-

Tungsten is an important candidate of plasma-facing material for fusion reactors. Its irradiation response, especially the post-irradiation annealing (PIA) behavior needs further investigating. In addition, the practice of the “inside-outside” contrast method of determining the characteristics of irradiation induced dislocation loops has not been utilized frequently, and the present research serves as an example to present some practical considerations. In the present work, a tungsten thin-foil specimen is irradiated at 400 ℃ with 58 keV D+ to a final fluence of 1× 1017 cm–2, corresponding to a dose of about 0.1 dpa. The specimen is prepared through the electro-polishing method by using a NaOH based electrolyte. The ion irradiation is carried out directly on the electro-polished specimen. The irradiated specimen is followed by isothermal annealing at 900 ℃ for 1 h. The as-irradiated and post-irradiation annealing modified defects are investigated with a transmission electron microscope (TEM) operated at 200 kV. The irradiation defects are characterized by using TEM bright-field imaging for the same imaging field with different g vectors around the three major zone axes: the [001], [111], and [011] zone axis of the body-center cubic lattice of W. For each g vector, the ± g are characterized, and the corresponding contrast-extinctions and “inside-outside” contrasts of selected dislocation loops are identified. The indices of the g vectors around different zone axes are assigned consistently with the Kikuchi map. As a result, the D+ irradiation increases a fine distribution of dislocation loops with an average size of (11.10±5.41) nm and a bulk density of 2.40×1022 /m3. Voids are not observed obviously. The post-irradiation annealing causes the loop size to increase and the loop density to decrease, with numbers of (18.25±16.92) nm and 1.19×1022 /m3, respectively. Through the contrast-extinction analysis, the dislocation loops in the irradiated and annealed specimen are identified to be a /2

$\langle {111} \rangle$ -type dislocation loops. The post-irradiation annealing also causes the coalescence of large loops and forms large irregular-shaped dislocation loops. Voids with typical sizes of 1–2 nm are also observed in the annealed specimen. The PIA modified microstructure is consistent with the stage IV or stage V characterization of classical PIA induced microstructures. Through the “one-step” inside-outside contrast method, the dislocation loops are identified as an interstitial type. The influcing factors for the “one-step” method are discussed and the importance of consistent indexing is also noted.-

Keywords:

- tungsten /

- ion irradiation /

- dislocation loops /

- inside-outside contrast

[1] Gavila P, Riccardi B, Constans S, Jouvelot J L, Vastra I, Missirlian M, Richou M 2011 Fusion Eng. Des. 86 1652

Google Scholar

Google Scholar

[2] Konings R, Pintsuk G. 2012 Comprehensive Nuclear Materials (Vol. 4) (Amsterdam: Elsevier Inc.) pp551–581

[3] 谭晓月 2018 博士学位论文(合肥: 合肥工业大学)

Tan X Y 2018 Ph. D. Dissertation (Hefei: Hefei University of Technology) (in Chinese)

[4] 易晓鸥, 韩文妥, 刘平平, Francesco F, 詹倩, 万发荣 2021 金属学报 57 15

Yi X O, Han W T, Liu P P, Francesco F, Zhan Q, Wan F R 2021 Acta Metall. Sin. 57 15

[5] Yi X, Jenkins M L, Hattar K, Edmondson P, Roberts S 2015 Acta Mater. 92 163

Google Scholar

Google Scholar

[6] Yi X, Jenkins M L, Kirk M A, Zhou Z, Roberts S 2016 Acta Mater. 112 105

Google Scholar

Google Scholar

[7] Ran G, Huang S, Huang Z, Yan Q, Xu J, Li N, Wang L 2014 J. Nucl. Mater. 455 320

Google Scholar

Google Scholar

[8] 丁孝禹, 罗来马, 黄丽枚, 罗广南, 李萍, 吴玉程 2015 稀有金属 39 9

Ding X Y, Luo L M, Huang L M, Luo G N, Li P, Wu Y C 2015 Chin. J. Rare Met. 39 9

[9] 吴玉程, 林锦山, 罗来马, 昝祥, 朱晓勇, 陈俊凌 2017 机械工程学报 53 25

Wu Y C, Lin J S, Luo L M, Ji X, Zhu X Y, Chen J L 2017 J. Mech. Eng. 53 25

[10] Xu H, Stoller R E, Osetsky, Terentyev D 2013 Phys. Rev. Lett. 110 265503

Google Scholar

Google Scholar

[11] Ding Y F, Li Y P, Liu X Y, Ran G, Huang X, Han Q, Chen Y, Huang J, Zhou Z 2021 Tungsten 3 14

[12] Hu X, Koyanagi T, Fukuda M, Katoh Y, Snead L, Wirth B 2016 J. Nucl. Mater. 470 278

Google Scholar

Google Scholar

[13] Ferroni F, Yi X, Arakawa K, Fitzgerald S, Edmondson P, Roberts S 2015 Acta Mater. 90 380

Google Scholar

Google Scholar

[14] 万发荣 1993 金属材料的辐照损伤 (北京: 科学出版社)

Wan F R 1993 Irradiation Damage on Metal Materials (Beijing: Science Publisher) (in Chinese)

[15] Du Y, Cui L, Han W, Wan F 2019 Acta Metall. Sin. 32 566

Google Scholar

Google Scholar

[16] Li R, Xue L, Watanabe H, Yi X, Han W, Liu P, Zhan Q, Wan F 2022 Mater. Charact. 185 111755

Google Scholar

Google Scholar

[17] 李然然 2022 博士学位论文 (北京: 北京科技大学)

Li R R 2022 Ph. D. Dissertation (Beijing: University of Science and Technology Beijing) (in Chinese)

[18] 黄依娜, 万发荣, 焦志杰 2011 60 036802

Google Scholar

Google Scholar

Huang Y N, Wan F R, Jiao Z J 2011 Acta Phys. Sin. 60 036802

Google Scholar

Google Scholar

[19] Williams D B, Carter C B 1996 Transmission Electron Microscopy: A Textbook for Materials Science (New York: Plenum Press)

[20] Jenkins M L, Kirk M A 2001 Characterization of Radiation Damage by Transmission Electron Microscopy (Bristol and Philadelphia: Institute of Physics Publishing) p74

[21] Loretto M H, Smallman R E 1975 Defect Analysis in Electron Microscopy (London: Chapman and Hall Ltd.) p77

[22] Stoller R E, Toloczko M B, Was G S, Certain A, Dwaraknath S, Garner F 2013 Nucl. Instrum. Meth. Phys. Res. , Sect. B 310 75

Google Scholar

Google Scholar

[23] 吴杏芳, 柳得橹 1998 电子显微分析实用方法 (北京: 冶金工业出版社) 第103页

Wu X F, Liu D L 1998 Practical Methods for Electron Microscopy (Beijing: Metallurgical Industry Press) p103 (in Chinese)

[24] Was G S 2017 Fundamentals of Radiation Materials Science: Metals and Alloys (Second edition) (New York: Springer Science+Business Media) p301

[25] Marian J, Wirth B D, Perlado J M 2002 Phys. Rev. Lett. 88 255507

Google Scholar

Google Scholar

[26] Johnson R A 1964 Phys. Rev. 134.5A 1329

[27] Wirth B D, Odette G R, Maroudas D, Lucas G E 2000 J. Nucl. Mater. 276 33

Google Scholar

Google Scholar

[28] Osetsky Y N, Serra A, Singh B N, Gobulov S I 2000 Philos. Mag. A 80 2131

Google Scholar

Google Scholar

[29] Masters B C 1965 Philos. Mag. 11 881

Google Scholar

Google Scholar

[30] Jiang S, Zhou F, Zhang G, Zhou F, Zhang G, Yi X, Yu C, Wang X, Rao W 2021 Tungsten 3 11

[31] 杜玉峰, 崔丽娟, 万发荣 2019 工程科学学报 41 13

Du Y F, Cui L J, Wan F R 2019 Chin. J. Eng. 41 13

[32] Matsui T, Muto S, Tanabe T 2000 J. Nucl. Mater. 283 1139

[33] Nagata S, Takahiro K, Horiike S, Yamaguchi S 1999 J. Nucl. Mater. 266 1151

[34] Keys L K, Moteff J 1970 J. Nucl. Mater. 34 260

Google Scholar

Google Scholar

[35] Bowkett K M, Ralph B 1969 Proc. Roy. Soc. A 312 51

[36] Iwakiri H, Morishita K, Yoshida N 2002 J. Nucl. Mater. 307-311 135

[37] 余永宁 2012 材料科学基础 (第2版) (北京: 高等教育出版社) 第352页

Yu Y N 2012 Fundamentals of Materials Science (Ver. 2) (Beijing: Higher Education Press) p352 (in Chinese)

[38] Hull D, Bacon D J 2011 Introduction to Dislocations (5th Ed.) (Amsterdam: Elsevier Inc.) p15

-

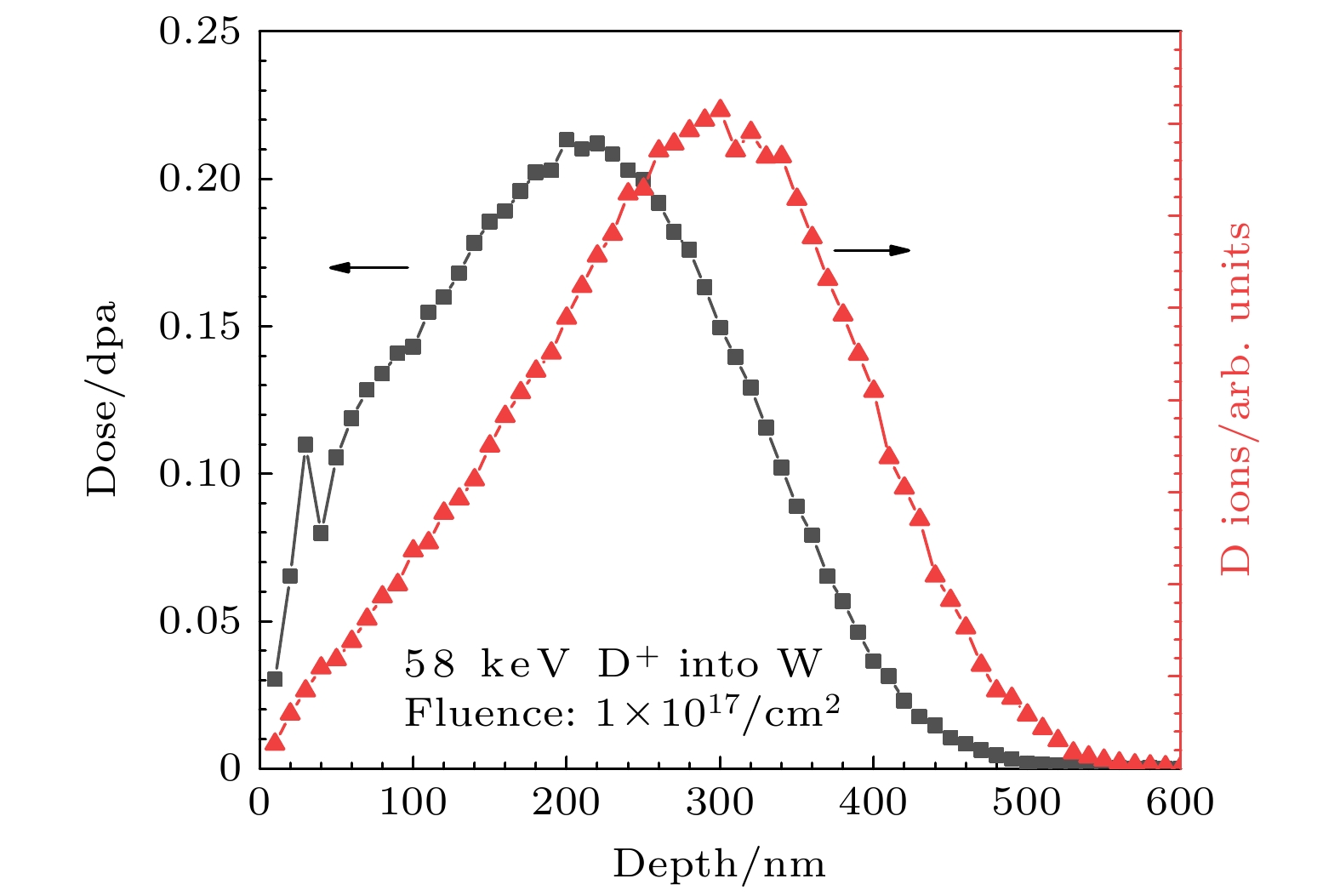

图 1 SRIM 2013 软件模拟58 keV, 1× 1017 cm–2 D+ 辐照纯钨金属中的辐照剂量(单位: dpa)以及注入D+随深度分布图. SRIM计算使用K-P模式, D原子量为2.014 amu, W的移位域能为90 eV [22]

Figure 1. The irradiation dose and D+ depth distributions for 58 keV, 1× 1017 cm–2 D+ irradiation of pure tungsten as calculated by SRIM 2013 software. The calculation is performed in the K-P quick calculation mode, with the atomic weight of D set as 2.014 amu and the displacement threshold energy for W set as 90 eV [22].

图 2 (a) 400 ℃ D+辐照后钨中某一区域的辐照缺陷的明场像观; (b) 该区域的g(

$ 10\bar 1 $ )双束衍射条件下的CBED图(为便于观察将衬度反转), 用于计算图(a)中区域的样品厚度; (c) 离子辐照后900 ℃/1 h 退火后的位错环明场像观察; (d) 明场像的衍射条件图, g = ($ \bar 110 $ ); (e), (f) 欠焦和过焦条件下, 离子辐照退火后在样品薄区观察到的空洞缺陷Figure 2. (a) TEM bright-field (BF) imaging of an area in the 400 ℃ D+ irradiated sample; (b) a CBED pattern obtained under g(

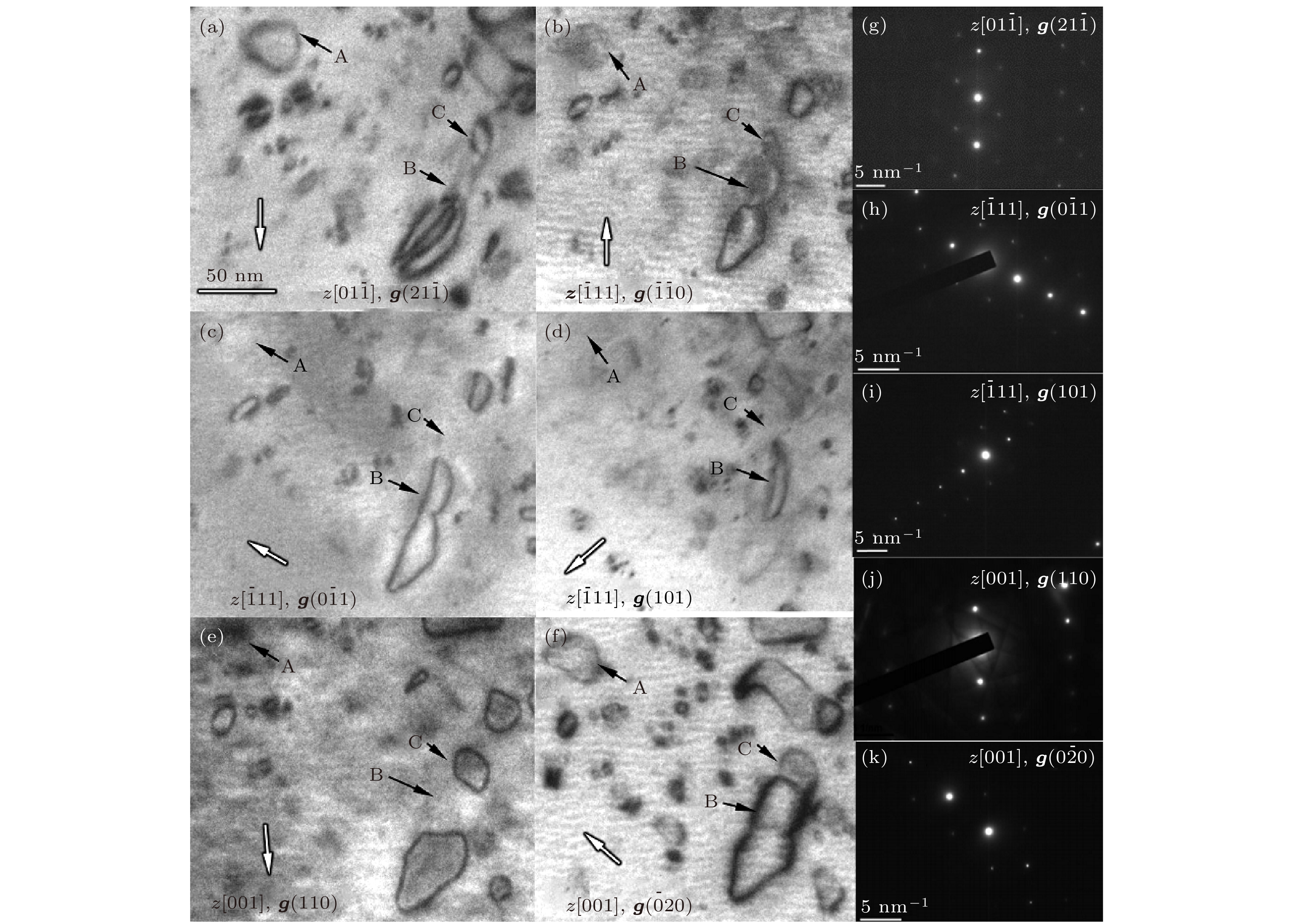

$ 10\bar 1 $ ) vector (contrast inverted for observation convenience), which is used for calculation of the specimen thickness of the area in Figure (a); (c) BF imaging of the dislocation loops in the irradiated and 900 ℃/1 h annealed specimen; (d) diffraction pattern showing the diffraction condition of Figure (c),$ g =(\bar 110) $ ; (e), (f) void structures observed in the irradiated and annealed specimen in underfocus and overfocus conditions, respectively.图 4 (a)—(f) 纯钨试样经400 ℃、 58 keV、 1017 cm–2 D+ 注入后900 ℃退火1 h得到的位错环结构在不同g矢量明场观察结果; (g)—(k) 各明场像衍射条件的对应衍射图案

Figure 4. (a)–(f) BF characterizations of the dislocation loops under different diffraction conditions in the 400 ℃, 58 keV, 1017 cm–2 D+ irradiated and 900 ℃/1 h annealed tungsten sample; (g)–(k) diffraction patterns showing the corresponding diffraction conditions for the BF images.

图 5 纯钨试样经过离子辐照并退火后的位错环形貌, 分别在[001]晶带轴的 (a) g(200) 和 (b) g(020) 衍射条件下进行明场像观察. 图中用数字标记了18个典型位错环

Figure 5. Morphology of dislocation loops in the irradiated and annealed tungsten sample observed in BF images taken under (a) g(200) and (b) g(020) vectors of the [001] zone axis, respectively. A total of 18 typical loops are marked with numbers correspondingly.

图 6 离子辐照后退火的纯钨试样中同一视场在不同衍射矢量下的明场像观察. 选择[001], [111]和[011]三个晶带轴下的多个± g矢量, 并确保各g矢量的偏移矢量sg > 0. 选择了三个位错环A, B, C并对其在不同衍射条件下的inside-outside衬度进行统计

Figure 6. BF images showing the dislocation loops in the same area of the irradiated and annealed tungsten sample. Multiple ±g vectors are selected in the [001], [111] and [011] zone axis, and the deviation vector sg is set to sg > 0 for these imaging conditions. Three typical loops (A, B, C) are tracked with respect to their inside-outside contrasts under different imaging conditions.

图 7 按照FS-RH法定义的柏氏矢量 (a) 先在缺陷晶体做闭合回路; (b) 先在完整晶体做闭合回路. 图中刃位错核心处的 “•”符号代表位错线的正方向为从纸外进入纸内的方向

Figure 7. The definition of Burger’s vector following the FS–RH convention: (a) First drawing the closed circuit in defected crystal; (b) first drawing the closed circuit in the perfect crystal. The “•” sign in the edge dislocation core means that the positive direction of the dislocation line is going into the paper.

表 1 图4中的位错环显衬消衬情况总结. “√”表示位错环未消衬, “×”表示位错环消衬

Table 1. The contrast visibility conditions for the dislocation loops observed in Fig. 4. ‘√’ means the loop is visible and ‘×’ means the loop show contrast extinction.

$ \boldsymbol z = [01\bar 1] $ $ \boldsymbol z = [\bar 111] $ z = [001] $ \boldsymbol g(21\bar 1) $ $ \boldsymbol g(\bar 1\bar 10) $ $ \boldsymbol g(0\bar 11) $ g(101) g(110) $ \boldsymbol g(0\bar 20) $ Loop A √ × × × × √ Loop B × √ √ √ × √ Loop C √ √ × × √ √ 表 2 图6中标号的位错环(A, B, C)在各个衍射矢量下的inside-outside衬度情况. I-inside衬度; O-outside衬度; ×-消衬; √-不消衬, 但inside-outside衬度不明显

Table 2. The inside-outside contrasts of the selected loops (A, B, C) in Fig. 6. Meanings of the different signs: I-inside contrast; O-outside contrast; ×-contrast extinction; √-visible, but with uncertain inside-outside contrasts.

z, g z = [001], $ \boldsymbol B = [00\bar 1] $ z = [111], $ \boldsymbol B = [\bar 1\bar 1\bar 1] $ z = [011], $\boldsymbol B = [0\bar 1\bar 1]$ $ 1\bar 10 $ $ \bar 110 $ $ 020 $ $ 0\bar 20 $ $ 200 $ $ \bar 200 $ $ 110 $ $ \bar 1\bar 10 $ $ 1\bar 21 $ $ \bar12\bar1 $ $ 2\bar1\bar1 $ $ \bar211 $ $ 0\bar11 $ $ 01\bar1 $ $ \bar1\bar12 $ $ 11\bar2 $ $ 21\bar1 $ $ \bar2\bar11 $ Loop A √ √ √ √ I O × × I O I O × × O I I O Loop B I O √ √ I O × × I O I O × × O I I O Loop C I O O I I O × × I O I O × × O I I O 表 3 影响位错环性质判定的各因素的影响效果列表. (g · b)s与inside-outside衬度的关系参照[20]. 各符号意义为: I-inside衬度; O-outside 衬度; V-loop-空位型位错环; I-loop-间隙型位错环; n的朝向是相对电子束方向B, 后者定义为向下

Table 3. Factors affecting the identification of interstitial or vacancy character of dislocation loops and list of effects. The relations between (

$ \boldsymbol g \cdot \boldsymbol b $ )s and the inside-outside contrasts is following [20]. Meanings of different signs: I-inside contrast; O-outside contrast; V-loop: vacancy loop; I-loop - interstitial loop; the direction of n is respective of the electron beam direction B which is pointing downwards.b定义方式 先在缺陷处画闭合回路 先在完整晶体画闭合回路 n 定义 n朝上 n朝下 n朝上 n朝下 (g · b)s > 0 O I I O (g · b)s < 0 I O O I b · n > 0 I-loop I-loop V-loop V-loop b · n < 0 V-loop V-loop I-loop I-loop b · B > 0 V-loop I-loop I-loop V-loop b · B < 0 I-loop V-loop V-loop I-loop -

[1] Gavila P, Riccardi B, Constans S, Jouvelot J L, Vastra I, Missirlian M, Richou M 2011 Fusion Eng. Des. 86 1652

Google Scholar

Google Scholar

[2] Konings R, Pintsuk G. 2012 Comprehensive Nuclear Materials (Vol. 4) (Amsterdam: Elsevier Inc.) pp551–581

[3] 谭晓月 2018 博士学位论文(合肥: 合肥工业大学)

Tan X Y 2018 Ph. D. Dissertation (Hefei: Hefei University of Technology) (in Chinese)

[4] 易晓鸥, 韩文妥, 刘平平, Francesco F, 詹倩, 万发荣 2021 金属学报 57 15

Yi X O, Han W T, Liu P P, Francesco F, Zhan Q, Wan F R 2021 Acta Metall. Sin. 57 15

[5] Yi X, Jenkins M L, Hattar K, Edmondson P, Roberts S 2015 Acta Mater. 92 163

Google Scholar

Google Scholar

[6] Yi X, Jenkins M L, Kirk M A, Zhou Z, Roberts S 2016 Acta Mater. 112 105

Google Scholar

Google Scholar

[7] Ran G, Huang S, Huang Z, Yan Q, Xu J, Li N, Wang L 2014 J. Nucl. Mater. 455 320

Google Scholar

Google Scholar

[8] 丁孝禹, 罗来马, 黄丽枚, 罗广南, 李萍, 吴玉程 2015 稀有金属 39 9

Ding X Y, Luo L M, Huang L M, Luo G N, Li P, Wu Y C 2015 Chin. J. Rare Met. 39 9

[9] 吴玉程, 林锦山, 罗来马, 昝祥, 朱晓勇, 陈俊凌 2017 机械工程学报 53 25

Wu Y C, Lin J S, Luo L M, Ji X, Zhu X Y, Chen J L 2017 J. Mech. Eng. 53 25

[10] Xu H, Stoller R E, Osetsky, Terentyev D 2013 Phys. Rev. Lett. 110 265503

Google Scholar

Google Scholar

[11] Ding Y F, Li Y P, Liu X Y, Ran G, Huang X, Han Q, Chen Y, Huang J, Zhou Z 2021 Tungsten 3 14

[12] Hu X, Koyanagi T, Fukuda M, Katoh Y, Snead L, Wirth B 2016 J. Nucl. Mater. 470 278

Google Scholar

Google Scholar

[13] Ferroni F, Yi X, Arakawa K, Fitzgerald S, Edmondson P, Roberts S 2015 Acta Mater. 90 380

Google Scholar

Google Scholar

[14] 万发荣 1993 金属材料的辐照损伤 (北京: 科学出版社)

Wan F R 1993 Irradiation Damage on Metal Materials (Beijing: Science Publisher) (in Chinese)

[15] Du Y, Cui L, Han W, Wan F 2019 Acta Metall. Sin. 32 566

Google Scholar

Google Scholar

[16] Li R, Xue L, Watanabe H, Yi X, Han W, Liu P, Zhan Q, Wan F 2022 Mater. Charact. 185 111755

Google Scholar

Google Scholar

[17] 李然然 2022 博士学位论文 (北京: 北京科技大学)

Li R R 2022 Ph. D. Dissertation (Beijing: University of Science and Technology Beijing) (in Chinese)

[18] 黄依娜, 万发荣, 焦志杰 2011 60 036802

Google Scholar

Google Scholar

Huang Y N, Wan F R, Jiao Z J 2011 Acta Phys. Sin. 60 036802

Google Scholar

Google Scholar

[19] Williams D B, Carter C B 1996 Transmission Electron Microscopy: A Textbook for Materials Science (New York: Plenum Press)

[20] Jenkins M L, Kirk M A 2001 Characterization of Radiation Damage by Transmission Electron Microscopy (Bristol and Philadelphia: Institute of Physics Publishing) p74

[21] Loretto M H, Smallman R E 1975 Defect Analysis in Electron Microscopy (London: Chapman and Hall Ltd.) p77

[22] Stoller R E, Toloczko M B, Was G S, Certain A, Dwaraknath S, Garner F 2013 Nucl. Instrum. Meth. Phys. Res. , Sect. B 310 75

Google Scholar

Google Scholar

[23] 吴杏芳, 柳得橹 1998 电子显微分析实用方法 (北京: 冶金工业出版社) 第103页

Wu X F, Liu D L 1998 Practical Methods for Electron Microscopy (Beijing: Metallurgical Industry Press) p103 (in Chinese)

[24] Was G S 2017 Fundamentals of Radiation Materials Science: Metals and Alloys (Second edition) (New York: Springer Science+Business Media) p301

[25] Marian J, Wirth B D, Perlado J M 2002 Phys. Rev. Lett. 88 255507

Google Scholar

Google Scholar

[26] Johnson R A 1964 Phys. Rev. 134.5A 1329

[27] Wirth B D, Odette G R, Maroudas D, Lucas G E 2000 J. Nucl. Mater. 276 33

Google Scholar

Google Scholar

[28] Osetsky Y N, Serra A, Singh B N, Gobulov S I 2000 Philos. Mag. A 80 2131

Google Scholar

Google Scholar

[29] Masters B C 1965 Philos. Mag. 11 881

Google Scholar

Google Scholar

[30] Jiang S, Zhou F, Zhang G, Zhou F, Zhang G, Yi X, Yu C, Wang X, Rao W 2021 Tungsten 3 11

[31] 杜玉峰, 崔丽娟, 万发荣 2019 工程科学学报 41 13

Du Y F, Cui L J, Wan F R 2019 Chin. J. Eng. 41 13

[32] Matsui T, Muto S, Tanabe T 2000 J. Nucl. Mater. 283 1139

[33] Nagata S, Takahiro K, Horiike S, Yamaguchi S 1999 J. Nucl. Mater. 266 1151

[34] Keys L K, Moteff J 1970 J. Nucl. Mater. 34 260

Google Scholar

Google Scholar

[35] Bowkett K M, Ralph B 1969 Proc. Roy. Soc. A 312 51

[36] Iwakiri H, Morishita K, Yoshida N 2002 J. Nucl. Mater. 307-311 135

[37] 余永宁 2012 材料科学基础 (第2版) (北京: 高等教育出版社) 第352页

Yu Y N 2012 Fundamentals of Materials Science (Ver. 2) (Beijing: Higher Education Press) p352 (in Chinese)

[38] Hull D, Bacon D J 2011 Introduction to Dislocations (5th Ed.) (Amsterdam: Elsevier Inc.) p15

Catalog

Metrics

- Abstract views: 6109

- PDF Downloads: 105

- Cited By: 0

DownLoad:

DownLoad: