-

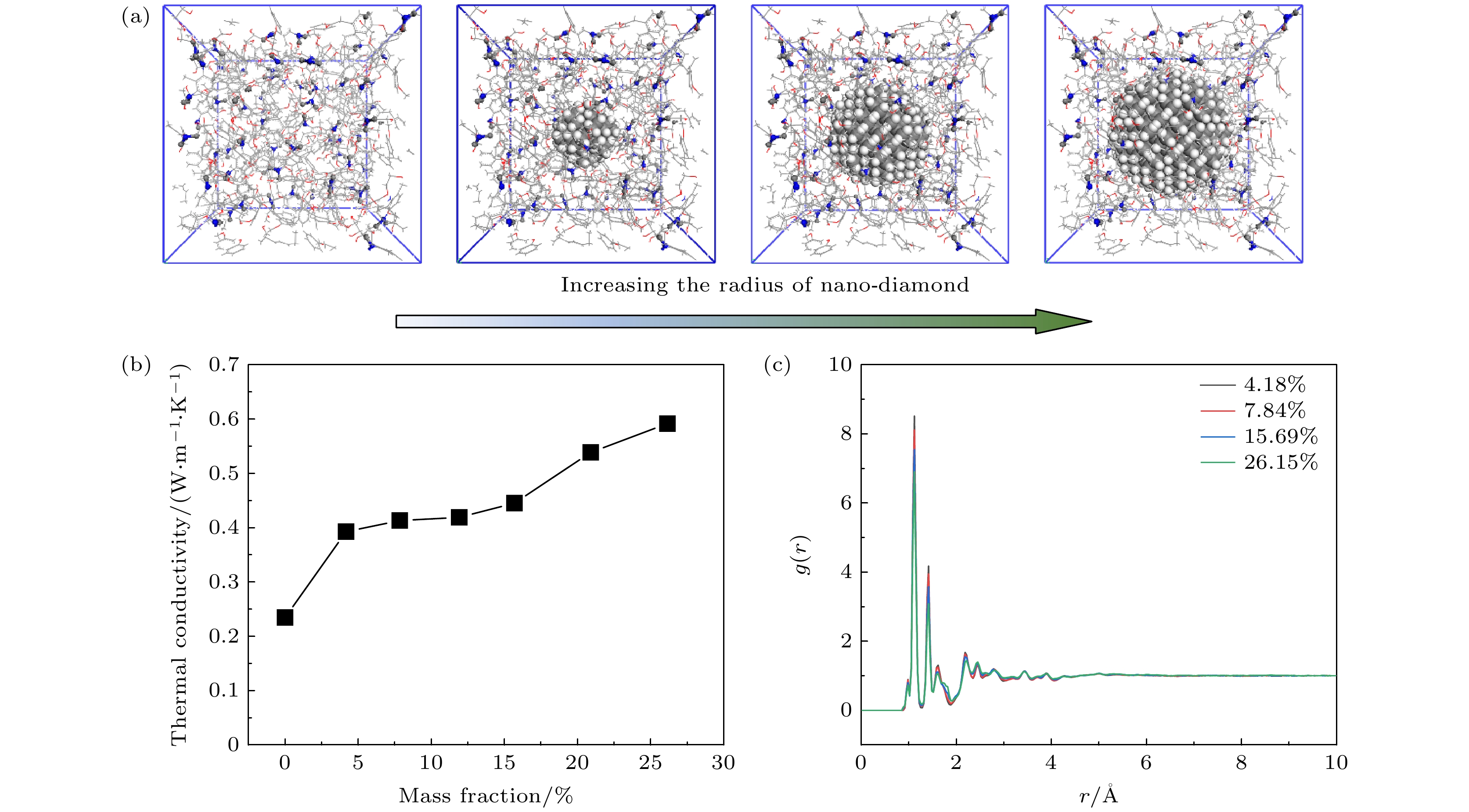

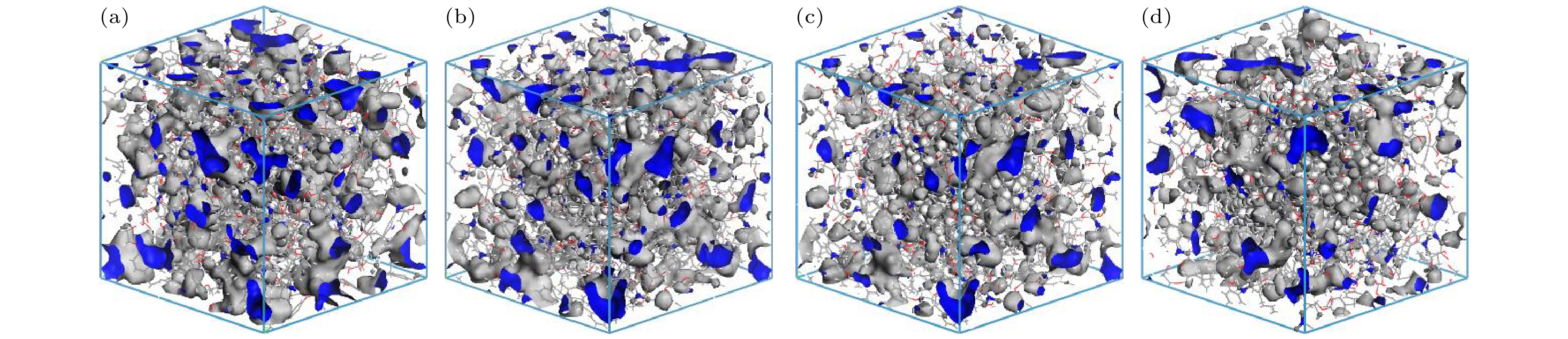

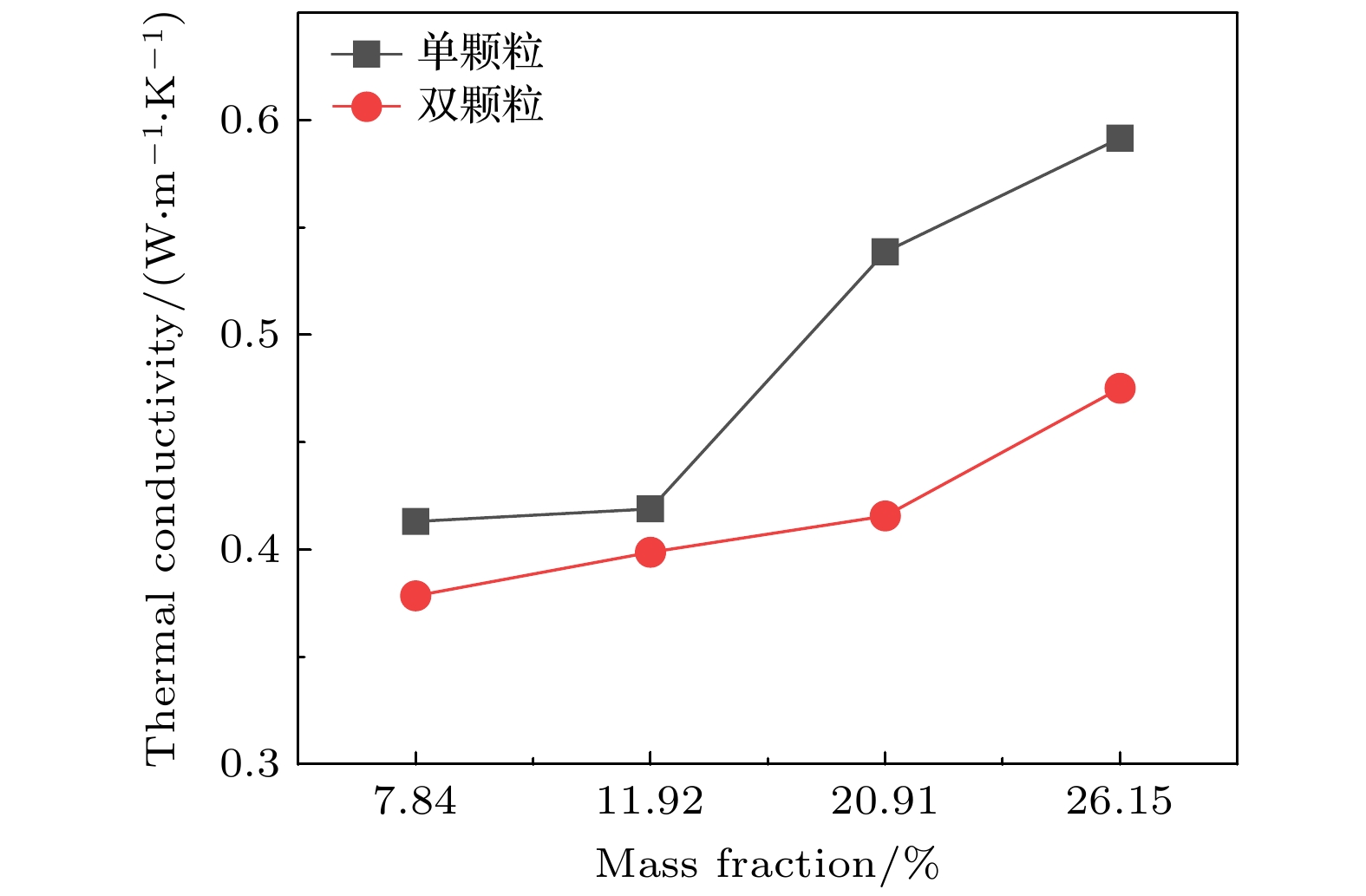

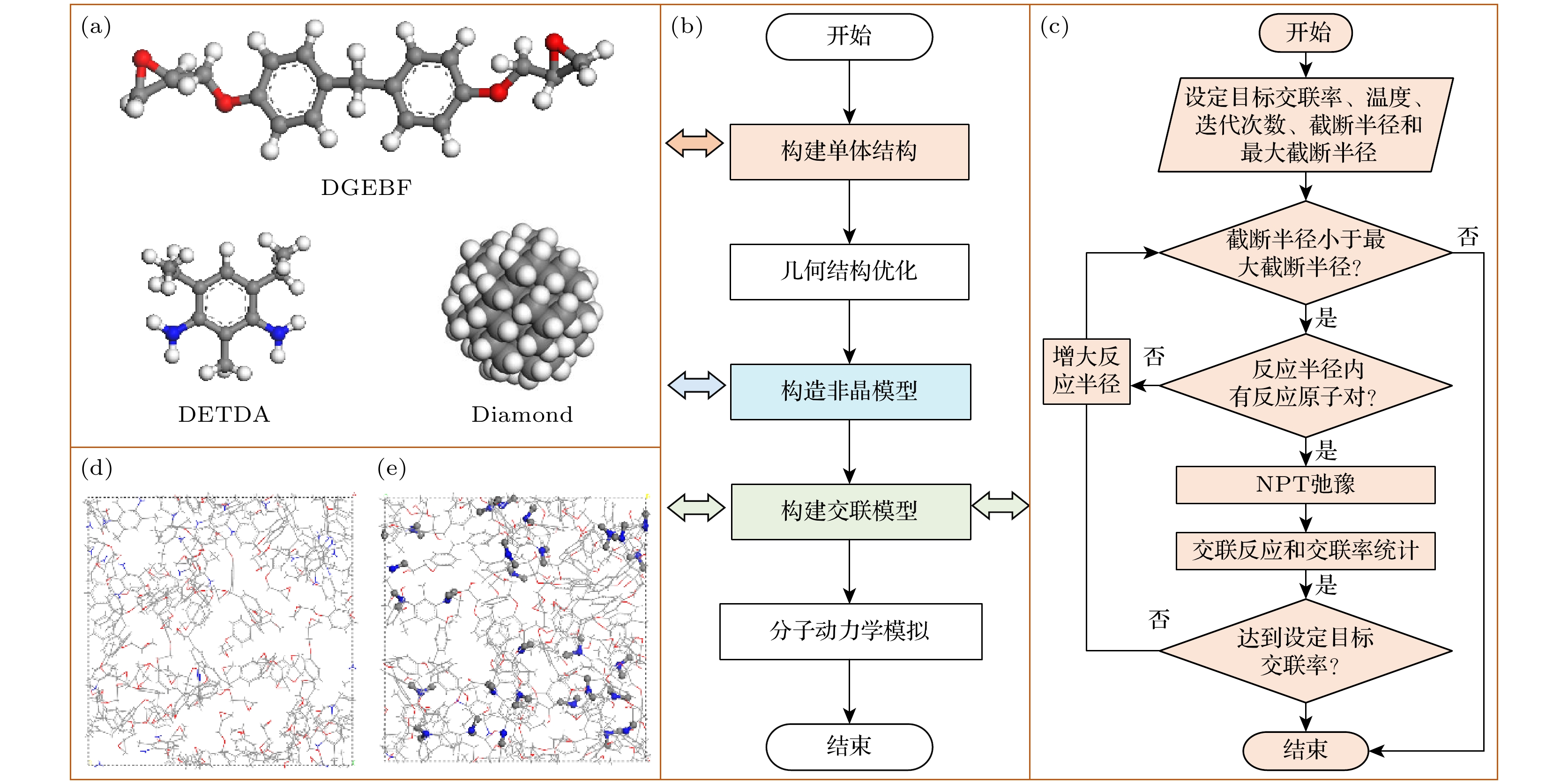

提高环氧树脂热界面材料热导率对解决5G等微电子芯片高热流密度散热问题具有重要意义. 采用非平衡态分子动力学方法, 重点研究了纳米金刚石填料的不同填充方式对环氧树脂基复合物热导率的影响. 结果表明, 单颗粒填充方式下, 复合物热导率随金刚石尺寸的增大而增大, 大尺寸金刚石填料可以降低复合物的自由体积分数, 对热导率的提升效果更显著; 多颗粒填充方式下, 复合物热导率随颗粒数的增多呈先增大后减小的趋势, 增加颗粒数可以减小复合物的自由体积分数, 但具有更大的比表面积及界面热阻, 其对热导率的削弱作用更为显著. 此外, 同一质量分数下, 增大纳米金刚石颗粒尺寸比增加颗粒数对复合物热导率的提升效果更为显著. 本文研究对具有高热导率的纳米金刚石/环氧树脂复合物热界面材料的设计和制备具有指导意义.Improving the thermal conductivity (TC) of epoxy resin thermal interface material is of great significance in tackling the heat dissipation problem of high heat flux in microelectronic chips such as 5G. Using non-equilibrium molecular dynamics (MD) method, the effects of two different filling styles of nano-diamond fillers on the TC of EP based composites are investigated. The results show that the TC of the composite increases with the diamond size when single-particle filling is used, and that a larger diamond size leads to a more significant reduction of the free volume fraction and thus an improvement of the TC. In the multi-particle packing, the composite TC first increases and then decreases with increasing particle number. Increasing the number of particles reduces the free volume fraction, but also results in a larger specific surface area and interfacial thermal resistance, which has a more significant weakening effect on the TC. Moreover, within the same mass fraction of nano-diamond filler, increasing the filler size has a more significant TC improvement on the composite than increasing the number of particles. This study is instructive for the design and preparation of high thermal conductivity nanodiamond/epoxy resin composites.

-

Keywords:

- epoxy resin /

- diamond /

- thermal conductivity /

- molecular dynamic simulation

[1] Singha S, Thomas M J 2008 IEEE Trans. Dielectr. Electr. Insul. 15 2

Google Scholar

Google Scholar

[2] Li M, Zhou H, Zhang Y, Liao Y, Zhou H 2018 Carbon 130 295

Google Scholar

Google Scholar

[3] Han Y, Shi X, Wang S, Ruan K, Lu C, Guo Y, Gu J 2021 Composites Part B 210 108666

Google Scholar

Google Scholar

[4] Chen H, Ginzburg V V, Yang J, Yang Y, Liu W, Huang Y, Du L, Chen B 2016 Prog. Polym. Sci. 59 41

Google Scholar

Google Scholar

[5] Liu X, Yu X, Yang Z, Zhuang X, Guo H, Luo X, Chen J, Liang Y, Chen Y 2023 J. Electron. Mater. 52 2831

Google Scholar

Google Scholar

[6] Wang X, Sun L, Zhang X, Zhang S, Wang J, Zhang Y 2020 J. Mol. Liq. 309 113162

Google Scholar

Google Scholar

[7] Wang Y, Chang Z, Gao K, Li Z, Hou G, Liu J, Zhang L 2021 Polymer 224 123697

Google Scholar

Google Scholar

[8] Lian G, Tuan C C, Li L, Jiao S, Wang Q, Moon K S, Cui D, Wong C P 2016 Chem. Mater. 28 6096

Google Scholar

Google Scholar

[9] Wu H, Gao J, Xiong Y, Zhu Q, Yue Y 2021 Int. J. Heat Mass Transfer 178 121634

Google Scholar

Google Scholar

[10] Nejad S M, Srivastava R, Bellussi F M, Thielemann H C, Asinari P, Fasano M 2021 Int. J. Therm. Sci. 159 106588

Google Scholar

Google Scholar

[11] Fasanella N A, Sundararaghavan V 2016 JOM 68 1396

Google Scholar

Google Scholar

[12] Yang K, Chen W, Zhao Y, Ding L, Du B, Zhang S, Yang W 2021 Compos. Sci. Technol. 221 109178

Google Scholar

Google Scholar

[13] Kang E, Choi S, Choi C, Shim S E 2012 Colloids Surf. A 415 255

Google Scholar

Google Scholar

[14] Cho H B, Konno A, Fujihara T, Suzuki T, Tanaka S, Jiang W, Suematsu H, Niihara K, Nakayama T 2011 Compos. Sci. Technol. 72 112

Google Scholar

Google Scholar

[15] Sun M, Yang L, Liu K, Gao G, Su Z, Gao G, Liu B, Wang W, Han J, Dai B 2019 Composites Part A 127 105618

Google Scholar

Google Scholar

[16] Neitzel I, Mochalin V, Knoke I, Palmese G R, Gogotsi Y 2011 Compos. Sci. Technol. 71 710

Google Scholar

Google Scholar

[17] Alder B J, Wainwright T E 1957 J. Chem. Phys. 27 1208

Google Scholar

Google Scholar

[18] Yang X, Wang X, Wang W, Fu Y, Xie Q 2020 Int. J. Heat Mass Transfer 159 120105

Google Scholar

Google Scholar

[19] Zhu M, Li J, Chen J, Song H, Zhang H 2019 Comput. Mater. Sci. 164 108

Google Scholar

Google Scholar

[20] Li C, Strachan A 2011 Polymer 52 2920

Google Scholar

Google Scholar

[21] Hansen J P, McDonald I R 2013 Theory of Simple Liquids: with Applications to Soft Matter (4th Ed.) (Washington, DC: Academic Press) pp311–362

[22] Alaghemandi M, Müller-Plathe F, Böhm M C 2011 J. Chem. Phys. 135 184905

Google Scholar

Google Scholar

[23] Shavikloo M, Kimiagar S 2017 Comput. Mater. Sci. 139 330

Google Scholar

Google Scholar

[24] Müller-Plathe F 1997 J. Chem. Phys. 106 6082

Google Scholar

Google Scholar

[25] Ikeshoji T, Hafskjold B 1994 Mol. Phys. 81 251

Google Scholar

Google Scholar

[26] Choi J, Shin H, Cho M 2016 Polymer 89 159

Google Scholar

Google Scholar

[27] Xiong Q L, Meguid S A 2015 Eur. Polym. J. 69 1

Google Scholar

Google Scholar

[28] Li S, Yu X, Bao H, Yang N 2018 J. Phys. Chem. C 122 13140

Google Scholar

Google Scholar

[29] Huo R, Zhang Z, Athir N, Fan Y, Liu J, Shi L 2020 Phys. Chem. Chem. Phys. 22 19735

Google Scholar

Google Scholar

[30] Wan X, Demir B, An M, Walsh T R, Yang N 2021 Int. J. Heat Mass Transfer 180 121821

Google Scholar

Google Scholar

[31] Liu X, Rao Z 2020 Comput. Mater. Sci. 172 109298

Google Scholar

Google Scholar

[32] 徐文雪, 梁新刚, 徐向华, 祝渊 2020 69 196601

Google Scholar

Google Scholar

Xu W X, Liang X G, Xu X H, Zhu Y 2020 Acta Phys. Sin. 69 196601

Google Scholar

Google Scholar

[33] An M, Demir B, Wan X, Meng H, Yang N, Walsh T R 2019 Adv. Theor. Simul. 2 1800153

Google Scholar

Google Scholar

[34] Kikugawa G, Desai T G, Keblinski P, Ohara T 2013 J. Appl. Phys. 114 034302

Google Scholar

Google Scholar

[35] Pashayi K, Fard H R, Lai F, Iruvanti S, Plawsky J, Borca-Tasciuc T 2012 J. Appl. Phys. 111 104310

Google Scholar

Google Scholar

[36] Fu J, Shi L, Zhang D, Zhong Q, Chen Y 2010 Polym. Eng. Sci. 50 1809

Google Scholar

Google Scholar

[37] Swartz E T, Pohl R O 1989 Rev. Mod. Phys. 61 605

Google Scholar

Google Scholar

[38] Wang Y, Yang C, Mai Y W, Zhang Y 2016 Carbon 102 311

Google Scholar

Google Scholar

[39] Wang Y, Yang C, Pei Q X, Zhang Y 2016 ACS Appl. Mater. Interfaces 8 8272

Google Scholar

Google Scholar

[40] Li C, Medvedev G A, Lee E W, Kim J, Caruthers J M, Strachan A 2012 Polymer 53 4222

Google Scholar

Google Scholar

-

表 1 不同粒径复合物的自由体积

Table 1. Free volumes of composites with different particle sizes.

金刚石粒径/nm 金刚石质量分数/% 占有体积/Å3 自由体积/Å3 自由体积分数/% 0 0 31583.63 7827.48 19.86 1.0 4.18 32166.77 6164.56 16.08 1.2 7.84 32714.45 5616.88 14.65 1.4 11.92 33333.22 4998.11 13.04 1.6 15.69 33869.13 4462.21 11.64 1.8 20.91 34920.74 3410.59 8.90 2.0 26.15 35555.49 2775.84 7.24 表 2 不同颗粒数复合物的自由体积

Table 2. Free volumes of composites with different particle numbers.

金刚石数目/个 金刚石质量分数/% 占有体积/Å3 自由体积/Å3 自由体积分数/% 0 0 31583.63 7827.48 19.86 1 4.18 32166.77 6164.56 16.08 2 8.03 32852.43 5478.91 14.29 3 11.58 33638.61 4692.72 12.24 4 14.86 33818.23 4513.11 11.77 6 20.75 35202.99 3128.34 8.16 10 30.38 36910.39 1420.94 3.71 -

[1] Singha S, Thomas M J 2008 IEEE Trans. Dielectr. Electr. Insul. 15 2

Google Scholar

Google Scholar

[2] Li M, Zhou H, Zhang Y, Liao Y, Zhou H 2018 Carbon 130 295

Google Scholar

Google Scholar

[3] Han Y, Shi X, Wang S, Ruan K, Lu C, Guo Y, Gu J 2021 Composites Part B 210 108666

Google Scholar

Google Scholar

[4] Chen H, Ginzburg V V, Yang J, Yang Y, Liu W, Huang Y, Du L, Chen B 2016 Prog. Polym. Sci. 59 41

Google Scholar

Google Scholar

[5] Liu X, Yu X, Yang Z, Zhuang X, Guo H, Luo X, Chen J, Liang Y, Chen Y 2023 J. Electron. Mater. 52 2831

Google Scholar

Google Scholar

[6] Wang X, Sun L, Zhang X, Zhang S, Wang J, Zhang Y 2020 J. Mol. Liq. 309 113162

Google Scholar

Google Scholar

[7] Wang Y, Chang Z, Gao K, Li Z, Hou G, Liu J, Zhang L 2021 Polymer 224 123697

Google Scholar

Google Scholar

[8] Lian G, Tuan C C, Li L, Jiao S, Wang Q, Moon K S, Cui D, Wong C P 2016 Chem. Mater. 28 6096

Google Scholar

Google Scholar

[9] Wu H, Gao J, Xiong Y, Zhu Q, Yue Y 2021 Int. J. Heat Mass Transfer 178 121634

Google Scholar

Google Scholar

[10] Nejad S M, Srivastava R, Bellussi F M, Thielemann H C, Asinari P, Fasano M 2021 Int. J. Therm. Sci. 159 106588

Google Scholar

Google Scholar

[11] Fasanella N A, Sundararaghavan V 2016 JOM 68 1396

Google Scholar

Google Scholar

[12] Yang K, Chen W, Zhao Y, Ding L, Du B, Zhang S, Yang W 2021 Compos. Sci. Technol. 221 109178

Google Scholar

Google Scholar

[13] Kang E, Choi S, Choi C, Shim S E 2012 Colloids Surf. A 415 255

Google Scholar

Google Scholar

[14] Cho H B, Konno A, Fujihara T, Suzuki T, Tanaka S, Jiang W, Suematsu H, Niihara K, Nakayama T 2011 Compos. Sci. Technol. 72 112

Google Scholar

Google Scholar

[15] Sun M, Yang L, Liu K, Gao G, Su Z, Gao G, Liu B, Wang W, Han J, Dai B 2019 Composites Part A 127 105618

Google Scholar

Google Scholar

[16] Neitzel I, Mochalin V, Knoke I, Palmese G R, Gogotsi Y 2011 Compos. Sci. Technol. 71 710

Google Scholar

Google Scholar

[17] Alder B J, Wainwright T E 1957 J. Chem. Phys. 27 1208

Google Scholar

Google Scholar

[18] Yang X, Wang X, Wang W, Fu Y, Xie Q 2020 Int. J. Heat Mass Transfer 159 120105

Google Scholar

Google Scholar

[19] Zhu M, Li J, Chen J, Song H, Zhang H 2019 Comput. Mater. Sci. 164 108

Google Scholar

Google Scholar

[20] Li C, Strachan A 2011 Polymer 52 2920

Google Scholar

Google Scholar

[21] Hansen J P, McDonald I R 2013 Theory of Simple Liquids: with Applications to Soft Matter (4th Ed.) (Washington, DC: Academic Press) pp311–362

[22] Alaghemandi M, Müller-Plathe F, Böhm M C 2011 J. Chem. Phys. 135 184905

Google Scholar

Google Scholar

[23] Shavikloo M, Kimiagar S 2017 Comput. Mater. Sci. 139 330

Google Scholar

Google Scholar

[24] Müller-Plathe F 1997 J. Chem. Phys. 106 6082

Google Scholar

Google Scholar

[25] Ikeshoji T, Hafskjold B 1994 Mol. Phys. 81 251

Google Scholar

Google Scholar

[26] Choi J, Shin H, Cho M 2016 Polymer 89 159

Google Scholar

Google Scholar

[27] Xiong Q L, Meguid S A 2015 Eur. Polym. J. 69 1

Google Scholar

Google Scholar

[28] Li S, Yu X, Bao H, Yang N 2018 J. Phys. Chem. C 122 13140

Google Scholar

Google Scholar

[29] Huo R, Zhang Z, Athir N, Fan Y, Liu J, Shi L 2020 Phys. Chem. Chem. Phys. 22 19735

Google Scholar

Google Scholar

[30] Wan X, Demir B, An M, Walsh T R, Yang N 2021 Int. J. Heat Mass Transfer 180 121821

Google Scholar

Google Scholar

[31] Liu X, Rao Z 2020 Comput. Mater. Sci. 172 109298

Google Scholar

Google Scholar

[32] 徐文雪, 梁新刚, 徐向华, 祝渊 2020 69 196601

Google Scholar

Google Scholar

Xu W X, Liang X G, Xu X H, Zhu Y 2020 Acta Phys. Sin. 69 196601

Google Scholar

Google Scholar

[33] An M, Demir B, Wan X, Meng H, Yang N, Walsh T R 2019 Adv. Theor. Simul. 2 1800153

Google Scholar

Google Scholar

[34] Kikugawa G, Desai T G, Keblinski P, Ohara T 2013 J. Appl. Phys. 114 034302

Google Scholar

Google Scholar

[35] Pashayi K, Fard H R, Lai F, Iruvanti S, Plawsky J, Borca-Tasciuc T 2012 J. Appl. Phys. 111 104310

Google Scholar

Google Scholar

[36] Fu J, Shi L, Zhang D, Zhong Q, Chen Y 2010 Polym. Eng. Sci. 50 1809

Google Scholar

Google Scholar

[37] Swartz E T, Pohl R O 1989 Rev. Mod. Phys. 61 605

Google Scholar

Google Scholar

[38] Wang Y, Yang C, Mai Y W, Zhang Y 2016 Carbon 102 311

Google Scholar

Google Scholar

[39] Wang Y, Yang C, Pei Q X, Zhang Y 2016 ACS Appl. Mater. Interfaces 8 8272

Google Scholar

Google Scholar

[40] Li C, Medvedev G A, Lee E W, Kim J, Caruthers J M, Strachan A 2012 Polymer 53 4222

Google Scholar

Google Scholar

计量

- 文章访问数: 6056

- PDF下载量: 117

- 被引次数: 0

下载:

下载: