-

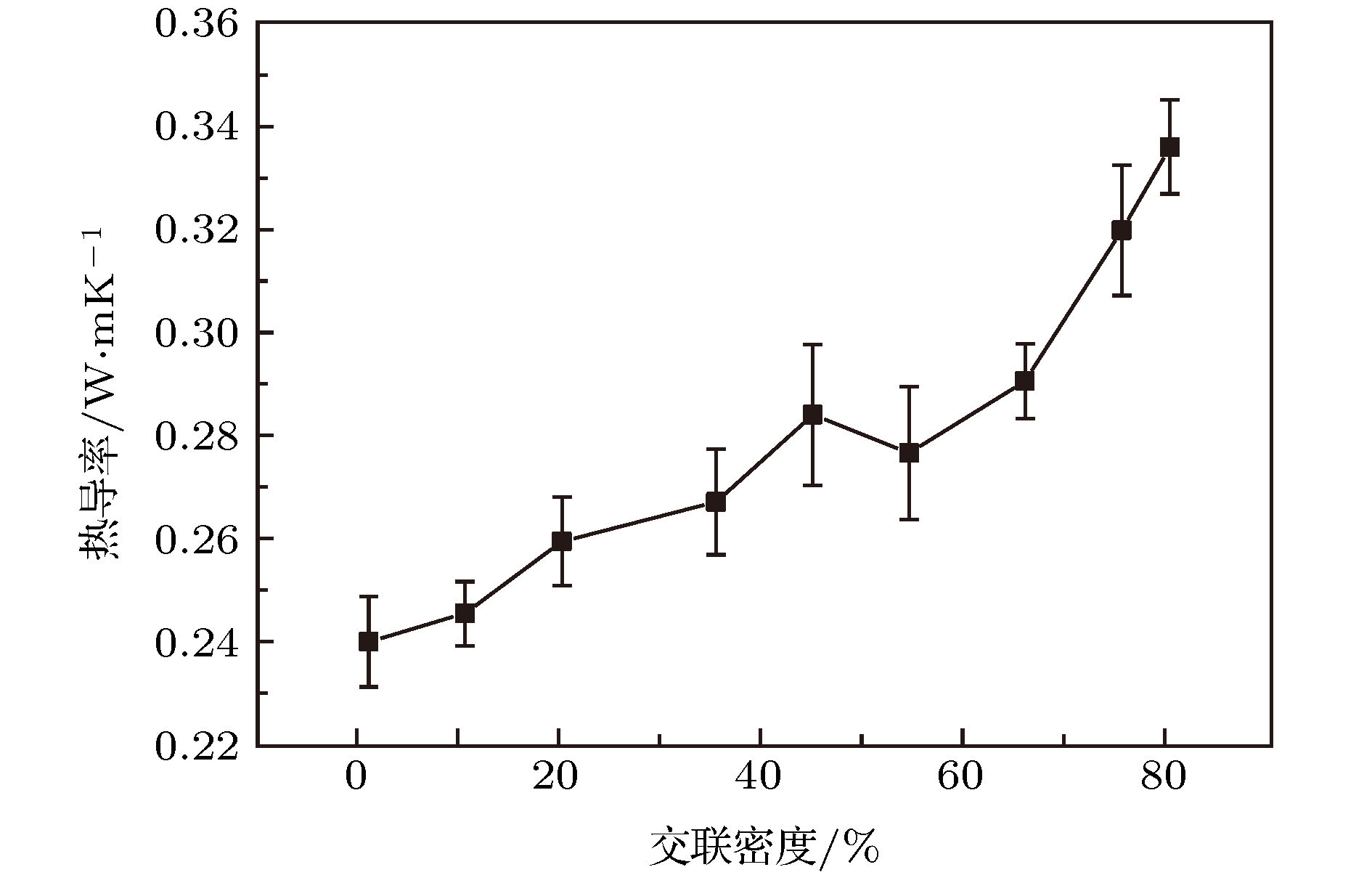

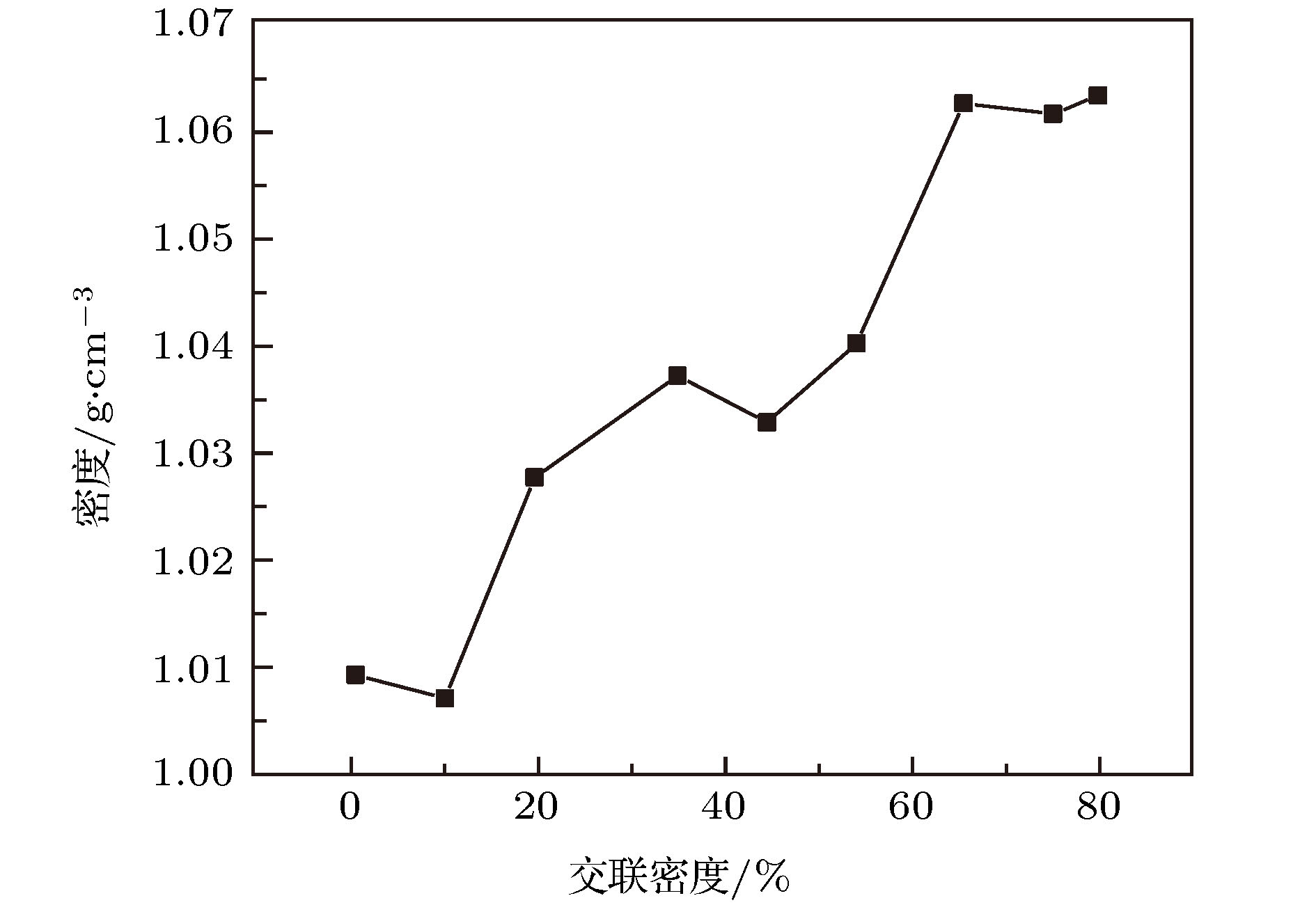

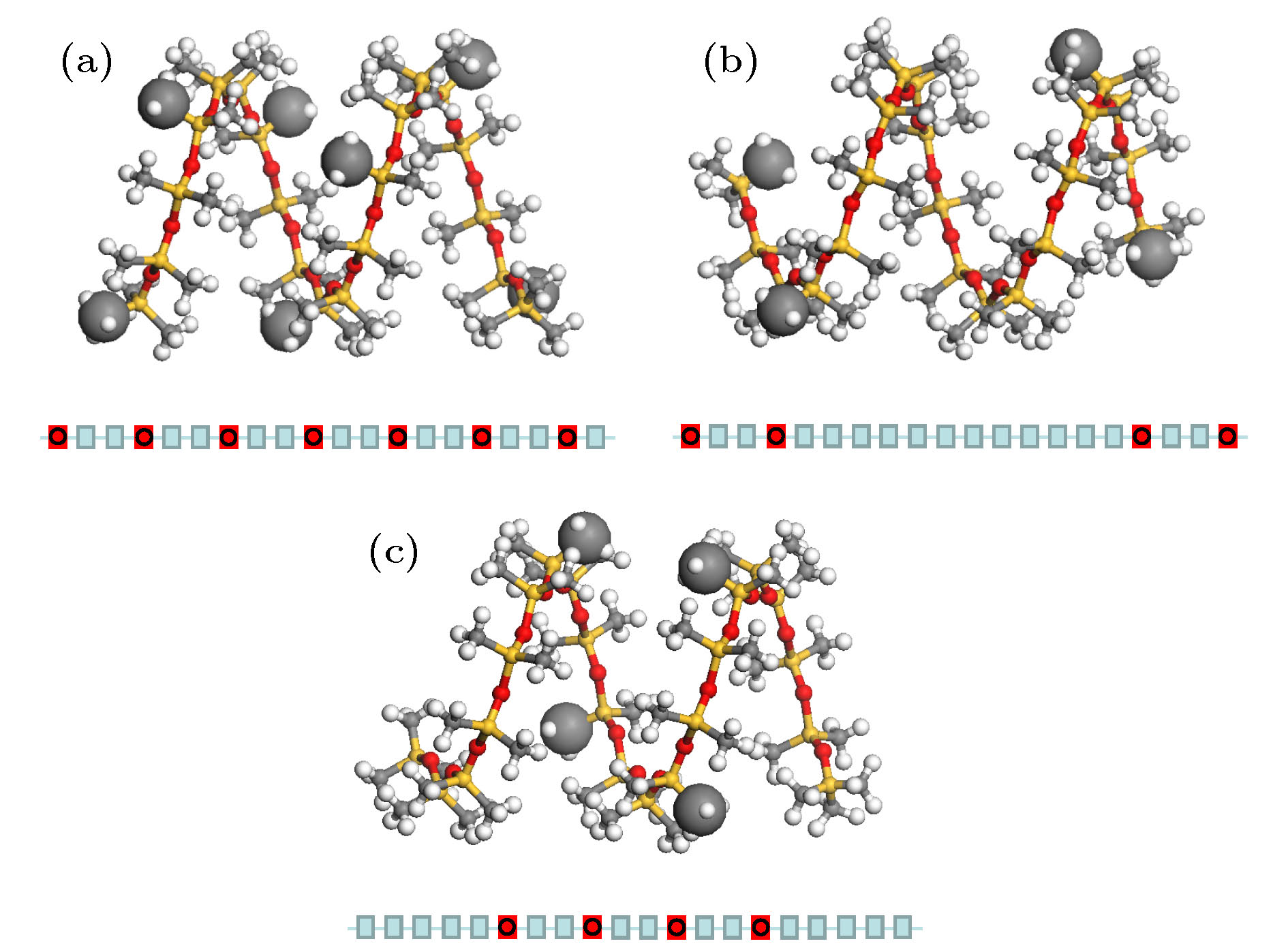

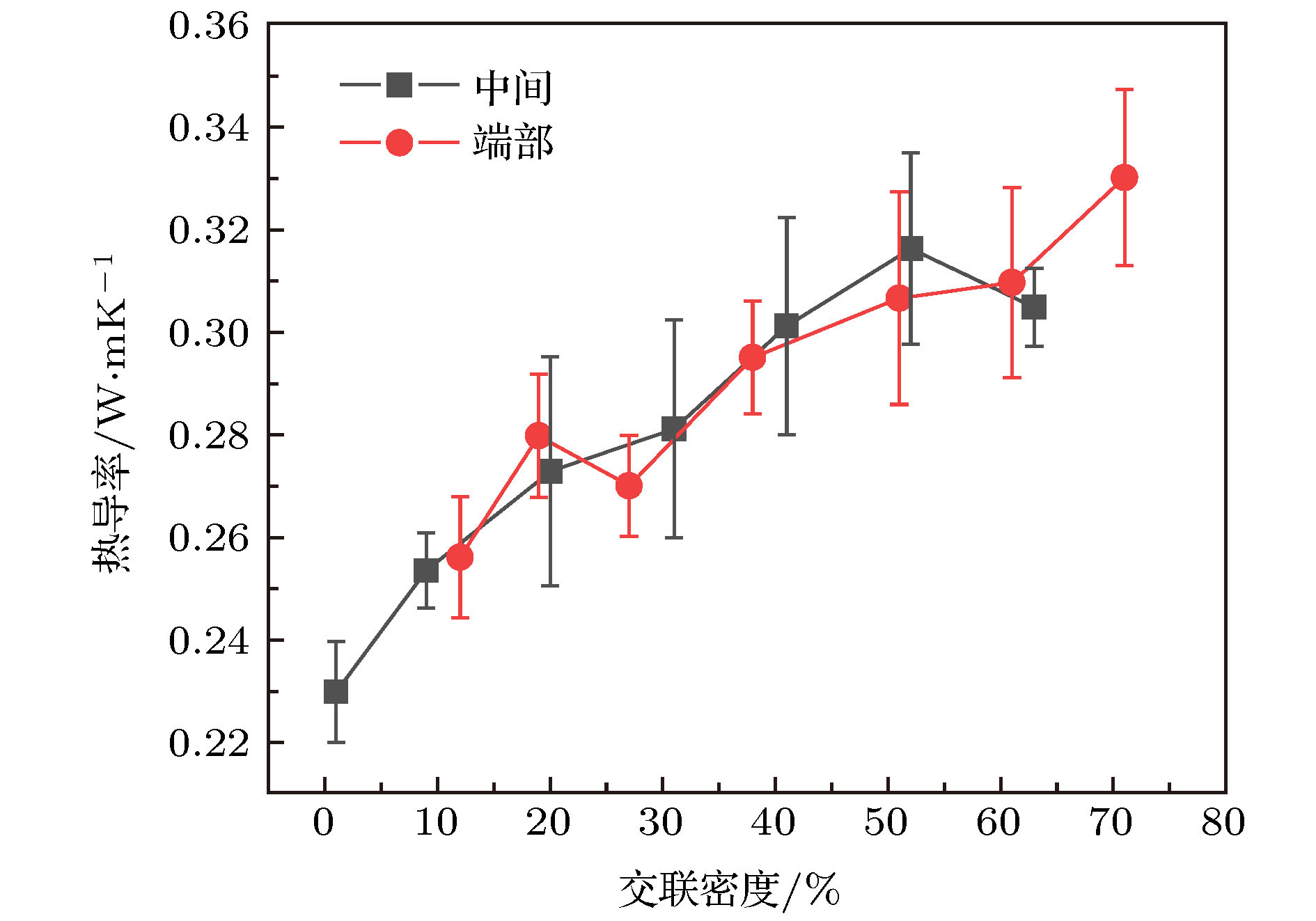

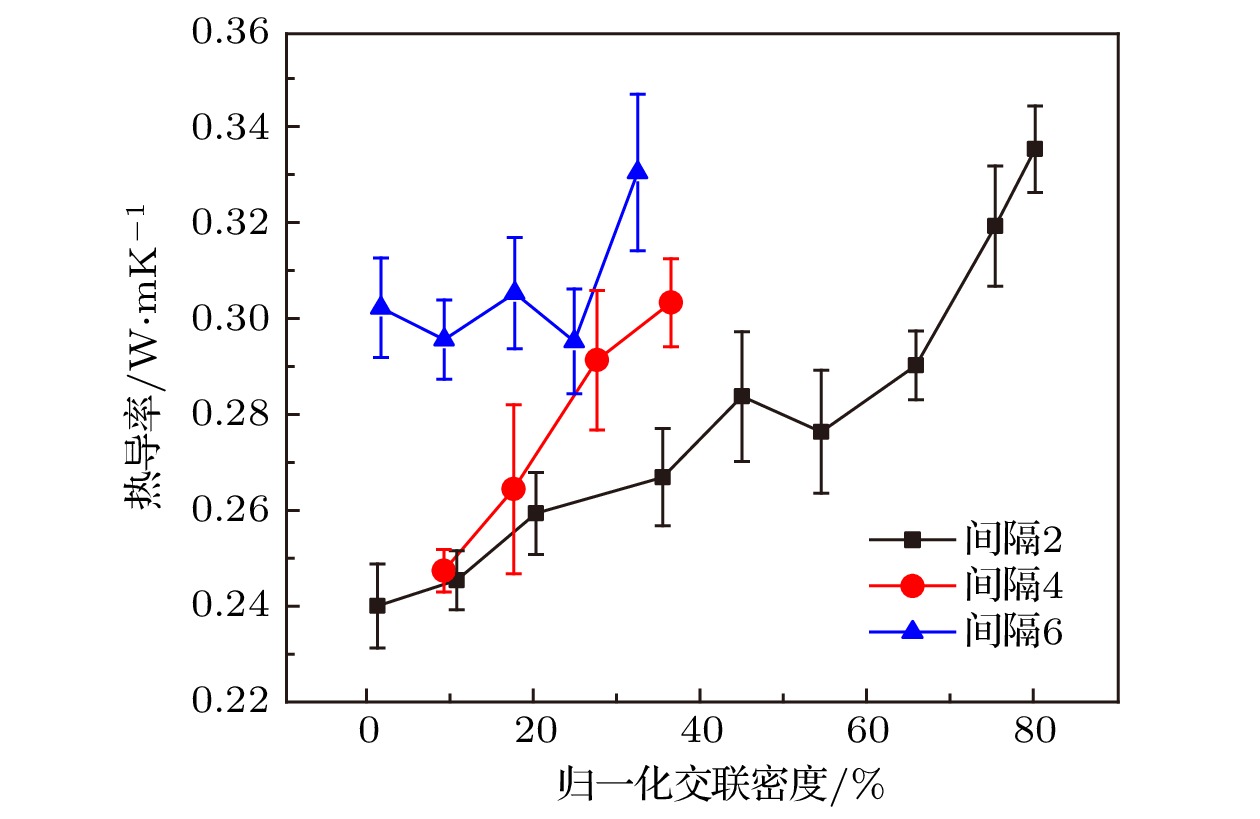

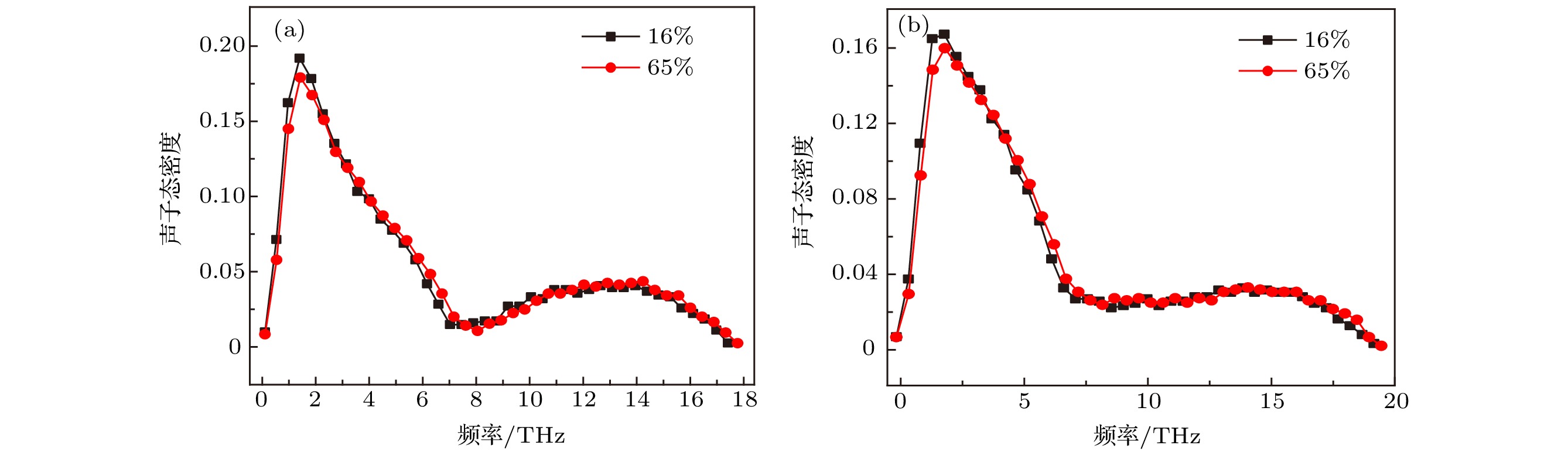

Silicone rubber has an important application as a thermal interface material for its advantages in insulation, heat resistance, etc. The thermal conductivities at different crosslinking densities are calculated by non-equilibrium molecular dynamics. The results show that the thermal conductivity increases with crosslinking density increasing. The thermal conductivity can increase by 40% when the crosslinking density is 80%, which is because the spatial network structure formed by crosslinking shortens the length of heat transfer along the atomic chain, which makes the thermal conductivity increase greatly. The position of crosslinking bond has little effect on the thermal conductivity under the same crosslinking density, i.e. there is no significant difference in the thermal conductivity of the cross-linked structure between the end-cross-linking position and the middle-cross-linking position. However, the increase of the interval between the crosslinking points is beneficial to the increase of the thermal conductivity. The phonon densities of state under different crosslinking densities are calculated, and the heat conduction mechanism of crosslinking structure is analyzed.

-

Keywords:

- silicone rubber /

- thermal conductivity /

- crosslinking density /

- non-equilibrium molecular dynamic

[1] Balandin A A 2009 IEEE Spectrum 46 34

Google Scholar

Google Scholar

[2] 李琴, 刘海东, 朱敏波 2006 电子工艺技术 27 165

Google Scholar

Google Scholar

Li Q, Liu H D, Zhu M B 2006 Electron. Process Technol. 27 165

Google Scholar

Google Scholar

[3] 杨邦朝, 陈文媛, 曾理, 胡永达 中国电子学会第十四届电子元件学术年会论文集, 中国西宁, 2006年8月15—19日 第111页

Yang B C, Chen W Y, Zeng L, Hu Y D 2006 China Academic Journal Electronic Publishing House, Xining, China, August 15–19, 2006 p111 (in Chinese)

[4] Liu C H, Huang H, Wu Y, Fan S 2004 Appl. Phys. Lett. 84 4248

Google Scholar

Google Scholar

[5] 陈杰, 张欢 2018 广州化学 43 35

Google Scholar

Google Scholar

Chen J, Zhang H 2018 Guangzhou Chem. 43 35

Google Scholar

Google Scholar

[6] Kanari K, Ozawa a 1973 Polym. J. 4 372

Google Scholar

Google Scholar

[7] Kikugawa G, Desai T G, Keblinski P, Ohara T 2013 J. Appl. Phys. 114 034302

Google Scholar

Google Scholar

[8] Li J, Zhang X, Yuen M F, Liu L, Zhang K 2014 15th International Conference on Electronic Packaging Technology (ICEPT), Chengdu, China, August 12–15, 2014 p329

[9] Terao T, Lussetti E, Müller-Plathe F 2007 Phys. Rev. E 75 057701

Google Scholar

Google Scholar

[10] Luo T, Esfarjani K, Shiomi J, Henry A, Gang C 2011 J. Appl. Phys. 109 074321

Google Scholar

Google Scholar

[11] NOSÉ S 1984 Mol. Phys. 52 255

Google Scholar

Google Scholar

[12] Xu W, Wu Y, Zhu Y, Liang X G 2020 Chin. Phys. B 29 46601

Google Scholar

Google Scholar

[13] Algaer E, Müller-Plathe F 2012 Soft Mater. 10 42-80

[14] 黄文润 2009 热硫化硅橡胶 (成都: 四川科学技术出版社)

Huang W R 2009 Heat Vulcanizing Silicone Rubber (Chengdu: Sichuan Science and Technology Press) (in Chinese)

[15] Sun H 1998 J. Phys. Chem. B 102 7338

Google Scholar

Google Scholar

[16] Popovic R S, 王韶晖 1998 橡胶参考资料 28 8

Google Scholar

Google Scholar

Popovic R S, Wang S H 1998 Rubber Ref. 28 8

Google Scholar

Google Scholar

[17] 胡东红, 吴季怀, 沈振 1998 华侨大学学报: 自然科学版 19 375

Google Scholar

Google Scholar

Hu D H, Wu J H, Shen Z 1998 J. Huaqiao Univ., Nat. Sci. 19 375

Google Scholar

Google Scholar

[18] Stoica T J 1994 Mater. Res. Bull. 29 813

Google Scholar

Google Scholar

[19] Heino P 2007 Eur. Phys. J. B 60 171

Google Scholar

Google Scholar

[20] Kong L T 2011 Comput. Phys. Commun. 182 2201

Google Scholar

Google Scholar

[21] Kong L T, Bartels G, Campañá C, Denniston C, Müser M H 2009 Comput. Phys. Commun. 180 1004

Google Scholar

Google Scholar

[22] Campañá C, Mueser M H 2006 Phys. Rev. B 74 075420

Google Scholar

Google Scholar

-

表 1 归一化交联密度的计算

Table 1. Calculation of normalized crosslinking density.

体积 交联密度 归一化交联密度 间隔2 V2 C2 C2 间隔4 V4 C4 $C4 \times V2/V4$ 间隔6 V6 C6 $ C6 \times V2/V6 $ -

[1] Balandin A A 2009 IEEE Spectrum 46 34

Google Scholar

Google Scholar

[2] 李琴, 刘海东, 朱敏波 2006 电子工艺技术 27 165

Google Scholar

Google Scholar

Li Q, Liu H D, Zhu M B 2006 Electron. Process Technol. 27 165

Google Scholar

Google Scholar

[3] 杨邦朝, 陈文媛, 曾理, 胡永达 中国电子学会第十四届电子元件学术年会论文集, 中国西宁, 2006年8月15—19日 第111页

Yang B C, Chen W Y, Zeng L, Hu Y D 2006 China Academic Journal Electronic Publishing House, Xining, China, August 15–19, 2006 p111 (in Chinese)

[4] Liu C H, Huang H, Wu Y, Fan S 2004 Appl. Phys. Lett. 84 4248

Google Scholar

Google Scholar

[5] 陈杰, 张欢 2018 广州化学 43 35

Google Scholar

Google Scholar

Chen J, Zhang H 2018 Guangzhou Chem. 43 35

Google Scholar

Google Scholar

[6] Kanari K, Ozawa a 1973 Polym. J. 4 372

Google Scholar

Google Scholar

[7] Kikugawa G, Desai T G, Keblinski P, Ohara T 2013 J. Appl. Phys. 114 034302

Google Scholar

Google Scholar

[8] Li J, Zhang X, Yuen M F, Liu L, Zhang K 2014 15th International Conference on Electronic Packaging Technology (ICEPT), Chengdu, China, August 12–15, 2014 p329

[9] Terao T, Lussetti E, Müller-Plathe F 2007 Phys. Rev. E 75 057701

Google Scholar

Google Scholar

[10] Luo T, Esfarjani K, Shiomi J, Henry A, Gang C 2011 J. Appl. Phys. 109 074321

Google Scholar

Google Scholar

[11] NOSÉ S 1984 Mol. Phys. 52 255

Google Scholar

Google Scholar

[12] Xu W, Wu Y, Zhu Y, Liang X G 2020 Chin. Phys. B 29 46601

Google Scholar

Google Scholar

[13] Algaer E, Müller-Plathe F 2012 Soft Mater. 10 42-80

[14] 黄文润 2009 热硫化硅橡胶 (成都: 四川科学技术出版社)

Huang W R 2009 Heat Vulcanizing Silicone Rubber (Chengdu: Sichuan Science and Technology Press) (in Chinese)

[15] Sun H 1998 J. Phys. Chem. B 102 7338

Google Scholar

Google Scholar

[16] Popovic R S, 王韶晖 1998 橡胶参考资料 28 8

Google Scholar

Google Scholar

Popovic R S, Wang S H 1998 Rubber Ref. 28 8

Google Scholar

Google Scholar

[17] 胡东红, 吴季怀, 沈振 1998 华侨大学学报: 自然科学版 19 375

Google Scholar

Google Scholar

Hu D H, Wu J H, Shen Z 1998 J. Huaqiao Univ., Nat. Sci. 19 375

Google Scholar

Google Scholar

[18] Stoica T J 1994 Mater. Res. Bull. 29 813

Google Scholar

Google Scholar

[19] Heino P 2007 Eur. Phys. J. B 60 171

Google Scholar

Google Scholar

[20] Kong L T 2011 Comput. Phys. Commun. 182 2201

Google Scholar

Google Scholar

[21] Kong L T, Bartels G, Campañá C, Denniston C, Müser M H 2009 Comput. Phys. Commun. 180 1004

Google Scholar

Google Scholar

[22] Campañá C, Mueser M H 2006 Phys. Rev. B 74 075420

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 13076

- PDF Downloads: 274

- Cited By: 0

DownLoad:

DownLoad: