-

The materials with low thermal conductivity (κ) are both fundamentally interesting and technologically important in applications relevant to thermal energy conversion and thermal management, such as thermoelectric conversion devices, thermal barrier coatings, and thermal storage. Therefore, understanding the physical mechanisms of glass-like heat conduction in crystalline materials is essential for the development and design of low-κ materials. In this work, the microscopic phonon mechanism of glass-like low κ in binary simple crystal Yb3TaO7 with fluorite structure is investigated by using the equilibrium molecular dynamics, phonon spectral energy density, and lattice dynamics. Meanwhile, the weberite-structured Yb3TaO7 is also mentioned for comparison. The calculated κ indicates that fluorite Yb3TaO7 has a glass-like low κ while weberite Yb3TaO7 has a crystal κ. Such a low κ in fluorite Yb3TaO7 is mainly due to the large difference in interatomic force between O-Yb and O-Ta. This different atomic bonding can significantly soften the phonon mode and thus limit phonon transport. To further describe the microscopic phonon thermal conduction, the single-channel model based on the phonon gas model is first used to calculate the total κ. However, the single-channel model significantly underestimates the κ, suggesting the presence of non-normal phonons in Yb3TaO7. Based on this, vibrational mode decomposition is conducted throughout the entire phonon spectrum of fluorite- and weberite-type Yb3TaO7. It is found that most modes in fluorite Yb3TaO7 fall in the Ioffe–Regel regime and exhibit a strongly diffusive nature. Such diffusive modes cannot be described by the phonon gas model. Based on the decomposed phonon modes, the dual-channel model involving diffusive mode and propagating mode is used to describe the phonon thermal conduction, by which the obtained results accord well with the experimental values. The vast majority (> 90%) of heat in fluorite Yb3TaO7 is found to be transported by diffusive modes rather than propagating modes. Consequently, the κ of fluorite Yb3TaO7 increases with temperature rising, exhibiting a unique glass-like nature. In particular, contrary to conventional wisdom, the optical phonon mode in fluorite Yb3TaO7 plays a significant or even decisive role in thermal conduction, which could serve as a new physical factor to adjust κ in solid materials. Overall, the new understanding of the link between chemical bonding and glass-like κ can contribute to the development and design of low-κ materials.

-

Keywords:

- glass-like thermal conductivity /

- phonon transport /

- diffusive phonons /

- thermal barrier coatings

[1] Padture N P, Gell M, Jordan E H 2002 Science 296 280

Google Scholar

Google Scholar

[2] Wu J, Wei X, Padture N P, Klemens P G, Gell M, Garcia E, Miranzo P, Osendi M I 2003 Chem. Inform. 34 3031

[3] Schelling P K, Phillpot S R 2001 J. Am. Ceram. Soc. 84 2997

Google Scholar

Google Scholar

[4] Zhu J, Meng X, Zhang P, Li Z, Xu J, Reece M J, Gao F 2021 J. Eur. Ceram. Soc. 41 2861

Google Scholar

Google Scholar

[5] Chevalier J, Gremillard L, Virkar A V, Clarke D R 2009 J. Am. Ceram. Soc. 92 1901

Google Scholar

Google Scholar

[6] Anupam A, Kottada R S, Kashyap S, Meghwal A, Murty B S, Berndt C C, Ang A S M 2020 Appl. Surf. Sci. 505 144117

Google Scholar

Google Scholar

[7] 李世彬, 吴志明, 袁凯, 廖乃镘, 李伟, 蒋亚东 2008 57 3126

Google Scholar

Google Scholar

Li S B, Wu Z M, Yuan K, Liao N M, Li W, Jiang Y D 2008 Acta Phys. Sin. 57 3126

Google Scholar

Google Scholar

[8] King G, Thompson C M, Greedanb J E, Llobet A 2013 J. Mater. Chem. A. 1 10487

Google Scholar

Google Scholar

[9] Chen L, Hu M, Wu F, Song P, Feng J 2019 J. Alloys Compd. 788 1231

Google Scholar

Google Scholar

[10] Schlichting K W, Padture N P, Klemens P G 2001 J. Mater. Sci. 36 3003

Google Scholar

Google Scholar

[11] Zarichnyak Y P, Ramazanova A E, Emirov S N 2013 Phys. Solid State 55 2436

Google Scholar

Google Scholar

[12] Stanek C R, Minervini L, Grimes R W 2002 J. Am. Ceram. Soc. 85 2792

Google Scholar

Google Scholar

[13] Tealdi C, Islam M S, Malavasi L, Flor G 2004 J. Solid State Chem. 177 4359

Google Scholar

Google Scholar

[14] 张智奇, 钱胜, 王瑞金, 朱泽飞 2019 68 054401

Google Scholar

Google Scholar

Zhang Z Q, Qian S, W R J, Zhu Z F 2019 Acta Phys. Sin. 68 054401

Google Scholar

Google Scholar

[15] Thomas J A, Turney J E, Iutzi R M, Amon C H, McGaughey A J 2010 Phys. Rev. B 81 081411

Google Scholar

Google Scholar

[16] Turney J E, Landry E S, McGaughey A J H, Amon C H 2009 Phys. Rev. B 79 064301

Google Scholar

Google Scholar

[17] Su R, Yuan Z, Wang J, Zhang Z 2015 Phys. Rev. E 91 012136

Google Scholar

Google Scholar

[18] Su R X, Yuan Z Q, Wang J, Zheng Z G 2016 Front. Phys. 11 114401

Google Scholar

Google Scholar

[19] 郑翠红, 杨剑, 谢国锋, 周五星, 欧阳滔 2022 71 056101

Google Scholar

Google Scholar

Zheng C H, Yang J, Xie G F, Zhou W X, Ouyang T 2022 Acta Phys. Sin. 71 056101

Google Scholar

Google Scholar

[20] Lee C H, Gan C K 2017 Phys. Rev. B 96 035105

Google Scholar

Google Scholar

[21] Lü W, Henry A 2016 Sci. Rep. 6 35720

Google Scholar

Google Scholar

[22] Yang B, Chen G 2003 Phys. Rev. B 67 195311

Google Scholar

Google Scholar

[23] Dechaumphai E, Chen R 2012 J. Appl. Phys. 111 073508

Google Scholar

Google Scholar

[24] Luo Y X, Yang X L, Feng T L, Wang J Y, Ruan X L 2020 Nat. Commun. 11 1

Google Scholar

Google Scholar

[25] Kumar G, Vangessel F G, Elton D C, Chung P W 2019 MRS Adv. 4 2191

Google Scholar

Google Scholar

[26] Seyf H R, Henry A 2016 J. Appl. Phys. 120 25101

Google Scholar

Google Scholar

[27] Beltukov Y M, Kozub V I, Parshin D A 2013 Phys. Rev. B 87 134203

Google Scholar

Google Scholar

[28] Allen P B, Feldman J L 1993 Phys. Rev. B 48 12581

Google Scholar

Google Scholar

[29] Clarke D R 2003 Surf. Coat. Technol. 163 67

[30] Cahill D G, Watson S K, Pohl R O 1992 Phys. Rev. B 46 6131

Google Scholar

Google Scholar

[31] Morelli D T, Heremans J P, Slack G A 2002 Phys. Rev. B 66 195304

Google Scholar

Google Scholar

[32] Slack G A 1973 J. Phys. Chem. Solids 34 321

Google Scholar

Google Scholar

-

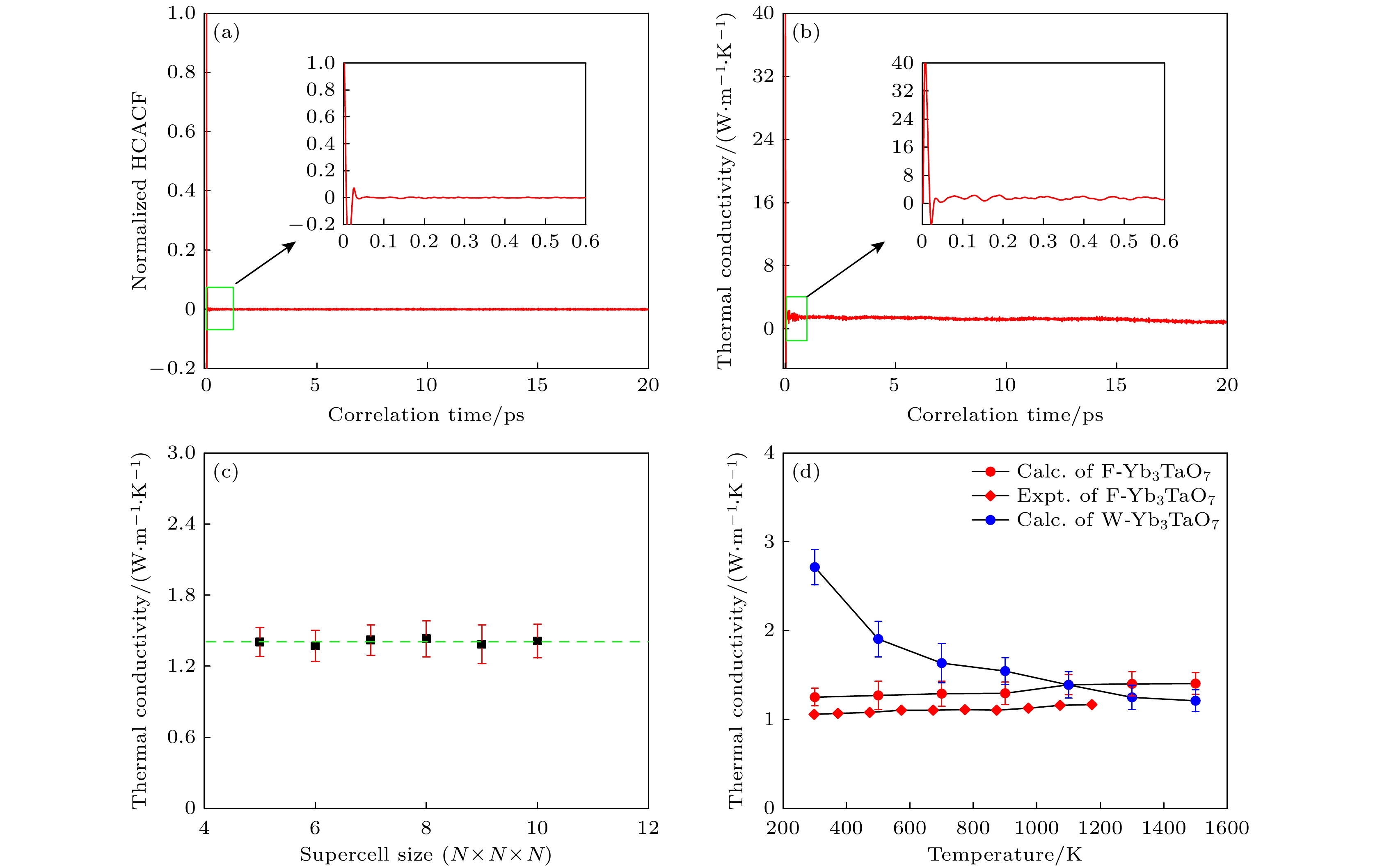

图 2 1500 K温度下的热导率计算结果 (a) 归一化热流关联函数随关联时间的变化关系; (b) 热导率随关联时间的变化关系; (c) 不同超胞的热导率; (d) 热导率随温度的变化关系

Figure 2. Calculated thermal conductivity at 1500 K: (a) Normalized HCACF versus correlation time; (2) thermal conductivity versus correlation time; (c) calculated thermal conductivity with different supercell; (d) temperature dependence of thermal conductivity.

原子间作用 A/eV ρ/Å C/(eV·Å6) O—O 9547.96 0.2192 32.00 O—Ta 1315.57 0.3690 0 O—Yb 1649.80 0.3386 16.57 表 2 计算的La2Zr2O7和Yb3TaO7的晶格常数、格林艾森常数和弹性模量

Table 2. Calculated lattice constants, Grüneisen constants, and elastic modulus for La2Zr2O7 and Yb3TaO7.

-

[1] Padture N P, Gell M, Jordan E H 2002 Science 296 280

Google Scholar

Google Scholar

[2] Wu J, Wei X, Padture N P, Klemens P G, Gell M, Garcia E, Miranzo P, Osendi M I 2003 Chem. Inform. 34 3031

[3] Schelling P K, Phillpot S R 2001 J. Am. Ceram. Soc. 84 2997

Google Scholar

Google Scholar

[4] Zhu J, Meng X, Zhang P, Li Z, Xu J, Reece M J, Gao F 2021 J. Eur. Ceram. Soc. 41 2861

Google Scholar

Google Scholar

[5] Chevalier J, Gremillard L, Virkar A V, Clarke D R 2009 J. Am. Ceram. Soc. 92 1901

Google Scholar

Google Scholar

[6] Anupam A, Kottada R S, Kashyap S, Meghwal A, Murty B S, Berndt C C, Ang A S M 2020 Appl. Surf. Sci. 505 144117

Google Scholar

Google Scholar

[7] 李世彬, 吴志明, 袁凯, 廖乃镘, 李伟, 蒋亚东 2008 57 3126

Google Scholar

Google Scholar

Li S B, Wu Z M, Yuan K, Liao N M, Li W, Jiang Y D 2008 Acta Phys. Sin. 57 3126

Google Scholar

Google Scholar

[8] King G, Thompson C M, Greedanb J E, Llobet A 2013 J. Mater. Chem. A. 1 10487

Google Scholar

Google Scholar

[9] Chen L, Hu M, Wu F, Song P, Feng J 2019 J. Alloys Compd. 788 1231

Google Scholar

Google Scholar

[10] Schlichting K W, Padture N P, Klemens P G 2001 J. Mater. Sci. 36 3003

Google Scholar

Google Scholar

[11] Zarichnyak Y P, Ramazanova A E, Emirov S N 2013 Phys. Solid State 55 2436

Google Scholar

Google Scholar

[12] Stanek C R, Minervini L, Grimes R W 2002 J. Am. Ceram. Soc. 85 2792

Google Scholar

Google Scholar

[13] Tealdi C, Islam M S, Malavasi L, Flor G 2004 J. Solid State Chem. 177 4359

Google Scholar

Google Scholar

[14] 张智奇, 钱胜, 王瑞金, 朱泽飞 2019 68 054401

Google Scholar

Google Scholar

Zhang Z Q, Qian S, W R J, Zhu Z F 2019 Acta Phys. Sin. 68 054401

Google Scholar

Google Scholar

[15] Thomas J A, Turney J E, Iutzi R M, Amon C H, McGaughey A J 2010 Phys. Rev. B 81 081411

Google Scholar

Google Scholar

[16] Turney J E, Landry E S, McGaughey A J H, Amon C H 2009 Phys. Rev. B 79 064301

Google Scholar

Google Scholar

[17] Su R, Yuan Z, Wang J, Zhang Z 2015 Phys. Rev. E 91 012136

Google Scholar

Google Scholar

[18] Su R X, Yuan Z Q, Wang J, Zheng Z G 2016 Front. Phys. 11 114401

Google Scholar

Google Scholar

[19] 郑翠红, 杨剑, 谢国锋, 周五星, 欧阳滔 2022 71 056101

Google Scholar

Google Scholar

Zheng C H, Yang J, Xie G F, Zhou W X, Ouyang T 2022 Acta Phys. Sin. 71 056101

Google Scholar

Google Scholar

[20] Lee C H, Gan C K 2017 Phys. Rev. B 96 035105

Google Scholar

Google Scholar

[21] Lü W, Henry A 2016 Sci. Rep. 6 35720

Google Scholar

Google Scholar

[22] Yang B, Chen G 2003 Phys. Rev. B 67 195311

Google Scholar

Google Scholar

[23] Dechaumphai E, Chen R 2012 J. Appl. Phys. 111 073508

Google Scholar

Google Scholar

[24] Luo Y X, Yang X L, Feng T L, Wang J Y, Ruan X L 2020 Nat. Commun. 11 1

Google Scholar

Google Scholar

[25] Kumar G, Vangessel F G, Elton D C, Chung P W 2019 MRS Adv. 4 2191

Google Scholar

Google Scholar

[26] Seyf H R, Henry A 2016 J. Appl. Phys. 120 25101

Google Scholar

Google Scholar

[27] Beltukov Y M, Kozub V I, Parshin D A 2013 Phys. Rev. B 87 134203

Google Scholar

Google Scholar

[28] Allen P B, Feldman J L 1993 Phys. Rev. B 48 12581

Google Scholar

Google Scholar

[29] Clarke D R 2003 Surf. Coat. Technol. 163 67

[30] Cahill D G, Watson S K, Pohl R O 1992 Phys. Rev. B 46 6131

Google Scholar

Google Scholar

[31] Morelli D T, Heremans J P, Slack G A 2002 Phys. Rev. B 66 195304

Google Scholar

Google Scholar

[32] Slack G A 1973 J. Phys. Chem. Solids 34 321

Google Scholar

Google Scholar

-

5-20221581补充材料.pdf

5-20221581补充材料.pdf

Catalog

Metrics

- Abstract views: 7531

- PDF Downloads: 99

- Cited By: 0

DownLoad:

DownLoad: