-

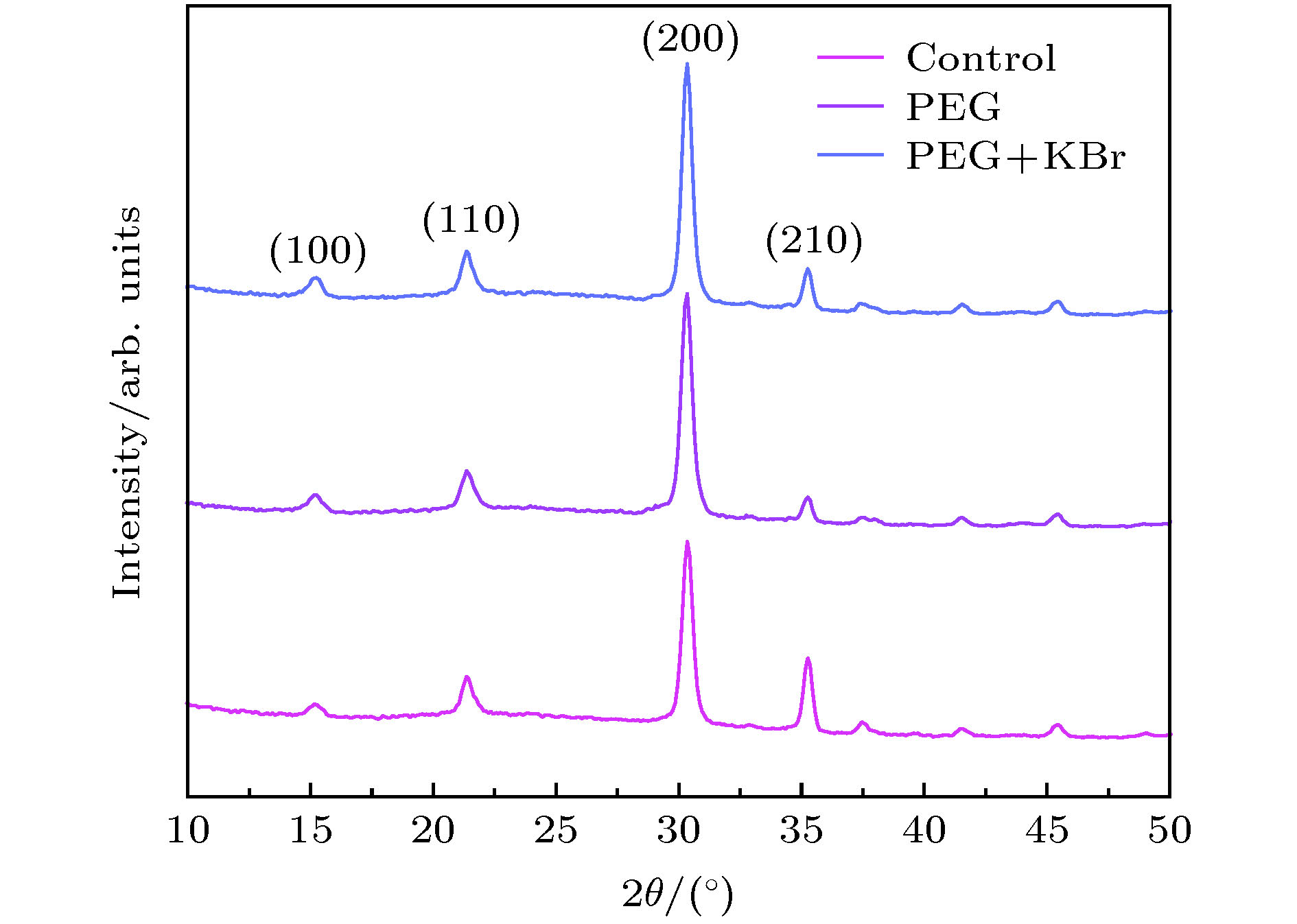

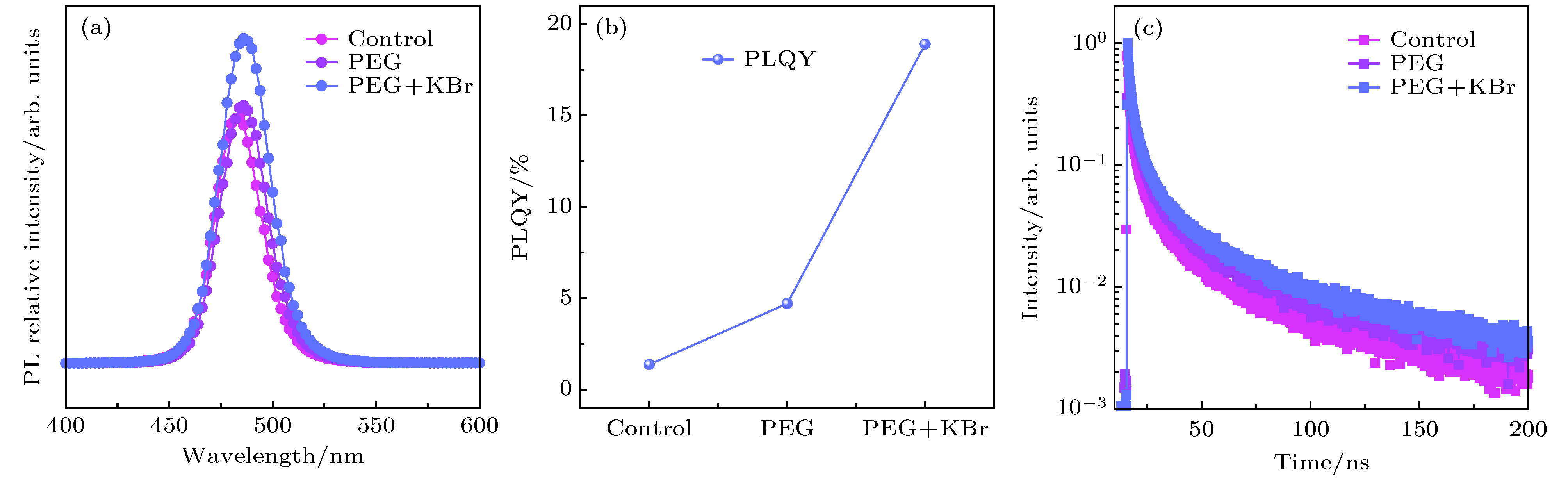

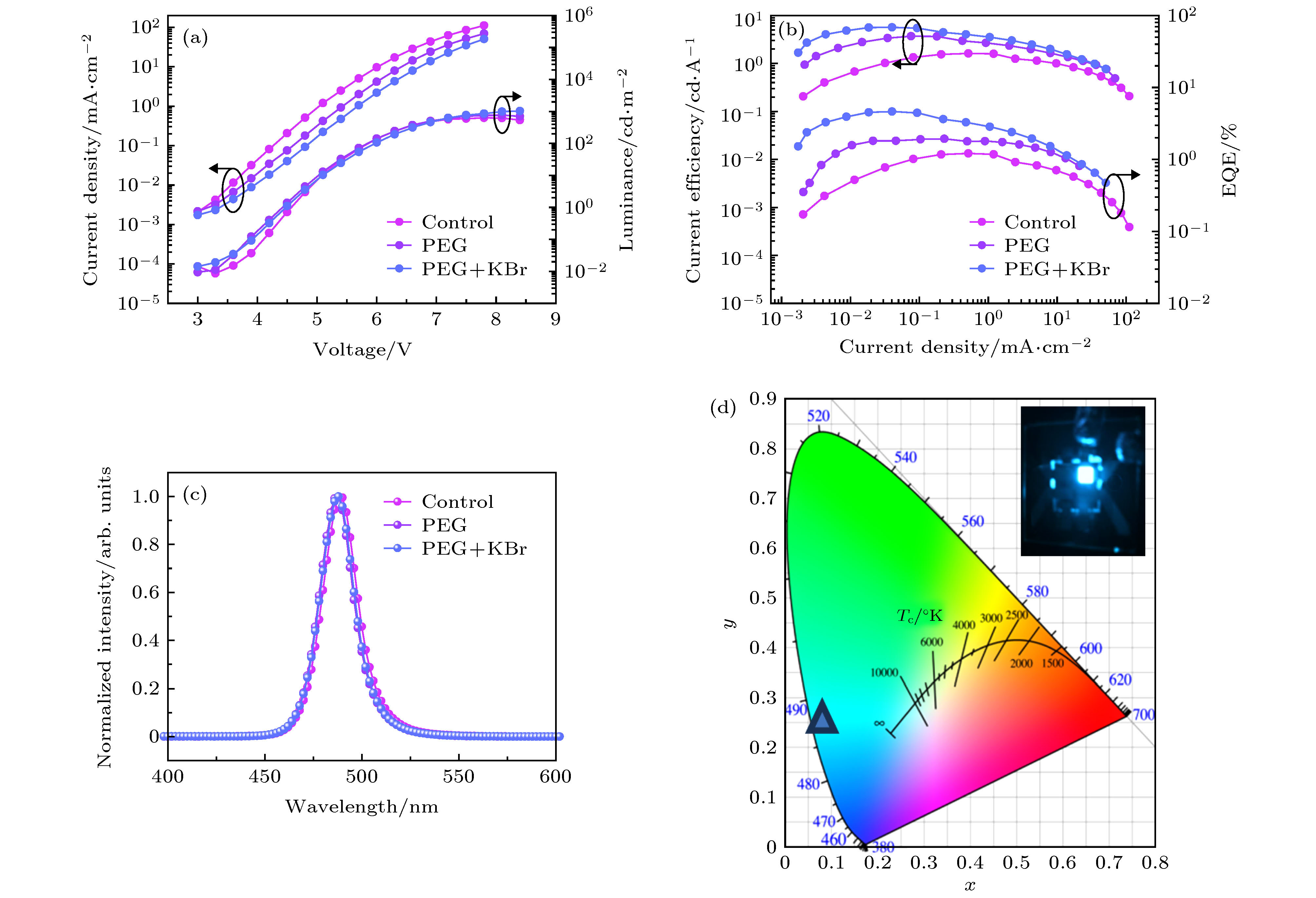

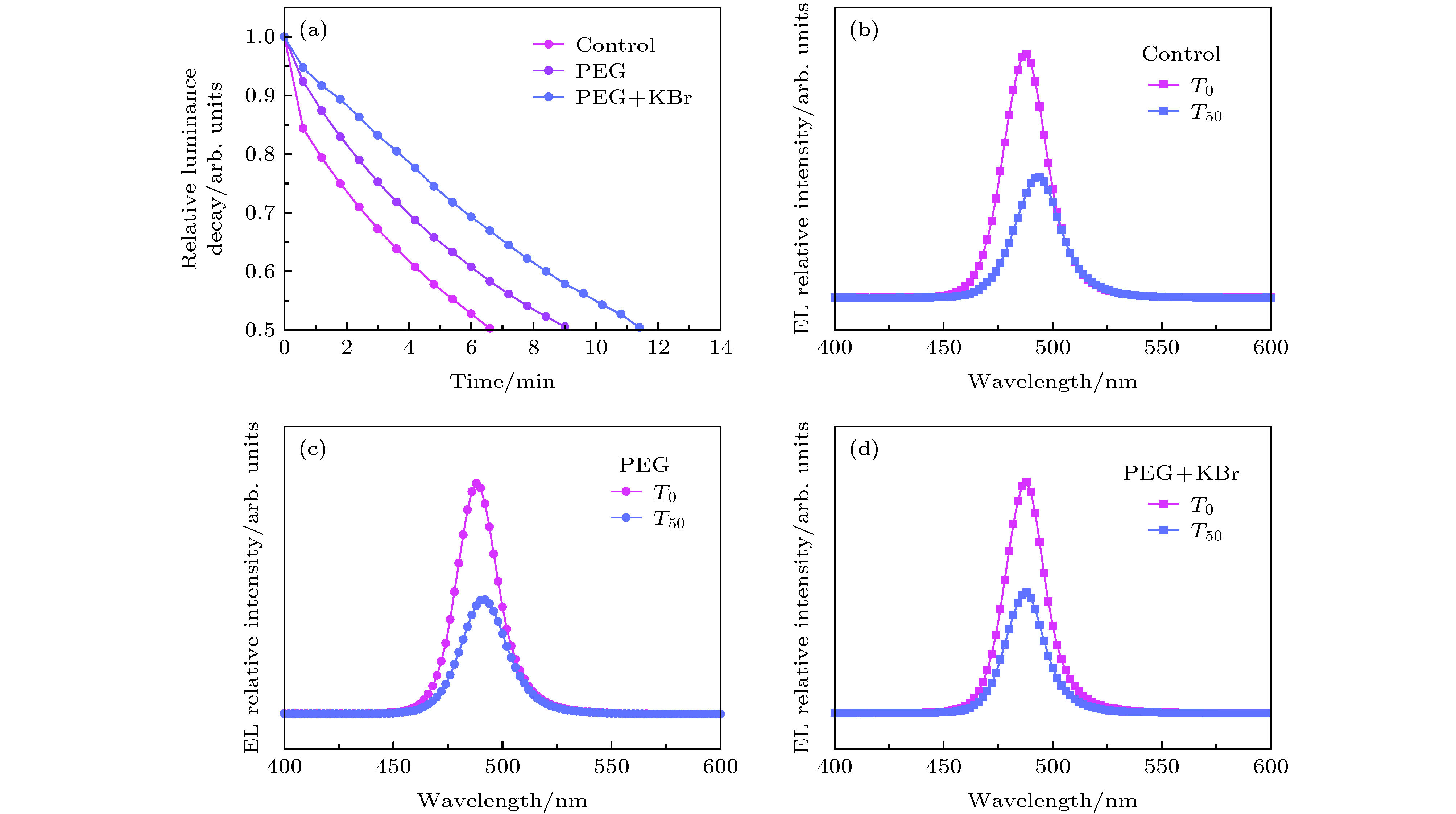

钙钛矿材料由于具备带隙易调、光致发光量子产率高、色纯度高、载流子迁移率高、可低温溶液加工、电荷传输性能优良等优点, 在照明显示领域大放异彩. 近年来, 通过控制化学计量比、尺寸工程和钝化缺陷等多种策略对钙钛矿微观结构进行调控, 极大地提高了钙钛矿发光二极管(perovskite light emitting diodes, PeLEDs)的性能. 目前,除蓝光外, 绿光、红光、近红外PeLEDs的外量子效率(EQE)均已超过20%. 造成蓝光器件性能停滞不前的主要原因是蓝光钙钛矿薄膜较差的覆盖率以及光谱不稳定. 为提高钙钛矿薄膜质量及器件性能, 本文在准二维钙钛矿材料PEAxCsPbBr3–yCly的基础上, 通过引入双添加剂聚乙二醇(PEG)和溴化钾(KBr), 钝化薄膜表面缺陷态, 减小晶粒尺寸, 抑制离子迁移与非辐射复合损耗, 进而提升蓝光钙钛矿器件的效率及光谱稳定性. 最终在488 nm处获得最大亮度为1049 cd·m–2, 电流效率为5.68 cd·A–1, 外量子效率为4.6%的蓝光PeLEDs. 相比于不含添加剂的器件, 效率提升了近3倍, 且具有良好的光谱稳定性和工作寿命.Solution-processable metal halide perovskites materials have many advantages, such as adjustable band gap, high photoluminescence quantum yield (PLQY), high color purity, high carrier mobility, low temperature solution process, excellent charge transport property and so on. These make them potential application in the display field. In the past few years, the device performance of perovskite light emitting devices (PeLEDs) have been greatly improved by manipulating the perovskite microstructures through various strategies, such as stoichiometry control, dimensional engineering, defect passivation and so on. At present, except for blue PeLEDs, the external quantum efficiencies (EQEs) over 20% have been achieved for green, red, and near-infrared PeLEDs. The low efficiency of blue PeLEDs is retarding their potential applications in full-color display and solid-state lighting. The main reasons in blue PeLEDs are the poor film coverage of blue perovskite materials and the spectral instability during device operation. In order to improve the quality of perovskite film and device performance, the quasi two-dimensional perovskite materials phenylethylammonium cesium lead bromide chloride (PEAxCsPbBr3–yCly) are used as the main perovskite emission material, by partially replacing Br with Cl to enlarge their bandgap to achieve the blue emission. The Lewis base polyethyleneglycol (PEG) is introduced to passivate the surface trapping defects and improve perovskite film coverage. The potassium bromide (KBr) is introduced to reduce perovskite grain size, suppress mobile ion migration and exhibit excellent spectral stability. Dual additives PEG and KBr are incorporated into the quasi-2D blue perovskite for inhibiting the nonradiative losses by passivating the traps in the perovskite films. Eventually, the PEAxCsPbBr3–yCly + PEG + KBr based blue PeLEDs with the emission peak of 488 nm are accompanied, which maximum brightness, current efficiency, and external quantum efficiency reached 1049 cd·m–2, of 5.68 cd·A–1, and of 4.6%, respectively, with high color purity (the Commission Internationale de L'Eclairage (CIE) chromaticity coordinates is (0.0747, 0.2570)) and the narrow full width at half maximum (FWHM) of 20 nm. Compare to the devices without additives, the efficiency has increased by nearly 3 times. Furthermore, the devices also show better spectral stability and operation lifetime. This work provides an effective method of blue PeLEDs toward the practical applications.

-

Keywords:

- perovskite materials /

- blue emission /

- light emitting diodes /

- defect passivation

[1] Zhang X, Liu H, Wang W, Zhang J, Xu B, Karen K L, Zheng Y, Liu S, Chen S, Wang K, Sun X W 2017 Adv. Mater. 29 1606405

Google Scholar

Google Scholar

[2] 姚鑫, 丁艳丽, 张晓丹, 赵颖 2015 64 038805

Google Scholar

Google Scholar

Yao X, Ding Y L, Zhang X D, Zhao Y 2015 Acta Phys. Sin. 64 038805

Google Scholar

Google Scholar

[3] Stranks S D, Eperon G E, Grancini G, Menelaou C, Alcocer M J, Leijtens T, Herz L M, Petrozza A, Snaith H J 2013 Science 342 341

Google Scholar

Google Scholar

[4] Liu D, Kelly T L 2014 Nat. Photonics 8 133

Google Scholar

Google Scholar

[5] Dong Q, Fang Y, Shao Y, Mulligan P, Qiu J, Cao L, Huang J 2015 Science 347 967

Google Scholar

Google Scholar

[6] Brenner P, Stulz M, Kapp D, Abzieher T, Paetzold U W, Quintilla A, Howard I A, Kalt H, Lemmer U 2016 Appl. Phys. Lett. 109 141106

Google Scholar

Google Scholar

[7] Wang Y C, Li H, Hong Y H, Hong K B, Chen F C, Hsu C H, Lee R K, Conti C, Kao T S, Lu T C 2019 ACS Nano 13 5421

Google Scholar

Google Scholar

[8] Xiao Z G, Kerner R A, Zhao L F, Tran N L, Lee K M, Koh T W, Scholes G D, Rand B P 2017 Nat. Photonics 11 108

Google Scholar

Google Scholar

[9] Wang N, Cheng L, Ge R, Zhang S, Miao Y, Zou W, Yi C, Sun Y, Cao Y, Yang R, Wei Y, Guo Q, Ke Y, Yu M, Jin Y, Liu Y, Ding Q, Di D, Yang L, Xing G, Tian H, Jin C, Gao F, Friend R H, Wang J, Huang W 2016 Nat. Photonics 10 699

Google Scholar

Google Scholar

[10] Lin K, Xing J, Quan L N, de Arquer F P G, Gong X W, Lu J X, Xie L Q, Zhao W J, Zhang D, Yan C Z, Li W Q, Liu X Y, Lu Y, Kirman J, Sargent E H, Xiong Q H, Wei Z H 2018 Nature 562 245

Google Scholar

Google Scholar

[11] Turkevych I, Kazaoui S, Belich N A, Grishko A Y, Fateev S A, Petrov A A, Urano T, Aramaki S, Kosar S, Kondo M, Goodilin E A, Graetzel M, Tarasov A B 2019 Nat. Nanotechnol. 14 57

Google Scholar

Google Scholar

[12] Tavakoli M M, Yadav P, Prochowicz D, Sponspeller M, Osheov A, Bulovic V, Kong J 2019 Adv. Energy Mater. 9 1803587

Google Scholar

Google Scholar

[13] Tan Z K, Moghaddam R S, Lai M L, Docampo P, Higler R, Deschler F, Price M, Sadhanala A, Pazos L M, Credgington D, Hanusch F, Bein T, Snaith H J, Friend R H 2014 Nat. Nanotechnol. 9 687

Google Scholar

Google Scholar

[14] Cho H, Jeong S H, Park M H, Kim Y H, Wolf C, Lee C L, Heo J H, Sadhanala A, Myoung N, Yoo S, Im S H, Friend R H, Lee T W 2015 Science 350 1222

Google Scholar

Google Scholar

[15] Yantara N, Bhaumik S, Yan F, Sabba D, Dewi H A, Mathews N, Boix P P, Demir H V, Mhaisalkar S 2015 J. Phys. Chem. Lett. 6 4360

Google Scholar

Google Scholar

[16] Cheng L P, Huang J S, Shen Y, Li G P, Liu X K, Li W, Wang Y H, Li Y Q, Jiang Y, Gao F, Lee C S, Tang J X 2019 Adv. Opt. Mater. 7 1801534

Google Scholar

Google Scholar

[17] Fang Z, Chen W, Shi Y, Zhao J, Chu S, Zhang J, Xiao Z 2020 Adv. Funct. Mater. 30 1909754

Google Scholar

Google Scholar

[18] Li Z, Chen Z, Yang Y, Xue Q, Yip H L, Cao Y 2019 Nat. Commun. 10 1027

Google Scholar

Google Scholar

[19] Wang K H, Peng Y, Ge J, Jiang S, Zhu B S, Yao J, Yin Y C, Yang J N, Zhang Q, Yao H B 2018 ACS Photonics 6 667

Google Scholar

Google Scholar

[20] Cao Y, Wang N, Tian H, Guo J, Wei Y, Chen H, Miao Y, Zou W, Pan K, He Y, Cao H, Ke Y, Xu M, Wang Y, Yang M, Du K, Fu Z, Kong D, Dai D, Jin Y, Li G, Li H, Peng Q, Wang J, Huang W 2018 Nature 562 249

Google Scholar

Google Scholar

[21] Xu W, Hu Q, Bai S, Bao C, Miao Y, Yuan Z, Borzda T, Barker A J, Tyukalova E, Hu Z, Kawecki M, Wang H, Yan Z, Liu X, Shi X, Uvdal K, Fahlman M, Zhang W, Duchamp M, Liu J M, Petrozza A, Wang J, Liu L M, Huang W, Gao F 2019 Nat. Photonics 13 418

Google Scholar

Google Scholar

[22] Liu Y, Cui J, Du K, Tian H, He Z, Zhou Q, Yang Z, Deng Y, Chen D, Zuo X, Ren Y, Wang L, Zhu H, Zhao B, Di D, Wang J, Friend R H, Jin Y 2019 Nat. Photonics 13 760

Google Scholar

Google Scholar

[23] Wang Q, Wang X, Yang Z, Zhou N, Deng Y, Zhao J, Xiao X, Rudd P, Moran A, Yan Y, Huang J 2019 Nat. Commun. 10 5633

Google Scholar

Google Scholar

[24] Kumawat N K, Dey A, Kumar A, Gopinathan S P, Narasimhan K L, Kabra D 2015 ACS Appl. Mater. Interfaces 7 13119

Google Scholar

Google Scholar

[25] Kim H P, Kim J, Kim B S, Kim H M, Kim J, Yusoff A R b M, Jang J, Nazeeruddin M K 2017 Adv. Opt. Mater. 5 1600920

Google Scholar

Google Scholar

[26] Wang Q, Ren J, Peng X F, Ji X X, Yang X H 2017 ACS Appl. Mater. Interfaces 9 29901

Google Scholar

Google Scholar

[27] Vashishtha P, Ng M, Shivarudraiah S B, Halpert J E 2018 Chem. Mater. 31 83

Google Scholar

Google Scholar

[28] Cheng L, Cao Y, Ge R, Wei Y Q, Wang N N, Wang J P, Huang W 2017 Chin. Chem. Lett. 28 29

Google Scholar

Google Scholar

[29] 段聪聪, 程露, 殷垚, 朱琳 2019 68 158503

Google Scholar

Google Scholar

Duan C C, Chen L, Yin Y, Zhu L 2019 Acta Phys. Sin. 68 158503

Google Scholar

Google Scholar

[30] Jiang Y, Qin C, Cui M, He T, Liu K, Huang Y, Luo M, Zhang L, Xu H, Li S, Wei J, Liu Z, Wang H, Kim G H, Yuan M, Chen J 2019 Nat. Commun. 10 1868

Google Scholar

Google Scholar

[31] Ren Z, Xiao X, Ma R, Lin H, Wang K, Sun X W, Choy W C H 2019 Adv. Funct. Mater. 29 1905339

Google Scholar

Google Scholar

[32] Zheng F, Chen W, Bu T, Ghiggino K P, Huang F, Cheng Y, Tapping P, Kee T W, Jia B, Wen X 2019 Adv. Energy Mater. 9 1901016

Google Scholar

Google Scholar

[33] 黎振超, 陈梓铭, 邹广锐兴, 叶轩立, 曹镛 2019 68 158505

Google Scholar

Google Scholar

Li Z C, Chen Z M, Zou G R X, Yip H L, Cao Y 2019 Acta Phys. Sin. 68 158505

Google Scholar

Google Scholar

[34] Li G, Tan Z K, Di D, Lai M L, Jiang L, Lim J H W, Friend R H, Greenham N C 2015 Nano Lett. 15 2640

Google Scholar

Google Scholar

[35] Edri E, Kirmayer S, Kulbak M, Hodes G, Cahen D 2014 J. Phys. Chem. Lett. 5 429

Google Scholar

Google Scholar

[36] Shi H, Du M H 2014 Phys. Rev. B 90 174103

Google Scholar

Google Scholar

[37] Zou W, Li R, Zhang S, Liu Y, Wang N, Cao Y, Miao Y, Xu M, Guo Q, Di D, Zhang L, Yi C, Gao F, Friend R H, Wang J, Huang W 2018 Nat. Commun. 9 608

Google Scholar

Google Scholar

[38] Yang Y, Zheng Y, Cao W, Titov A, Hyvonen J, Manders J R, Xue J, Holloway P H, Qian L 2015 Nat. Photonics 9 259

Google Scholar

Google Scholar

[39] 王继飞, 林东旭, 袁永波 2019 68 158501

Google Scholar

Google Scholar

Wang J F, Lin D X, Yuan Y B 2019 Acta Phys. Sin. 68 158501

Google Scholar

Google Scholar

-

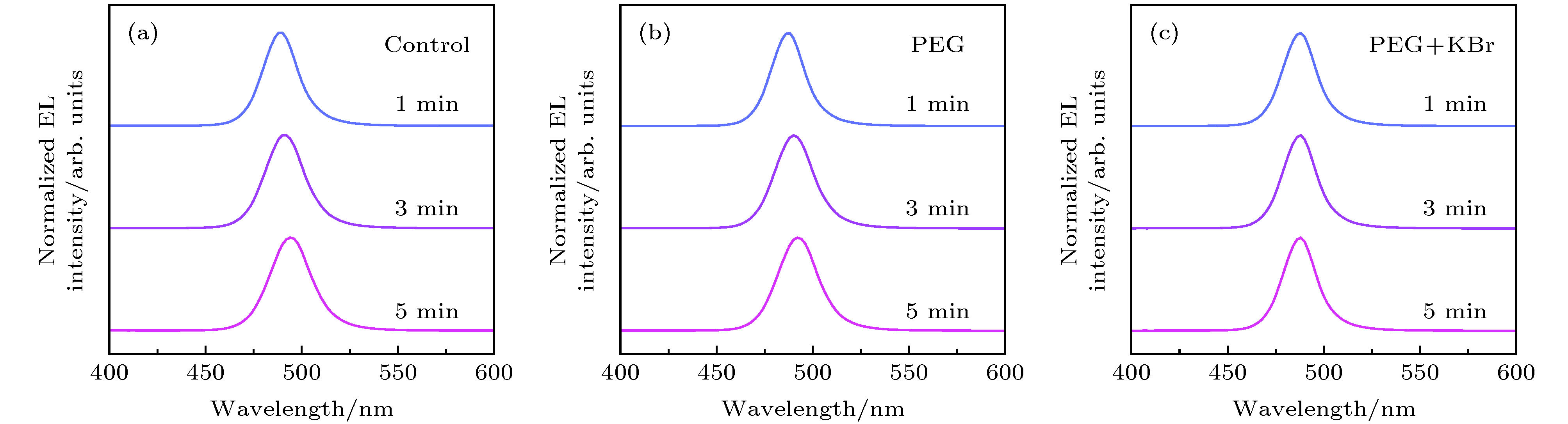

图 7 含有不同添加剂的PeLEDs电学性能表征 (a)电流密度-电压-亮度(J-V-L); (b)电流效率-电流密度-外量子效率(CE-J-EQE); (c)归一化后的EL光谱图; (d)国际照明委员会(CIE)色坐标图

Fig. 7. Electrical performance characteristics of PeLEDs with different additives: (a) Current density-voltage-luminance(J-V-L); (b) current efficiency-current density-external quantum efficiency(CE-J-EQE); (c) the normalized EL spectra; (d) the Commission Internationale de I’Eclairage (CIE) coordinates

表 1 含有不同添加剂钙钛矿发光层的蓝光PeLEDs性能

Table 1. The performance of blue PeLEDs with different additive perovskite materials.

Devices Max.

L/cd·m–2CE/cd·A–1 EQE/% EL

peak/nmControl 779 1.62 1.2 488 PEG 1038 3.69 3.0 488 PEG+KBr 1049 5.68 4.6 488 -

[1] Zhang X, Liu H, Wang W, Zhang J, Xu B, Karen K L, Zheng Y, Liu S, Chen S, Wang K, Sun X W 2017 Adv. Mater. 29 1606405

Google Scholar

Google Scholar

[2] 姚鑫, 丁艳丽, 张晓丹, 赵颖 2015 64 038805

Google Scholar

Google Scholar

Yao X, Ding Y L, Zhang X D, Zhao Y 2015 Acta Phys. Sin. 64 038805

Google Scholar

Google Scholar

[3] Stranks S D, Eperon G E, Grancini G, Menelaou C, Alcocer M J, Leijtens T, Herz L M, Petrozza A, Snaith H J 2013 Science 342 341

Google Scholar

Google Scholar

[4] Liu D, Kelly T L 2014 Nat. Photonics 8 133

Google Scholar

Google Scholar

[5] Dong Q, Fang Y, Shao Y, Mulligan P, Qiu J, Cao L, Huang J 2015 Science 347 967

Google Scholar

Google Scholar

[6] Brenner P, Stulz M, Kapp D, Abzieher T, Paetzold U W, Quintilla A, Howard I A, Kalt H, Lemmer U 2016 Appl. Phys. Lett. 109 141106

Google Scholar

Google Scholar

[7] Wang Y C, Li H, Hong Y H, Hong K B, Chen F C, Hsu C H, Lee R K, Conti C, Kao T S, Lu T C 2019 ACS Nano 13 5421

Google Scholar

Google Scholar

[8] Xiao Z G, Kerner R A, Zhao L F, Tran N L, Lee K M, Koh T W, Scholes G D, Rand B P 2017 Nat. Photonics 11 108

Google Scholar

Google Scholar

[9] Wang N, Cheng L, Ge R, Zhang S, Miao Y, Zou W, Yi C, Sun Y, Cao Y, Yang R, Wei Y, Guo Q, Ke Y, Yu M, Jin Y, Liu Y, Ding Q, Di D, Yang L, Xing G, Tian H, Jin C, Gao F, Friend R H, Wang J, Huang W 2016 Nat. Photonics 10 699

Google Scholar

Google Scholar

[10] Lin K, Xing J, Quan L N, de Arquer F P G, Gong X W, Lu J X, Xie L Q, Zhao W J, Zhang D, Yan C Z, Li W Q, Liu X Y, Lu Y, Kirman J, Sargent E H, Xiong Q H, Wei Z H 2018 Nature 562 245

Google Scholar

Google Scholar

[11] Turkevych I, Kazaoui S, Belich N A, Grishko A Y, Fateev S A, Petrov A A, Urano T, Aramaki S, Kosar S, Kondo M, Goodilin E A, Graetzel M, Tarasov A B 2019 Nat. Nanotechnol. 14 57

Google Scholar

Google Scholar

[12] Tavakoli M M, Yadav P, Prochowicz D, Sponspeller M, Osheov A, Bulovic V, Kong J 2019 Adv. Energy Mater. 9 1803587

Google Scholar

Google Scholar

[13] Tan Z K, Moghaddam R S, Lai M L, Docampo P, Higler R, Deschler F, Price M, Sadhanala A, Pazos L M, Credgington D, Hanusch F, Bein T, Snaith H J, Friend R H 2014 Nat. Nanotechnol. 9 687

Google Scholar

Google Scholar

[14] Cho H, Jeong S H, Park M H, Kim Y H, Wolf C, Lee C L, Heo J H, Sadhanala A, Myoung N, Yoo S, Im S H, Friend R H, Lee T W 2015 Science 350 1222

Google Scholar

Google Scholar

[15] Yantara N, Bhaumik S, Yan F, Sabba D, Dewi H A, Mathews N, Boix P P, Demir H V, Mhaisalkar S 2015 J. Phys. Chem. Lett. 6 4360

Google Scholar

Google Scholar

[16] Cheng L P, Huang J S, Shen Y, Li G P, Liu X K, Li W, Wang Y H, Li Y Q, Jiang Y, Gao F, Lee C S, Tang J X 2019 Adv. Opt. Mater. 7 1801534

Google Scholar

Google Scholar

[17] Fang Z, Chen W, Shi Y, Zhao J, Chu S, Zhang J, Xiao Z 2020 Adv. Funct. Mater. 30 1909754

Google Scholar

Google Scholar

[18] Li Z, Chen Z, Yang Y, Xue Q, Yip H L, Cao Y 2019 Nat. Commun. 10 1027

Google Scholar

Google Scholar

[19] Wang K H, Peng Y, Ge J, Jiang S, Zhu B S, Yao J, Yin Y C, Yang J N, Zhang Q, Yao H B 2018 ACS Photonics 6 667

Google Scholar

Google Scholar

[20] Cao Y, Wang N, Tian H, Guo J, Wei Y, Chen H, Miao Y, Zou W, Pan K, He Y, Cao H, Ke Y, Xu M, Wang Y, Yang M, Du K, Fu Z, Kong D, Dai D, Jin Y, Li G, Li H, Peng Q, Wang J, Huang W 2018 Nature 562 249

Google Scholar

Google Scholar

[21] Xu W, Hu Q, Bai S, Bao C, Miao Y, Yuan Z, Borzda T, Barker A J, Tyukalova E, Hu Z, Kawecki M, Wang H, Yan Z, Liu X, Shi X, Uvdal K, Fahlman M, Zhang W, Duchamp M, Liu J M, Petrozza A, Wang J, Liu L M, Huang W, Gao F 2019 Nat. Photonics 13 418

Google Scholar

Google Scholar

[22] Liu Y, Cui J, Du K, Tian H, He Z, Zhou Q, Yang Z, Deng Y, Chen D, Zuo X, Ren Y, Wang L, Zhu H, Zhao B, Di D, Wang J, Friend R H, Jin Y 2019 Nat. Photonics 13 760

Google Scholar

Google Scholar

[23] Wang Q, Wang X, Yang Z, Zhou N, Deng Y, Zhao J, Xiao X, Rudd P, Moran A, Yan Y, Huang J 2019 Nat. Commun. 10 5633

Google Scholar

Google Scholar

[24] Kumawat N K, Dey A, Kumar A, Gopinathan S P, Narasimhan K L, Kabra D 2015 ACS Appl. Mater. Interfaces 7 13119

Google Scholar

Google Scholar

[25] Kim H P, Kim J, Kim B S, Kim H M, Kim J, Yusoff A R b M, Jang J, Nazeeruddin M K 2017 Adv. Opt. Mater. 5 1600920

Google Scholar

Google Scholar

[26] Wang Q, Ren J, Peng X F, Ji X X, Yang X H 2017 ACS Appl. Mater. Interfaces 9 29901

Google Scholar

Google Scholar

[27] Vashishtha P, Ng M, Shivarudraiah S B, Halpert J E 2018 Chem. Mater. 31 83

Google Scholar

Google Scholar

[28] Cheng L, Cao Y, Ge R, Wei Y Q, Wang N N, Wang J P, Huang W 2017 Chin. Chem. Lett. 28 29

Google Scholar

Google Scholar

[29] 段聪聪, 程露, 殷垚, 朱琳 2019 68 158503

Google Scholar

Google Scholar

Duan C C, Chen L, Yin Y, Zhu L 2019 Acta Phys. Sin. 68 158503

Google Scholar

Google Scholar

[30] Jiang Y, Qin C, Cui M, He T, Liu K, Huang Y, Luo M, Zhang L, Xu H, Li S, Wei J, Liu Z, Wang H, Kim G H, Yuan M, Chen J 2019 Nat. Commun. 10 1868

Google Scholar

Google Scholar

[31] Ren Z, Xiao X, Ma R, Lin H, Wang K, Sun X W, Choy W C H 2019 Adv. Funct. Mater. 29 1905339

Google Scholar

Google Scholar

[32] Zheng F, Chen W, Bu T, Ghiggino K P, Huang F, Cheng Y, Tapping P, Kee T W, Jia B, Wen X 2019 Adv. Energy Mater. 9 1901016

Google Scholar

Google Scholar

[33] 黎振超, 陈梓铭, 邹广锐兴, 叶轩立, 曹镛 2019 68 158505

Google Scholar

Google Scholar

Li Z C, Chen Z M, Zou G R X, Yip H L, Cao Y 2019 Acta Phys. Sin. 68 158505

Google Scholar

Google Scholar

[34] Li G, Tan Z K, Di D, Lai M L, Jiang L, Lim J H W, Friend R H, Greenham N C 2015 Nano Lett. 15 2640

Google Scholar

Google Scholar

[35] Edri E, Kirmayer S, Kulbak M, Hodes G, Cahen D 2014 J. Phys. Chem. Lett. 5 429

Google Scholar

Google Scholar

[36] Shi H, Du M H 2014 Phys. Rev. B 90 174103

Google Scholar

Google Scholar

[37] Zou W, Li R, Zhang S, Liu Y, Wang N, Cao Y, Miao Y, Xu M, Guo Q, Di D, Zhang L, Yi C, Gao F, Friend R H, Wang J, Huang W 2018 Nat. Commun. 9 608

Google Scholar

Google Scholar

[38] Yang Y, Zheng Y, Cao W, Titov A, Hyvonen J, Manders J R, Xue J, Holloway P H, Qian L 2015 Nat. Photonics 9 259

Google Scholar

Google Scholar

[39] 王继飞, 林东旭, 袁永波 2019 68 158501

Google Scholar

Google Scholar

Wang J F, Lin D X, Yuan Y B 2019 Acta Phys. Sin. 68 158501

Google Scholar

Google Scholar

计量

- 文章访问数: 15625

- PDF下载量: 389

- 被引次数: 0

下载:

下载: