-

Ferroelectric domain structures and ferroelectric properties in the hetero-epitaxially constrained ferroelectric thin films can be manipulated by substrate misfit strain. In this work, three kinds of phase structures of PbZr(1–x)TixO3 thin films, including tetragonal, tetragonal- rhombohedral-mixed and rhombohedral phases, are investigated. Firstly, the ferroelectric domain structures at different substrate misfit biaxial strains are obtained by the phase-field simulation. Then we calculate the polarization-electric field hysteresis loops at different misfit strains, and obtain the coercive field, saturation polarization, and remnant polarization. In the tetragonal PbZr(1–x)TixO3 (x = 0.8) thin film, compressive strain contributes to the formation of out-of-plane c1/c2 domain, and tensile strain favors in-plane a1/a2 domain formation. With the increase of compressive strain, the tetragonal phase and the rhombohedral phase coexist in PbZr(1–x)TixO3 (x = 0.48) film near the morphotropic phase boundary, while the tensile strain reduces the rhombohedral domain size. In the rhombohedral PbZr(1–x)TixO3 (x = 0.2) film, the rhombohedral domains are steady states under compressive strain and tensile strain. As the misfit strain changes from –1.0% to 1.0%, the value of the coercive field, saturation polarization and remnant polarization decrease. Among them, for tetragonal-rhombohedral mixed phase, the reductions of saturation field and remnant polarization are larger than for tetragonal phase and rhombohedral phase. The coercive field of mixed phase decreases rapidly under the compressive strain, but deceases slowly under the tensile strain. It is worth noting that the remnant polarization decreases faster than the saturation polarization in three components of ferroelectric thin film. Due to the electromechanical coupling, when x = 0.48 at the morphotropic phase boundary it is shown that the remnant polarization reduction is faster than those of the other two types of ferroelectric thin films, and the small coercive field is obtained in the case of large tensile strain. Therefore, tensile strain can effectively improve the energy storage efficiency in ferroelectric thin films, and the efficiency of x = 0.48 thin film increases significantly compared with that of x = 0.8 or 0.2 thin film. Both the ratio of rhombohedral/tetragonal phase and the domain size will play a significant role in ferroelectric performance. Therefore, our results contribute to the understanding of the electromechanical coupling mechanism of PbZr(1–x)TixO3, and provide guidance for the experimental design of ferroelectric functional thin film materials.

-

Keywords:

- phase-field simulation /

- misfit strain /

- ferroelectric domain structure /

- hysteresis loops

[1] Xu F, Trolier-McKinstry S, Ren W, Xu B, Xie Z L, Hemker K J 2001 J. Appl. Phys. 89 1336

Google Scholar

Google Scholar

[2] Kim D J, Maria J P, Kingon A I, Streiffer S K 2003 J. Appl. Phys. 93 5568

Google Scholar

Google Scholar

[3] Karthik J, Martin L 2011 Phys. Rev. B 84 024102

Google Scholar

Google Scholar

[4] Karthik J, Damodaran A R, Martin L W 2012 Phys. Rev. Lett. 108 167601

Google Scholar

Google Scholar

[5] 赵晓英, 刘世建, 褚君浩, 戴宁, 胡古今 2008 57 5968

Google Scholar

Google Scholar

Zhao X Y, Liu S J, Chu J H, Dai N, Hu G J 2008 Acta Phys. Sin. 57 5968

Google Scholar

Google Scholar

[6] Arimoto Y, Ishiwara H 2004 MRS Bull. 29 823

Google Scholar

Google Scholar

[7] Ganapathi K L, Rath M, Rao M S R 2019 Semicond. Sci. Technol. 34 055016

Google Scholar

Google Scholar

[8] Won S S, Seo H, Kawahara M, Glinsek S, Lee J, Kim Y, Jeong C K, Kingon A I, Kim S H 2019 Nano Energy 55 182

Google Scholar

Google Scholar

[9] Hoshyarmanesh H, Ebrahimi N, Jafari A, Hoshyarmanesh P, Kim M, Park H H 2019 Sensors 19 13

Google Scholar

Google Scholar

[10] Gupta R, Gupta V, Tomar M 2020 Mater. Sci. Semicond. Process. 105 104723

Google Scholar

Google Scholar

[11] Rath M, Varadarajan E, Premkumar S, Shinde S, Natarajan V, Rao M S R 2019 Ferroelectrics 551 17

Google Scholar

Google Scholar

[12] Yao Z H, Song Z, Hao H, Yu Z Y, Cao M H, Zhang S J, Lanagan M T, Liu H X 2017 Adv. Mater. 29 1601727

Google Scholar

Google Scholar

[13] Pan H, Li F, Liu Y, Zhang Q, Wang M, Lan S, Zheng Y, Ma J, Gu L, Shen Y, Yu P, Zhang S, Chen L Q, Lin Y H, Nan C W 2019 Science 365 578

Google Scholar

Google Scholar

[14] Wang J J, Su Y J, Wang B, Ouyang J, Ren Y, Chen L Q 2020 Nano Energy 72 104665

Google Scholar

Google Scholar

[15] Li A D, Mak C L, Wong K H, Shao Q Y, Wang Y J, Wu D, Ming N B 2002 J. Cryst. Growth 235 307

Google Scholar

Google Scholar

[16] Ehara Y, Shimizu T, Yasui S, Oikawa T, Shiraishi T, Tanaka H, Kanenko N, Maran R, Yamada T, Imai Y Sakata O, Valanoor N, Funakubo H 2019 Phys. Rev. B 100 104116

Google Scholar

Google Scholar

[17] Izyumskaya N, Alivov Y I, Cho S J, Morkoç H, Lee H, Kang Y S 2007 Crit. Rev. Solid. State Mater. Sci. 32 111

Google Scholar

Google Scholar

[18] Choi K J, Biegalski M, Li Y L, Sharan A, Schubert J, Uecker R, Reiche P, Chen Y B, Pan X Q, Gopalan V, Chen L Q, Schlom D G, Eom C B 2004 Science 306 1005

Google Scholar

Google Scholar

[19] Noguchi Y, Maki H, Kitanaka Y, Matsuo H, Miyayama M 2018 Appl. Phys. Lett. 113 012903

Google Scholar

Google Scholar

[20] Li Y L, Chen L Q 2006 Appl. Phys. Lett. 88 072905

Google Scholar

Google Scholar

[21] Pertsev N A, Tagantsev A K, Setter N 2000 Phys. Rev. B 61 R825

Google Scholar

Google Scholar

[22] Haeni J H, Irvin P, Chang W, Uecker R, Reiche P, Li Y L, Choudhury S, Tian W, Hawley M E, Craigo B, Tagantsev A K, Pan X Q, Streiffer S K, Chen L Q, Kirchoefer S W, Levy J, Schlom D G 2004 Nature 430 758

Google Scholar

Google Scholar

[23] Zhang J X, Li Y L, Choudhury S, Chen L Q, Chu Y H, Zavaliche F, Cruz M P, Ramesh R, Jia Q X 2008 J. Appl. Phys. 103 094111

Google Scholar

Google Scholar

[24] Ren W, Yang Y, Diéguez O, Íñiguez J, Choudhury N, Bellaiche L 2013 Phys. Rev. Lett. 110 187601

Google Scholar

Google Scholar

[25] Zhang Y, Xue F, Chen Z H, Liu J M, Chen L Q 2020 Acta Mater. 183 110

Google Scholar

Google Scholar

[26] Li Y L, Hu S Y, Liu Z K, Chen L Q 2002 Acta Mater. 50 395

Google Scholar

Google Scholar

[27] Li Y L, Hu S Y, Chen L Q 2005 J. Appl. Phys. 97 034112

Google Scholar

Google Scholar

[28] Yu Q, Li J, Zhu F, Li J 2014 J. Mater. Chem. C 2 5836

Google Scholar

Google Scholar

[29] Lu X Y, Chen Z H, Cao Y, Tang Y L, Xu R J, Saremi S, Zhang Z, You L, Dong Y Q, Das S, Zhang H B, Zheng L M, Wu H P, Lv W M, Xie G Q, Liu X J, Li J Y, Chen L, Chen L Q, Cao W W, Martin L W 2019 Nat. Commun. 10 3951

Google Scholar

Google Scholar

[30] Nguyen M D, Dekkers M, Houwman E, Steenwelle R, Wan X, Roelofs A, Schmitz-Kempen T, Rijnders G 2011 Appl. Phys. Lett. 99 252904

Google Scholar

Google Scholar

[31] Xue F, Wang J J, Sheng G, Huang E, Cao Y, Huang H-H, Munroe P, Mahjoub R, Li Y, Valanoor N, Chen L 2013 Acta Mater. 61 2909

Google Scholar

Google Scholar

[32] Lin F Y, Cheng X, Chen L Q, Sinnott S B 2018 J. Am. Ceram. Soc. 101 4783

Google Scholar

Google Scholar

[33] Devonshire A F 1949 The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science 40 1040

Google Scholar

Google Scholar

[34] Chen L Q 2008 J. Am. Ceram. Soc. 91 1835

Google Scholar

Google Scholar

[35] Chen L Q 2002 Ann. Rev. Mater. Res. 32 113

Google Scholar

Google Scholar

[36] Li Y L, Hu S Y, Liu Z K, Chen L Q 2001 Appl. Phys. Lett. 78 3878

Google Scholar

Google Scholar

[37] Li Y L, Choudhury S, Liu Z K, Chen L Q 2003 Appl. Phys. Lett. 83 1608

Google Scholar

Google Scholar

[38] Shu W L, Wang J, Zhang T Y 2012 J. Appl. Phys. 112 064108

Google Scholar

Google Scholar

[39] Wang J J, Wang B, Chen L Q 2019 Ann. Rev. Mater. Res. 49 127

Google Scholar

Google Scholar

[40] Li Y L, Chen L Q, Asayama G, Schlom D G, Zurbuchen M A, Streiffer S K 2004 J. Appl. Phys. 95 6332

Google Scholar

Google Scholar

[41] Chen L Q, Shen J 1998 Comput. Phys. Commun. 108 147

Google Scholar

Google Scholar

[42] Haun M J, Zhuang Z Q, Furman E, Jang S J, Cross L E 1989 Ferroelectrics 99 45

Google Scholar

Google Scholar

[43] Hu H L, Chen L Q 1998 J. Am. Ceram. Soc. 81 492

[44] Damjanovic D 2005 J. Am. Ceram. Soc. 88 2663

Google Scholar

Google Scholar

[45] Liu W F, Ren X B 2009 Phys. Rev. Lett. 103 257602

Google Scholar

Google Scholar

[46] Li F, Lin D B, Chen Z B, Cheng Z X, Wang J L, Li C C, Xu Z, Huang Q W, Liao X Z, Chen L Q, Shrout T R, Zhang S J 2018 Nat. Mater. 17 349

Google Scholar

Google Scholar

[47] Liao Z Y, Xue F, Sun W, Song D S, Zhang Q Q, Li J F, Chen L Q, Zhu J 2017 Phys. Rev. B 95 214101

Google Scholar

Google Scholar

[48] Liu H, Chen J, Huang H B, Fan L L, Ren Y, Pan Z, Deng J X, Chen L Q, Xing X R 2018 Phys. Rev. Lett. 120 055501

Google Scholar

Google Scholar

[49] Ma Z, Ma Y, Chen Z, Zheng F, Gao H, Liu H, Chen H 2018 Ceram. Int. 44 4338

Google Scholar

Google Scholar

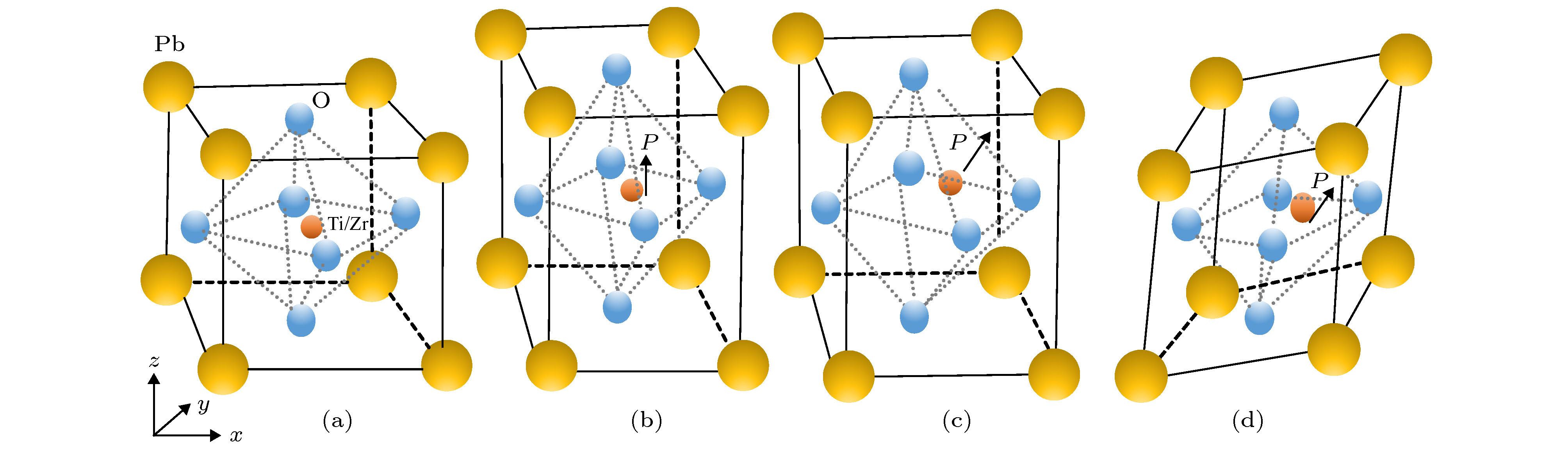

-

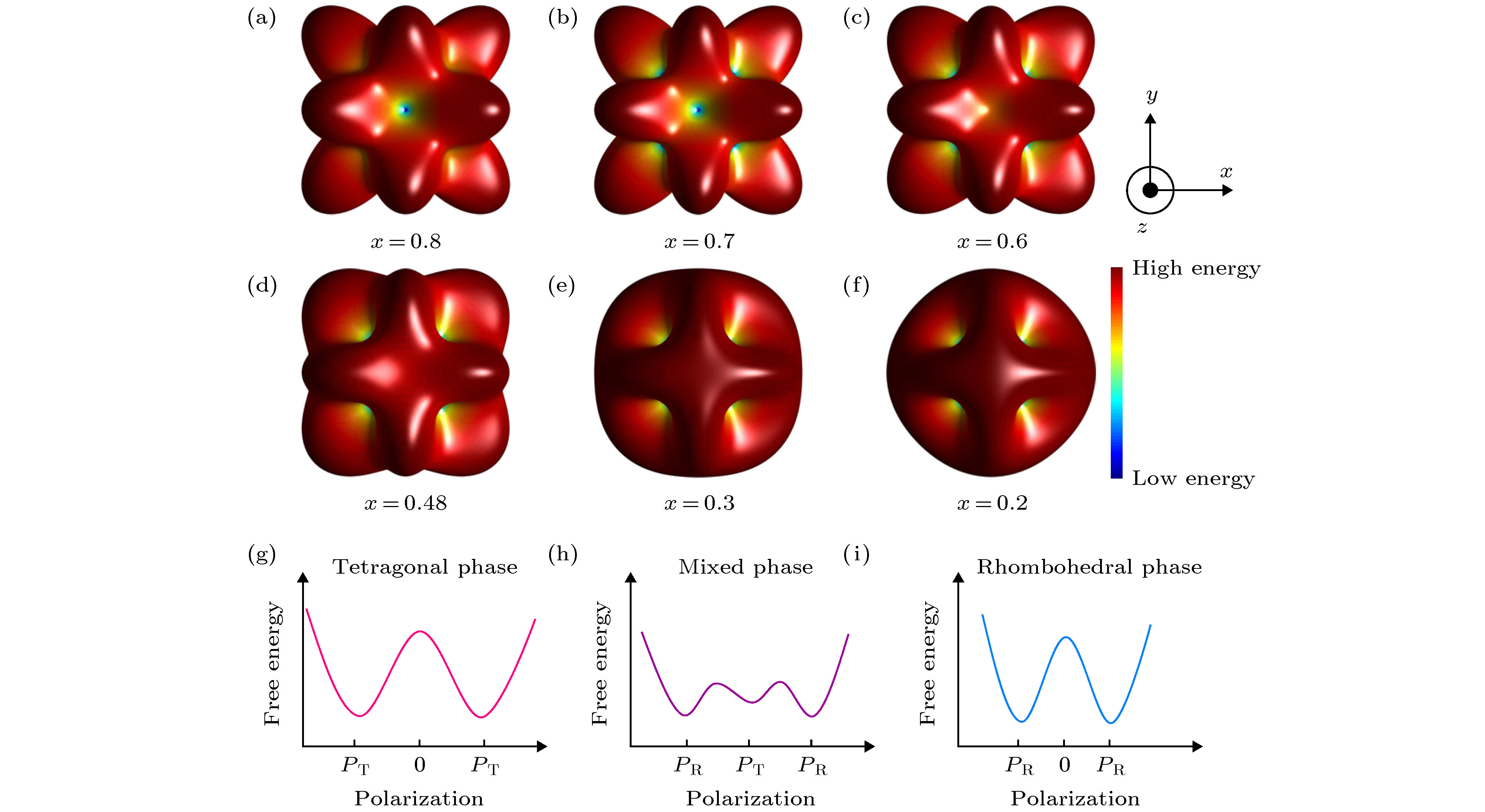

图 2 (a)−(f)室温下随Ti成分降低(x = 0.8—0.2) PZT的三维自由能曲面, 蓝色代表最小值, 红色代表最大值; (g)−(i) T相、R/T混合相及R相二维自由能双势阱示意图

Figure 2. (a)−(f) Free energy surface of PZT with the decrease of Ti composition (x = 0.8–0.2) at room temperature. Blue and red color represents the minimum and maximum value respectively; (g)−(i) Schematic of double well potential of tetragonal phase (g), mixed phase (h) and rhombohedral phase (i).

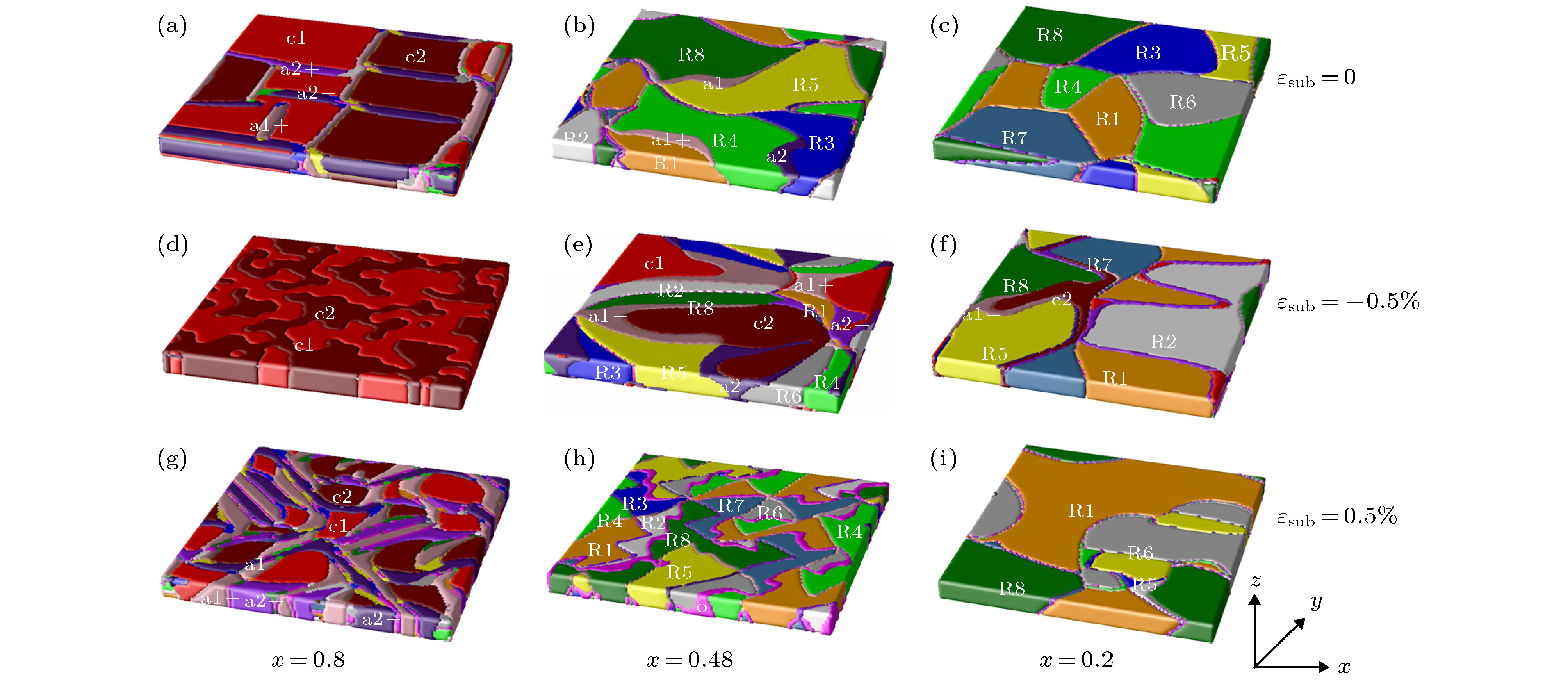

图 3 相场模拟PZT薄膜在不同基底失配应变下的畴结构 (a)—(c)分别对应于PZT (x = 0.8)薄膜εsub = 0, εsub = –0.5%, εsub = 0.5%; (d)—(f)分别对应于PZT (x = 0.48)薄膜εsub = 0, εsub = –0. 5%, εsub = 0.5%; (g)—(h)分别对应于PZT (x = 0.2)薄膜εsub = 0, εsub = –0.5%, εsub = 0.5%

Figure 3. Domain structures of PZT (x = 0.8, x = 0.48, x = 0.2) thin film with different substrate biaxial misfit strain (εsub = 0, εsub = –0.5%, εsub = 0.5%): (a)−(c) Domain structures of PZT (x = 0.8) thin films at εsub = 0, εsub = –0.5%, εsub = 0.5%; (d)−(f) domain structures of PZT (x = 0.48) thin films at εsub = 0, εsub = –0.5%, εsub = 0.5%; (g)−(h) domain structures of PZT (x = 0.2) thin films at εsub = 0, εsub = –0.5%, εsub = 0.5%.

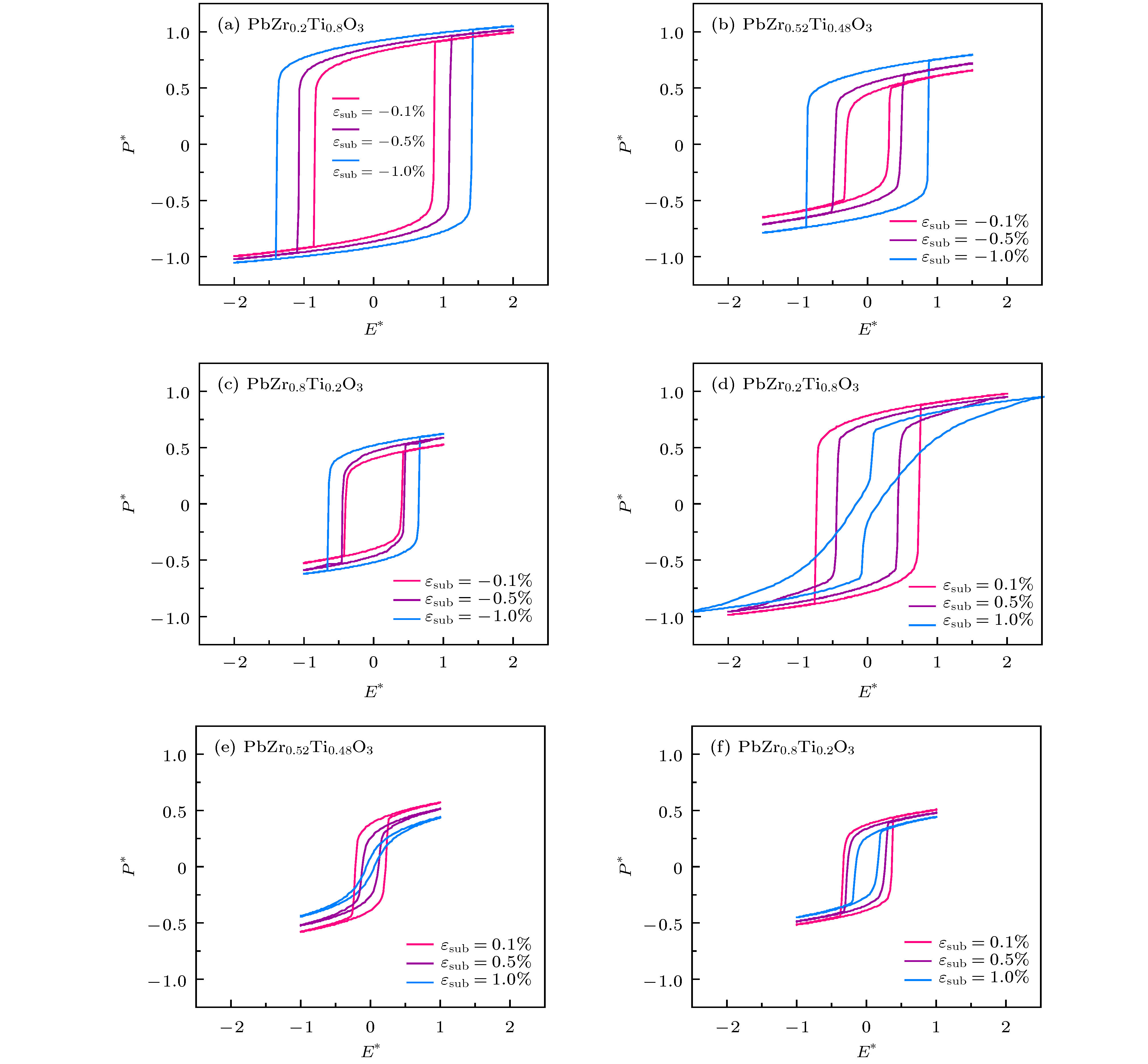

图 4 室温下PZT铁电薄膜四方相(x = 0.8), 混合相(x = 0.48)以及菱方相(x = 0.2)在不同的基底失配应变下(εsub = ± 0.1%, ± 0.5%, ± 1.0%)的电滞回线, 其中P *和E *表示归一化后的极化强度和电场强度值 (a)−(c)分别表示压应变下四方相、混合相和菱方相的电滞回线; (d)−(f)分别表示拉应变下四方相、混合相和菱方相的电滞回线

Figure 4. Hysteresis loops of PZT thin films with three Ti components at different substrate biaxial misfit strains (εsub = ± 0.1%, ± 0.5%, ± 1.0%), and P * and E * are normalized polarization and electric field: (a)−(c) The case of compressive strains; (d)−(f) the case of tensile strains.

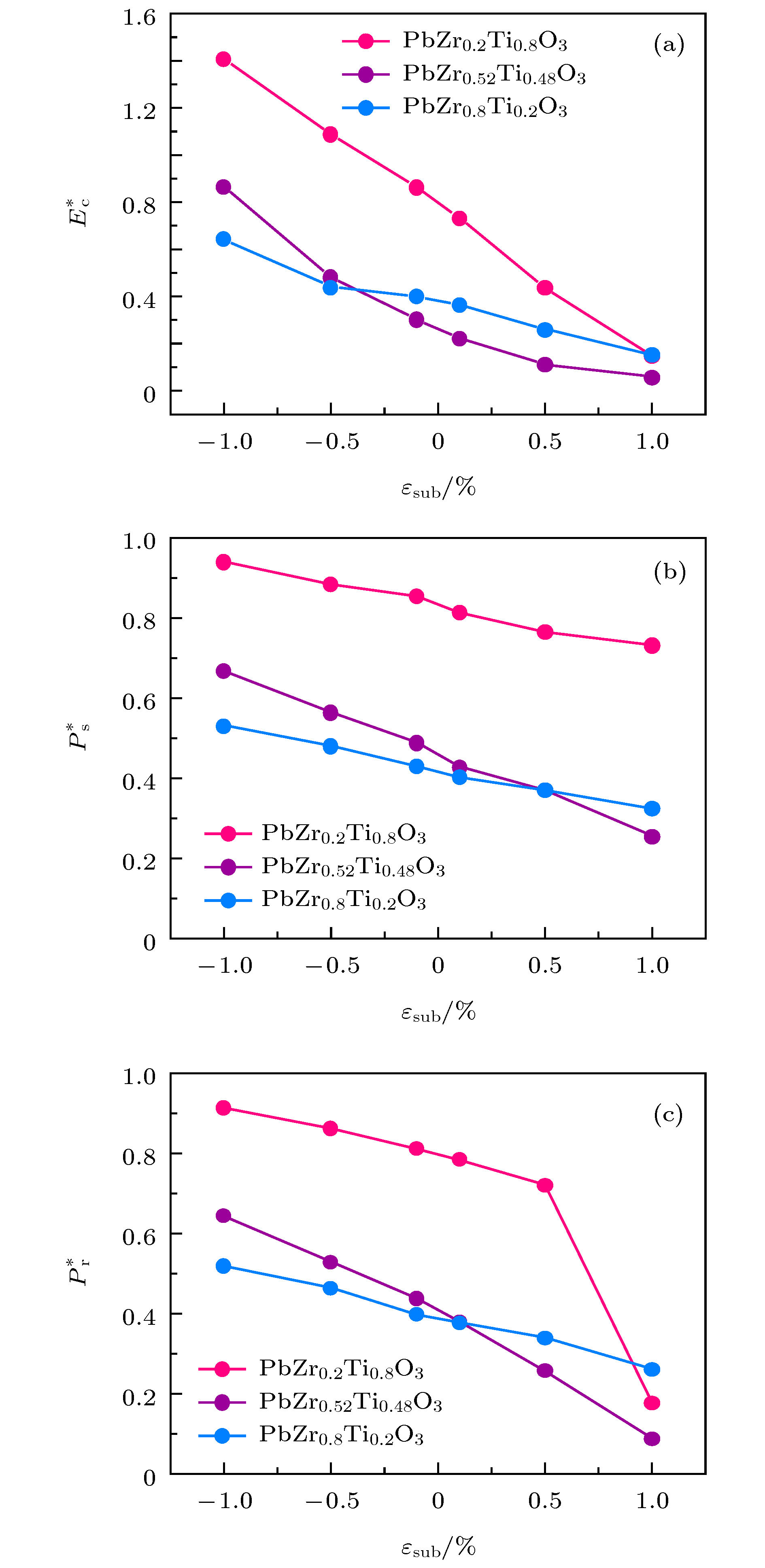

图 5 三种相PZT铁电薄膜的矫顽场、饱和极化和剩余极化值与基底应变的关系 (a) 矫顽场Ec*; (b) 饱和极化值Ps*; (c) 剩余极化值Pr*

Figure 5. Normalized coercive field (Ec*), saturation polarization (Pr*), and remnant polarization (Ps*) as a function of substrate misfit strain (εsub), where three PZT ferroelectric thin films with x = 0.8, 0.48 and 0.2 Ti component are considered: (a) Coercive field vs. strain; (b) saturation polarization vs. strain; (c) remnant polarization vs. strain.

表 1 三种成分PZT铁电薄膜介电刚度系数和电致伸缩常数

Table 1. Corresponding material constants for the Landau free energy, the electrostrictive coefficients of three components PZT thin films.

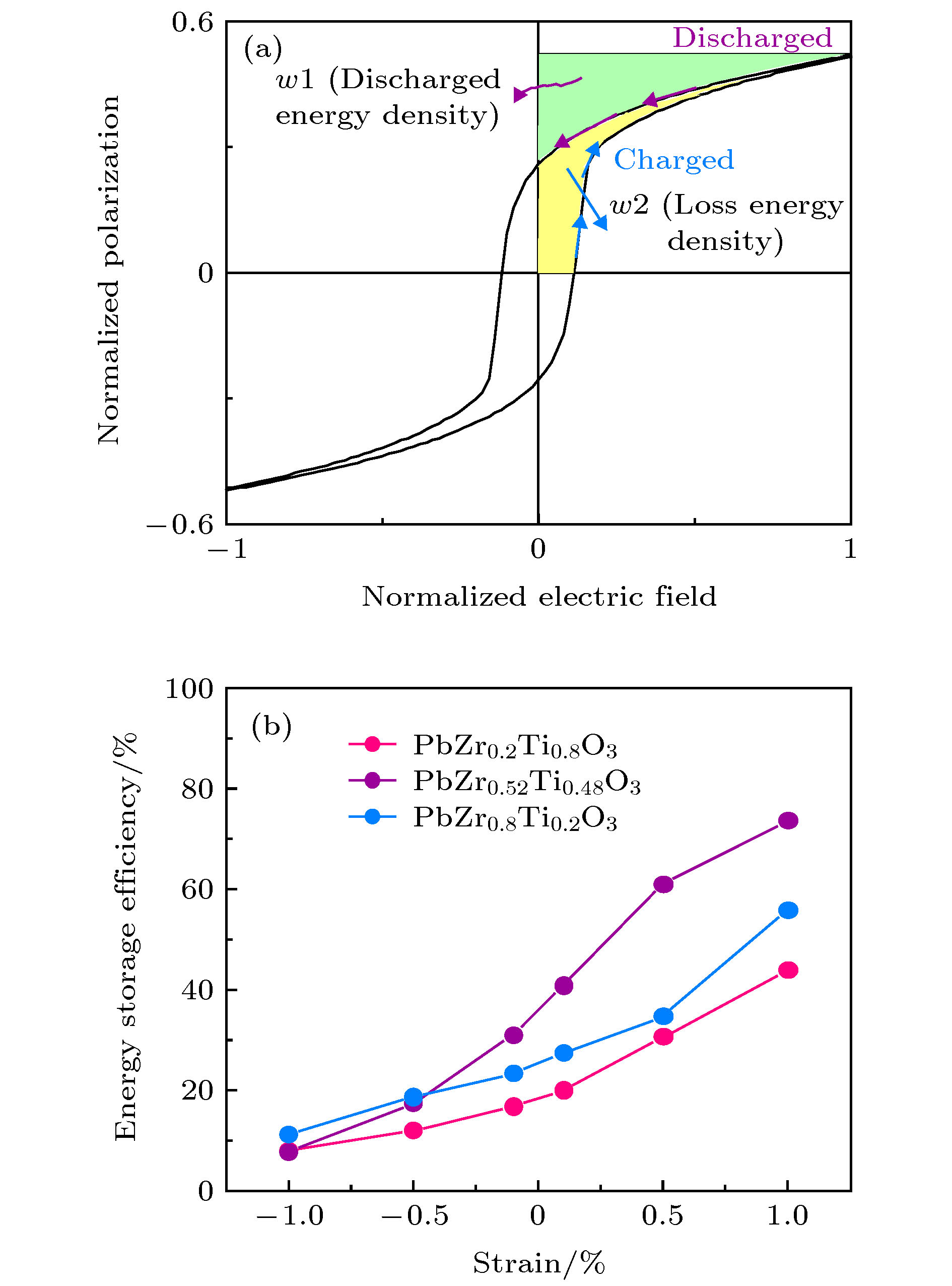

Coefficients PbZr0.2Ti0.8O3 PbZr0.52Ti0.48O3 PbZr0.8Ti0.2O3 $ {a}_{1} $/C–2·m2·N 3.44 × 105(T – 456.38) 1.45 × 105(T – 387.06) 2.71 × 105(T – 300.57) $ {a}_{11} $/C–4·m6·N –3.05 × 107 5.83 × 107 3.13 × 108 $ {a}_{12} $/C–4·m6·N 6.32 × 108 1.82 × 108 –3.45 × 106 $ {a}_{111} $/C–6·m10·N 2.47 × 108 1.50 × 108 4.29 × 108 $ {a}_{112} $/C–6·m10·N 9.68 × 108 6.88 × 108 1.81 × 109 $ {a}_{123} $/C–6·m10·N –4.90 × 109 –3.24 × 109 –7.54 × 109 $ {Q}_{11} $/C–2·m4 0.081 0.094 0.056 $ {Q}_{12} $/C–2·m4 –0.024 –0.044 –0.017 $ {Q}_{44} $/C–2·m4 0.032 0.040 0.026 表 2 三种PZT薄膜材料在不同应变下的储能效率值η

Table 2. Energy storage efficiency values of the PZT thin films under different strains.

Strain/% Energy storage efficienc η/% PbZr0.2Ti0.8O3 PbZr0.52Ti0.48O3 PbZr0.8Ti0.2O3 –1.0 8.0 7.8 11.2 –0.5 12.0 17.4 18.7 –0.1 16.8 31.0 23.4 0.1 20.0 40.6 27.4 0.5 30.7 61.0 34.7 1.0 43.9 73.6 55.8 -

[1] Xu F, Trolier-McKinstry S, Ren W, Xu B, Xie Z L, Hemker K J 2001 J. Appl. Phys. 89 1336

Google Scholar

Google Scholar

[2] Kim D J, Maria J P, Kingon A I, Streiffer S K 2003 J. Appl. Phys. 93 5568

Google Scholar

Google Scholar

[3] Karthik J, Martin L 2011 Phys. Rev. B 84 024102

Google Scholar

Google Scholar

[4] Karthik J, Damodaran A R, Martin L W 2012 Phys. Rev. Lett. 108 167601

Google Scholar

Google Scholar

[5] 赵晓英, 刘世建, 褚君浩, 戴宁, 胡古今 2008 57 5968

Google Scholar

Google Scholar

Zhao X Y, Liu S J, Chu J H, Dai N, Hu G J 2008 Acta Phys. Sin. 57 5968

Google Scholar

Google Scholar

[6] Arimoto Y, Ishiwara H 2004 MRS Bull. 29 823

Google Scholar

Google Scholar

[7] Ganapathi K L, Rath M, Rao M S R 2019 Semicond. Sci. Technol. 34 055016

Google Scholar

Google Scholar

[8] Won S S, Seo H, Kawahara M, Glinsek S, Lee J, Kim Y, Jeong C K, Kingon A I, Kim S H 2019 Nano Energy 55 182

Google Scholar

Google Scholar

[9] Hoshyarmanesh H, Ebrahimi N, Jafari A, Hoshyarmanesh P, Kim M, Park H H 2019 Sensors 19 13

Google Scholar

Google Scholar

[10] Gupta R, Gupta V, Tomar M 2020 Mater. Sci. Semicond. Process. 105 104723

Google Scholar

Google Scholar

[11] Rath M, Varadarajan E, Premkumar S, Shinde S, Natarajan V, Rao M S R 2019 Ferroelectrics 551 17

Google Scholar

Google Scholar

[12] Yao Z H, Song Z, Hao H, Yu Z Y, Cao M H, Zhang S J, Lanagan M T, Liu H X 2017 Adv. Mater. 29 1601727

Google Scholar

Google Scholar

[13] Pan H, Li F, Liu Y, Zhang Q, Wang M, Lan S, Zheng Y, Ma J, Gu L, Shen Y, Yu P, Zhang S, Chen L Q, Lin Y H, Nan C W 2019 Science 365 578

Google Scholar

Google Scholar

[14] Wang J J, Su Y J, Wang B, Ouyang J, Ren Y, Chen L Q 2020 Nano Energy 72 104665

Google Scholar

Google Scholar

[15] Li A D, Mak C L, Wong K H, Shao Q Y, Wang Y J, Wu D, Ming N B 2002 J. Cryst. Growth 235 307

Google Scholar

Google Scholar

[16] Ehara Y, Shimizu T, Yasui S, Oikawa T, Shiraishi T, Tanaka H, Kanenko N, Maran R, Yamada T, Imai Y Sakata O, Valanoor N, Funakubo H 2019 Phys. Rev. B 100 104116

Google Scholar

Google Scholar

[17] Izyumskaya N, Alivov Y I, Cho S J, Morkoç H, Lee H, Kang Y S 2007 Crit. Rev. Solid. State Mater. Sci. 32 111

Google Scholar

Google Scholar

[18] Choi K J, Biegalski M, Li Y L, Sharan A, Schubert J, Uecker R, Reiche P, Chen Y B, Pan X Q, Gopalan V, Chen L Q, Schlom D G, Eom C B 2004 Science 306 1005

Google Scholar

Google Scholar

[19] Noguchi Y, Maki H, Kitanaka Y, Matsuo H, Miyayama M 2018 Appl. Phys. Lett. 113 012903

Google Scholar

Google Scholar

[20] Li Y L, Chen L Q 2006 Appl. Phys. Lett. 88 072905

Google Scholar

Google Scholar

[21] Pertsev N A, Tagantsev A K, Setter N 2000 Phys. Rev. B 61 R825

Google Scholar

Google Scholar

[22] Haeni J H, Irvin P, Chang W, Uecker R, Reiche P, Li Y L, Choudhury S, Tian W, Hawley M E, Craigo B, Tagantsev A K, Pan X Q, Streiffer S K, Chen L Q, Kirchoefer S W, Levy J, Schlom D G 2004 Nature 430 758

Google Scholar

Google Scholar

[23] Zhang J X, Li Y L, Choudhury S, Chen L Q, Chu Y H, Zavaliche F, Cruz M P, Ramesh R, Jia Q X 2008 J. Appl. Phys. 103 094111

Google Scholar

Google Scholar

[24] Ren W, Yang Y, Diéguez O, Íñiguez J, Choudhury N, Bellaiche L 2013 Phys. Rev. Lett. 110 187601

Google Scholar

Google Scholar

[25] Zhang Y, Xue F, Chen Z H, Liu J M, Chen L Q 2020 Acta Mater. 183 110

Google Scholar

Google Scholar

[26] Li Y L, Hu S Y, Liu Z K, Chen L Q 2002 Acta Mater. 50 395

Google Scholar

Google Scholar

[27] Li Y L, Hu S Y, Chen L Q 2005 J. Appl. Phys. 97 034112

Google Scholar

Google Scholar

[28] Yu Q, Li J, Zhu F, Li J 2014 J. Mater. Chem. C 2 5836

Google Scholar

Google Scholar

[29] Lu X Y, Chen Z H, Cao Y, Tang Y L, Xu R J, Saremi S, Zhang Z, You L, Dong Y Q, Das S, Zhang H B, Zheng L M, Wu H P, Lv W M, Xie G Q, Liu X J, Li J Y, Chen L, Chen L Q, Cao W W, Martin L W 2019 Nat. Commun. 10 3951

Google Scholar

Google Scholar

[30] Nguyen M D, Dekkers M, Houwman E, Steenwelle R, Wan X, Roelofs A, Schmitz-Kempen T, Rijnders G 2011 Appl. Phys. Lett. 99 252904

Google Scholar

Google Scholar

[31] Xue F, Wang J J, Sheng G, Huang E, Cao Y, Huang H-H, Munroe P, Mahjoub R, Li Y, Valanoor N, Chen L 2013 Acta Mater. 61 2909

Google Scholar

Google Scholar

[32] Lin F Y, Cheng X, Chen L Q, Sinnott S B 2018 J. Am. Ceram. Soc. 101 4783

Google Scholar

Google Scholar

[33] Devonshire A F 1949 The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science 40 1040

Google Scholar

Google Scholar

[34] Chen L Q 2008 J. Am. Ceram. Soc. 91 1835

Google Scholar

Google Scholar

[35] Chen L Q 2002 Ann. Rev. Mater. Res. 32 113

Google Scholar

Google Scholar

[36] Li Y L, Hu S Y, Liu Z K, Chen L Q 2001 Appl. Phys. Lett. 78 3878

Google Scholar

Google Scholar

[37] Li Y L, Choudhury S, Liu Z K, Chen L Q 2003 Appl. Phys. Lett. 83 1608

Google Scholar

Google Scholar

[38] Shu W L, Wang J, Zhang T Y 2012 J. Appl. Phys. 112 064108

Google Scholar

Google Scholar

[39] Wang J J, Wang B, Chen L Q 2019 Ann. Rev. Mater. Res. 49 127

Google Scholar

Google Scholar

[40] Li Y L, Chen L Q, Asayama G, Schlom D G, Zurbuchen M A, Streiffer S K 2004 J. Appl. Phys. 95 6332

Google Scholar

Google Scholar

[41] Chen L Q, Shen J 1998 Comput. Phys. Commun. 108 147

Google Scholar

Google Scholar

[42] Haun M J, Zhuang Z Q, Furman E, Jang S J, Cross L E 1989 Ferroelectrics 99 45

Google Scholar

Google Scholar

[43] Hu H L, Chen L Q 1998 J. Am. Ceram. Soc. 81 492

[44] Damjanovic D 2005 J. Am. Ceram. Soc. 88 2663

Google Scholar

Google Scholar

[45] Liu W F, Ren X B 2009 Phys. Rev. Lett. 103 257602

Google Scholar

Google Scholar

[46] Li F, Lin D B, Chen Z B, Cheng Z X, Wang J L, Li C C, Xu Z, Huang Q W, Liao X Z, Chen L Q, Shrout T R, Zhang S J 2018 Nat. Mater. 17 349

Google Scholar

Google Scholar

[47] Liao Z Y, Xue F, Sun W, Song D S, Zhang Q Q, Li J F, Chen L Q, Zhu J 2017 Phys. Rev. B 95 214101

Google Scholar

Google Scholar

[48] Liu H, Chen J, Huang H B, Fan L L, Ren Y, Pan Z, Deng J X, Chen L Q, Xing X R 2018 Phys. Rev. Lett. 120 055501

Google Scholar

Google Scholar

[49] Ma Z, Ma Y, Chen Z, Zheng F, Gao H, Liu H, Chen H 2018 Ceram. Int. 44 4338

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 14616

- PDF Downloads: 577

- Cited By: 0

DownLoad:

DownLoad: