-

Formation and evolution of interstitial dislocation loop induced by radiation damage in a material are confirmed to seriously affect the performance of the material under irradiation. For example, in body-centered cubic Fe based alloy, 1/2

$\left\langle 111 \right\rangle $ and$\left\langle 100 \right\rangle $ are mainly formed during the irradiation, which is related to various degradations of material properties. Thus, the understanding of their effect on radiation damages of material is always one of the hottest topics in nuclear material society. Previous studies have shown the surface effect on 1/2$\left\langle 111 \right\rangle $ loop through the investigation of the interaction between 1/2$\left\langle 111 \right\rangle $ loop and {111} surface. Considering the difference in property between 1/2$\left\langle 111 \right\rangle $ loop and$\left\langle 100 \right\rangle $ loop, in this work the interaction between a$\left\langle 100 \right\rangle $ loop and {100} surface is studied in detail through the molecular dynamics method. The simulation results indicate that the factors including Burgers vector of loop, loop-to-surface depth, interaction between pre-existing$\left\langle 100 \right\rangle $ loops, and temperature, all seriously affect the interaction between loop and surface. Especially, the present results show for the first time the evolution of Burgers vector of$\left\langle 100 \right\rangle $ loop from$\left\langle 100 \right\rangle $ to 1/2$\left\langle 111 \right\rangle $ and its one-dimensional diffusion to surface. According to these results, we also further explore the surface evolution after its interaction with loop. The appearance of atomic island results in the rugged surface morphology. All these results provide a new insight into the radiation damage to the surface of material.-

Keywords:

- radiation damage /

- dislocation loop /

- molecular dynamics simulation /

- surface effect

[1] Masters B C 1965 Philos. Mag. 11 881

Google Scholar

Google Scholar

[2] Yao Z, Hernández-Mayoral M, Jenkins M L, Kirk M A 2008 Philos. Mag. 88 2851

Google Scholar

Google Scholar

[3] Dudarev S L, Bullough R, Derlet P M 2008 Phys. Rev. Lett. 100 135503

Google Scholar

Google Scholar

[4] Hernández-Mayoral M, Yao Z, Jenkins M L, Kirk M A 2008 Philos. Mag. 88 2881

Google Scholar

Google Scholar

[5] Jenkins M L, Yao Z, Hernández-Mayoral M, Kirk M A 2009 J. Nucl. Mater. 389 197

[6] Yao Z, Jenkins M L, Hernández-Mayoral M, Kirk M A 2010 Philos. Mag. 90 4623

Google Scholar

Google Scholar

[7] Prokhodtseva A, Décamps B, Schäublin R 2013 J. Nucl. Mater. 442 S786

Google Scholar

Google Scholar

[8] Arakawa K, Hatanaka M, Kuramoto E, Ono K, Mori H 2006 Phys. Rev. Lett. 96 125506

Google Scholar

Google Scholar

[9] 黄依娜, 万发荣, 焦治杰 2011 60 036802

Google Scholar

Google Scholar

Huang Y N, Wan F R, Jiao Z J 2011 Acta Phys. Sin. 60 036802

Google Scholar

Google Scholar

[10] 姜少宁, 万发荣, 龙毅, 刘传歆, 詹倩, 大貫惣明 2013 62 166801

Google Scholar

Google Scholar

Jiang S N, Wan F R, Long Y, Liu C X, Zhan Q, Ohnuki S 2013 Acta Phys. Sin. 62 166801

Google Scholar

Google Scholar

[11] 杜玉峰, 崔丽娟, 万发荣 2019 工程科学学报 41 1016

Google Scholar

Google Scholar

Du Y F, Cui L J, Wan F R 2019 Chinese Journal of Engineering 41 1016

Google Scholar

Google Scholar

[12] 崔丽娟, 高进, 杜玉峰, 张高伟, 张磊, 龙毅, 杨善武, 詹倩, 万发荣 2016 65 066102

Google Scholar

Google Scholar

Cui L J, Gao J, Du Y F, Zhang G W, Zhang L, Long Y, Yang S W, Zhan Q, Wan F R 2016 Acta Phys. Sin. 65 066102

Google Scholar

Google Scholar

[13] Gao N, Setyawan W, Kurtz Richard J, Wang Z G 2017 J. Nucl. Mater. 493 62

Google Scholar

Google Scholar

[14] Gao N, Shen T L, Kurtz R, Wang Z G, Gao F 2017 Scrip. Mater. 136 64

Google Scholar

Google Scholar

[15] Cui M H, Gao N, Wang D, Gao X, Wang Z G 2019 Nucl. Instr. Meth. B

Google Scholar

Google Scholar

[16] Li F B, Ran G, Gao N, Zhao SQ, Li N 2019 Chin. Phys. B 28 085203

Google Scholar

Google Scholar

[17] Gao N, Cui M H, Setyawan W, Kurtz R J 2018 J. Appl. Phys. 124 235105

Google Scholar

Google Scholar

[18] Bastecka J 1964 Czechosovak J. Phys. 14 430

Google Scholar

Google Scholar

[19] Terentyev D A, Osetsky Y N, Bacon D J 2010 Acta Mater. 58 2477

Google Scholar

Google Scholar

[20] Wirth B D, Odette G R, Maroudas D, Lucas G E 2000 J. Nucl. Mater. 276 33

Google Scholar

Google Scholar

[21] Osetsky Y N, Bacon D J, Serra A, Singh B N, Golubov S I 2000 J. Nucl. Mater. 276 65

Google Scholar

Google Scholar

[22] Fikar J, Groger R 2015 Acta Mater 99 392

Google Scholar

Google Scholar

[23] Fikar J, Groger R, Schaeublin R 2017 J. Nucl. Mater. 497 161

Google Scholar

Google Scholar

[24] Fikar J, Groger R, Schaeublin R 2017 Nucl. Instr. Meth. B 393 186

Google Scholar

Google Scholar

[25] Stukowski A 2010 Modell Simul Mater Sci Eng 18 015012

Google Scholar

Google Scholar

[26] Ackland G J, Mendelev M I, Srolovitz D J, Han S, BarashevA V 2004 J. Phys.: Condens. Matter 16 S2629

Google Scholar

Google Scholar

[27] 李国旺, 黄吝根, 杨顺华 1992 41 69

Google Scholar

Google Scholar

Li G W, Huang L G, Yang S H 1992 Acta Phys. Sin. 41 69

Google Scholar

Google Scholar

-

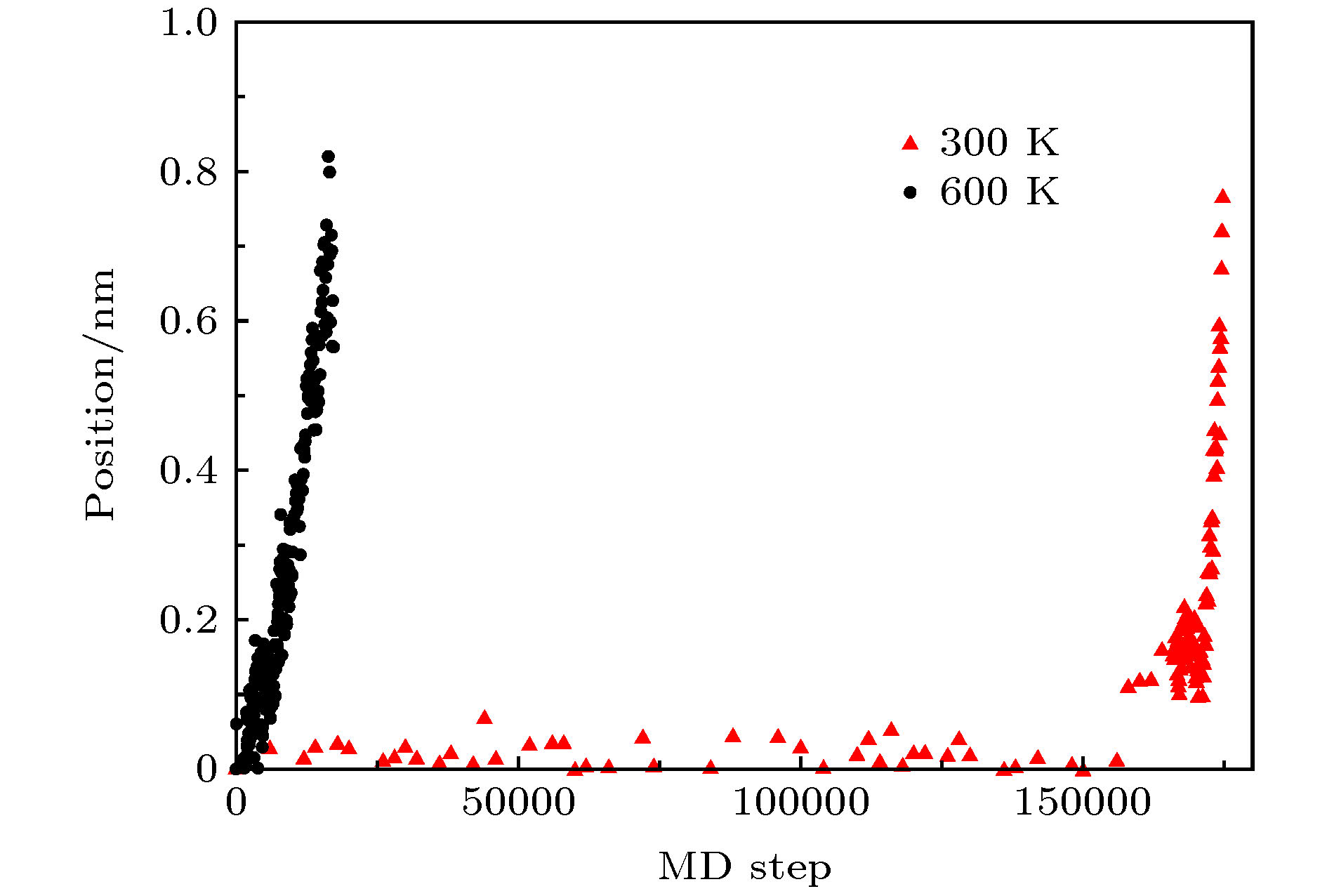

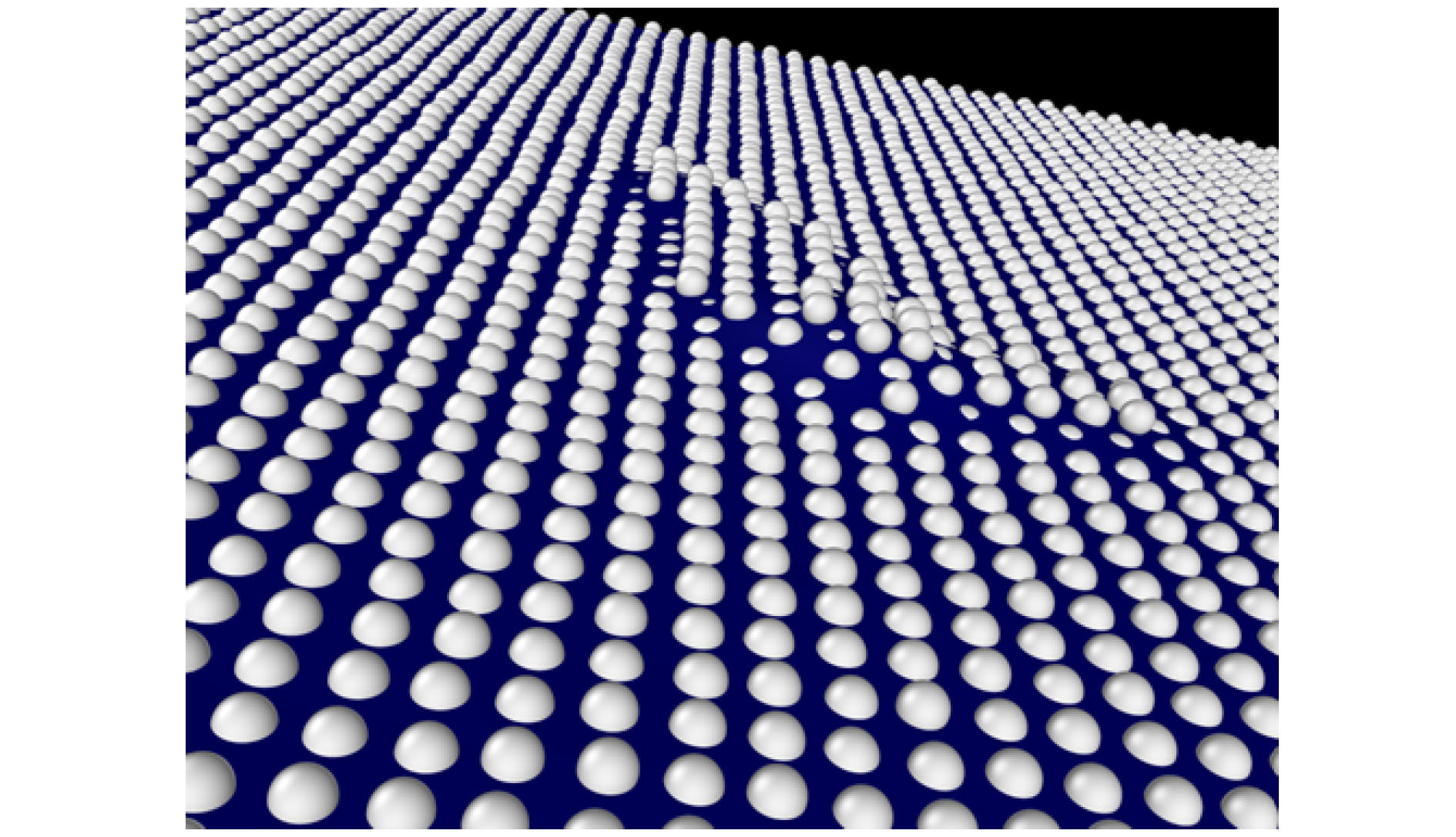

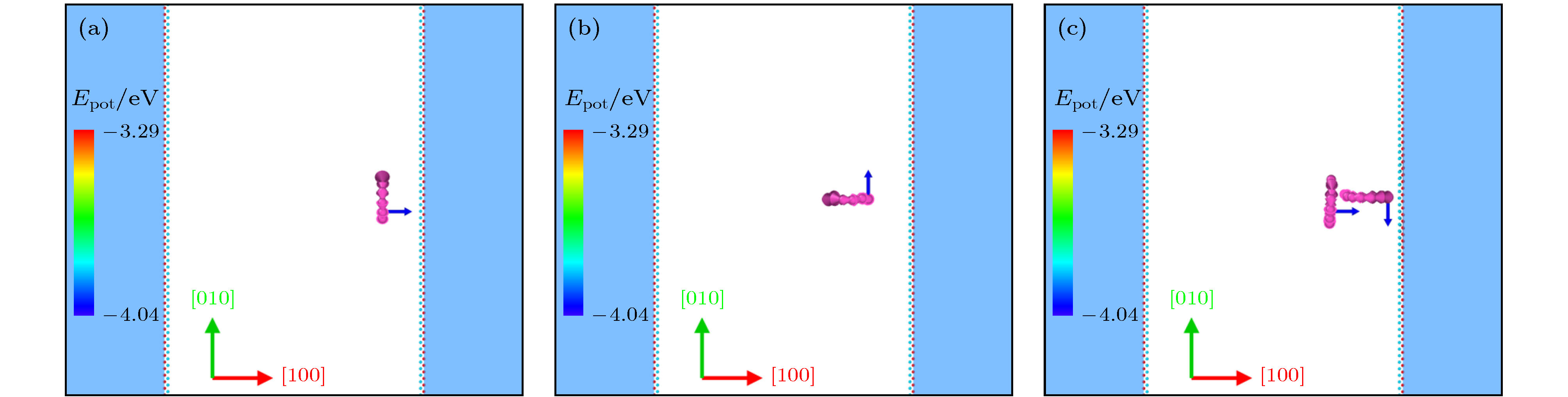

图 1

$\left\langle 100 \right\rangle $ 间隙型位错环与表面相互作用计算模型示意图 (a)和(b)单个位错环与表面的相互作用模型, 其中位错环伯格斯矢量分别平行(a)和垂直(b)于表面法线方向; (c)两个不同的具有相互作用的伯格斯矢量的$\left\langle 100 \right\rangle $ 位错环与表面相互作用的微观模型; 图中位错环和表面原子的颜色根据其势能Epot大小确定, 如图中的能量颜色棒表示, 在表面之外为真空层, 以模拟表面与位错环的相互作用过程Figure 1. Schematic of interaction between

$\left\langle 100 \right\rangle $ loop(s) with {100} surface: (a) and (b) Interaction between a single$\left\langle 100 \right\rangle $ loop with surface with Burgers vector parallel (a) or perpendicular (b) to the normal line of surface; (c) interaction between two interacting$\left\langle 100 \right\rangle $ loops and {100} surface. The atoms in loops and surface are colored by their potential energies Epot as marked by the color bar in the Fig. 1.图 2

$\left\langle 100 \right\rangle $ 位错环伯格斯矢量平行于表面法线方向, 300 K时位错环的演化过程 (a)−(c)位错环向表面运动过程示意图; (d)−(g)位错环与表面发生反应过程; (h)位错环最终被表面吸收后的状态Figure 2. Evolution of a

$\left\langle 100 \right\rangle $ dislocation loop at 300 K with its Burgers vector along the normal direction of surface of {100}. The motion processes of loop are shown in panel (a) to (c) before its interaction with surface, which are shown in panel (d) to (g). Panel (h) is the final state after the absorption of loop by surface.图 3

$\left\langle 100 \right\rangle $ 位错环伯格斯矢量垂直于表面法线方向时不同温度下位错环的演化过程 (a)温度为300 K, 模拟时间为224 ps; (b)温度为300 K、模拟时间653.6 ps; (c)温度为585 K, 模拟时间为1731.4 ps; (d)温度为740 K, 模拟时间为523.9 ps; (e)温度为970 K, 模拟时间为822.5 ps; (f)温度为1220 K, 模拟时间为129.9 ps; (g)温度为1220 K, 模拟时间为139.9 ps; (h)温度为1220 K, 模拟时间为149.9 psFigure 3. Evolution of a

$\left\langle 100 \right\rangle $ dislocation loop at different temperatures with its Burgers vector perpendicular to the normal direction of {100} surface. The results simulated at 300 K are shown in (a) and (b) with simulation time up to 224 ps and 653.6 ps, respectively. The results simulated at 585 K, 740 K and 970 K are shown in (c) to (e) with simulation time up to 1731.4 ps, 523.9 ps, 822.5 ps, respectively. The results at 1220 K with simulation time up to 129.9 ps, 139.9 ps, 149.9 ps are shown in (f) to (h), respectively.图 5 伯格斯矢量相互垂直的双位错环的演化过程 (a)−(c)模拟温度为300 K, 模拟时间分别为10 ps, 20 ps, 30 ps; (d)−(h)模拟温度为900 K, 模拟时间分别为98.5 ps, 108.4 ps, 118.3 ps, 128.1 ps, 138 ps

Figure 5. Evolution of two

$ \left\langle 100 \right\rangle $ dislocation loops at 300 K and 900 K with Burgers vector perpendicular to each other The results obtained at 300 K are shown (a) to (c) with simulation time up to 10 ps, 20 ps, 30 ps, respectively. The results obtained at 900 K are shown (d) to (h) with simulation time up to 98.5 ps, 108.4 ps, 118.3 ps, 128.1 ps, 138 ps, respectively. -

[1] Masters B C 1965 Philos. Mag. 11 881

Google Scholar

Google Scholar

[2] Yao Z, Hernández-Mayoral M, Jenkins M L, Kirk M A 2008 Philos. Mag. 88 2851

Google Scholar

Google Scholar

[3] Dudarev S L, Bullough R, Derlet P M 2008 Phys. Rev. Lett. 100 135503

Google Scholar

Google Scholar

[4] Hernández-Mayoral M, Yao Z, Jenkins M L, Kirk M A 2008 Philos. Mag. 88 2881

Google Scholar

Google Scholar

[5] Jenkins M L, Yao Z, Hernández-Mayoral M, Kirk M A 2009 J. Nucl. Mater. 389 197

[6] Yao Z, Jenkins M L, Hernández-Mayoral M, Kirk M A 2010 Philos. Mag. 90 4623

Google Scholar

Google Scholar

[7] Prokhodtseva A, Décamps B, Schäublin R 2013 J. Nucl. Mater. 442 S786

Google Scholar

Google Scholar

[8] Arakawa K, Hatanaka M, Kuramoto E, Ono K, Mori H 2006 Phys. Rev. Lett. 96 125506

Google Scholar

Google Scholar

[9] 黄依娜, 万发荣, 焦治杰 2011 60 036802

Google Scholar

Google Scholar

Huang Y N, Wan F R, Jiao Z J 2011 Acta Phys. Sin. 60 036802

Google Scholar

Google Scholar

[10] 姜少宁, 万发荣, 龙毅, 刘传歆, 詹倩, 大貫惣明 2013 62 166801

Google Scholar

Google Scholar

Jiang S N, Wan F R, Long Y, Liu C X, Zhan Q, Ohnuki S 2013 Acta Phys. Sin. 62 166801

Google Scholar

Google Scholar

[11] 杜玉峰, 崔丽娟, 万发荣 2019 工程科学学报 41 1016

Google Scholar

Google Scholar

Du Y F, Cui L J, Wan F R 2019 Chinese Journal of Engineering 41 1016

Google Scholar

Google Scholar

[12] 崔丽娟, 高进, 杜玉峰, 张高伟, 张磊, 龙毅, 杨善武, 詹倩, 万发荣 2016 65 066102

Google Scholar

Google Scholar

Cui L J, Gao J, Du Y F, Zhang G W, Zhang L, Long Y, Yang S W, Zhan Q, Wan F R 2016 Acta Phys. Sin. 65 066102

Google Scholar

Google Scholar

[13] Gao N, Setyawan W, Kurtz Richard J, Wang Z G 2017 J. Nucl. Mater. 493 62

Google Scholar

Google Scholar

[14] Gao N, Shen T L, Kurtz R, Wang Z G, Gao F 2017 Scrip. Mater. 136 64

Google Scholar

Google Scholar

[15] Cui M H, Gao N, Wang D, Gao X, Wang Z G 2019 Nucl. Instr. Meth. B

Google Scholar

Google Scholar

[16] Li F B, Ran G, Gao N, Zhao SQ, Li N 2019 Chin. Phys. B 28 085203

Google Scholar

Google Scholar

[17] Gao N, Cui M H, Setyawan W, Kurtz R J 2018 J. Appl. Phys. 124 235105

Google Scholar

Google Scholar

[18] Bastecka J 1964 Czechosovak J. Phys. 14 430

Google Scholar

Google Scholar

[19] Terentyev D A, Osetsky Y N, Bacon D J 2010 Acta Mater. 58 2477

Google Scholar

Google Scholar

[20] Wirth B D, Odette G R, Maroudas D, Lucas G E 2000 J. Nucl. Mater. 276 33

Google Scholar

Google Scholar

[21] Osetsky Y N, Bacon D J, Serra A, Singh B N, Golubov S I 2000 J. Nucl. Mater. 276 65

Google Scholar

Google Scholar

[22] Fikar J, Groger R 2015 Acta Mater 99 392

Google Scholar

Google Scholar

[23] Fikar J, Groger R, Schaeublin R 2017 J. Nucl. Mater. 497 161

Google Scholar

Google Scholar

[24] Fikar J, Groger R, Schaeublin R 2017 Nucl. Instr. Meth. B 393 186

Google Scholar

Google Scholar

[25] Stukowski A 2010 Modell Simul Mater Sci Eng 18 015012

Google Scholar

Google Scholar

[26] Ackland G J, Mendelev M I, Srolovitz D J, Han S, BarashevA V 2004 J. Phys.: Condens. Matter 16 S2629

Google Scholar

Google Scholar

[27] 李国旺, 黄吝根, 杨顺华 1992 41 69

Google Scholar

Google Scholar

Li G W, Huang L G, Yang S H 1992 Acta Phys. Sin. 41 69

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 9859

- PDF Downloads: 104

- Cited By: 0

DownLoad:

DownLoad: