-

Temperature is the most intuitive and widespread in various physical quantities. Violent changes in temperature usually implies the appearing of fluctuations in physical properties of an object. Therefore, temperature is often an important indicator. With the development of science and technology, the scales in many fields are being more and more miniaturized. However, there are no mature temperature measurement systems in the case where the spatial scale is less than 10 μm. In addition to the requirement for spatial resolution, the sensor ought to exert no dramatic influence on the object to be measured. The nitrogen vacancy (NV) center in diamond is a stable luminescence defect. The measurements of its spectrum and spin state can be used to obtain the information about physical quantities near the color center, such as temperature and electro-magnetic field. Owing to its stable chemical properties and high thermal conductivity, the NV center can be applied to the noninvasive detection for nano-scale researches. It can also be used in the life field because it is non-toxic to cells. Moreover, combined with different techniques, such as optical fiber, scanning thermal microscopy, NV center can be used to measure the local temperatures in different scenarios. This review focuses on the temperature properties, the method of measuring temperature, and relevant applications of NV centers.

-

Keywords:

- nitrogen-vacancy center /

- quantum sensing /

- temperature sensing

[1] van Oort E, Manson N B, Glasbeek M 1988 J. Phys. C: Solid State Phys. 21 4385

Google Scholar

Google Scholar

[2] Gruber A 1997 Science 276 2012

Google Scholar

Google Scholar

[3] Jelezko F, Gaebel T, Popa I, Domhan M, Gruber A, Wrachtrup J 2004 Phys. Rev. Lett. 93 130501

Google Scholar

Google Scholar

[4] Fuchs G D, Dobrovitski V V, Hanson R, Batra A, Weis C D, Schenkel T, Awschalom D D 2008 Phys. Rev. Lett. 101 117601

Google Scholar

Google Scholar

[5] Neumann P, Kolesov R, Jacques V, Beck J, Tisler J, Batalov A, Rogers L, Manson N B, Balasubramanian G, Jelezko F, Wrachtrup J 2009 New J. Phys. 11 013017

Google Scholar

Google Scholar

[6] Childress L, Hanson R 2013 MRS Bull. 38 134

Google Scholar

Google Scholar

[7] Chen X, Zou C, Gong Z, Dong C, Guo G, Sun F 2015 Light Sci. Appl. 4 e230

Google Scholar

Google Scholar

[8] Han K Y, Kim S K, Eggeling C, Hell S W 2010 Nano Lett. 10 3199

Google Scholar

Google Scholar

[9] Arroyo-Camejo S, Adam M P, Besbes M, Hugonin J P, Jacques V, Greffet J J, Roch J F, Hell S W, Treussart F 2013 ACS Nano 7 10912

Google Scholar

Google Scholar

[10] Maze J R, Stanwix P L, Hodges J S, Hong S, Taylor J M, Cappellaro P, Jiang L, Dutt M V G, Togan E, Zibrov A S, Yacoby A, Walsworth R L, Lukin M D 2008 Nature 455 644

Google Scholar

Google Scholar

[11] Dolde F, Fedder H, Doherty M W, Nbauer T, Rempp F, Balasubramanian G, Wolf T, Reinhard F, Hollenberg L C L, Jelezko F, Wrachtrup J 2011 Nat. Phys. 7 459

Google Scholar

Google Scholar

[12] Ovartchaiyapong P, Lee K W, Myers B A, Jayich A C B 2014 Nat. Commun. 5 4429

Google Scholar

Google Scholar

[13] Acosta V M, Bauch E, Ledbetter M P, Waxman A, Bouchard L S, Budker D 2010 Phys. Rev. Lett. 104 070801

Google Scholar

Google Scholar

[14] Chen X D, Dong C H, Sun F W, Zou C L, Cui J M, Han Z F, Guo G C 2011 Appl. Phys. Lett. 99 161903

Google Scholar

Google Scholar

[15] Hayashi T, Fukuda N, Uchiyama S, Inada N 2015 PLoS One 10 e0117677

Google Scholar

Google Scholar

[16] Jaque D, del Rosal B, Rodrguez E M, Maestro L M, Haro-Gonzlez P, Sol J G 2014 Nanomedicine 9 1047

Google Scholar

Google Scholar

[17] Somero G N 1995 Annu. Rev. Physiol. 57 43

Google Scholar

Google Scholar

[18] Suzuki M, Tseeb V, Oyama K, Ishiwata S I 2007 Biophys. J. 92 2

Google Scholar

Google Scholar

[19] Zohar O, Ikeda M, Shinagawa H, Inoue H, Nakamura H, Elbaum D, Alkon D L, Yoshioka T 1998 Biophys. J. 74 82

Google Scholar

Google Scholar

[20] Astakhov V P, Outeiro J 2019 Importance of Temperature in Metal Cutting and Its Proper Measurement/Modeling (Cham: Springer International Publishing) pp1–47

[21] Shi L, Dames C, Lukes J R, Reddy P, Duda J, Cahill D G, Lee J, Marconnet A, Goodson K E, Bahk J H, Shakouri A, Prasher R S, Felts J, King W P, Han B, Bischof J C 2015 Nanoscale and Microscale Thermophys. Eng. 19 127

Google Scholar

Google Scholar

[22] Brites C D S, Balabhadra S, Carlos L D 2019 Adv. Opt. Mater. 7 1801239

Google Scholar

Google Scholar

[23] Doherty M W, Acosta V M, Jarmola A, Barson M S J, Manson N B, Budker D, Hollenberg L C L 2014 Phys. Rev. B 90 041201

Google Scholar

Google Scholar

[24] Li C C, Gong M, Chen X D, Li S, Zhao B W, Dong Y, Guo G C, Sun F W 2017 Diamond Relat. Mater. 74 119

Google Scholar

Google Scholar

[25] Schirhagl R, Chang K, Loretz M, Degen C L 2014 Annu. Rev. Phys. Chem. 65 83

Google Scholar

Google Scholar

[26] Toyli D M, Christle D J, Alkauskas A, Buckley B B, Van de Walle C G, Awschalom D D 2012 Phys. Rev. X 2 031001

Google Scholar

Google Scholar

[27] Toyli D M, de las Casas C F, Christle D J, Dobrovitski V V, Awschalom D D 2013 Proc. Natl. Acad. Sci. 110 8417

Google Scholar

Google Scholar

[28] Neumann P, Jakobi I, Dolde F, Burk C, Reuter R, Waldherr G, Honert J, Wolf T, Brunner A, Shim J H, Suter D, Sumiya H, Isoya J, Wrachtrup J 2013 Nano Lett. 13 2738

Google Scholar

Google Scholar

[29] Kucsko G, Maurer P C, Yao N Y, Kubo M, Noh H J, Lo P K, Park H, Lukin M D 2013 Nature 500 54

Google Scholar

Google Scholar

[30] Fedotov I V, Blakley S, Serebryannikov E E, Safronov N A, Velichansky V L, Scully M O, Zheltikov A M 2014 Appl. Phys. Lett. 105 261109

Google Scholar

Google Scholar

[31] Kraus H, Soltamov V A, Fuchs F, Simin D, Sperlich A, Baranov P G, Astakhov G V, Dyakonov V 2015 Sci. Rep. 4 5303

Google Scholar

Google Scholar

[32] Plakhotnik T, Aman H, Chang H C 2015 Nanotechnology 26 245501

Google Scholar

Google Scholar

[33] Laraoui A, Aycock-Rizzo H, Gao Y, Lu X, Riedo E, Meriles C A 2015 Nat. Commun. 6 8954

Google Scholar

Google Scholar

[34] Jelezko F, Wrachtrup J 2006 Phys. Status Solidi A 203 3207

Google Scholar

Google Scholar

[35] Wojciechowski A M, Karadas M, Osterkamp C, Jankuhn S, Meijer J, Jelezko F, Huck A, Andersen U L 2018 Appl. Phys. Lett. 113 013502

Google Scholar

Google Scholar

[36] Tzeng Y K, Tsai P C, Liu H Y, Chen O Y, Hsu H, Yee F G, Chang M S, Chang H C 2015 Nano Lett. 15 3945

Google Scholar

Google Scholar

[37] Wang J, Feng F, Zhang J, Chen J, Zheng Z, Guo L, Zhang W, Song X, Guo G, Fan L, Zou C, Lou L, Zhu W, Wang G 2015 Phys. Rev. B 91 155404

Google Scholar

Google Scholar

[38] Konzelmann P, Rendler T, Bergholm V, Zappe A, Pfannenstill V, Garsi M, Ziem F, Niethammer M, Widmann M, Lee S Y, Neumann P, Wrachtrup J 2018 New J. Phys. 20 123013

Google Scholar

Google Scholar

[39] Plakhotnik T, Doherty M W, Cole J H, Chapman R, Manson N B 2014 Nano Lett. 14 4989

Google Scholar

Google Scholar

[40] Zhang S C, Li S, Du B, Dong Y, Zheng Y, Lin H B, Zhao B W, Zhu W, Wang G Z, Chen X D, Guo G C, Sun F W 2019 Opt. Mater. Express 9 4634

Google Scholar

Google Scholar

[41] Wang N, Liu G Q, Leong W H, Zeng H, Feng X, Li S H, Dolde F, Fedder H, Wrachtrup J, Cui X D, Yang S, Li Q, Liu R B 2018 Phys. Rev. X 8 011042

Google Scholar

Google Scholar

[42] Liu C F, Leong W H, Xia K, Feng X, Finkler A, Denisenko A, Wrachtrup J, Li Q, Liu R B 2021 National Science Review 8 nwaa194

Google Scholar

Google Scholar

[43] Hayashi K, Matsuzaki Y, Taniguchi T, Shimo-Oka T, Nakamura I, Onoda S, Ohshima T, Morishita H, Fujiwara M, Saito S, Mizuochi N 2018 Phys. Rev. Appl. 10 034009

Google Scholar

Google Scholar

[44] Vetrone F, Naccache R, Zamarrn A, Juarranz de la Fuente A, Sanz-Rodrguez F, Martinez Maestro L, Martn Rodriguez E, Jaque D, Garca Sol J, Capobianco J A 2010 ACS Nano 4 3254

Google Scholar

Google Scholar

[45] Ermakova Y G, Lanin A A, Fedotov I V, Roshchin M, Kelmanson I V, Kulik D, Bogdanova Y A, Shokhina A G, Bilan D S, Staroverov D B, Balaban P M, Fedotov A B, Sidorov-Biryukov D A, Nikitin E S, Zheltikov A M, Belousov V V 2017 Nat. Commun. 8 15362

Google Scholar

Google Scholar

[46] Yukawa H, Fujiwara M, Kobayashi K, Kumon Y, Miyaji K, Nishimura Y, Oshimi K, Umehara Y, Teki Y, Iwasaki T, Hatano M, Hashimoto H, Baba Y 2020 Nanoscale Adv. 2 1859

Google Scholar

Google Scholar

[47] Simpson D A, Morrisroe E, McCoey J M, Lombard A H, Mendis D C, Treussart F, Hall L T, Petrou S, Hollenberg L C L 2017 ACS Nano 11 12077

Google Scholar

Google Scholar

[48] Fujiwara M, Sun S, Dohms A, Nishimura Y, Suto K, Takezawa Y, Oshimi K, Zhao L, Sadzak N, Umehara Y, Teki Y, Komatsu N, Benson O, Shikano Y, Kage-Nakadai E 2020 Sci. Adv. 6 eaba9636

Google Scholar

Google Scholar

[49] Tsai P C, Epperla C P, Huang J S, Chen O Y, Wu C C, Chang H C 2017 Angew.Chem. Int. Ed. 56 3025

Google Scholar

Google Scholar

[50] Mamaluy D, Gao X 2015 Appl. Phys. Lett. 106 193503

Google Scholar

Google Scholar

[51] Yue Y, Wang X 2012 Nano Rev. 3 11586

Google Scholar

Google Scholar

[52] Foy C, Zhang L, Trusheim M E, Bagnall K R, Walsh M, Wang E N, Englund D R 2020 ACS Appl. Mater. Interfaces 12 26525

Google Scholar

Google Scholar

[53] Andrich P, Li J, Liu X, Heremans F J, Nealey P F, Awschalom D D 2018 Nano Lett. 18 4684

Google Scholar

Google Scholar

[54] Zhang S C, Dong Y, Du B, Lin H B, Li S, Zhu W, Wang G Z, Chen X D, Guo G C, Sun F W 2021 Rev. Sci. Instrum. 92 044904

Google Scholar

Google Scholar

[55] Tetienne J P, Lombard A, Simpson D A, Ritchie C, Lu J, Mulvaney P, Hollenberg L C L 2016 Nano Lett. 16 326

Google Scholar

Google Scholar

-

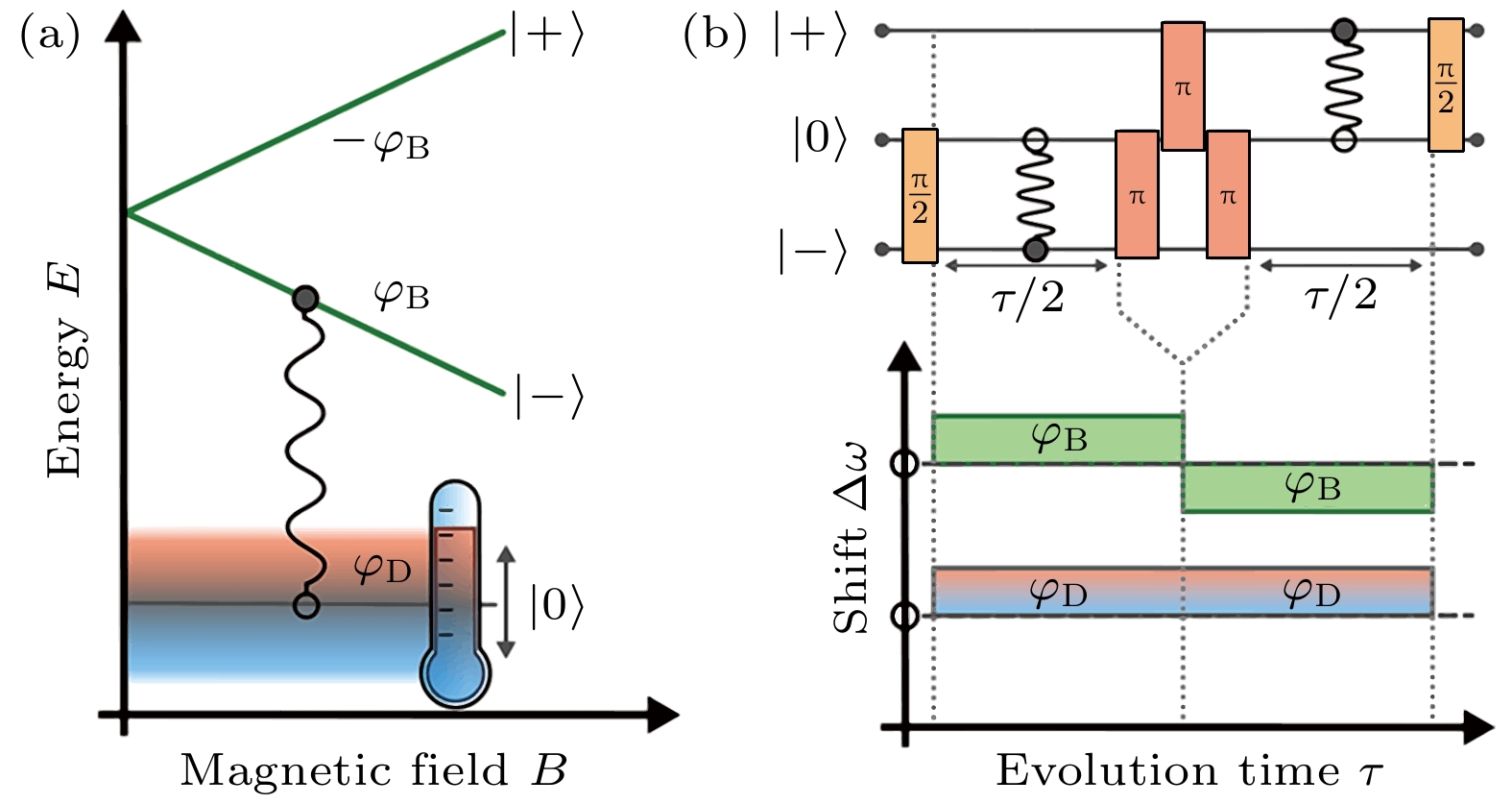

图 4 利用自旋操作消除磁场相位的影响提高温度的灵敏度. 图(b)中的

$ \pi/2 $ 用于产生叠加态, 3个$ \pi $ 脉冲用于改变相位的符号, 去除磁相位的影响[28]Figure 4. Spin operation is used to improve the temperature sensitivity by removing the effect of the magnetic field. The

$ \pi/2 $ pulse in the panel (b) is used to generate the superposition state, and three$ \pi $ pulses are used to change the sign of the phase and remove the effect of the magnetic phase[28]图 6 细胞内测温[29] (a)共聚焦下的荧光图, 虚线部分是细胞膜, 白色叉的部分表示金纳米颗粒的位置, 用来加热细胞. 圆圈表示纳米金刚石的位置. 旁边的颜色条是荧光的计数率. (b)不同金纳米颗粒的荧光条件下, 金刚石的温度差

Figure 6. Intracellular thermometry[29]. (a) Fluorescence with confocal microscopy. The dashed part shows the cell membrane. The cross shows the position of gold nanoparticles, which is used to heat the cell. The circle shows the position of nanodiamond. The color bar next to it shows the count rate of fluorescence. (b) Temperature difference of diamond under different fluorescence conditions of gold nanoparticles

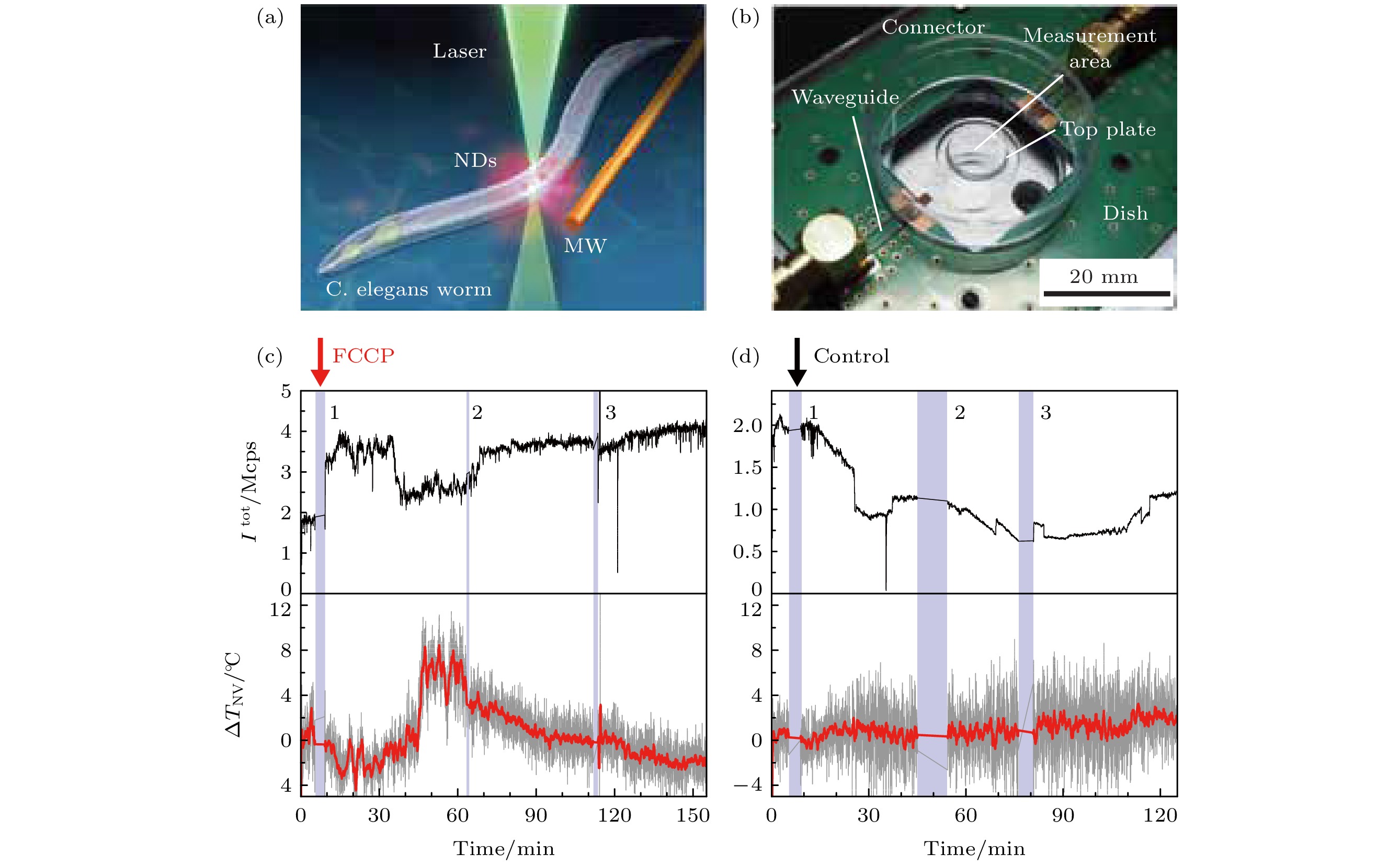

图 7 一体化细胞测温[48] (a)线虫示意图; (b)测量的样品室, 集成了微波、NV色心和细胞生活环境; (c)下半幅图为药物刺激下的温度变化反应, 上半幅图为对应的荧光强度; (d) 对照组

Figure 7. Integrated cellular thermometry[48]: (a) Schematic diagram of Caenorhabditis elegans worms; (b) sample chamber: integrated microwave, NV color center and cell living environment; (c) the lower half shows the temperature change response to drug stimulation, and the upper half shows the corresponding fluorescence intensity; (d) the control

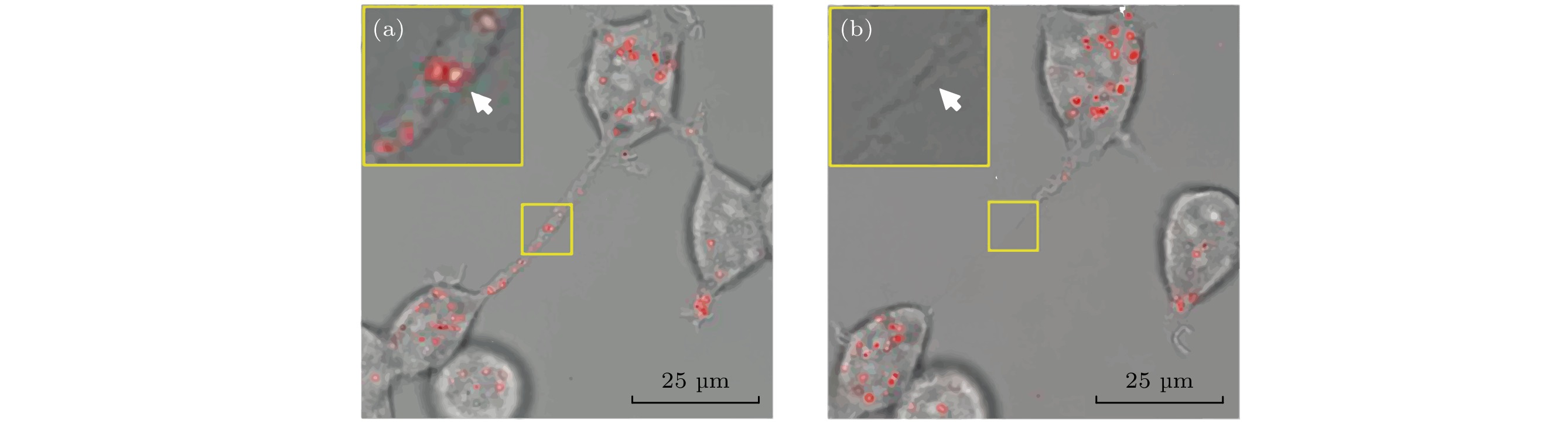

图 8 利用金刚石控制细胞的存活[49] (a)绿色的是蛋白质, 红色的是与金纳米颗粒混合的荧光纳米金刚石; (b)利用功率为330 μW的594 nm激光照射6 s后产生的结果: 细胞的膜隧道纳米管破裂了

Figure 8. Using diamond to control cell survival[49]: (a) The green is protein and the red is fluorescent nanodiamond mixed with gold nanoparticles; (b) obtained results after a 594 nm laser irradiation at a power of 330 μW for 6 s: the membrane tunneling nanotubes of the cell ruptured

图 9 NV色心对材料的温度和磁场进行表征[52] (a)测量装置示意图, 插图的红色小点为纳米金刚石; (b)氮化镓高电子迁移率晶体管成像示意图; (c) 高分辨率磁场测量(功率为290 mW); (d), (e) 功率为1和1.73 W下沟道阻挡层的温度分布

Figure 9. Characterizing the temperature and magnetic field of the material with NV center[52]: (a) Schematic diagram of the measurement device, and the red dots in the inset are nanodiamonds; (b) imaging schematic of a gallium nitride high-electron mobility transistor; (c) high-resolution magnetic field measurement (290 mW); (d), (e) temperature distribution of the channel stop at different powers of 1 and 1.73 W

图 10 利用PDMS进行局部测温[53] (a)纳米金刚石转移到PDMS上的微纳加工工艺; (b)通过ODMR拟合提取出温度信息, 并对温度进行重建之后的温度分布图

Figure 10. Local temperature measurement with PDMS[53]: (a) Processing of nanodiamond transferred to PDMS; (b) temperature distribution after extracting the temperature information by ODMR fitting and reconstructing the temperature

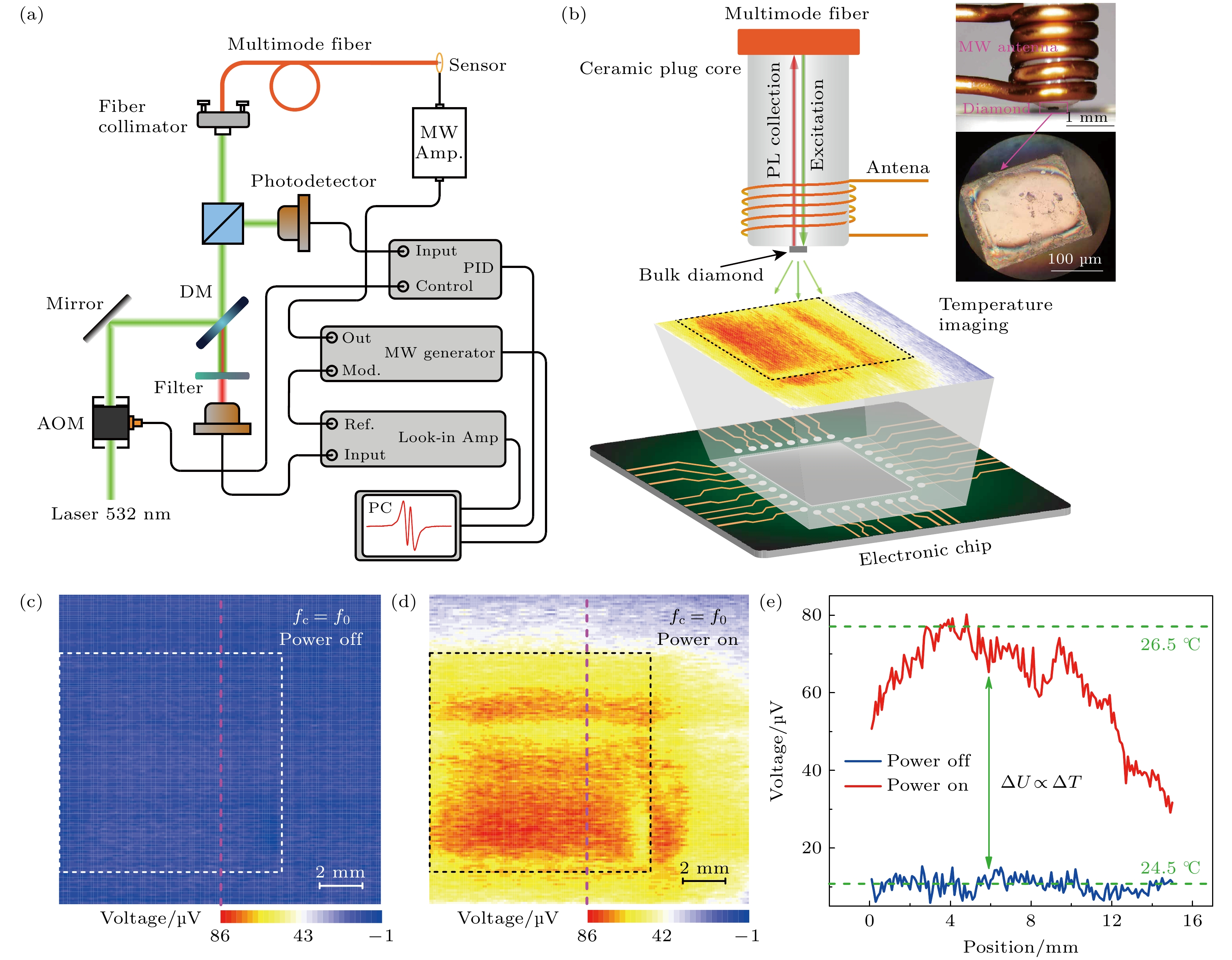

图 11 利用光纤传感对芯片温度分布进行测量[54] (a)测量的系统, 结合了锁相放大系统与光纤系统; (b)色心传感装置示意图, 红色的螺旋线表示微波天线; (c), (d)芯片未通电与通电时的温度分布图; (e)对应于图(c)和图(d)的红色虚线测量值

Figure 11. Chip temperature distribution is measured using fiber optic sensing[54]: (a) System of measurement, combining the phase-locked amplification system with the fiber optic system; (b) schematic diagram of the color center sensing device, with the red spiral lines indicating the microwave antenna; (c), (d) temperature distribution of the chip when it is powered off and on; (e) corresponds to the red dashed line measurements in panel (c) and (d)

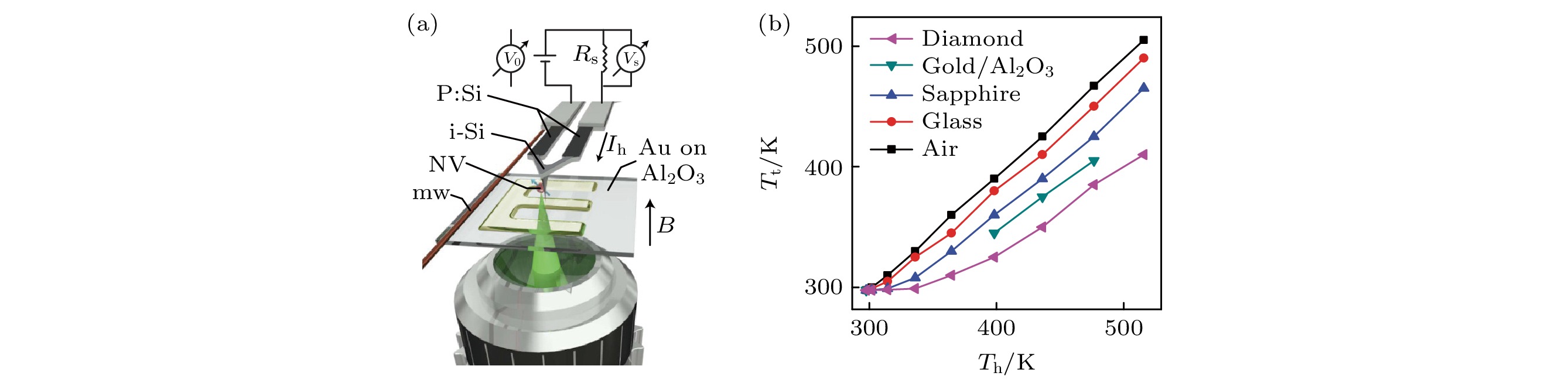

图 12 对材料热导率进行测量[33] (a)实验装置, 电流沿着AFM的悬梁臂, 通过加热悬梁臂间接加热粘在上面的金刚石色心. 色心发出的荧光通过一个高数值孔径的显微镜收集. (b)与不同介质接触后金刚石的温度, 横坐标为加热的温度, 纵坐标为金刚石的温度

Figure 12. Measuring the thermal conductivity of materials[33]. (a) Experimental setup, where current is flowing along the cantilever arm of the AFM and indirectly heats a diamond color center attached to it by heating the cantilever arm. The fluorescence emitted from NV center is collected through a microscope in a high numerical aperture. (b) Temperature of the diamond contact with different mediums. The horizontal coordinate is the temperature of heating and the vertical coordinate is the temperature of the diamond

表 1 NV色心的测量灵敏度

Table 1. Measurement sensitivity with NV color centers.

温度灵敏度/$({\rm{mK} }\cdot{ {\rm{Hz}^{-1/2} } })$ 方法 样品 NV色心浓度或者碳含量 参考文献 0.43 利用自旋锁相结合ODMR 块状 0.1—1 × 106 (99.99% ${ }^{12} {\rm{C}}$) [35] 0.76 增加NV色心的浓度 块状 2.84 × 106 [43] 1.6 借助磁场消磁测量温度 块状 0.15 × 106 [40] 5 对自旋能级进行相干操控 块状 99.995% ${ }^{12} {\rm{C}}$ [28] 9 对自旋能级进行相干操控 块状 99.99% ${ }^{12}{\rm{ C}}$ [29] 10 对自旋能级进行相干操控 块状 1.1% 13C [27] 10.1 利用多脉冲进行相干操控 块状 1.1% 13C [37] 11 利用居里温度下磁场的改变推算出温度 100 nm 500个NV [41] 0.076 利用居里温度下磁场的改变推算出温度 金刚石立柱 单个NV [42] 130 对自旋能级进行相干操控 50 nm 无相关数据 [28] 300 NV色心电子态的超精细结构 50 nm 100个NV [32] -

[1] van Oort E, Manson N B, Glasbeek M 1988 J. Phys. C: Solid State Phys. 21 4385

Google Scholar

Google Scholar

[2] Gruber A 1997 Science 276 2012

Google Scholar

Google Scholar

[3] Jelezko F, Gaebel T, Popa I, Domhan M, Gruber A, Wrachtrup J 2004 Phys. Rev. Lett. 93 130501

Google Scholar

Google Scholar

[4] Fuchs G D, Dobrovitski V V, Hanson R, Batra A, Weis C D, Schenkel T, Awschalom D D 2008 Phys. Rev. Lett. 101 117601

Google Scholar

Google Scholar

[5] Neumann P, Kolesov R, Jacques V, Beck J, Tisler J, Batalov A, Rogers L, Manson N B, Balasubramanian G, Jelezko F, Wrachtrup J 2009 New J. Phys. 11 013017

Google Scholar

Google Scholar

[6] Childress L, Hanson R 2013 MRS Bull. 38 134

Google Scholar

Google Scholar

[7] Chen X, Zou C, Gong Z, Dong C, Guo G, Sun F 2015 Light Sci. Appl. 4 e230

Google Scholar

Google Scholar

[8] Han K Y, Kim S K, Eggeling C, Hell S W 2010 Nano Lett. 10 3199

Google Scholar

Google Scholar

[9] Arroyo-Camejo S, Adam M P, Besbes M, Hugonin J P, Jacques V, Greffet J J, Roch J F, Hell S W, Treussart F 2013 ACS Nano 7 10912

Google Scholar

Google Scholar

[10] Maze J R, Stanwix P L, Hodges J S, Hong S, Taylor J M, Cappellaro P, Jiang L, Dutt M V G, Togan E, Zibrov A S, Yacoby A, Walsworth R L, Lukin M D 2008 Nature 455 644

Google Scholar

Google Scholar

[11] Dolde F, Fedder H, Doherty M W, Nbauer T, Rempp F, Balasubramanian G, Wolf T, Reinhard F, Hollenberg L C L, Jelezko F, Wrachtrup J 2011 Nat. Phys. 7 459

Google Scholar

Google Scholar

[12] Ovartchaiyapong P, Lee K W, Myers B A, Jayich A C B 2014 Nat. Commun. 5 4429

Google Scholar

Google Scholar

[13] Acosta V M, Bauch E, Ledbetter M P, Waxman A, Bouchard L S, Budker D 2010 Phys. Rev. Lett. 104 070801

Google Scholar

Google Scholar

[14] Chen X D, Dong C H, Sun F W, Zou C L, Cui J M, Han Z F, Guo G C 2011 Appl. Phys. Lett. 99 161903

Google Scholar

Google Scholar

[15] Hayashi T, Fukuda N, Uchiyama S, Inada N 2015 PLoS One 10 e0117677

Google Scholar

Google Scholar

[16] Jaque D, del Rosal B, Rodrguez E M, Maestro L M, Haro-Gonzlez P, Sol J G 2014 Nanomedicine 9 1047

Google Scholar

Google Scholar

[17] Somero G N 1995 Annu. Rev. Physiol. 57 43

Google Scholar

Google Scholar

[18] Suzuki M, Tseeb V, Oyama K, Ishiwata S I 2007 Biophys. J. 92 2

Google Scholar

Google Scholar

[19] Zohar O, Ikeda M, Shinagawa H, Inoue H, Nakamura H, Elbaum D, Alkon D L, Yoshioka T 1998 Biophys. J. 74 82

Google Scholar

Google Scholar

[20] Astakhov V P, Outeiro J 2019 Importance of Temperature in Metal Cutting and Its Proper Measurement/Modeling (Cham: Springer International Publishing) pp1–47

[21] Shi L, Dames C, Lukes J R, Reddy P, Duda J, Cahill D G, Lee J, Marconnet A, Goodson K E, Bahk J H, Shakouri A, Prasher R S, Felts J, King W P, Han B, Bischof J C 2015 Nanoscale and Microscale Thermophys. Eng. 19 127

Google Scholar

Google Scholar

[22] Brites C D S, Balabhadra S, Carlos L D 2019 Adv. Opt. Mater. 7 1801239

Google Scholar

Google Scholar

[23] Doherty M W, Acosta V M, Jarmola A, Barson M S J, Manson N B, Budker D, Hollenberg L C L 2014 Phys. Rev. B 90 041201

Google Scholar

Google Scholar

[24] Li C C, Gong M, Chen X D, Li S, Zhao B W, Dong Y, Guo G C, Sun F W 2017 Diamond Relat. Mater. 74 119

Google Scholar

Google Scholar

[25] Schirhagl R, Chang K, Loretz M, Degen C L 2014 Annu. Rev. Phys. Chem. 65 83

Google Scholar

Google Scholar

[26] Toyli D M, Christle D J, Alkauskas A, Buckley B B, Van de Walle C G, Awschalom D D 2012 Phys. Rev. X 2 031001

Google Scholar

Google Scholar

[27] Toyli D M, de las Casas C F, Christle D J, Dobrovitski V V, Awschalom D D 2013 Proc. Natl. Acad. Sci. 110 8417

Google Scholar

Google Scholar

[28] Neumann P, Jakobi I, Dolde F, Burk C, Reuter R, Waldherr G, Honert J, Wolf T, Brunner A, Shim J H, Suter D, Sumiya H, Isoya J, Wrachtrup J 2013 Nano Lett. 13 2738

Google Scholar

Google Scholar

[29] Kucsko G, Maurer P C, Yao N Y, Kubo M, Noh H J, Lo P K, Park H, Lukin M D 2013 Nature 500 54

Google Scholar

Google Scholar

[30] Fedotov I V, Blakley S, Serebryannikov E E, Safronov N A, Velichansky V L, Scully M O, Zheltikov A M 2014 Appl. Phys. Lett. 105 261109

Google Scholar

Google Scholar

[31] Kraus H, Soltamov V A, Fuchs F, Simin D, Sperlich A, Baranov P G, Astakhov G V, Dyakonov V 2015 Sci. Rep. 4 5303

Google Scholar

Google Scholar

[32] Plakhotnik T, Aman H, Chang H C 2015 Nanotechnology 26 245501

Google Scholar

Google Scholar

[33] Laraoui A, Aycock-Rizzo H, Gao Y, Lu X, Riedo E, Meriles C A 2015 Nat. Commun. 6 8954

Google Scholar

Google Scholar

[34] Jelezko F, Wrachtrup J 2006 Phys. Status Solidi A 203 3207

Google Scholar

Google Scholar

[35] Wojciechowski A M, Karadas M, Osterkamp C, Jankuhn S, Meijer J, Jelezko F, Huck A, Andersen U L 2018 Appl. Phys. Lett. 113 013502

Google Scholar

Google Scholar

[36] Tzeng Y K, Tsai P C, Liu H Y, Chen O Y, Hsu H, Yee F G, Chang M S, Chang H C 2015 Nano Lett. 15 3945

Google Scholar

Google Scholar

[37] Wang J, Feng F, Zhang J, Chen J, Zheng Z, Guo L, Zhang W, Song X, Guo G, Fan L, Zou C, Lou L, Zhu W, Wang G 2015 Phys. Rev. B 91 155404

Google Scholar

Google Scholar

[38] Konzelmann P, Rendler T, Bergholm V, Zappe A, Pfannenstill V, Garsi M, Ziem F, Niethammer M, Widmann M, Lee S Y, Neumann P, Wrachtrup J 2018 New J. Phys. 20 123013

Google Scholar

Google Scholar

[39] Plakhotnik T, Doherty M W, Cole J H, Chapman R, Manson N B 2014 Nano Lett. 14 4989

Google Scholar

Google Scholar

[40] Zhang S C, Li S, Du B, Dong Y, Zheng Y, Lin H B, Zhao B W, Zhu W, Wang G Z, Chen X D, Guo G C, Sun F W 2019 Opt. Mater. Express 9 4634

Google Scholar

Google Scholar

[41] Wang N, Liu G Q, Leong W H, Zeng H, Feng X, Li S H, Dolde F, Fedder H, Wrachtrup J, Cui X D, Yang S, Li Q, Liu R B 2018 Phys. Rev. X 8 011042

Google Scholar

Google Scholar

[42] Liu C F, Leong W H, Xia K, Feng X, Finkler A, Denisenko A, Wrachtrup J, Li Q, Liu R B 2021 National Science Review 8 nwaa194

Google Scholar

Google Scholar

[43] Hayashi K, Matsuzaki Y, Taniguchi T, Shimo-Oka T, Nakamura I, Onoda S, Ohshima T, Morishita H, Fujiwara M, Saito S, Mizuochi N 2018 Phys. Rev. Appl. 10 034009

Google Scholar

Google Scholar

[44] Vetrone F, Naccache R, Zamarrn A, Juarranz de la Fuente A, Sanz-Rodrguez F, Martinez Maestro L, Martn Rodriguez E, Jaque D, Garca Sol J, Capobianco J A 2010 ACS Nano 4 3254

Google Scholar

Google Scholar

[45] Ermakova Y G, Lanin A A, Fedotov I V, Roshchin M, Kelmanson I V, Kulik D, Bogdanova Y A, Shokhina A G, Bilan D S, Staroverov D B, Balaban P M, Fedotov A B, Sidorov-Biryukov D A, Nikitin E S, Zheltikov A M, Belousov V V 2017 Nat. Commun. 8 15362

Google Scholar

Google Scholar

[46] Yukawa H, Fujiwara M, Kobayashi K, Kumon Y, Miyaji K, Nishimura Y, Oshimi K, Umehara Y, Teki Y, Iwasaki T, Hatano M, Hashimoto H, Baba Y 2020 Nanoscale Adv. 2 1859

Google Scholar

Google Scholar

[47] Simpson D A, Morrisroe E, McCoey J M, Lombard A H, Mendis D C, Treussart F, Hall L T, Petrou S, Hollenberg L C L 2017 ACS Nano 11 12077

Google Scholar

Google Scholar

[48] Fujiwara M, Sun S, Dohms A, Nishimura Y, Suto K, Takezawa Y, Oshimi K, Zhao L, Sadzak N, Umehara Y, Teki Y, Komatsu N, Benson O, Shikano Y, Kage-Nakadai E 2020 Sci. Adv. 6 eaba9636

Google Scholar

Google Scholar

[49] Tsai P C, Epperla C P, Huang J S, Chen O Y, Wu C C, Chang H C 2017 Angew.Chem. Int. Ed. 56 3025

Google Scholar

Google Scholar

[50] Mamaluy D, Gao X 2015 Appl. Phys. Lett. 106 193503

Google Scholar

Google Scholar

[51] Yue Y, Wang X 2012 Nano Rev. 3 11586

Google Scholar

Google Scholar

[52] Foy C, Zhang L, Trusheim M E, Bagnall K R, Walsh M, Wang E N, Englund D R 2020 ACS Appl. Mater. Interfaces 12 26525

Google Scholar

Google Scholar

[53] Andrich P, Li J, Liu X, Heremans F J, Nealey P F, Awschalom D D 2018 Nano Lett. 18 4684

Google Scholar

Google Scholar

[54] Zhang S C, Dong Y, Du B, Lin H B, Li S, Zhu W, Wang G Z, Chen X D, Guo G C, Sun F W 2021 Rev. Sci. Instrum. 92 044904

Google Scholar

Google Scholar

[55] Tetienne J P, Lombard A, Simpson D A, Ritchie C, Lu J, Mulvaney P, Hollenberg L C L 2016 Nano Lett. 16 326

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 15944

- PDF Downloads: 634

- Cited By: 0

DownLoad:

DownLoad: