-

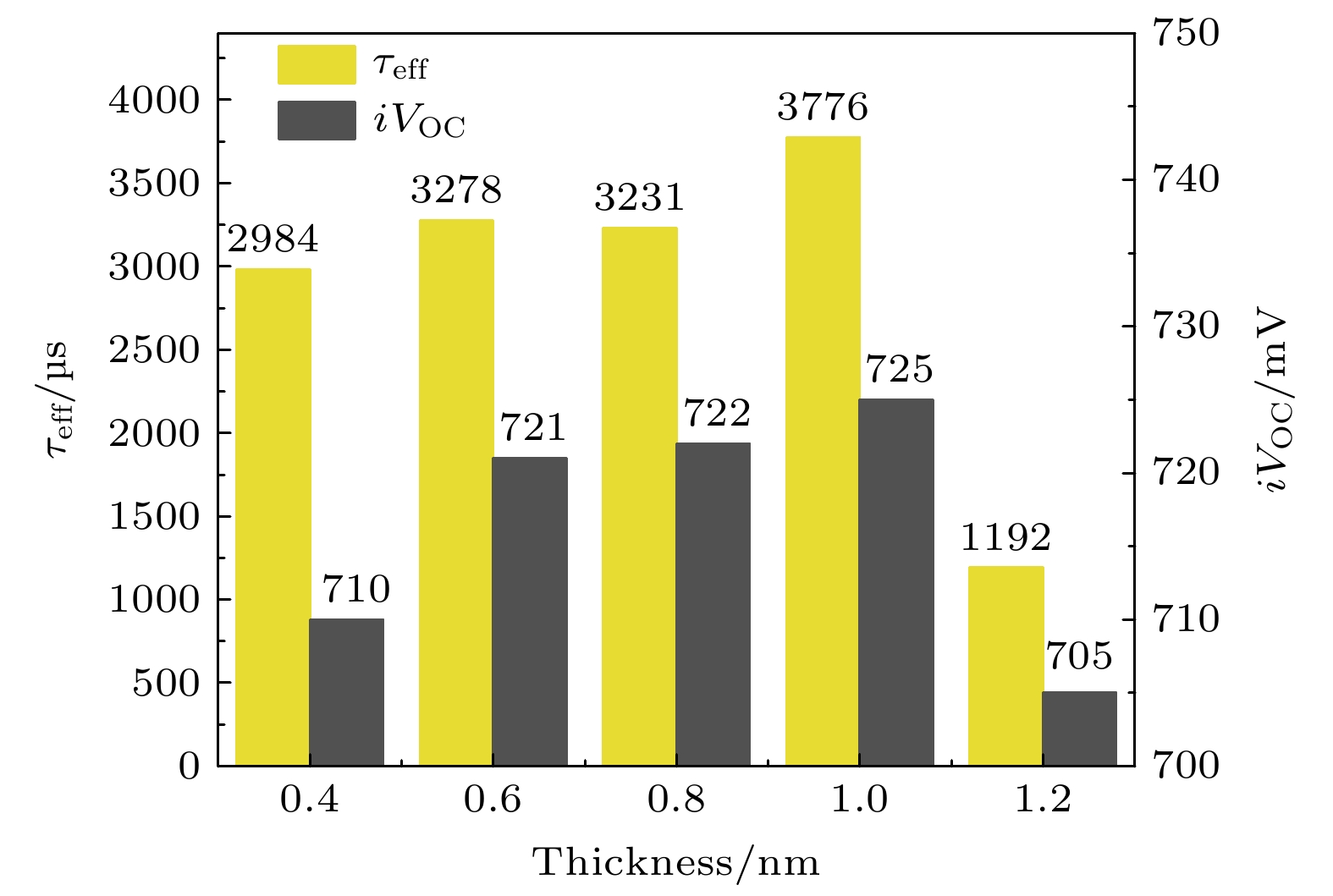

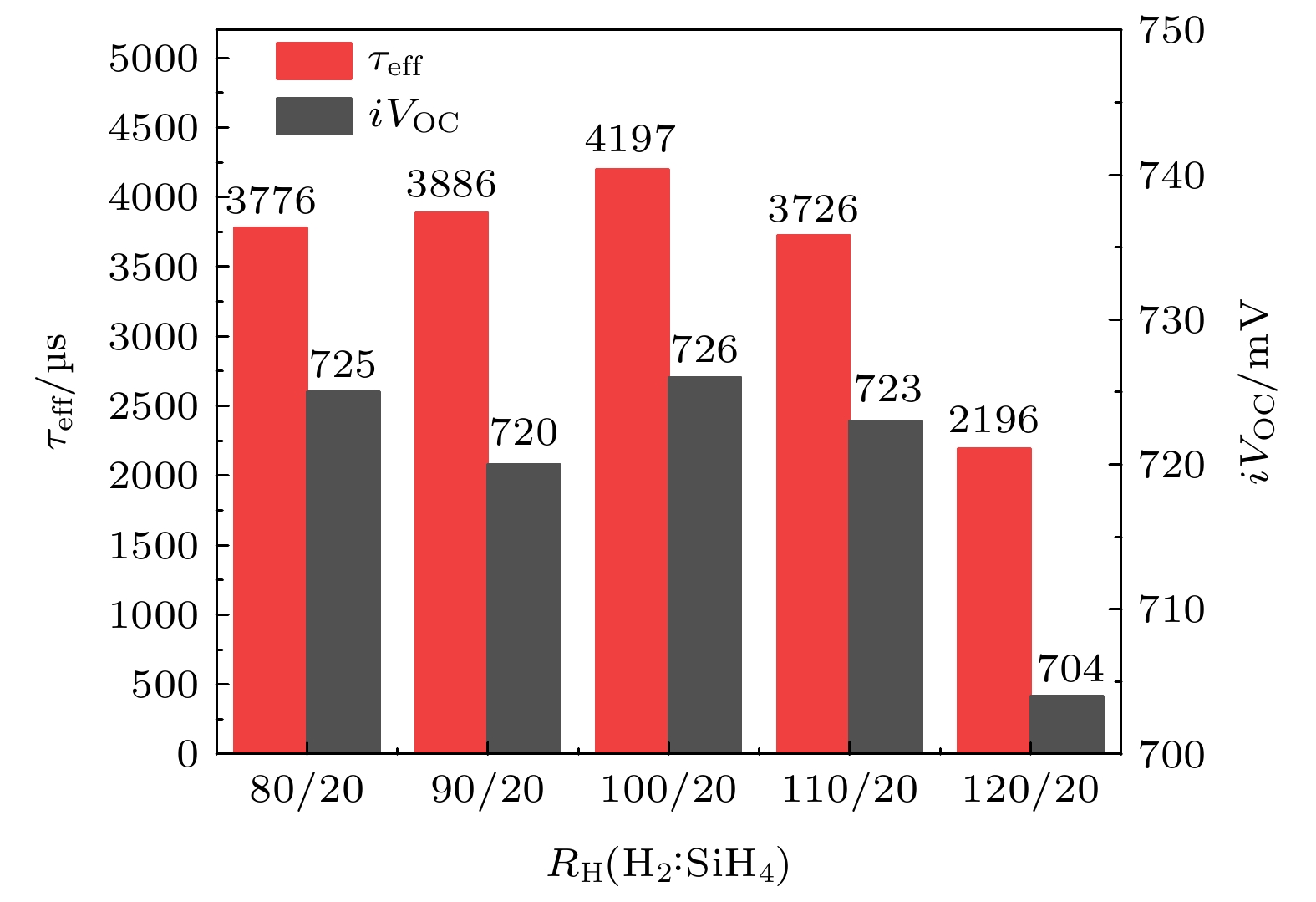

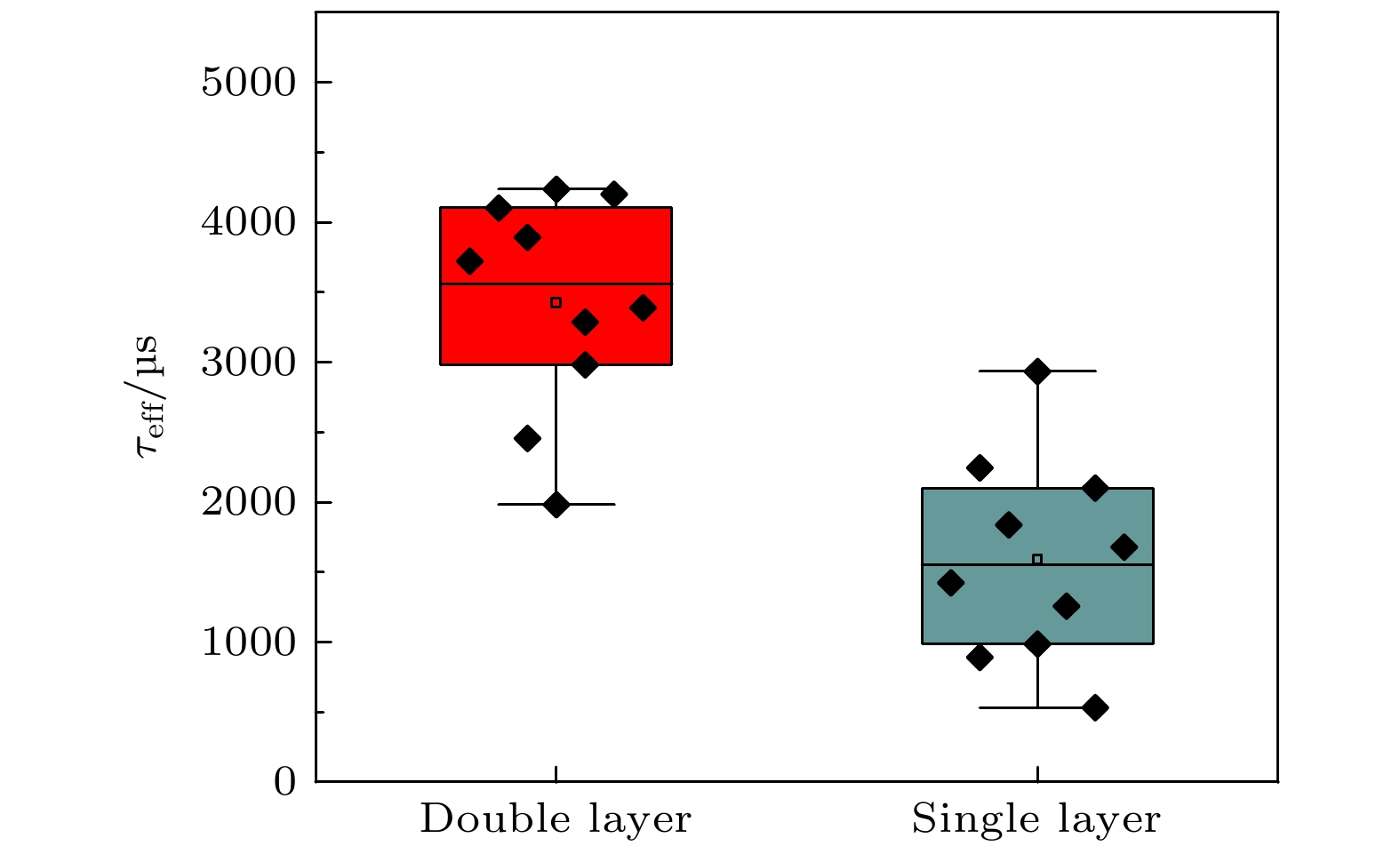

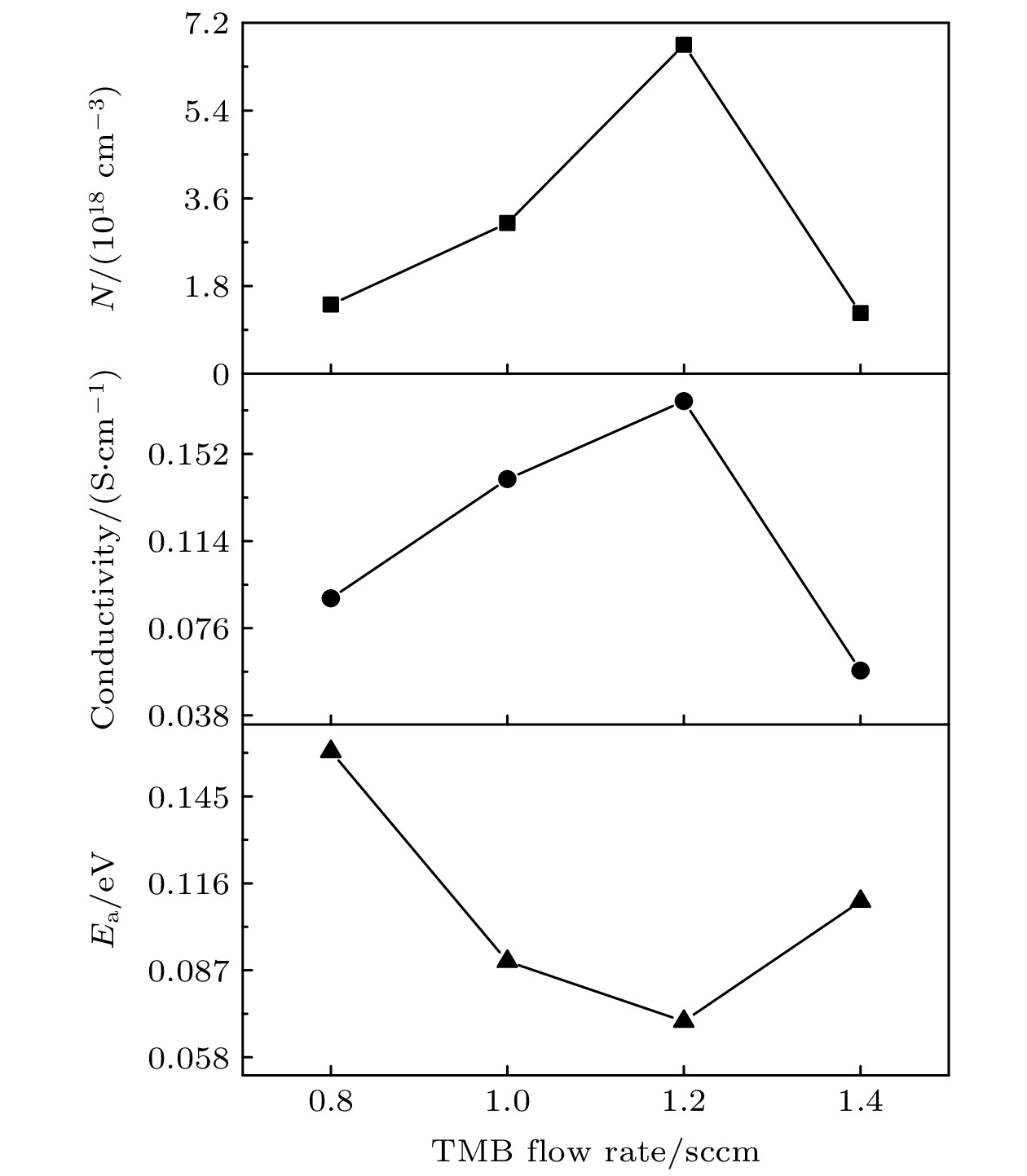

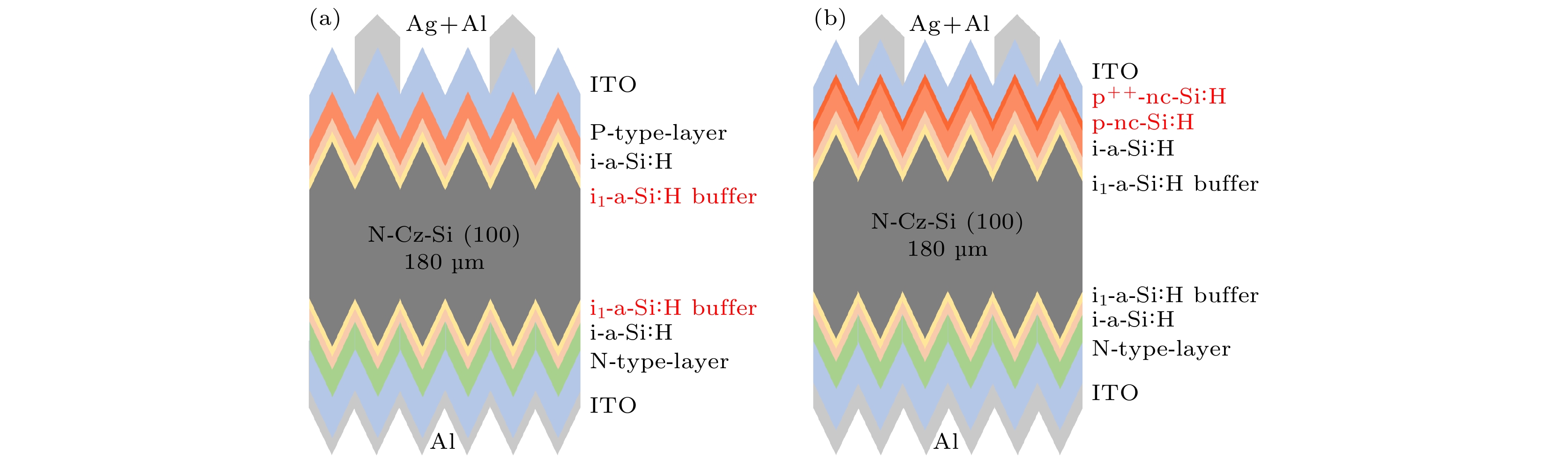

本征钝化层及p型发射层对硅异质结太阳电池的性能具有重要的影响. 本文在常规钝化层与晶硅衬底(c-Si)之间插入一层低功率、高氢稀释比沉积的超薄缓冲层, 以此来提高钝化效果, 并拓宽钝化层工艺窗口. 此外, 设计并制备了具有宽带隙、高电导特性的重掺杂纳米晶硅/轻掺杂p型双层复合发射极. 实验结果表明, 双层钝化层具有更加稳定与优异的钝化效果, 钝化样品的少子寿命达到4.197 ms, 隐含开路电压(implied-VOC, iVOC)达到726 mV. 同时双层复合发射层中, 轻掺杂的掺杂层可以减弱掺杂剂向本征钝化层的扩散, 保证良好的钝化效果, 而重掺杂的掺杂层不仅能够提供足够的内建电场, 而且可以改善掺杂层与氧化铟锡薄膜的接触特性, 进而提升电池的输出特性. 并且高氢稀释比的前掺杂层还可以对钝化层起到氢处理的作用, 减少钝化层表面的悬挂键, 从而增强化学钝化效果, 进而提高电池的开路电压. 最终, 基于商业化制绒的硅片, 获得了效率达到20.96%的硅异质结太阳电池, 其中开路电压为710 mV, 短路电流密度为39.88 mA/cm2, 填充因子为74.02%.

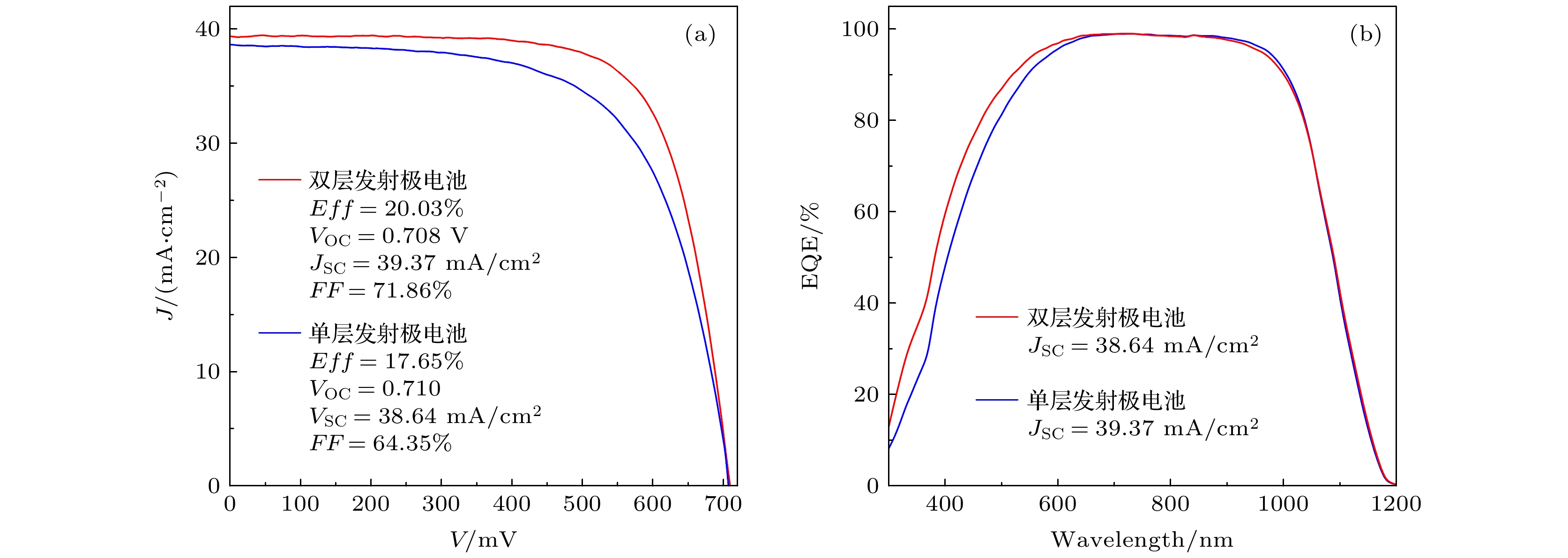

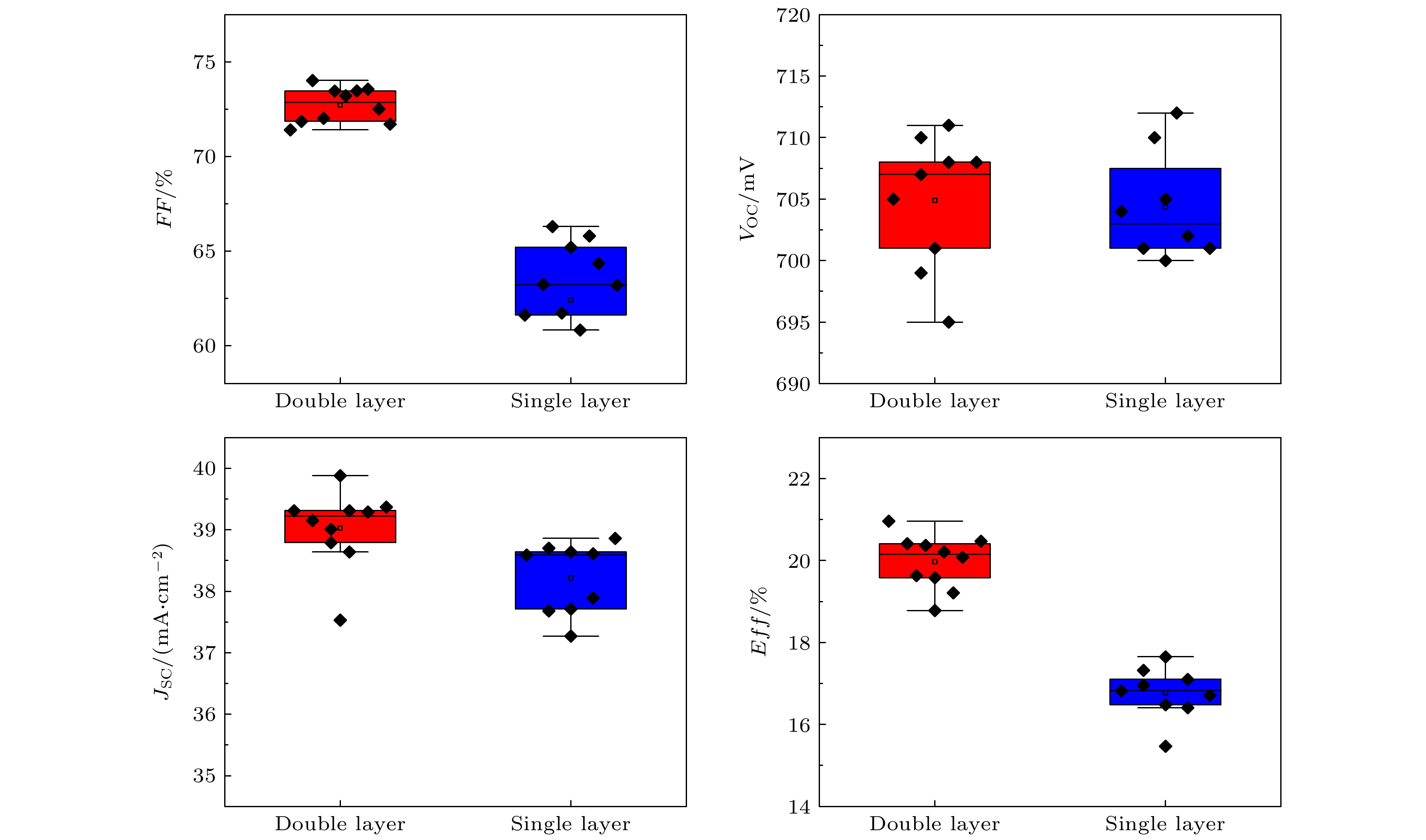

Silicon heterojunction (SHJ) solar cells have attracted much attention in the international photovoltaic market due to their high efficiencies and low costs. The quality of amorphous silicon/crystalline silicon (a-Si:H/c-Si) interfaces of SHJ solar cells has a key influence on the device performance. Therefore, the carrier recombination rate of a-Si:H/c-Si interface needs to be effectively controlled. In addition, as the important component of SHJ solar cells, the p-type emitter must meet the requirements for high conductivity, high light transmittance, and energy band matching with c-Si. The research contents and the relevant achievements of this paper include the following aspects. Firstly, in order to reduce the surface defects and realize the energy band alignment of a-Si:H/c-Si interface, the effect of passivation layer on passivation effect is studied. An ultra-thin buffer layer deposited by a low power and a high hydrogen dilution ratio is inserted between the conventional passivation layer and c-Si to improve the passivation effect and broaden the process window of passivation layer. The effects of the buffer layer thickness and hydrogen dilution ratio on passivation quality are further studied, and the best experimental conditions of buffer layer are obtained. The experimental results show that the sample with double-layered passivation layer is more stable than the conventional passivation layer. The minority carrier lifetime of the sample with single conventional passivation layer is 3.8 ms and the iVOC is 712 mV, while the minority carrier lifetime of the sample with double-layered passivation layer is 4.197 ms and the iVOC is 726 mV. Secondly, for the p-type emitters of silicon heterojunction solar cells, the effects of doping level on the photoelectric properties of p-type hydrogenated nanocrystalline silicon (nc-Si:H) thin films are studied. On this basis, the p++-nc-Si:H/p-nc-Si:H double-layer emitter with wide band gap and high conductivity is designed and fabricated. By analyzing the optical and electrical properties of different emitters, it is found that p-nc-Si:H has good electrical and optical properties. Owing to the high doping efficiency of nc-Si, a small amount of doping can obtain high conductivity. Lightly doped p-nc-Si:H provides a better contact with the passivation layer, while heavily doped p++-nc-Si:H can not only provide enough built-in electric field, but also improve the contact characteristics of p/ITO, thus enhancing the output characteristics of the cell. At the same time, the deposition of p-nc-Si:H layer with high hydrogen dilution ratio can also implement the hydrogen plasma treatment on the passivation layer, the reduction of the dangling bonds on the surface of the c-Si, the enhancement of the chemical passivation effect, and thus improving the open circuit voltage of the cell. Finally, a silicon heterojunction solar cell with an efficiency of 20.96% is obtained based on the commercial czochralski silicon wafer, with an open circuit voltage of 710 mV, a short circuit current density of 39.88 mA/cm2 and filling factor of 74.02%. -

Keywords:

- silicon heterojunction solar cell /

- passivation layer /

- emitter /

- composite structure

[1] 李志学, 吴硕锋, 雷理钊 2018 价格月刊 12 1

Google Scholar

Google Scholar

Li Z X, Wu S F, Lei L Z 2018 Prices Monthly 12 1

Google Scholar

Google Scholar

[2] 陈晨, 张巍, 贾锐, 张代生, 邢钊, 金智, 刘新宇 2013 中国科学 43 708

Google Scholar

Google Scholar

Chen C, Zhang W, Jia R, Zhang D S, Xing Z, Jin Z, Liu X Y 2013 Science China 43 708

Google Scholar

Google Scholar

[3] Rehman A U, Lee S H 2013 Sci. World J. 11 470347

Google Scholar

Google Scholar

[4] Yoshikawa K, Yoshida W, Irie T, Kawasaki H, Konishi K, Ishibashi H, Asatani T, Adachi D, Kanematsu M, Uzu H, Yamamoto K 2017 Sol. Energy Mater. Sol. Cells 173 37

Google Scholar

Google Scholar

[5] Taguchi M, Yano A, Tohoda S, Matsuyama K, Nakamura Y, Nishiwaki T, Fujita K, Maruyama E 2014 IEEE J. Photovoltaics 4 96

Google Scholar

Google Scholar

[6] Okuda K, Okamoto H, Hamakawa Y 1983 Jpn. J. Appl. Phys. 22 L605

Google Scholar

Google Scholar

[7] Neumuller A, Sergeev O, Heise S J, Bereznev S, Volobujeva O, Salas J F L, Vehse M, Agert C 2018 Nano Energy 43 228

Google Scholar

Google Scholar

[8] Geissbuhler J, De Wolf S, Demaurex B, Seif J P, Alexander D T L, Barraud L, Ballif C 2013 Appl. Phys. Lett. 102 23

Google Scholar

Google Scholar

[9] Mews M, Schulze T F, Mingirulli N, Korte L 2013 Appl. Phys. Lett. 102 122106

Google Scholar

Google Scholar

[10] Paviet-Salomon B, Tomasi A, Descoeudres A, Barraud L, Nicolay S, Despeisse M, Wolf S D, Ballif C 2015 IEEE J. Photovoltaics 5 1293

Google Scholar

Google Scholar

[11] Ru X, Qu M, Wang J, Ruan T, Yang M, Peng F, Long W, Zheng K, Yan H, Xu X 2020 Sol. Energy Mater. Sol. Cells 215 110643

Google Scholar

Google Scholar

[12] Wu Z, Zhang L, Chen R, Liu W, Li Z, Meng F, Liu Z 2019 Appl. Surf. Sci. 475 504

Google Scholar

Google Scholar

[13] Korte L, Conrad E, Angermann H, Stangl R, Schmidt M 2009 Sol. Energy Mater. Sol. Cells 93 905

Google Scholar

Google Scholar

[14] Ling Z P, Ge J, Mueller T, Wong J, Aberle A G 2012 Energy Procedia 15 118

Google Scholar

Google Scholar

[15] Pysch D, Meinhard C, Harder N P, Hermle M, Glunz S W 2011 J. Appl. Phys. 110 094516

Google Scholar

Google Scholar

[16] Lee Y, Kim H, Iftiquar S M, Kim S, Kim S, Ahn S, Lee Y J, Dao V A, Yi J 2014 J. Appl. Phys. 116 244506

Google Scholar

Google Scholar

[17] Boccard M, Monnard R, Antognini L, Ballif C 2018 AIP Conf. Proc. 1999 040003

[18] Richter A, Smirnov V, Lambertz A, Nomoto K, Welter K, Ding K N 2018 Sol. Energy Mater. Sol. Cells 174 196

Google Scholar

Google Scholar

[19] Li Z, Zhang L, Wu Z, Liu W, Chen R, Meng F, Liu Z 2020 J. Appl. Phys. 128 045309

Google Scholar

Google Scholar

[20] Ding K N, Aeberhard U, Finger F, Rau U 2012 Phys. Status Solidi R 6 193

Google Scholar

Google Scholar

[21] Mazzarella L, Kirner S, Gabriel O, Schmidt S S, Korte L, Stannowski B, Rech B, Schlatmann R 2017 Phys. Atatus Solidi A 214 1532958

Google Scholar

Google Scholar

[22] Descoeudres A, Barraud L, De Wolf S, Strahm B, Lachenal D, Guérin C, Holman Z C, Zicarelli F, Demaurex B, Seif J, Holovsky J, Ballif C 2011 Appl. Phys. Lett. 99 123506

Google Scholar

Google Scholar

[23] Fujiwara H, Kaneko T, Kondo M 2007 Appl. Phys. Lett. 91 133508

Google Scholar

Google Scholar

[24] De Wolf S, Beaucarne G 2006 Appl. Phys. Lett. 88 022104

Google Scholar

Google Scholar

[25] De Wolf S, Kondo M 2007 Appl. Phys. Lett. 91 112109

Google Scholar

Google Scholar

[26] Mazzarella L, Kirner S, Stannowski B, Korte L, Rech B, Schlatmann R 2015 Appl. Phys. Lett. 106 023902

Google Scholar

Google Scholar

[27] 张晓丹, 赵颖, 高艳涛, 陈飞, 朱锋, 魏长春, 孙建, 耿新华 2006 55 6697

Google Scholar

Google Scholar

Zhang X D, Zhao Y, Gao Y T, Chen F, Zhu F, Wei C C, Sun J, Geng X H 2006 Acta Phys. Sin. 55 6697

Google Scholar

Google Scholar

[28] Mews M, Liebhaber M, Rech B, Korte L 2015 Appl. Phys. Lett. 107 013902

Google Scholar

Google Scholar

[29] Kanevce A, Metzger W K 2009 J. Appl. Phys. 105 094507

Google Scholar

Google Scholar

[30] Madani Ghahfarokhi O, von Maydell K, Agert C 2014 Appl. Phys. Lett. 104 113901

Google Scholar

Google Scholar

[31] Mishima T, Taguchi M, Sakata H, Maruyama E 2011 Sol. Energy Mater. Sol. Cells 95 18

Google Scholar

Google Scholar

[32] Masuko K, Shigematsu M, Hashiguchi T, Fujishima D, Kai M, Yoshimura N, Yamaguchi T, Ichihashi Y, Mishima T, Matsubara N, Yamanishi T, Takahama T, Taguchi M, Maruyama E, Okamoto S 2014 IEEE J. Photovoltaics 4 1433

Google Scholar

Google Scholar

[33] Hao L C, Zhang M, Ni M, Shen X L, Feng X D 2019 J. Electron. Mater. 48 4688

Google Scholar

Google Scholar

-

表 1 重掺杂层不同氢稀释比的电池具体参数

Table 1. J -V parameters of SHJ solar cells with different hydrogen dilution ratio in the p++-nc-Si:H layer.

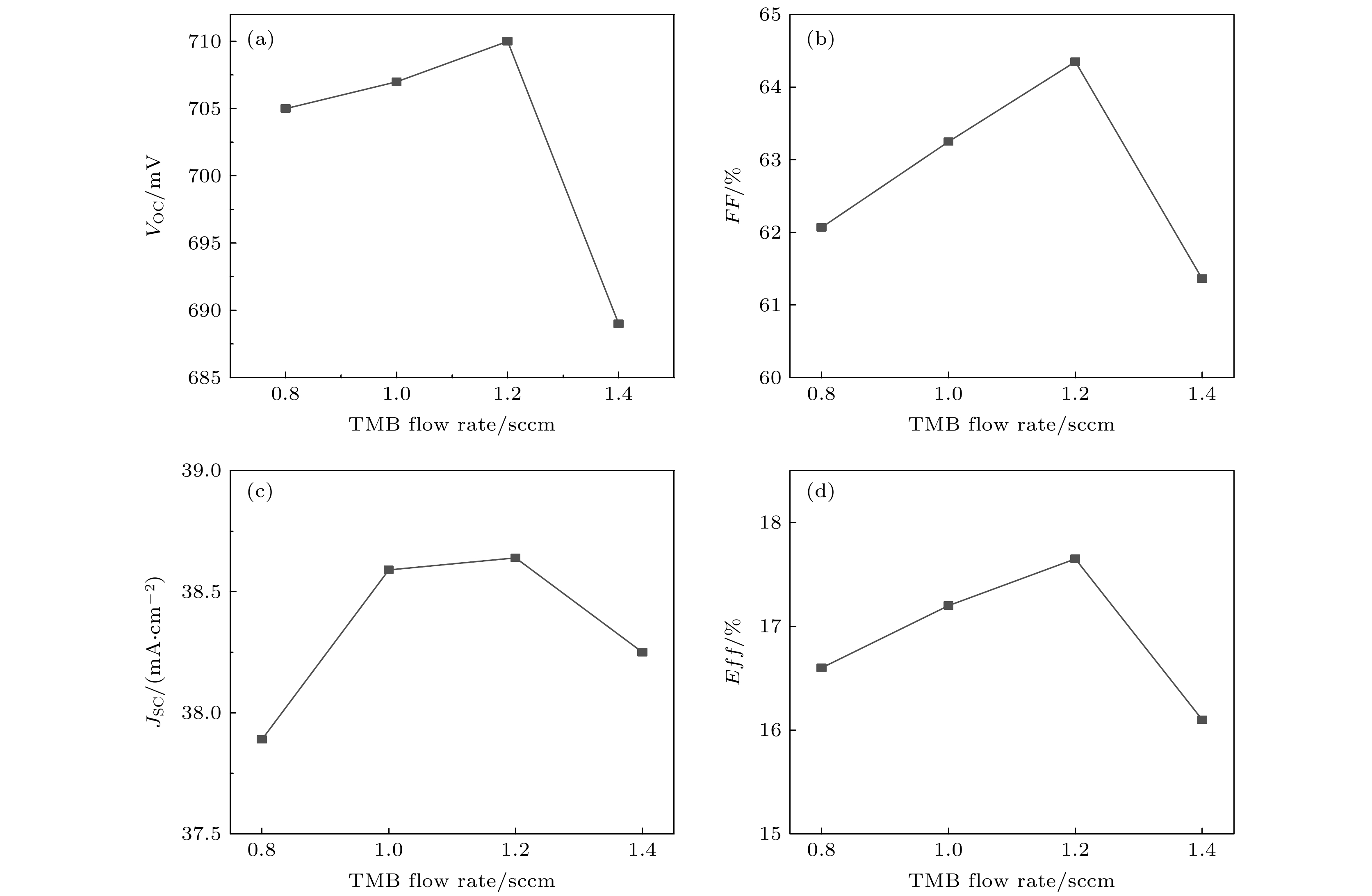

H2∶SiH4∶TMB JSC/mA·cm–2 VOC/V FF/% Eff /% 120∶4∶4 38.7 0.709 66.57 18.26 160∶4∶4 38.91 0.710 69.08 19.08 200∶4∶4 39.15 0.709 70.84 19.66 240∶4∶4 38.4 0.708 65.56 17.8 表 2 重掺杂层不同掺杂量的电池具体参数

Table 2. J -V parameters of SHJ solar cells with different TMB flow rate in the p++-nc-Si:H layer.

H2∶SiH4∶TMB JSC/mA·cm–2 VOC/V FF/% Eff/% 200∶4∶4 39.15 0.709 70.84 19.66 200∶4∶4.8 39.37 0.708 71.86 20.03 200∶4∶5.6 38.79 0.709 69.71 19.17 200∶4∶6.4 38.7 0.710 63.20 17.3 -

[1] 李志学, 吴硕锋, 雷理钊 2018 价格月刊 12 1

Google Scholar

Google Scholar

Li Z X, Wu S F, Lei L Z 2018 Prices Monthly 12 1

Google Scholar

Google Scholar

[2] 陈晨, 张巍, 贾锐, 张代生, 邢钊, 金智, 刘新宇 2013 中国科学 43 708

Google Scholar

Google Scholar

Chen C, Zhang W, Jia R, Zhang D S, Xing Z, Jin Z, Liu X Y 2013 Science China 43 708

Google Scholar

Google Scholar

[3] Rehman A U, Lee S H 2013 Sci. World J. 11 470347

Google Scholar

Google Scholar

[4] Yoshikawa K, Yoshida W, Irie T, Kawasaki H, Konishi K, Ishibashi H, Asatani T, Adachi D, Kanematsu M, Uzu H, Yamamoto K 2017 Sol. Energy Mater. Sol. Cells 173 37

Google Scholar

Google Scholar

[5] Taguchi M, Yano A, Tohoda S, Matsuyama K, Nakamura Y, Nishiwaki T, Fujita K, Maruyama E 2014 IEEE J. Photovoltaics 4 96

Google Scholar

Google Scholar

[6] Okuda K, Okamoto H, Hamakawa Y 1983 Jpn. J. Appl. Phys. 22 L605

Google Scholar

Google Scholar

[7] Neumuller A, Sergeev O, Heise S J, Bereznev S, Volobujeva O, Salas J F L, Vehse M, Agert C 2018 Nano Energy 43 228

Google Scholar

Google Scholar

[8] Geissbuhler J, De Wolf S, Demaurex B, Seif J P, Alexander D T L, Barraud L, Ballif C 2013 Appl. Phys. Lett. 102 23

Google Scholar

Google Scholar

[9] Mews M, Schulze T F, Mingirulli N, Korte L 2013 Appl. Phys. Lett. 102 122106

Google Scholar

Google Scholar

[10] Paviet-Salomon B, Tomasi A, Descoeudres A, Barraud L, Nicolay S, Despeisse M, Wolf S D, Ballif C 2015 IEEE J. Photovoltaics 5 1293

Google Scholar

Google Scholar

[11] Ru X, Qu M, Wang J, Ruan T, Yang M, Peng F, Long W, Zheng K, Yan H, Xu X 2020 Sol. Energy Mater. Sol. Cells 215 110643

Google Scholar

Google Scholar

[12] Wu Z, Zhang L, Chen R, Liu W, Li Z, Meng F, Liu Z 2019 Appl. Surf. Sci. 475 504

Google Scholar

Google Scholar

[13] Korte L, Conrad E, Angermann H, Stangl R, Schmidt M 2009 Sol. Energy Mater. Sol. Cells 93 905

Google Scholar

Google Scholar

[14] Ling Z P, Ge J, Mueller T, Wong J, Aberle A G 2012 Energy Procedia 15 118

Google Scholar

Google Scholar

[15] Pysch D, Meinhard C, Harder N P, Hermle M, Glunz S W 2011 J. Appl. Phys. 110 094516

Google Scholar

Google Scholar

[16] Lee Y, Kim H, Iftiquar S M, Kim S, Kim S, Ahn S, Lee Y J, Dao V A, Yi J 2014 J. Appl. Phys. 116 244506

Google Scholar

Google Scholar

[17] Boccard M, Monnard R, Antognini L, Ballif C 2018 AIP Conf. Proc. 1999 040003

[18] Richter A, Smirnov V, Lambertz A, Nomoto K, Welter K, Ding K N 2018 Sol. Energy Mater. Sol. Cells 174 196

Google Scholar

Google Scholar

[19] Li Z, Zhang L, Wu Z, Liu W, Chen R, Meng F, Liu Z 2020 J. Appl. Phys. 128 045309

Google Scholar

Google Scholar

[20] Ding K N, Aeberhard U, Finger F, Rau U 2012 Phys. Status Solidi R 6 193

Google Scholar

Google Scholar

[21] Mazzarella L, Kirner S, Gabriel O, Schmidt S S, Korte L, Stannowski B, Rech B, Schlatmann R 2017 Phys. Atatus Solidi A 214 1532958

Google Scholar

Google Scholar

[22] Descoeudres A, Barraud L, De Wolf S, Strahm B, Lachenal D, Guérin C, Holman Z C, Zicarelli F, Demaurex B, Seif J, Holovsky J, Ballif C 2011 Appl. Phys. Lett. 99 123506

Google Scholar

Google Scholar

[23] Fujiwara H, Kaneko T, Kondo M 2007 Appl. Phys. Lett. 91 133508

Google Scholar

Google Scholar

[24] De Wolf S, Beaucarne G 2006 Appl. Phys. Lett. 88 022104

Google Scholar

Google Scholar

[25] De Wolf S, Kondo M 2007 Appl. Phys. Lett. 91 112109

Google Scholar

Google Scholar

[26] Mazzarella L, Kirner S, Stannowski B, Korte L, Rech B, Schlatmann R 2015 Appl. Phys. Lett. 106 023902

Google Scholar

Google Scholar

[27] 张晓丹, 赵颖, 高艳涛, 陈飞, 朱锋, 魏长春, 孙建, 耿新华 2006 55 6697

Google Scholar

Google Scholar

Zhang X D, Zhao Y, Gao Y T, Chen F, Zhu F, Wei C C, Sun J, Geng X H 2006 Acta Phys. Sin. 55 6697

Google Scholar

Google Scholar

[28] Mews M, Liebhaber M, Rech B, Korte L 2015 Appl. Phys. Lett. 107 013902

Google Scholar

Google Scholar

[29] Kanevce A, Metzger W K 2009 J. Appl. Phys. 105 094507

Google Scholar

Google Scholar

[30] Madani Ghahfarokhi O, von Maydell K, Agert C 2014 Appl. Phys. Lett. 104 113901

Google Scholar

Google Scholar

[31] Mishima T, Taguchi M, Sakata H, Maruyama E 2011 Sol. Energy Mater. Sol. Cells 95 18

Google Scholar

Google Scholar

[32] Masuko K, Shigematsu M, Hashiguchi T, Fujishima D, Kai M, Yoshimura N, Yamaguchi T, Ichihashi Y, Mishima T, Matsubara N, Yamanishi T, Takahama T, Taguchi M, Maruyama E, Okamoto S 2014 IEEE J. Photovoltaics 4 1433

Google Scholar

Google Scholar

[33] Hao L C, Zhang M, Ni M, Shen X L, Feng X D 2019 J. Electron. Mater. 48 4688

Google Scholar

Google Scholar

计量

- 文章访问数: 9771

- PDF下载量: 319

- 被引次数: 0

下载:

下载: