-

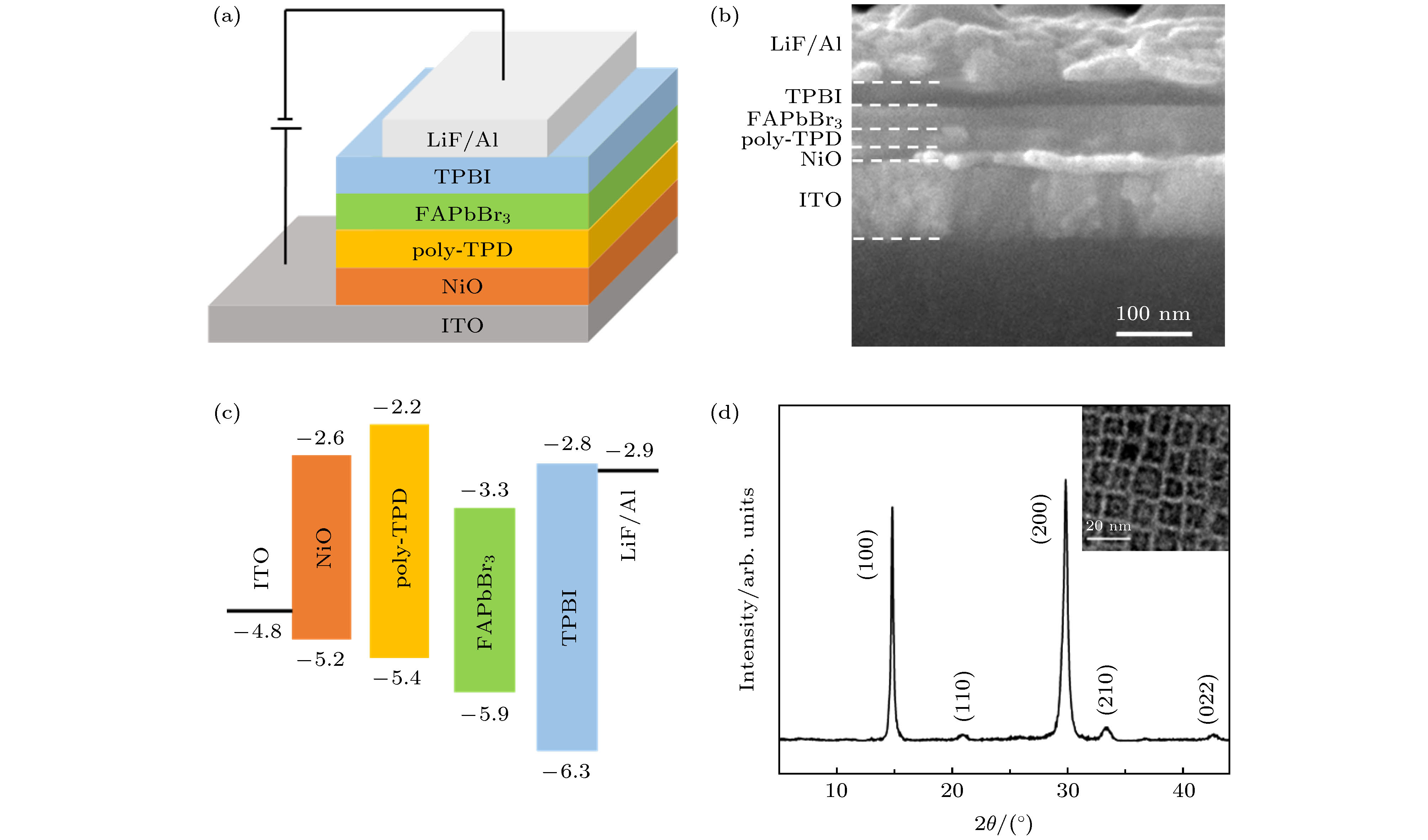

Formamidinium lead bromide (FAPbBr3) perovskite nanocrystals (NCs) have attracted great attention due to their remarkable performances of low cost, high color purity and tunable band gap. However, in a typical FAPbBr3 perovskite light-emitting diode(LED), PEDOT:PSS, with hygroscopic and acidic nature, serves as a hole injection layer (HIL), thus leading to the device stability to decrease seriously. Device stability is one critical issue that needs improving for future applications. Here in this study, the nickel oxide (NiO) film prepared by the solution method is adopted as the HIL of the FAPbBr3 perovskite LED to substitute detrimental PEDOT:PSS. Compared with the control device with PEDOT:PSS HIL, the resulting LED based on NiO film has the operating lifetime twice as great as that based on the PEDOT:PSS film. For further enhancing the performance of FAPbBr3 LED, two metal dopants (Cs and Li) are introduced to improve the hole injection capability of NiO film and the charge carriers’ balance of device. With Hall measurements, both NiO and Cs/Li-doped NiO demonstrate a full p-type semiconductor characteristic. Increasing the doping concentration in the film can increase the carrier concentration and reduce the carrier mobility. This decreased carrier mobility results from the increased scattering due to grain boundaries and impurity phases, seriously at high Cs/Li concentration. As a result, the device, based on the NiO film (doping 2 mol% Cs) shows the best performance with a maximum brightness value of 2970 cd/m2, current efficiency of 43 cd/A and external quantum efficiency (EQE) of 11.0%, thus its efficiency is increased nearly by twice compared with that of the PEDOT:PSS-based device. The results pave the way for making highly efficient and stability perovskite LEDs based on FAPbBr3 NCs.

-

Keywords:

- formamidinium lead bromide perovskite nanocrystals /

- nickel oxide /

- metal dopants /

- light emitting diodes

[1] Cho H, Jeong S H, Park M H, Kim Y H, Wolf C, Lee C L, Heo J H, Sadhanala A, Myoung N, Yoo S, Im S H, Friend R H, Lee T W 2015 Science 350 1222

Google Scholar

Google Scholar

[2] Tan Z K, Moghaddam R S, Lai M L, Docampo P, Higler R, Deschler F, Price M, Sadhanala A, Pazos L M, Credgington D, Hanusch F, Bein T, Snaith H J, Friend R H 2014 Nat. Nanotechnol. 9 687

Google Scholar

Google Scholar

[3] Yuan M, Quan L N, Comin R, Walters G, Sabatini R, Voznyy O, Hoogland S, Zhao Y, Beauregard E M, Kanjanaboos P, Lu Z, Kim D H, Sargent E H 2016 Nat. Nanotechnol. 11 872

Google Scholar

Google Scholar

[4] Xiao Z, Kerner R A, Zhao L, Tran N L, Lee K M, Koh T W, Scholes G D, Rand B P 2017 Nat. Photonics 11 108

Google Scholar

Google Scholar

[5] Kim Y H, Cho H, Heo J H, Kim T S, Myoung N, Lee C L, Im S H, Lee T W 2015 Adv. Mater. 27 1248

Google Scholar

Google Scholar

[6] Byun J, Cho H, Wolf C, Jang M, Sadhanala A, Friend R H, Yang H, Lee T W 2016 Adv. Mater. 28 7515

Google Scholar

Google Scholar

[7] Fu Y, Zhu H, Schrader A W, Liang D, Ding Q, Joshi P, Hwang L, Zhu X Y, Jin S 2016 Nano Lett. 16 1000

Google Scholar

Google Scholar

[8] Manser J S, Christians J A, Kamat P V 2016 Chem. Rev. 116 12956

Google Scholar

Google Scholar

[9] Protesescu L, Yakunin S, Bodnarchuk M I, Bertolotti F, Masciocchi N, Guagliardi A, Kovalenko M V 2016 J. Am. Chem. Soc. 138 14202

Google Scholar

Google Scholar

[10] Song J, Hu W, Wang X F, Chen G, Tian W, Miyasaka T J 2016 Mater. Chem. A 4 8435

Google Scholar

Google Scholar

[11] Smecca E, Numata Y, Deretzis I, Pellegrino G, Boninelli S, Miyasaka T, LaMagna A, Alberti A 2016 Phys. Chem. Chem. Phys. 18 13413

Google Scholar

Google Scholar

[12] Perumal A, Shendre S, Li M, Tay Y K E, Sharma V K, Chen S, Wei Z, Liu Q, Gao Y, Buenconsejo P J S, Tan S T, Gan C L, Xiong Q, Sum T C, Demir H V 2016 Sci. Rep. 6 36733

Google Scholar

Google Scholar

[13] Kim Y H, Lee G H, Kim Y T, Wolf C, Yun H J, Kwon W, Park C G, Lee T W 2017 Nano Energy 38 51

Google Scholar

Google Scholar

[14] Cui J, Meng F P, Zhang H, Cao K, Yuan H, Cheng Y, Huang F, Wang M K 2014 ACS Appl. Mater. Interfaces 6 22862

Google Scholar

Google Scholar

[15] Cao F, Wang H, Shen P, Li X, Zheng Y, Shang Y Q, Zhang J H, Ning Z, Yang X 2017 Adv. Funct. Mater. 27 1704278

Google Scholar

Google Scholar

[16] Chih Y, Wang J, Yang R, Liu C, Chang Y, Fu Y, Lai W, Chen P, Wen T, Huang Y, Tsao C, Guo T 2016 Adv. Mater. 28 8687

Google Scholar

Google Scholar

[17] Wang Z, Luo Z, Zhao C, Guo Q, Wang Y, Wang F, Bian X, Alsaedi A, Hayat T, Tan Z 2017 J. Phys. Chem. C 121 28132

Google Scholar

Google Scholar

[18] Lee S, Kim D B, Hamilton L, Daboczi M, Nam Y S, Lee B R, Zhao B, Jang C H, Friend R, Kim J, Song M H 2018 Adv. Sci. 5 1801350

Google Scholar

Google Scholar

[19] Wang H, Zhang X, Wu Q, Cao F, Yang D, Shang Y, Ning Z, Zhang W, Zheng W, Yan Y, Kershaw S V, Zhang L, Rogach A L, Yang X 2019 Nat. Commun. 10 665

Google Scholar

Google Scholar

[20] Wang H, Li X, Yuan M, Yang X 2018 Small 14 1703410

Google Scholar

Google Scholar

[21] Levchun L, OsvetA, Tang X F 2017 Nano Lett. 17 2765

[22] Empedocles S A, Bawendi M G 1997 Science 278 2114

Google Scholar

Google Scholar

[23] Mashford B S, Stevenson M, Popvic Z, Hamilton C, Zhou Z, Breen C, Steckel J, Bulovic V, Bawendi M, Coe-Sullivan S, Kazlas P T 2013 Nat. Photonics 7 407

Google Scholar

Google Scholar

[24] Park S Y, Kim H R, Kang Y J, Kim D H, Kang J W 2010 Sol. Energy Mater. Sol. Cells 94 2332

Google Scholar

Google Scholar

[25] Yang Y X, Zheng Y, Cao W R, Titov A, Hyvonen J, Manders J R, Xue J G, Holloway P H, Qian L 2015 Nat. Photonics 9 259

Google Scholar

Google Scholar

[26] Dai X, Zhang Z, Jin Y, Niu Y, Cao H, Liang X, Chen L, Wang J, Peng X 2014 Nature 515 96

Google Scholar

Google Scholar

[27] Kim H P, Kim J, Kim B S, Kim H M, Kim J, Yusoff A R B M, Jang J, Nazeeruddin M K 2017 Adv. Opt. Mater. 5 1600920

Google Scholar

Google Scholar

[28] Fu F, Feurer T, Weiss T P, Pisoni S, Avancini E, Andres C, Buecheler S, Tiwari A N 2016 Nat. Energy 2 16190

[29] Shi Z, Li Y, Zhang Y, Chen Y, Li X, Wu D, Xu T, Shan C, Du G 2017 Nano Lett. 17 313

Google Scholar

Google Scholar

[30] Shi Z, Li S, Li Y, Ji H, Li X, Wu D, Xu T, Chen Y, Tian Y, Zhang Y, Shan C, Du G 2018 ACS Nano 12 1462

Google Scholar

Google Scholar

[31] Alidoust N, Carter E A 2015 Phys. Chem. Chem. Phys. 17 18098

Google Scholar

Google Scholar

[32] Kim J H, Liang P W, Williams S T, Cho N, Chueh C C, Glaz M S, Ginger D S, Jen A K Y 2015 Adv. Mater. 27 695

Google Scholar

Google Scholar

[33] Zhang J, Cai G, Zhou D, Tang H, Wang X, Gu C, Tu J 2014 J. Mater. Chem. C 2 7013

Google Scholar

Google Scholar

[34] Popescu I, Skoufa Z, Heracleous E, Lemonidou A, Marcu I C 2015 Phys. Chem. Chem. Phys. 17 8138

Google Scholar

Google Scholar

[35] Muthukumaran P, Raju C V, Sumathi C, Ravi G, Solairaj D, Rameshthangam P, Wilson J, Rajendrane S, Alwarappan S 2016 New J. Chem. 40 2741

Google Scholar

Google Scholar

[36] Chen S C, Kuo T Y, Lin Y C, Lin H C 2011 Thin Solid Films 519 4944

Google Scholar

Google Scholar

[37] Hwang J D, Ho T H 2017 Mater. Sci. Semicond. Process. 71 396

Google Scholar

Google Scholar

[38] Chen W, Wu Y, Fan J, Djurišic A B, Liu F, Tam H W, Ng A, Surya C, Chan W K, Wang D, He Z B 2018 Adv. Energy Mater. 8 1703519

Google Scholar

Google Scholar

-

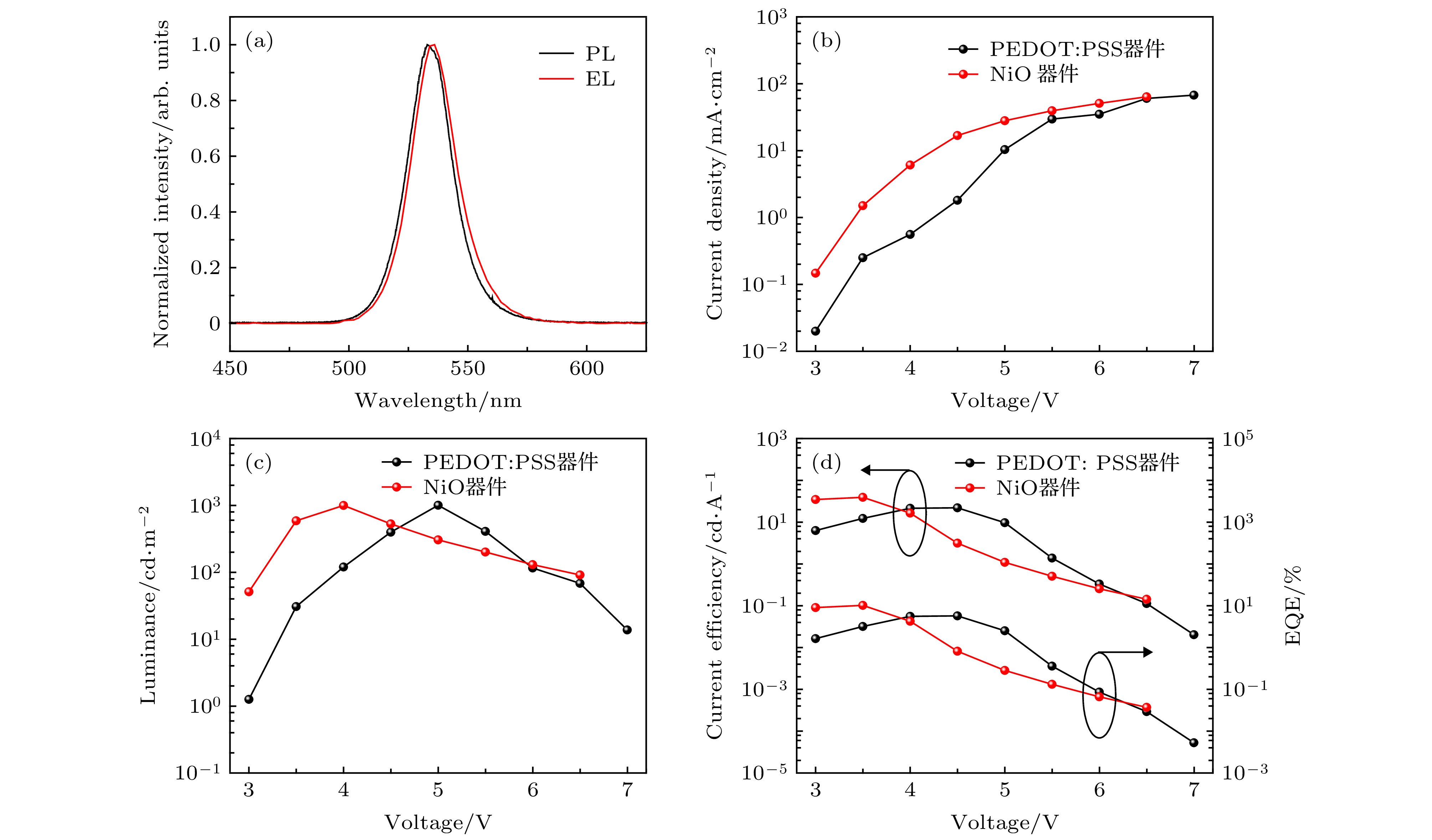

图 2 (a) 器件的归一化电致发光和光致发光光谱; PEDOT:PSS和NiO空穴注入层器件的(b) 电流密度-电压曲线, (c) 亮度-电压曲线和(d)电流密度-外量子效率-电压特性

Figure 2. (a) Normalized electroluminescence and photoluminescence spectra of the device; (b) J-V characteristics, (c) L-V characteristics, and (d) CE-EQE-V characteristics of the PEDOT:PSS- and NiO-based device.

图 4 掺杂不同浓度(2, 4, 6 mol%)Cs的NiO器件的(a) 电流密度-亮度-电压特性和(b)电流效率-外量子效率-电压特性; 掺杂不同浓度(2, 4, 6 mol%)Li的NiO器件的(c) 电流密度-亮度-电压特性和(d)电流效率-外量子效率-电压特性

Figure 4. (a) J-L-V characteristics of the devices with Cs: NiO; (b) CE-EQE-V characteristics of the devices with Cs: NiO; (c) J-L-V characteristics of the devices with Li: NiO; (d) CE-EQE-V characteristics of the devices with Li: NiO at different concentrations (2, 4 and 6 mol%).

表 1 金属掺杂NiO的器件性能

Table 1. The performance of devices with metal-doped NiO.

金属掺

杂浓度Von/V a Lmax/

cd·m–2 bCE/

cd·A–1 cEQE/% d 2 mol% Cs 3 2970 43.0 11.0 4 mol% Cs 3 2610 27.8 7.1 6 mol% Cs 3 2090 8.7 2.2 2 mol% Li 3 2500 32.3 8.3 4 mol% Li 3 3490 41.8 10.7 6 mol% Li 3 2950 16.0 4.1 a开启电压, 亮度为1 cd·m–2 时的电压; b最高的亮度; c最高的电流效率; d最高的外量子效率. 表 2 Cs掺杂NiO薄膜的电学性能

Table 2. Electrical properties of Cs-doped NiO films.

金属掺杂浓度 ρ/Ω·cm a μ/cm2·V–1·s–1 b p/cm–3 c 0 2.6 × 10–1 1.7 2.1 × 1018 2 mol% Cs 1.8 × 10–1 1.5 5.3 × 1018 4 mol% Cs 1.7 × 10–1 0.5 6.0 × 1018 6 mol% Cs 1.4 × 10–1 0.2 7.4 × 1018 2 mol% Li 2.2 × 10–1 1.3 4.6 × 1018 4 mol% Li 1.8 × 10–1 1.1 5.7 × 1018 6 mol% Li 1.5 × 10–1 0.3 6.9 × 1018 a电阻率; b迁移率; c载流子浓度(空穴). -

[1] Cho H, Jeong S H, Park M H, Kim Y H, Wolf C, Lee C L, Heo J H, Sadhanala A, Myoung N, Yoo S, Im S H, Friend R H, Lee T W 2015 Science 350 1222

Google Scholar

Google Scholar

[2] Tan Z K, Moghaddam R S, Lai M L, Docampo P, Higler R, Deschler F, Price M, Sadhanala A, Pazos L M, Credgington D, Hanusch F, Bein T, Snaith H J, Friend R H 2014 Nat. Nanotechnol. 9 687

Google Scholar

Google Scholar

[3] Yuan M, Quan L N, Comin R, Walters G, Sabatini R, Voznyy O, Hoogland S, Zhao Y, Beauregard E M, Kanjanaboos P, Lu Z, Kim D H, Sargent E H 2016 Nat. Nanotechnol. 11 872

Google Scholar

Google Scholar

[4] Xiao Z, Kerner R A, Zhao L, Tran N L, Lee K M, Koh T W, Scholes G D, Rand B P 2017 Nat. Photonics 11 108

Google Scholar

Google Scholar

[5] Kim Y H, Cho H, Heo J H, Kim T S, Myoung N, Lee C L, Im S H, Lee T W 2015 Adv. Mater. 27 1248

Google Scholar

Google Scholar

[6] Byun J, Cho H, Wolf C, Jang M, Sadhanala A, Friend R H, Yang H, Lee T W 2016 Adv. Mater. 28 7515

Google Scholar

Google Scholar

[7] Fu Y, Zhu H, Schrader A W, Liang D, Ding Q, Joshi P, Hwang L, Zhu X Y, Jin S 2016 Nano Lett. 16 1000

Google Scholar

Google Scholar

[8] Manser J S, Christians J A, Kamat P V 2016 Chem. Rev. 116 12956

Google Scholar

Google Scholar

[9] Protesescu L, Yakunin S, Bodnarchuk M I, Bertolotti F, Masciocchi N, Guagliardi A, Kovalenko M V 2016 J. Am. Chem. Soc. 138 14202

Google Scholar

Google Scholar

[10] Song J, Hu W, Wang X F, Chen G, Tian W, Miyasaka T J 2016 Mater. Chem. A 4 8435

Google Scholar

Google Scholar

[11] Smecca E, Numata Y, Deretzis I, Pellegrino G, Boninelli S, Miyasaka T, LaMagna A, Alberti A 2016 Phys. Chem. Chem. Phys. 18 13413

Google Scholar

Google Scholar

[12] Perumal A, Shendre S, Li M, Tay Y K E, Sharma V K, Chen S, Wei Z, Liu Q, Gao Y, Buenconsejo P J S, Tan S T, Gan C L, Xiong Q, Sum T C, Demir H V 2016 Sci. Rep. 6 36733

Google Scholar

Google Scholar

[13] Kim Y H, Lee G H, Kim Y T, Wolf C, Yun H J, Kwon W, Park C G, Lee T W 2017 Nano Energy 38 51

Google Scholar

Google Scholar

[14] Cui J, Meng F P, Zhang H, Cao K, Yuan H, Cheng Y, Huang F, Wang M K 2014 ACS Appl. Mater. Interfaces 6 22862

Google Scholar

Google Scholar

[15] Cao F, Wang H, Shen P, Li X, Zheng Y, Shang Y Q, Zhang J H, Ning Z, Yang X 2017 Adv. Funct. Mater. 27 1704278

Google Scholar

Google Scholar

[16] Chih Y, Wang J, Yang R, Liu C, Chang Y, Fu Y, Lai W, Chen P, Wen T, Huang Y, Tsao C, Guo T 2016 Adv. Mater. 28 8687

Google Scholar

Google Scholar

[17] Wang Z, Luo Z, Zhao C, Guo Q, Wang Y, Wang F, Bian X, Alsaedi A, Hayat T, Tan Z 2017 J. Phys. Chem. C 121 28132

Google Scholar

Google Scholar

[18] Lee S, Kim D B, Hamilton L, Daboczi M, Nam Y S, Lee B R, Zhao B, Jang C H, Friend R, Kim J, Song M H 2018 Adv. Sci. 5 1801350

Google Scholar

Google Scholar

[19] Wang H, Zhang X, Wu Q, Cao F, Yang D, Shang Y, Ning Z, Zhang W, Zheng W, Yan Y, Kershaw S V, Zhang L, Rogach A L, Yang X 2019 Nat. Commun. 10 665

Google Scholar

Google Scholar

[20] Wang H, Li X, Yuan M, Yang X 2018 Small 14 1703410

Google Scholar

Google Scholar

[21] Levchun L, OsvetA, Tang X F 2017 Nano Lett. 17 2765

[22] Empedocles S A, Bawendi M G 1997 Science 278 2114

Google Scholar

Google Scholar

[23] Mashford B S, Stevenson M, Popvic Z, Hamilton C, Zhou Z, Breen C, Steckel J, Bulovic V, Bawendi M, Coe-Sullivan S, Kazlas P T 2013 Nat. Photonics 7 407

Google Scholar

Google Scholar

[24] Park S Y, Kim H R, Kang Y J, Kim D H, Kang J W 2010 Sol. Energy Mater. Sol. Cells 94 2332

Google Scholar

Google Scholar

[25] Yang Y X, Zheng Y, Cao W R, Titov A, Hyvonen J, Manders J R, Xue J G, Holloway P H, Qian L 2015 Nat. Photonics 9 259

Google Scholar

Google Scholar

[26] Dai X, Zhang Z, Jin Y, Niu Y, Cao H, Liang X, Chen L, Wang J, Peng X 2014 Nature 515 96

Google Scholar

Google Scholar

[27] Kim H P, Kim J, Kim B S, Kim H M, Kim J, Yusoff A R B M, Jang J, Nazeeruddin M K 2017 Adv. Opt. Mater. 5 1600920

Google Scholar

Google Scholar

[28] Fu F, Feurer T, Weiss T P, Pisoni S, Avancini E, Andres C, Buecheler S, Tiwari A N 2016 Nat. Energy 2 16190

[29] Shi Z, Li Y, Zhang Y, Chen Y, Li X, Wu D, Xu T, Shan C, Du G 2017 Nano Lett. 17 313

Google Scholar

Google Scholar

[30] Shi Z, Li S, Li Y, Ji H, Li X, Wu D, Xu T, Chen Y, Tian Y, Zhang Y, Shan C, Du G 2018 ACS Nano 12 1462

Google Scholar

Google Scholar

[31] Alidoust N, Carter E A 2015 Phys. Chem. Chem. Phys. 17 18098

Google Scholar

Google Scholar

[32] Kim J H, Liang P W, Williams S T, Cho N, Chueh C C, Glaz M S, Ginger D S, Jen A K Y 2015 Adv. Mater. 27 695

Google Scholar

Google Scholar

[33] Zhang J, Cai G, Zhou D, Tang H, Wang X, Gu C, Tu J 2014 J. Mater. Chem. C 2 7013

Google Scholar

Google Scholar

[34] Popescu I, Skoufa Z, Heracleous E, Lemonidou A, Marcu I C 2015 Phys. Chem. Chem. Phys. 17 8138

Google Scholar

Google Scholar

[35] Muthukumaran P, Raju C V, Sumathi C, Ravi G, Solairaj D, Rameshthangam P, Wilson J, Rajendrane S, Alwarappan S 2016 New J. Chem. 40 2741

Google Scholar

Google Scholar

[36] Chen S C, Kuo T Y, Lin Y C, Lin H C 2011 Thin Solid Films 519 4944

Google Scholar

Google Scholar

[37] Hwang J D, Ho T H 2017 Mater. Sci. Semicond. Process. 71 396

Google Scholar

Google Scholar

[38] Chen W, Wu Y, Fan J, Djurišic A B, Liu F, Tam H W, Ng A, Surya C, Chan W K, Wang D, He Z B 2018 Adv. Energy Mater. 8 1703519

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 16806

- PDF Downloads: 287

- Cited By: 0

DownLoad:

DownLoad: