-

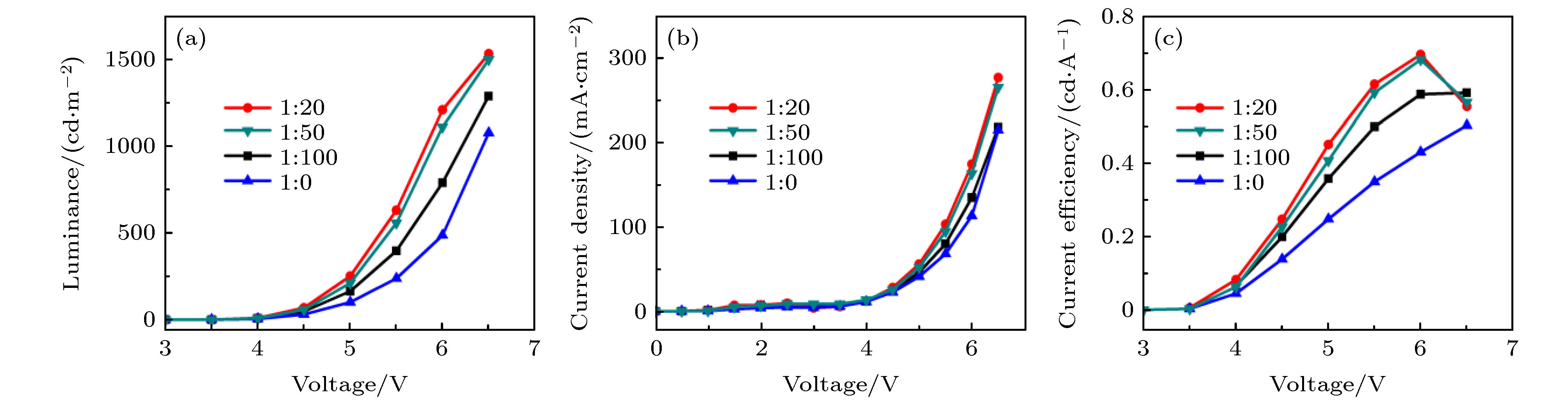

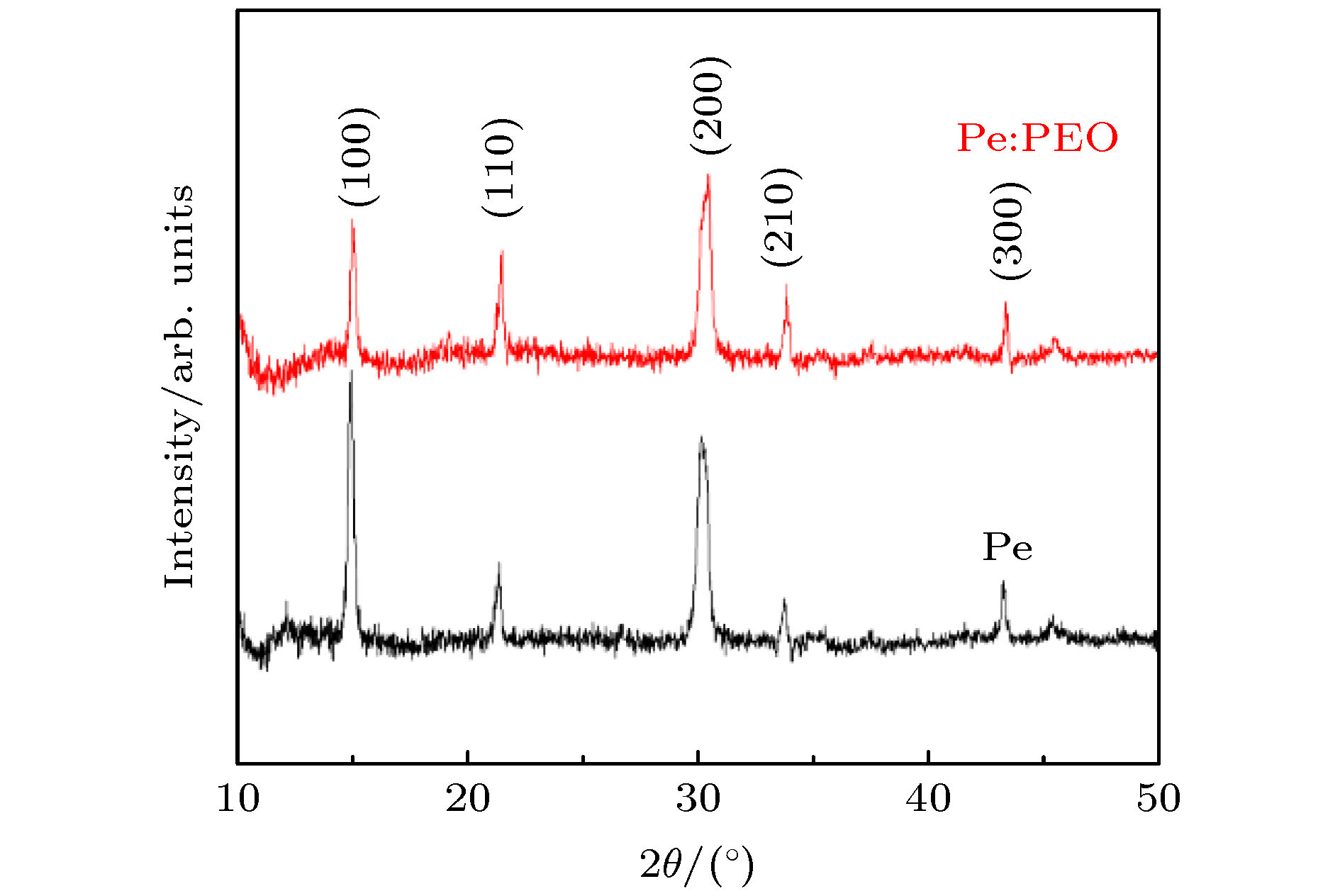

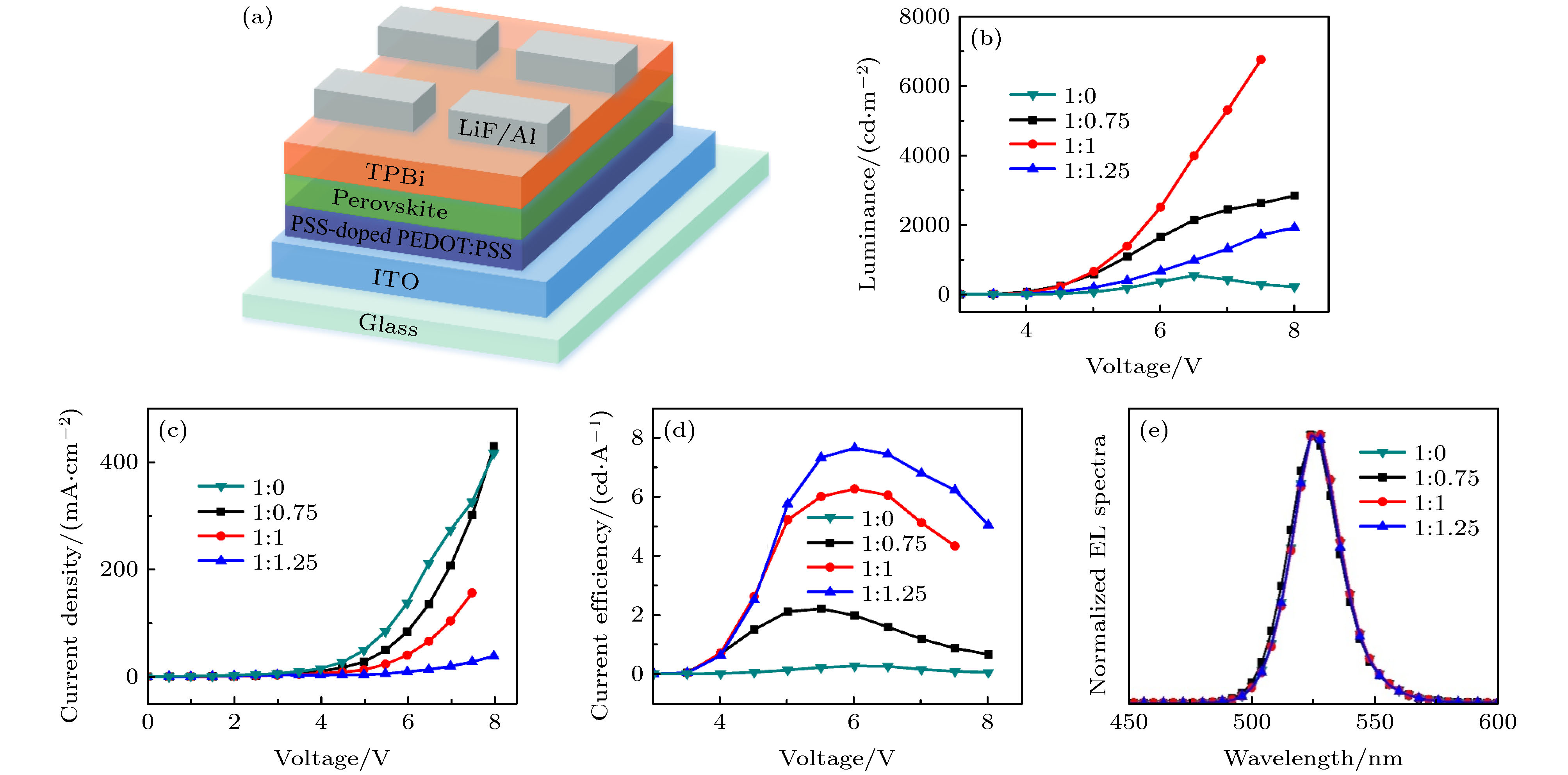

有机金属卤化钙钛矿作为发射体具有极高的色纯度和极低的成本, 但钙钛矿层普遍较差的形貌制约了器件的性能. 引入合适的聚合物可有效改善旋涂型钙钛矿薄膜的均匀性. 本文引入聚(4-苯乙烯磺酸盐) (PSS)改性的聚(3,4-乙撑二氧噻吩):PSS (PEDOT: PSS) 作为空穴注入层(HIL), 结合一步旋涂制备的三溴化铅甲基胺(MAPbBr3)和聚(环氧乙烷)(PEO)复合膜作为发光层, 制备了高效绿光钙钛矿发光二极管. 其中, PSS增加了PEDOT:PSS功函数, 降低了其与钙钛矿发光层间的注入势垒; 而掺杂PEO的钙钛矿膜致密且均匀, 覆盖率可以达到100%. 基于改性的空穴注入层和复合发光层, 我们最终获得了最大亮度为2476 cd·m–2、最大电流效率为7.6 cd·A–1的高效钙钛矿发光二极管.Appreciable progress of organometal halide perovskite materials has been achieved in recent years due to their controllable synthesis and excellent optoelectronic properties. And the potential uses of these perovskites in photovoltaics, light-emitting diodes (LEDs), photodetectors and lasers have been successfully demonstrated. Although organometal halide perovskites appear as emitters with extremely high color purity and low cost, the device performance is significantly limited by poor morphology of the perovskite layer. The addition of the polymer into the perovskite layer is a convenient and effective method to improve the homogeneity of the spin-coated perovskite film. In this work, we fabricate green perovskite light emitting diodes (PeLEDs) with poly(styrenesulfonate) (PSS)-modified poly(3,4-ethylenedioxythiophene):PSS (PEDOT:PSS) as the hole injection layer (HIL) and a single spin coating composite film consisting of methylammonium lead tribromide (MAPbBr3) and poly(ethylene oxide) (PEO) as the emissive layer. The PSS doping increases the work function of PEDOT:PSS and reduces the injection barrier between PEDOT:PSS HIL and MAPbBr3 perovskite, thus balancing the carriers within the PeLEDs. The PEO doping enables the MAPbBr3 to become a dense and uniform perovskite film with a ~100% coverage. With the above approaches, highly efficient PeLEDs with maximum luminance and current efficiency of 2476 cd·m–2 and 7.6 cd·A–1 are eventually acquired. This work provides a method of fabricating the high-coverage and high-efficiency PeLEDs.

-

Keywords:

- perovskite /

- light emitting diode /

- composite film /

- charge injection

[1] Yang W S, Park BW, Jung E H, Jeon N J, Kim Y C, Lee D U, Shin S S, Seo J, Kim E K, Noh J H, Seok S I 2017 Science 356 1376

Google Scholar

Google Scholar

[2] Stranks S D, Snaith H J 2015 Nat. Nanotechnol. 10 391

Google Scholar

Google Scholar

[3] Adjokatse S, Fang H H, Loi M A 2017 Mater. Today 20 413

Google Scholar

Google Scholar

[4] Kim Y H, Cho H, Heo J H, Kim T S, Myoung N S, Lee L C, Im S H, Lee T W 2015 Adv. Mater. 27 1248

Google Scholar

Google Scholar

[5] Yu J C, Kim D W, Kim D B, Jung E D, Park J H, Lee A Y, Lee B R, Nuzzo D D, Friend R H, Song M H 2016 Adv. Mater. 28 6906

Google Scholar

Google Scholar

[6] Huang C F, Keshtov M L, Chen F C 2016 ACS Appl. Mater. Interfaces 8 27006

Google Scholar

Google Scholar

[7] Era M, Morimoto S, Tsutsui T, Saito S 1994 Appl. Phys. Lett. 65 676

Google Scholar

Google Scholar

[8] Tan Z K, Moghaddam R S, Lai M L, Docampo P, Higler R, Deschler F, Price M, Sadhanala A, Pazos L M, Credgington D, Hanusch F, Bein T, Snaith H J, Friend R H 2014 Nat. Nanotechnol. 9 687

Google Scholar

Google Scholar

[9] Sessolo M, Gil E L, Longo G, Bolink H J 2016 Top. Curr. Chem. 374 1

Google Scholar

Google Scholar

[10] Naphade R, Zhao B, Richter J M, Booker E, Krishnamurthy S, Friend I H, Sadhanala A, Ogale S 2017 Adv. Mater. Interfaces. 4 1700562

Google Scholar

Google Scholar

[11] Zhang X L, Wang W G, Xu B, Liu S, Dai H T, Bian D, Chen S M, Wang K, Sun X W 2017 Nano Energy 37 40

Google Scholar

Google Scholar

[12] Yu J C, Kim D B, Jung E D, Lee B R, Song M H 2016 Nanoscale 8 7036

Google Scholar

Google Scholar

[13] Wang Z, Cheng T, Wang F, Dai S, Tan Z 2016 Small 12 4412

Google Scholar

Google Scholar

[14] Yantara N, Bhaumik S, Yan F, Sabba D, Dewi H A, Mathews N A, Boix P P, Demir H V, Mhaisalkar S 2015 J. Phys. Chem. Lett. 6 4360

Google Scholar

Google Scholar

[15] Li G, Tan Z K, Di D, Lai M L, Jiang L, Lim J H, Friend R H, Greenham N C 2015 Nano Lett. 15 2640

Google Scholar

Google Scholar

[16] Ji X, Peng X, Lei Y, Liu Z, Yang X 2017 Org. Electron. 43 167

Google Scholar

Google Scholar

[17] Chen P, Xiong Z, Wu X, Shao M, Ma X, Xiong ZH, Gao C 2017 J. Phys. Chem. Lett. 8 1810

Google Scholar

Google Scholar

[18] Cho H, Jeong S H, Park M H, Kim Y H, Wolf C, Lee C L, Heo J H, Sadhanala A, Myoung N, Yoo S, Im S H, Friend R H, Lee T W 2015 Science 350 1222

Google Scholar

Google Scholar

[19] Masi S, Rizzo A, Aiello F, Balzano F, Uccello-Barretta G, Listorti A, Gigli G, Colella S 2015 Nanoscale 7 18956

Google Scholar

Google Scholar

[20] Ng Y F, Kulkarni S A, Parida S, Jamaludin N F, Yantara N, Bruno A, Soci C, Mhaisalkar S, Mathews N 2017 Chem. Commun. 53 12004

Google Scholar

Google Scholar

[21] Peng X F, Wu X Y, Ji X X, Ren J, Wang Q, Li G Q, Yang X H 2017 J. Phys. Chem. Lett. 8 4691

Google Scholar

Google Scholar

[22] Groenendaal L, Jonas F, Freitag D, Pielartzik H, Reynolds J R 2000 Adv. Mater. 12 481

Google Scholar

Google Scholar

[23] Chan W C, Maxwel D J, Gao X, Bailey R E, Han M, Nie S 2002 Curr. Opin. Biotechnol. 13 1340

[24] Vengrenovich R D, Gudyma Y V, Yarema S V 2001 Semiconductors 35 1378

Google Scholar

Google Scholar

[25] Noh J H, Im S H, Heo J H, Mandal T N, Seok S I 2013 Nano Lett. 13 1764

Google Scholar

Google Scholar

[26] Zhang X Y, Lin H, Huang H, Reckmeier C, Zhang Y, Choy W C H, Rogach A L 2016 Nano Lett. 16 1415

Google Scholar

Google Scholar

[27] Yu H T, Lu Y, Feng Z Q, Wu Y N, Liu Z W, Xia P F, Qian J, Chen Y F, Liu L H, Cao K, Chen S F, Huang W 2019 Nanoscale 11 9103

Google Scholar

Google Scholar

-

图 6 (a) 使用了MAPbBr3:PEO的器件结构示意图; 不同MAPbBr3:PEO体积比钙钛矿所制备出发光器件的(b)亮度-电压, (c)电流密度-电压, (d)电流效率-电压和(e)电致发光光谱曲线

Fig. 6. (a) PeLED structure using MAPbBr3:PEO, and the (b) luminance, (c) current density-voltage, (d) current efficiency-voltage and (e) electroluminant curves of PeLEDs with varying volume ratio of MAPbBr3:PEO.

-

[1] Yang W S, Park BW, Jung E H, Jeon N J, Kim Y C, Lee D U, Shin S S, Seo J, Kim E K, Noh J H, Seok S I 2017 Science 356 1376

Google Scholar

Google Scholar

[2] Stranks S D, Snaith H J 2015 Nat. Nanotechnol. 10 391

Google Scholar

Google Scholar

[3] Adjokatse S, Fang H H, Loi M A 2017 Mater. Today 20 413

Google Scholar

Google Scholar

[4] Kim Y H, Cho H, Heo J H, Kim T S, Myoung N S, Lee L C, Im S H, Lee T W 2015 Adv. Mater. 27 1248

Google Scholar

Google Scholar

[5] Yu J C, Kim D W, Kim D B, Jung E D, Park J H, Lee A Y, Lee B R, Nuzzo D D, Friend R H, Song M H 2016 Adv. Mater. 28 6906

Google Scholar

Google Scholar

[6] Huang C F, Keshtov M L, Chen F C 2016 ACS Appl. Mater. Interfaces 8 27006

Google Scholar

Google Scholar

[7] Era M, Morimoto S, Tsutsui T, Saito S 1994 Appl. Phys. Lett. 65 676

Google Scholar

Google Scholar

[8] Tan Z K, Moghaddam R S, Lai M L, Docampo P, Higler R, Deschler F, Price M, Sadhanala A, Pazos L M, Credgington D, Hanusch F, Bein T, Snaith H J, Friend R H 2014 Nat. Nanotechnol. 9 687

Google Scholar

Google Scholar

[9] Sessolo M, Gil E L, Longo G, Bolink H J 2016 Top. Curr. Chem. 374 1

Google Scholar

Google Scholar

[10] Naphade R, Zhao B, Richter J M, Booker E, Krishnamurthy S, Friend I H, Sadhanala A, Ogale S 2017 Adv. Mater. Interfaces. 4 1700562

Google Scholar

Google Scholar

[11] Zhang X L, Wang W G, Xu B, Liu S, Dai H T, Bian D, Chen S M, Wang K, Sun X W 2017 Nano Energy 37 40

Google Scholar

Google Scholar

[12] Yu J C, Kim D B, Jung E D, Lee B R, Song M H 2016 Nanoscale 8 7036

Google Scholar

Google Scholar

[13] Wang Z, Cheng T, Wang F, Dai S, Tan Z 2016 Small 12 4412

Google Scholar

Google Scholar

[14] Yantara N, Bhaumik S, Yan F, Sabba D, Dewi H A, Mathews N A, Boix P P, Demir H V, Mhaisalkar S 2015 J. Phys. Chem. Lett. 6 4360

Google Scholar

Google Scholar

[15] Li G, Tan Z K, Di D, Lai M L, Jiang L, Lim J H, Friend R H, Greenham N C 2015 Nano Lett. 15 2640

Google Scholar

Google Scholar

[16] Ji X, Peng X, Lei Y, Liu Z, Yang X 2017 Org. Electron. 43 167

Google Scholar

Google Scholar

[17] Chen P, Xiong Z, Wu X, Shao M, Ma X, Xiong ZH, Gao C 2017 J. Phys. Chem. Lett. 8 1810

Google Scholar

Google Scholar

[18] Cho H, Jeong S H, Park M H, Kim Y H, Wolf C, Lee C L, Heo J H, Sadhanala A, Myoung N, Yoo S, Im S H, Friend R H, Lee T W 2015 Science 350 1222

Google Scholar

Google Scholar

[19] Masi S, Rizzo A, Aiello F, Balzano F, Uccello-Barretta G, Listorti A, Gigli G, Colella S 2015 Nanoscale 7 18956

Google Scholar

Google Scholar

[20] Ng Y F, Kulkarni S A, Parida S, Jamaludin N F, Yantara N, Bruno A, Soci C, Mhaisalkar S, Mathews N 2017 Chem. Commun. 53 12004

Google Scholar

Google Scholar

[21] Peng X F, Wu X Y, Ji X X, Ren J, Wang Q, Li G Q, Yang X H 2017 J. Phys. Chem. Lett. 8 4691

Google Scholar

Google Scholar

[22] Groenendaal L, Jonas F, Freitag D, Pielartzik H, Reynolds J R 2000 Adv. Mater. 12 481

Google Scholar

Google Scholar

[23] Chan W C, Maxwel D J, Gao X, Bailey R E, Han M, Nie S 2002 Curr. Opin. Biotechnol. 13 1340

[24] Vengrenovich R D, Gudyma Y V, Yarema S V 2001 Semiconductors 35 1378

Google Scholar

Google Scholar

[25] Noh J H, Im S H, Heo J H, Mandal T N, Seok S I 2013 Nano Lett. 13 1764

Google Scholar

Google Scholar

[26] Zhang X Y, Lin H, Huang H, Reckmeier C, Zhang Y, Choy W C H, Rogach A L 2016 Nano Lett. 16 1415

Google Scholar

Google Scholar

[27] Yu H T, Lu Y, Feng Z Q, Wu Y N, Liu Z W, Xia P F, Qian J, Chen Y F, Liu L H, Cao K, Chen S F, Huang W 2019 Nanoscale 11 9103

Google Scholar

Google Scholar

计量

- 文章访问数: 9034

- PDF下载量: 95

- 被引次数: 0

下载:

下载: