-

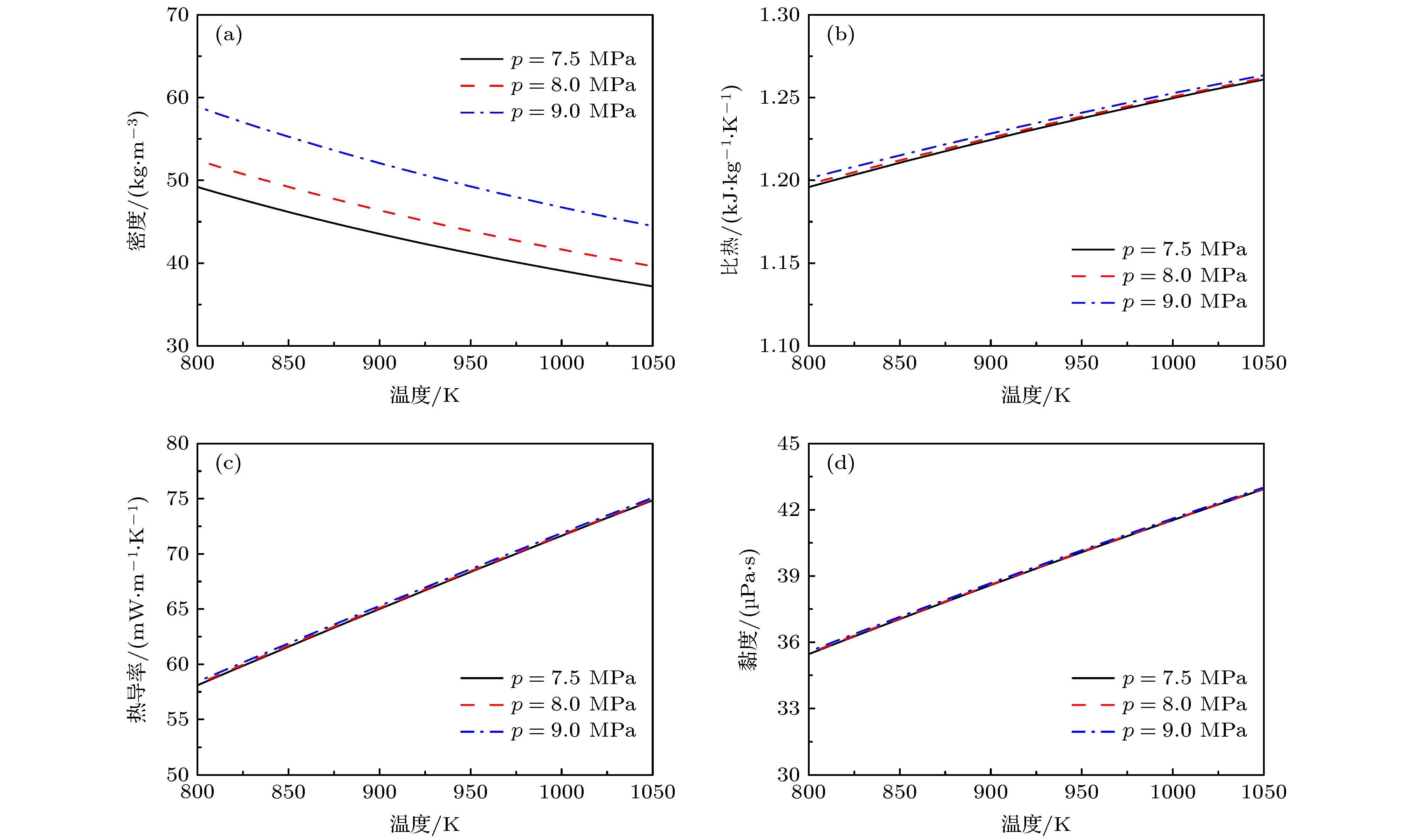

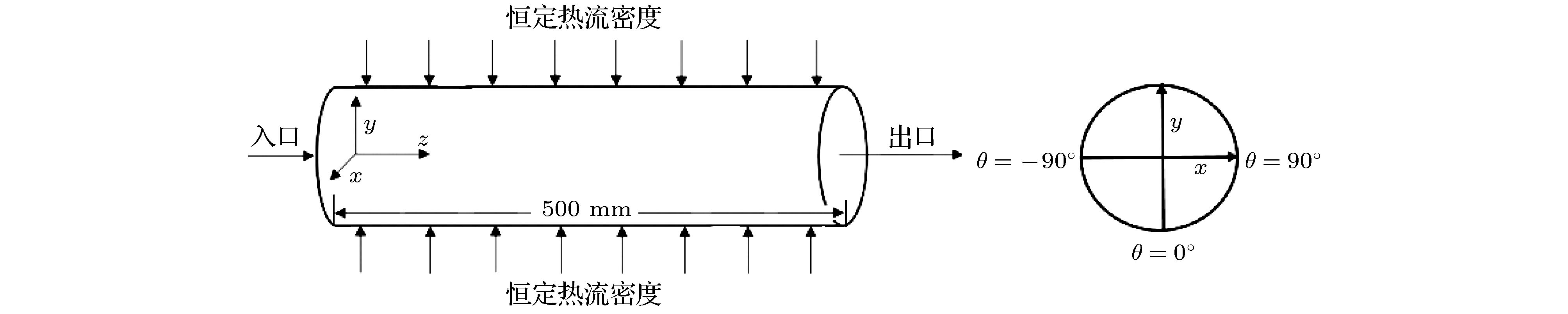

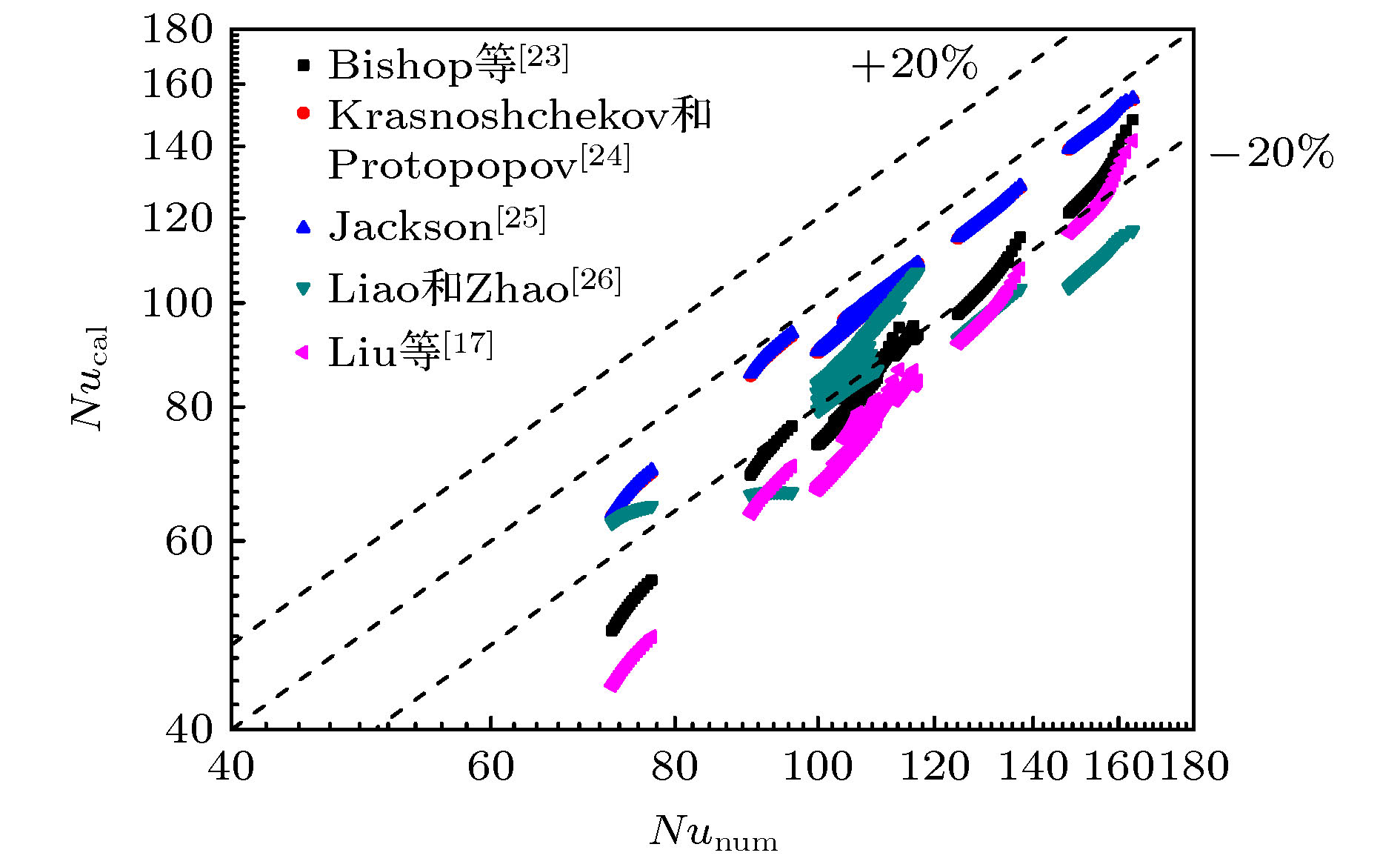

Supercritical CO2 can be used as a heat transfer fluid in a solar receiver, especially for a concentrating solar thermal power tower system. Such applications require better understanding of the heat transfer characteristics of supercritical CO2 in the solar receiver tube in a high temperature region. However, most of the existing experimental and numerical studies of the heat transfer characteristics of supercritical CO2 in tubes near the critical temperature region, and the corresponding heat transfer characteristics in the high temperature region are conducted. In this paper, a three-dimensional steady-state numerical simulation with the standard k-ε turbulent model is established by using ANSYS FLUENT for the flow and heat transfer of supercritical CO2 in a heated circular tube with an inner diameter of 6 mm and a length of 500 mm in the high temperature region. The effects of the fluid temperature (823–1023 K), the flow direction (horizontal, downward and upward), the pressure (7.5–9 MPa), the mass flux (200–500 kg·m–2·s–1) and the heat flux (100–800 kW·m–2) on the convection heat transfer coefficient and Nusselt number are discussed. The results show that the convection heat transfer coefficient increases while Nusselt number decreases nearly linearly with fluid temperature increasing. Both fluid direction and pressure have negligible effects on the convection heat transfer coefficient and Nusselt number. Moreover, the convective heat transfer coefficient and Nusselt number are enhanced greatly with the increasing of mass flux and the decreasing of heat flux, which is more obvious at a higher heat flux. The influences of buoyancy and flow acceleration on the heat transfer characteristics are also investigated. The buoyancy effect can be ignored within the present parameter range. However, the flow acceleration induced by the high heat flux significantly deteriorates the heat transfer preformation. Moreover, eight heat transfer correlations of supercritical fluid in tubes are evaluated and compared with the present numerical data. The comparison indicates that the correlations based on the thermal property modification show better performance in the heat transfer prediction in the high temperature region than those based on the dimensionless number modification. And Nusselt number predicted by the best correlation has a mean absolute relative deviation of 8.1% compared with the present numerical results, with all predicted data points located in the deviation bandwidth of ±20%. The present work can provide a theoretical guidance for the optimal design and safe operation of concentrating solar receivers where supercritical CO2 is used as a heat transfer fluid.

-

Keywords:

- supercritical CO2 /

- heat transfer /

- solar receiver tube /

- numerical simulation

[1] Singh A S, Choudhary T, Sanjay S https://www.sae.org/publications/technical-papers/content/2019-01-1391/ [2020-9-20]

[2] 吴毅, 王佳莹, 王明坤, 戴义平 2016 西安交通大学学报 50 108

Google Scholar

Google Scholar

Wu Y, Wang J Y, Wang M K, Dai Y P 2016 J. Xi'an Jiaotong Univ. 50 108

Google Scholar

Google Scholar

[3] Turchi C S, Ma Z, Neises T W, Wagner M J 2013 J. Sol. Energy Eng. 135 041007

Google Scholar

Google Scholar

[4] Neises T, Turchi C 2014 Energy Procedia 49 1187

Google Scholar

Google Scholar

[5] 黄凯欣, 饶政华, 廖胜明 2018 太阳能学报 39 44

Google Scholar

Google Scholar

Huang X K, Rao Z H, Liao S M 2018 Acta Energiae Solaris Sinica 39 44

Google Scholar

Google Scholar

[6] Benoit H, Spreafico L, Gauthier D, Flamant G 2016 Renew. Sust. Energ. Rev. 55 298

Google Scholar

Google Scholar

[7] Mehos M, Turchi C, Vidal J, Wagner J, Ma Z, Ho C, Kolb W, Andraka C, Kruizenga A https://www.nrel.gov/docs/fy17osti/67464.pdf [2020-9-20]

[8] Cabeza L F, de Gracia A, Fernández A I, Farid M M 2017 Appl. Therm. Eng. 125 799

Google Scholar

Google Scholar

[9] Xie J, Liu D, Yan H, Xie G, Boetcher S K 2020 Int. J. Heat Mass Transfer 149 119233

Google Scholar

Google Scholar

[10] Kim D E, Kim M H 2010 Nucl. Eng. Des. 240 3336

Google Scholar

Google Scholar

[11] Bovard S, Abdi M, Nikou M R K, Daryasafar A 2017 J. Supercrit. Fluids 119 88

Google Scholar

Google Scholar

[12] Qiu Y, Li M J, He Y L, Tao W Q 2016 Appl. Therm. Eng. 115 1255

Google Scholar

Google Scholar

[13] 刘占斌, 何雅玲, 王坤, 马朝, 姜涛 2019 化工学报 70 3329

Google Scholar

Google Scholar

Liu Z B, He Y L, Wang K, Ma Z, Jiang T 2019 J. Chem. Ind. Eng. (China) 70 3329

Google Scholar

Google Scholar

[14] Lemmon E W, Huber M L, McLinden M O http://www.nist.gov/srd/nist23.cfm [2020-9-20]

[15] Launder B E, Spalding D B 1972 Mathematical Models of Turbulence (London: Academic Press) p169

[16] Kim D E, Kim M H 2011 Int. J. Heat Fluid Flow 32 176

Google Scholar

Google Scholar

[17] Liu S, Huang Y, Liu G, Wang J, Leung L K 2017 Int. J. Heat Mass Transfer 106 1144

Google Scholar

Google Scholar

[18] Hall W B, Jackson J D 1969 Mech. Eng. 91 66

[19] Zhang Q, Li H, Kong X, Liu J, Lei X 2018 Int. J. Heat Mass Transfer 122 469

Google Scholar

Google Scholar

[20] Lei Y, Chen Z 2018 Int. J. Refrig. 90 46

Google Scholar

Google Scholar

[21] Xiang M, Guo J, Huai X, Cui X 2017 J. Supercrit. Fluids 130 389

Google Scholar

Google Scholar

[22] Xu R N, Luo F, Jiang P X 2017 Int. J. Heat Mass Transfer 110 576

Google Scholar

Google Scholar

[23] Bishop A A, Sandberg R O, Tong L S 1965 Report WCAP-2056 (Pittsburgh: Westinghouse Electric Corporation) p85

[24] Kranoshchekov E A, Protopopov V S 1966 High Temp. 4 375

[25] Jackson J D 2013 Nucl. Eng. Des. 264 24

Google Scholar

Google Scholar

[26] Liao S M, Zhao T S 2002 Int. J. Heat Mass Transfer 45 5025

Google Scholar

Google Scholar

-

图 5 模型计算结果与文献[16]实验数据的对比 (a) 壁面温度; (b) 对流传热系数; 其中, 工况1, G = 868 kg·m–2·s–1, q = 231.0 kW·m–2, p = 9.22 MPa; 工况2, G = 873 kg·m–2·s–1, q = 216.2 kW·m–2, p = 9.09 MPa; 工况3, G = 874 kg·m–2·s–1, q = 191.8 kW·m–2, p = 8.71 MPa

Figure 5. Comparisons between numerical results and experimental data of Ref. [16]: (a) Wall temperature; (b) convective heat transfer coefficient. Case 1: G = 868 kg·m–2·s–1, q = 231.0 kW·m–2, p = 9.22 MPa. Case 2: G = 873 kg·m–2·s–1, q = 216.2 kW·m–2, p = 9.09 MPa. Case 3: G = 874 kg·m–2·s–1, q = 191.8 kW·m–2, p = 8.71 MPa.

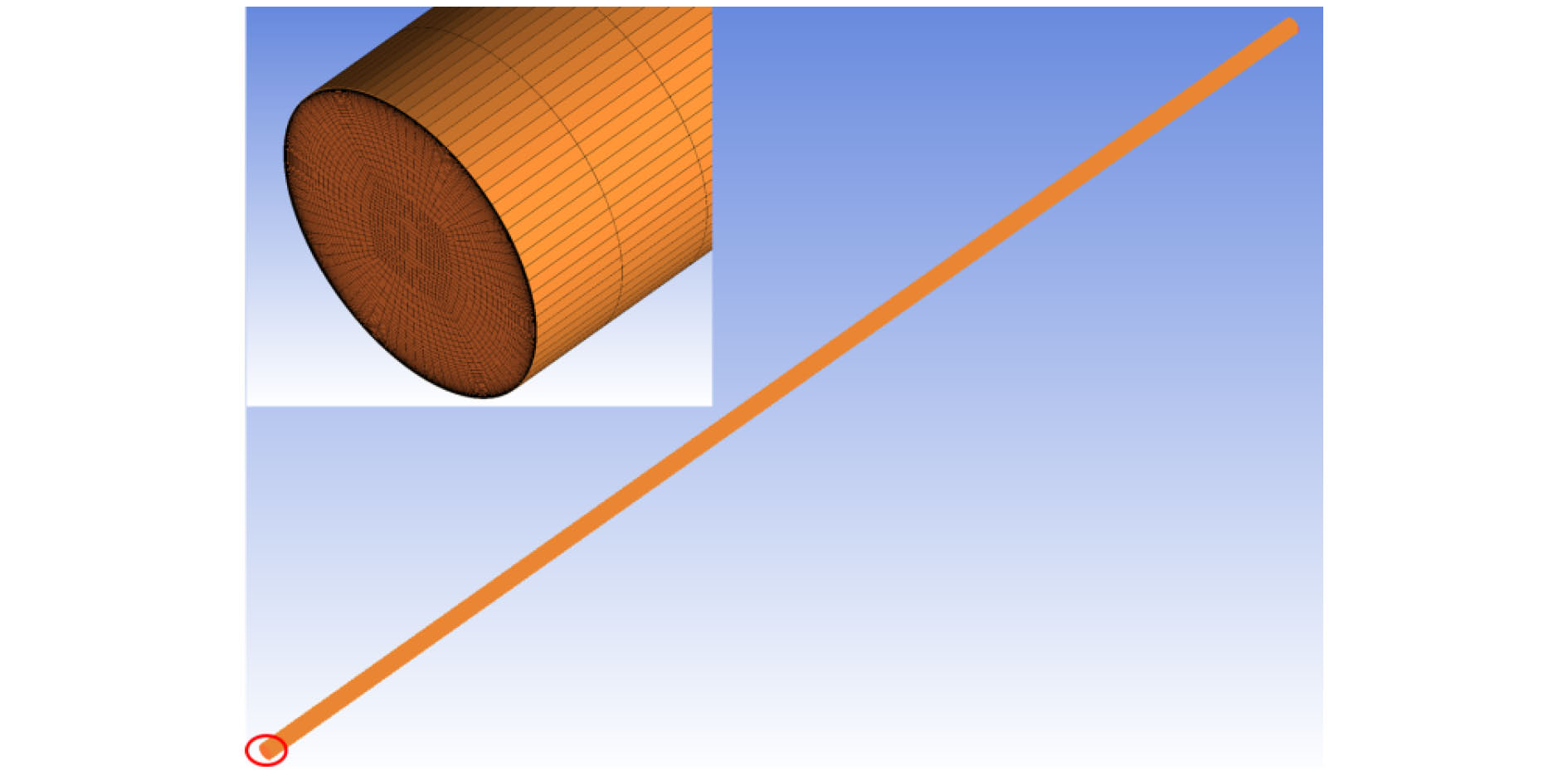

表 1 网格无关性验证结果

Table 1. Verification for grid independence.

算例 网格数量 Tw,o/K Tw,o的相对偏差/% ho/(kW·m–2·K–1) ho的相对偏差/% 1 2652250 1441.9 0 1236.7 0 2 1332250 1442.2 0.02 1236.4 0.02 3 841000 1442.9 0.07 1235.0 0.14 4 462250 1445.1 0.22 1230.1 0.54 5 196000 1448.8 0.48 1223.3 1.09 表 2 传热关联式计算结果与模拟数据的对比

Table 2. Comparisons of the calculated heat transfer results by the correlations with the numerical results.

作者 关联式和工况条件 MARD/% η/% 基于热物性修正 Bishop 等[23] $Nu = 0.0069Re_{\rm{b} }^{0.9}\overline {Pr} _{\rm{b} }^{0.66}{\left( { { { {\rho _{\rm{w} } } } }/{ { {\rho _{\rm{b} } } } } } \right)^{0.43} }\left[ {1 + 2.4({D}/{L}) } \right]$ 22.2 22.3 工质: 水 p = 22.6—27.5 MPa, G = 680—3600 kg·m–2·s–1, q = 310—3500 kW·m–2 Krasnoshchekov和

Protopopov[24]$Nu = 0.023Re_{\rm{b} }^{0.8}Pr_{\rm{b} }^{0.5}{\left( {{ { {\rho _{\rm{w} } } } }/{ { {\rho _{\rm{b} } } } } } \right)^{0.3} }{\left( {{ {\overline { {c_{\rm{p} } } } } }/{ { {c_{ {\rm{p,b} } } } } } } \right)^{0.4} }$ 8.1 100 工质: CO2 p = 8—12 MPa, G = 2971 kg·m–2·s–1, q = 235—500 kW·m–2, Tin = 301.7—472 K 流动方向: 水平 Jackson[25] $Nu = 0.023Re_{\rm{b} }^{0.8}\overline {Pr} _{\rm{b} }^{0.5}{\left( { { { {\rho _{\rm{w} } } } }/{ { {\rho _{\rm{b} } } } } } \right)^{0.3} }$ 9.0 100 工质: CO2 p = 7.8—9.8 MPa, Reb = 8×104—5×105, q ≤ 2600 kW·m–2 基于无量纲数修正 Liao和Zhao[26] 垂直向上: 18.1 60.7 $Nu = 0.354Re_{\rm{b} }^{0.8}Pr_{\rm{b} }^{0.4}{\left( {{ { {\rho _{\rm{w} } } } }/{ { {\rho _{\rm{b} } } } } } \right)^{1.297} }{\left( {{ {\overline { {c_{\rm{p} } } } } }/{ { {c_{ {\rm{p,b} } } } } } } \right)^{0.296} }Bo_{\rm{m} }^{ {\rm{0} }{\rm{.157} } }$ 垂直向下: $Nu = 0.643Re_{\rm{b} }^{0.8}Pr_{\rm{b} }^{0.4}{\left( { { { {\rho _{\rm{w} } } } }/{ { {\rho _{\rm{b} } } } } } \right)^{2.154} }{\left( { { {\overline { {c_{\rm{p} } } } } }/{ { {c_{ {\rm{p,b} } } } } } } \right)^{0.751} }Bo_{\rm{m} }^{ {\rm{0} }{\rm{.186} } }$ 水平: $Nu = 0.124Re_{\rm{b} }^{0.8}Pr_{\rm{b} }^{0.4}{\left( {{ { {\rho _{\rm{w} } } } }/{ { {\rho _{\rm{b} } } } } } \right)^{0.842} }{\left( {{ {\overline { {c_{\rm{p} } } } } }/{ { {c_{ {\rm{p,b} } } } } } } \right)^{0.384} }Bo_{\rm{b} }^{ {\rm{0} }{\rm{.203} } },~ Bo = { {Gr} }/{ {Re_{\rm{b} }^{2.7} } }$ 工质: CO2 p = 7.4—12 MPa, G = 236—1179 kg·m–2·s–1, q = 10—200 kW·m–2, Tin = 295—385 K Kim 等[10] $Nu = 0.226Re_{\rm{b}}^{1.174}Pr_{\rm{b}}^{1.057}{\left( {{{{\rho _{\rm{w}}}}}/{{{\rho _{\rm{b}}}}}} \right)^{0.571}}{\left( {{{\overline {{c_{\rm{p}}}} }}/{{{c_{{\rm{p,b}}}}}}} \right)^{1.032}}A{c^{0.489}}B{u^{0.0021}}$ 42.3 11.0 $Ac = \dfrac{ { {q^ + } } }{ {Re_{\rm b}^{0.625} } }{\left( {\dfrac{ { {\rho _{\rm{b} } } }}{ { {\rho _{\rm{w} } } } } } \right)^{0.5} }\left( {\dfrac{ { {\mu _{\rm{w} } } }}{ { {\mu _{\rm{b} } } } } } \right), ~Bu = \dfrac{ {G{r_{\rm{q} } } }}{ {Re_{\rm{b} }^{3.425}Pr_{}^{0.8} } }{\left( {\dfrac{ { {\rho _{\rm{b} } } }}{ { {\rho _{\rm{w} } } } } } \right)^{0.5} }\left( {\dfrac{ { {\mu _{\rm{w} } } }}{ { {\mu _{\rm{b} } } } } } \right)$ 工质: CO2 p = 7.46—10.29 MPa, G = 208—874 kg·m–2·s–1, q = 38—234 kW·m–2, Tin = 302—388 K 流动方向: 垂直向上 Bovard 等[11] $Nu = 0.040063Re_{\rm{b}}^{1.40418}Pr_{\rm{b}}^{0.97767359}{\left( {\dfrac{{{\rho _{\rm{w}}}}}{{{\rho _{\rm{b}}}}}} \right)^{0.573108}}{\left( {\dfrac{{\overline {{c_{\rm{p}}}} }}{{{c_{{\rm{p,b}}}}}}} \right)^{0.11577}}A{c^{0.396203}}B{u^{0.13746}}$ 82.8 0 $Ac = \dfrac{{{q^ + }}}{{Re_b^{0.625}}}{\left( {\dfrac{{{\rho _{\rm{b}}}}}{{{\rho _{\rm{w}}}}}} \right)^{0.5}}\left( {\dfrac{{{\mu _{\rm{w}}}}}{{{\mu _{\rm{b}}}}}} \right),~ Bu = \dfrac{{G{r_{\rm{m}}}}}{{Re_{\rm{b}}^{3.425}Pr_{}^{0.8}}}{\left( {\dfrac{{{\rho _{\rm{b}}}}}{{{\rho _{\rm{w}}}}}} \right)^{0.5}}\left( {\dfrac{{{\mu _{\rm{w}}}}}{{{\mu _{\rm{b}}}}}} \right)$ 工质: CO2 p = 6.5—8.335 MPa, G = 51—236 kg·m–2·s–1, q = 52—85 kW·m–2, Tin = 302 K 流动方向: 垂直向上 Liu 等[17] $Nu = 0.00075Re_{\rm{b}}^{0.93}\overline {Pr} _{\rm{b}}^{0.68}{\left( {\dfrac{{{\rho _{\rm{w}}}}}{{{\rho _{\rm{b}}}}}} \right)^{0.42}}\exp \left( {B{u^{ - 0.023}}} \right)\exp \left( {A{c^{0.079}}} \right)\left[ {1 + 2.63/\left( {L/D} \right)} \right]$ 28.7 3.5 $Bu = \dfrac{{G{r_{\rm{m}}}}}{{Re_{\rm{b}}^{2.625}Pr_{\rm{w}}^{0.4}}}{\left( {\dfrac{{{\rho _{\rm{b}}}}}{{{\rho _{\rm{w}}}}}} \right)^{0.5}}\left( {\dfrac{{{\mu _{\rm{w}}}}}{{{\mu _{\rm{b}}}}}} \right),~ Ac = \dfrac{{4{q^ + }}}{{Re_b^{0.625}}}{\left( {\dfrac{{{\rho _{\rm{b}}}}}{{{\rho _{\rm{w}}}}}} \right)^{0.5}}\left( {\dfrac{{{\mu _{\rm{w}}}}}{{{\mu _{\rm{b}}}}}} \right)$ 工质: CO2 p = 7.4—10.6 MPa, G = 298.8—1506.5 kg·m–2·s–1, q = 4.7—296 kW·m–2, Tin = 257—322 K 流动方向: 垂直向上 Zhang等[19] $Nu = \left\{ \begin{gathered} 0.00672Re_{\rm{b} }^{1.414}\overline {Pr} _{\rm{b} }^{ - 0.005}{\left( {\dfrac{ { {\rho _{\rm{w} } } } }{ { {\rho _{\rm{b} } } } } } \right)^{0.448} }{\left( {\dfrac{ {\overline { {c_{\rm{p} } } } } }{ { {c_{ {\rm{p,b} } } } } } } \right)^{0.218} }Bo_{\rm{m} }^{ {\rm{0} }{\rm{.586} } },\quad {H_{\rm{b} } } < 0.9{H_{ {\rm{pc} } } } \\ 0.056Re_{\rm{b} }^{0.829}\overline {Pr} _{\rm{b} }^{0.35}{\left( {\dfrac{ { {\rho _{\rm{w} } } } }{ { {\rho _{\rm{b} } } } } } \right)^{ - 0.095} }{\left( {\dfrac{ {\overline { {c_{\rm{p} } } } } }{ { {c_{ {\rm{p,b} } } } } } } \right)^{0.214} }Bo_{\rm{m} }^{ {\rm{0} }{\rm{.142} } }, \quad {H_{\rm{b} } } \geqslant 0.9{H_{ {\rm{pc} } } } \\\end{gathered} \right.$ 64.9 0 工质: CO2 p = 7.5—10.5 MPa, G = 50—500 kg·m–2·s–1, q = 5—100 kW·m–2, Tin = 266—313 K 流动方向: 垂直向上 -

[1] Singh A S, Choudhary T, Sanjay S https://www.sae.org/publications/technical-papers/content/2019-01-1391/ [2020-9-20]

[2] 吴毅, 王佳莹, 王明坤, 戴义平 2016 西安交通大学学报 50 108

Google Scholar

Google Scholar

Wu Y, Wang J Y, Wang M K, Dai Y P 2016 J. Xi'an Jiaotong Univ. 50 108

Google Scholar

Google Scholar

[3] Turchi C S, Ma Z, Neises T W, Wagner M J 2013 J. Sol. Energy Eng. 135 041007

Google Scholar

Google Scholar

[4] Neises T, Turchi C 2014 Energy Procedia 49 1187

Google Scholar

Google Scholar

[5] 黄凯欣, 饶政华, 廖胜明 2018 太阳能学报 39 44

Google Scholar

Google Scholar

Huang X K, Rao Z H, Liao S M 2018 Acta Energiae Solaris Sinica 39 44

Google Scholar

Google Scholar

[6] Benoit H, Spreafico L, Gauthier D, Flamant G 2016 Renew. Sust. Energ. Rev. 55 298

Google Scholar

Google Scholar

[7] Mehos M, Turchi C, Vidal J, Wagner J, Ma Z, Ho C, Kolb W, Andraka C, Kruizenga A https://www.nrel.gov/docs/fy17osti/67464.pdf [2020-9-20]

[8] Cabeza L F, de Gracia A, Fernández A I, Farid M M 2017 Appl. Therm. Eng. 125 799

Google Scholar

Google Scholar

[9] Xie J, Liu D, Yan H, Xie G, Boetcher S K 2020 Int. J. Heat Mass Transfer 149 119233

Google Scholar

Google Scholar

[10] Kim D E, Kim M H 2010 Nucl. Eng. Des. 240 3336

Google Scholar

Google Scholar

[11] Bovard S, Abdi M, Nikou M R K, Daryasafar A 2017 J. Supercrit. Fluids 119 88

Google Scholar

Google Scholar

[12] Qiu Y, Li M J, He Y L, Tao W Q 2016 Appl. Therm. Eng. 115 1255

Google Scholar

Google Scholar

[13] 刘占斌, 何雅玲, 王坤, 马朝, 姜涛 2019 化工学报 70 3329

Google Scholar

Google Scholar

Liu Z B, He Y L, Wang K, Ma Z, Jiang T 2019 J. Chem. Ind. Eng. (China) 70 3329

Google Scholar

Google Scholar

[14] Lemmon E W, Huber M L, McLinden M O http://www.nist.gov/srd/nist23.cfm [2020-9-20]

[15] Launder B E, Spalding D B 1972 Mathematical Models of Turbulence (London: Academic Press) p169

[16] Kim D E, Kim M H 2011 Int. J. Heat Fluid Flow 32 176

Google Scholar

Google Scholar

[17] Liu S, Huang Y, Liu G, Wang J, Leung L K 2017 Int. J. Heat Mass Transfer 106 1144

Google Scholar

Google Scholar

[18] Hall W B, Jackson J D 1969 Mech. Eng. 91 66

[19] Zhang Q, Li H, Kong X, Liu J, Lei X 2018 Int. J. Heat Mass Transfer 122 469

Google Scholar

Google Scholar

[20] Lei Y, Chen Z 2018 Int. J. Refrig. 90 46

Google Scholar

Google Scholar

[21] Xiang M, Guo J, Huai X, Cui X 2017 J. Supercrit. Fluids 130 389

Google Scholar

Google Scholar

[22] Xu R N, Luo F, Jiang P X 2017 Int. J. Heat Mass Transfer 110 576

Google Scholar

Google Scholar

[23] Bishop A A, Sandberg R O, Tong L S 1965 Report WCAP-2056 (Pittsburgh: Westinghouse Electric Corporation) p85

[24] Kranoshchekov E A, Protopopov V S 1966 High Temp. 4 375

[25] Jackson J D 2013 Nucl. Eng. Des. 264 24

Google Scholar

Google Scholar

[26] Liao S M, Zhao T S 2002 Int. J. Heat Mass Transfer 45 5025

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 12464

- PDF Downloads: 208

- Cited By: 0

DownLoad:

DownLoad: