-

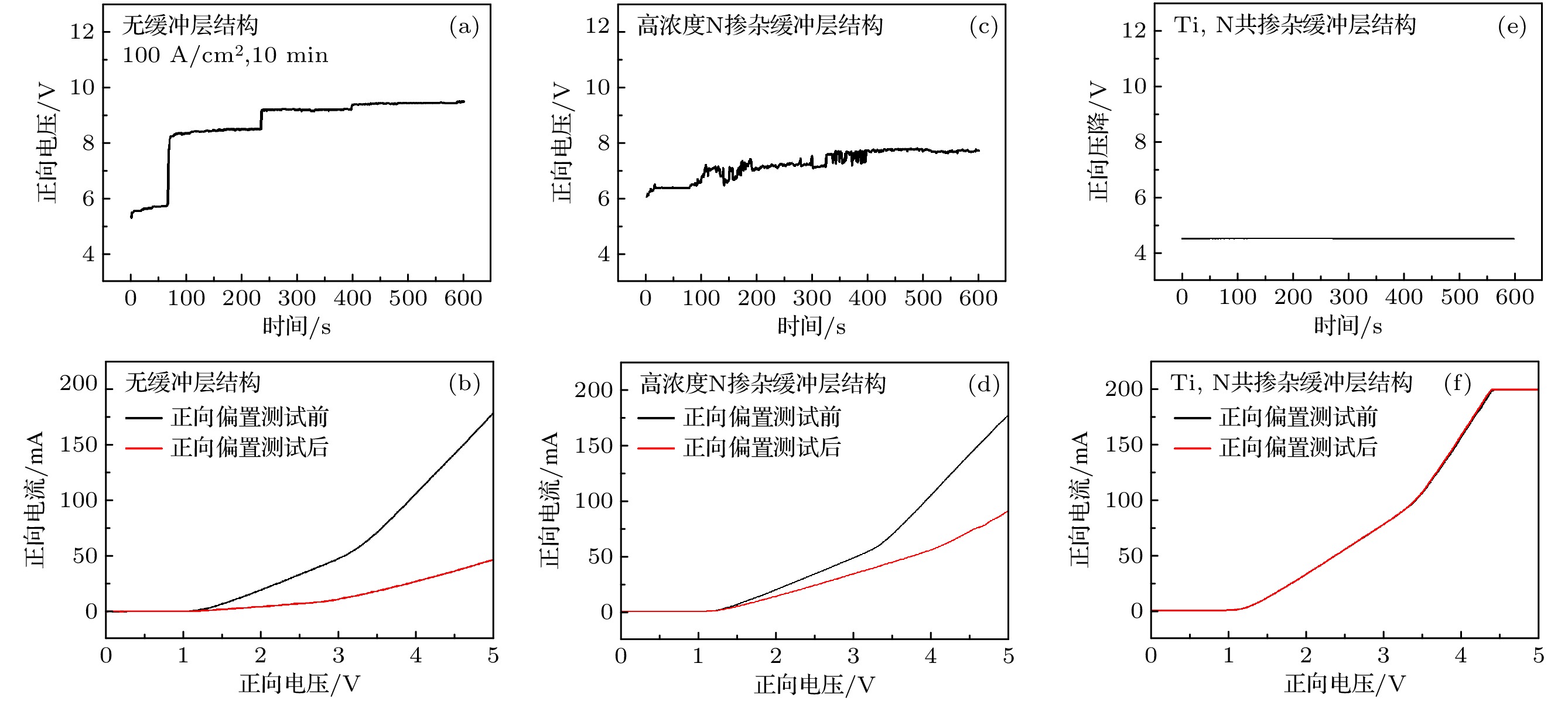

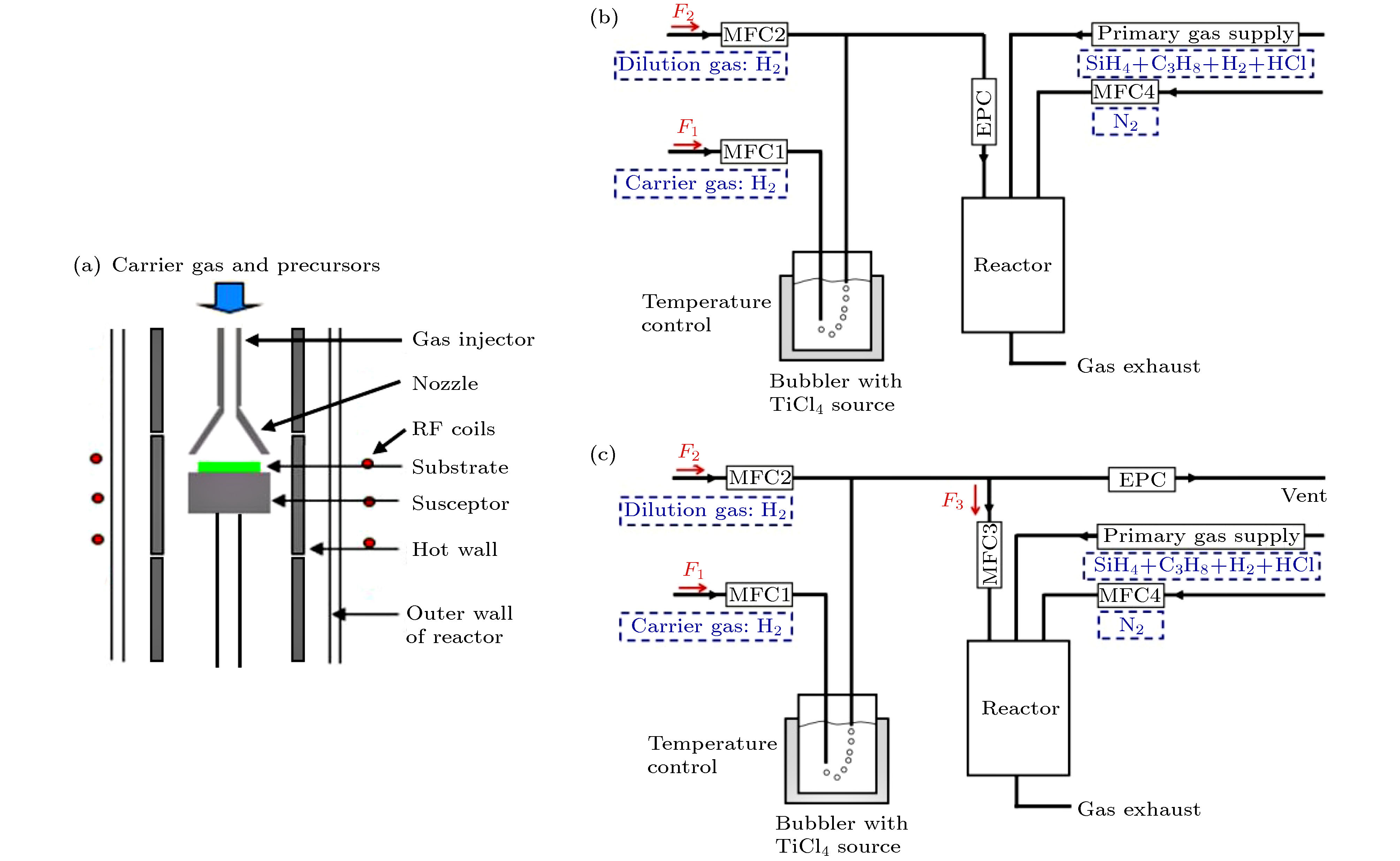

“Bipolar degradation” phenomenon has severely impeded the development of 4H-SiC bipolar devices. Their defect mechanism is the expansion of Shockley-type stacking faults from basal plane dislocations under the condition of electron-hole recombination. To suppress the “bipolar degradation” phenomenon, not only do the basal plane dislocations in the 4H-SiC drift layer need eliminating, but also a recombination-enhancing buffer layer is required to prevent the minority carriers of holes from reaching the epilayer/substrate interface where high-density basal plane dislocation segments exist. In this paper, Ti and N co-doped 4H-SiC buffer layers are grown to further shorten the minority carrier lifetime. Firstly, the dependence of Ti doping concentration on TiCl4 flow rate in 4H-SiC epilayers is determined by using single-dilution gas line and double-dilution gas line. Then the p+ layer and p++ layer in PiN diode are obtained by aluminum ion implantation at room temperature and 500 ℃ followed by high temperature activation annealing. Finally, 4H-SiC PiN diodes with a Ti, N co-doped buffer layer are fabricated and tested with a forward current density of 100 A/cm2 for 10 min. Comparing with the PiN diodes without a buffer layer and with a buffer layer only doped with high concentration of nitrogen, the forward voltage drop stability of those diodes with a 2 μm-thick Ti, N co-doped buffer layer (Ti: 3.70 × 1015 cm–3 and N: 1.01 × 1019 cm–3) is greatly improved.

-

Keywords:

- 4H-SiC /

- Ti doping /

- recombination-enhancing buffer layer /

- bipolar degradation

[1] Lendenmann H, Dahlquist F, Johansson N, Soderholm R, Nilsson P A, Bergman J P, Skytt P 2001 Mater. Sci. Forum. 353–356 727

Google Scholar

Google Scholar

[2] Skowronski M, Liu J Q, Vetter W M, Dudley M, Hallin C, Lendenmann H 2002 J. Appl. Phys. 92 4699

Google Scholar

Google Scholar

[3] Caldwell J D, Stahlbush R E, Ancona M G, Glembocki O J, Hobart K D 2010 J. Appl. Phys. 108 044503

Google Scholar

Google Scholar

[4] Maeda K, Hirano R, Sato Y, Tajima M 2012 Mater. Sci. Forum. 725 35

Google Scholar

Google Scholar

[5] Ha S, Mieszkowski P, Skowronski M, Rowland L B 2002 J. Cryst. Growth 244 257

Google Scholar

Google Scholar

[6] Tsuchida H, Kamata I, Miyazawa T, Ito M, Zhang X, Nagano M 2018 Mater. Sci. Semicond. Process. 78 2

Google Scholar

Google Scholar

[7] Tanaka A, Matsuhata H, Kawabata N, Mori D, Inoue K, Ryo M, Fujimoto T, Tawara T, Miyazato M, Miyajima M, Fukuda K, Ohtsuki A, Tomohisa T, Tsuchida H, Yonezawa Y, Kimoto T 2016 J. Appl. Phys. 119 095711

Google Scholar

Google Scholar

[8] Sumakeris J J, Bergman P, Das M K, Hallin C, Hull B A, Janzen E, Lendenmann H, O’Loughlin M J, Paisley M J, Ha S Y, Skowronski M, Palmour J W, Carter Jr C H 2006 Mater. Sci. Forum. 527-529 141

Google Scholar

Google Scholar

[9] Hori T, Danno K, Kimoto T 2007 J. Cryst. Growth. 306 297

Google Scholar

Google Scholar

[10] Stahlbush R E, VanMil B L, Myers Ward R L, Lew K K, Gaskill D K, Eddy Jr C R 2009 Appl. Phys. Lett. 94 041916

Google Scholar

Google Scholar

[11] Mahadik N A, Stahlbush R E, Ancona M G, Lmhoff E A, Hobart K D, Myers-Ward R L, Eddy Jr C R, Gaskill D K, Kub F J 2012 Appl. Phys. Lett. 100 042102

Google Scholar

Google Scholar

[12] Tawara T, Miyazawa T, Ryo M, Miyazato M, Fujimoto T, Takenaka K, Matsunaga S, Miyajima M, Otsuki A, Yonezawa Y, Kato T, Okumura H, Kimoto T, Tsuchida H 2016 J. Appl. Phys. 120 115101

Google Scholar

Google Scholar

[13] Miyazawa T, Tawara T, Tsuchida H 2017 Mater. Sci. Forum. 897 67

Google Scholar

Google Scholar

[14] Miyazawa T, Tawara T, Takanashi R, Tsuchida H 2016 Appl. Phys. Express 9 111301

Google Scholar

Google Scholar

[15] Murata K, Tawara T, Yang A, Takanashi R, Miyazawa T, Tsuchida H 2019 J. Appl. Phys. 126 045711

Google Scholar

Google Scholar

[16] Tawara T, Miyazawa T, Ryo M, Miyazato M, Fujimoto T, Takenaka K, Matsunaga S, Miyajima M, Otsuki A, Yonezawa Y, Kato T, Okumura H, Kimoto T, Tsuchida H 2017 Mater. Sci. Forum. 897 419

Google Scholar

Google Scholar

[17] Dalibor T, Pensl G, Matsunami H, Kimoto T, Choyke W J, Schoner A, Nordell N 1997 Phys. Status Solidi A 162 199

Google Scholar

Google Scholar

[18] Hobgood H M, Glass R C, Augustine G, Hopkins R H, Jenny J, Skowronski M, Mitchel W C, Roth M 1995 Appl. Phys. Lett. 66 1364

Google Scholar

Google Scholar

[19] Dalibor T, Pensl G, Nordell N, Schoner A 1997 Phys. Rev. B 55 13618

Google Scholar

Google Scholar

[20] Maier K, Muller H D, Schneider J 1992 Mater. Sci. Forum. 83–87 1183

Google Scholar

Google Scholar

-

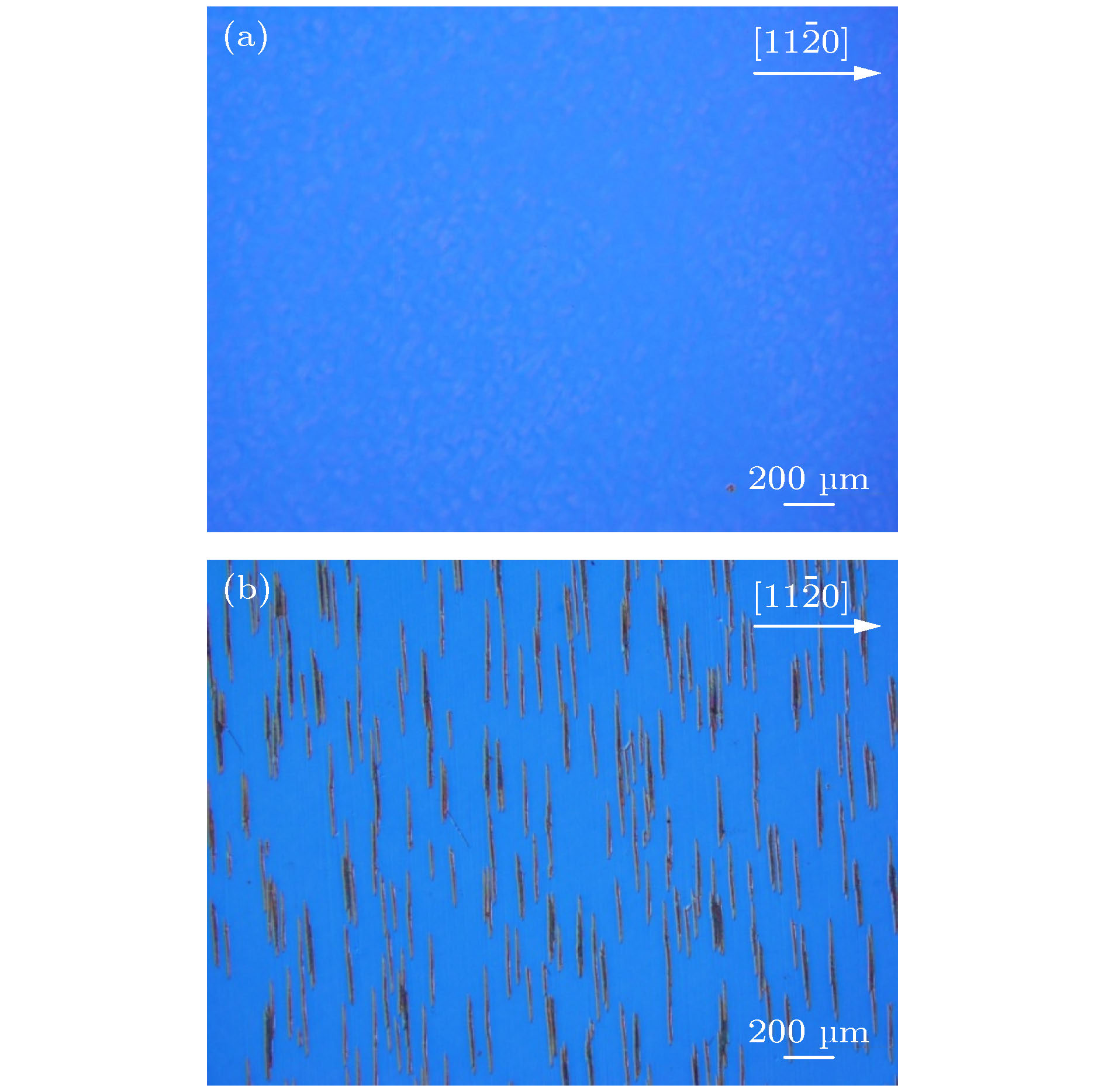

图 4 Ti, N共掺杂4H-SiC缓冲层表面形貌(Nd = 1.01 × 1019 cm–3) (a) Ti掺杂浓度为3.70 × 1015 cm–3; (b) Ti掺杂浓度为3.71 × 1016 cm–3

Figure 4. Optical microscope images of the Ti and N co-doped 4H-SiC buffer layer surface with Ti doping concentrations of (a) 3.70 × 1015 cm–3 and (b) 3.71 × 1016 cm–3. Both with Nd = 1.01 × 1019 cm–3.

图 5 无缓冲层、仅含高浓度N掺杂缓冲层、含Ti和N共掺杂缓冲层的4H-SiC PiN二极管的正向特性 (a), (c), (e)在100 A/cm2电流密度下10 min, 正向压降随时间的变化; (b), (d), (f)正向偏置前后正向电流-电压曲线的对比

Figure 5. (a), (c), (e) Change of forward voltage drop vs. time and (b), (d), (f) comparison between the forward I-V characteristics before and after being biased for 10 min at a current density of 100 A/cm2 for 4H-SiC PiN diodes without a buffer layer, with a highly N-doped buffer layer, and with a Ti and N co-doped buffer layer.

表 1 Ti掺杂实验参数

Table 1. Experimental parameters of Ti doping.

稀释管路 MFC1 MFC2 MFC3 TiCl4掺杂摩尔流量 /sccm /slm /sccm /(mol·min–1) 单稀释 1.25 9.800 — 7.25 × 10–7 5 9.800 — 2.90 × 10–6 50 9.800 — 2.90 × 10–5 双稀释 50 0.100 5 8.95 × 10–7 50 0.075 5 1.14 × 10–6 50 0.040 5 1.62 × 10–6 -

[1] Lendenmann H, Dahlquist F, Johansson N, Soderholm R, Nilsson P A, Bergman J P, Skytt P 2001 Mater. Sci. Forum. 353–356 727

Google Scholar

Google Scholar

[2] Skowronski M, Liu J Q, Vetter W M, Dudley M, Hallin C, Lendenmann H 2002 J. Appl. Phys. 92 4699

Google Scholar

Google Scholar

[3] Caldwell J D, Stahlbush R E, Ancona M G, Glembocki O J, Hobart K D 2010 J. Appl. Phys. 108 044503

Google Scholar

Google Scholar

[4] Maeda K, Hirano R, Sato Y, Tajima M 2012 Mater. Sci. Forum. 725 35

Google Scholar

Google Scholar

[5] Ha S, Mieszkowski P, Skowronski M, Rowland L B 2002 J. Cryst. Growth 244 257

Google Scholar

Google Scholar

[6] Tsuchida H, Kamata I, Miyazawa T, Ito M, Zhang X, Nagano M 2018 Mater. Sci. Semicond. Process. 78 2

Google Scholar

Google Scholar

[7] Tanaka A, Matsuhata H, Kawabata N, Mori D, Inoue K, Ryo M, Fujimoto T, Tawara T, Miyazato M, Miyajima M, Fukuda K, Ohtsuki A, Tomohisa T, Tsuchida H, Yonezawa Y, Kimoto T 2016 J. Appl. Phys. 119 095711

Google Scholar

Google Scholar

[8] Sumakeris J J, Bergman P, Das M K, Hallin C, Hull B A, Janzen E, Lendenmann H, O’Loughlin M J, Paisley M J, Ha S Y, Skowronski M, Palmour J W, Carter Jr C H 2006 Mater. Sci. Forum. 527-529 141

Google Scholar

Google Scholar

[9] Hori T, Danno K, Kimoto T 2007 J. Cryst. Growth. 306 297

Google Scholar

Google Scholar

[10] Stahlbush R E, VanMil B L, Myers Ward R L, Lew K K, Gaskill D K, Eddy Jr C R 2009 Appl. Phys. Lett. 94 041916

Google Scholar

Google Scholar

[11] Mahadik N A, Stahlbush R E, Ancona M G, Lmhoff E A, Hobart K D, Myers-Ward R L, Eddy Jr C R, Gaskill D K, Kub F J 2012 Appl. Phys. Lett. 100 042102

Google Scholar

Google Scholar

[12] Tawara T, Miyazawa T, Ryo M, Miyazato M, Fujimoto T, Takenaka K, Matsunaga S, Miyajima M, Otsuki A, Yonezawa Y, Kato T, Okumura H, Kimoto T, Tsuchida H 2016 J. Appl. Phys. 120 115101

Google Scholar

Google Scholar

[13] Miyazawa T, Tawara T, Tsuchida H 2017 Mater. Sci. Forum. 897 67

Google Scholar

Google Scholar

[14] Miyazawa T, Tawara T, Takanashi R, Tsuchida H 2016 Appl. Phys. Express 9 111301

Google Scholar

Google Scholar

[15] Murata K, Tawara T, Yang A, Takanashi R, Miyazawa T, Tsuchida H 2019 J. Appl. Phys. 126 045711

Google Scholar

Google Scholar

[16] Tawara T, Miyazawa T, Ryo M, Miyazato M, Fujimoto T, Takenaka K, Matsunaga S, Miyajima M, Otsuki A, Yonezawa Y, Kato T, Okumura H, Kimoto T, Tsuchida H 2017 Mater. Sci. Forum. 897 419

Google Scholar

Google Scholar

[17] Dalibor T, Pensl G, Matsunami H, Kimoto T, Choyke W J, Schoner A, Nordell N 1997 Phys. Status Solidi A 162 199

Google Scholar

Google Scholar

[18] Hobgood H M, Glass R C, Augustine G, Hopkins R H, Jenny J, Skowronski M, Mitchel W C, Roth M 1995 Appl. Phys. Lett. 66 1364

Google Scholar

Google Scholar

[19] Dalibor T, Pensl G, Nordell N, Schoner A 1997 Phys. Rev. B 55 13618

Google Scholar

Google Scholar

[20] Maier K, Muller H D, Schneider J 1992 Mater. Sci. Forum. 83–87 1183

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 10519

- PDF Downloads: 145

- Cited By: 0

DownLoad:

DownLoad: