-

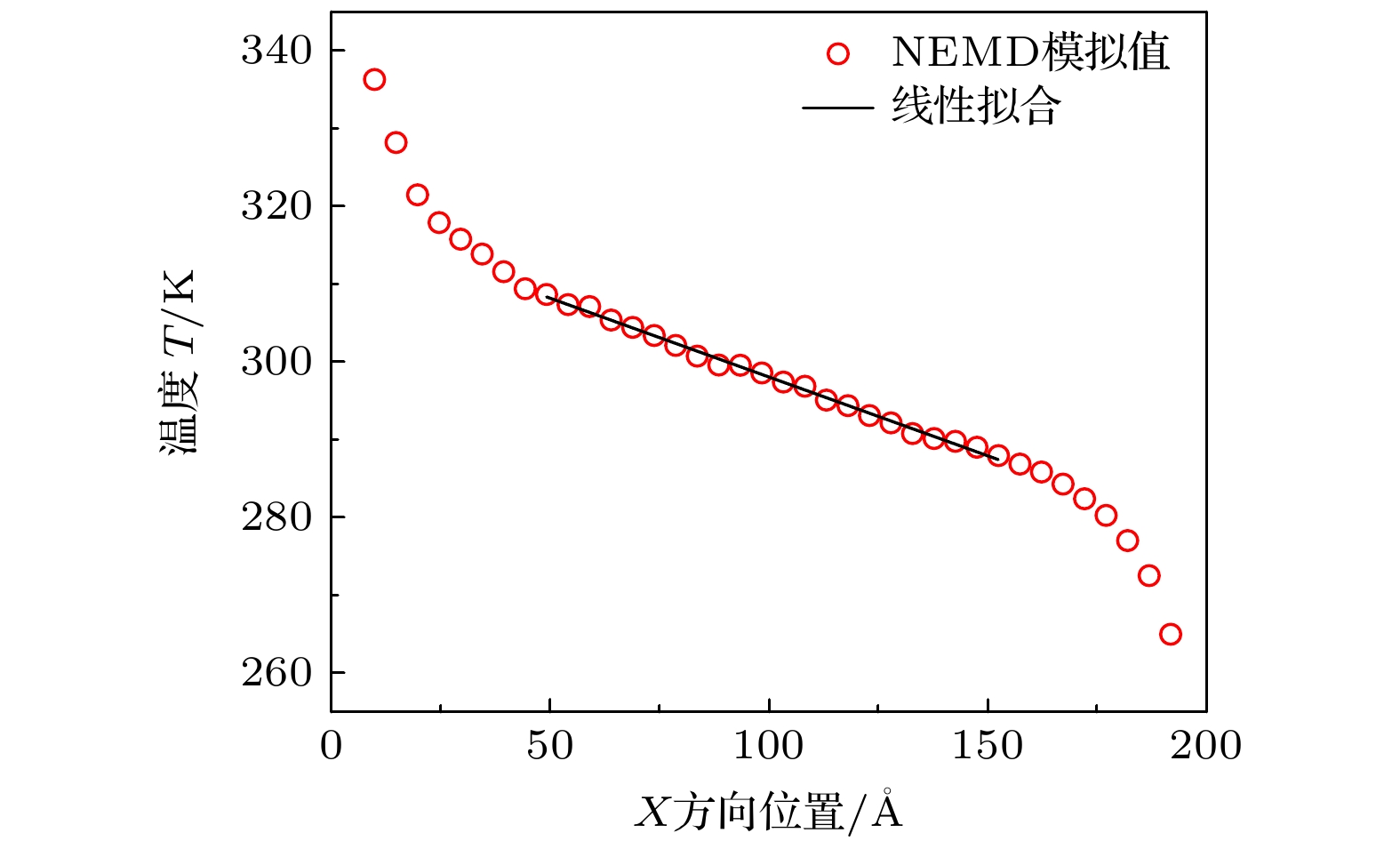

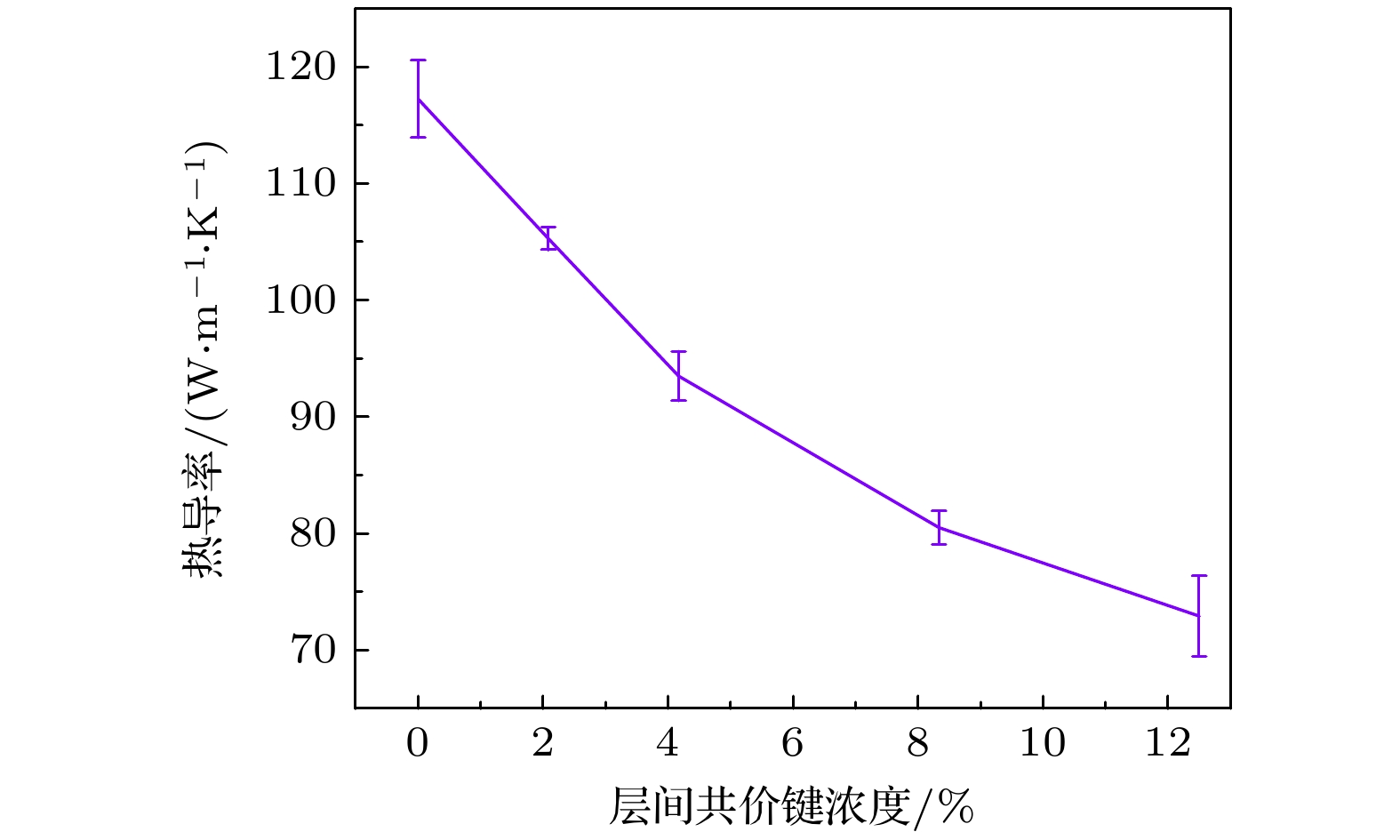

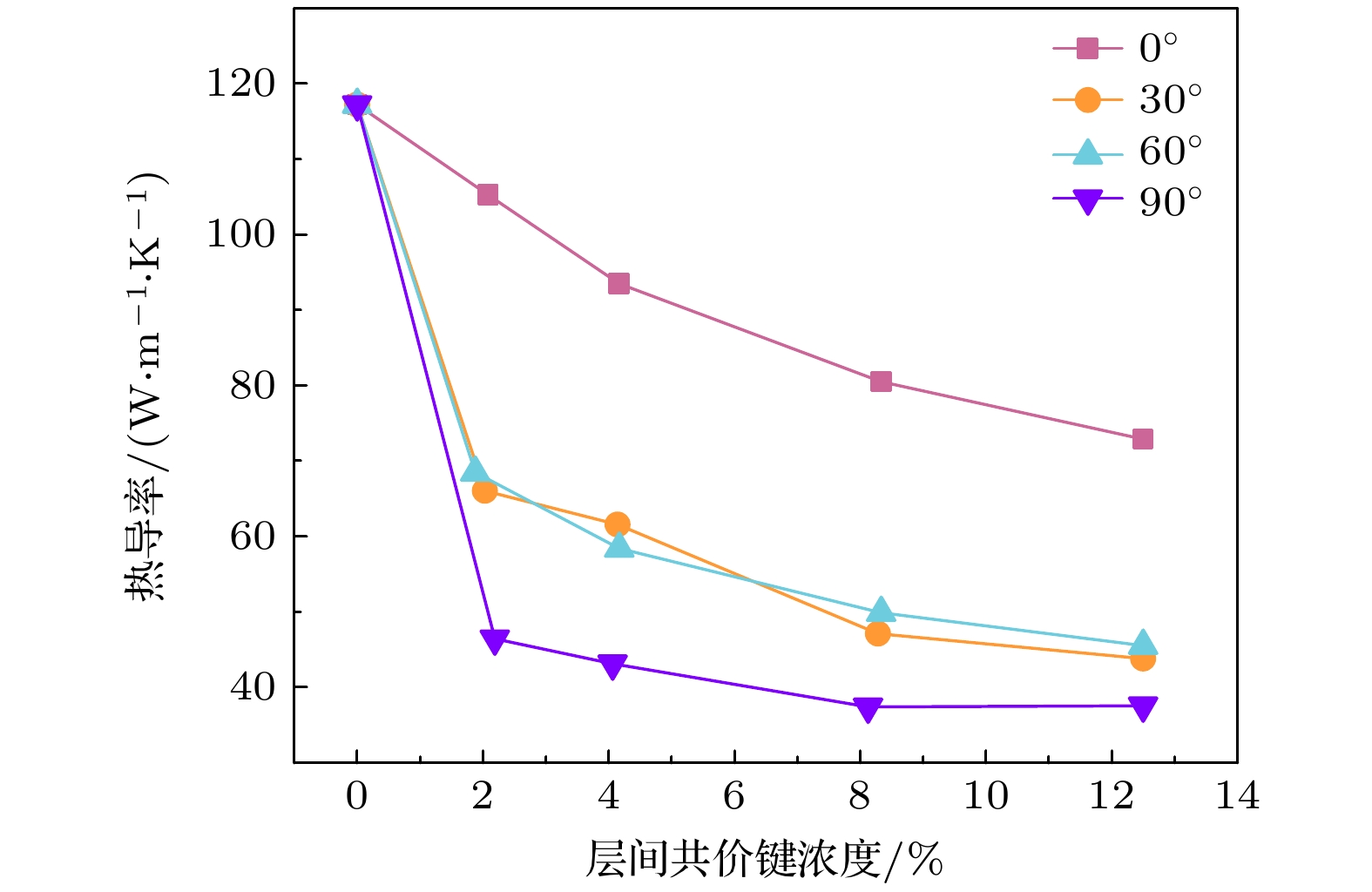

The interlayer bonding of graphene is a method of modifying graphene, which can change the mechanical property and conductivity of graphene, but also affect its thermal properties. In this paper, the non-equilibrium molecular dynamics method is used to study the thermal conductivity of bilayer graphene nanoribbon which is local carbon sp3 hybridization (covalent bond formed between layers) under different concentration and angle of interlayer covalent bond chain and different tensile strain. The mechanism of the change of the thermal conductivity of bilayer graphene nanoribbon is analyzed through the density of phonon states. The results are as follows. The thermal conductivity of bilayer graphene nanoribbon decreases with the increase of the interlayer covalent bond concentration due to the intensification of phonon scattering and the reduction of phonon group velocities and effective phonon mean free path. Moreover, the decrease rate of thermal conductivity depends on the distribution angle of covalent bond chain. With the increase of interlayer covalent bond concentration, when the interlayer covalent bond chain is parallel to the direction of heat flow, the thermal conductivity decreases slowest because the heat transfer channel along the heat flow direction is gradually affected; when the interlayer covalent bond chain is at an angle with respect to the direction of heat flow, the thermal conductivity decreases more rapidly, and the larger the angle, the faster the thermal conductivity decreases. The rapid decline of thermal conductivity is due to the formation of interfacial thermal resistance at the interlayer covalent bond chain, where strong phonon-interface scattering occurs. In addition, it is found that the thermal conductivity of bilayer graphene nanoribbon with interlayer bonding will be further reduced by tensile strain due to the intensification of phonon scattering and the reduction of phonon group velocity. The results show that the thermal conductivity of bilayer graphene nanoribbon can be controlled by interlayer bonding and tensile strain. These conclusions are of great significance in designing and thermally controlling of graphene based nanodevices.

-

Keywords:

- thermal conductivity /

- bilayer graphene nanoribbon /

- interlayer covalent bond /

- molecular dynamic

[1] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[2] King A, Johnson G, Engelberg D, Ludwig W, Marrow J 2008 Science 321 382

Google Scholar

Google Scholar

[3] Novoselov K S, Morozov S V, Mohinddin T M G, Ponomarenko L A, Elias D C, Yang R, Barbolina I I, Blake P, Booth T J, Jiang D, Giesbers J, Hill E W, Geim A K 2007 Phys. Status Solidi B 244 4106

Google Scholar

Google Scholar

[4] Pop E, Varshney V, Roy A K 2012 MRS Bull. 37 1273

Google Scholar

Google Scholar

[5] Geim A K, Novoselov K S 2007 Nat. Mater. 6 183

Google Scholar

Google Scholar

[6] Wu T, Zhang X, Yuan Q, Xue J, Lu G, Liu Z, Wang H, Wang H, Ding F, Yu Q, Xie X, Jiang M 2016 Nat. Mater. 15 43

Google Scholar

Google Scholar

[7] Ghosh S, Calizo I, Teweldebrhan D, Pokatilov E P, Nika D L, Balandin A A, Bao W, Miao F, Lau C N 2008 Appl. Phys. Lett. 92 151911

Google Scholar

Google Scholar

[8] Nika D L, Ghosh S, Pokatilov E P, Balandin A A 2009 Appl. Phys. Lett. 94 203103

Google Scholar

Google Scholar

[9] Xu Y, Chen X, Gu B, Duan W 2009 Appl. Phys. Lett. 95 233116

Google Scholar

Google Scholar

[10] Hu J, Ruan X, Chen Y P 2009 Nano Lett. 9 2730

Google Scholar

Google Scholar

[11] Kong B D, Paul S, Nardelli M B, Kim K W 2009 Phys. Rev. B 80 033406

Google Scholar

Google Scholar

[12] Cao H, Guo Z, Xiang H, Gong X 2012 Phys. Lett. A 376 525

Google Scholar

Google Scholar

[13] Chien S, Yang Y, Chen C O 2011 Appl. Phys. Lett. 98 33107

Google Scholar

Google Scholar

[14] Pei Q, Sha Z, Zhang Y 2011 Carbon 49 4752

Google Scholar

Google Scholar

[15] 杨平, 王晓亮, 李培, 王欢, 张立强, 谢方伟 2012 61 076501

Google Scholar

Google Scholar

Yang P, Wang X L, Li P, Wang H, Zhang L Q, Xie F W 2012 Acta Phys. Sin. 61 076501

Google Scholar

Google Scholar

[16] Morpurgo A F, Vandersypen L M K, Oostinga J B, Heersche H B, Liu X 2008 Nat. Mater. 7 151

Google Scholar

Google Scholar

[17] Deng C C, Huang Y W, An M, Yang N 2021 Mater. Today Phys. 16 100305

Google Scholar

Google Scholar

[18] 潘东楷, 宗志成, 杨诺 2022 71 086302

Google Scholar

Google Scholar

Pan D K, Zong Z C, Yang N 2022 Acta Phys. Sin. 71 086302

Google Scholar

Google Scholar

[19] Ghosh S, Bao W, Nika D L, Subrina S, Pokatilov E P, Lau C N, Balandin A A 2010 Nat. Mater. 9 555

Google Scholar

Google Scholar

[20] Wei Z, Ni Z, Bi K, Chen M, Chen Y 2011 Carbon 49 2653

Google Scholar

Google Scholar

[21] Yu X X, Ma D K, Deng C C, Wan X, An M, Meng H, Li X B, Huang X M, Yang N 2021 Chin. Phys. Lett. 38 014401

Google Scholar

Google Scholar

[22] Li Z, Wang Y, Ma M, Ma H, Hu W, Zhang X, Zhuge Z, Zhang S, Luo K, Gao Y, Sun L, Soldatov A V, Wu Y, Liu B, Li B, Ying P, Zhang Y, Xu B, He J, Yu D, Liu Z, Zhao Z, Yue Y, Tian Y, Li X 2023 Nat. Mater. 22 42

Google Scholar

Google Scholar

[23] Peng B, Locascio M, Zapol P, Li S, Mielke S L, Schatz G C, Espinosa H D 2008 Nat. Nanotechnol. 3 626

Google Scholar

Google Scholar

[24] Kanasaki J, Inami E, Tanimura K, Ohnishi H, Nasu K 2009 Phys. Rev. Lett. 102 87402

Google Scholar

Google Scholar

[25] Kvashnin A G, Chernozatonskii L A, Yakobson B I, Sorokin P B 2014 Nano Lett. 14 676

Google Scholar

Google Scholar

[26] Rajabpour A, Vaez Allaei S M 2012 Appl. Phys. Lett. 101 53115

Google Scholar

Google Scholar

[27] Guo T, Sha Z, Liu X, Zhang G, Guo T, Pei Q, Zhang Y 2015 Appl. Phys. A 120 1275

Google Scholar

Google Scholar

[28] Yang L, Wan X, Ma D K, Jiang Y, Yang N 2021 Phys. Rev. B 103 155305

Google Scholar

Google Scholar

[29] 宗志成, 潘东楷, 邓世琛, 万骁, 杨哩娜, 马登科, 杨诺 2023 72 034401

Google Scholar

Google Scholar

Song Z C, Pan D K, Deng S C, Wan X, Yang L N, Ma D K, Yang N 2023 Acta Phys. Sin. 72 034401

Google Scholar

Google Scholar

[30] Chen Y, Wan J, Chen Y, Qin H, Liu Y, Pei Q, Zhang Y 2023 Int. J. Therm. Sci. 183 107871

Google Scholar

Google Scholar

[31] Fan L, Yao W 2021 Diamond Relat. Mater. 118 108521

Google Scholar

Google Scholar

[32] Huang Y W, Feng W T, Yu X X, Deng C C, Yang N 2020 Chin. Phys. B 29 126303

Google Scholar

Google Scholar

[33] Feng W T, Yu X X, Wang Y, Ma D K, Sun Z J, Deng C C, Yang N 2019 Phys. Chem. Chem. Phys. 21 25072

Google Scholar

Google Scholar

[34] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[35] Stuart S J, Tutein A B, Harrison J A 2000 J. Chem. Phys. 112 6472

Google Scholar

Google Scholar

[36] Girifalco L A, Hodak M, Lee R S 2000 Phys. Rev. B 62 13104

Google Scholar

Google Scholar

[37] Xu X F, Pereira L F C, Wang Y, Wu J, Zhang K W, Zhao X M, Bae S, Tinh Bui C T, Xie R G, Thong J T L, Hong B H, Loh K P, Donadio D, Li B W, Ozyilmaz B 2014 Nat. Commun. 5 3689

Google Scholar

Google Scholar

[38] Hao F, Fang D, Xu Z 2011 Appl. Phys. Lett. 99 041901

Google Scholar

Google Scholar

[39] Wei N, Xu L, Wang H, Zheng J 2011 Nanotechnology 22 105705

Google Scholar

Google Scholar

[40] Polanco C A, Lindsay L 2018 Phys. Rev. B 98 014306

Google Scholar

Google Scholar

[41] Dong L, Wu X S, Hu Y, Xu X F, Bao H 2021 Chin. Phys. Lett. 38 027202

Google Scholar

Google Scholar

[42] Zhu G P, Zhao C W, Wang X W, Wang J 2021 Chin. Phys. Lett. 38 024401

Google Scholar

Google Scholar

[43] Guo Z, Zhang D, Gong X 2009 Appl. Phys. Lett. 95 163103

Google Scholar

Google Scholar

[44] Meng H, Maruyama S G, Xiang R, Yang N 2021 Int. J. Heat Mass Transfer 180 121773

Google Scholar

Google Scholar

[45] Xu K, Deng S C, Liang T, Cao X Z, Han M, Zeng X L, Zhang Z S, Yang N, Wu J Y 2022 Nanoscale 14 3078

Google Scholar

Google Scholar

[46] Wang X, Demir B, An M, Walsh T R, Yang N 2021 Int. J. Heat Mass Transfer 180 121821

Google Scholar

Google Scholar

[47] Mohiuddin T M G, Lombardo A, Nair R R, Bonetti A, Savini G, Jalil R, Bonini N, Basko D M, Galiotis C, Marzari N, Novoselov K S, Geim A K, Ferrari A C 2009 Phys. Rev. B 79 205433

Google Scholar

Google Scholar

-

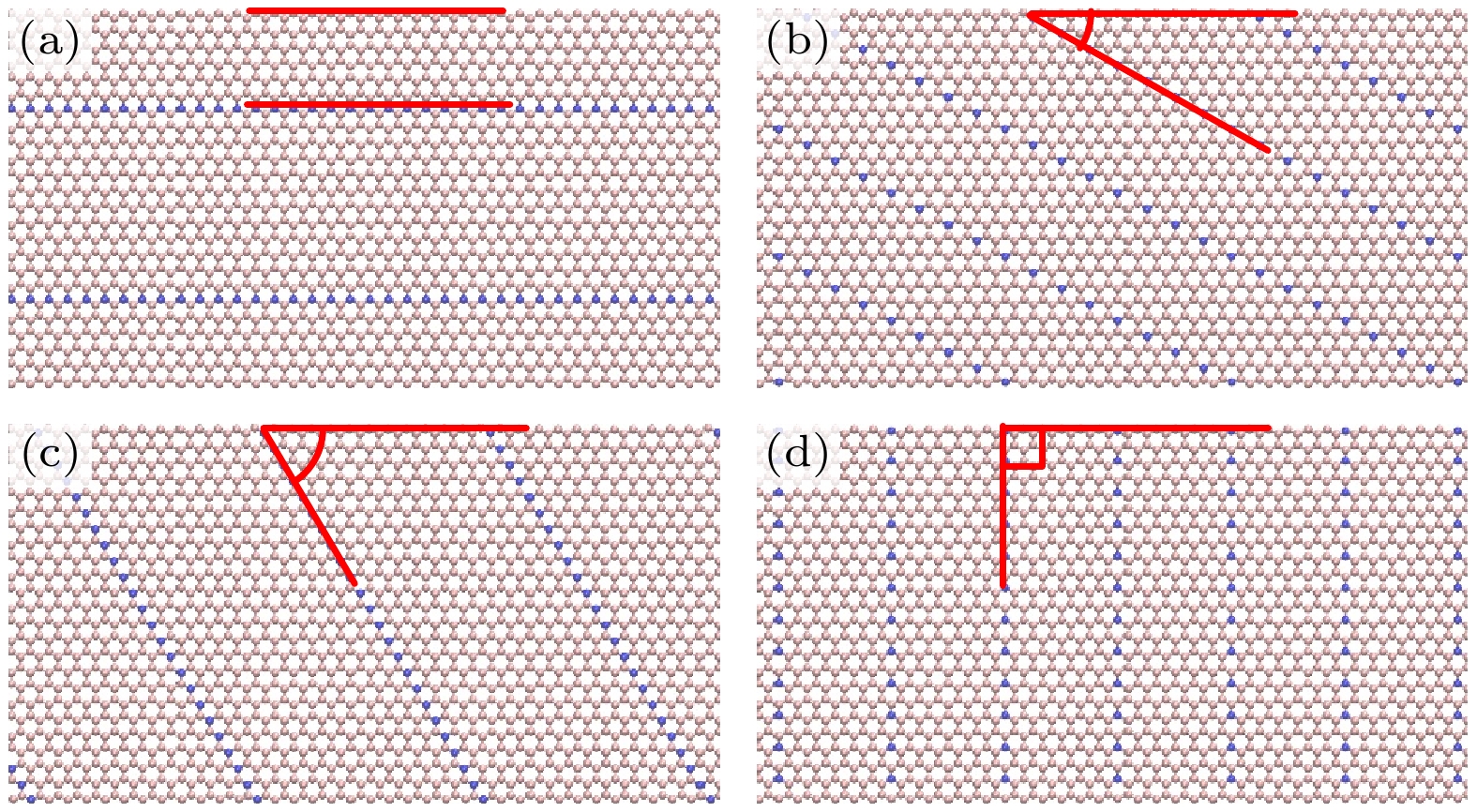

图 3 不同层间共价键浓度的模型图 (a) 层间共价键浓度为2.08%; (b) 层间共价键浓度为4.16%; (c) 层间共价键浓度为8.33%; (d) 层间共价键浓度为12.5%

Figure 3. Snapshot of model diagram of different interlayer covalent bond concentration: (a) interlayer covalent bond concentration of 2.08%; (b) interlayer covalent bond concentration of 4.16%; (c) interlayer covalent bond concentration of 8.33%; (d) interlayer covalent bond concentration of 12.5%

图 5 (a) 不同层间共价键浓度的双层石墨烯的面内PDOS; (b) 不同层间共价键浓度的双层石墨烯的面外PDOS; (c) 相同模型共价键区域和非共价键区域的面内PDOS; (d) 相同模型共价键区域和非共价键区域的面外PDOS

Figure 5. (a) In-plane PDOS of bilayer graphene with different interlayer covalent concentration; (b) the out-plane PDOS of bilayer graphene with different interlayer covalent concentration; (c) the in-plane PDOS of covalent and noncovalent bond regions in the same model; (d) the in-plane PDOS of covalent and noncovalent bond regions in the same model.

图 6 层间共价键链呈不同角度时的模型图 (a) 层间共价键链呈0°; (b) 层间共价键链呈30°; (c) 层间共价键链呈60°; (d) 层间共价键链呈90°

Figure 6. Snapshot of model diagram of interlayer covalent bond chain at different angles: (a) 0° interlayer covalent bond chain; (b) 30° interlayer covalent bond chain; (c) 60° interlayer covalent bond chain; (d) 90° interlayer covalent bond chain

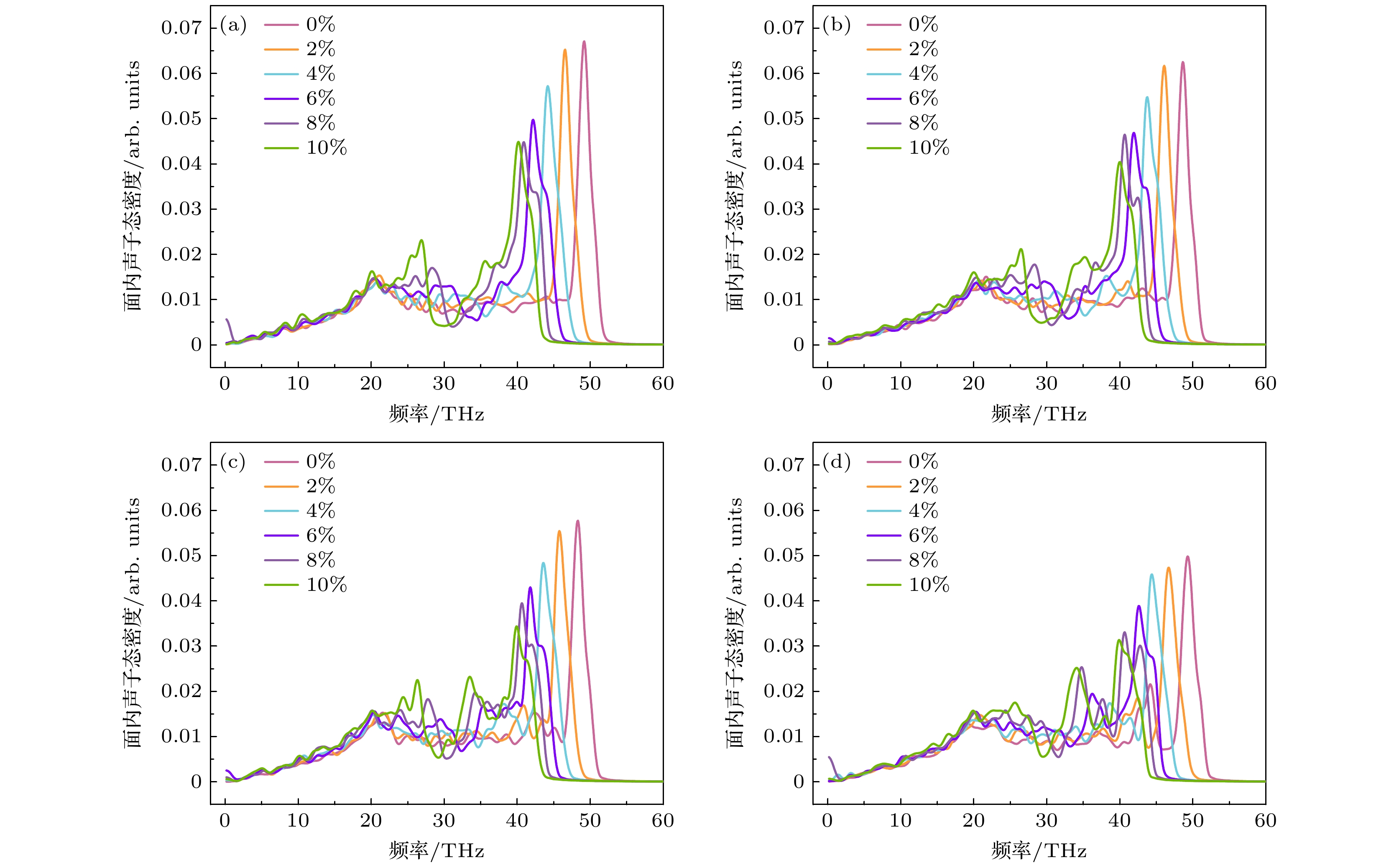

图 9 不同拉伸应变下具有层间共价键的双层石墨烯的面内声子态密度 (a) 层间共价键浓度为2.08%; (b) 层间共价键浓度为4.16%; (c) 层间共价键浓度为8.33%; (d) 层间共价键浓度为12.5%

Figure 9. In-plane PDOS of bilayer graphene with interlayer covalent bonds under different tensile strains: (a) Interlayer covalent bond concentration of 2.08%; (b) interlayer covalent bond concentration of 4.16%; (c) interlayer covalent bond concentration of 8.33%; (d) interlayer covalent bond concentration 12.5% interlayer covalent bond concentration.

-

[1] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[2] King A, Johnson G, Engelberg D, Ludwig W, Marrow J 2008 Science 321 382

Google Scholar

Google Scholar

[3] Novoselov K S, Morozov S V, Mohinddin T M G, Ponomarenko L A, Elias D C, Yang R, Barbolina I I, Blake P, Booth T J, Jiang D, Giesbers J, Hill E W, Geim A K 2007 Phys. Status Solidi B 244 4106

Google Scholar

Google Scholar

[4] Pop E, Varshney V, Roy A K 2012 MRS Bull. 37 1273

Google Scholar

Google Scholar

[5] Geim A K, Novoselov K S 2007 Nat. Mater. 6 183

Google Scholar

Google Scholar

[6] Wu T, Zhang X, Yuan Q, Xue J, Lu G, Liu Z, Wang H, Wang H, Ding F, Yu Q, Xie X, Jiang M 2016 Nat. Mater. 15 43

Google Scholar

Google Scholar

[7] Ghosh S, Calizo I, Teweldebrhan D, Pokatilov E P, Nika D L, Balandin A A, Bao W, Miao F, Lau C N 2008 Appl. Phys. Lett. 92 151911

Google Scholar

Google Scholar

[8] Nika D L, Ghosh S, Pokatilov E P, Balandin A A 2009 Appl. Phys. Lett. 94 203103

Google Scholar

Google Scholar

[9] Xu Y, Chen X, Gu B, Duan W 2009 Appl. Phys. Lett. 95 233116

Google Scholar

Google Scholar

[10] Hu J, Ruan X, Chen Y P 2009 Nano Lett. 9 2730

Google Scholar

Google Scholar

[11] Kong B D, Paul S, Nardelli M B, Kim K W 2009 Phys. Rev. B 80 033406

Google Scholar

Google Scholar

[12] Cao H, Guo Z, Xiang H, Gong X 2012 Phys. Lett. A 376 525

Google Scholar

Google Scholar

[13] Chien S, Yang Y, Chen C O 2011 Appl. Phys. Lett. 98 33107

Google Scholar

Google Scholar

[14] Pei Q, Sha Z, Zhang Y 2011 Carbon 49 4752

Google Scholar

Google Scholar

[15] 杨平, 王晓亮, 李培, 王欢, 张立强, 谢方伟 2012 61 076501

Google Scholar

Google Scholar

Yang P, Wang X L, Li P, Wang H, Zhang L Q, Xie F W 2012 Acta Phys. Sin. 61 076501

Google Scholar

Google Scholar

[16] Morpurgo A F, Vandersypen L M K, Oostinga J B, Heersche H B, Liu X 2008 Nat. Mater. 7 151

Google Scholar

Google Scholar

[17] Deng C C, Huang Y W, An M, Yang N 2021 Mater. Today Phys. 16 100305

Google Scholar

Google Scholar

[18] 潘东楷, 宗志成, 杨诺 2022 71 086302

Google Scholar

Google Scholar

Pan D K, Zong Z C, Yang N 2022 Acta Phys. Sin. 71 086302

Google Scholar

Google Scholar

[19] Ghosh S, Bao W, Nika D L, Subrina S, Pokatilov E P, Lau C N, Balandin A A 2010 Nat. Mater. 9 555

Google Scholar

Google Scholar

[20] Wei Z, Ni Z, Bi K, Chen M, Chen Y 2011 Carbon 49 2653

Google Scholar

Google Scholar

[21] Yu X X, Ma D K, Deng C C, Wan X, An M, Meng H, Li X B, Huang X M, Yang N 2021 Chin. Phys. Lett. 38 014401

Google Scholar

Google Scholar

[22] Li Z, Wang Y, Ma M, Ma H, Hu W, Zhang X, Zhuge Z, Zhang S, Luo K, Gao Y, Sun L, Soldatov A V, Wu Y, Liu B, Li B, Ying P, Zhang Y, Xu B, He J, Yu D, Liu Z, Zhao Z, Yue Y, Tian Y, Li X 2023 Nat. Mater. 22 42

Google Scholar

Google Scholar

[23] Peng B, Locascio M, Zapol P, Li S, Mielke S L, Schatz G C, Espinosa H D 2008 Nat. Nanotechnol. 3 626

Google Scholar

Google Scholar

[24] Kanasaki J, Inami E, Tanimura K, Ohnishi H, Nasu K 2009 Phys. Rev. Lett. 102 87402

Google Scholar

Google Scholar

[25] Kvashnin A G, Chernozatonskii L A, Yakobson B I, Sorokin P B 2014 Nano Lett. 14 676

Google Scholar

Google Scholar

[26] Rajabpour A, Vaez Allaei S M 2012 Appl. Phys. Lett. 101 53115

Google Scholar

Google Scholar

[27] Guo T, Sha Z, Liu X, Zhang G, Guo T, Pei Q, Zhang Y 2015 Appl. Phys. A 120 1275

Google Scholar

Google Scholar

[28] Yang L, Wan X, Ma D K, Jiang Y, Yang N 2021 Phys. Rev. B 103 155305

Google Scholar

Google Scholar

[29] 宗志成, 潘东楷, 邓世琛, 万骁, 杨哩娜, 马登科, 杨诺 2023 72 034401

Google Scholar

Google Scholar

Song Z C, Pan D K, Deng S C, Wan X, Yang L N, Ma D K, Yang N 2023 Acta Phys. Sin. 72 034401

Google Scholar

Google Scholar

[30] Chen Y, Wan J, Chen Y, Qin H, Liu Y, Pei Q, Zhang Y 2023 Int. J. Therm. Sci. 183 107871

Google Scholar

Google Scholar

[31] Fan L, Yao W 2021 Diamond Relat. Mater. 118 108521

Google Scholar

Google Scholar

[32] Huang Y W, Feng W T, Yu X X, Deng C C, Yang N 2020 Chin. Phys. B 29 126303

Google Scholar

Google Scholar

[33] Feng W T, Yu X X, Wang Y, Ma D K, Sun Z J, Deng C C, Yang N 2019 Phys. Chem. Chem. Phys. 21 25072

Google Scholar

Google Scholar

[34] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[35] Stuart S J, Tutein A B, Harrison J A 2000 J. Chem. Phys. 112 6472

Google Scholar

Google Scholar

[36] Girifalco L A, Hodak M, Lee R S 2000 Phys. Rev. B 62 13104

Google Scholar

Google Scholar

[37] Xu X F, Pereira L F C, Wang Y, Wu J, Zhang K W, Zhao X M, Bae S, Tinh Bui C T, Xie R G, Thong J T L, Hong B H, Loh K P, Donadio D, Li B W, Ozyilmaz B 2014 Nat. Commun. 5 3689

Google Scholar

Google Scholar

[38] Hao F, Fang D, Xu Z 2011 Appl. Phys. Lett. 99 041901

Google Scholar

Google Scholar

[39] Wei N, Xu L, Wang H, Zheng J 2011 Nanotechnology 22 105705

Google Scholar

Google Scholar

[40] Polanco C A, Lindsay L 2018 Phys. Rev. B 98 014306

Google Scholar

Google Scholar

[41] Dong L, Wu X S, Hu Y, Xu X F, Bao H 2021 Chin. Phys. Lett. 38 027202

Google Scholar

Google Scholar

[42] Zhu G P, Zhao C W, Wang X W, Wang J 2021 Chin. Phys. Lett. 38 024401

Google Scholar

Google Scholar

[43] Guo Z, Zhang D, Gong X 2009 Appl. Phys. Lett. 95 163103

Google Scholar

Google Scholar

[44] Meng H, Maruyama S G, Xiang R, Yang N 2021 Int. J. Heat Mass Transfer 180 121773

Google Scholar

Google Scholar

[45] Xu K, Deng S C, Liang T, Cao X Z, Han M, Zeng X L, Zhang Z S, Yang N, Wu J Y 2022 Nanoscale 14 3078

Google Scholar

Google Scholar

[46] Wang X, Demir B, An M, Walsh T R, Yang N 2021 Int. J. Heat Mass Transfer 180 121821

Google Scholar

Google Scholar

[47] Mohiuddin T M G, Lombardo A, Nair R R, Bonetti A, Savini G, Jalil R, Bonini N, Basko D M, Galiotis C, Marzari N, Novoselov K S, Geim A K, Ferrari A C 2009 Phys. Rev. B 79 205433

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 5986

- PDF Downloads: 268

- Cited By: 0

DownLoad:

DownLoad: