-

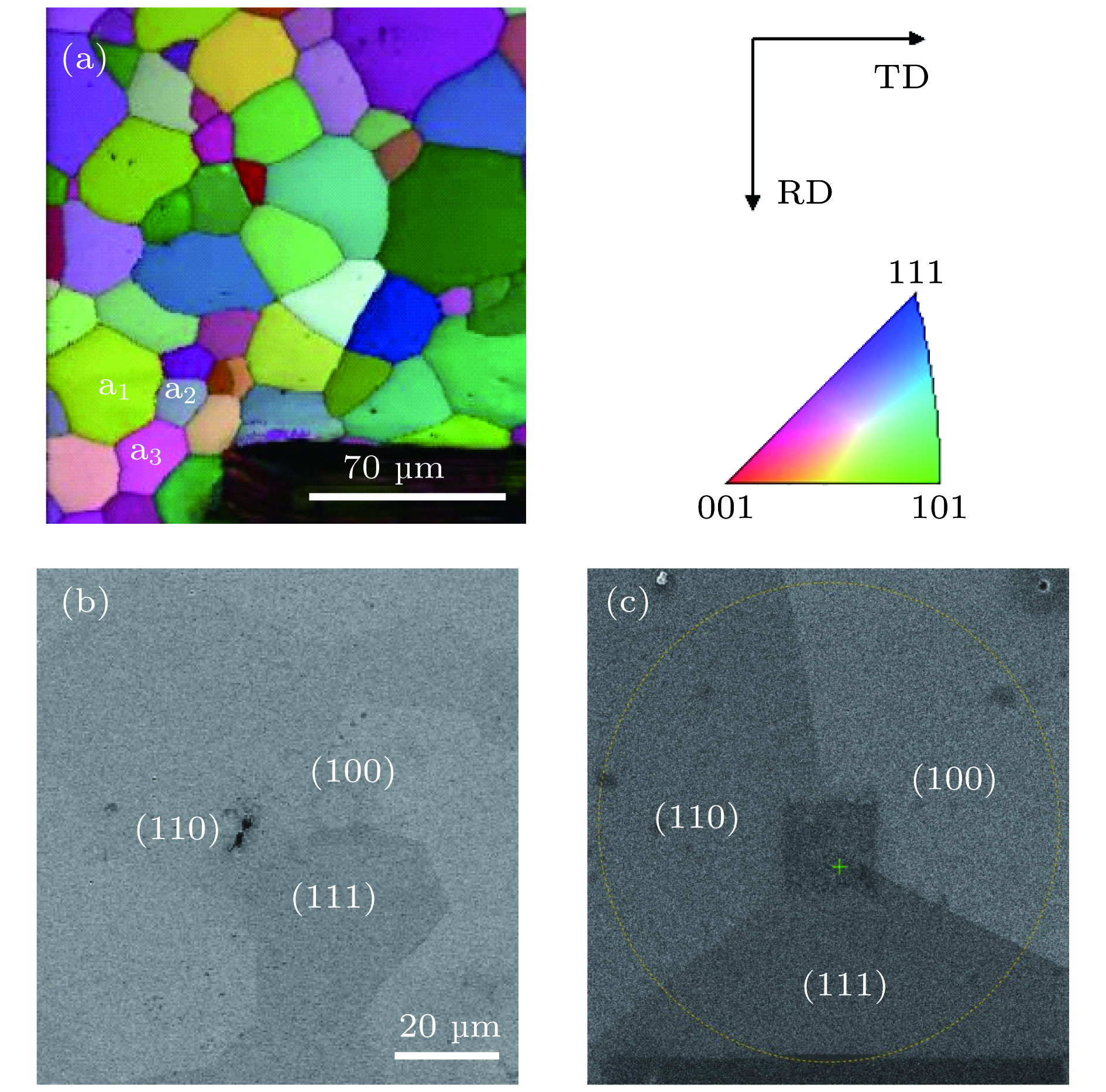

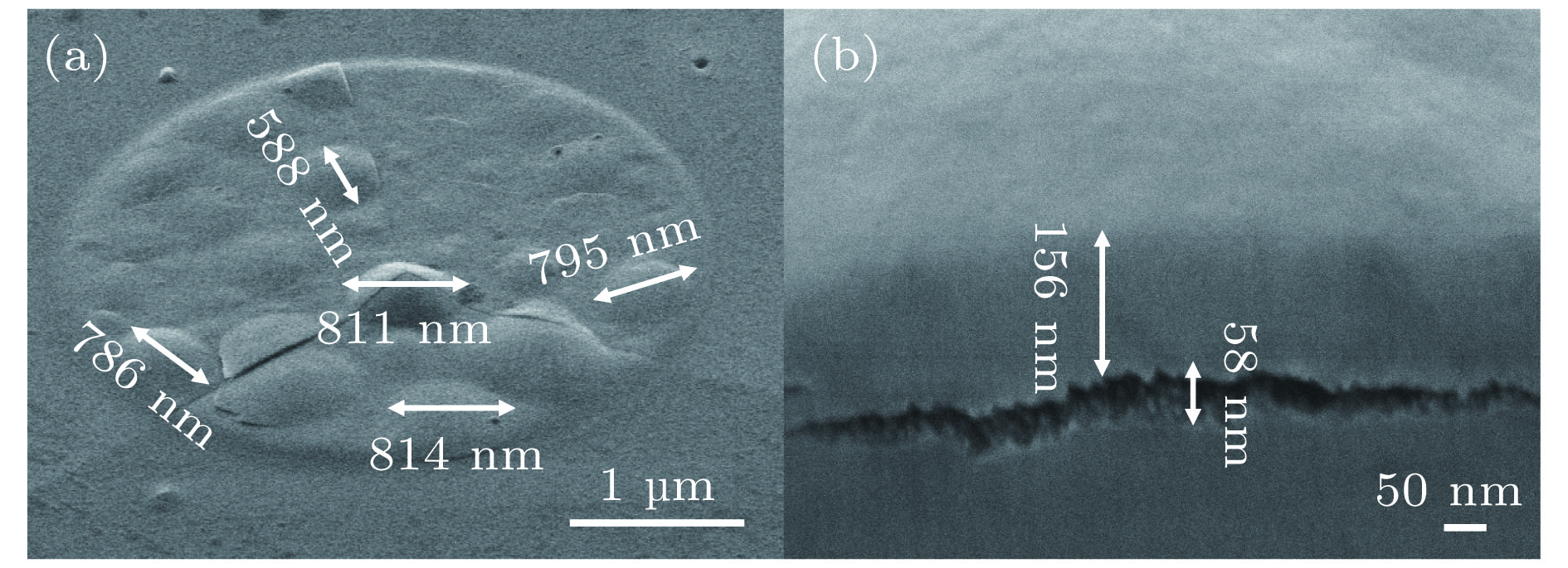

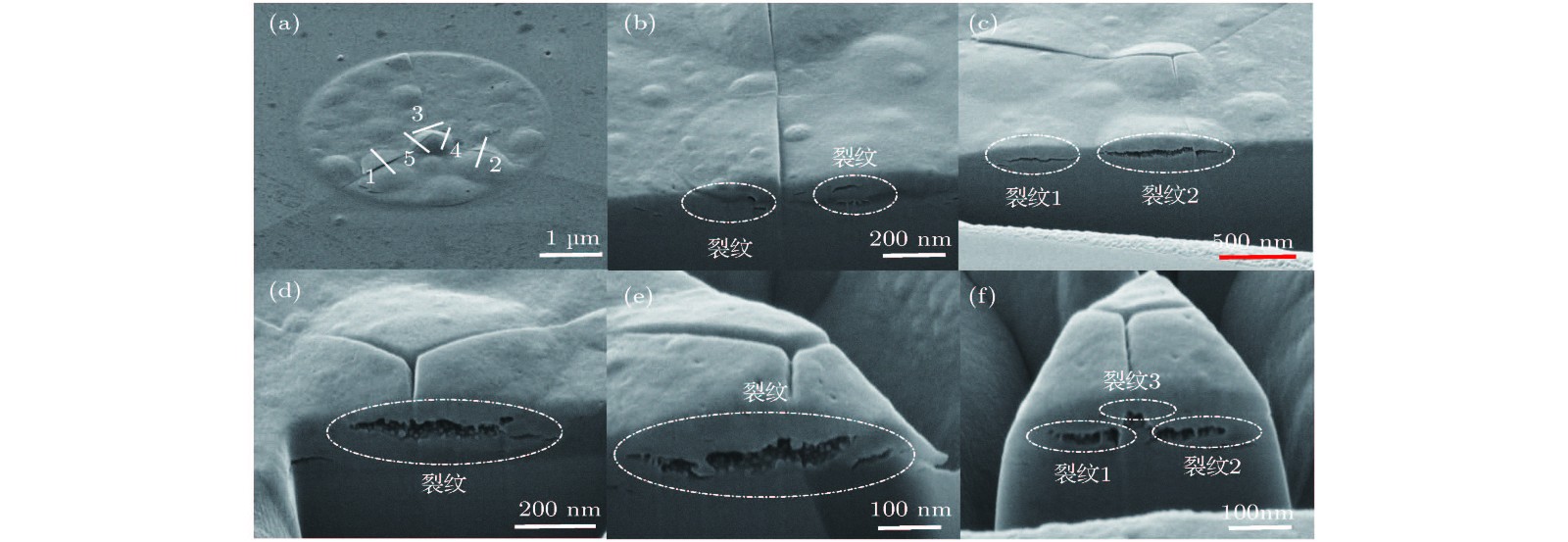

Nuclear fusion energy is a clean and safe energy resource with huge potential. Tungsten is the primary candidate for plasma facing materials (PFMs) in future nuclear reactors because of its high melting point, high thermal conductivity and high resistance to sputtering and erosion. However, the interaction between tungsten and helium plasma generated by deuterium-tritium nuclear reactions will result in the degeneration of tungsten through helium blistering in tungsten. The solubility of helium in tungsten is low, and it tends to aggregate at grain boundary, phase boundary, vacancies and dislocations, thus forming helium bubbles. These bubbles will lead to microstructure changes of surface and bulk phases, as well as a decrease in mechanical properties, which seriously affects the service life of material. Limited by experimental techniques, some basic problems for the growth of helium bubbles in tungsten are not clear, for instance, how the helium clusters migrate, and nucleation mechanisms. The study of complex helium bubble formation, evolution and its underlying mechanism in tungsten PFM necessitates advanced experimental techniques. Traditional methods such as ion implantation, scanning electron microscope and transmission electron microscope are inadequate for this task. Therefore, we propose the helium ion microscope method to investigate the aforementioned several aspects of helium in tungsten in situ and real-time. Here, a helium irradiation experiment is performed by helium ion microscope (HIM), featuring nanostructure fabrication, ion implantation and microscopic imaging. The HIM can generate an ion beam with energy in a range of 0.5−35 keV and an flux upto 1025 ions/m2/s. In the process of helium ion implantation, we observe in situ and real time the helium blistering and the morphological evolution on tungsten surface, in order to capture the helium implantation-induced microscopic damage evolution on tungsten surface and subsurface. From the results of in situ HIM experiments, it is believed that a strong orientation dependence of blistering is observed with the blister occurring preferentially on the surface of grains with normal direction close to (111), and surface blistering of tungsten is directly related to cracks immediately below the surface. The present study demonstrates that the HIM is a powerful tool for investigating the helium blistering behavior in tungsten and provides valuable experimental data and reference for designing PFMs.

-

Keywords:

- tungsten /

- helium behavior /

- helium ion microscope /

- real-time analysis of in situ

[1] Bolt H, Barabash V, Federici G, Linke J, Loate A, Roth J, Sato K 2002 J. Nucl. Mater. 43 307

[2] Lässer R, Baluc N, Boutard J L, Diegele E, Dudarev S, Möslang A, Pippan R, Riccardi B, Van der Schaaf B 2007 Fusion Eng. Des. 82 511

Google Scholar

Google Scholar

[3] Wilson W D, Bisson C L, Baskes M L 1981 Phys. Rev. B. 24 5618

[4] Shahram S, Akiyuki T, Koji N, Nasr G 2009 J. Nucl. Mater. 389 203

Google Scholar

Google Scholar

[5] Alimov V K, Wang Y W, Liang T R, Yu Q Z, Jia X J 2017 Fusion Eng. Des. 125 479

Google Scholar

Google Scholar

[6] Zhou H B, Li Y H, Lu G H 2016 Comp. Mater. Sci. 112 487

Google Scholar

Google Scholar

[7] Chen Z, Han W J, Yu J G, Laszlo K, Zhu K G , Wei Q M 2016 J. Nucl. Mater. 479 418

Google Scholar

Google Scholar

[8] Al-Ajlony A, Tripathi J K, Hassanein A 2017 J. Nucl. Mater. 488 1

Google Scholar

Google Scholar

[9] Wang L, Hao T, Zhao B L, Zhang T, Fang Q F, Liu C S, Wang X P, Cao L 2018 J. Nucl. Mater. 508 107

Google Scholar

Google Scholar

[10] Chen Z, Niu L L, Wang Z L, Tian L F, Laszlo K, Zhu K G, Wei Q M 2018 Acta Materialia 147 100

Google Scholar

Google Scholar

[11] Nishijima D, Ye M.Y, Ohno N 2004 J. Nucl. Mater. 329—333 1029

[12] Yang X, Hassanein A 2013 J. Nucl. Mater. 434 1

Google Scholar

Google Scholar

[13] Ananth M, Scipioni L , Notte J 2008 Am. Lab. 40 42

[14] Economou N P, Notte J A, Thompson W B 2011 Scanning 33 1

Google Scholar

Google Scholar

[15] Hlawacek G, Veligura V, Van Gastel R, Poelsema B 2014 J. Vac. Sci. Technol. B 32 020801

[16] Bergner F, Heintze C 2018 J. Nucl. Mater. 505 267

Google Scholar

Google Scholar

[17] Hasenhuetl E, Zhang Z X, Kiyohiro Y, Peng S, Akihiko K 2017 Nucl. Instrum. Methods Phys. Res. Sect. B 397 11

Google Scholar

Google Scholar

[18] Valles G, Panizo-Laiz M, Gonz_alez C, Martin-Bragado I, Gonz_alez-Arrabal R, Gordillo N, Iglesias R, Guerrero C L, Perlado J M 2017 Fusion Eng. Des. 125 479

Google Scholar

Google Scholar

[19] Fukumoto M, Kashiwagi H, Ohtsuka Y, Ueda Y, Nobuta Y, Yagyu J, Arai T, Taniguchi M, Inoue T, Sakamoto K 2009 J. Nucl. Mater. 386—388 768

[20] Miyamoto M, Mikami S, Nagashima H, Iijima N, Nishijima D, Doerner R P, Yoshida N, Watanabe H , Ueda Y, Sagara A 2015 J. Nucl. Mater. 463 333

Google Scholar

Google Scholar

[21] Liu F S, Rui H T, Peng S X, Zhu K G 2014 Nucl. Instrum. Methods Phys. Res. Sect. B 333 120

Google Scholar

Google Scholar

[22] Gilliam S B, Gidcumb S M, Forsythe D 2005 Nucl. Instrum. Methods Phys. Res. Sect. B 241 491

Google Scholar

Google Scholar

[23] Lindig S, Balden M, Kh Alimov V 2009 Phys. Scripta T 138 014040

[24] Smirnov R D, Krasheninnikov S I, Guterl J 2015 J. Nucl. Mater. 463 359

Google Scholar

Google Scholar

-

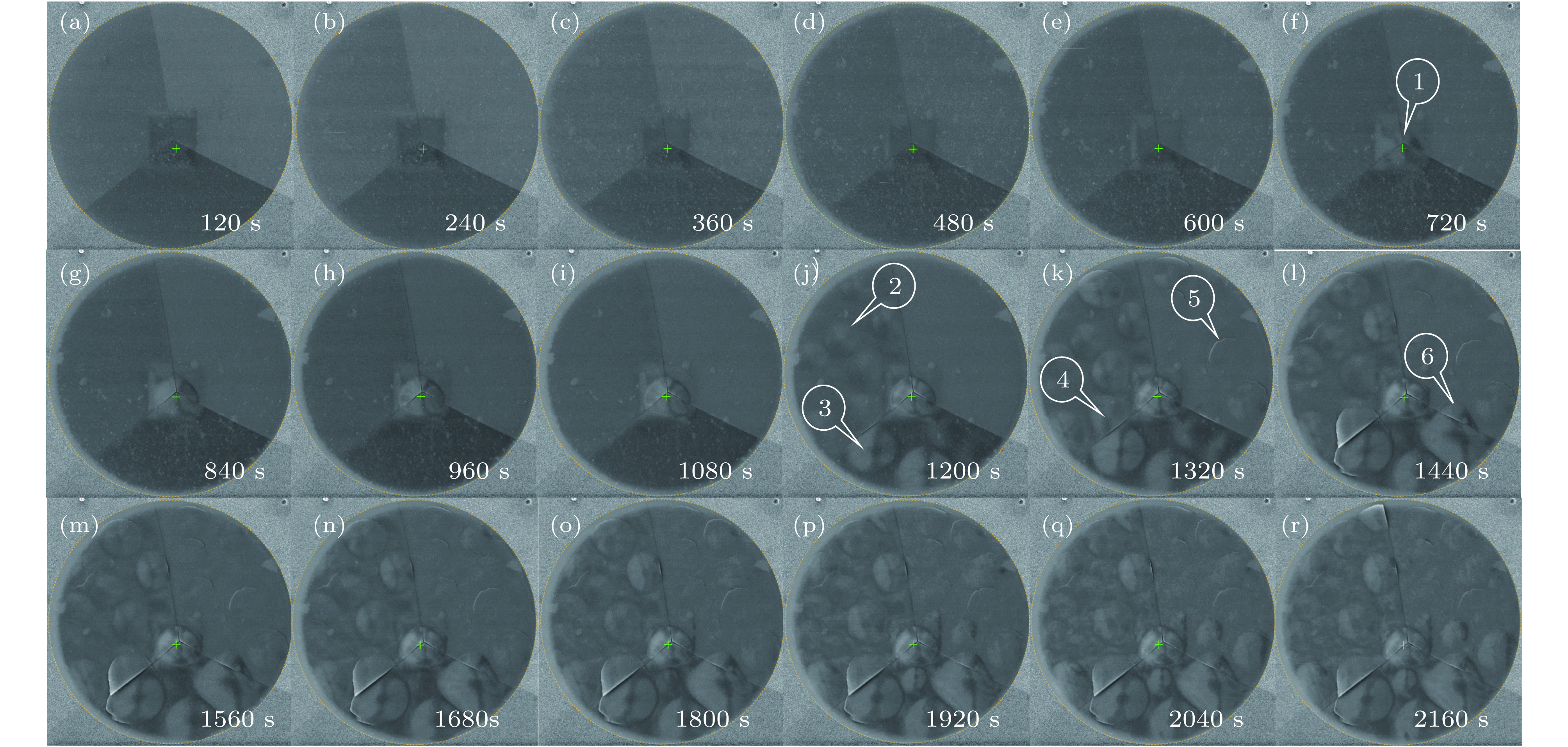

图 3 He泡生长过程的原位在线监测 (a) 120 s; (b) 240 s; (c) 360 s; (d) 480 s; (e) 600 s; (f) 720 s; (g) 840 s; (h) 960 s; (i) 1080 s; (j) 1200 s; (k) 1320 s; (l) 1440 s; (m) 1560 s; (n) 1680 s; (o) 1800 s; (p) 1920 s; (q) 2040 s; (r) 2160 s

Figure 3. In-situ observation of helium bubble growth during helium implantation: (a) 120 s; (b) 240 s; (c) 360 s; (d) 480 s; (e) 600 s; (f) 720 s; (g) 840 s; (h) 960 s; (i) 1080 s; (j) 1200 s; (k) 1320 s; (l) 1440 s; (m) 1560 s; (n) 1680 s; (o) 1800 s; (p) 1920 s; (q) 2040 s; (r) 2160 s.

-

[1] Bolt H, Barabash V, Federici G, Linke J, Loate A, Roth J, Sato K 2002 J. Nucl. Mater. 43 307

[2] Lässer R, Baluc N, Boutard J L, Diegele E, Dudarev S, Möslang A, Pippan R, Riccardi B, Van der Schaaf B 2007 Fusion Eng. Des. 82 511

Google Scholar

Google Scholar

[3] Wilson W D, Bisson C L, Baskes M L 1981 Phys. Rev. B. 24 5618

[4] Shahram S, Akiyuki T, Koji N, Nasr G 2009 J. Nucl. Mater. 389 203

Google Scholar

Google Scholar

[5] Alimov V K, Wang Y W, Liang T R, Yu Q Z, Jia X J 2017 Fusion Eng. Des. 125 479

Google Scholar

Google Scholar

[6] Zhou H B, Li Y H, Lu G H 2016 Comp. Mater. Sci. 112 487

Google Scholar

Google Scholar

[7] Chen Z, Han W J, Yu J G, Laszlo K, Zhu K G , Wei Q M 2016 J. Nucl. Mater. 479 418

Google Scholar

Google Scholar

[8] Al-Ajlony A, Tripathi J K, Hassanein A 2017 J. Nucl. Mater. 488 1

Google Scholar

Google Scholar

[9] Wang L, Hao T, Zhao B L, Zhang T, Fang Q F, Liu C S, Wang X P, Cao L 2018 J. Nucl. Mater. 508 107

Google Scholar

Google Scholar

[10] Chen Z, Niu L L, Wang Z L, Tian L F, Laszlo K, Zhu K G, Wei Q M 2018 Acta Materialia 147 100

Google Scholar

Google Scholar

[11] Nishijima D, Ye M.Y, Ohno N 2004 J. Nucl. Mater. 329—333 1029

[12] Yang X, Hassanein A 2013 J. Nucl. Mater. 434 1

Google Scholar

Google Scholar

[13] Ananth M, Scipioni L , Notte J 2008 Am. Lab. 40 42

[14] Economou N P, Notte J A, Thompson W B 2011 Scanning 33 1

Google Scholar

Google Scholar

[15] Hlawacek G, Veligura V, Van Gastel R, Poelsema B 2014 J. Vac. Sci. Technol. B 32 020801

[16] Bergner F, Heintze C 2018 J. Nucl. Mater. 505 267

Google Scholar

Google Scholar

[17] Hasenhuetl E, Zhang Z X, Kiyohiro Y, Peng S, Akihiko K 2017 Nucl. Instrum. Methods Phys. Res. Sect. B 397 11

Google Scholar

Google Scholar

[18] Valles G, Panizo-Laiz M, Gonz_alez C, Martin-Bragado I, Gonz_alez-Arrabal R, Gordillo N, Iglesias R, Guerrero C L, Perlado J M 2017 Fusion Eng. Des. 125 479

Google Scholar

Google Scholar

[19] Fukumoto M, Kashiwagi H, Ohtsuka Y, Ueda Y, Nobuta Y, Yagyu J, Arai T, Taniguchi M, Inoue T, Sakamoto K 2009 J. Nucl. Mater. 386—388 768

[20] Miyamoto M, Mikami S, Nagashima H, Iijima N, Nishijima D, Doerner R P, Yoshida N, Watanabe H , Ueda Y, Sagara A 2015 J. Nucl. Mater. 463 333

Google Scholar

Google Scholar

[21] Liu F S, Rui H T, Peng S X, Zhu K G 2014 Nucl. Instrum. Methods Phys. Res. Sect. B 333 120

Google Scholar

Google Scholar

[22] Gilliam S B, Gidcumb S M, Forsythe D 2005 Nucl. Instrum. Methods Phys. Res. Sect. B 241 491

Google Scholar

Google Scholar

[23] Lindig S, Balden M, Kh Alimov V 2009 Phys. Scripta T 138 014040

[24] Smirnov R D, Krasheninnikov S I, Guterl J 2015 J. Nucl. Mater. 463 359

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 9895

- PDF Downloads: 116

- Cited By: 0

DownLoad:

DownLoad: