-

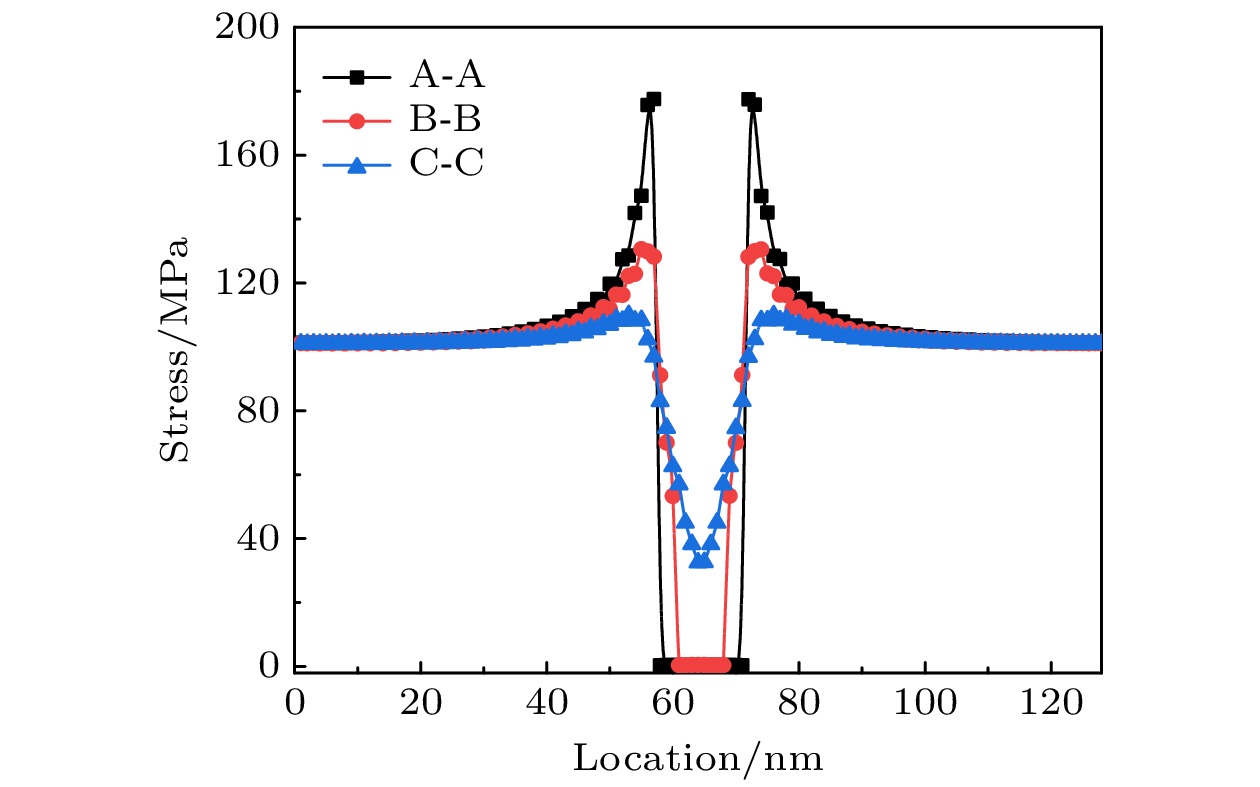

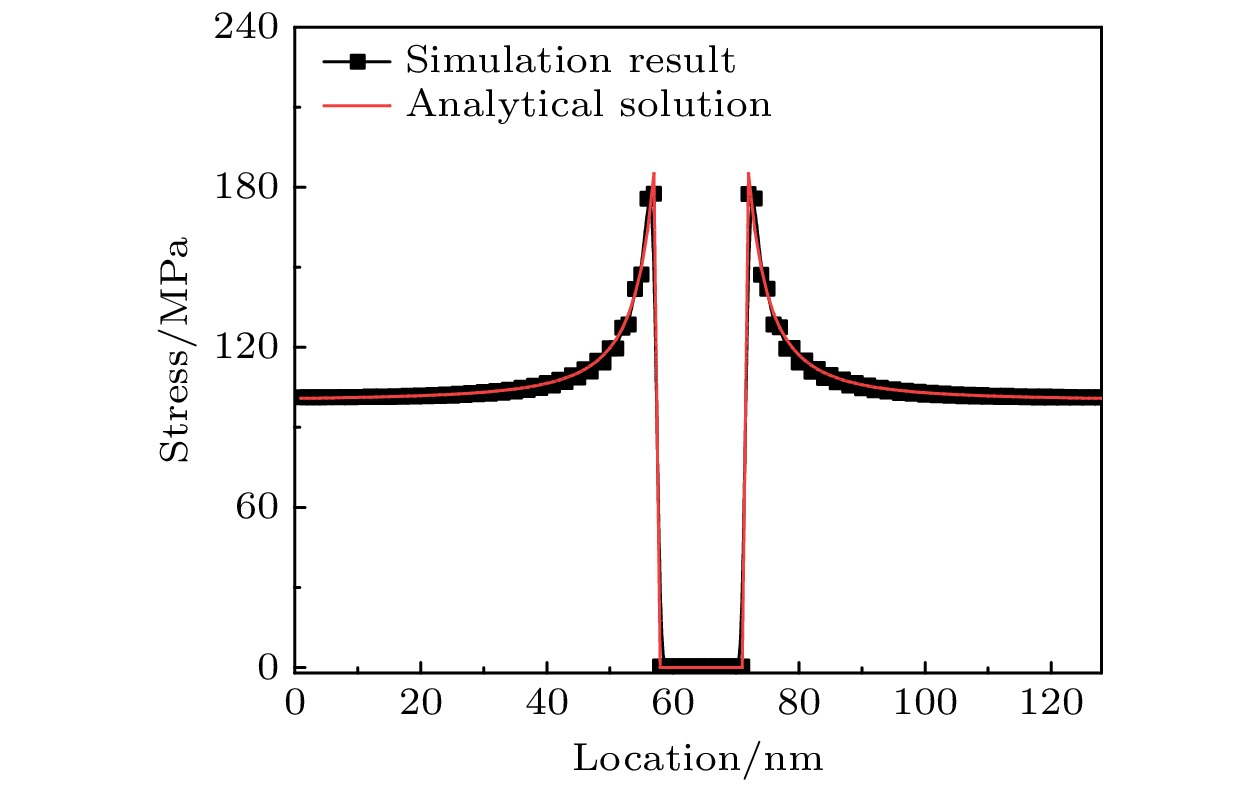

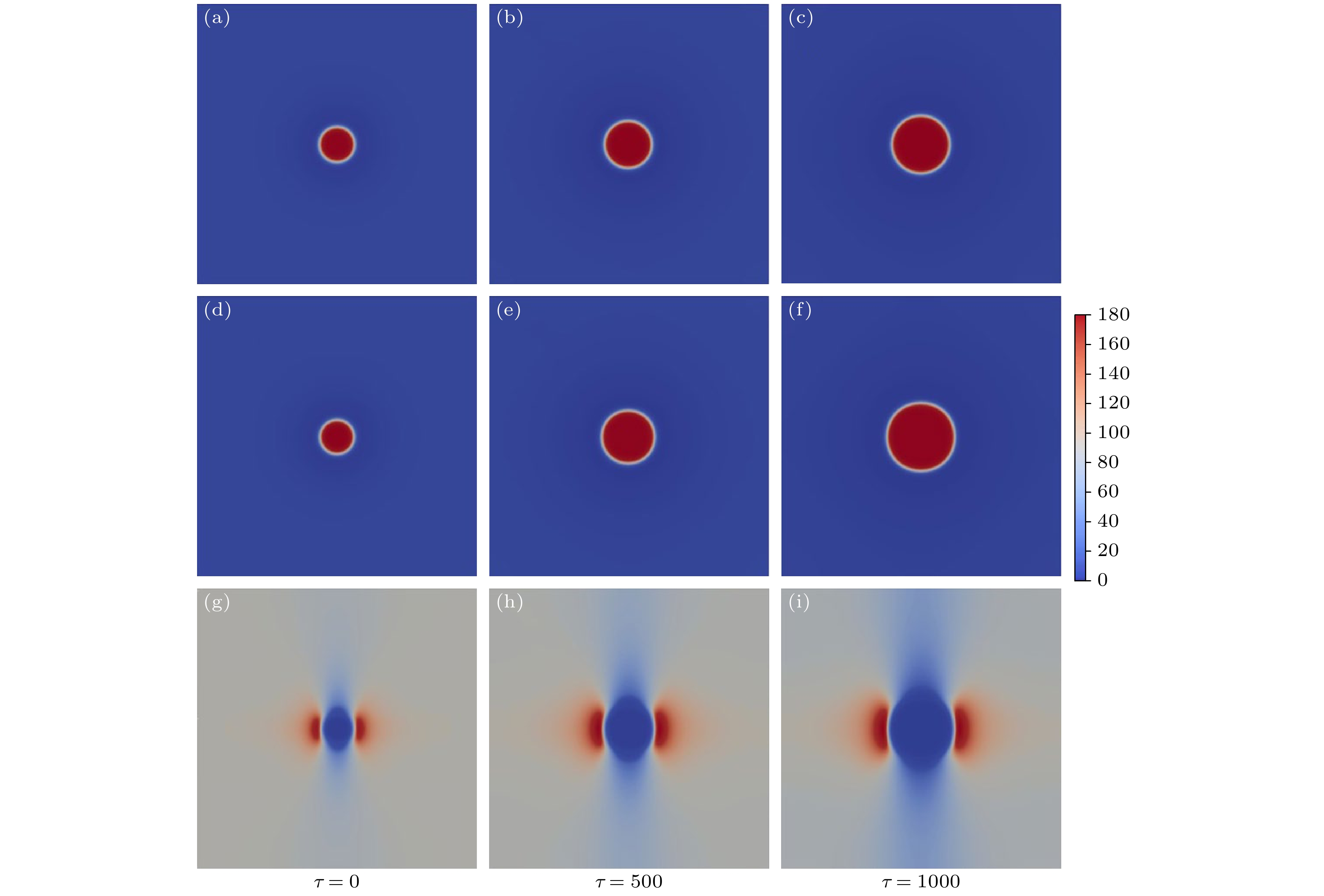

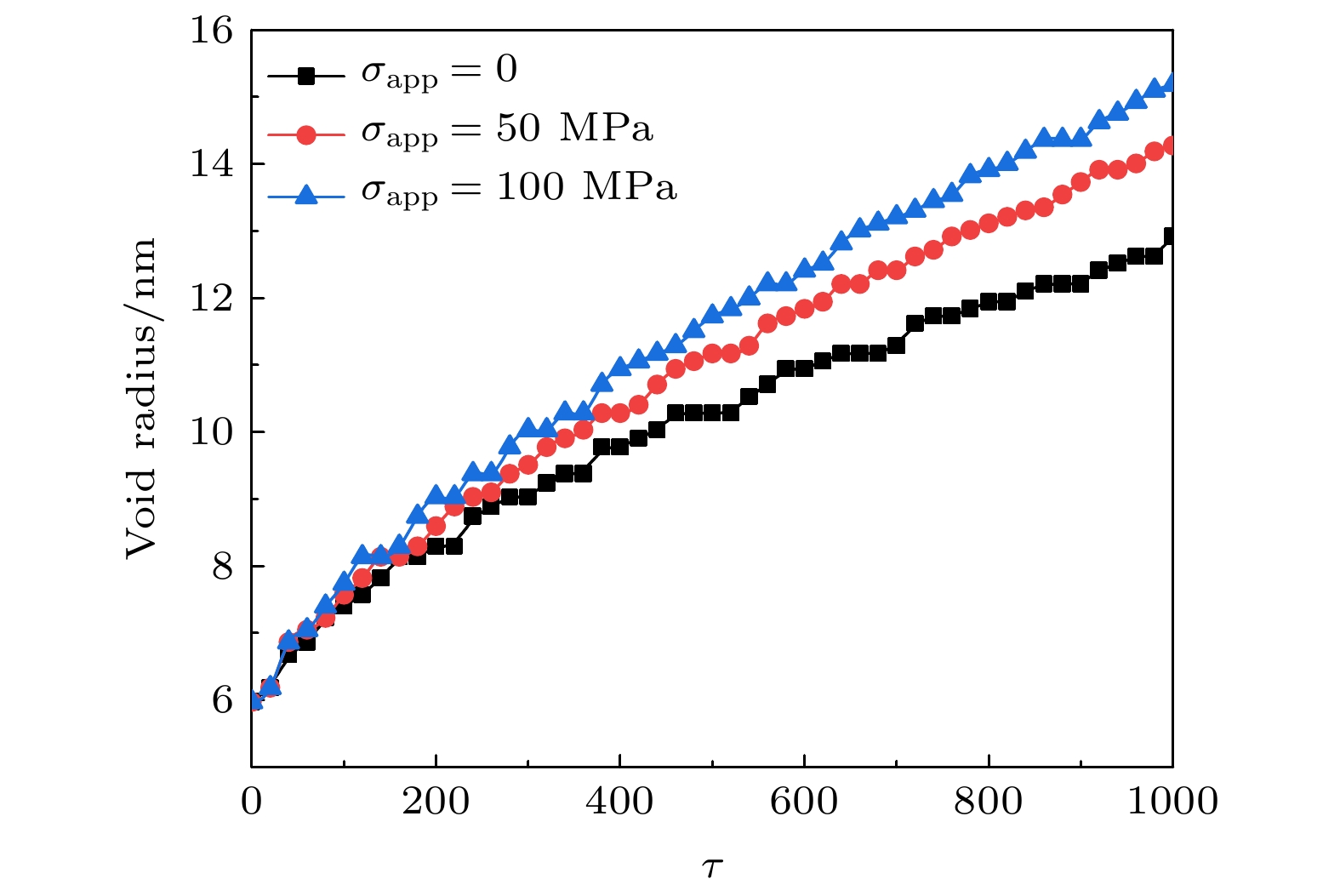

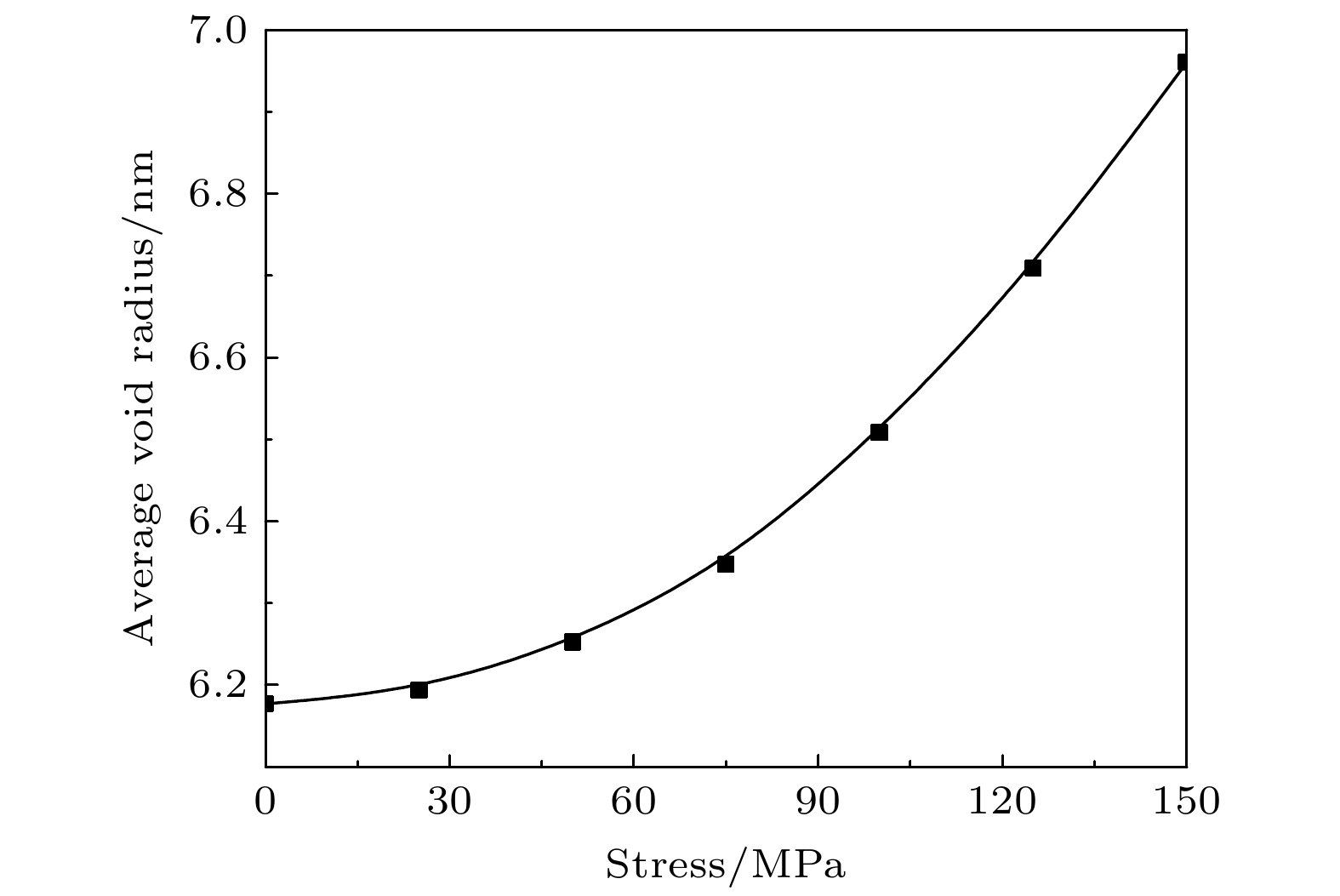

Owing to the migration and aggregation of point defects produced by cascade collision, a large number of cavities form easily during irradiation of the uranium dioxide (UO2) that is an important nuclear fuel. In addition, cavities are also inevitably introduced into the ceramic fuel during sintering. Moreover, the creep strain and thermal strain, caused by the extreme environment of high temperature and strong irradiation, significantly increase the applied stress of nuclear fuel. Therefore, it is crucial to investigate the microstructure evolution of the cavities in UO2 fuel under applied stress. In this work, a phase-field model of void evolution in UO2 under applied stress is established. Firstly, the elastic equilibrium equation is solved by the perturbation-iterative method, and the stress distribution around a single void under applied stress is calculated. The results show that the stress concentration is observed at the edge of the void, and the simulated stress distribution is consistent with the theoretically analytical results. Then, the evolution processes of a single void under different applied stresses are simulated by the phase-field model. The results show that the growth rate of void increases with the augment of applied stress. Finally, the effect of applied stress on grain growth and void evolution in polycrystalline are also studied. The results show that the applied stress will accelerate the void growth. With the increase of the applied stress, the effect of the applied stress on accelerating the void evolution increases.

-

Keywords:

- phase field model /

- void evolution /

- grain growth /

- applied stress

[1] Govers K, Lemehov S, Hou M, Verwerft M 2007 J. Nucl. Mater. 366 161

Google Scholar

Google Scholar

[2] 杨辉, 冯泽华, 王贺然, 张云鹏, 陈铮, 信天缘, 宋小蓉, 吴璐, 张静 2021 70 054601

Google Scholar

Google Scholar

Yang H, Feng Z H, Wang H R, Zhang Y P, Chen Z, Xin T Y, Song X R, Wu L, Zhang J 2021 Acta Phys. Sin. 70 054601

Google Scholar

Google Scholar

[3] 孙正阳, 杨超, 柳文波 2020 金属学报 56 1295

Sun Z Y, Yang C, Liu W B 2020 Acta Metall. Sin. 56 1295

[4] Solomon A A 1973 J. Am. Ceram. Soc. 56 164

Google Scholar

Google Scholar

[5] Brask D N 1979 J. Nucl. Mater. 83 265

Google Scholar

Google Scholar

[6] Porter D L, Takata M L, Wood E L 1983 J. Nucl. Mater. 116 272

Google Scholar

Google Scholar

[7] Sahu H K, Jung P 1985 J. Nucl. Mater. 136 154

Google Scholar

Google Scholar

[8] Brager H R, Garner F A, Guthrie G L 1977 J. Nucl. Mater. 66 301

Google Scholar

Google Scholar

[9] Jiang Y, Liu W, Li W, Sun Z, Xin Y, Chen P, Yun D 2021 Comput. Mater. Sci. 188 110176

Google Scholar

Google Scholar

[10] Millett P C, Rokkam S, El-Azab A, Tonks M, Wolf D 2009 Model. Simul. Mater. Sci. Eng. 17 64003

Google Scholar

Google Scholar

[11] Brailsford A D, Bullough R, Hayns M R 1976 J. Nucl. Mater. 60 246

Google Scholar

Google Scholar

[12] Wiedersich H 1972 Radiat. Eff. Defect. S. 12 111

Google Scholar

Google Scholar

[13] Millett P C, El-Azab A, Rokkam S, Tonks M, Wolf D 2011 Comput. Mater. Sci. 50 949

Google Scholar

Google Scholar

[14] Millett P C, El-Azab A, Wolf D 2011 Comput. Mater. Sci. 50 960

Google Scholar

Google Scholar

[15] Liu W B, Wang N, Ji Y Z, Song P C, Zhang C, Yang Z G, Chen L Q 2016 J. Nucl. Mater. 479 316

Google Scholar

Google Scholar

[16] 杨朝曦, 柳文波, 张璁雨, 贺新福, 孙正阳, 贾丽霞, 师田田, 恽迪 2021 70 116101

Google Scholar

Google Scholar

Yang Z X, Liu W B, Zhang C Y, He X F, Sun Z Y, Jia L X, Shi T T, Yun D 2021 Acta Phys. Sin. 70 116101

Google Scholar

Google Scholar

[17] Hu S Y, Chen L Q 2001 Acta Mater. 49 1879

Google Scholar

Google Scholar

[18] Wang J J, Bhattacharyya S, Li Q, Heo T W, Ma X Q, Chen L 2012 Phil. Mag. Lett. 92 327

[19] Kim D, Kim S G, Kim W T, Cho J, Han H N, Cha P 2011 Scr. Mater. 64 1079

Google Scholar

Google Scholar

[20] Chang K, Lee G, Kwon J 2016 Radiat. Eff. Defect. S. 171 242

Google Scholar

Google Scholar

[21] Salvo M, Sercombe J, Ménard J, Julien J, Helfer T, Désoyer T 2015 J. Nucl. Mater. 456 54

Google Scholar

Google Scholar

[22] Cahn J W, Hilliard J E 1958 J. Chem. Phys. 28 258

Google Scholar

Google Scholar

[23] Tonks M R, Zhang Y, Butterfield A, Bai X 2015 Model. Simul. Mater. Sci. Eng. 23 45009

Google Scholar

Google Scholar

[24] Wang Y U, Jin Y M, Khachaturyan A G 2002 J. Appl. Phys. 92 1351

Google Scholar

Google Scholar

[25] Sheng G, Bhattacharyya S, Zhang H, Chang K, Shang S L, Mathaudhu S N, Liu Z K, Chen L Q 2012 Mater. Sci. Eng. A 554 67

Google Scholar

Google Scholar

[26] Tonks M, Millett P 2011 Mater. Sci. Eng. A 528 4086

Google Scholar

Google Scholar

[27] Yan L L, Liu C Z, Ying Y Z, Zheng C 2014 Chinese Phys. B 23 69102

Google Scholar

Google Scholar

[28] Wang Y U, Jin Y M, Khachaturyan A G 2002 J. Appl. Phys. 91 6435

Google Scholar

Google Scholar

[29] Moelans N, Blanpain B, Wollants P 2008 Calphad 32 268

Google Scholar

Google Scholar

[30] Chen L Q, Shen J 1998 Comput. Phys. Commun. 108 147

Google Scholar

Google Scholar

[31] Kang K H, Ryu H J, Song K C, Yang M S 2002 J. Nucl. Mater. 301 242

Google Scholar

Google Scholar

[32] Aagesen L K, Schwen D, Tonks M R, Zhang Y 2019 Comput. Mater. Sci. 161 35

Google Scholar

Google Scholar

[33] Kinoshita M 1997 J. Nucl. Mater. 248 185

Google Scholar

Google Scholar

[34] Freyss M, Petit T, Crocombette J 2005 J. Nucl. Mater. 347 44

Google Scholar

Google Scholar

[35] Xiao H, Long C, Chen H, Tian X, Wei T, Zhao Y, Gao W 2015 Appl. Surf. Sci. 351 517

Google Scholar

Google Scholar

[36] Chen T, Chen D, Sencer B H, Shao L 2014 J. Nucl. Mater. 452 364

Google Scholar

Google Scholar

[37] Fritz I J 1976 J. Appl. Phys. 47 4353

Google Scholar

Google Scholar

[38] Jin Y M, Wang Y U, Khachaturyan A G 2003 Philos. Mag. 83 1587

Google Scholar

Google Scholar

[39] 徐芝纶 1982 弹性力学(上卷) (北京: 高等教育出版社) 第89页

Xu Z L 1982 Elasticity (Vol. 1) (Beijing: Higher Education Press) p89 (in Chinese)

[40] Wang H, Biswas S, Han Y, Tomar V 2018 Comput. Mater. Sci. 150 169

Google Scholar

Google Scholar

[41] Heo T W, Bhattacharyya S, Chen L 2013 Philos. Mag. 93 1468

Google Scholar

Google Scholar

[42] Aagesen L K, Gao Y, Schwen D, Ahmed K 2018 Phys. Rev. E 98 23309

Google Scholar

Google Scholar

[43] 孙正阳, 王昱天, 柳文波 2020 金属学报 56 1643

Google Scholar

Google Scholar

Sun Z Y, Wang L T, Liu W B 2020 Acta Metall. Sin. 56 1643

Google Scholar

Google Scholar

[44] Liu W B, Ji Y Z, Tan P K, Zang H, He C H, Yun D, Zhang C, Yang Z G 2016 Materials 9 105

Google Scholar

Google Scholar

-

表 1 模拟中使用的UO2参数

Table 1. Parameters of UO2 used in the simulation

参量 符号 取值 参考文献 绝对温度 T 1173 K 玻尔兹曼常数 kB 1.381 × 10–23 J/K 晶格常数 a 0.552 nm [31] 迁移率 L 1.56 × 10–11 m3/(J·s) [32] 梯度自由能参数 κ 3.38 × 10–8 J/m [32] 空位扩散系数 $ {D_{\text{v}}} $ 5.586 × 10–18 m2/s [33] 空位形成能 $ E_{\text{v}}^{\text{f}} $ 5.10 eV [34] 表面能 ${\gamma _{\text{s}}}$ 1.76 eV [35] 晶界能 ${\gamma _{{\text{GB}}}}$ 1.67 eV [36] 弹性模量 C11 389.3 GPa [37] C12 118.7 GPa [37] C44 59.7 GPa [37] -

[1] Govers K, Lemehov S, Hou M, Verwerft M 2007 J. Nucl. Mater. 366 161

Google Scholar

Google Scholar

[2] 杨辉, 冯泽华, 王贺然, 张云鹏, 陈铮, 信天缘, 宋小蓉, 吴璐, 张静 2021 70 054601

Google Scholar

Google Scholar

Yang H, Feng Z H, Wang H R, Zhang Y P, Chen Z, Xin T Y, Song X R, Wu L, Zhang J 2021 Acta Phys. Sin. 70 054601

Google Scholar

Google Scholar

[3] 孙正阳, 杨超, 柳文波 2020 金属学报 56 1295

Sun Z Y, Yang C, Liu W B 2020 Acta Metall. Sin. 56 1295

[4] Solomon A A 1973 J. Am. Ceram. Soc. 56 164

Google Scholar

Google Scholar

[5] Brask D N 1979 J. Nucl. Mater. 83 265

Google Scholar

Google Scholar

[6] Porter D L, Takata M L, Wood E L 1983 J. Nucl. Mater. 116 272

Google Scholar

Google Scholar

[7] Sahu H K, Jung P 1985 J. Nucl. Mater. 136 154

Google Scholar

Google Scholar

[8] Brager H R, Garner F A, Guthrie G L 1977 J. Nucl. Mater. 66 301

Google Scholar

Google Scholar

[9] Jiang Y, Liu W, Li W, Sun Z, Xin Y, Chen P, Yun D 2021 Comput. Mater. Sci. 188 110176

Google Scholar

Google Scholar

[10] Millett P C, Rokkam S, El-Azab A, Tonks M, Wolf D 2009 Model. Simul. Mater. Sci. Eng. 17 64003

Google Scholar

Google Scholar

[11] Brailsford A D, Bullough R, Hayns M R 1976 J. Nucl. Mater. 60 246

Google Scholar

Google Scholar

[12] Wiedersich H 1972 Radiat. Eff. Defect. S. 12 111

Google Scholar

Google Scholar

[13] Millett P C, El-Azab A, Rokkam S, Tonks M, Wolf D 2011 Comput. Mater. Sci. 50 949

Google Scholar

Google Scholar

[14] Millett P C, El-Azab A, Wolf D 2011 Comput. Mater. Sci. 50 960

Google Scholar

Google Scholar

[15] Liu W B, Wang N, Ji Y Z, Song P C, Zhang C, Yang Z G, Chen L Q 2016 J. Nucl. Mater. 479 316

Google Scholar

Google Scholar

[16] 杨朝曦, 柳文波, 张璁雨, 贺新福, 孙正阳, 贾丽霞, 师田田, 恽迪 2021 70 116101

Google Scholar

Google Scholar

Yang Z X, Liu W B, Zhang C Y, He X F, Sun Z Y, Jia L X, Shi T T, Yun D 2021 Acta Phys. Sin. 70 116101

Google Scholar

Google Scholar

[17] Hu S Y, Chen L Q 2001 Acta Mater. 49 1879

Google Scholar

Google Scholar

[18] Wang J J, Bhattacharyya S, Li Q, Heo T W, Ma X Q, Chen L 2012 Phil. Mag. Lett. 92 327

[19] Kim D, Kim S G, Kim W T, Cho J, Han H N, Cha P 2011 Scr. Mater. 64 1079

Google Scholar

Google Scholar

[20] Chang K, Lee G, Kwon J 2016 Radiat. Eff. Defect. S. 171 242

Google Scholar

Google Scholar

[21] Salvo M, Sercombe J, Ménard J, Julien J, Helfer T, Désoyer T 2015 J. Nucl. Mater. 456 54

Google Scholar

Google Scholar

[22] Cahn J W, Hilliard J E 1958 J. Chem. Phys. 28 258

Google Scholar

Google Scholar

[23] Tonks M R, Zhang Y, Butterfield A, Bai X 2015 Model. Simul. Mater. Sci. Eng. 23 45009

Google Scholar

Google Scholar

[24] Wang Y U, Jin Y M, Khachaturyan A G 2002 J. Appl. Phys. 92 1351

Google Scholar

Google Scholar

[25] Sheng G, Bhattacharyya S, Zhang H, Chang K, Shang S L, Mathaudhu S N, Liu Z K, Chen L Q 2012 Mater. Sci. Eng. A 554 67

Google Scholar

Google Scholar

[26] Tonks M, Millett P 2011 Mater. Sci. Eng. A 528 4086

Google Scholar

Google Scholar

[27] Yan L L, Liu C Z, Ying Y Z, Zheng C 2014 Chinese Phys. B 23 69102

Google Scholar

Google Scholar

[28] Wang Y U, Jin Y M, Khachaturyan A G 2002 J. Appl. Phys. 91 6435

Google Scholar

Google Scholar

[29] Moelans N, Blanpain B, Wollants P 2008 Calphad 32 268

Google Scholar

Google Scholar

[30] Chen L Q, Shen J 1998 Comput. Phys. Commun. 108 147

Google Scholar

Google Scholar

[31] Kang K H, Ryu H J, Song K C, Yang M S 2002 J. Nucl. Mater. 301 242

Google Scholar

Google Scholar

[32] Aagesen L K, Schwen D, Tonks M R, Zhang Y 2019 Comput. Mater. Sci. 161 35

Google Scholar

Google Scholar

[33] Kinoshita M 1997 J. Nucl. Mater. 248 185

Google Scholar

Google Scholar

[34] Freyss M, Petit T, Crocombette J 2005 J. Nucl. Mater. 347 44

Google Scholar

Google Scholar

[35] Xiao H, Long C, Chen H, Tian X, Wei T, Zhao Y, Gao W 2015 Appl. Surf. Sci. 351 517

Google Scholar

Google Scholar

[36] Chen T, Chen D, Sencer B H, Shao L 2014 J. Nucl. Mater. 452 364

Google Scholar

Google Scholar

[37] Fritz I J 1976 J. Appl. Phys. 47 4353

Google Scholar

Google Scholar

[38] Jin Y M, Wang Y U, Khachaturyan A G 2003 Philos. Mag. 83 1587

Google Scholar

Google Scholar

[39] 徐芝纶 1982 弹性力学(上卷) (北京: 高等教育出版社) 第89页

Xu Z L 1982 Elasticity (Vol. 1) (Beijing: Higher Education Press) p89 (in Chinese)

[40] Wang H, Biswas S, Han Y, Tomar V 2018 Comput. Mater. Sci. 150 169

Google Scholar

Google Scholar

[41] Heo T W, Bhattacharyya S, Chen L 2013 Philos. Mag. 93 1468

Google Scholar

Google Scholar

[42] Aagesen L K, Gao Y, Schwen D, Ahmed K 2018 Phys. Rev. E 98 23309

Google Scholar

Google Scholar

[43] 孙正阳, 王昱天, 柳文波 2020 金属学报 56 1643

Google Scholar

Google Scholar

Sun Z Y, Wang L T, Liu W B 2020 Acta Metall. Sin. 56 1643

Google Scholar

Google Scholar

[44] Liu W B, Ji Y Z, Tan P K, Zang H, He C H, Yun D, Zhang C, Yang Z G 2016 Materials 9 105

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7462

- PDF Downloads: 123

- Cited By: 0

DownLoad:

DownLoad: