-

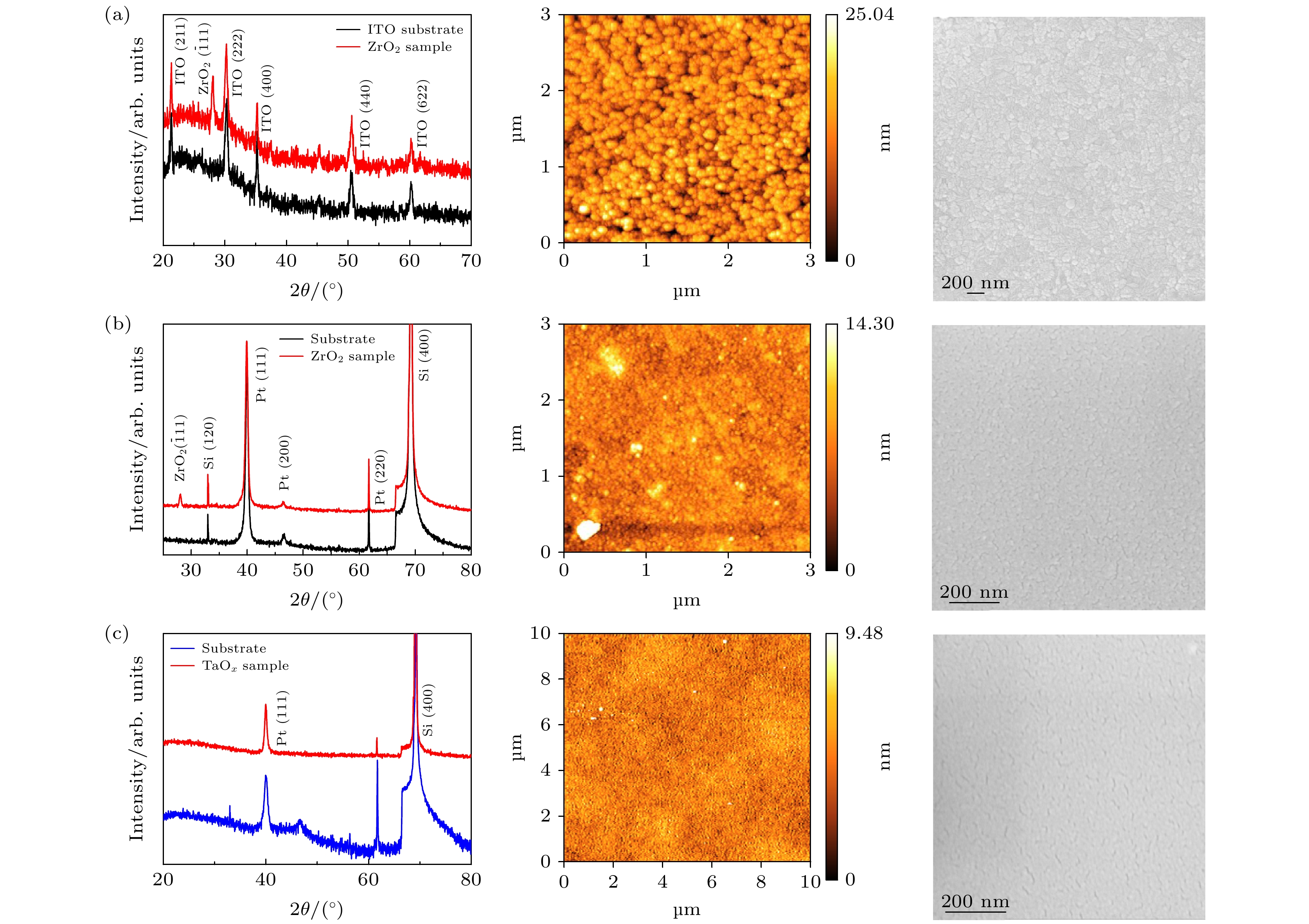

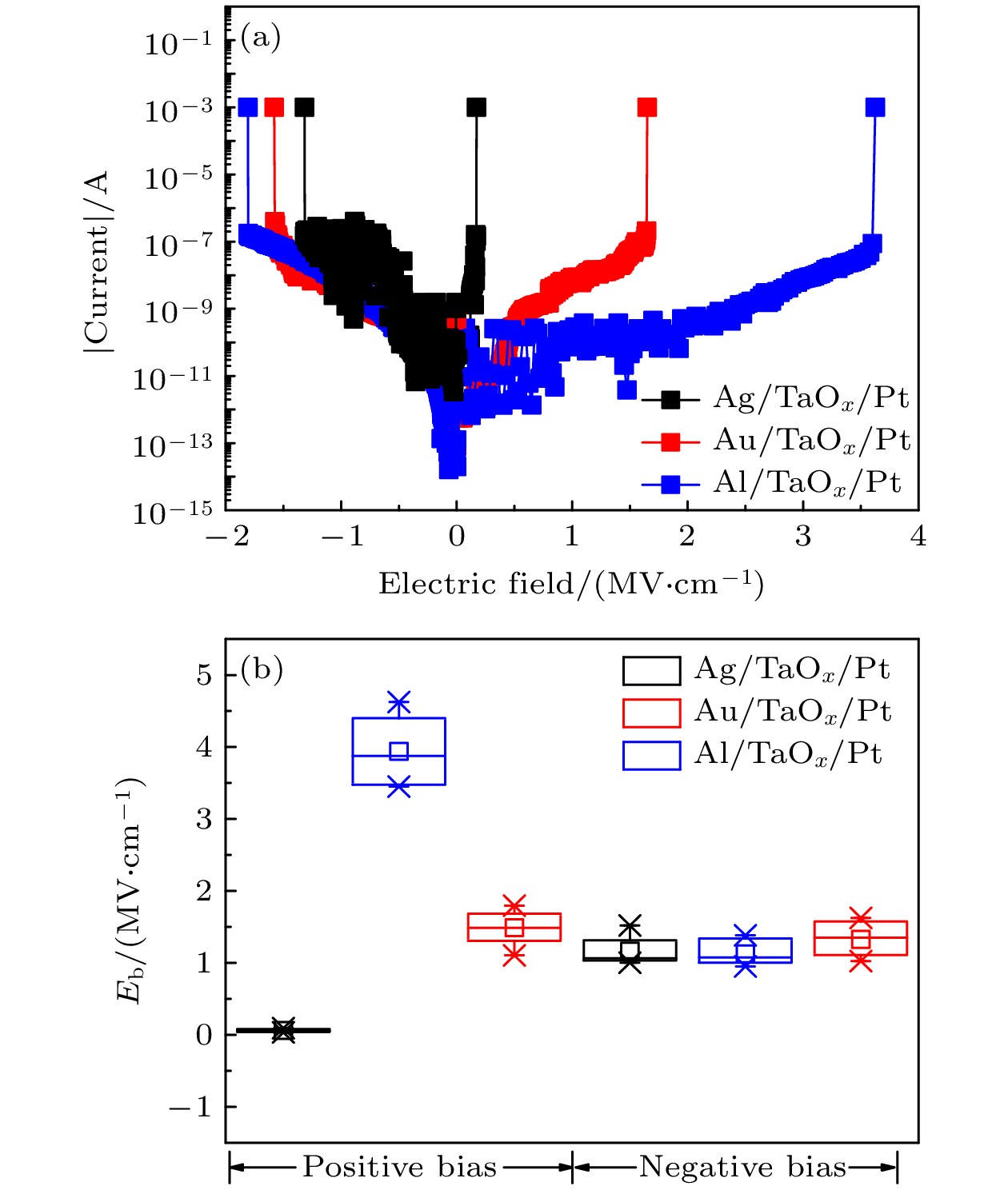

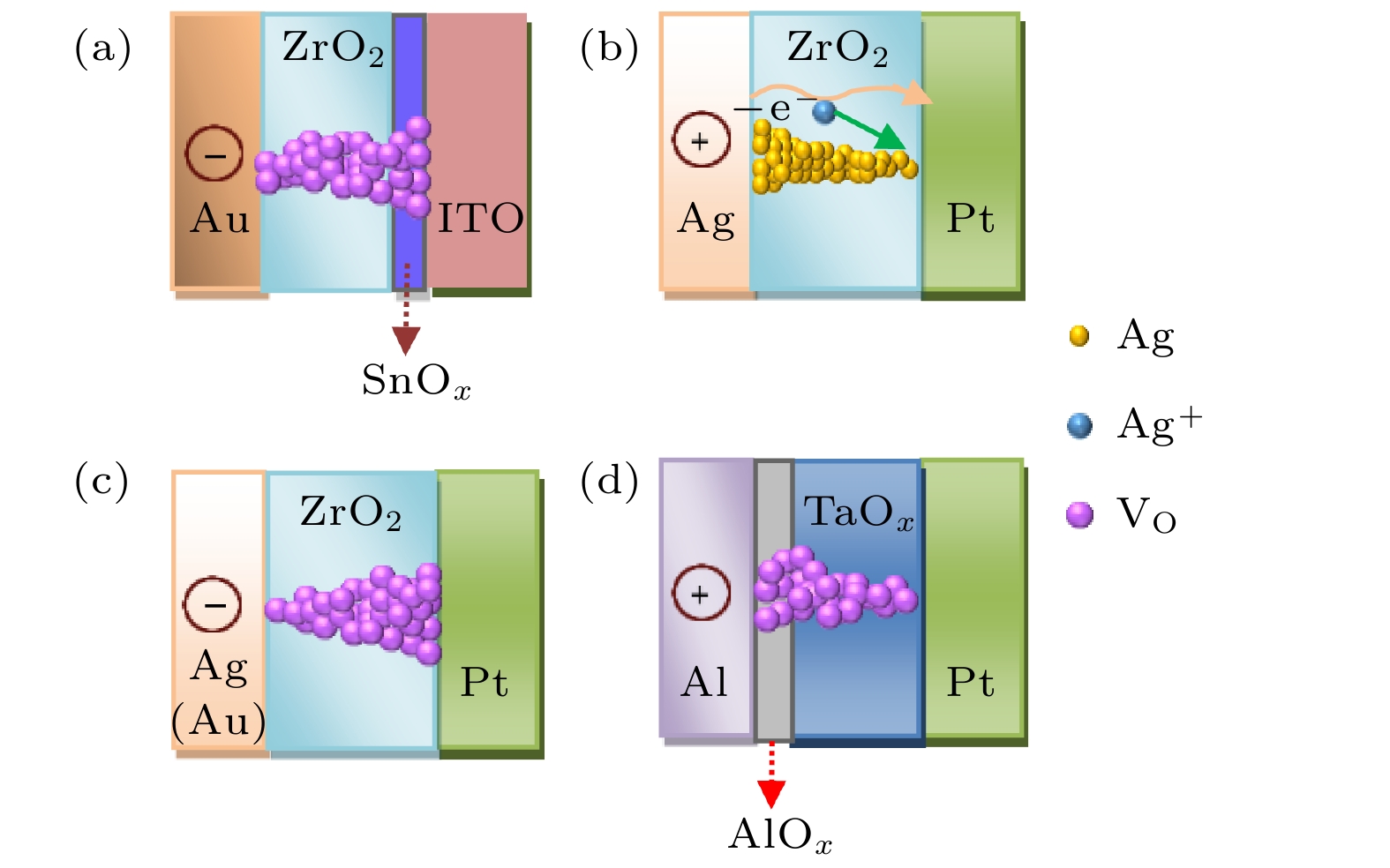

The memristors and the energy storage capacitors have the same sandwich structure, but the operating voltages required by the two devices are significantly different. Therefore, in the same device, it is necessary to study the influencing factors of operating voltage and adjust the operating voltage of the devices to realize the applications of the device in diverse fields. The polycrystalline ZrO2 and amorphous TaOx thin films are deposited on ITO conductive glass and Pt/Si substrates by reactive magnetron sputtering technology. Au, Ag and Al metal materials are selected as the top electrodes to construct a variety of metal/insulator/metal sandwich capacitors. The breakdown strengths of these devices under different bias polarities are studied. The results demonstrate that the breakdown strength is slightly larger for the ZrO2 based capacitor with ITO as the bottom electrode than for the Pt electrode device under negative bias. The breakdown electric field of the device with Ag as the top electrode shows obvious dependence on bias polarity, no matter whether the bottom electrode is ITO or Pt. The breakdown strength is reduced by more than an order of magnitude under a positive bias (2.13 MV/cm) compared with under a negative bias (0.17 MV/cm) of Ag/ZrO2/ITO device. The breakdown strength of the Al/TaOx/Pt device is enhanced under the forward bias (3.6 MV/cm), contrary to the Ag electrode device, which is nearly twice higher than the breakdown electric field under the negative bias (1.81 MV/cm). The different breakdown behaviors of the above devices can be explained by the migration and rearrangement of oxygen between the oxide electrode and the dielectric interface layer; the dissolution, migration and reduction of the electrochemically active metal electrode; and the redox reaction between the chemically active metal electrode and the oxide dielectric interface. The ZrO2 based capacitor with ITO electrode undergoes a redox reaction of Sn4+ in the ITO under negative bias, forming an insulating layer at the interface between the dielectric layer and the ITO electrode, which contributes a larger breakdown electric field. In addition, the electrochemical metallization process happens to the Ag electrode device under positive bias, and the breakdown electric field is smaller than negative bias due to the large diffusion coefficient of Ag ions in the film, while breakdown is dominated by the defect characteristics of the dielectric film under negative bias. The Al/TaOx/Pt devices can form AlOx oxide layer under positive bias, spontaneously, which can inhibit the leakage current, and also act as a series resistance to disperse part of the voltage and enhance the breakdown voltage of the device. The experimental results have guided significance in designing and operating the devices with different operating voltage requirements, such as memristors and dielectric energy storage capacitors. -

Keywords:

- oxide films /

- electrode materials /

- bias polarity /

- breakdown mechanism /

- memristors /

- capacitors

[1] Chua L 1971 IEEE Trans. Circuit Theory 18 507

Google Scholar

Google Scholar

[2] Hao X 2013 J. Adv. Dielectr. 3 1330001

Google Scholar

Google Scholar

[3] Palneedi H, Peddigari M, Hwang G T, Jeong D Y, Ryu J 2018 Adv. Funct. Mater. 28 1803665

Google Scholar

Google Scholar

[4] Zheng T, Wu J, Xiao D, Zhu J 2018 Prog. Mater Sci. 98 552

Google Scholar

Google Scholar

[5] Wang Y, Jie W, Yang C, Wei X, Hao J 2019 Adv. Funct. Mater. 29 1808118

Google Scholar

Google Scholar

[6] Wang Y, Hu L, Wei X, Zhuge F 2020 Appl. Phys. Lett. 116 221602

Google Scholar

Google Scholar

[7] Choi J, Park S, Lee J, Hong K, Kim D H, Moon C W, Park G D, Suh J, Hwang J, Kim S Y, Jung H S, Park N G, Han S, Nam K T, Jang H W 2016 Adv. Mater. 28 6562

Google Scholar

Google Scholar

[8] Hu L, Fu S, Chen Y, Cao H, Liang L, Zhang H, Gao J, Wang J, Zhuge F 2017 Adv. Mater. 29 1606927

Google Scholar

Google Scholar

[9] Guo J, Wang L, Liu Y, Zhao Z, Zhu E, Lin Z, Wang P, Jia C, Yang S, Lee S J, Huang W, Huang Y, Duan X 2020 Matter 2 965

Google Scholar

Google Scholar

[10] Guo X, Wang Q, Lü X, Yang H, Sun K, Yang D, Zhang H, Hasegawa T, He D 2020 Nanoscale 12 4320

Google Scholar

Google Scholar

[11] Liu Y, Ye C, Chang K C, Li L, Jiang B, Xia C, Liu L, Zhang X, Liu X, Xia T, Peng Z, Cao G, Cheng G, Ke S, Wang J 2020 Small 16 2004619

Google Scholar

Google Scholar

[12] McPherson J W, Jinyoung K, Shanware A, Mogul H, Rodriguez J 2003 IEEE Trans. Electron Devices 50 1771

Google Scholar

Google Scholar

[13] Yang L, Kong X, Li F, Hao H, Cheng Z, Liu H, Li J F, Zhang S 2019 Prog. Mater Sci. 102 72

Google Scholar

Google Scholar

[14] Pan F, Gao S, Chen C, Song C, Zeng F 2014 Mater. Sci. Eng. R. 83 1

Google Scholar

Google Scholar

[15] 庞华, 邓宁 2014 63 147301

Google Scholar

Google Scholar

Pang H, Deng N 2014 Acta Phys. Sin. 63 147301

Google Scholar

Google Scholar

[16] Liu Q, Sun J, Lü H, Long S, Yin K, Wan N, Li Y, Sun L, Liu M 2012 Adv. Mater. 24 1844

Google Scholar

Google Scholar

[17] Liu S, Lu N, Zhao X, Xu H, Banerjee W, Lü H, Long S, Li Q, Liu Q, Liu M 2016 Adv. Mater. 28 10623

Google Scholar

Google Scholar

[18] Li Q, Qiu L, Wei X, Dai B, Zeng H 2016 Sci. Rep. 6 29347

Google Scholar

Google Scholar

[19] Tian B, Nukala P, Hassine M B, Zhao X, Wang X, Shen H, Wang J, Sun S, Lin T, Sun J, Ge J, Huang R, Duan C, Reiss T, Varela M, Dkhil B, Meng X, Chu J 2017 Phys. Chem. Chem. Phys. 19 16960

Google Scholar

Google Scholar

[20] Gao W, Yao M, Yao X 2017 Ceram. Int. 43 13069

Google Scholar

Google Scholar

[21] Gao W, Yao M, Yao X 2018 ACS Appl. Mater. Interfaces 10 28745

Google Scholar

Google Scholar

[22] Hou C, Huang W, Zhao W, Zhang D, Yin Y, Li X 2017 ACS Appl. Mater. Interfaces 9 20484

Google Scholar

Google Scholar

[23] Panda D, Tseng T Y 2013 Thin Solid Films 531 1

Google Scholar

Google Scholar

[24] Kudoh Y, Akami K, Matsuya Y 1999 Synth. Met. 102 973

Google Scholar

Google Scholar

[25] Matsuhashi H, Nishikawa S 1994 Jpn. J. Appl. Phys. 33 1293

Google Scholar

Google Scholar

[26] Atanassova E, Paskaleva A 2007 Microelectron. Reliab. 47 913

Google Scholar

Google Scholar

[27] Lee M J, Lee C B, Lee D, Lee S R, Chang M, Hur J H, Kim Y B, Kim C J, Seo D H, Seo S, Chung U I, Yoo I K, Kim K 2011 Nat. Mater. 10 625

Google Scholar

Google Scholar

[28] Wu M C, Wu T H, Tseng T Y 2012 J. Appl. Phys. 111 014505

Google Scholar

Google Scholar

[29] Liu Q, Long S, Wang W, Tanachutiwat S, Li Y, Wang Q, Zhang M, Huo Z, Chen J, Liu M 2010 IEEE Electron Device Lett. 31 1299

Google Scholar

Google Scholar

[30] Li Y, Long S, Zhang M, Liu Q, Shao L, Zhang S, Wang Y, Zuo Q, Liu S, Liu M 2009 IEEE Electron Device Lett. 31 117

Google Scholar

Google Scholar

[31] Li C, Wang F, Zhang J, She Y, Zhang Z, Liu L, Liu Q, Hao Y, Zhang K 2020 ECS J. Solid State Sci. Technol 9 041005

Google Scholar

Google Scholar

[32] Atanassova E, Spassov D, Paskaleva A 2006 Microelectron. Eng. 83 1918

Google Scholar

Google Scholar

[33] Kindsmüller A, Meledin A, Mayer J, Waser R, Wouters D J 2019 Nanoscale 11 18201

Google Scholar

Google Scholar

[34] Yuan X C, Tang J L, Zeng H Z, Wei X H 2014 Nanoscale Res. Lett. 9 268

Google Scholar

Google Scholar

[35] Ye C, Zhan C, Tsai T M, Chang K C, Chen M C, Chang T C, Deng T, Wang H 2014 Appl. Phys. Express 7 034101

Google Scholar

Google Scholar

[36] Zhang J, Wang F, Li C, Shan X, Liang A, Hu K, Li Y, Liu Q, Hao Y, Zhang K 2020 Appl. Surf. Sci. 526 146723

Google Scholar

Google Scholar

[37] Wu M C, Ting Y H, Chen J Y, Wu W W 2019 Adv. Sci. 6 1902363

Google Scholar

Google Scholar

[38] Kuo C C, Chen I C, Shih C C, Chang K C, Huang C H, Chen P H, Chang T, Tsai T M, Chang J S, Huang J C 2015 IEEE Electron Device Lett. 36 1321

Google Scholar

Google Scholar

-

图 6 器件在施加偏压下的击穿机理示意图 (a)负偏压下的Au/ZrO2/ITO器件; (b), (c) 正负偏压下的Ag/ZrO2/Pt器件; (d) 正偏压下的Al/TaOx/Pt器件

Figure 6. Schematic diagrams of the breakdown mechanisms of the devices under different applied biases: (a) The Au/ZrO2/ITO device under negative bias; (b), (c) Ag/ZrO2/Pt devices under positive and negative biases, respectively; (d) the Al/TaOx/Pt device under positive bias.

-

[1] Chua L 1971 IEEE Trans. Circuit Theory 18 507

Google Scholar

Google Scholar

[2] Hao X 2013 J. Adv. Dielectr. 3 1330001

Google Scholar

Google Scholar

[3] Palneedi H, Peddigari M, Hwang G T, Jeong D Y, Ryu J 2018 Adv. Funct. Mater. 28 1803665

Google Scholar

Google Scholar

[4] Zheng T, Wu J, Xiao D, Zhu J 2018 Prog. Mater Sci. 98 552

Google Scholar

Google Scholar

[5] Wang Y, Jie W, Yang C, Wei X, Hao J 2019 Adv. Funct. Mater. 29 1808118

Google Scholar

Google Scholar

[6] Wang Y, Hu L, Wei X, Zhuge F 2020 Appl. Phys. Lett. 116 221602

Google Scholar

Google Scholar

[7] Choi J, Park S, Lee J, Hong K, Kim D H, Moon C W, Park G D, Suh J, Hwang J, Kim S Y, Jung H S, Park N G, Han S, Nam K T, Jang H W 2016 Adv. Mater. 28 6562

Google Scholar

Google Scholar

[8] Hu L, Fu S, Chen Y, Cao H, Liang L, Zhang H, Gao J, Wang J, Zhuge F 2017 Adv. Mater. 29 1606927

Google Scholar

Google Scholar

[9] Guo J, Wang L, Liu Y, Zhao Z, Zhu E, Lin Z, Wang P, Jia C, Yang S, Lee S J, Huang W, Huang Y, Duan X 2020 Matter 2 965

Google Scholar

Google Scholar

[10] Guo X, Wang Q, Lü X, Yang H, Sun K, Yang D, Zhang H, Hasegawa T, He D 2020 Nanoscale 12 4320

Google Scholar

Google Scholar

[11] Liu Y, Ye C, Chang K C, Li L, Jiang B, Xia C, Liu L, Zhang X, Liu X, Xia T, Peng Z, Cao G, Cheng G, Ke S, Wang J 2020 Small 16 2004619

Google Scholar

Google Scholar

[12] McPherson J W, Jinyoung K, Shanware A, Mogul H, Rodriguez J 2003 IEEE Trans. Electron Devices 50 1771

Google Scholar

Google Scholar

[13] Yang L, Kong X, Li F, Hao H, Cheng Z, Liu H, Li J F, Zhang S 2019 Prog. Mater Sci. 102 72

Google Scholar

Google Scholar

[14] Pan F, Gao S, Chen C, Song C, Zeng F 2014 Mater. Sci. Eng. R. 83 1

Google Scholar

Google Scholar

[15] 庞华, 邓宁 2014 63 147301

Google Scholar

Google Scholar

Pang H, Deng N 2014 Acta Phys. Sin. 63 147301

Google Scholar

Google Scholar

[16] Liu Q, Sun J, Lü H, Long S, Yin K, Wan N, Li Y, Sun L, Liu M 2012 Adv. Mater. 24 1844

Google Scholar

Google Scholar

[17] Liu S, Lu N, Zhao X, Xu H, Banerjee W, Lü H, Long S, Li Q, Liu Q, Liu M 2016 Adv. Mater. 28 10623

Google Scholar

Google Scholar

[18] Li Q, Qiu L, Wei X, Dai B, Zeng H 2016 Sci. Rep. 6 29347

Google Scholar

Google Scholar

[19] Tian B, Nukala P, Hassine M B, Zhao X, Wang X, Shen H, Wang J, Sun S, Lin T, Sun J, Ge J, Huang R, Duan C, Reiss T, Varela M, Dkhil B, Meng X, Chu J 2017 Phys. Chem. Chem. Phys. 19 16960

Google Scholar

Google Scholar

[20] Gao W, Yao M, Yao X 2017 Ceram. Int. 43 13069

Google Scholar

Google Scholar

[21] Gao W, Yao M, Yao X 2018 ACS Appl. Mater. Interfaces 10 28745

Google Scholar

Google Scholar

[22] Hou C, Huang W, Zhao W, Zhang D, Yin Y, Li X 2017 ACS Appl. Mater. Interfaces 9 20484

Google Scholar

Google Scholar

[23] Panda D, Tseng T Y 2013 Thin Solid Films 531 1

Google Scholar

Google Scholar

[24] Kudoh Y, Akami K, Matsuya Y 1999 Synth. Met. 102 973

Google Scholar

Google Scholar

[25] Matsuhashi H, Nishikawa S 1994 Jpn. J. Appl. Phys. 33 1293

Google Scholar

Google Scholar

[26] Atanassova E, Paskaleva A 2007 Microelectron. Reliab. 47 913

Google Scholar

Google Scholar

[27] Lee M J, Lee C B, Lee D, Lee S R, Chang M, Hur J H, Kim Y B, Kim C J, Seo D H, Seo S, Chung U I, Yoo I K, Kim K 2011 Nat. Mater. 10 625

Google Scholar

Google Scholar

[28] Wu M C, Wu T H, Tseng T Y 2012 J. Appl. Phys. 111 014505

Google Scholar

Google Scholar

[29] Liu Q, Long S, Wang W, Tanachutiwat S, Li Y, Wang Q, Zhang M, Huo Z, Chen J, Liu M 2010 IEEE Electron Device Lett. 31 1299

Google Scholar

Google Scholar

[30] Li Y, Long S, Zhang M, Liu Q, Shao L, Zhang S, Wang Y, Zuo Q, Liu S, Liu M 2009 IEEE Electron Device Lett. 31 117

Google Scholar

Google Scholar

[31] Li C, Wang F, Zhang J, She Y, Zhang Z, Liu L, Liu Q, Hao Y, Zhang K 2020 ECS J. Solid State Sci. Technol 9 041005

Google Scholar

Google Scholar

[32] Atanassova E, Spassov D, Paskaleva A 2006 Microelectron. Eng. 83 1918

Google Scholar

Google Scholar

[33] Kindsmüller A, Meledin A, Mayer J, Waser R, Wouters D J 2019 Nanoscale 11 18201

Google Scholar

Google Scholar

[34] Yuan X C, Tang J L, Zeng H Z, Wei X H 2014 Nanoscale Res. Lett. 9 268

Google Scholar

Google Scholar

[35] Ye C, Zhan C, Tsai T M, Chang K C, Chen M C, Chang T C, Deng T, Wang H 2014 Appl. Phys. Express 7 034101

Google Scholar

Google Scholar

[36] Zhang J, Wang F, Li C, Shan X, Liang A, Hu K, Li Y, Liu Q, Hao Y, Zhang K 2020 Appl. Surf. Sci. 526 146723

Google Scholar

Google Scholar

[37] Wu M C, Ting Y H, Chen J Y, Wu W W 2019 Adv. Sci. 6 1902363

Google Scholar

Google Scholar

[38] Kuo C C, Chen I C, Shih C C, Chang K C, Huang C H, Chen P H, Chang T, Tsai T M, Chang J S, Huang J C 2015 IEEE Electron Device Lett. 36 1321

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 9064

- PDF Downloads: 127

- Cited By: 0

DownLoad:

DownLoad: