-

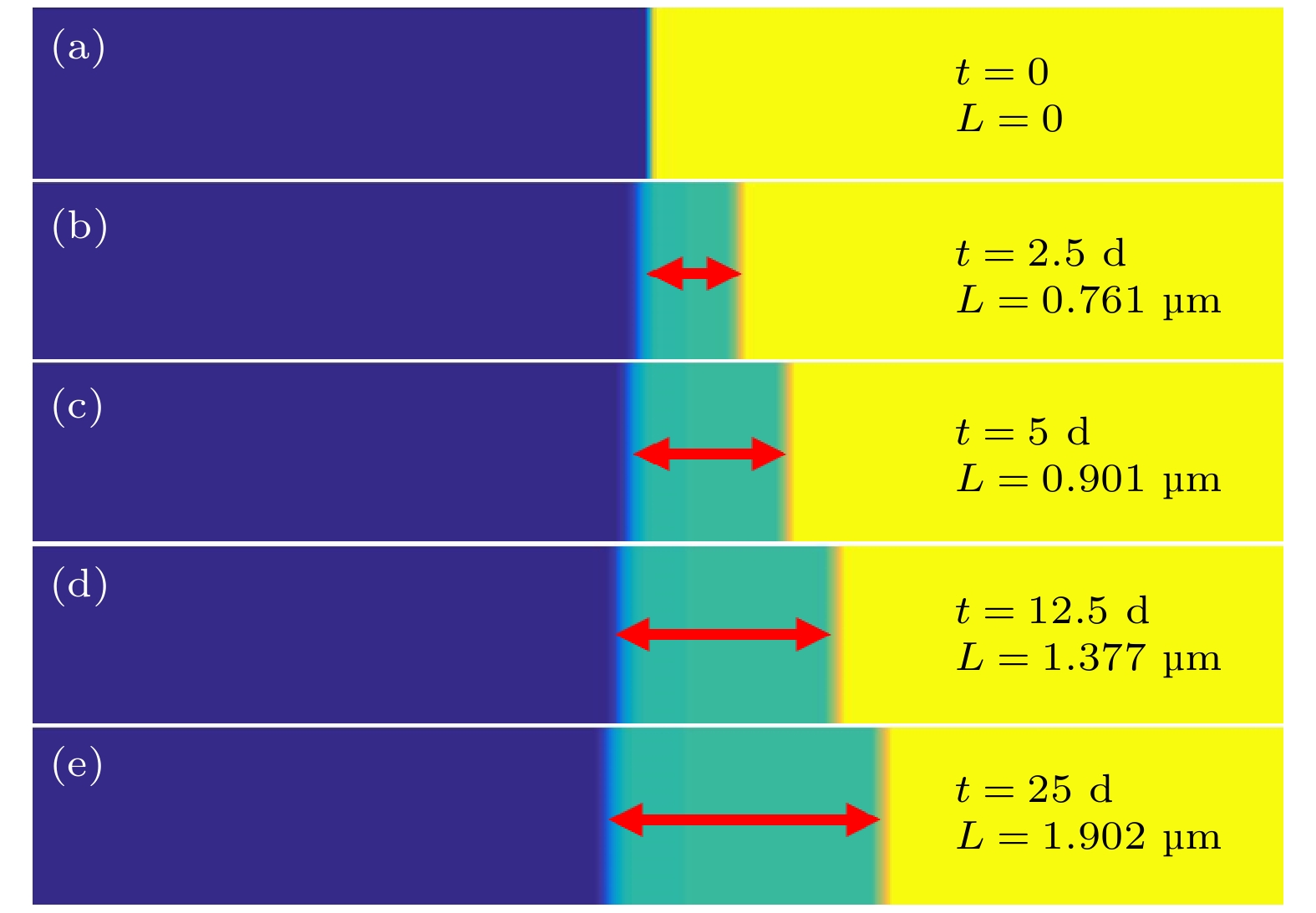

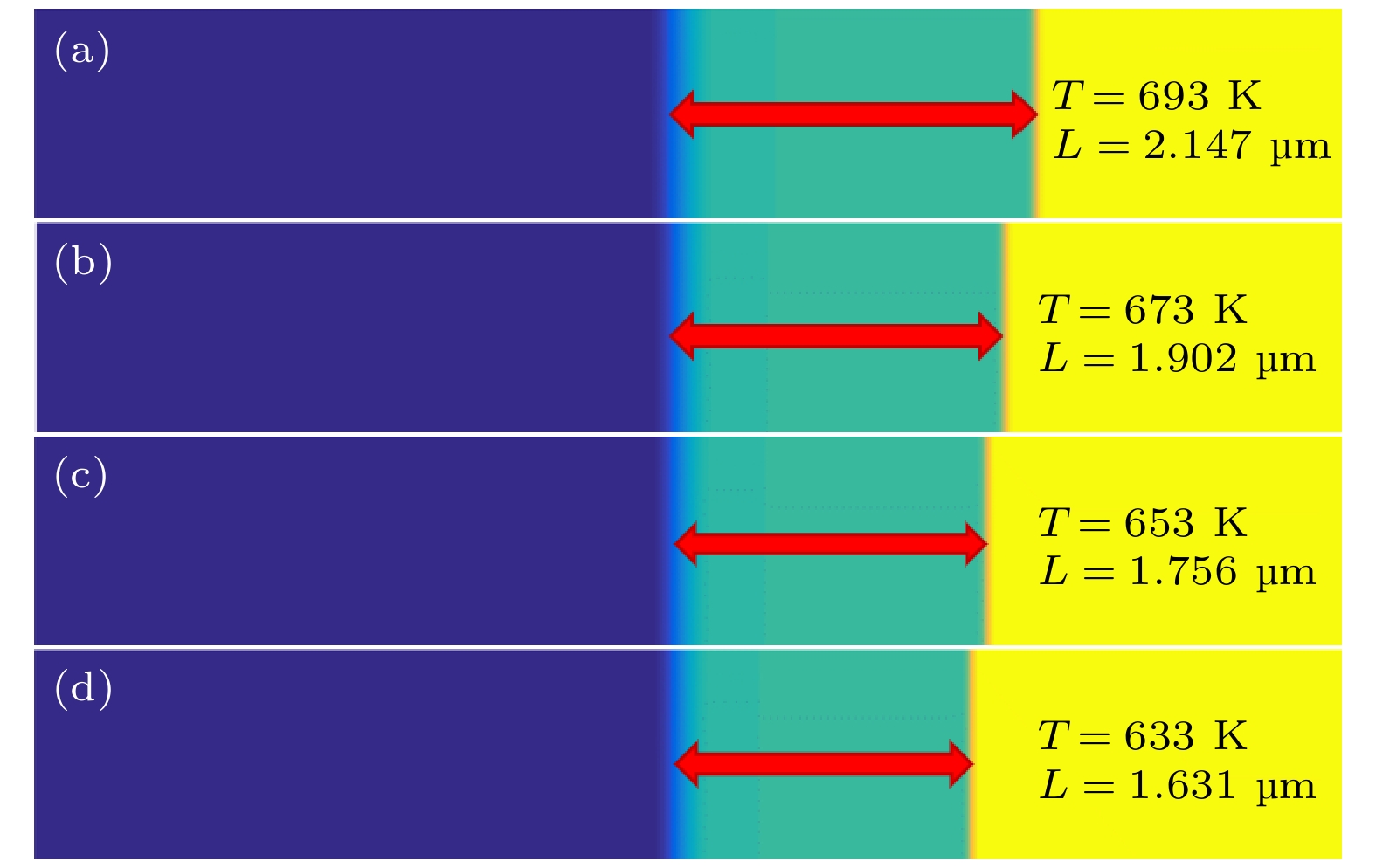

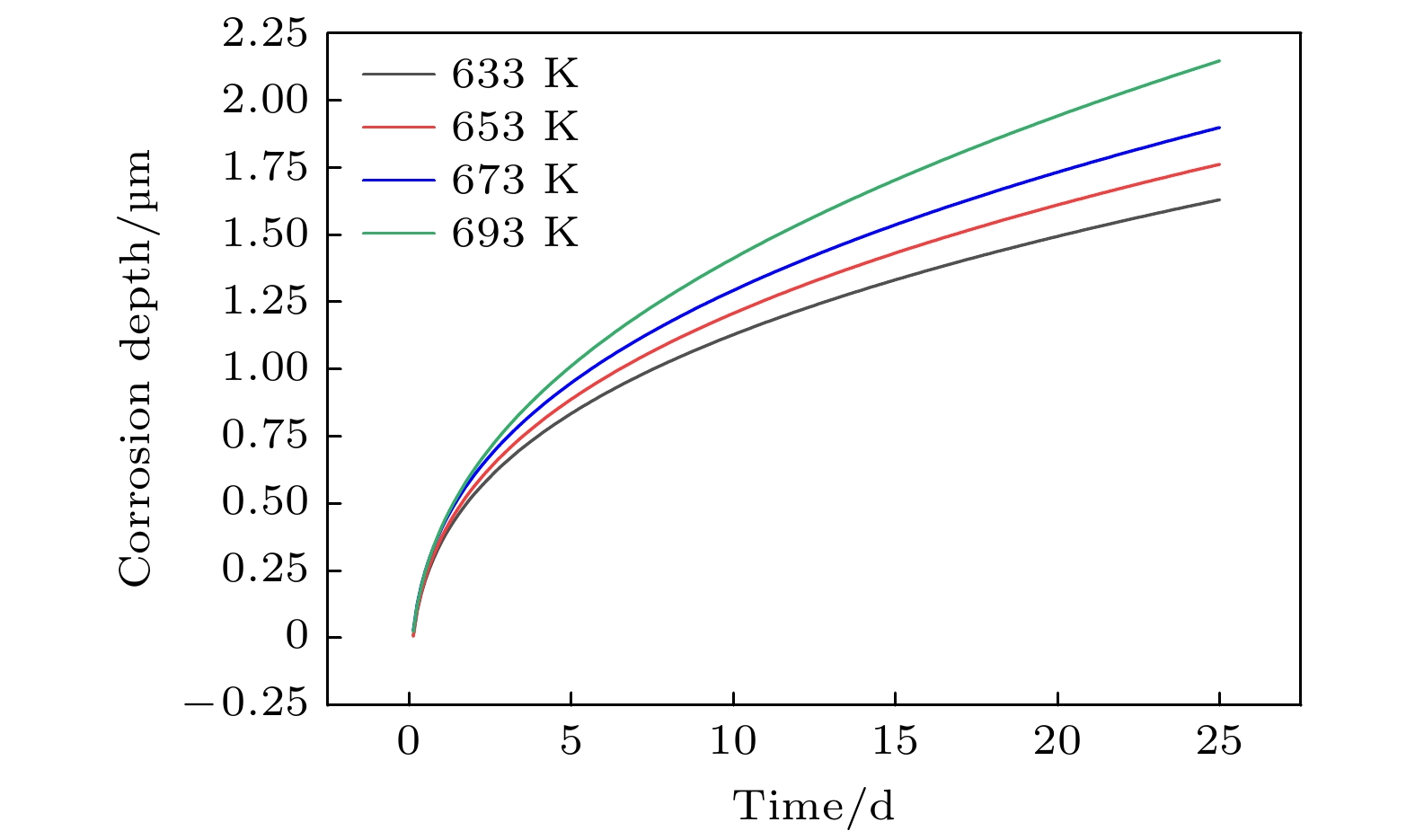

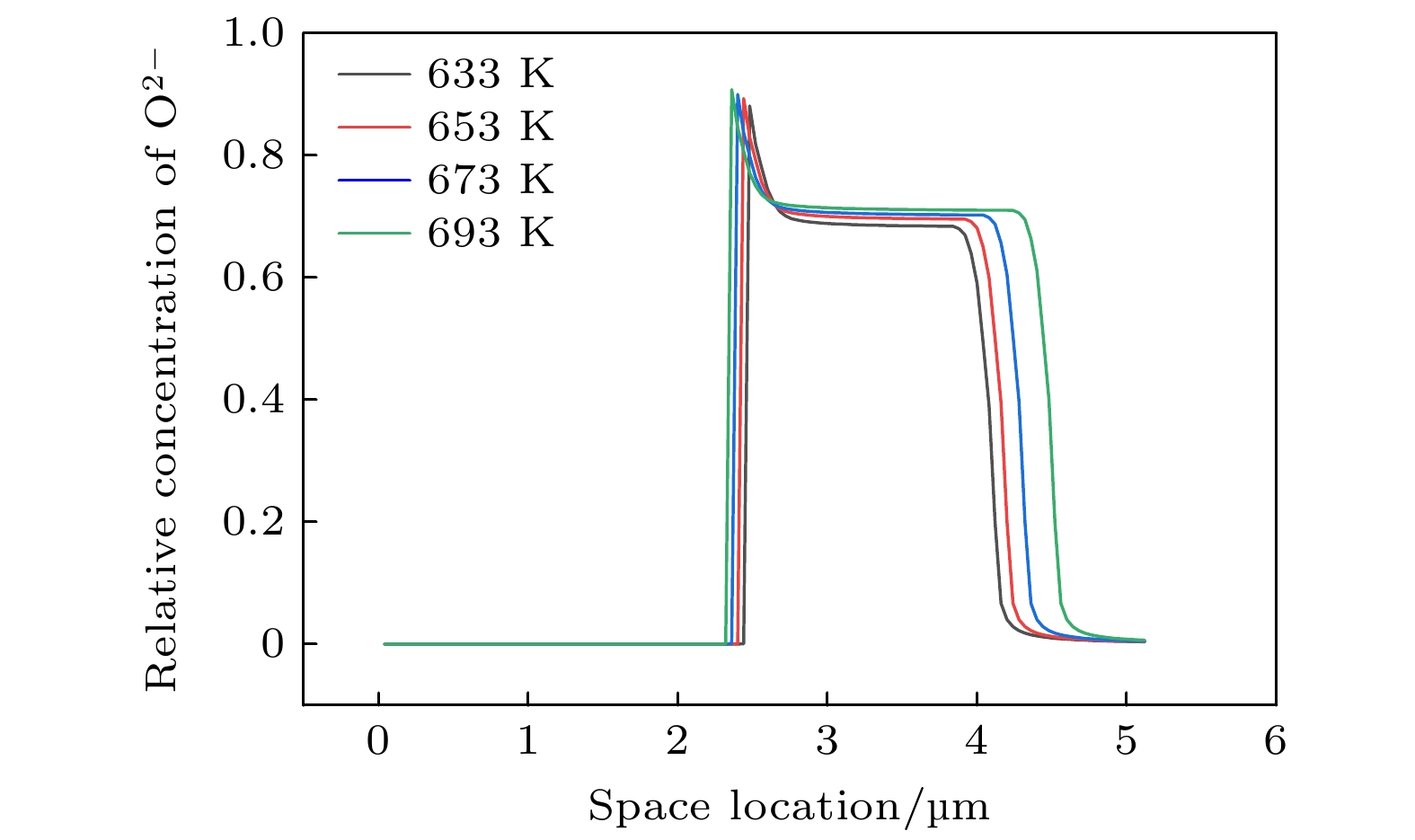

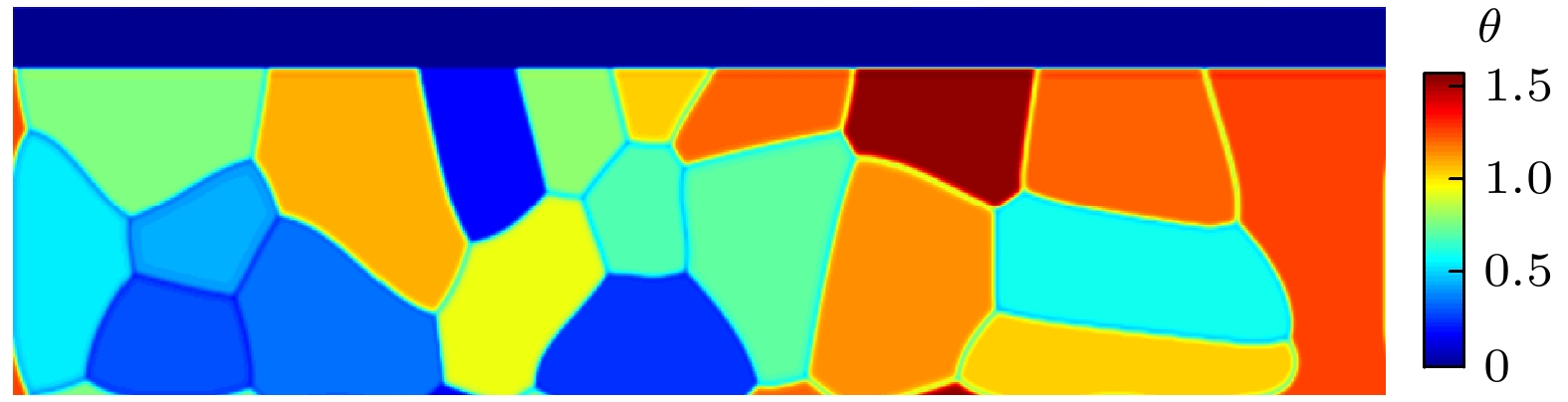

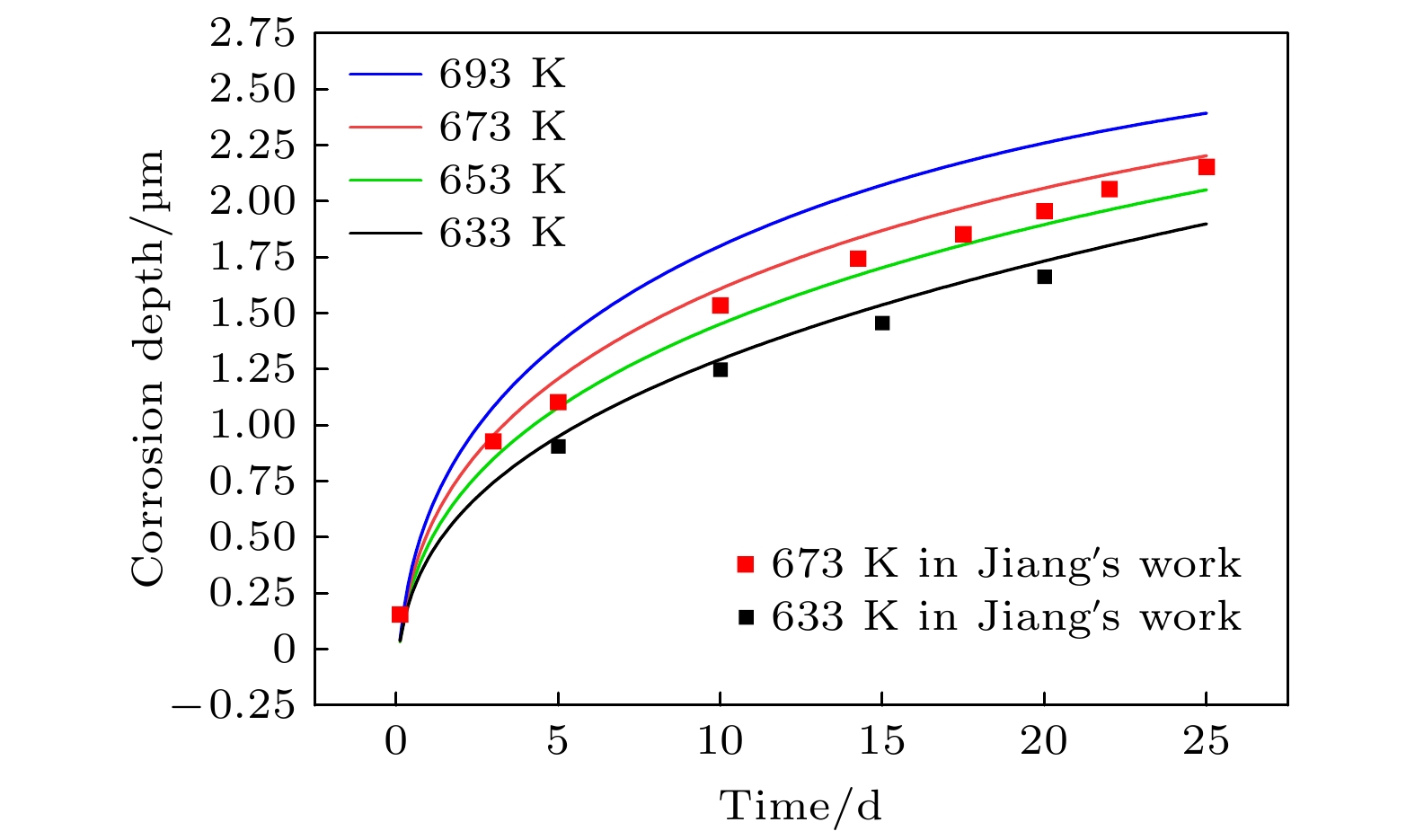

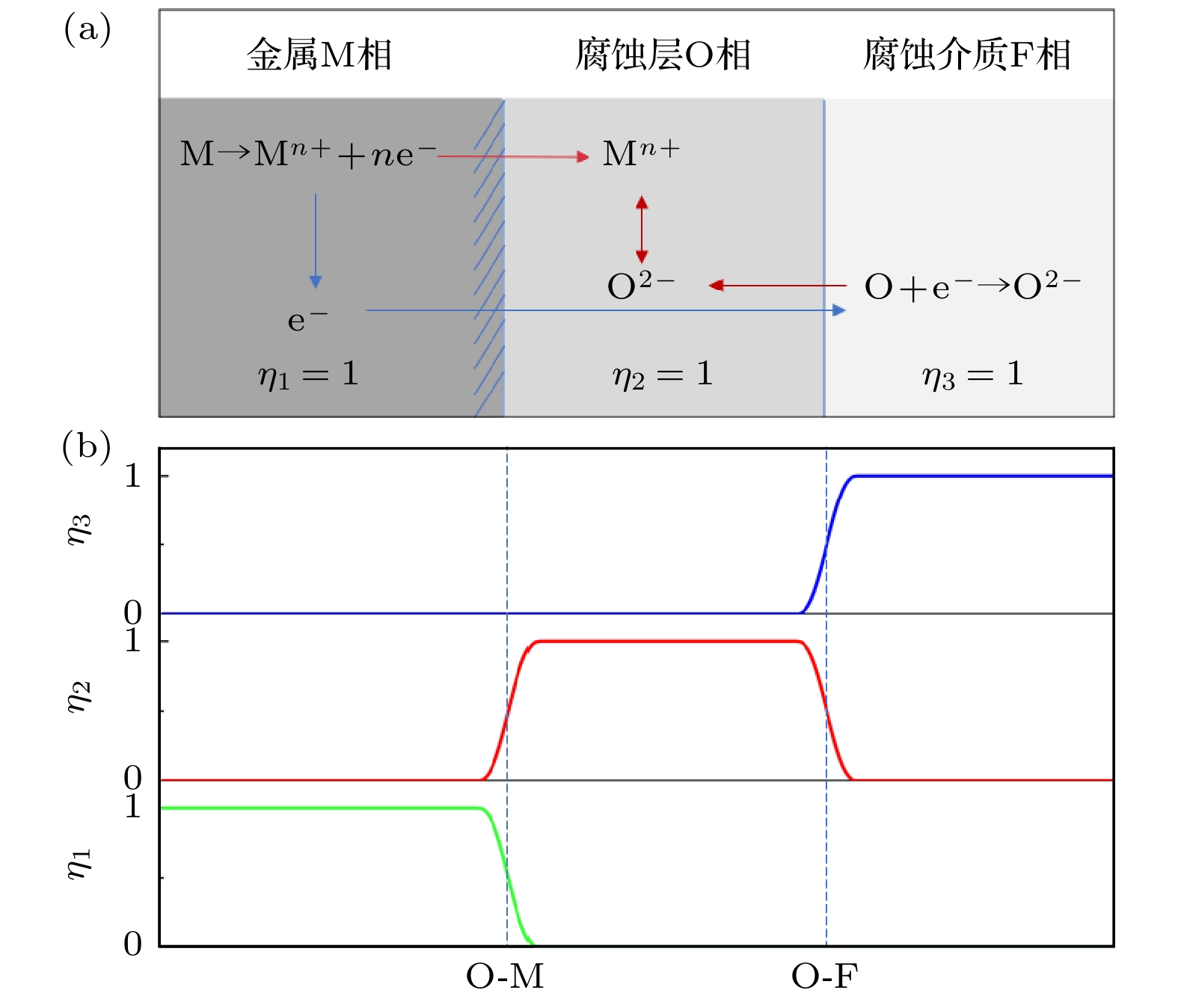

Due to the small neutron absorption cross section and excellent thermal creep performance, zirconium alloy is one of the most important cladding materials for fuel rods in commercial fission reactors. However, quantitative analysis of the effects of temperature and grain boundaries on the corrosion microstructure evolution of zirconium alloys is still needed. The establishing of a phase field simulation for the corrosion process of polycrystalline zirconium alloy and the systematical investigating of the thermodynamic influence are both very important. In this study, the phase field model of the corrosion process in zirconium alloys is developed by combining corrosion electrochemistry through calculating the interfacial energy at the metal-oxide and oxide-fluid boundaries. Then the model is used to investigate the uniform corrosion behavior on the surface of Zr-2.5Sn alloy, which demonstrates that the corrosion kinetic curve follows a cubic rule. Subsequently, the influence of temperature on the corrosion thickening curve of zirconium alloy is examined, and good agreement between simulation and experimental results is achieved. It is observed that during early stage of oxide layer formation, there is a high growth rate with minimal temperature dependence; however, as the oxide layer thickness increases, temperature becomes a significant factor affecting its growth rate, with higher temperatures resulting in faster corrosion rates. Furthermore, the effect of polycrystalline zirconium alloy matrices on corrosion rate is investigated, revealing that the grain boundaries accelerate oxide layer thickening due to enhanced oxygen diffusion rates. At metal-oxide interface, O2– bands are formed in areas with higher O2– concentration along these grain boundaries towards the metal matrix, which mainly influences oxidation-corrosion rate during the initial oxidation stage.

-

Keywords:

- phase-field simulation /

- Zr-Sn alloy /

- corrosion kinetics /

- grain boundary corrosion

[1] Kai J J, Huang W I, Chou H Y 1990 J. Nucl. Mater. 170 193

Google Scholar

Google Scholar

[2] Zhao W Z, Quan Q W, Zhang S M, Yang X Y, Wen H Y, Wu Y C, Liu X B, Cao X Z, Wang B Y 2023 Radiat. Phys. Chem. 209 110986

Google Scholar

Google Scholar

[3] Jones R H, Simonen E P 1994 Mater. Sci. Eng. 176 211

Google Scholar

Google Scholar

[4] Hu J, Liu J L, Lozano P S, Grovenor C R M, Christensen M, Wolf W, Wimmer E, Mader E V 2019 Acta Mater. 180 105

Google Scholar

Google Scholar

[5] Cann C D, So C B, Styles R C, Coleman C E 1993 J. Nucl. Mater. 205 267

Google Scholar

Google Scholar

[6] Wei T G, Dai X, Long C S, Sun C, Long S J, Zheng J Y, Wang P F, Jia Y Z, Zhang J S 2021 Corros. Sci. 192 109808

Google Scholar

Google Scholar

[7] Tian Z, Peng J C, Lin X D, Hu Y Y, Yao M Y, Xie Y P, Liang X, Zhou B X 2024 Corros. Sci. 202 111937

Google Scholar

Google Scholar

[8] Ferreirós P A, Polack E C S, Lanzani L A, Alonso P R, Quirós P D, Mieza J I, Rubiolo G H 2021 J. Nucl. Mater. 553 153039

Google Scholar

Google Scholar

[9] Jiang G Y, Xu D H, Yang W P, Liu L, Zhi Y W, Yang J Q 2022 Prog. Nucl. Energy 154 104490

Google Scholar

Google Scholar

[10] Yuan R, Xie Y P, Li T, Xu C H, Yao M Y, Xu J X, Guo H B, Zhou B X 2021 Acta Mater. 209 116804

Google Scholar

Google Scholar

[11] Mcdeavitt S M, Billings G W, Indacochea J E 2002 J. Mater. Sci. 37 3765

Google Scholar

Google Scholar

[12] Jerlerud P R, Toffolon M C, Joubert J M, Sundman B 2008 CALPHAD 32 593

Google Scholar

Google Scholar

[13] Asle Zaeem M, El Kadiri H 2014 Comput. Mater. Sci. 89 122

Google Scholar

Google Scholar

[14] 张更, 王巧, 沙立婷, 李亚捷, 王达, 施思齐 2020 69 226401

Google Scholar

Google Scholar

Zhang G, Wang Q, Sha L T, Li Y J, Wang D, Shi S Q 2020 Acta Phys. Sin 69 226401

Google Scholar

Google Scholar

[15] Chen L Q, Zhao Y 2022 Prog. Mater. Sci. 124 100868

Google Scholar

Google Scholar

[16] Chen L Q 2002 Annu. Rev. Mater. Res. 32 113

Google Scholar

Google Scholar

[17] 刘续希, 柳文波, 李博岩, 贺新福, 杨朝曦, 恽迪 2022 金属学报 58 943

Liu X X, Liu W B, Li B Y, He X F, Yang Z X, Yun D 2022 Acta Metal. Sin 58 943

[18] Mai W, Soghrati S 2017 Corros. Sci. 125 87

Google Scholar

Google Scholar

[19] Fang X R, Pan Z C, Ma R J, Chen A R 2023 Comuput. Methods Appl. Mech. Engrg. 414 116196

Google Scholar

Google Scholar

[20] 冯力, 王智平, 路阳, 朱昌盛 2008 57 1084

Google Scholar

Google Scholar

Feng L, Wang Z P, Lu Y, Zhu C S 2008 Acta Phys. Sin 57 1084

Google Scholar

Google Scholar

[21] Yang C, Huang H B, Liu W B, Wang J S, Wang J, Jafri H M, Liu Y, Han G M, Song H F, Chen L Q 2021 Adv. Theor. Simul. 4 2000162

Google Scholar

Google Scholar

[22] Zhou F Y, Qiu K J, Bian D, Zheng Y F, Lin J P 2014 J. Mater. Sci. Technol. 30 299

Google Scholar

Google Scholar

[23] Dinsdale A T 1991 CALPHAD 15 317

Google Scholar

Google Scholar

[24] Aricó S F, Gribaudo L M, 1999 Scripta Mater. 41 159

Google Scholar

Google Scholar

[25] Wang C, Zinkevich M, Aldinger F 2004 CALPHAD 28 281

Google Scholar

Google Scholar

[26] Yin T, Lee J, Moosavi K E, Jung I H 2021 Ceram. Int. 47 29267

Google Scholar

Google Scholar

[27] Isomäki I, Hämäläinen M, Gierlotka W, Onderka B, Fitzner K 2006 J. Alloys Compd. 422 173

Google Scholar

Google Scholar

[28] Fang X R, Pan Z C, Chen A R, Tian H, Ma R J 2023 Eng. Fract. Mech. 281 109131

Google Scholar

Google Scholar

[29] Allen S M, Cahn J W 1979 Acta Metall. 27 1085

Google Scholar

Google Scholar

[30] Larché F C, Cahn J W 1985 Acta Metall. 33 331

Google Scholar

Google Scholar

[31] Cahn J W 1961 Acta Metall. 9 795

Google Scholar

Google Scholar

[32] Cox B, Pemsler J P 1968 J. Nucl. Mater. 28 73

Google Scholar

Google Scholar

[33] Ritchie I G, Atrens A 1977 J. Nucl. Mater. 67 254

Google Scholar

Google Scholar

[34] Keneshea F J, Douglass D L 1971 Oxid. Met. 3 1

Google Scholar

Google Scholar

[35] 姜彦博, 柳文波, 孙志鹏, 喇永孝, 恽迪 2022 71 026103

Google Scholar

Google Scholar

Jiang Y B, Liu W B, Sun Z P, La Y X, Yun D 2022 Acta Phys. Sin 71 026103

Google Scholar

Google Scholar

[36] Qiu K, Wang R, Peng C, Lu X, Wang N 2015 CALPHAD 48 175

Google Scholar

Google Scholar

[37] Fisher E, Renken C 1964 Phys. Rev. 135 A482

Google Scholar

Google Scholar

[38] Fogaing E Y, Lorgouilloux Y, Huger M, Gault C P 2006 J. Mater. Sci. 41 7663

Google Scholar

Google Scholar

[39] Mirgorodsky A, Smirnov M, Quintard P 1997 Phys. Rev. B 55 19

Google Scholar

Google Scholar

[40] 刘建章 2007 核结构材料 (北京: 化学工业出版社) 第89页

Liu J Z 2007 Nuclear Structure Material (Beijing: Chemical Industry Press) p89

[41] Fan D, Chen L Q 1997 Acta Mater. 45 611

Google Scholar

Google Scholar

[42] Bi Y B, Zhang X L, Lu L, Xu Z F, Xie Z G, Chen B B, Liang Z X, Sun Z Q, Luo Z 2023 J. Mater. Res. Technol. 26 5888

Google Scholar

Google Scholar

[43] Gwinner B, Bataillon C, Chelagemdib R, Gruet N, Lorentz V, Puga B 2023 Electrochim. Acta 470 143334

Google Scholar

Google Scholar

[44] Zhang M H, Liu S D, Jiang J Y, Wei W C 2023 T Nonferr Metal. Soc. 33 1963

Google Scholar

Google Scholar

[45] Liu J L, Yu H B, Karamched P, Hu J, He G Z, Goran D, Hughes G M, Wilkinson A J, Sergio L P, Grovenor C R 2019 Acta Mater. 179 328

Google Scholar

Google Scholar

-

表 1 Zr-Sn合金自由能参数

Table 1. Free energy parameters of Zr-Sn alloys.

Parameter Value Reference EZr/(J·m–3) $-7827.6 + 125.65T - 24.1618T\ln T - 4.38{\rm e}^{-3} T^3 + 34971T^{-1} $ [23] ESn/(J·m–3) $2524.7 + 4.00T - 8.26T \lnT - 16.81{\rm e}^{-3} T^2 + 2.62 {\rm e}^{-6}T^3 - 1.08{\rm e}^6 T^{-1} $ [23] EO/(J·m–3) $-3480.9 - 25.50T - 11.13T\ln T - 5.10 {\rm e}^{-3}T^2 + 0.66 {\rm e}^{-6}T^3 - 38365T^{-1} $ [23] AZrSn $-148022.5+19.41T+(173681.9-22T)(c_{\rm Zr}-c_{\rm Sn}) + 104271.96(c_{\rm Zr}-c_{Sn})^2 $ [24] AZrO $-37876.66+17.2915T - 4471.4(c_{\rm Zr}-c_{\rm O}) $ [25] ASnO 140878 – 23.9326T [26, 35] $g_2^0$ $-1117869+420.3T - 69.6T\ln T - 0.003766T^2 + 702910T^{-1} +4.59 {\rm e}^{-21}T^7 $ [25] $ g_3^0 $ 0 k2/(J·m–3) 2.5 × 105 [13] k3/(J·m–3) 2.5 × 105 [13] Temperature/K D1/(m2·s–1) D2/(m2·s–1) D3/(m2·s–1) DGB/(m2·s–1) 633 3.99×10–17 1.61×10–17 2.98×10–17 1.46×10–16 653 1.26×10–16 5.18×10–17 8.77×10–17 8.11×10–16 673 3.09×10–16 1.11×10–16 2.25×10–16 3.76×10–15 693 1.04×10–15 3.69×10–16 7.64×10–16 2.82×10–14 表 3 锆合金基体及氧化层的弹性模量分量

Table 3. Elastic modulus of Zr alloy and oxide layer.

-

[1] Kai J J, Huang W I, Chou H Y 1990 J. Nucl. Mater. 170 193

Google Scholar

Google Scholar

[2] Zhao W Z, Quan Q W, Zhang S M, Yang X Y, Wen H Y, Wu Y C, Liu X B, Cao X Z, Wang B Y 2023 Radiat. Phys. Chem. 209 110986

Google Scholar

Google Scholar

[3] Jones R H, Simonen E P 1994 Mater. Sci. Eng. 176 211

Google Scholar

Google Scholar

[4] Hu J, Liu J L, Lozano P S, Grovenor C R M, Christensen M, Wolf W, Wimmer E, Mader E V 2019 Acta Mater. 180 105

Google Scholar

Google Scholar

[5] Cann C D, So C B, Styles R C, Coleman C E 1993 J. Nucl. Mater. 205 267

Google Scholar

Google Scholar

[6] Wei T G, Dai X, Long C S, Sun C, Long S J, Zheng J Y, Wang P F, Jia Y Z, Zhang J S 2021 Corros. Sci. 192 109808

Google Scholar

Google Scholar

[7] Tian Z, Peng J C, Lin X D, Hu Y Y, Yao M Y, Xie Y P, Liang X, Zhou B X 2024 Corros. Sci. 202 111937

Google Scholar

Google Scholar

[8] Ferreirós P A, Polack E C S, Lanzani L A, Alonso P R, Quirós P D, Mieza J I, Rubiolo G H 2021 J. Nucl. Mater. 553 153039

Google Scholar

Google Scholar

[9] Jiang G Y, Xu D H, Yang W P, Liu L, Zhi Y W, Yang J Q 2022 Prog. Nucl. Energy 154 104490

Google Scholar

Google Scholar

[10] Yuan R, Xie Y P, Li T, Xu C H, Yao M Y, Xu J X, Guo H B, Zhou B X 2021 Acta Mater. 209 116804

Google Scholar

Google Scholar

[11] Mcdeavitt S M, Billings G W, Indacochea J E 2002 J. Mater. Sci. 37 3765

Google Scholar

Google Scholar

[12] Jerlerud P R, Toffolon M C, Joubert J M, Sundman B 2008 CALPHAD 32 593

Google Scholar

Google Scholar

[13] Asle Zaeem M, El Kadiri H 2014 Comput. Mater. Sci. 89 122

Google Scholar

Google Scholar

[14] 张更, 王巧, 沙立婷, 李亚捷, 王达, 施思齐 2020 69 226401

Google Scholar

Google Scholar

Zhang G, Wang Q, Sha L T, Li Y J, Wang D, Shi S Q 2020 Acta Phys. Sin 69 226401

Google Scholar

Google Scholar

[15] Chen L Q, Zhao Y 2022 Prog. Mater. Sci. 124 100868

Google Scholar

Google Scholar

[16] Chen L Q 2002 Annu. Rev. Mater. Res. 32 113

Google Scholar

Google Scholar

[17] 刘续希, 柳文波, 李博岩, 贺新福, 杨朝曦, 恽迪 2022 金属学报 58 943

Liu X X, Liu W B, Li B Y, He X F, Yang Z X, Yun D 2022 Acta Metal. Sin 58 943

[18] Mai W, Soghrati S 2017 Corros. Sci. 125 87

Google Scholar

Google Scholar

[19] Fang X R, Pan Z C, Ma R J, Chen A R 2023 Comuput. Methods Appl. Mech. Engrg. 414 116196

Google Scholar

Google Scholar

[20] 冯力, 王智平, 路阳, 朱昌盛 2008 57 1084

Google Scholar

Google Scholar

Feng L, Wang Z P, Lu Y, Zhu C S 2008 Acta Phys. Sin 57 1084

Google Scholar

Google Scholar

[21] Yang C, Huang H B, Liu W B, Wang J S, Wang J, Jafri H M, Liu Y, Han G M, Song H F, Chen L Q 2021 Adv. Theor. Simul. 4 2000162

Google Scholar

Google Scholar

[22] Zhou F Y, Qiu K J, Bian D, Zheng Y F, Lin J P 2014 J. Mater. Sci. Technol. 30 299

Google Scholar

Google Scholar

[23] Dinsdale A T 1991 CALPHAD 15 317

Google Scholar

Google Scholar

[24] Aricó S F, Gribaudo L M, 1999 Scripta Mater. 41 159

Google Scholar

Google Scholar

[25] Wang C, Zinkevich M, Aldinger F 2004 CALPHAD 28 281

Google Scholar

Google Scholar

[26] Yin T, Lee J, Moosavi K E, Jung I H 2021 Ceram. Int. 47 29267

Google Scholar

Google Scholar

[27] Isomäki I, Hämäläinen M, Gierlotka W, Onderka B, Fitzner K 2006 J. Alloys Compd. 422 173

Google Scholar

Google Scholar

[28] Fang X R, Pan Z C, Chen A R, Tian H, Ma R J 2023 Eng. Fract. Mech. 281 109131

Google Scholar

Google Scholar

[29] Allen S M, Cahn J W 1979 Acta Metall. 27 1085

Google Scholar

Google Scholar

[30] Larché F C, Cahn J W 1985 Acta Metall. 33 331

Google Scholar

Google Scholar

[31] Cahn J W 1961 Acta Metall. 9 795

Google Scholar

Google Scholar

[32] Cox B, Pemsler J P 1968 J. Nucl. Mater. 28 73

Google Scholar

Google Scholar

[33] Ritchie I G, Atrens A 1977 J. Nucl. Mater. 67 254

Google Scholar

Google Scholar

[34] Keneshea F J, Douglass D L 1971 Oxid. Met. 3 1

Google Scholar

Google Scholar

[35] 姜彦博, 柳文波, 孙志鹏, 喇永孝, 恽迪 2022 71 026103

Google Scholar

Google Scholar

Jiang Y B, Liu W B, Sun Z P, La Y X, Yun D 2022 Acta Phys. Sin 71 026103

Google Scholar

Google Scholar

[36] Qiu K, Wang R, Peng C, Lu X, Wang N 2015 CALPHAD 48 175

Google Scholar

Google Scholar

[37] Fisher E, Renken C 1964 Phys. Rev. 135 A482

Google Scholar

Google Scholar

[38] Fogaing E Y, Lorgouilloux Y, Huger M, Gault C P 2006 J. Mater. Sci. 41 7663

Google Scholar

Google Scholar

[39] Mirgorodsky A, Smirnov M, Quintard P 1997 Phys. Rev. B 55 19

Google Scholar

Google Scholar

[40] 刘建章 2007 核结构材料 (北京: 化学工业出版社) 第89页

Liu J Z 2007 Nuclear Structure Material (Beijing: Chemical Industry Press) p89

[41] Fan D, Chen L Q 1997 Acta Mater. 45 611

Google Scholar

Google Scholar

[42] Bi Y B, Zhang X L, Lu L, Xu Z F, Xie Z G, Chen B B, Liang Z X, Sun Z Q, Luo Z 2023 J. Mater. Res. Technol. 26 5888

Google Scholar

Google Scholar

[43] Gwinner B, Bataillon C, Chelagemdib R, Gruet N, Lorentz V, Puga B 2023 Electrochim. Acta 470 143334

Google Scholar

Google Scholar

[44] Zhang M H, Liu S D, Jiang J Y, Wei W C 2023 T Nonferr Metal. Soc. 33 1963

Google Scholar

Google Scholar

[45] Liu J L, Yu H B, Karamched P, Hu J, He G Z, Goran D, Hughes G M, Wilkinson A J, Sergio L P, Grovenor C R 2019 Acta Mater. 179 328

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 5311

- PDF Downloads: 107

- Cited By: 0

DownLoad:

DownLoad: