-

With the rapid development of photovoltaic technology, crystalline silicon (c-Si) solar cells, as the mainstream photovoltaic devices, have received significant attention due to their excellent performances. In particular, silicon heterojunction (SHJ) solar cells, tunnel oxide passivated contact (TOPCon), and passivated emitter and rear cell (PERC) represent the cutting-edge technologies in c-Si solar cells. The surface passivation layer of crystalline silicon solar cells, as one of the key factors to improve cell performances, has been closely linked to the development of crystalline silicon solar cells. Due to the complex mechanism of passivation layer and the high requirements of experimental research, achieving high quality surface passivation is challenging. In this paper, the key issues and research progress of interface passivation technologies for SHJ, TOPCon, and PERC solar cells are comprehensively reviewed. Firstly, the research progress of key technological breakthrough in SHJ solar cell is reviewed systematically, and the influences of growth conditions and doping layer on the passivation performances of SHJ solar cell are discussed in detail. Secondly, the important strategies and research achievements for improving the passivation performances of TOPCon and PERC solar cells in the past five years are systematically described. Finally, the development trend of passivation layer technology is prospected. This review provides valuable insights for improving future technology and enhancing performance of c-Si solar cells.

[1] Renewables 2023 Analysis and forecasts to 2028, Yasmina A, Ana A B, Piotr B https://www.iea.org/reports/renewables-2023 [2024-9-5]

[2] Renewables 2022 Yasmina A, Heymi B, Trevor C https://www.iea.org/reports/renewables-2022 [2024-9-5]

[3] Singh G K 2013 Energy 53 1

Google Scholar

Google Scholar

[4] Shen W Z, Zhao Y X, Liu F 2022 Front. Energy 16 1

Google Scholar

Google Scholar

[5] Breaking through 24%, Chang J https://www.hengdian.com/zh-cn/news/detail-10754 [2024-9-5]

[6] Allen T G, Bullock J, Yang X B, Javey A, De Wolf S 2019 Nat. Energy 4 914

Google Scholar

Google Scholar

[7] Dullweber T, Schmidt J 2016 IEEE J. Photovolt. 6 1366

Google Scholar

Google Scholar

[8] Rise to 26.89%, jinkosolar https://www.jinkosolar.com/site/newsdetail/1748 [2024-9-5]

[9] Ullah H, Czapp S, Szultka S, Tariq H, Qasim U B, Imran H 2023 Energies 16 715

Google Scholar

Google Scholar

[10] Ma S, Du D X, Ding D, Gao C, Li Z P, Wu X Y, Zou S, Su X, Kong X Y, Liao B, Shen W Z 2024 Sol. Energ. Mat. Sol. C. 275 113024

Google Scholar

Google Scholar

[11] Schmidt J, Peibst R, Brendel R 2018 Sol Energ. Mat. Sol. C. 187 39

Google Scholar

Google Scholar

[12] Global News At 26.81%, LONGi https://www.longi.com/en/news/propelling-the-transformation/ [2024-9-5]

[13] Taguchi M, Yano, A, Tohoda S, Matsuyama K, Nakamura Y, Nishiwaki T, Fujita K, Maruyama E 2014 IEEE J. Photovolt. 4 96

Google Scholar

Google Scholar

[14] Masuko K, Shigematsu M, Hashiguchi T, Fujishima D, Kai M, Yoshimura N, Yamaguchi T, Ichihashi Y, Mishima T, Matsubara N, Yamanishi T, Takahama T, Taguchi M, Maruyama E, Okamoto S 2014 IEEE J. Photovolt. 4 1433

Google Scholar

Google Scholar

[15] Adachi D, Hernández J L, Yamamoto K 2015 Appl. Phys. Lett. 107 233506

Google Scholar

Google Scholar

[16] Haschke J, Dupré O, Boccard M, Ballif C 2018 Sol. Energ. Mat. Sol. C. 187 140

Google Scholar

Google Scholar

[17] 陈剑辉, 杨静, 沈艳娇, 李锋, 陈静伟, 刘海旭, 许颖, 麦耀华 2015 64 198801

Google Scholar

Google Scholar

Chen J H, Yang J, Shen Y J, Li F, Chen J W, Liu H X, Xu Y, Mai Y H 2015 Acta Phys. Sin. 64 198801

Google Scholar

Google Scholar

[18] Schuttauf J W A, van der Werf K H M, Kielen I M, Kielen I M, van Sark W G J H M, Rath J K, Schropp R E I 2011 Appl. Phys. Lett. 98 153514

Google Scholar

Google Scholar

[19] 肖有鹏, 王涛, 魏秀琴, 周浪 2017 66 108801

Google Scholar

Google Scholar

Xiao Y P, Wang T, Wei X Q, Zhou L 2017 Acta Phys. Sin. 66 108801

Google Scholar

Google Scholar

[20] Kerr M J, Cuevas A, Sinton R A 2002 J. Appl. Phys. 91 399

Google Scholar

Google Scholar

[21] Nagel H, Berge C, Aberle A G 1999 J. Appl. Phys. 86 6218

Google Scholar

Google Scholar

[22] Panigrahi J, Komarala V K 2021 J. Non-Cryst. Solids 574 121166

Google Scholar

Google Scholar

[23] Shi C H, Shi J J, Guan Z S, Ge J 2023 Materials 16 3144

Google Scholar

Google Scholar

[24] 沈文忠, 高超, 李正平 2023 钙钛矿/晶硅异质结叠层太阳电池 (北京: 科学出版社)第45页

Shen W Z, Gao C, Li Z P 2023 Perovskite/Silicon-Heterojunction Tandem Solar Cells (Beijing: Science Press) p45

[25] Tanaka M, Taguchi M, Matsuyama T, Sawada T, Tsuda S, NakanoS, Hanafusa H, Kuwano Y 1992 Jpn. J. Appl. Phys. 31 3518

Google Scholar

Google Scholar

[26] De Wolf S, Kondo M 2007 Appl. Phys. Lett. 90 042111

Google Scholar

Google Scholar

[27] Chu Y H, Lee C C, Chang T H, Chang S Y, Chang J Y, Li T, Chen I C 2014 Thin Solid Films 570 591

Google Scholar

Google Scholar

[28] Sriraman S, Agarwal S, Aydil E S, Maroudas D 2002 Nature 418 62

Google Scholar

Google Scholar

[29] Liu W, Zhang L, Chen R, Meng F, Guo W, Bao J, Liu Z 2016 J. Appl. Phys. 120 175301

Google Scholar

Google Scholar

[30] Wronski C R, Collins R W, Pearce J M, Koval R J, Ferlauto A S, Ferreira G M, Chen C 2002 NREL/SR 520 32692

Google Scholar

Google Scholar

[31] Wang T H, Iwaniczko E, Page M R, Levi D H, Yan Y, Branz H M, Wang Q 2006 Thin Solid Films 501 284

Google Scholar

Google Scholar

[32] Ruan T Y, Qub M H, Qu X L, Ru X N, Wang J Q, He Y C, Zheng K, Lin B H H F, Xu X X, Zhang Y Z, Yan H 2020 Thin Solid Films 711 138305

Google Scholar

Google Scholar

[33] Lee K S, Yeon C B, Yun S J, Jung K H, Lima J W 2014 ECS Solid State Letters 3 33

Google Scholar

Google Scholar

[34] Zeng Q G, Li L W, Meng H C, Wu X Y, Wei X Q, Zhou L 2024 J Mater. Sci: Mater. Electron. 35 476

Google Scholar

Google Scholar

[35] Peng C W, He C R, Wu H F, Huang S, Yu C, Su X D, Zou S 2024 Sol. Energ. Mat. Sol. C 273 112952

Google Scholar

Google Scholar

[36] Jiang K, Yang Y H, Yan Z, Huang S L, Li X D, Li Z F, Zhou Y N, Zhang L P, Meng F Y, Liu Z X, Liu W Z 2022 Sol. Energ. Mat. Sol. C 243 111801

Google Scholar

Google Scholar

[37] Soman A, Das U K, Hegedus S S 2023 ACS Appl. Electron. Mater. 5 803

Google Scholar

Google Scholar

[38] Morales-Vilches A B, Wang E C, Henschel T, Kubicki M, Cruz A, Janke S, Korte L, Schlatmann R, Stannowski B 2020 Phys. Status. Solidi. A 217 1900518

Google Scholar

Google Scholar

[39] Ru X N, Qu M H, Wang J Q, Ruan T Y, Yang M, Peng F G, Long W, Zheng K, Yan H, Xu X X 2020 Sol. Energ. Mat. Sol. C. 215 110643

Google Scholar

Google Scholar

[40] Liu C S, Wu C Y, Chen I W, Lee H C, Hong L S 2013 Prog. Photovolt: Res. Appl. 21 326

Google Scholar

Google Scholar

[41] Page M R, Iwaniczko E, Xu Y Q, Roybal L, Hasoon F, Wang Q, Crandall R S 2011 Thin Solid Films 519 4527

Google Scholar

Google Scholar

[42] He J, Li W, Wang Y, Mu J L, An K, Chou X J 2015 Mater. Lett. 161 175

Google Scholar

Google Scholar

[43] Pandey A, Bhattacharya S, Panigrahi J, Mandal S, Komarala V K 2022 Phys. Status Solidi A 219 2200183

Google Scholar

Google Scholar

[44] Nunomura1 S, Sakata I, Misawa T, Kawai S, Kamataki K, Koga K, Shiratani M 2023 Jpn. J. Appl. Phys. 62 SL1027

Google Scholar

Google Scholar

[45] Macco B, Melskens J, Podraza N J, Arts K, Pugh C, Thomas O, Kessels W M M 2017 J. Appl. Phys 122 035302

Google Scholar

Google Scholar

[46] Wu Z P, Zhang L P, Chen R F, Liu W Z, Li Z F, Meng F Y, Liu Z X 2019 Appl. Surf. Sci. 475 504

Google Scholar

Google Scholar

[47] Tomasil A, Sahli F, Fannil L, Seif J P, de Nicolas S M, Holm N, Geissblihler J, Paviet-Salomon B, Loper P, Nicolay S, De Wolf S, Ballif C 2016 IEEE. J. Photovolt. 6 17

Google Scholar

Google Scholar

[48] Morell G, Katiyar R S, Weisz S Z, Jia H, Shinar J, Balberg I 1995 J. Appl. Phys. 78 5120

Google Scholar

Google Scholar

[49] Iqbal Z, Veprek S 1982 J. Phys. C: Solid State Phys. 15 377

Google Scholar

Google Scholar

[50] De Wolf S, Kondo M 2007 Appl. Phys. Lett. 91 112109

Google Scholar

Google Scholar

[51] Biegelsen D K, Street R A, Tsai CC, Knights J C 1979 Phys. Rev. B 20 4839

Google Scholar

Google Scholar

[52] Beyer W, Wagner H 1983 J. Non-Cryst. Solids 59 161

Google Scholar

Google Scholar

[53] Yabumoto N, Saito K, Morita M, Ohmi T 1991 Jpn. J. Appl. Phys. 30 L419

Google Scholar

Google Scholar

[54] Beyer W, Wagner H, Chevallier J, Reichelt K 1982 90 145

[55] Beyer W 1991 Phys. Rev. B Condens. Matter 170 105

Google Scholar

Google Scholar

[56] Beyer W, Wagner H, Mell H 1981 Solid State. Commun. 39 375

Google Scholar

Google Scholar

[57] Street R A, Tsai CC, Kakalios J, Jackson W B 1987 Philos. Mag. B 56 305

Google Scholar

Google Scholar

[58] Nasuno Y, Kondo M, Matsuda A, Fukuhori H, Kanemitsu Y 2002 Appl. Phys. Lett. 81 3155

Google Scholar

Google Scholar

[59] Dreon J, Jeangros Q, Cattin J, Haschke J, Antognini L, Ballif C, Boccard M 2020 Nano Energy 70 104495

Google Scholar

Google Scholar

[60] Holman Z C, Descoeudres A, Barraud L, Fernandez F Z, Sei J P, De Wolf S, Ballif C 2012 IEEE J. Photovolt. 2 7

Google Scholar

Google Scholar

[61] Ding K N, Aeberhard U, Finger F, Rau U 2013 J. Appl. Phys. 113 134501

Google Scholar

Google Scholar

[62] Boccard M, Holman Z C 2015 J. Appl. Phys. 118 065704

Google Scholar

Google Scholar

[63] Jiang K, Liu W Z, Yang Y H, Yan Z, Huang S L, Li Z F, Li X D, Zhang L P, Liu Z X 2022 J. Mater. Sci.: Mater. Electron. 33 416

Google Scholar

Google Scholar

[64] Fujiwara H, Kaneko T, Kondo M 2007 Appl. Phys. Lett. 91 133508

Google Scholar

Google Scholar

[65] Mews M, Liebhaber M, Rech B, Korte L 2015 Appl. Phys. Lett. 107 013902

Google Scholar

Google Scholar

[66] Wu Z P, Zhang L P, Liu W Z, Chen R F, Li Z F, Meng F Y, Liu Z X 2020 J. Mater. Sci. Mater. El. 31 9468

Google Scholar

Google Scholar

[67] Wen L L, Zhao L, Wang G H, Jia X J, Xu X H, Qu S Y, Li X T, Zhang X Y, Xin K, Xiao J H, Wang W J 2023 Sol. Energ. Mat. Sol. C. 258 112429

Google Scholar

Google Scholar

[68] Wu X Y, Wang X T, Lv R R, Song H, Yu Y J, Sen C D, Cheng Y H, Khan M U, Ciesla A, Xu T, Zhang G C, Hoex B 2025 Sol. Energ. Mat. Sol. C. 282 113325

Google Scholar

Google Scholar

[69] Sinha A, Qian J D, Moffitt S L, Hurst K, Terwilliger K, Miller D C, Schelhas L T, Hacke P 2023 Prog. Photovoltaics 31 36

Google Scholar

Google Scholar

[70] Yang L, Hu Z C, He Q Y, Liu Z K, Zeng Y H, Yang L F, Yu X G, Yang D R 2024 Sol. Energ. Mat. Sol. C 275 113022

Google Scholar

Google Scholar

[71] Yang J L, Tang Y H, Zhou C L, Chen S N, Cheng S Z, Wang L C, Zhou S, Jia X J, Wang W J, Xu X H, Xiao J H, Wei W W 2024 Sol. Energ. Mat. Sol. C 276 113062

Google Scholar

Google Scholar

[72] Feldmann F, Bivour M, Reichel C, Hermle M, Glunz S W 2014 Sol. Energ. Mat. Sol. C 120 270

Google Scholar

Google Scholar

[73] Padi S P, Khokhar M Q, Chowdhury S, Cho E C, Yi J 2021 Trans. Electr. Electro. 22 557

Google Scholar

Google Scholar

[74] Wang Q Q, Wu W P, Yuan N Y, Li Y L, Zhang Y, Ding J N 2020 Sol. Energ. Mat. Sol. C 208 110423

Google Scholar

Google Scholar

[75] Huang J B, Zhao Z C, Li M, Chen J, Zhou X R, Deng X X, Li B, Shen K L, Cheng Q Y, Cai X W 2023 Sol. Energ. Mat. Sol. C. 260 112489

Google Scholar

Google Scholar

[76] Xing H Y, Liu Z K, Yang Z H, Liao M D, Wu Q Q, Lin N, Liu W, Ding C F, Zeng Y H, Yan B J, Ye J C 2023 Sol. Energ. Mat. Sol. C 257 112354

Google Scholar

Google Scholar

[77] Yang L, Ou Y L, Lv X, Lin N, Zeng Y H, Hu Z C, Yuan S, Ye J C, Yu X G, Yang D R 2024 Energy Environ. Mater. 7 e12795

Google Scholar

Google Scholar

[78] 钱金忠, 左克祥, 王安, 杜东亚, 凡金星, 高纪凡 2023 太阳能 353 9

Google Scholar

Google Scholar

Qian J Z, Zuo K X, Wang A, Du D Y, Fan J X, Gao J F 2023 Solar Energy 353 9

Google Scholar

Google Scholar

[79] Ghosh D K, Das G, Bose S, Mukhopadhyay S, Sengupta A 2024 Energy Technol. 12 2400238

Google Scholar

Google Scholar

[80] Richter A, Benick J, Feldmann F, Fell A, Hermle M, Glunz S W 2017 Sol. Energ. Mat. Sol. C 173 96

Google Scholar

Google Scholar

[81] Yan D, Cuevas A, Phang S P, Wan Y, Macdonald D 2018 Appl. Phys. Lett. 113 061603

Google Scholar

Google Scholar

[82] Richter A, Benick J, Müller R, Feldmann F, Reichel C, Hermle M, Glunz S W 2018 Prog. Photovolt. Res. Appl. 26 579

Google Scholar

Google Scholar

[83] Richter A, Müller R, Benick J, Feldmann F, Steinhauser B, Reichel C, Fell A, Bivour M, Hermle M, Glunz S W 2021 Nat. Energy 6 429

Google Scholar

Google Scholar

[84] Yu H L, Liu W, Du H J, Liu Z K, Liao M D, Song N, Yang Z H, Zeng Y H, Ye J C 2024 Nano Energy 125 109556

Google Scholar

Google Scholar

[85] Ma D, Liu W, Xiao M J, Yang Z H, Liu Z K, Liao M D, Han Q L, Cheng H, Xing H Y, Ding Z T, Yan B J, Wang Y D, Zeng Y H, Ye J C 2022 Sol. Energy 242 1

Google Scholar

Google Scholar

[86] Du H J, Lin Y R, Wang Z X, Liao M D, Liu Z K, Luo X J, Cao Y H, Fu L M, Liu W, Yan B J, Yang Z H, Yuan Z Z, Zeng Y H, Ye J C 2024 Mat. Sci. Semicon. Proc. 170 107969

Google Scholar

Google Scholar

[87] Li W K, Zhou R, Wang Y K, Su Q F, Yang J, Xi M, Liu Y S 2024 Appl. Surf. Sci. 673 160835

Google Scholar

Google Scholar

[88] Wang Q Q, Gu S W, Guo K Y, Peng H, Wu W P, Ding J N 2024 Sol. Energ. Mat. Sol. C. 273 112959

Google Scholar

Google Scholar

[89] Blakers A W, Wang A, Milne A M, Zhao J, Green M A 1989 Appl. Phys. Lett. 55 1363

Google Scholar

Google Scholar

[90] Saint-Cast P, Benick J, Kania D, Weiss L, Hofmann M, Rentsch J, Preu R, Glunz S W 2010 IEEE Electron. Device Lett. 31 695

Google Scholar

Google Scholar

[91] Töfflingera J A, Laadesb A, Leendertza C, Montañeza L M, Kortea L, Stürzebecher U, Sperlichc H P, Recha B 2014 Energy Procedia 55 845

Google Scholar

Google Scholar

[92] Gatz S, Hannebauer H, Hesse R, Werner F, Schmidt A, Dullweber T, Schmidt J, Bothe K, Brendel R 2011 Phys. Status Solidi Rapid Res. Lett. 5 147

Google Scholar

Google Scholar

[93] Kim J, Ju M, Kim Y, Yi J 2022 Mat. Sci. Semicon. Proc. 148 106833

Google Scholar

Google Scholar

[94] Tong R, Zhang S C, Liu D M, Zhang W P, Wang Y T, Liu X F 2021 Sol. Energ. Mat. Sol. C. 231 111319

Google Scholar

Google Scholar

[95] Liu P K, Cheng Y L, Wang L K 2020 Int. J. Photoenergy 2020 6686797

Google Scholar

Google Scholar

[96] Kashyap S, Madan J, Pandey R, Ramanujam J 2022 Opt. Mater. 128 112399

Google Scholar

Google Scholar

[97] Mouri T K, Upadhyaya A, Rohatgi A, Ok Y W, Hua A, Hauschild D, Weinhardt L, Heske C, Upadhyaya V, Rounsaville B, Shafarman W N, Das U K 2023 IEEE 50th Photovoltaic Specialists Conference (PVSC) San Juan, PR, USA, June 11–16, 2023 p1

[98] Jang J S, Kim H S, Karade V C, Park S W, Kim C W, Kim J H 2024 J. Alloys Compd. 970 172691

Google Scholar

Google Scholar

[99] Wei P F, Tong R, Liu X F, Wei Y, Zhang Y A, Liu X, Dai J, Yin H P, Liu D M 2024 Mat. Sci. Semicon. Proc. 170 107947

Google Scholar

Google Scholar

-

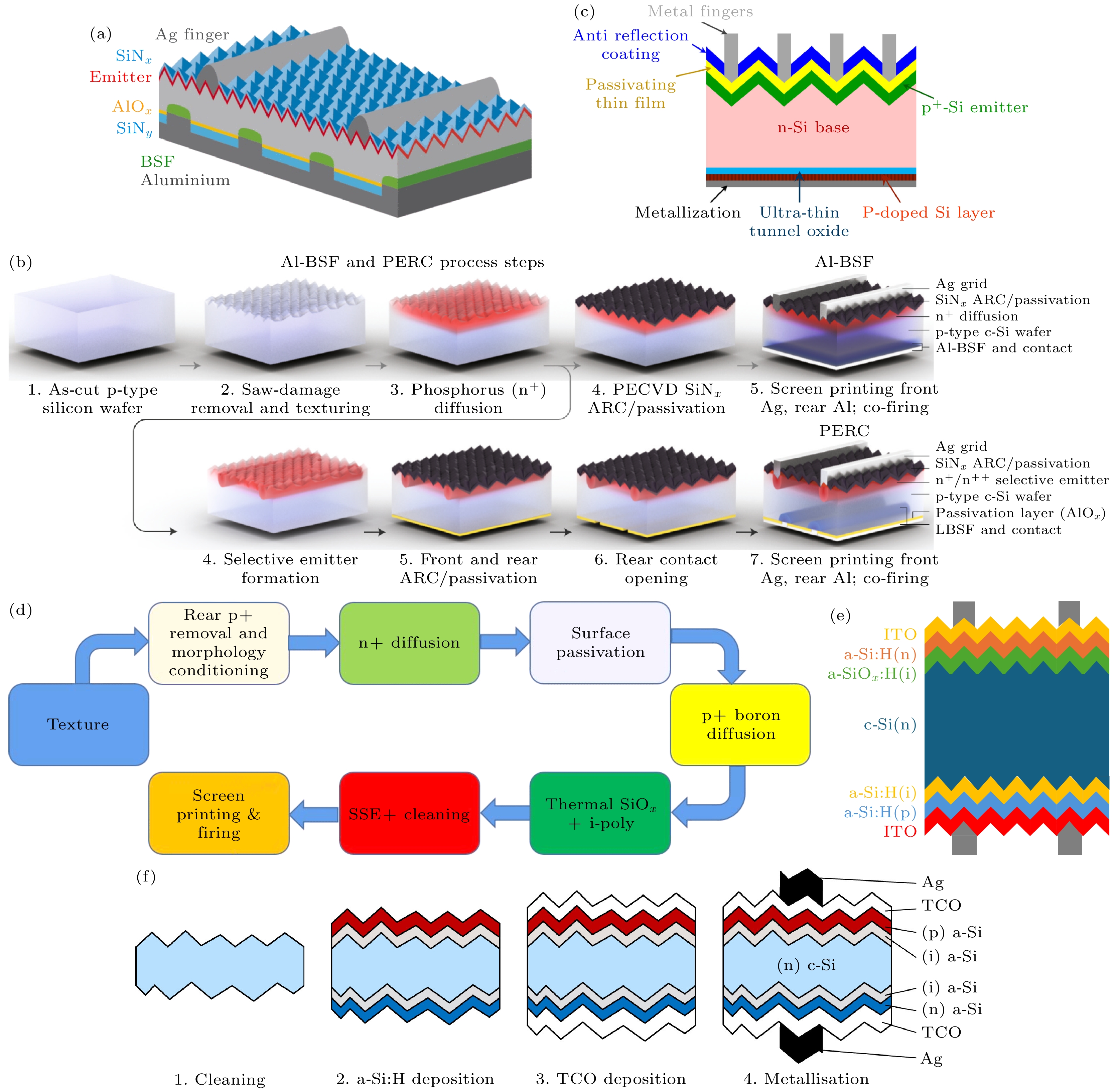

图 1 (a), (b) PERC太阳电池结构[7]和制造流程图[6]; (c), (d) TOPCon太阳电池结构和制造流程图[9]; (e), (f) SHJ太阳电池结构图和制造流程图[16]

Figure 1. (a), (b) PERC solar cell structure[7] and manufacturing process diagram[6]; (c), (d) TOPCon solar cell structure and manufacturing process diagram[9]; (e), (f) SHJ solar cell structure diagram and manufacturing process diagram[16].

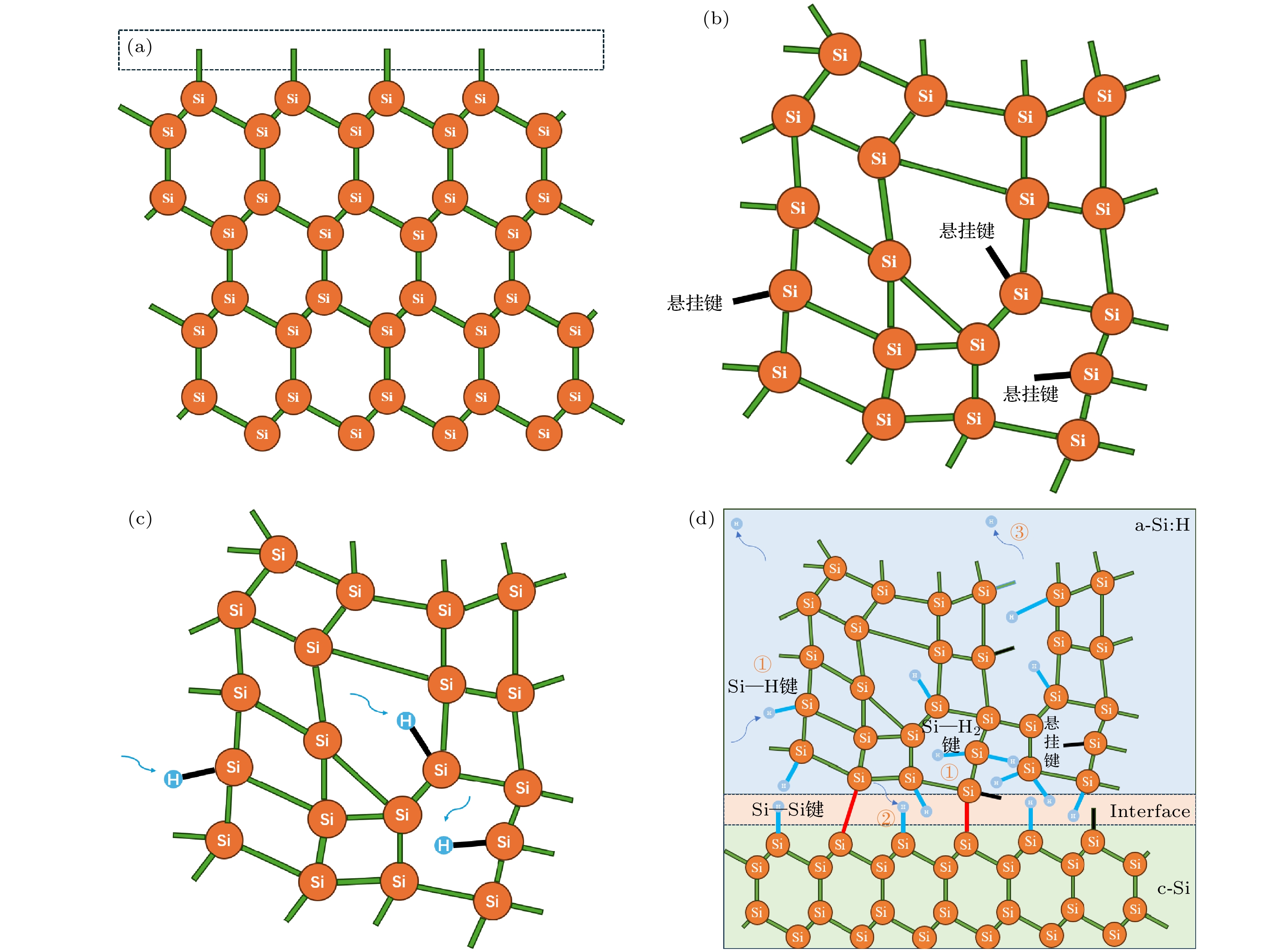

图 2 (a) c-Si材料原子结构示意图, $ \left\langle{110}\right\rangle $晶向[24]; (b) a-Si材料原子结构示意图[24]; (c) a-Si:H材料原子结构示意图[24]; (d) a-Si:H钝化c-Si结构示意图

Figure 2. (a) Schematic diagram of c-Si material atomic structure, $ \left\langle{110}\right\rangle $ crystal orientation[24]; (b) schematic diagram of a-Si material atomic structure[24]; (c) schematic diagram of a-Si:H material atomic structure[24]; (d) schematic diagram of a-Si:H passivated c-Si structure.

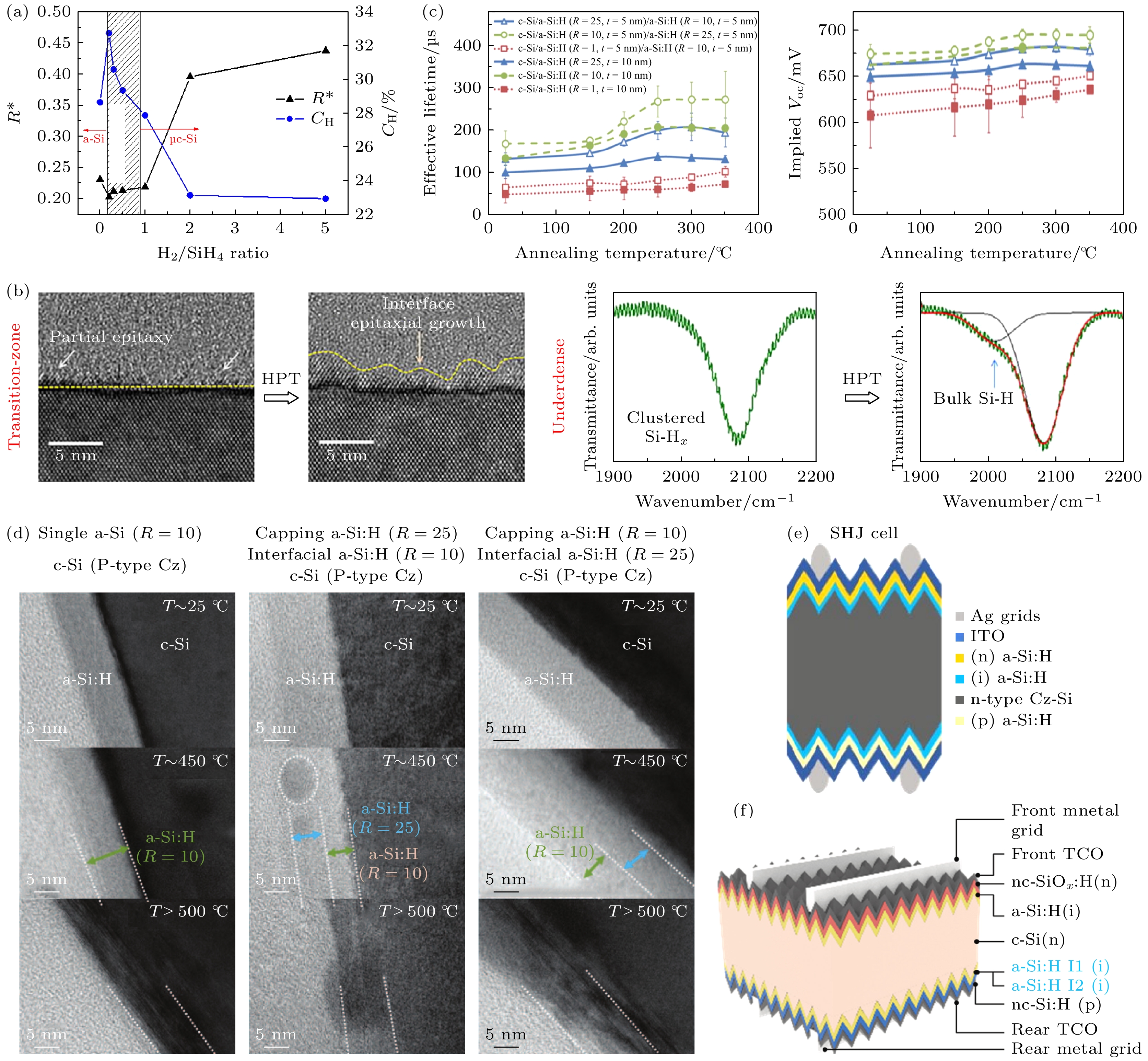

图 3 (a) 薄膜的R*和CH随氢稀释比RH ($ {R_{\text{H}}} = {{{f_{{{\text{H}}_2}}}} {/} {{f_{{\text{Si}}{{\text{H}}_4}}}}} $)的变化, 灰色区域是非晶-微晶过渡区[27]; (b) HPT前后的过渡区的i-a-Si:H与c-Si(n)的交界面的HR-TEM图像, 以及HPT前后的低密度的本征非晶硅的傅里叶红外光谱[29]; (c) 对于各种a-Si:H钝化膜采用连续热退火工艺(Δn = 1015 cm–3)的平均有效τeff和iVoc[33]; (d) 不同T和RH下的单、双层i-a-Si:H结构的TEM图像[33]; (e) 单层钝化的SHJ太阳电池结构图[34]; (f)双层钝化的SHJ太阳电池结构图[35]

Figure 3. (a) Changes of microstructural factor (R*) and hydrogen content (CH) of the film with hydrogen dilution ratio $ ({R_{\text{H}}} = {{{f_{{{\text{H}}_2}}}} {/} {{f_{{\text{Si}}{{\text{H}}_4}}}}}) $, where the gray area represents the amorphous-microcrystalline transition region[27]; (b) HR-TEM images of the interface between i-a-Si and c-Si in the transition zone before and after HPT, as well as Fourier transform infrared spectra of low-density intrinsic amorphous silicon before and after HPT[29]; (c) the average effective τeff and iVoc of various a-Si:H passivation films using continuous thermal annealing process (Δn =1015 cm–3)[33]; (d) TEM images of single-layer and double-layer i-a-Si:H structures at various T and RH levels[33]; (e) structure diagram of SHJ solar cell with single-layer passivation[34]; (f) structure diagram of SHJ solar cell with double-layer passivation[35].

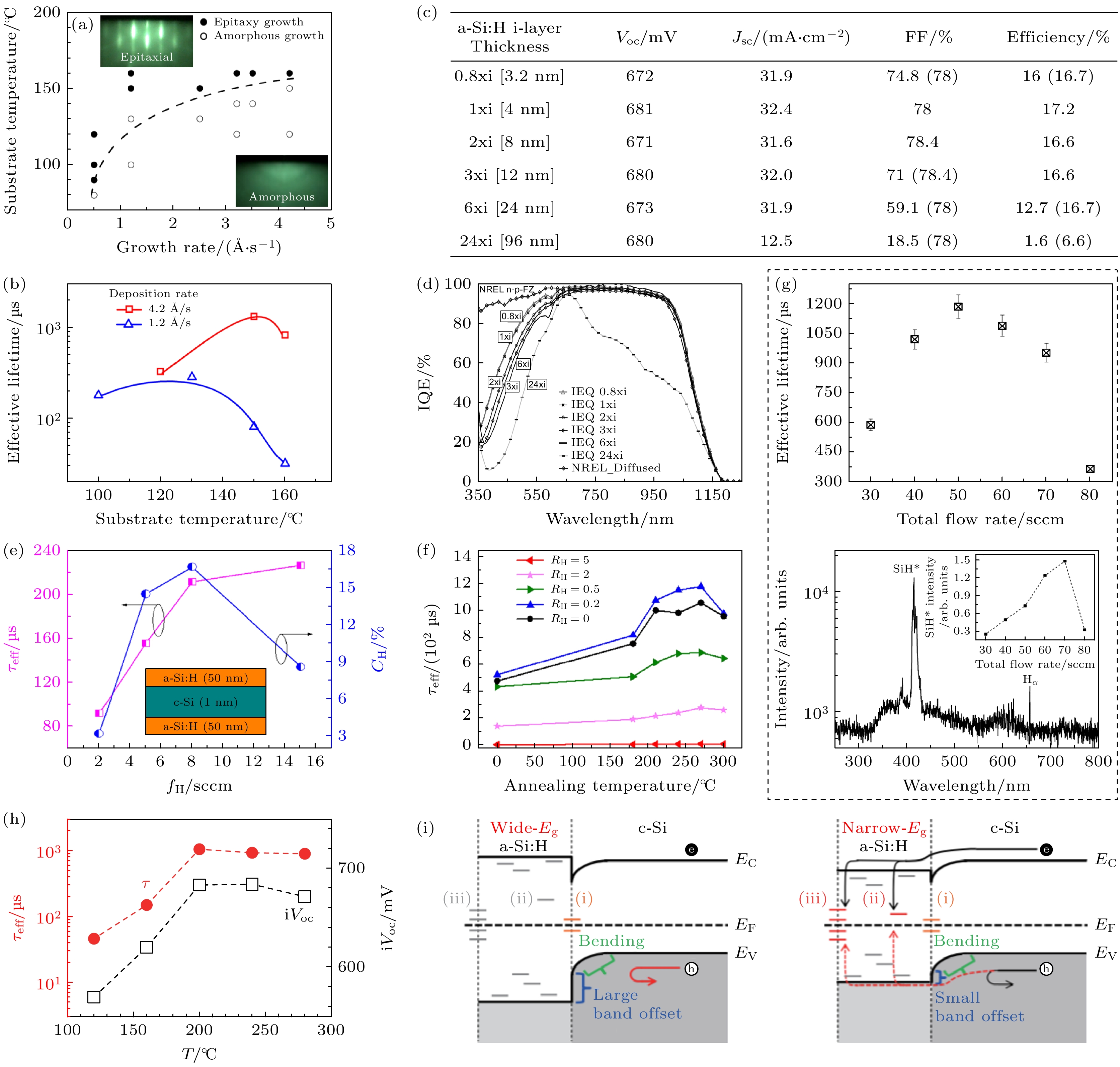

图 4 (a) 不同沉积速率的i-a-Si:H相变为c-Si的临界温度[40]; (b)两种沉积速率下不同衬底温度的有效τeff[40]; (c) 不同i层厚度条件下的I-V性能[41]; (d)不同i层厚度的SHJ太阳电池的内量子效率(IQE)图, 其中参考电池为p型扩散结电池[41]; (e) 不同氢气流量(fH)下的τeff和CH, 插图显示了钝化结构[42]; (f) 不同RH下i-a-Si:H钝化c-Si的有效τeff, 且τeff随退火温度变化[27]; (g) 上图为不同FR下i-a-Si:H层钝化c-Si的τeff, 下图为30 cm/min (标准状况)的FR放电的光学发射光谱(OES). 插图为在不同气体FR下的SiH*的积分强度[43]; (h) 不同衬底温度T下的τeff和iVoc[44]; (i) c-Si/a-Si:H界面能带图和载流子动力学示意图, 左图和右图分别对应宽带隙(Eg)的a-Si:H和窄带隙的a-Si:H[44]

Figure 4. (a) Critical temperatures for the phase transition from i-a-Si:H to c-Si at different deposition rates[40]; (b) effective τeff at various substrate temperatures for two deposition rates[40]; (c) I-V performance under different i-layer thicknesses[41]; (d) internal quantum efficiency (IQE) maps of SHJ solar cells with various i-layer thicknesses, with a reference cell being a p-type diffused junction cell[41]; (e) τeff and CH under different hydrogen flow rates (fH), inset showing the passivation structure[42]; (f) effective τeff for i-a-Si:H passivating c-Si under different RH, with τeff varying with annealing temperature[27]; (g) τeff of c-Si passivated by i-a-Si:H layers at different FR (up), optical emission spectrum (OES) spectrum of FR discharge at 30 cm/min under standard temperature and pressure (down), the inset shows the integrated intensity of SiH* under different FR[43]; (h) τeff and iVoc at various substrate temperatures T[44]; (i) energy band diagram and carrier dynamics schematic at the c-Si/a-Si:H interface, with the left and right figures corresponding to wide bandgap (Eg) a-Si:H and narrow bandgap a-Si:H, respectively[44].

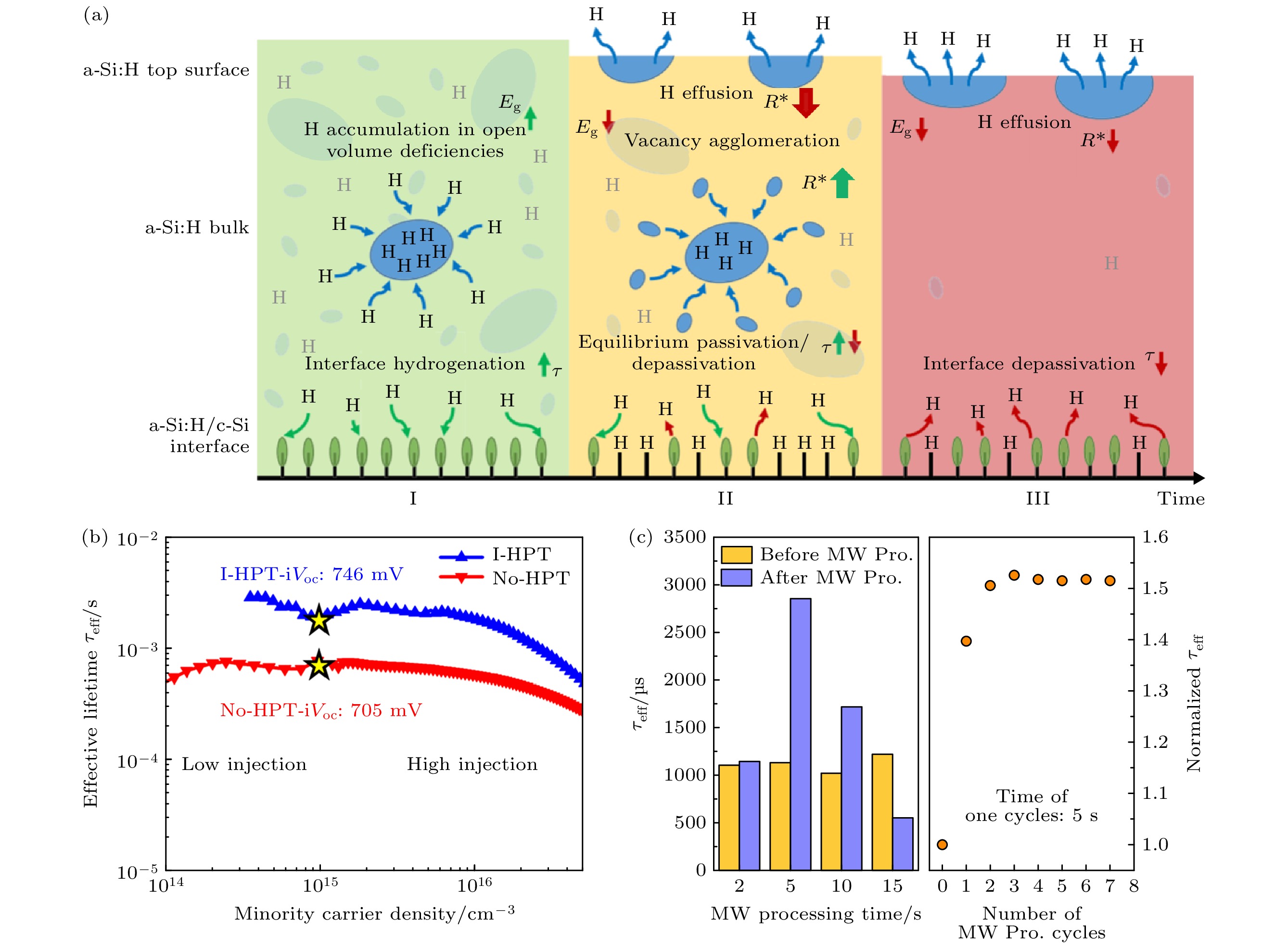

图 5 (a) 在退火过程中a-Si:H基体内部微观变化的3个阶段(I, II, III)示意图, 每个阶段分为3个部分, 分别为c-Si/a-Si:H界面、a-Si:H膜的基体内部和a-Si:H表面处, 且c-Si/a-Si:H界面处的椭圆体表示未钝化的悬挂键[45]; (b) 不同注入水平下, 有I-HPT和无HPT的有效寿命τeff的比较[37]; (c) 左图为微波处理的前后τeff的变化, 右图为归一化τeff与微波处理周期数的关系[34]

Figure 5. (a) Schematic illustration of three stages (I, II, III) of microstructural changes within the a-Si:H matrix during annealing, each stage divided into three parts: c-Si/a-Si:H interface, interior of the a-Si:H film, and a-Si:H surface, ellipsoids at the c-Si/a-Si:H interface represent unpassivated dangling bonds[45]; (b) comparison of effective lifetimes (τeff) between I-HPT and No-HPT at different injection levels[37]; (c) left: changes in τeff before and after microwave treatment; right: relationship between normalized τeff and the number of microwave treatment cycles[34].

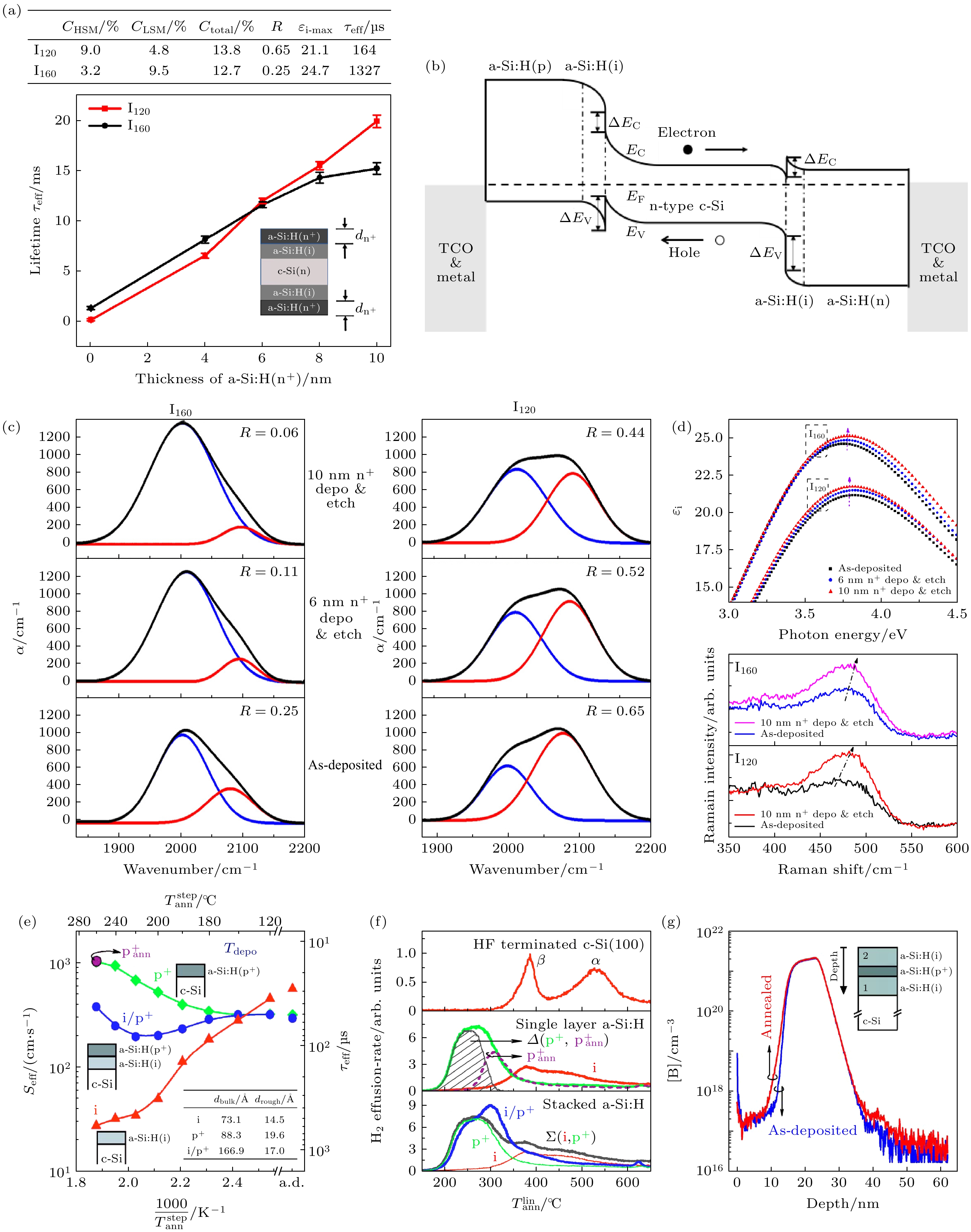

图 6 (a) 用i-a-Si:H/n-a-Si:H钝化的c-Si(n)的τeff值与n-a-Si:H厚度的关系[46]; (b) n型SHJ太阳电池能带图[23]; (c) 左图对应于10 nm厚度的致密i-a-Si:H, 分别被0, 6和10 nm厚度的n-a-Si:H沉积后的傅里叶红外光谱(FTIR), 右图为对应于10 nm厚度的低密度i-a-Si:H, 分别被0, 6和10 nm厚度的n-a-Si:H沉积后的FTIR[46]; (d) 上图为在不同厚度下n-a-Si:H沉积过程中, 两种密度的i-a-Si:H的介电函数虚部的强度, 下图为拉曼强度的变化[46]; (e) 分步退火温度对钝化质量的影响, 由在Fz-Si(n)表面上所沉积的本征和掺杂a-Si:H薄膜的有效表面复合速率(Seff)和τeff表示[50]; (f)线性梯度退火对a-Si:H薄膜中H2逸出率的影响, 上方图为c-Si表面的H2逸出率数据; 中间图为单层a-Si:H薄膜的H2逸出率数据, 下方图为堆叠膜的H2逸出率数据[50]; (g) 测试结构的深度与硼浓度的关系, 插图为测试所用结构, 且退火条件与图(e)的条件相同[50]

Figure 6. (a) Relationship between the τeff value of c-Si(n) passivated with i-a-Si:H/n-a-Si:H and the thickness of n-a-Si:H[46]; (b) energy band diagram of an n-type SHJ solar cell[23]; (c) Fourier transform infrared spectroscopy (FTIR) spectra of 10 nm thick dense i-a-Si:H deposited with 0, 6, and 10 nm thick n-a-Si:H, respectively (left), FTIR spectra of 10 nm thick low-density i-a-Si:H deposited with 0, 6, and 10 nm thick n-a-Si:H, respectively (right); (d) intensity of the imaginary part of the dielectric function of two densities of i-a-Si:H during n-a-Si:H deposition at various thicknesses (up), changes in Raman intensity (down)[46]; (e) impact of stepwise annealing temperatures on passivation quality, represented by the effective surface recombination velocity (Seff) and τeff of intrinsic and doped a-Si:H films deposited on Fz-Si(n) surfaces; (f) influence of linear gradient annealing on the H2 evolution rate in a-Si:H films, with upper panel showing H2 evolution rate data on c-Si surfaces, middle panel for single-layer a-Si:H films, and lower panel for stacked films; (g) depth profile of boron concentration in the tested structure shown, with the inset illustrating the tested structure used and the annealing conditions identical to those in Fig. (e)[50].

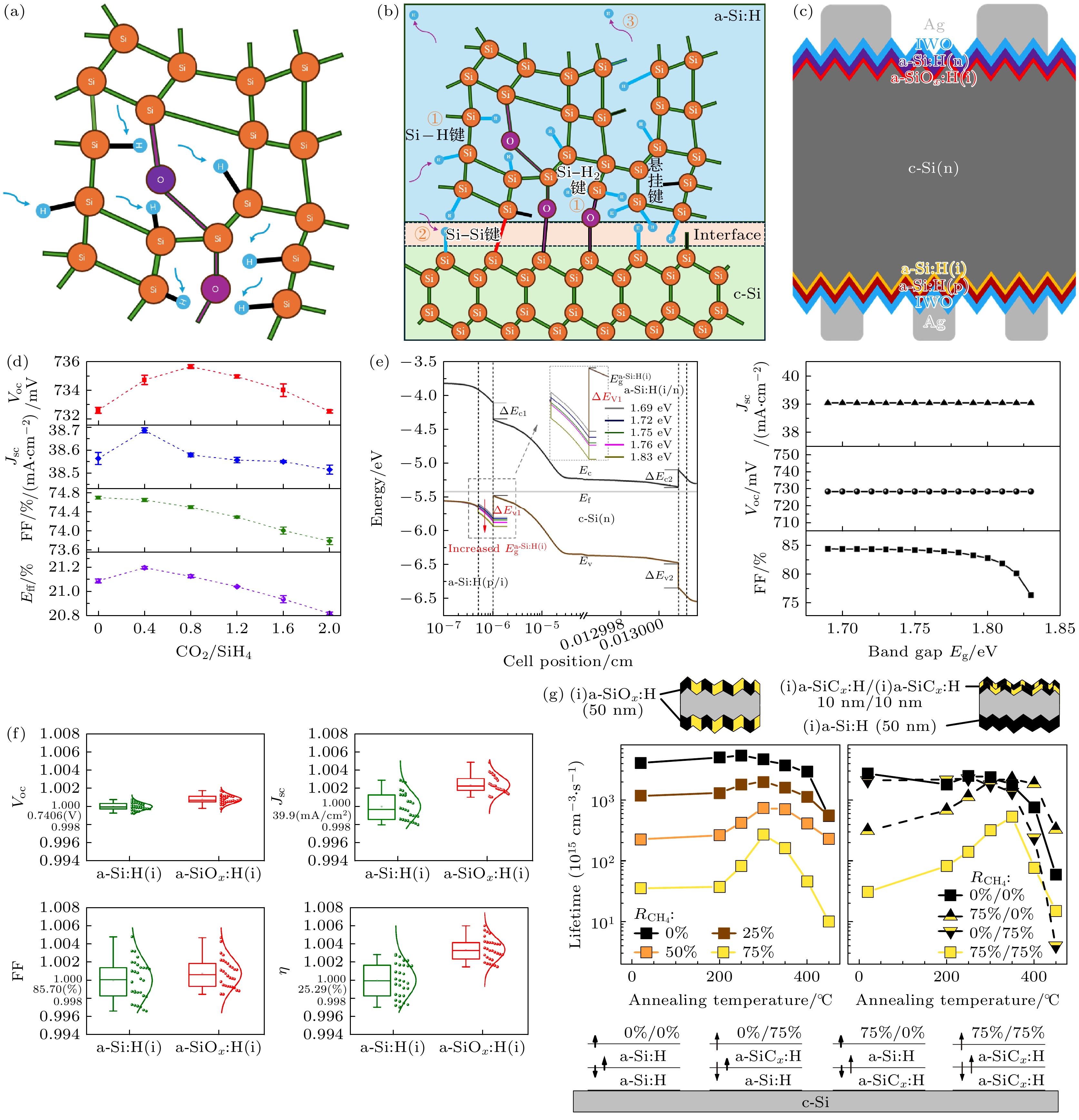

图 7 (a) i-a-SiOx:H材料原子结构示意图; (b) i-a-SiOx:H钝化c-Si的微观结构示意图; (c) i-a-SiOx:H钝化的SHJ太阳电池的器件结构图[63]; (d)不同CO2/SiH4下的SHJ太阳电池的I-V性能[63]; (e)左图为不同Eg下的i-a-Si:H层的SHJ太阳电池的能带图(如虚线所示, ΔEV被放大并作为插图), 右图为不同Eg对SHJ电池的Jsc, Voc和FF的影响[66]; (f)优化后的3层a- SiOx:H (i0, i1, i2) 的SHJ太阳电池的I-V性能与未优化a-Si:H (i0, i1, i2) 的SHJ太阳电池的I-V性能的比较[67]; (g) 连续20 min退火后c-Si的有效τeff, 所述的钝化结构左侧图为两侧分别沉积不同$ {R_{{\text{C}}{{\text{H}}_{4}}}} $($ {R_{{\text{C}}{{\text{H}}_{4}}}} = {{{f_{{\text{C}}{{\text{H}}_{4}}}}} {/} {\left( {{f_{{\text{C}}{{\text{H}}_{4}}}} + {f_{{\text{Si}}{{\text{H}}_{4}}}}} \right)}} $) 的a-SiCx:H膜, a-SiCx:H膜的厚度为50 nm, 右侧图为背面沉积50 nm厚的a-Si:H膜, 正面沉积两层10 nm厚的本征a-SiCx:H堆叠层, 其中RCH4为0%或75%, 下方图为在适中温度下退火的第1阶段时, 这种堆叠层中氢运动的示意图(从左到右分别为0%/0%, 0%/75%, 75%/0%和75%/75%)[62]

Figure 7. (a) Schematic illustration of the atomic structure of i-a-SiOx:H material[63]; (b) schematic diagram of the microstructure of c-Si passivated by i-a-SiOx:H[63]; (c) device structure diagram of the i-a-SiOx:H passivated SHJ solar cell[63]; (d) I-V performance of SHJ solar cells under different CO2/SiH4 ratios[63]; (e) the left figure illustrates the band diagram of the SHJ solar cell with an a-Si:H(i) layer featuring various Eg, where the deviation of the valence band (ΔEV) is zoomed in and presented as an inset (indicated by dashed lines), the right figure demonstrates the simulated impact of different Eg values on the Jsc, Voc, and FF of the SHJ solar cell[66]; (f) comparison of the I-V performance between optimized triple-layer a-SiOx:H (i0, i1, i2) and unoptimized a-Si:H (i0, i1, i2) passivated SHJ solar cells[67]; (g) effective τeff of c-Si after continuous annealing for 20 min. the passivation structures are described as follows, the left figure shows a-SiCx:H films with different $ {R_{{\text{C}}{{\text{H}}_{4}}}} $ ($ {R_{{\text{C}}{{\text{H}}_{4}}}} = {{{f_{{\text{C}}{{\text{H}}_{4}}}}} {/} {\left( {{f_{{\text{C}}{{\text{H}}_{4}}}} + {f_{{\text{Si}}{{\text{H}}_{4}}}}} \right)}} $) deposited on both sides, with a thickness of 50 nm for the a-SiCx:H films. the right figure depicts a 50 nm thick a-Si:H film deposited on the back and a two-layer stack of 10 nm thick intrinsic a-SiCx:H films on the front, with ${R_{{\text{C}}{{\text{H}}_{4}}}} $ set at 0% or 75%, the bottom figure illustrates the schematic of hydrogen movement within this stacked layer during the first stage of annealing at a moderate temperature (from left to right was 0%/0%, 0%/75%, 75%/0%, and 75%/75%)[62].

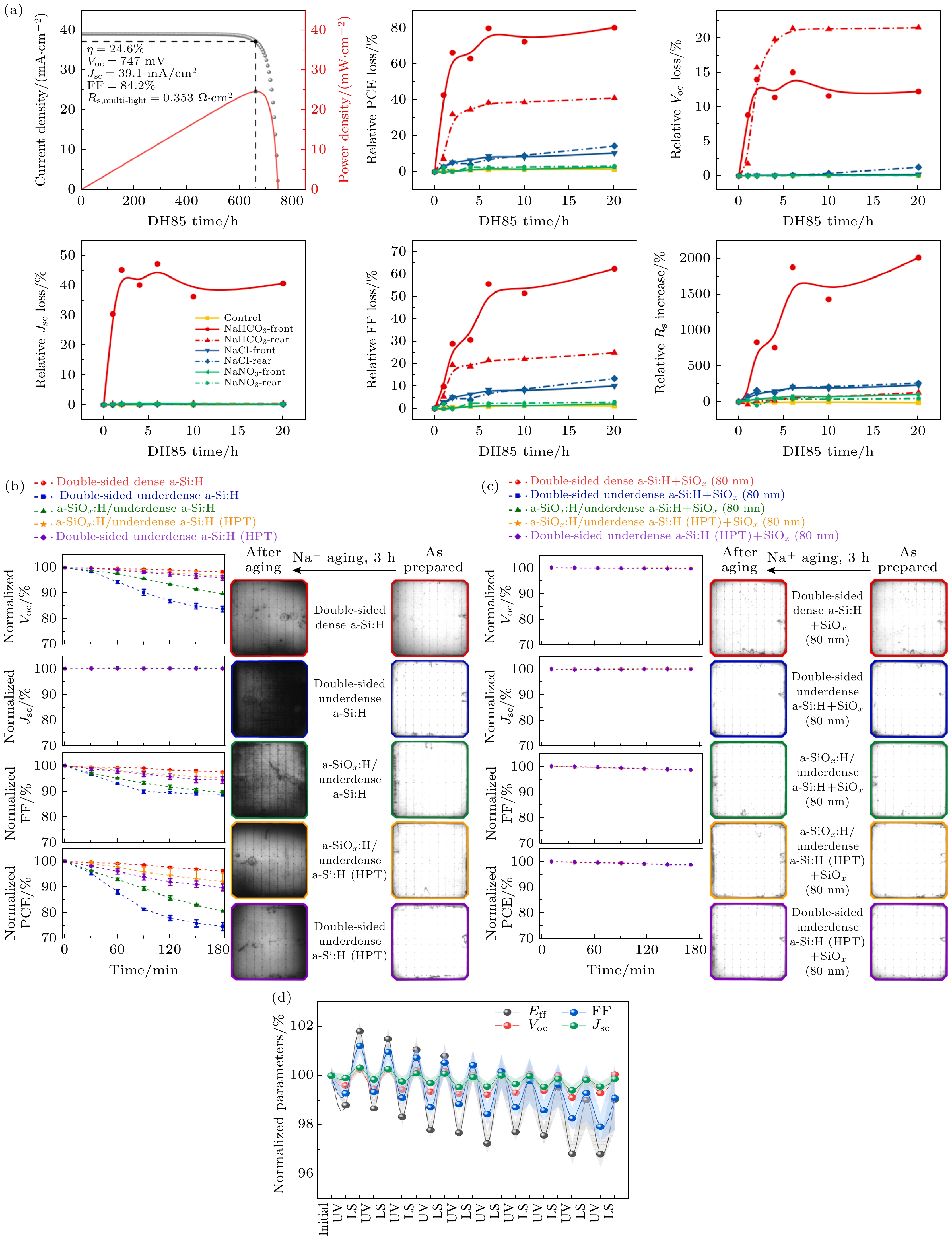

图 8 (a)实验批次中性能最佳的SHJ电池的I-V曲线, 以及随着DH85持续时间变化, 各组电池PCE, Jsc, Voc, FF和Rs的相对变化[68]; (b)钠离子老化试验中裸露的SHJ太阳电池参数退化百分比和钠离子老化试验前后裸露的SHJ太阳电池的光致发光(PL)图像[36]; (c) 在钠离子老化试验中, 带有80 nm厚SiOx层的SHJ太阳电池参数退化百分比和钠离子老化试验前后, 带有80 nm厚SiOx层的SHJ太阳电池的PL图像[36]; (d) SHJ太阳能电池在UV照射和LS处理循环过程中的归一化性能变化[71]

Figure 8. (a) I-V curve of the champion SHJ cell from the experiment batch, and relative changes in PCE, Jsc, Voc, FF, and Rs as a function of DH85 duration for each group[68]; (b) percentage degradation of parameters for exposed SHJ solar cells during sodium ion aging tests, along with Photoluminescence (PL) images of the exposed SHJ solar cells before and after the sodium ion aging tests[36]; (c) percentage degradation of parameters for SHJ solar cells with an 80-nm-thick SiOx layer during sodium ion aging tests, along with PL images of the SHJ solar cells with an 80-nm-thick SiOx layer before and after the sodium ion aging tests[36]; (d) normalized performance changes of SHJ solar cells during UV irradiation and LS treatment cycles[71].

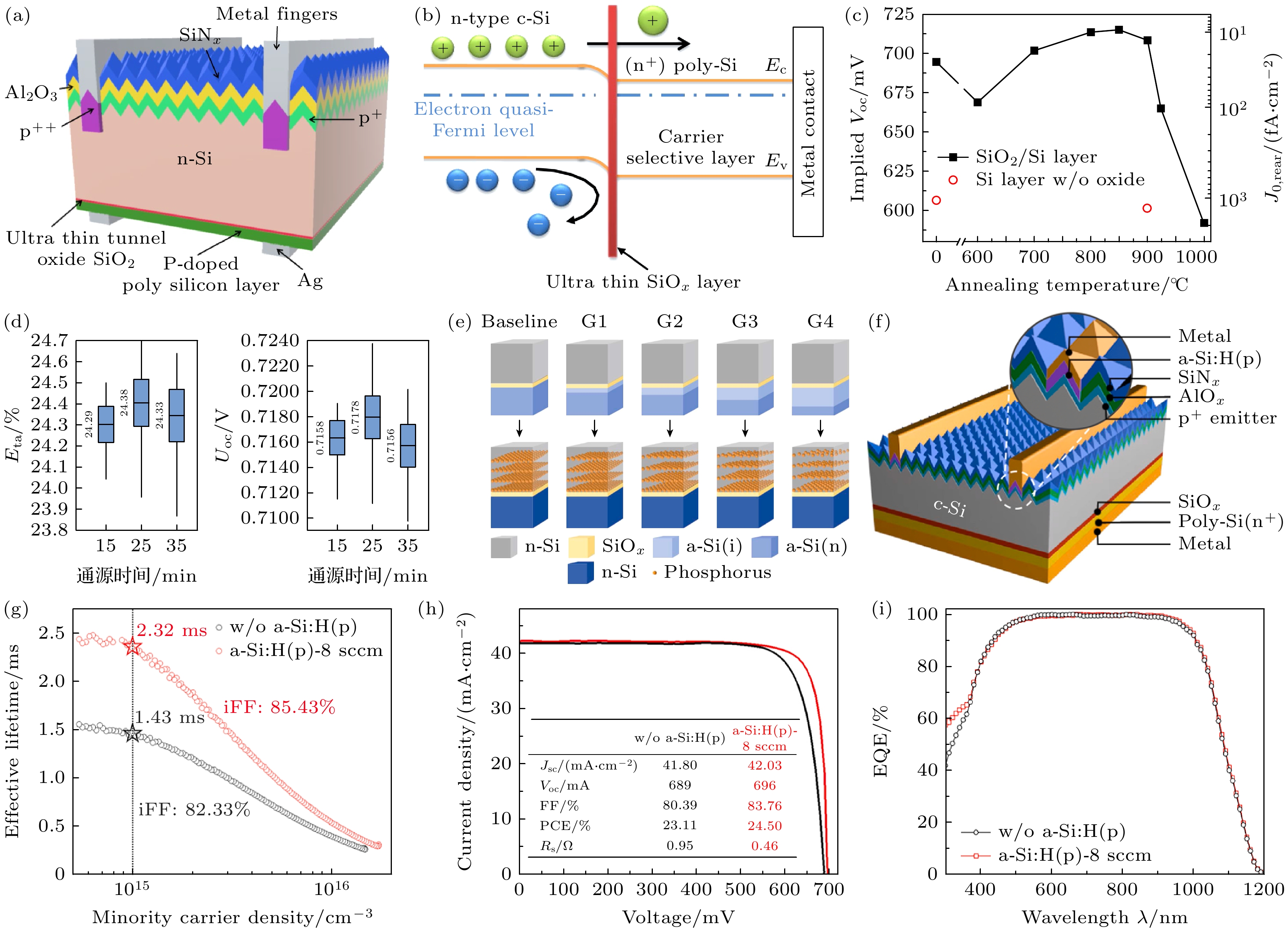

图 9 (a) TOPCon太阳能电池结构图[73]; (b) 载流子通过TOPCon太阳电池隧穿氧化物传输的能带图[73]; (c) TOPCon界面钝化的iVoc作为退火温度的函数, 没有隧穿氧化物(红色圆圈)的样品清楚地强调了隧穿氧化物层对于表面钝化的重要性[72]; (d) 不同通源时间下制备的 TOPCon 太阳电池的Eff和Voc[78]; (e) 不同厚度i-a-Si:H退火过程中磷向Si衬底中的扩散示意图, i-a-Si:H的厚度分别为0, 10, 20, 30和40 nm, 对应于对照组、G1组、G2组、G3组和G4组[10]; (f) 采用p-a-Si:H的TOPCon太阳电池示意图[84]; (g) 采用和未采用p-a-Si:H的TOPCon太阳电池的有效τeff曲线与Δn的函数关系[84]; (h) J-V特性曲线[84]; (i) EQE曲线[84]

Figure 9. (a) Schematic diagram of the TOPCon solar cell structure[73]; (b) energy band diagram illustrating carrier transport through the tunnel oxide in a TOPCon solar cell[73]; (c) the iVoc of TOPCon interface passivation as a function of annealing temperature, the sample without a tunneling oxide layer (red circles) clearly emphasizes the importance of the tunneling oxide layer for surface passivation[72]; (d) the Eff and Voc of TOPCon solar cells prepared under different exposure times to the dopant source[78]; (e) illustration of phosphorus diffusion into the Si substrate during the annealing process for various thicknesses of i-a-Si:H. the thicknesses of i-a-Si:H are 0, 10, 20, 30, and 40 nm, corresponding to the control group, Group G1, Group G2, Group G3, and Group G4, respectively[10]; (f) schematic of a TOPCon solar cell employing p-a-Si:H[84]; (g) effective τeff curves as a function of Δn for TOPCon solar cells with and without p-a-Si:H[84]; (h) J-V characteristic curves[84]; (i) EQE curves[84].

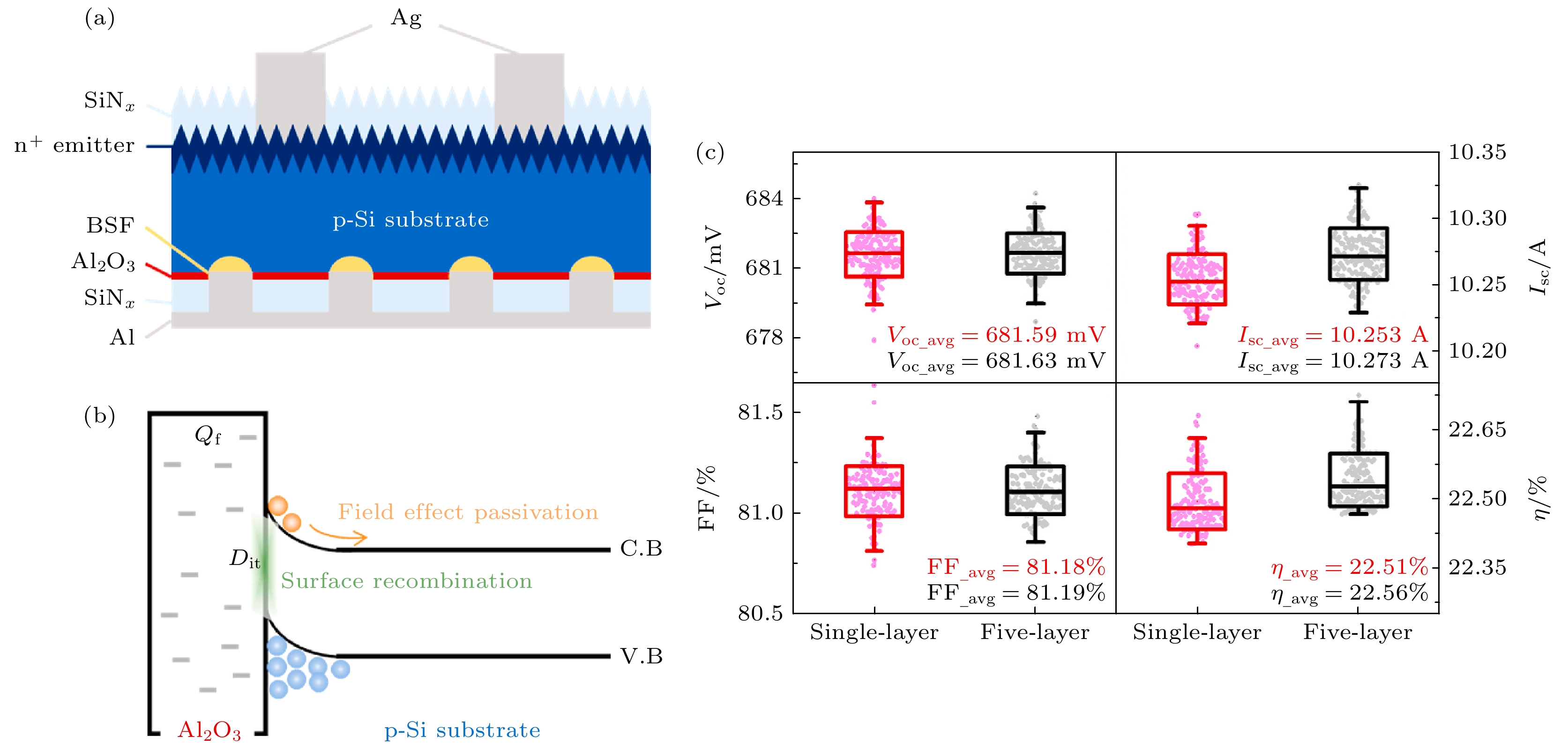

图 10 (a) p型PERC太阳能电池的结构图[93]; (b) 与Al2O3和p-Si衬底相关的钝化机制[93]; (c) 5层和单层SiNx:H薄膜太阳电池的效率比较, 单层SiNx:H膜的厚度为150 nm, 而5层膜的厚度为20/10/10/10/100 nm[94]

Figure 10. (a) Schematic diagrams of structure of p-type PERC solar cell[93]; (b) mechanism of passivation correlated with Al2O3 and p-Si substrate[93]; (c) efficiency comparison for the solar cells with five-layer and single layer SiNx:H films. the thickness of the single-layer SiNx:H film is 150 nm, and the thicknesses for the five-layer films are 20/10/10/10/100 nm[94].

表 1 不同RH的i-a-Si:H薄膜的特征参数[33]

Table 1. Characteristic parameters of i-a-Si:H thin films with different RH[33].

RH SiH4 flow/

sccmH2 flow/

sccmR* τeff/μs iVoc/mV 纯 c-Si — — — 0.98 520 RH = 1 40 40 0.970 8.2 538 RH = 10 40 400 0.143 148.1 668 RH = 25 40 1000 0.076 127.1 661 表 2 具有不同RH的界面层和覆盖层的i-a-Si:H双层钝化性能参数[33]

Table 2. Performance parameters of i-a-Si:H double- layer passivation with interface and cover layers with different RH[33].

双层钝化(c-Si/界面层/覆盖层) τeff/μs iVoc/mV c-Si/i-a-Si:H(RH = 1)/

i-a-Si:H(RH = 10)33.9 606 c-Si/i-a-Si:H(RH = 25)/

i-a-Si:H(RH = 10)138.9 665 c-Si/i-a-Si:H(RH = 10)/

i-a-Si:H(RH = 25)197.6 683 表 3 具有单层和双层钝化结构的SHJ器件性能

Table 3. Performance of SHJ devices with single- and double-layer passivation structures.

表 4 不同SiOx生长方法的器件应用

Table 4. Application of devices with different SiOx growth methods.

表 5 高性能TOPCon太阳电池结构比较[79]

Table 5. Comparison of high performance TOPCon solar cells structures.

c-Si Cell structure Voc/mV Jsc/(mA·cm–2) FF/% η/% Ref. n Metal/SiNx+MgF2/Al2O3/p+-Siemitter/n-c-Si/SiOx/n+-poly Si

layer/Metal(n-TOPCon)724.9 42.5 83.3 25.7 [80] p Metal/SiNx/P-doped emitter/p-c-Si/SiOx/B-doped p-poly Si

layer/Metal(p-TOPCon)701 41.1 79.9 23 [81] p Metal/SiNx-MgF2/Al2O3/p+-Si/p-c-Si/SiOx/ 714.2 42.4 80.8 24.3 [82] p P-doped n-poly Si layer/Metal(TOPCoRE)Metal/SiNx/Al2O3/

B-diffusion FSF/p-c-Si/SiOx/P-doped n-poly Si layer/

Metal (TOPCoRE)732.3 42.05 84.3 26 [83] 表 6 改进TOPCon太阳电池性能的方法

Table 6. Methods for improving TOPCon solar cells performance.

改善方法 Jsc/(mA·cm–2) Voc/mV FF/% η/% Year Refs. 生长两步氧化 41.80 707.0 83.0 24.60 2022 [85] 正面金属电极和硼发射极之间沉积局部p-a-Si:H 42.03 696.0 83.76 24.50 2024 [84] 在钝化层中插入本征非晶硅(i-a-Si:H)层 40.60 715.0 82.30 23.83 2024 [10] 利用管式PECVD制备掺C poly-Si(n+) 40.81 700.4 82.70 23.64 2024 [86] RS-ALD法制备高质量Al2O3薄膜 — 736.3 84.05 25.78 2024 [87] 中温光浸泡工艺 42.10 729.0 84.0 25.80 2024 [88] 表 7 改进PERC太阳电池钝化性能的方法

Table 7. Methods for improving passivation performance of PERC solar cells.

改善方法 Jsc/(mA·cm–2) Voc/mV FF/% η/% Year Ref. 利用臭氧氧化制备氧化铝层 37.89 590 75.70 16.92 2020 [95] 5层 SiNx:H 薄膜 10.273 681.63 81.19 22.56 2021 [94] 背面以 HfO2 作为钝化材料钝化 39.67 662.9 79.26 20.84 2022 [93] 离子注入SiOx Ny:H 40.80 686 81.54 22.80 2022 [96] 发射极表面通过硫化氢(H2S)气体反应钝化 40.03 649 76.79 19.93 2023 [97] 利用SiO2/Al2O3双层钝化 38.73 649 79.00 19.90 2024 [98] 多层SiNx/SiOxNy/SiNx钝化 41.70 682 80.57 22.91 2024 [99] -

[1] Renewables 2023 Analysis and forecasts to 2028, Yasmina A, Ana A B, Piotr B https://www.iea.org/reports/renewables-2023 [2024-9-5]

[2] Renewables 2022 Yasmina A, Heymi B, Trevor C https://www.iea.org/reports/renewables-2022 [2024-9-5]

[3] Singh G K 2013 Energy 53 1

Google Scholar

Google Scholar

[4] Shen W Z, Zhao Y X, Liu F 2022 Front. Energy 16 1

Google Scholar

Google Scholar

[5] Breaking through 24%, Chang J https://www.hengdian.com/zh-cn/news/detail-10754 [2024-9-5]

[6] Allen T G, Bullock J, Yang X B, Javey A, De Wolf S 2019 Nat. Energy 4 914

Google Scholar

Google Scholar

[7] Dullweber T, Schmidt J 2016 IEEE J. Photovolt. 6 1366

Google Scholar

Google Scholar

[8] Rise to 26.89%, jinkosolar https://www.jinkosolar.com/site/newsdetail/1748 [2024-9-5]

[9] Ullah H, Czapp S, Szultka S, Tariq H, Qasim U B, Imran H 2023 Energies 16 715

Google Scholar

Google Scholar

[10] Ma S, Du D X, Ding D, Gao C, Li Z P, Wu X Y, Zou S, Su X, Kong X Y, Liao B, Shen W Z 2024 Sol. Energ. Mat. Sol. C. 275 113024

Google Scholar

Google Scholar

[11] Schmidt J, Peibst R, Brendel R 2018 Sol Energ. Mat. Sol. C. 187 39

Google Scholar

Google Scholar

[12] Global News At 26.81%, LONGi https://www.longi.com/en/news/propelling-the-transformation/ [2024-9-5]

[13] Taguchi M, Yano, A, Tohoda S, Matsuyama K, Nakamura Y, Nishiwaki T, Fujita K, Maruyama E 2014 IEEE J. Photovolt. 4 96

Google Scholar

Google Scholar

[14] Masuko K, Shigematsu M, Hashiguchi T, Fujishima D, Kai M, Yoshimura N, Yamaguchi T, Ichihashi Y, Mishima T, Matsubara N, Yamanishi T, Takahama T, Taguchi M, Maruyama E, Okamoto S 2014 IEEE J. Photovolt. 4 1433

Google Scholar

Google Scholar

[15] Adachi D, Hernández J L, Yamamoto K 2015 Appl. Phys. Lett. 107 233506

Google Scholar

Google Scholar

[16] Haschke J, Dupré O, Boccard M, Ballif C 2018 Sol. Energ. Mat. Sol. C. 187 140

Google Scholar

Google Scholar

[17] 陈剑辉, 杨静, 沈艳娇, 李锋, 陈静伟, 刘海旭, 许颖, 麦耀华 2015 64 198801

Google Scholar

Google Scholar

Chen J H, Yang J, Shen Y J, Li F, Chen J W, Liu H X, Xu Y, Mai Y H 2015 Acta Phys. Sin. 64 198801

Google Scholar

Google Scholar

[18] Schuttauf J W A, van der Werf K H M, Kielen I M, Kielen I M, van Sark W G J H M, Rath J K, Schropp R E I 2011 Appl. Phys. Lett. 98 153514

Google Scholar

Google Scholar

[19] 肖有鹏, 王涛, 魏秀琴, 周浪 2017 66 108801

Google Scholar

Google Scholar

Xiao Y P, Wang T, Wei X Q, Zhou L 2017 Acta Phys. Sin. 66 108801

Google Scholar

Google Scholar

[20] Kerr M J, Cuevas A, Sinton R A 2002 J. Appl. Phys. 91 399

Google Scholar

Google Scholar

[21] Nagel H, Berge C, Aberle A G 1999 J. Appl. Phys. 86 6218

Google Scholar

Google Scholar

[22] Panigrahi J, Komarala V K 2021 J. Non-Cryst. Solids 574 121166

Google Scholar

Google Scholar

[23] Shi C H, Shi J J, Guan Z S, Ge J 2023 Materials 16 3144

Google Scholar

Google Scholar

[24] 沈文忠, 高超, 李正平 2023 钙钛矿/晶硅异质结叠层太阳电池 (北京: 科学出版社)第45页

Shen W Z, Gao C, Li Z P 2023 Perovskite/Silicon-Heterojunction Tandem Solar Cells (Beijing: Science Press) p45

[25] Tanaka M, Taguchi M, Matsuyama T, Sawada T, Tsuda S, NakanoS, Hanafusa H, Kuwano Y 1992 Jpn. J. Appl. Phys. 31 3518

Google Scholar

Google Scholar

[26] De Wolf S, Kondo M 2007 Appl. Phys. Lett. 90 042111

Google Scholar

Google Scholar

[27] Chu Y H, Lee C C, Chang T H, Chang S Y, Chang J Y, Li T, Chen I C 2014 Thin Solid Films 570 591

Google Scholar

Google Scholar

[28] Sriraman S, Agarwal S, Aydil E S, Maroudas D 2002 Nature 418 62

Google Scholar

Google Scholar

[29] Liu W, Zhang L, Chen R, Meng F, Guo W, Bao J, Liu Z 2016 J. Appl. Phys. 120 175301

Google Scholar

Google Scholar

[30] Wronski C R, Collins R W, Pearce J M, Koval R J, Ferlauto A S, Ferreira G M, Chen C 2002 NREL/SR 520 32692

Google Scholar

Google Scholar

[31] Wang T H, Iwaniczko E, Page M R, Levi D H, Yan Y, Branz H M, Wang Q 2006 Thin Solid Films 501 284

Google Scholar

Google Scholar

[32] Ruan T Y, Qub M H, Qu X L, Ru X N, Wang J Q, He Y C, Zheng K, Lin B H H F, Xu X X, Zhang Y Z, Yan H 2020 Thin Solid Films 711 138305

Google Scholar

Google Scholar

[33] Lee K S, Yeon C B, Yun S J, Jung K H, Lima J W 2014 ECS Solid State Letters 3 33

Google Scholar

Google Scholar

[34] Zeng Q G, Li L W, Meng H C, Wu X Y, Wei X Q, Zhou L 2024 J Mater. Sci: Mater. Electron. 35 476

Google Scholar

Google Scholar

[35] Peng C W, He C R, Wu H F, Huang S, Yu C, Su X D, Zou S 2024 Sol. Energ. Mat. Sol. C 273 112952

Google Scholar

Google Scholar

[36] Jiang K, Yang Y H, Yan Z, Huang S L, Li X D, Li Z F, Zhou Y N, Zhang L P, Meng F Y, Liu Z X, Liu W Z 2022 Sol. Energ. Mat. Sol. C 243 111801

Google Scholar

Google Scholar

[37] Soman A, Das U K, Hegedus S S 2023 ACS Appl. Electron. Mater. 5 803

Google Scholar

Google Scholar

[38] Morales-Vilches A B, Wang E C, Henschel T, Kubicki M, Cruz A, Janke S, Korte L, Schlatmann R, Stannowski B 2020 Phys. Status. Solidi. A 217 1900518

Google Scholar

Google Scholar

[39] Ru X N, Qu M H, Wang J Q, Ruan T Y, Yang M, Peng F G, Long W, Zheng K, Yan H, Xu X X 2020 Sol. Energ. Mat. Sol. C. 215 110643

Google Scholar

Google Scholar

[40] Liu C S, Wu C Y, Chen I W, Lee H C, Hong L S 2013 Prog. Photovolt: Res. Appl. 21 326

Google Scholar

Google Scholar

[41] Page M R, Iwaniczko E, Xu Y Q, Roybal L, Hasoon F, Wang Q, Crandall R S 2011 Thin Solid Films 519 4527

Google Scholar

Google Scholar

[42] He J, Li W, Wang Y, Mu J L, An K, Chou X J 2015 Mater. Lett. 161 175

Google Scholar

Google Scholar

[43] Pandey A, Bhattacharya S, Panigrahi J, Mandal S, Komarala V K 2022 Phys. Status Solidi A 219 2200183

Google Scholar

Google Scholar

[44] Nunomura1 S, Sakata I, Misawa T, Kawai S, Kamataki K, Koga K, Shiratani M 2023 Jpn. J. Appl. Phys. 62 SL1027

Google Scholar

Google Scholar

[45] Macco B, Melskens J, Podraza N J, Arts K, Pugh C, Thomas O, Kessels W M M 2017 J. Appl. Phys 122 035302

Google Scholar

Google Scholar

[46] Wu Z P, Zhang L P, Chen R F, Liu W Z, Li Z F, Meng F Y, Liu Z X 2019 Appl. Surf. Sci. 475 504

Google Scholar

Google Scholar

[47] Tomasil A, Sahli F, Fannil L, Seif J P, de Nicolas S M, Holm N, Geissblihler J, Paviet-Salomon B, Loper P, Nicolay S, De Wolf S, Ballif C 2016 IEEE. J. Photovolt. 6 17

Google Scholar

Google Scholar

[48] Morell G, Katiyar R S, Weisz S Z, Jia H, Shinar J, Balberg I 1995 J. Appl. Phys. 78 5120

Google Scholar

Google Scholar

[49] Iqbal Z, Veprek S 1982 J. Phys. C: Solid State Phys. 15 377

Google Scholar

Google Scholar

[50] De Wolf S, Kondo M 2007 Appl. Phys. Lett. 91 112109

Google Scholar

Google Scholar

[51] Biegelsen D K, Street R A, Tsai CC, Knights J C 1979 Phys. Rev. B 20 4839

Google Scholar

Google Scholar

[52] Beyer W, Wagner H 1983 J. Non-Cryst. Solids 59 161

Google Scholar

Google Scholar

[53] Yabumoto N, Saito K, Morita M, Ohmi T 1991 Jpn. J. Appl. Phys. 30 L419

Google Scholar

Google Scholar

[54] Beyer W, Wagner H, Chevallier J, Reichelt K 1982 90 145

[55] Beyer W 1991 Phys. Rev. B Condens. Matter 170 105

Google Scholar

Google Scholar

[56] Beyer W, Wagner H, Mell H 1981 Solid State. Commun. 39 375

Google Scholar

Google Scholar

[57] Street R A, Tsai CC, Kakalios J, Jackson W B 1987 Philos. Mag. B 56 305

Google Scholar

Google Scholar

[58] Nasuno Y, Kondo M, Matsuda A, Fukuhori H, Kanemitsu Y 2002 Appl. Phys. Lett. 81 3155

Google Scholar

Google Scholar

[59] Dreon J, Jeangros Q, Cattin J, Haschke J, Antognini L, Ballif C, Boccard M 2020 Nano Energy 70 104495

Google Scholar

Google Scholar

[60] Holman Z C, Descoeudres A, Barraud L, Fernandez F Z, Sei J P, De Wolf S, Ballif C 2012 IEEE J. Photovolt. 2 7

Google Scholar

Google Scholar

[61] Ding K N, Aeberhard U, Finger F, Rau U 2013 J. Appl. Phys. 113 134501

Google Scholar

Google Scholar

[62] Boccard M, Holman Z C 2015 J. Appl. Phys. 118 065704

Google Scholar

Google Scholar

[63] Jiang K, Liu W Z, Yang Y H, Yan Z, Huang S L, Li Z F, Li X D, Zhang L P, Liu Z X 2022 J. Mater. Sci.: Mater. Electron. 33 416

Google Scholar

Google Scholar

[64] Fujiwara H, Kaneko T, Kondo M 2007 Appl. Phys. Lett. 91 133508

Google Scholar

Google Scholar

[65] Mews M, Liebhaber M, Rech B, Korte L 2015 Appl. Phys. Lett. 107 013902

Google Scholar

Google Scholar

[66] Wu Z P, Zhang L P, Liu W Z, Chen R F, Li Z F, Meng F Y, Liu Z X 2020 J. Mater. Sci. Mater. El. 31 9468

Google Scholar

Google Scholar

[67] Wen L L, Zhao L, Wang G H, Jia X J, Xu X H, Qu S Y, Li X T, Zhang X Y, Xin K, Xiao J H, Wang W J 2023 Sol. Energ. Mat. Sol. C. 258 112429

Google Scholar

Google Scholar

[68] Wu X Y, Wang X T, Lv R R, Song H, Yu Y J, Sen C D, Cheng Y H, Khan M U, Ciesla A, Xu T, Zhang G C, Hoex B 2025 Sol. Energ. Mat. Sol. C. 282 113325

Google Scholar

Google Scholar

[69] Sinha A, Qian J D, Moffitt S L, Hurst K, Terwilliger K, Miller D C, Schelhas L T, Hacke P 2023 Prog. Photovoltaics 31 36

Google Scholar

Google Scholar

[70] Yang L, Hu Z C, He Q Y, Liu Z K, Zeng Y H, Yang L F, Yu X G, Yang D R 2024 Sol. Energ. Mat. Sol. C 275 113022

Google Scholar

Google Scholar

[71] Yang J L, Tang Y H, Zhou C L, Chen S N, Cheng S Z, Wang L C, Zhou S, Jia X J, Wang W J, Xu X H, Xiao J H, Wei W W 2024 Sol. Energ. Mat. Sol. C 276 113062

Google Scholar

Google Scholar

[72] Feldmann F, Bivour M, Reichel C, Hermle M, Glunz S W 2014 Sol. Energ. Mat. Sol. C 120 270

Google Scholar

Google Scholar

[73] Padi S P, Khokhar M Q, Chowdhury S, Cho E C, Yi J 2021 Trans. Electr. Electro. 22 557

Google Scholar

Google Scholar

[74] Wang Q Q, Wu W P, Yuan N Y, Li Y L, Zhang Y, Ding J N 2020 Sol. Energ. Mat. Sol. C 208 110423

Google Scholar

Google Scholar

[75] Huang J B, Zhao Z C, Li M, Chen J, Zhou X R, Deng X X, Li B, Shen K L, Cheng Q Y, Cai X W 2023 Sol. Energ. Mat. Sol. C. 260 112489

Google Scholar

Google Scholar

[76] Xing H Y, Liu Z K, Yang Z H, Liao M D, Wu Q Q, Lin N, Liu W, Ding C F, Zeng Y H, Yan B J, Ye J C 2023 Sol. Energ. Mat. Sol. C 257 112354

Google Scholar

Google Scholar

[77] Yang L, Ou Y L, Lv X, Lin N, Zeng Y H, Hu Z C, Yuan S, Ye J C, Yu X G, Yang D R 2024 Energy Environ. Mater. 7 e12795

Google Scholar

Google Scholar

[78] 钱金忠, 左克祥, 王安, 杜东亚, 凡金星, 高纪凡 2023 太阳能 353 9

Google Scholar

Google Scholar

Qian J Z, Zuo K X, Wang A, Du D Y, Fan J X, Gao J F 2023 Solar Energy 353 9

Google Scholar

Google Scholar

[79] Ghosh D K, Das G, Bose S, Mukhopadhyay S, Sengupta A 2024 Energy Technol. 12 2400238

Google Scholar

Google Scholar

[80] Richter A, Benick J, Feldmann F, Fell A, Hermle M, Glunz S W 2017 Sol. Energ. Mat. Sol. C 173 96

Google Scholar

Google Scholar

[81] Yan D, Cuevas A, Phang S P, Wan Y, Macdonald D 2018 Appl. Phys. Lett. 113 061603

Google Scholar

Google Scholar

[82] Richter A, Benick J, Müller R, Feldmann F, Reichel C, Hermle M, Glunz S W 2018 Prog. Photovolt. Res. Appl. 26 579

Google Scholar

Google Scholar

[83] Richter A, Müller R, Benick J, Feldmann F, Steinhauser B, Reichel C, Fell A, Bivour M, Hermle M, Glunz S W 2021 Nat. Energy 6 429

Google Scholar

Google Scholar

[84] Yu H L, Liu W, Du H J, Liu Z K, Liao M D, Song N, Yang Z H, Zeng Y H, Ye J C 2024 Nano Energy 125 109556

Google Scholar

Google Scholar

[85] Ma D, Liu W, Xiao M J, Yang Z H, Liu Z K, Liao M D, Han Q L, Cheng H, Xing H Y, Ding Z T, Yan B J, Wang Y D, Zeng Y H, Ye J C 2022 Sol. Energy 242 1

Google Scholar

Google Scholar

[86] Du H J, Lin Y R, Wang Z X, Liao M D, Liu Z K, Luo X J, Cao Y H, Fu L M, Liu W, Yan B J, Yang Z H, Yuan Z Z, Zeng Y H, Ye J C 2024 Mat. Sci. Semicon. Proc. 170 107969

Google Scholar

Google Scholar

[87] Li W K, Zhou R, Wang Y K, Su Q F, Yang J, Xi M, Liu Y S 2024 Appl. Surf. Sci. 673 160835

Google Scholar

Google Scholar

[88] Wang Q Q, Gu S W, Guo K Y, Peng H, Wu W P, Ding J N 2024 Sol. Energ. Mat. Sol. C. 273 112959

Google Scholar

Google Scholar

[89] Blakers A W, Wang A, Milne A M, Zhao J, Green M A 1989 Appl. Phys. Lett. 55 1363

Google Scholar

Google Scholar

[90] Saint-Cast P, Benick J, Kania D, Weiss L, Hofmann M, Rentsch J, Preu R, Glunz S W 2010 IEEE Electron. Device Lett. 31 695

Google Scholar

Google Scholar

[91] Töfflingera J A, Laadesb A, Leendertza C, Montañeza L M, Kortea L, Stürzebecher U, Sperlichc H P, Recha B 2014 Energy Procedia 55 845

Google Scholar

Google Scholar

[92] Gatz S, Hannebauer H, Hesse R, Werner F, Schmidt A, Dullweber T, Schmidt J, Bothe K, Brendel R 2011 Phys. Status Solidi Rapid Res. Lett. 5 147

Google Scholar

Google Scholar

[93] Kim J, Ju M, Kim Y, Yi J 2022 Mat. Sci. Semicon. Proc. 148 106833

Google Scholar

Google Scholar

[94] Tong R, Zhang S C, Liu D M, Zhang W P, Wang Y T, Liu X F 2021 Sol. Energ. Mat. Sol. C. 231 111319

Google Scholar

Google Scholar

[95] Liu P K, Cheng Y L, Wang L K 2020 Int. J. Photoenergy 2020 6686797

Google Scholar

Google Scholar

[96] Kashyap S, Madan J, Pandey R, Ramanujam J 2022 Opt. Mater. 128 112399

Google Scholar

Google Scholar

[97] Mouri T K, Upadhyaya A, Rohatgi A, Ok Y W, Hua A, Hauschild D, Weinhardt L, Heske C, Upadhyaya V, Rounsaville B, Shafarman W N, Das U K 2023 IEEE 50th Photovoltaic Specialists Conference (PVSC) San Juan, PR, USA, June 11–16, 2023 p1

[98] Jang J S, Kim H S, Karade V C, Park S W, Kim C W, Kim J H 2024 J. Alloys Compd. 970 172691

Google Scholar

Google Scholar

[99] Wei P F, Tong R, Liu X F, Wei Y, Zhang Y A, Liu X, Dai J, Yin H P, Liu D M 2024 Mat. Sci. Semicon. Proc. 170 107947

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 3314

- PDF Downloads: 254

- Cited By: 0

DownLoad:

DownLoad: