-

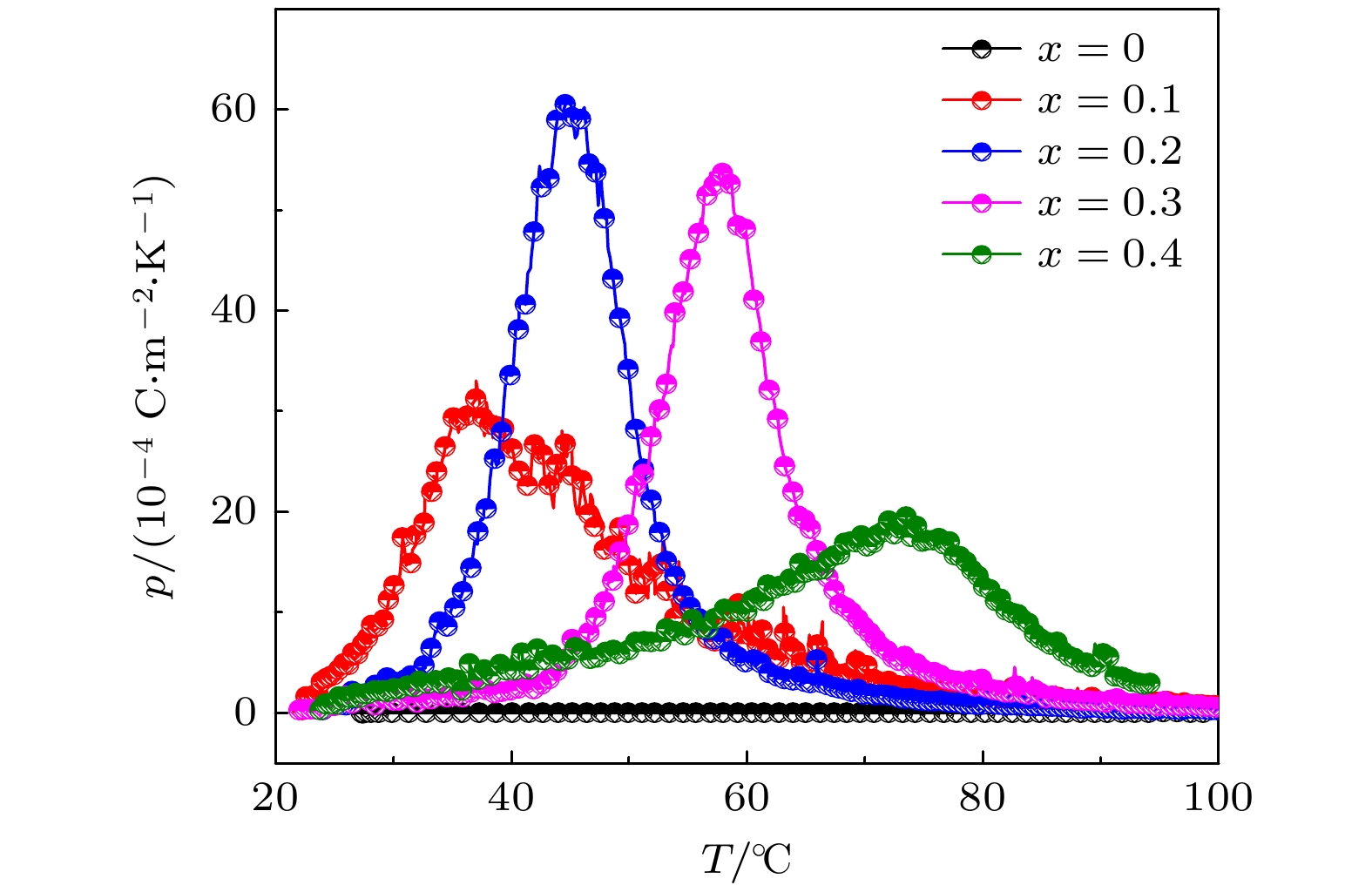

In this work, composite ceramics (1–x)Pb0.99Nb0.02[(Zr0.57Sn0.43)0.94Ti0.06]0.98O3:xAlN (abbreviated (1–x)PNZST:xAlN, x = 0, 0.1, 0.2, 0.3 and 0.4) are prepared by a two-step solid phase synthesis method. The crystal structures, micromorphologies, domain structure evolutions, ferroelectric, dielectric and pyroelectric properties of those composite ceramics are systematically investigated. The results show that the difference in thermal expansion coefficient between PNZST and AlN creates compressive stresses in the PNZST matrix when cooling down from the sintering temperature, then a metastable ferroelectric (FE) phase is induced in the anti-FE matrix by the AlN component-induced internal stress, and in turn ferroelectric/antiferroelectric phase boundary is constructed near room temperature. As the temperature increases, the ferroelectric-to-antiferroelectric phase transition causes a larger pyroelectric current peak. In particular, the composition with x = 0.1 exhibits a high pyroelectric coefficient p = 3.3×10–3 C⋅m–2⋅K–1 and figure-of-merit with current responsivity Fi = 3.16×10–9 m⋅V–1, voltage responsivity Fv = 0.613 m2⋅C–1, and detectivity Fd = 4.4×10–4 Pa–1/2 around human body temperature. Moreover, the enhanced pyroelectric coefficient exists in a broad operation temperature range with a large full width at half maximums of 16.3 ℃ at 37 ℃. With the increase of AlN content, the pyroelectric peak temperature of the composite ceramic is adjustable in a wide temperature range of 37–73 ℃, showing good temperature stability.

-

Keywords:

- pyroelectricity /

- composite ceramics /

- local stress field /

- ferroelectric domain

[1] Liu Z, Lu T, Dong X, Wang G, Liu Y 2021 IEEE Trans. Ultrason. Ferr. 68 242

Google Scholar

Google Scholar

[2] Jia J, Guo S, Yan S, Cao F, Yao C, Dong X, Wang G 2019 Appl. Phys. Lett. 114 032902

Google Scholar

Google Scholar

[3] Whatmore R W 1986 Rep. Prog. Phys. 49 1135

Google Scholar

Google Scholar

[4] Wang Y, Yuan G, Luo H, Li J, Viehland D 2017 Phys. Rev. Appl. 8 034032

Google Scholar

Google Scholar

[5] Domingo N, Bagués N, Santiso J, Catalan G 2015 Phys. Rev. B 91 094111

Google Scholar

Google Scholar

[6] Pandya S, Wilbur J, Kim J, Gao R, Dasgupta A, Dames C, Martin L W 2018 Nat. Mater. 17 432

Google Scholar

Google Scholar

[7] Yang M M, Luo Z D, Mi Z, Zhao J, Sharel P E, Alexe M 2020 Nature 584 377

Google Scholar

Google Scholar

[8] 郭少波, 闫世光, 曹菲, 姚春华, 王根水, 董显林 2020 69 127708

Google Scholar

Google Scholar

Guo S B, Yan S G, Cao F, Yao C H, Wang G S, Dong X L 2020 Acta Phys. Sin. 69 127708

Google Scholar

Google Scholar

[9] Xu Y Q, Wu N J, Ignatiev A 2000 J. Appl. Phys. 88 1004

Google Scholar

Google Scholar

[10] Zhang S, Lebrun L, Jeong D Y, Randall C A, Zhang Q, Shrout T R 2003 J. Appl. Phys. 93 9257

Google Scholar

Google Scholar

[11] Huang X, Tang Y, Wang F, Ming Leung C, Zhao X, Qin X, Wang T, Duan Z, Wu Y, Wang J, Shi W 2022 J. Am. Ceram. Soc. 105 327

Google Scholar

Google Scholar

[12] He H, Lu X, Hanc E, Chen C, Zhang H, Lu L 2020 J. Mater. Chem. C 8 1494

Google Scholar

Google Scholar

[13] Song K, Ma N, Mishra Y K, Adelung R, Yang Y 2019 Adv. Electron. Mater. 5 1800413

Google Scholar

Google Scholar

[14] Srikanth K S, Singh V P, Vaish R 2017 J. Eur. Ceram. Soc. 37 3943

Google Scholar

Google Scholar

[15] Patel S, Weyland F, Tan X, Novak N 2018 Energy Technology 6 865

Google Scholar

Google Scholar

[16] Li L, Liu H, Wang R X, Zhang H, Huang H, Lu M H, Zhang S T, Jiang S, Wu D, Chen Y F 2020 J. Mater. Chem. C 8 7820

Google Scholar

Google Scholar

[17] Liu B, Li L, Zhang S T, Zhou L, Tan X 2022 J. Am. Ceram. Soc. 105 794

Google Scholar

Google Scholar

[18] Riemer L M, Lalitha K V, Jiang X, Liu N, Dietz C, Stark R W, Groszewicz P B, Buntkowsky G, Chen J, Zhang S T, Rodel J, Koruza J 2017 Act. Mater. 136 271

Google Scholar

Google Scholar

[19] Yin J, Wang Y, Zhang Y, Wu B, Wu J 2018 Act. Mater. 158 269

Google Scholar

Google Scholar

[20] Tabary P, Servant C, Alary J A 2000 J. Eur. Ceram. Soc. 20 913

Google Scholar

Google Scholar

[21] 田野, 靳立, 冯玉军, 庄永勇, 徐卓, 魏晓勇 2017 物理学进展 37 155

Tian Y, Jin L, Feng Y J, Zhuang Y Y, Xu Z, Wei X 2017 Prog. Phys. 37 155

[22] Wang H, Jiang B, Thomas R S, Cao W 2004 IEEE Trans. Ultrason. Ferr. 51 908

Google Scholar

Google Scholar

[23] Lee H J, Zhang S, Luo J, Li F, Shrout T R 2010 Adv. Funct. Mater. 20 3154

Google Scholar

Google Scholar

[24] Shen M, Hu Z, Qiu Y, Qiu S, Li M Y, Zhang G, Zhang S, Yang Z, Kagawa F, Jiang S 2019 J. Eur. Ceram. Soc. 39 5243

Google Scholar

Google Scholar

[25] You D, Tan H, Yan Z, Gao H, Chen S, Ma W, Fan P, Tran N M, Liu Y, Salamon D, Zhang H 2022 ACS Appl. Mater. Inter. 14 17652

Google Scholar

Google Scholar

[26] Tan X, Frederick J, Ma C, Aulbach E, Marsilius M, Hong W, Granzow T, Jo W, Rödel J 2010 Phys. Rev. B 81 014103

Google Scholar

Google Scholar

[27] Tan X, Jo W, Granzow T, Frederick J, Aulbach E, Rödel J 2009 Appl. Phys. Lett. 94 042909

Google Scholar

Google Scholar

[28] Frederick J, Tan X, Jo W 2011 J. Am. Ceram. Soc. 94 1149

Google Scholar

Google Scholar

[29] He H, Tan X 2007 J. Phys. Condens. Matter. 19 136003

Google Scholar

Google Scholar

[30] Tan X, Frederick J, Ma C, Jo W, Rodel J 2010 Phys. Rev. Lett. 105 255702

Google Scholar

Google Scholar

[31] Yang X, Zhuo F, Wang C, Liu Y, Wang Z, He C, Long X 2020 Act. Mater. 186 523

Google Scholar

Google Scholar

[32] Li S, Nie H, Wang G, Liu N, Zhou M, Cao F, Dong X 2019 J. Mater. Chem. C 7 4403

Google Scholar

Google Scholar

[33] Zhou M, Liang R, Zhou Z, Dong X 2019 J. Am. Ceram. Soc. 103 193

Google Scholar

Google Scholar

[34] Thakre A, Maurya D, Kim D Y, Kim Y, Sriboriboon P, Yoo I R, Priya S, Cho K H, Song H C, Ryu J 2021 J. Eur. Ceram. Soc. 41 2524

Google Scholar

Google Scholar

[35] Whatmore R W 2021 Encyclopedia Mater. Tech. Ceram. Glasses 3 139

[36] Qiao P, Zhang Y, Chen X, Zhou M, Wang G, Dong X 2019 Ceram. Int. 45 7114

Google Scholar

Google Scholar

[37] Jiang X P, Chen Y, Lam K H, Choy S H, Wang J 2010 J. Alloys Compd. 506 323

Google Scholar

Google Scholar

[38] Liu Z, Ren W, Peng P, Guo S, Lu T, Liu Y, Dong X, Wang G 2018 Appl. Phys. Lett. 112 142903

Google Scholar

Google Scholar

[39] Srikanth K S, Patel S, Steiner S, Vaish R 2018 Scr. Mater. 146 146

Google Scholar

Google Scholar

[40] Chen H, Guo S, Dong X, Cao F, Mao C, Wang G 2017 J. Alloys Compd. 695 2723

Google Scholar

Google Scholar

-

图 2 (1–x)PNZST:xAlN (x = 0, 0.1, 0.2, 0.3和0.4)陶瓷的(a)—(e) SEM图像和(f)晶粒尺寸分布 (a) x = 0; (b) x = 0.1; (c) x = 0.2; (d) x = 0.3; (e) x = 0.4; (f)平均晶粒尺寸随AlN含量变化的关系

Figure 2. The SEM images (a)–(e) and grain size distribution (f) of (1–x)PNZST:xAlN: (a) x = 0; (b) x = 0.1; (c) x = 0.2; (d) x = 0.3; (e) x = 0.4; (f) the composition dependence of average grain size.

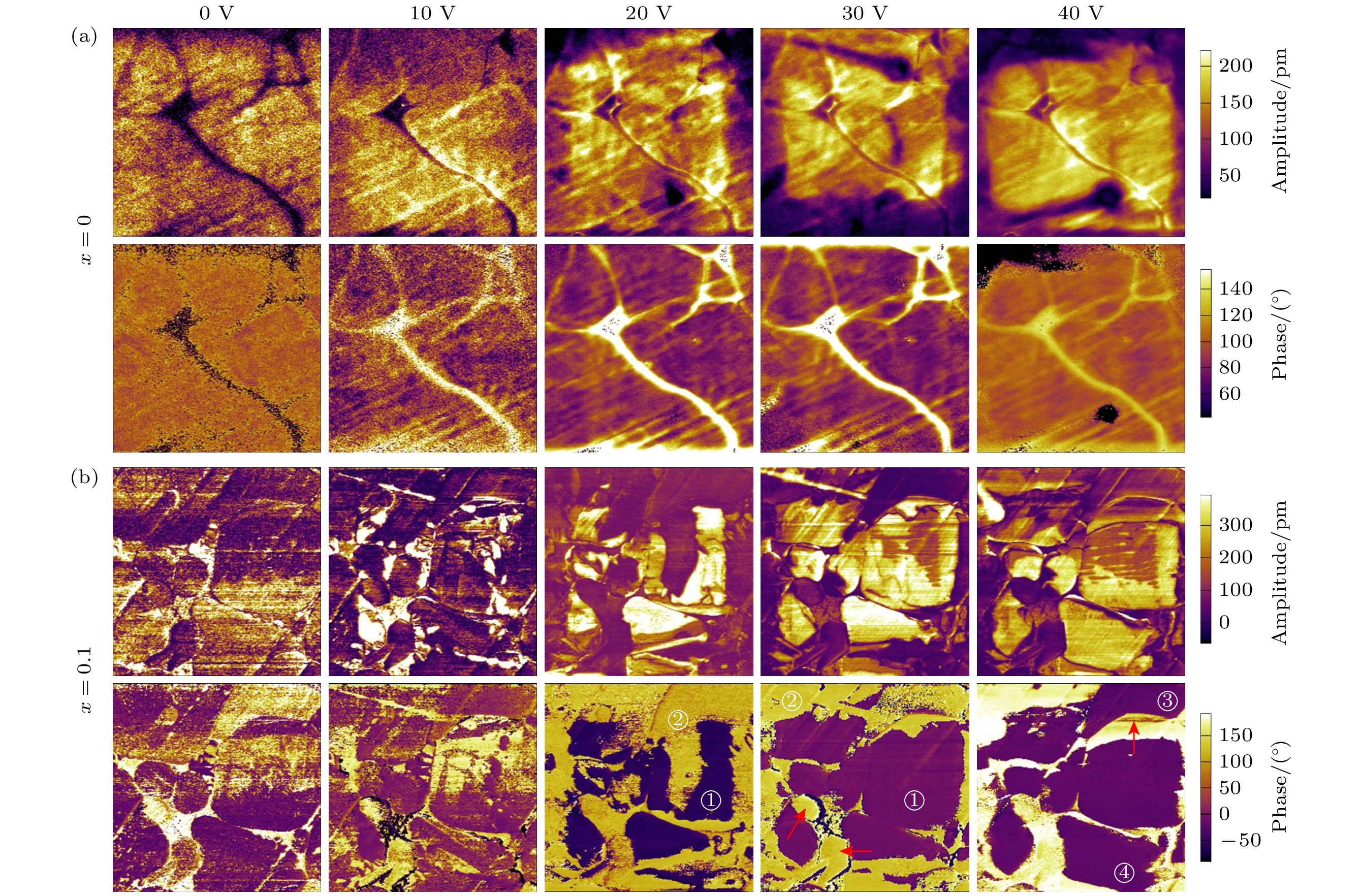

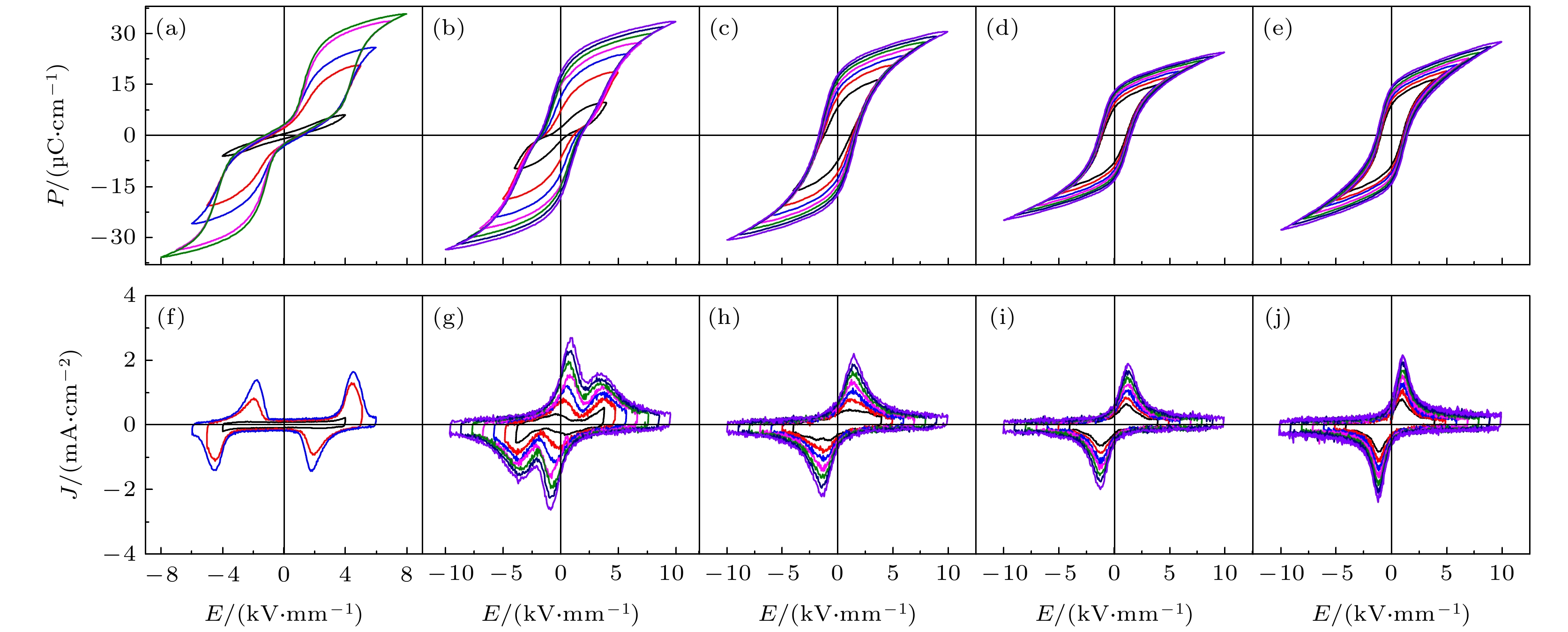

图 6 不同组分(1–x)PNZST:xAlN陶瓷样品在室温不同电场下的P-E (a)—(e)和J-E (f)—(j)曲线 (a), (f) x = 0; (b), (g) x = 0.1; (c), (h) x = 0.2; (d), (i) x = 0.3; (e), (j) x = 0.4

Figure 6. Electric field-dependent P-E loops (a)–(e) and J-E (f)–(j) curves of (1–x)PNZST:xAlN composite at room temperature: (a), (f) x = 0; (b), (g) x = 0.1; (c), (h) x = 0.2; (d), (i) x = 0.3; (e), (j) x = 0.4.

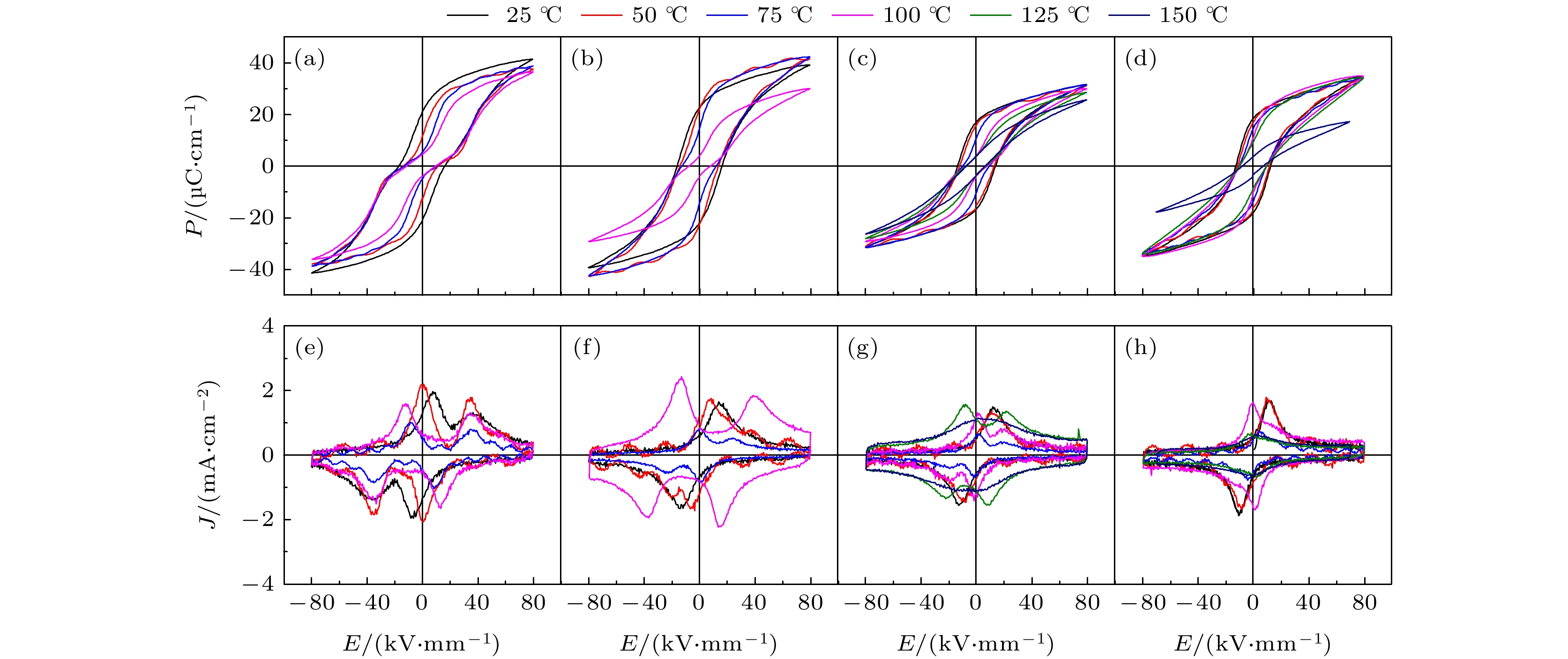

图 7 不同组分(1–x)PNZST:xAlN陶瓷样品在不同电场下的P-E (a)—(d)和J-E (e)—(h)曲线 (a), (e) x = 0.1; (b), (f) x = 0.2; (c), (g) x = 0.3; (d), (h) x = 0.4

Figure 7. Temperature-dependent P-E loops (a)–(d) and J-E curves (e)–(h) of (1–x)PNZST:xAlN composite at room temperature: (a), (e) x = 0.1; (b), (f) x = 0.2; (c), (g) x = 0.3; (d), (h) x = 0.4.

表 1 PNZST:AlN复合陶瓷与其他已报道的无铅材料和PZT基材料的热释电性能参数比较

Table 1. Comparison of the pyroelectric parameters of PNZST:AlN ceramics, other reported lead-free materials and PZT-based materials.

材料组成 介电常数εr 介电损耗tanδ 热释电系数p/

(10–4 C·m–2·K–1)电流优值因子Fi/

(10–10 m·V–1)电压优值因子Fv/

(10–2 m2·C–1)探测率优值因子Fd/

(10–5 Pa–1/2)文献 TGS 55 0.025 5.5 2.12 43 6.1 [1] LiTaO3 crystal 47 0.0005 2.3 0.72 17 15.7 [1] PVDF 11 0.02 0.3 0.13 13.4 0.9 [35] BNT-BT 403 0.011 2.42 2.68 1.53 [2] BNT-BT-ST 1278 0.109 5.7 2.08 1.8 0.589 [2] PLZT 511 0.014 4.0 1.66 3.6 2.07 [36] KNN-BKT 980 0.035 2.18 0.994 1.14 0.57 [37] BNT-BA-KNN 514 0.029 3.7 1.32 2.89 1.15 [38] BCT-BST 3500 0.025 2.05 1 0.32 0.41 [39] CSBN 328 0.033 1.24 0.6 2.03 0.61 [40] PZT-based 290 0.0027 3.8 6.0 5.8 [2] KBT-BT-NBT 660 0.23 2.58 0.92 1.5 0.53 [34] PIMNT film 2824 0.004 8.5 3.40 1.4 1.03 [11] x = 0.1 583.6 0.01 33.0 31.6 61.3 44.0 本工作 -

[1] Liu Z, Lu T, Dong X, Wang G, Liu Y 2021 IEEE Trans. Ultrason. Ferr. 68 242

Google Scholar

Google Scholar

[2] Jia J, Guo S, Yan S, Cao F, Yao C, Dong X, Wang G 2019 Appl. Phys. Lett. 114 032902

Google Scholar

Google Scholar

[3] Whatmore R W 1986 Rep. Prog. Phys. 49 1135

Google Scholar

Google Scholar

[4] Wang Y, Yuan G, Luo H, Li J, Viehland D 2017 Phys. Rev. Appl. 8 034032

Google Scholar

Google Scholar

[5] Domingo N, Bagués N, Santiso J, Catalan G 2015 Phys. Rev. B 91 094111

Google Scholar

Google Scholar

[6] Pandya S, Wilbur J, Kim J, Gao R, Dasgupta A, Dames C, Martin L W 2018 Nat. Mater. 17 432

Google Scholar

Google Scholar

[7] Yang M M, Luo Z D, Mi Z, Zhao J, Sharel P E, Alexe M 2020 Nature 584 377

Google Scholar

Google Scholar

[8] 郭少波, 闫世光, 曹菲, 姚春华, 王根水, 董显林 2020 69 127708

Google Scholar

Google Scholar

Guo S B, Yan S G, Cao F, Yao C H, Wang G S, Dong X L 2020 Acta Phys. Sin. 69 127708

Google Scholar

Google Scholar

[9] Xu Y Q, Wu N J, Ignatiev A 2000 J. Appl. Phys. 88 1004

Google Scholar

Google Scholar

[10] Zhang S, Lebrun L, Jeong D Y, Randall C A, Zhang Q, Shrout T R 2003 J. Appl. Phys. 93 9257

Google Scholar

Google Scholar

[11] Huang X, Tang Y, Wang F, Ming Leung C, Zhao X, Qin X, Wang T, Duan Z, Wu Y, Wang J, Shi W 2022 J. Am. Ceram. Soc. 105 327

Google Scholar

Google Scholar

[12] He H, Lu X, Hanc E, Chen C, Zhang H, Lu L 2020 J. Mater. Chem. C 8 1494

Google Scholar

Google Scholar

[13] Song K, Ma N, Mishra Y K, Adelung R, Yang Y 2019 Adv. Electron. Mater. 5 1800413

Google Scholar

Google Scholar

[14] Srikanth K S, Singh V P, Vaish R 2017 J. Eur. Ceram. Soc. 37 3943

Google Scholar

Google Scholar

[15] Patel S, Weyland F, Tan X, Novak N 2018 Energy Technology 6 865

Google Scholar

Google Scholar

[16] Li L, Liu H, Wang R X, Zhang H, Huang H, Lu M H, Zhang S T, Jiang S, Wu D, Chen Y F 2020 J. Mater. Chem. C 8 7820

Google Scholar

Google Scholar

[17] Liu B, Li L, Zhang S T, Zhou L, Tan X 2022 J. Am. Ceram. Soc. 105 794

Google Scholar

Google Scholar

[18] Riemer L M, Lalitha K V, Jiang X, Liu N, Dietz C, Stark R W, Groszewicz P B, Buntkowsky G, Chen J, Zhang S T, Rodel J, Koruza J 2017 Act. Mater. 136 271

Google Scholar

Google Scholar

[19] Yin J, Wang Y, Zhang Y, Wu B, Wu J 2018 Act. Mater. 158 269

Google Scholar

Google Scholar

[20] Tabary P, Servant C, Alary J A 2000 J. Eur. Ceram. Soc. 20 913

Google Scholar

Google Scholar

[21] 田野, 靳立, 冯玉军, 庄永勇, 徐卓, 魏晓勇 2017 物理学进展 37 155

Tian Y, Jin L, Feng Y J, Zhuang Y Y, Xu Z, Wei X 2017 Prog. Phys. 37 155

[22] Wang H, Jiang B, Thomas R S, Cao W 2004 IEEE Trans. Ultrason. Ferr. 51 908

Google Scholar

Google Scholar

[23] Lee H J, Zhang S, Luo J, Li F, Shrout T R 2010 Adv. Funct. Mater. 20 3154

Google Scholar

Google Scholar

[24] Shen M, Hu Z, Qiu Y, Qiu S, Li M Y, Zhang G, Zhang S, Yang Z, Kagawa F, Jiang S 2019 J. Eur. Ceram. Soc. 39 5243

Google Scholar

Google Scholar

[25] You D, Tan H, Yan Z, Gao H, Chen S, Ma W, Fan P, Tran N M, Liu Y, Salamon D, Zhang H 2022 ACS Appl. Mater. Inter. 14 17652

Google Scholar

Google Scholar

[26] Tan X, Frederick J, Ma C, Aulbach E, Marsilius M, Hong W, Granzow T, Jo W, Rödel J 2010 Phys. Rev. B 81 014103

Google Scholar

Google Scholar

[27] Tan X, Jo W, Granzow T, Frederick J, Aulbach E, Rödel J 2009 Appl. Phys. Lett. 94 042909

Google Scholar

Google Scholar

[28] Frederick J, Tan X, Jo W 2011 J. Am. Ceram. Soc. 94 1149

Google Scholar

Google Scholar

[29] He H, Tan X 2007 J. Phys. Condens. Matter. 19 136003

Google Scholar

Google Scholar

[30] Tan X, Frederick J, Ma C, Jo W, Rodel J 2010 Phys. Rev. Lett. 105 255702

Google Scholar

Google Scholar

[31] Yang X, Zhuo F, Wang C, Liu Y, Wang Z, He C, Long X 2020 Act. Mater. 186 523

Google Scholar

Google Scholar

[32] Li S, Nie H, Wang G, Liu N, Zhou M, Cao F, Dong X 2019 J. Mater. Chem. C 7 4403

Google Scholar

Google Scholar

[33] Zhou M, Liang R, Zhou Z, Dong X 2019 J. Am. Ceram. Soc. 103 193

Google Scholar

Google Scholar

[34] Thakre A, Maurya D, Kim D Y, Kim Y, Sriboriboon P, Yoo I R, Priya S, Cho K H, Song H C, Ryu J 2021 J. Eur. Ceram. Soc. 41 2524

Google Scholar

Google Scholar

[35] Whatmore R W 2021 Encyclopedia Mater. Tech. Ceram. Glasses 3 139

[36] Qiao P, Zhang Y, Chen X, Zhou M, Wang G, Dong X 2019 Ceram. Int. 45 7114

Google Scholar

Google Scholar

[37] Jiang X P, Chen Y, Lam K H, Choy S H, Wang J 2010 J. Alloys Compd. 506 323

Google Scholar

Google Scholar

[38] Liu Z, Ren W, Peng P, Guo S, Lu T, Liu Y, Dong X, Wang G 2018 Appl. Phys. Lett. 112 142903

Google Scholar

Google Scholar

[39] Srikanth K S, Patel S, Steiner S, Vaish R 2018 Scr. Mater. 146 146

Google Scholar

Google Scholar

[40] Chen H, Guo S, Dong X, Cao F, Mao C, Wang G 2017 J. Alloys Compd. 695 2723

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 8137

- PDF Downloads: 114

- Cited By: 0

DownLoad:

DownLoad: