-

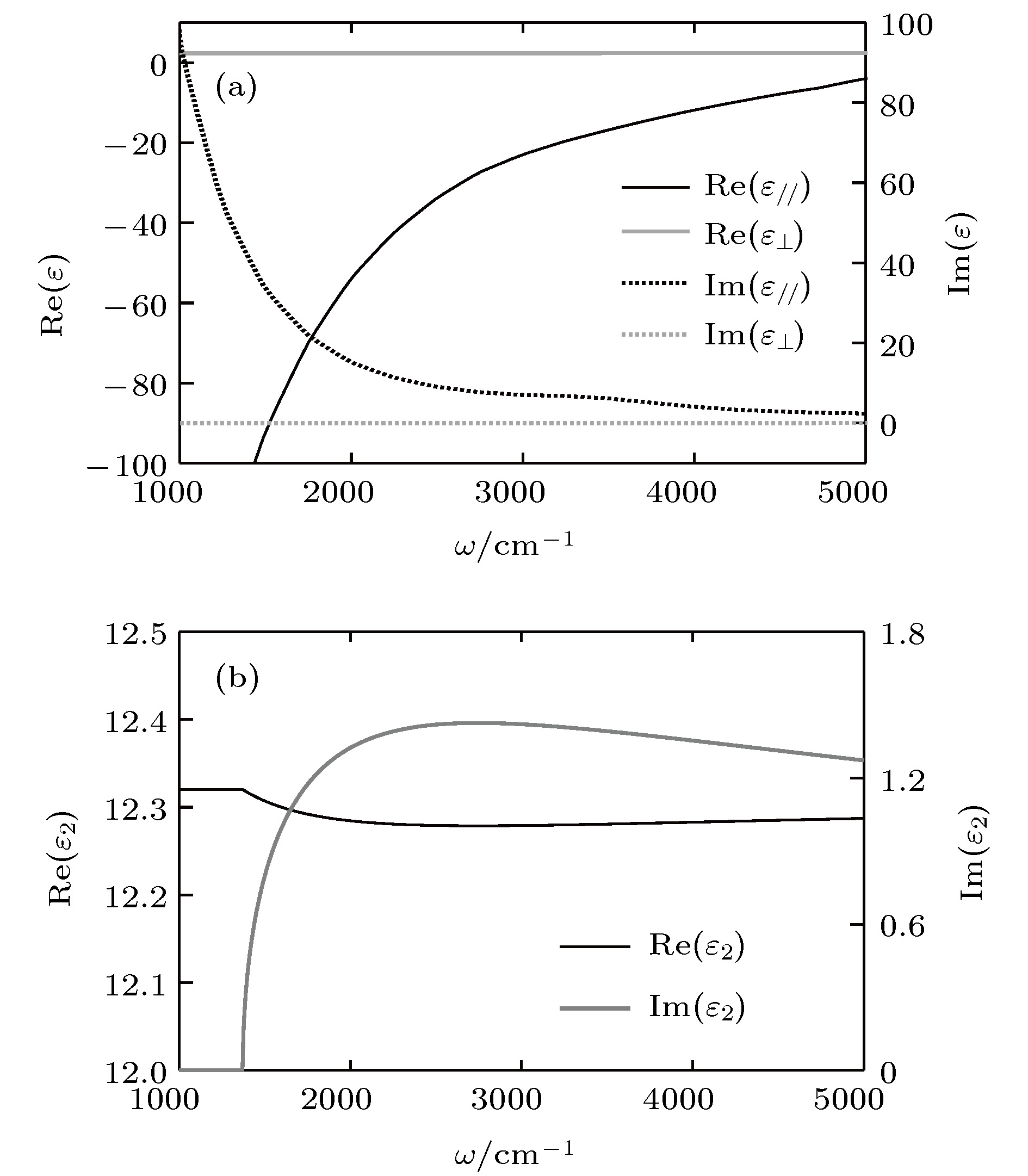

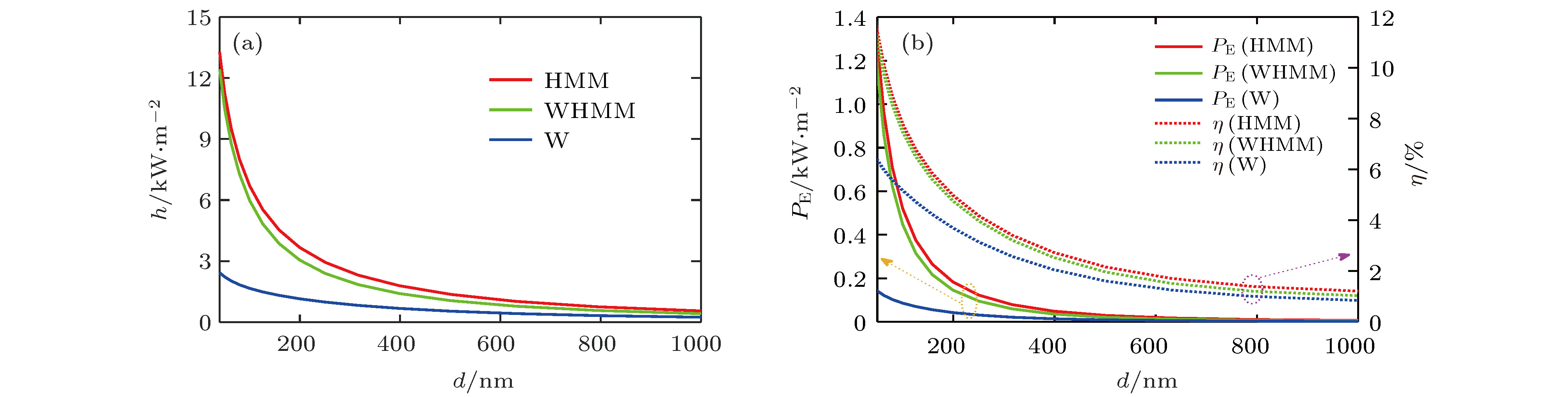

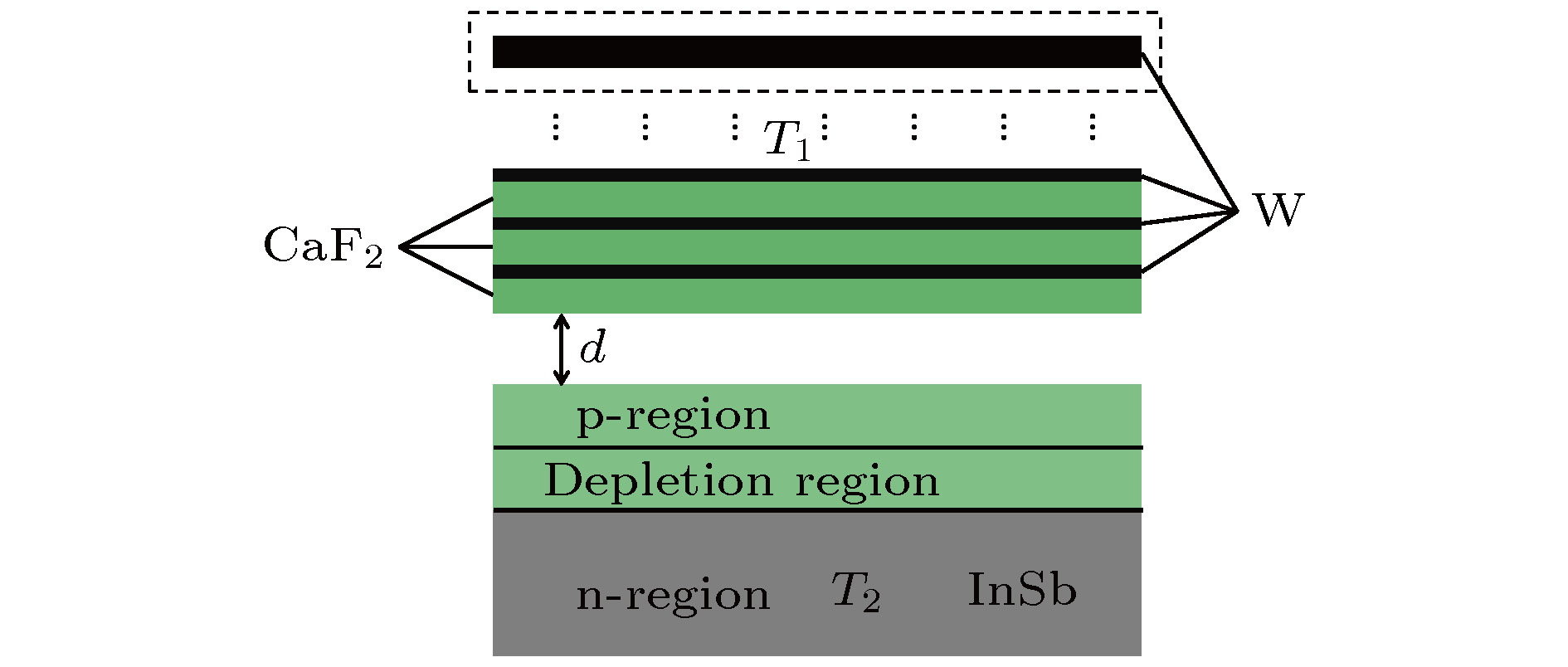

Thermophotovoltaic (TPV) device is a thermoelectric conversion method with great application prospects. In the far-field regime, the thermoelectric power is usually small due to the Planck blackbody radiation limit, but can be substantially enhanced in the near-field regime where evanescent waves will participate in the heat transfer by tunneling. In this aspect, the surface optical density of state is a key factor that will determine the transfer conversion of thermal photons. Plasmonic or phononic resonance materials have been discussed in the literature to acquire large heat flux. Besides, metamaterial is another way to pursue the design freedoms for the same purpose. In this work, we propose a [CaF2/W]n multilayer based infrared hyperbolic metamaterial (HMM) with high surface density of states as an emitter of a high-performance TPV cell made of an InSb p-n junction (energy bandgap = 0.17 eV). The effective medium theory (EMT) is utilized to describe the electromagnetic behavior of the HMM. The near-field heat flux is calculated based on electrodynamic wave theory and Green's function method, and the photocurrent of thermophotovoltaic device is derived using diffusion equation for semiconductor. For comparison, we design three different radiators, i.e. tungsten film (W), [GaF2/W]n multilayer hyperbolic metamaterial (HMM), and tungsten-grounded HMM (WHMM). Compared with the pure tungsten radiator, the artificial structure exhibits the hyperbolic dispersion characteristic in a wide frequency range, which gives rise to a higher local density of states, in particular in the hyperbolic-to-elliptic spectral transition region. As a result, the radiation power and the energy conversion efficiency are greatly enhanced, which are more easily realized by a matched emission band achieved by the structural design. We find that the thermophotovoltaic device with WHMM radiator has a similar power and conversion efficiency to that with the HMM radiator. The influence of the substrate can be ignored when the hyperbolic metamaterial is thicker than 140 nm, very beneficial to the actual fabrication of the device. By our system, with multilayer hyperbolic metamaterial (HMM) radiator, a high electric power >1 W/m2 and a conversion efficiency about 11% can be obtained at a bias temperature of 200 K and a 100 nm vacuum gap. Compared with nanowire arrays or natural hyperbolic material, the multilayer structure proposed in this paper has obvious advantages in bandwidth and manufacturing and may find important applications in near-field thermophotovoltaic device and other relevant areas.

-

Keywords:

- near-field thermal radiation /

- hyperbolic metamaterial /

- thermophotovoltaic cell /

- heat recycling

[1] Hoffert M I, Caldeira K, Jain A K, Haites E F, Harvey L D D, Potter S D, Schlesinger M E, Schneider S H, Watts R G, Wigley T M L, Wuebbles D J 1998 Nature 395 881

Google Scholar

Google Scholar

[2] BCS, Inc 2008 Waste Heat Recovery. Technology and Opportunities in U.S. Industry (Hinsdale: BCS) pp6–19

[3] Liu W S, Jie Q, Kim H S, Ren Z F 2015 Acta Mater. 87 357

Google Scholar

Google Scholar

[4] Alam H, Ramakrishna S 2013 Nano Energy 2 190

Google Scholar

Google Scholar

[5] Chan W R, Bermel P, Pilawa-Podgurski R C N, Marton C H, Jensen K F, Senkevich J J, Joannopoulos J D, Soljacic M, Celanovic I 2013 PNAS 110 5309

Google Scholar

Google Scholar

[6] Bierman D M, Lenert A, Chan W R, Bhatia B, Celanovic I, Soljacic M, Wang E N 2016 Nat. Energy 1 16068

Google Scholar

Google Scholar

[7] Whale M D, Cravalho E G 2002 IEEE Trans. Energy Convers. 17 130

Google Scholar

Google Scholar

[8] Yang J, Du W, Su Y, Fu Y, Gong S, He S, Ma Y 2018 Nat. Commun. 9 4033

Google Scholar

Google Scholar

[9] Thomas N H, Sherrott M C, Broulliet J, Atwater H A, Minnich A J 2019 Nano Lett. 19 3898

Google Scholar

Google Scholar

[10] Zhao B, Guizal B, Zhang Z M, Fan S, Antezza M 2017 Phys. Rev. B 95 245437

Google Scholar

Google Scholar

[11] Zwol P J, Thiele S, Berger C, Heer W A, Chevrier J 2012 Phys. Rev. Lett. 109 264301

Google Scholar

Google Scholar

[12] Liu B, Shen S 2013 Phys. Rev. B 87 115403

Google Scholar

Google Scholar

[13] Jin S, Lim M, Lee S S, Lee B J 2016 Opt. Express 24 A635

Google Scholar

Google Scholar

[14] Shi J, Liu B, Li P, Ng L Y, Shen S 2015 Nano Lett. 15 1217

Google Scholar

Google Scholar

[15] Park K, Basu S, King W P, Zhang Z M 2008 J. Quant. Spectrosc. Radiat. Transfer 109 305

Google Scholar

Google Scholar

[16] 于海童, 刘东, 杨震, 段远源 2018 67 024209

Google Scholar

Google Scholar

Yu H T, Liu D, Yang Z, Duan Y Y 2018 Acta Phys. Sin. 67 024209

Google Scholar

Google Scholar

[17] Zhao B, Santhanam P, Chen K, Buddhiraju S, Fan S 2018 Nano Lett. 18 5224

Google Scholar

Google Scholar

[18] Fiorino A, Zhu L, Thompson D, Mittapally R, Reddy P, Meyhofer E 2018 Nat. Nanotechnol. 13 806

Google Scholar

Google Scholar

[19] Papadakis G T, Buddhiraju S, Zhao Z, Zhao B, Fan S 2020 Nano Lett. 20 1654

Google Scholar

Google Scholar

[20] Datas A, Vaillon R 2019 Appl. Phys. Lett. 114 133501

Google Scholar

Google Scholar

[21] Malitson I H 1963 Appl. Opt. 2 1103

Google Scholar

Google Scholar

[22] Liu X L, Zhang R Z, Zhang Z M 2014 Int. J. Heat Mass Transfer 73 389

Google Scholar

Google Scholar

[23] Biehs S A, Tschikin M, Messina R, Ben-Abdallah P 2013 Appl. Phys. Lett. 102 131106

Google Scholar

Google Scholar

[24] Lim M K, Jin S K, Lee S S, Lee B J 2015 Opt. Express 23 A240

Google Scholar

Google Scholar

[25] Poddubny A, Iorsh I, Belov P, Kivshar Y 2013 Nat. Photonics 7 958

Google Scholar

Google Scholar

[26] Liu X L, Bright T J, Zhang Z M 2014 J. Heat Transfer 136 092703

Google Scholar

Google Scholar

[27] Zhang R Z, Zhang Z M 2017 J. Quant. Spectrosc. Radiat. Transfer 197 132

Google Scholar

Google Scholar

[28] Volokitin A I, Persson B N J 2007 Rev. Mod. Phys. 79 1291

Google Scholar

Google Scholar

[29] Volokitin A I, Persson B N J 1999 J. Phys. Condens. Matter 11 345

Google Scholar

Google Scholar

[30] Vaillon R, Robin L, Muresan C, Ménézo C 2006 Int. J. Heat Mass Transfer 49 4454

Google Scholar

Google Scholar

[31] Guo Y, Newman W, Cortes C L, Jacob Z 2012 ADOP 2012 1

[32] Francoeur M, Vaillon R, Mengüç M P 2011 IEEE Trans. Energy Convers. 26 686

Google Scholar

Google Scholar

[33] Lang S, Tschikin M, Biehs S A, Petrov A Y, Eich M 2014 Appl. Phys. Lett. 104 121903

Google Scholar

Google Scholar

[34] Laroche M, Carminati R, Greffet J 2006 J. Appl. Phys. 100 063704

Google Scholar

Google Scholar

[35] Baldasaro P F, Raynolds J E, Charache G W, DePoy D M, Ballinger C T, Donovan T, Borrego J M 2001 J. Appl. Phys. 89 3319

Google Scholar

Google Scholar

[36] Bright T J, Wang L P, Zhang Z M 2014 J. Heat Transfer 136 062701

Google Scholar

Google Scholar

-

图 5 间距为d = 50 nm时的电流谱 (a) p区

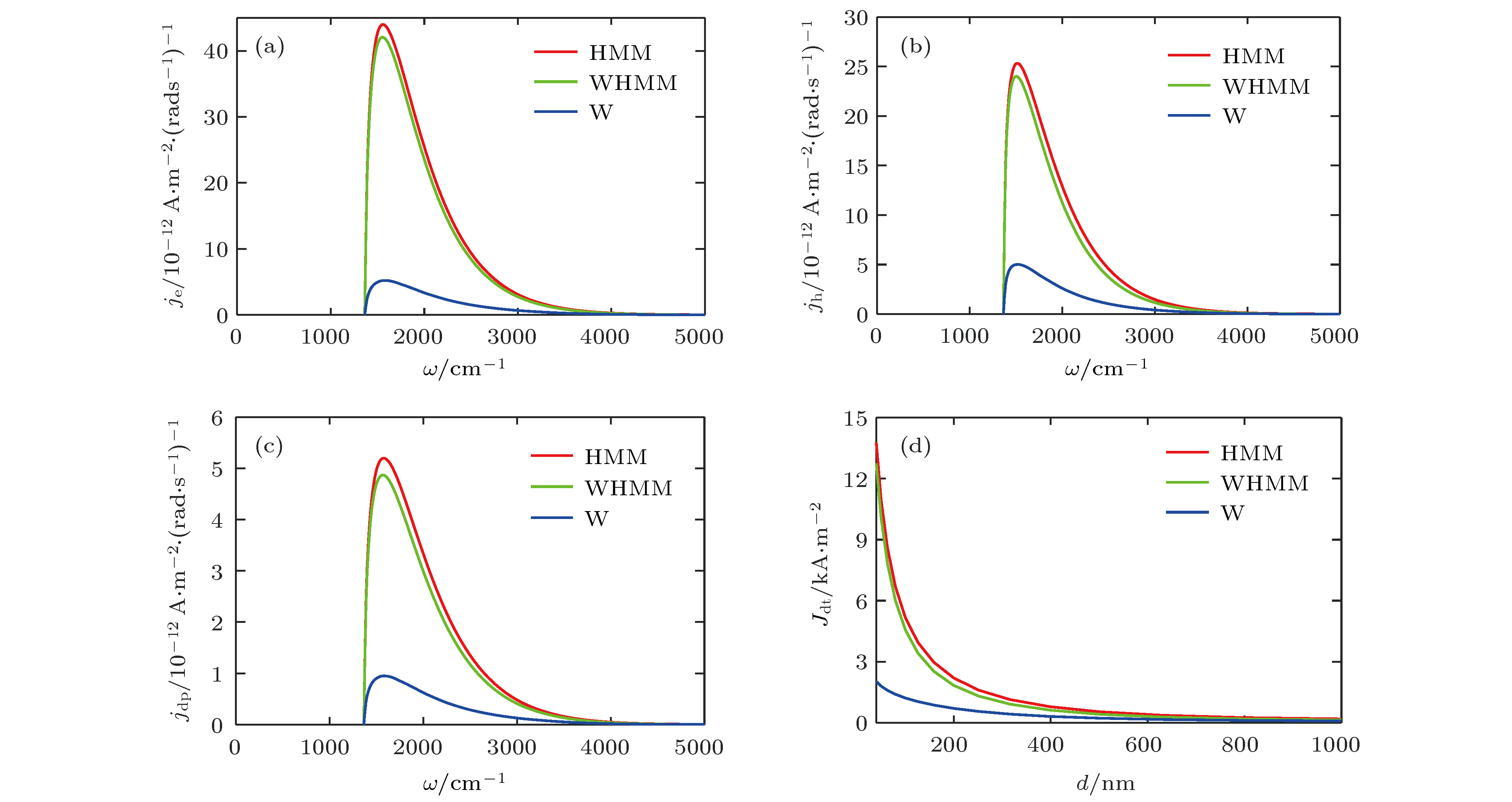

$ {j}_{\mathrm{e}}\left(\omega \right) $ ; (b) n区$ {j}_{\mathrm{h}}\left(\omega \right) $ ; (c) 耗尽层内$ {j}_{\mathrm{d}\mathrm{p}}\left(\omega \right) $ ; (d) p-n结内的总电流大小$ {j}_{\mathrm{t}} $ 随间距的变化Figure 5. Current density spectrum in the (a) p-region, (b) n-region, and (c) depletion region; (d) total current with respect to the vacuum gap width.

参数 p 区 n 区 载流子浓度/cm–3 NA = 1019 ND = 1019 扩散系数/cm2·s–1 De = 186 Dh = 5.21 弛豫时间/ns τe = 1.45 τh = 1.81 复合速率/m·s–1 up =104 un = 0 区域长度/μm Lp = 0.4 Ln = 10 -

[1] Hoffert M I, Caldeira K, Jain A K, Haites E F, Harvey L D D, Potter S D, Schlesinger M E, Schneider S H, Watts R G, Wigley T M L, Wuebbles D J 1998 Nature 395 881

Google Scholar

Google Scholar

[2] BCS, Inc 2008 Waste Heat Recovery. Technology and Opportunities in U.S. Industry (Hinsdale: BCS) pp6–19

[3] Liu W S, Jie Q, Kim H S, Ren Z F 2015 Acta Mater. 87 357

Google Scholar

Google Scholar

[4] Alam H, Ramakrishna S 2013 Nano Energy 2 190

Google Scholar

Google Scholar

[5] Chan W R, Bermel P, Pilawa-Podgurski R C N, Marton C H, Jensen K F, Senkevich J J, Joannopoulos J D, Soljacic M, Celanovic I 2013 PNAS 110 5309

Google Scholar

Google Scholar

[6] Bierman D M, Lenert A, Chan W R, Bhatia B, Celanovic I, Soljacic M, Wang E N 2016 Nat. Energy 1 16068

Google Scholar

Google Scholar

[7] Whale M D, Cravalho E G 2002 IEEE Trans. Energy Convers. 17 130

Google Scholar

Google Scholar

[8] Yang J, Du W, Su Y, Fu Y, Gong S, He S, Ma Y 2018 Nat. Commun. 9 4033

Google Scholar

Google Scholar

[9] Thomas N H, Sherrott M C, Broulliet J, Atwater H A, Minnich A J 2019 Nano Lett. 19 3898

Google Scholar

Google Scholar

[10] Zhao B, Guizal B, Zhang Z M, Fan S, Antezza M 2017 Phys. Rev. B 95 245437

Google Scholar

Google Scholar

[11] Zwol P J, Thiele S, Berger C, Heer W A, Chevrier J 2012 Phys. Rev. Lett. 109 264301

Google Scholar

Google Scholar

[12] Liu B, Shen S 2013 Phys. Rev. B 87 115403

Google Scholar

Google Scholar

[13] Jin S, Lim M, Lee S S, Lee B J 2016 Opt. Express 24 A635

Google Scholar

Google Scholar

[14] Shi J, Liu B, Li P, Ng L Y, Shen S 2015 Nano Lett. 15 1217

Google Scholar

Google Scholar

[15] Park K, Basu S, King W P, Zhang Z M 2008 J. Quant. Spectrosc. Radiat. Transfer 109 305

Google Scholar

Google Scholar

[16] 于海童, 刘东, 杨震, 段远源 2018 67 024209

Google Scholar

Google Scholar

Yu H T, Liu D, Yang Z, Duan Y Y 2018 Acta Phys. Sin. 67 024209

Google Scholar

Google Scholar

[17] Zhao B, Santhanam P, Chen K, Buddhiraju S, Fan S 2018 Nano Lett. 18 5224

Google Scholar

Google Scholar

[18] Fiorino A, Zhu L, Thompson D, Mittapally R, Reddy P, Meyhofer E 2018 Nat. Nanotechnol. 13 806

Google Scholar

Google Scholar

[19] Papadakis G T, Buddhiraju S, Zhao Z, Zhao B, Fan S 2020 Nano Lett. 20 1654

Google Scholar

Google Scholar

[20] Datas A, Vaillon R 2019 Appl. Phys. Lett. 114 133501

Google Scholar

Google Scholar

[21] Malitson I H 1963 Appl. Opt. 2 1103

Google Scholar

Google Scholar

[22] Liu X L, Zhang R Z, Zhang Z M 2014 Int. J. Heat Mass Transfer 73 389

Google Scholar

Google Scholar

[23] Biehs S A, Tschikin M, Messina R, Ben-Abdallah P 2013 Appl. Phys. Lett. 102 131106

Google Scholar

Google Scholar

[24] Lim M K, Jin S K, Lee S S, Lee B J 2015 Opt. Express 23 A240

Google Scholar

Google Scholar

[25] Poddubny A, Iorsh I, Belov P, Kivshar Y 2013 Nat. Photonics 7 958

Google Scholar

Google Scholar

[26] Liu X L, Bright T J, Zhang Z M 2014 J. Heat Transfer 136 092703

Google Scholar

Google Scholar

[27] Zhang R Z, Zhang Z M 2017 J. Quant. Spectrosc. Radiat. Transfer 197 132

Google Scholar

Google Scholar

[28] Volokitin A I, Persson B N J 2007 Rev. Mod. Phys. 79 1291

Google Scholar

Google Scholar

[29] Volokitin A I, Persson B N J 1999 J. Phys. Condens. Matter 11 345

Google Scholar

Google Scholar

[30] Vaillon R, Robin L, Muresan C, Ménézo C 2006 Int. J. Heat Mass Transfer 49 4454

Google Scholar

Google Scholar

[31] Guo Y, Newman W, Cortes C L, Jacob Z 2012 ADOP 2012 1

[32] Francoeur M, Vaillon R, Mengüç M P 2011 IEEE Trans. Energy Convers. 26 686

Google Scholar

Google Scholar

[33] Lang S, Tschikin M, Biehs S A, Petrov A Y, Eich M 2014 Appl. Phys. Lett. 104 121903

Google Scholar

Google Scholar

[34] Laroche M, Carminati R, Greffet J 2006 J. Appl. Phys. 100 063704

Google Scholar

Google Scholar

[35] Baldasaro P F, Raynolds J E, Charache G W, DePoy D M, Ballinger C T, Donovan T, Borrego J M 2001 J. Appl. Phys. 89 3319

Google Scholar

Google Scholar

[36] Bright T J, Wang L P, Zhang Z M 2014 J. Heat Transfer 136 062701

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7757

- PDF Downloads: 111

- Cited By: 0

DownLoad:

DownLoad: