar

[24] Hamaoka T, Satoh Y, Matsui H 2013 J. Nucl. Mater. 433 180

Google Scholar

Google Scholar

[25] Hayashi T, Fukmuto K, Matsui H 2002 J. Nucl. Mater. 307 993

[26] Satoh Y, Abe Y, Abe H, Matsukawa Y, Kano S, Ohnuki S, Hashimoto N 2016 Philos. Mag. 96 2219

Google Scholar

Google Scholar

[27] Amino T, Arakawa K, Mori H 2016 Sci. Rep. 6 26099

Google Scholar

Google Scholar

[28] Williams D B, Carter C B 2009 Transmission Electron Microscopy (New York: Springer Science+Business Media) p68

[29] Stoller R E, Toloczko M B, Was G S, Certain A G, Dwaraknath S, Garner F A 2013 Nucl. Instrum. Methods Phys. Res., Sect. B 310 75

Google Scholar

Google Scholar

[30] Astm-Committee 2003 Standard Practice for Neutron Radiation Damage Simulation by Charged-particle Irradiation (West Conshohocken: Copyright © ASTM International) p8

[31] 戎咏华 2006 分析电子显微学导论 (北京: 高等教育出版社) 第28页

Rong Y H 2006 Introduction to Analytical Electron Microscopy (Beijing: Higher Education Press) p28 (in Chinese)

[32] Ono K, Kino T, Furuno S, Hojou K, Izui K, Mizuno K, Ito K 1991 J. Nucl. Mater. 179-181 978

Google Scholar

Google Scholar

[33] Kuramoto E 2009 Materia Jpn. 48 111

Google Scholar

Google Scholar

[34] Schulthess T C, Turchi P E A, Gonis A, Nieh T G 1998 Acta Mater. 46 2215

Google Scholar

Google Scholar

[35] Sarma V S, Wang J, Jian W W, Kauffmann A, Conrad H, Freudenberger J, Zhu Y T 2010 Mater. Sci. Eng., A 527 7624

Google Scholar

Google Scholar

[36] Gallagher P 1970 Metall. Trans. 1 2429

Google Scholar

Google Scholar

[37] Kim J, Lee S, De Cooman B C 2011 Scr. Mater. 65 363

Google Scholar

Google Scholar

[38] Yan J A, Wang C Y, Wang S Y 2004 Phys. Rev. B 70 174101

Google Scholar

Google Scholar

[39] Portavoce A, Treglia G 2014 Acta Mater. 65 1

Google Scholar

Google Scholar

[40] Tapasa K, Barashev A V, Bacon D J, Osetsky Y N 2007 J. Nucl. Mater. 361 52

Google Scholar

Google Scholar

-

图 2 不同电子束斑中心位置的电子辐照下位错环的一维迁移运动 (a)原位观察对应的运动学双束衍射条件(g = 111), 一维迁移方向(//柏氏矢量B = 1/3

$\left\langle {111} \right\rangle $ 或者1/2$\left\langle {110} \right\rangle $ 方向)以及与其最相近的两组晶向; (b), (c)电子辐照期间电子束斑中心与观察区域的相对位置; (d)—(i)位错环在电子辐照下的一维迁移现象. 不同形状符号所对应的数字“1, 2, 3, ···11”分别指第“1, 2, 3, ···11”编号位错环Fig. 2. One-dimensional motion of dislocation loops under electron irradiation at different electron beam center locations: (a) Diffraction pattern illustrating the two-beam kinematical condition during in-situ observation (g = 111), and one-dimensional motion direction (// the direction of Burgers vector, B =1/3

$\left\langle {111} \right\rangle $ or 1/2$\left\langle {110} \right\rangle $ ) and the two groups of crystal orientation closest to it; (b), (c) the positions of electron beam center for different durations of electron irradiation; (d)−(i) one-dimensional motion of dislocation loops under electron irradiation. Shapes numbered “1, 2, 3, ···11” correspond to dislocation loops “1, 2, 3, ···11”, respectively.图 3 相同电子辐照条件下两个相邻区域不同位错环的一维迁移运动 (a)运动学双束条件下的电子衍射图(

$ g = {\bar 2}20 $ ); (b)一维迁移方向(//柏氏矢量B = 1/3$ \left\langle {111} \right\rangle $ 或者1/2$ \left\langle {110} \right\rangle $ 的方向)以及与其最相近的两组晶向; (c)—(j)位错环12—14在电子辐照下的一维迁移现象Fig. 3. One-dimensional motion of dislocation loops in two adjacent regions under the same electron irradiation: (a) Diffraction pattern illustrating the two-beam kinematical imaging condition (

$g = {\bar 2}20 $ ); (b) one-dimensional motion direction (// the direction of Burgers vector, B = 1/3$ \left\langle {111} \right\rangle $ or 1/2$ \left\langle {110} \right\rangle $ ) and the two groups of crystal orientation closest to it; (c)−(j) one-dimensional motion of dislocation loops 12−14 under electron irradiation.图 4 相邻两个位错环的一维迁移距离与电子束辐照时间的关系 (a)运动学双束条件下的电子衍射图(g = 200); (b)一维迁移方向(//柏氏矢量B = 1/3

$ \left\langle {111} \right\rangle $ 或者1/2$ \left\langle {110} \right\rangle $ 的方向)以及与其最相近的两组晶向; (c)位错环16和17一维迁移距离随辐照时间的变化; (d)—(k)位错环在电子辐照下的一维迁移现象. 黑色箭头表示一维迁移方向Fig. 4. The relationship between one-dimensional motion distance and electron irradiation time of two adjacent dislocation loops: (a) Diffraction pattern illustrating the two-beam kinematical imaging condition (g = 200); (b) one-dimensional motion direction (// the direction of Burgers vector, B = 1/3

$ \left\langle {111} \right\rangle $ or 1/2$ \left\langle {110} \right\rangle $ ) and the two groups of crystal orientation closest to it; (c) the one-dimensional migration distance of dislocation loops (16, 17) under electron irradiation as a function of time; (d)−(k) the one-dimensional motion of dislocation loops 16, 17 under electron irradiation. The black arrows indicate the direction of one-dimensional motion of dislocation loops.表 1 不同辐照时间内位错环1—7的一维迁移距离、平均迁移速率以及轨迹长度

Table 1. The migration distance, average migration speed and migration track length of one-dimensional motion for dislocation loops 1–7 for different durations of electron irradiation.

辐照时间/s 0 20 42 65 126 209 位错环1 迁移距离/nm × 600 57 0 152 0 平均速率/(nm·s–1) × 30 2.59 0 2.47 0 轨迹长度/nm 326 917 890 405 0 0 位错环2 迁移距离/nm × 144 46 187 307 133 平均速率/(nm·s–1) × 7.2 2.09 8.13 5.03 1.6 轨迹长度/nm 178 334 260 305 478 222 位错环3 迁移距离/nm × 257 57 61 0 100 平均速率/(nm·s–1) × 12.9 2.59 2.65 0 1.2 轨迹长度/nm 165 370 174 175 91 131 位错环4 迁移距离/nm × 192 41 78 41 50 平均速率/(nm·s–1) × 9.6 1.86 3.39 0.67 0.6 轨迹长度/nm 487 259 190 148 0 0 位错环5 迁移距离/nm × 109 0 78 52 61 平均速率/(nm·s–1) × 5.45 0 3.39 0.85 0.73 轨迹长度/nm 292 231 139 243 0 0 位错环6 迁移距离/nm × 244 44 30 0 0 平均速率/(nm·s–1) × 12.2 2 1.3 0 0 轨迹长度/nm 161 288 210 137 114 110 位错环7 迁移距离/nm × 139 48 39 0 44 平均速率/(nm·s–1) × 6.95 2.18 1.7 0 0.53 轨迹长度/nm 107 265 152 157 82 0 *迁移距离为不同时间段位错环的一维迁移距离; 平均速率为该时间与前一时间点之间的平均迁移速率; 轨迹长度为对应时间点一维迁移所能显示出的迁移轨迹. 所有数据均是基于图2进行统计计算的结果. “×”表示对应条件下无相关数据. -

[1] 万发荣 1993 金属材料的辐照损伤 (北京: 科学出版社) 第7页

Wan F R 1993 Irradiation Damage of Metal Materials (Beijing: Science Press) p7 (in Chinese)

[2] 郭立平, 罗凤凤, 于雁霞 2016 核材料辐照位错环 (北京: 国防工业出版社) 第37页

Guo L P, Luo F F, Yu Y X 2016 Dislocation loops in irradiated nuclear materials (Beijing: National Defense Industry Press) p37 (in Chinese)

[3] Du Y F, Cui L J, Han W T, Wan F R 2019 Acta Metall. Sin. 32 566

Google Scholar

Google Scholar

[4] Terentyev D, He X, Bonny G, Bakaev A, Zhurkin E, Malerba L 2015 J. Nucl. Mater. 457 173

Google Scholar

Google Scholar

[5] 万发荣 2020 工程科学学报 42 1535

Google Scholar

Google Scholar

Wan F R 2020 Chin. J. Eng. 42 1535

Google Scholar

Google Scholar

[6] Hwang T, Hasegawa A, Tomura K, Ebisawa N, Toyama T, Nagai Y, Fukuda M, Miyazawa T, Tanaka T, Nogami S 2018 J. Nucl. Mater. 507 78

Google Scholar

Google Scholar

[7] Ipatova I, Wady P T, Shubeita S M, Barcellini C, Impagnatiello A, Jimenez-Melero E 2018 J. Microsc. 270 110

Google Scholar

Google Scholar

[8] Satoh Y, Abe H, Matsukawa Y, Matsunaga T, Kano S, Arai S, Yamamoto Y, Tanaka N 2015 Philos. Mag. 95 1587

Google Scholar

Google Scholar

[9] Wang J, Hou Q, Zhang B L 2021 Solid State Commun. 325 114158

Google Scholar

Google Scholar

[10] Chen D, Murakami K, Abe H, Li Z, Sekimura N 2019 Acta Mater. 163 78

Google Scholar

Google Scholar

[11] Marian J, Wirth B D, Caro A, Sadigh B, Odette G R, Perlado J M, de la Rubia T D 2002 Phys. Rev. B 65 144102

Google Scholar

Google Scholar

[12] Arakawa K, Ono K, Isshiki M, Mimura K, Uchikoshi M, Mori H 2007 Science 318 956

Google Scholar

Google Scholar

[13] Osetsky Y N, Bacon D J, Serra A 1999 Philos. Mag. Lett. 79 273

Google Scholar

Google Scholar

[14] Abe Y, Satoh Y, Hashimoto N, Ohnuki S 2020 Philos. Mag. 100 110

Google Scholar

Google Scholar

[15] Nandipati G, Setyawan W, Roche K J, Kurtz R J, Wirth B D 2020 J. Nucl. Mater. 542 152402

Google Scholar

Google Scholar

[16] Satoh Y, Matsui H, Hamaoka T 2008 Phys. Rev. B 77 094135

Google Scholar

Google Scholar

[17] Satoh Y, Matsui H 2009 Philos. Mag. 89 1489

Google Scholar

Google Scholar

[18] Osetsky Y N, Bacon D J, Serra A, Singh B N, Golubov S I 2000 J. Nucl. Mater. 276 65

Google Scholar

Google Scholar

[19] Matsukawa Y, Zinkle S J 2007 Science 318 959

Google Scholar

Google Scholar

[20] Derlet P M, Gilbert M R, Dudarev S L 2011 Phys. Rev. B 84 134109

Google Scholar

Google Scholar

[21] Wirth B D, Odette G R, Maroudas D, Lucas G E 2000 J. Nucl. Mater. 276 33

Google Scholar

Google Scholar

[22] Wirth B D 2000 Ph D Dissertation (Santa Barbara: University of California)

[23] Arakawa K, Hatanaka M, Mori H, Ono K 2004 J. Nucl. Mater. 329 1194

Google Scholar

Google Scholar

[24] Hamaoka T, Satoh Y, Matsui H 2013 J. Nucl. Mater. 433 180

Google Scholar

Google Scholar

[25] Hayashi T, Fukmuto K, Matsui H 2002 J. Nucl. Mater. 307 993

[26] Satoh Y, Abe Y, Abe H, Matsukawa Y, Kano S, Ohnuki S, Hashimoto N 2016 Philos. Mag. 96 2219

Google Scholar

Google Scholar

[27] Amino T, Arakawa K, Mori H 2016 Sci. Rep. 6 26099

Google Scholar

Google Scholar

[28] Williams D B, Carter C B 2009 Transmission Electron Microscopy (New York: Springer Science+Business Media) p68

[29] Stoller R E, Toloczko M B, Was G S, Certain A G, Dwaraknath S, Garner F A 2013 Nucl. Instrum. Methods Phys. Res., Sect. B 310 75

Google Scholar

Google Scholar

[30] Astm-Committee 2003 Standard Practice for Neutron Radiation Damage Simulation by Charged-particle Irradiation (West Conshohocken: Copyright © ASTM International) p8

[31] 戎咏华 2006 分析电子显微学导论 (北京: 高等教育出版社) 第28页

Rong Y H 2006 Introduction to Analytical Electron Microscopy (Beijing: Higher Education Press) p28 (in Chinese)

[32] Ono K, Kino T, Furuno S, Hojou K, Izui K, Mizuno K, Ito K 1991 J. Nucl. Mater. 179-181 978

Google Scholar

Google Scholar

[33] Kuramoto E 2009 Materia Jpn. 48 111

Google Scholar

Google Scholar

[34] Schulthess T C, Turchi P E A, Gonis A, Nieh T G 1998 Acta Mater. 46 2215

Google Scholar

Google Scholar

[35] Sarma V S, Wang J, Jian W W, Kauffmann A, Conrad H, Freudenberger J, Zhu Y T 2010 Mater. Sci. Eng., A 527 7624

Google Scholar

Google Scholar

[36] Gallagher P 1970 Metall. Trans. 1 2429

Google Scholar

Google Scholar

[37] Kim J, Lee S, De Cooman B C 2011 Scr. Mater. 65 363

Google Scholar

Google Scholar

[38] Yan J A, Wang C Y, Wang S Y 2004 Phys. Rev. B 70 174101

Google Scholar

Google Scholar

[39] Portavoce A, Treglia G 2014 Acta Mater. 65 1

Google Scholar

Google Scholar

[40] Tapasa K, Barashev A V, Bacon D J, Osetsky Y N 2007 J. Nucl. Mater. 361 52

Google Scholar

Google Scholar

计量

- 文章访问数: 8563

- PDF下载量: 164

- 被引次数: 0

下载:

下载: