-

钙钛矿发光二极管具有色纯度高, 发光层材料带隙可调等优点, 目前其外量子效率已经超过20%, 在平板显示和照明领域有很好的商业化前景. 然而, 同有机发光二极管类似, 钙钛矿发光二极管同样存在衬底模式、表面等离子体模式、波导模式引起的内部损耗问题, 在一定程度上限制了钙钛矿发光二极管的性能提升. 因此, 需要优化器件的材料和几何结构以获得更好的膜间光学导纳匹配, 改善钙钛矿发光二极管光提取效率以增强器件的发光性能. 当前, 通过改变电极材料、增加等离子体激元、引入微纳结构以及优化钙钛矿薄膜和器件结构, 可以增强钙钛矿发光二极管光提取效率, 通过增强光提取效率后的钙钛矿发光二极管外量子效率可达 28.2%, 电流效率可达88.7 cd/A. 本文针对钙钛矿发光二极管材料与结构的改变, 从以上四个方面进行重点阐述. 此外, 进一步分析了这四种方法在提升器件光提取效率方面存在的优点和面临的问题, 从而为钙钛矿发光二极管的制备和优化提供一定的借鉴.Perovskite light emitting diodes (PeLEDs) have developed rapidly in recent years due to their advantages of tenability of band gap and high color purity. At present, the external quantum efficiency of PeLED has rised up to 20%. Like the scenario of organic light emitting diode, there exist various internal losses in PeLED with low light extraction efficiency. It arises from the absorption of substrates, waveguide transmission and surface plasmon resonance of metal electrode. To improve the luminescence performance of PeLED, a well-matched optical admittance between the thin-films inside the devices is required. In this paper, the strategies of enhancing the light extraction efficiency are adopted as the materials and structures in PeLED are concerned. The applications of alternative electrode in PeLED are discussed, such as graphene, silver nanowires, metal transparent electrode and some new-types of electrodes. In addition, the plasma effect is also introduced into the PeLED to deflect the emitting light. What is more, the nano-structure grating is inserted into device to reduce the optical losses due to the large refractive index difference between the interfaces in device. Therefore, the external quantum efficiency of PeLED rises up to 28.2%, and the current efficiency can reach 88.7 cd/A.

-

Keywords:

- perovskite /

- light emitting diodes /

- light extraction /

- efficiency

[1] Wang J P, Wang N N, Jin Y Z, Si J J, Tan Z K, Du H, Cheng L, Dai X L, Bai S, He H P, Ye Z Z, Lai M L, Friend R H, Huang W 2015 Adv. Mater. 27 2311

Google Scholar

Google Scholar

[2] Meng F Y, Liu X Y, Chen Y X, Cai X Y, Li M K, Shi T T, Chen Z M, Chen D C, Yip H L, Ramanan C, Blom P W M, Su S J 2020 Adv. Funct. Mater. 2020 1910167

Google Scholar

Google Scholar

[3] Lee S J, Park J H, Nam Y S, Lee B R, Zhao B D, Nuzzo D D, Jung E D, Jeon H, Kim J Y, Jeong H Y, Friend R H, Song M H 2018 ACS Nano 12 3417

Google Scholar

Google Scholar

[4] Tan Z K, Moghaddam R S, Lai M L, Docampo P, Higler R, Deschler F, Price M, Sadhanala A, Pazos L M, Credgington D, Hanusch F, Bein T, Snaith H J, Friend R H 2014 Nat. Nanotechnol. 9 687

Google Scholar

Google Scholar

[5] Quan L N, Arquer F P G D, Sabatini R P, Sargent E H 2018 Adv. Mater. 30 1801996

Google Scholar

Google Scholar

[6] Wei Z H, Xing J 2019 J. Phys. Chem. Lett. 10 3035

Google Scholar

Google Scholar

[7] Zou Y, Yuan Z, Bai S, Gao F, Sun B 2019 Mater. Today Nano 5 100028

Google Scholar

Google Scholar

[8] Veldhuis S A, Boix P P, Yantara N, Li M, Sum T C, Mathews N, Mhaisalkar S G 2016 Adv. Mater. 28 6804

Google Scholar

Google Scholar

[9] Park M H, Park J, Lee J, So H S, Kim H, Jeong S H, Han T H, Wolf C, Lee H, Yoo S, Lee T W 2019 Adv. Funct. Mater. 29 1902017

Google Scholar

Google Scholar

[10] Fang Z B, Chen W J, Shi Y L, Zhao J, Chu S L, Zhang J, Xiao Z G 2020 Adv. Funct. Mater. 30 1909754

Google Scholar

Google Scholar

[11] Cao Y, Wang N N, Tian H, Guo J S, Wei Y Q, Chen H, Miao Y F, Zou W, Pan K, He Y R, Cao H, Ke Y, Xu M M, Wang Y, Yang M, Du K, Fu Z, Kong D C, Dai D X, Jin Y Z, Li G Q, Li H, Peng Q M, Wang J P, Huang W 2018 Nature 562 249

Google Scholar

Google Scholar

[12] Shen Y, Cheng L P, Li Y Q, Li W, Chen J D, Lee S T, Tang J X 2019 Adv. Mater. 31 1901517

Google Scholar

Google Scholar

[13] Lin K B, Xing J, Quan L N, Arquer F P G D, Gong X W, Lu J X, Xie L Q, Zhao W J, Zhang D, Yan C Z, Li W Q, Liu X Y, Lu Y, Kirman J, Sargent E H, Xiong Q H, Wei Z H 2018 Nature 562 245

Google Scholar

Google Scholar

[14] Zhao B D, Bai S, Kim V, Lamboll R, Shivanna R, Auras F, Richter J M, Yang L, Dai L J, Alsari M, She X J, Liang L S, Zhang J B, Lilliu S, Gao P, Snaith H J, Wang J P, Greenham N C, Friend R H, Di D W 2018 Nat. Photonics 12 783

Google Scholar

Google Scholar

[15] Zhao X F, Tan Z K 2019 Nat. Photonics 4851 50

[16] Xu W D, Hu Q, Bai S, Bao C X, Miao Y F, Yuan Z C, Borzda T, Barker A J, Tyukalova E, Hu Z J, Kawecki M, Wang H Y, Yan Z B, Liu X J, Shi X B, Uvdal K, Fahlman M, Zhang W J, Duchamp M, Liu J M, Petrozza A, Wang J P, Liu L M, Huang W, Gao F 2019 Nat. Photonics 13 418

[17] Bao C X, Xu W D, Yang J, Bai S, Teng P P, Yang Y, Wang J P, Zhao N, Zhang W J, Huang W, Gao F 2020 Nat. Electron. 3 156

Google Scholar

Google Scholar

[18] 方晓敏, 江孝伟, 赵建伟 2018 激光与光电子学进展 55 082302

Google Scholar

Google Scholar

Fang X M, Jiang X W, Zhao J W 2018 Laser Optoelectronics Progress 55 082302

Google Scholar

Google Scholar

[19] Hong K, Lee J L 2011 Electron. Mater. Lett. 7 77

Google Scholar

Google Scholar

[20] Meng S S, Li Y Q, Tang J X 2018 Org. Electron. 61 351

Google Scholar

Google Scholar

[21] 李国龙, 黄卓寅, 李衎, 甄红宇, 沈伟东, 刘旭 2011 60 077207

Google Scholar

Google Scholar

Li G L, Huang Z Y, Li K, Zhen H Y, Shen W D, Liu X 2011 Acta. Phys. Sin. 60 077207

Google Scholar

Google Scholar

[22] Hsu C W, Lee Y C, Chen H L, Chou Y F 2012 Photonic. Nanostruct. 10 523

Google Scholar

Google Scholar

[23] Gao C H, Zhang Y, Ma X J, Yu F X, Jia Y L, Lei Y L, Chen P, Sun W W, Xiong Z H 2018 Org. Electron. 58 88

Google Scholar

Google Scholar

[24] Zhou Y, Wu G M, Gao D W, Xing G J, Zhu Y Y, Zhang Z Q, Cao Y 2012 Adv. Mat. Res. 465 268

Google Scholar

Google Scholar

[25] Seo H K, Kim H, Lee J, Park M H, Jeong S H, Kim Y H, Kwon S J, Han T H, Yoo S, Lee T W 2017 Adv. Mater. 29 1605587

Google Scholar

Google Scholar

[26] Lu M, Zhang X Y, Bai X, Wu H, Shen X Y, Zhang Y, Zhang W, Zheng W T, Song H W, Yu W W, Rogach A L 2018 ACS Energy Lett. 3 1571

Google Scholar

Google Scholar

[27] Liu Y S, Guo S, Yi F S, Feng J, Sun H B 2018 Opt. Lett. 43 5524

Google Scholar

Google Scholar

[28] Liu Y F, Ding T, Wang H R, Zhang Y T, Chen C, Chen X T, Duan Y 2020 Appl. Surf. Sci. 504 144442

Google Scholar

Google Scholar

[29] Jeong S H, Woo S H, Han T H, Park M H, Cho H, Kim Y H, Cho H, Kim Y H, Cho H, Kim H, Yoo S, Lee T W 2017 Npg. Asia. Mater. 9 e411

Google Scholar

Google Scholar

[30] Wu H, Zhang Y, Zhang X Y, Lu M, Sun C, Bai X, Zhang T Q, Sun G, Yu W W 2018 Adv. Electron. Mater. 4 1700285

Google Scholar

Google Scholar

[31] Miao Y F, Cheng L, Zou W, Gu L H, Zhang J, Guo Q, Peng Q M, Xu M M, He Y R, Zhang S T, Cao Y, Li R Z, Wang N N, Huang W, Wang J P 2020 Light Sci. Appl. 9 89

Google Scholar

Google Scholar

[32] Woo R W 1902 Proc. Phys. Soc. London 18 269

Google Scholar

Google Scholar

[33] Zhang X L, Xu B, Wang W G, Liu S, Zheng Y J, Chen S M, Wang K, Sun X W 2017 ACS. Appl. Mater. Inter. 9 4926

Google Scholar

Google Scholar

[34] Chen P, Xiong Z Y, Wu X Y, Shao M, Meng Y, Xiong Z H, Gao C H 2017 J. Phys. Chem. Lett. 8 3961

Google Scholar

Google Scholar

[35] Zhang Y H, Sun H Q, Zhang S, Li S P, Wang X, Zhang X, Liu T Y, Guo Z Y 2019 Opt. Mater. 89 563

Google Scholar

Google Scholar

[36] Mao J, Sha W E I, Zhang H, Ren X G, Zhuang J Q, Roy V A L, Wong K S, Choy W C H 2017 Adv. Funct. Mater. 27 1606525

Google Scholar

Google Scholar

[37] Jeon S H, Zhao L F, Jung Y J, Kim J W, Kim S Y, Kang H, Jeong J H, Rand B P, Lee J H 2019 Small 15 1900135

Google Scholar

Google Scholar

[38] Zhang Q P, Tavakoli M M, Gu L L, Zhang D Q, Tang L, Gao Y, Guo J, Lin Y J, Leung S F, Poddar S, Fu Y, Fan Z Y 2019 Nat. Commun. 10 727

Google Scholar

Google Scholar

[39] Zhao L F, Lee K M, Roh K D, Khan S U Z, Rand B P 2019 Adv. Mater. 31 1805836

Google Scholar

Google Scholar

[40] Lu J X, Feng W J, Mei G D, Sun J Y, Yan C Z, Zhang D, Lin K B, Wu D, Wang K, Wei Z H 2020 Adv. Sci. 7 2000689

Google Scholar

Google Scholar

-

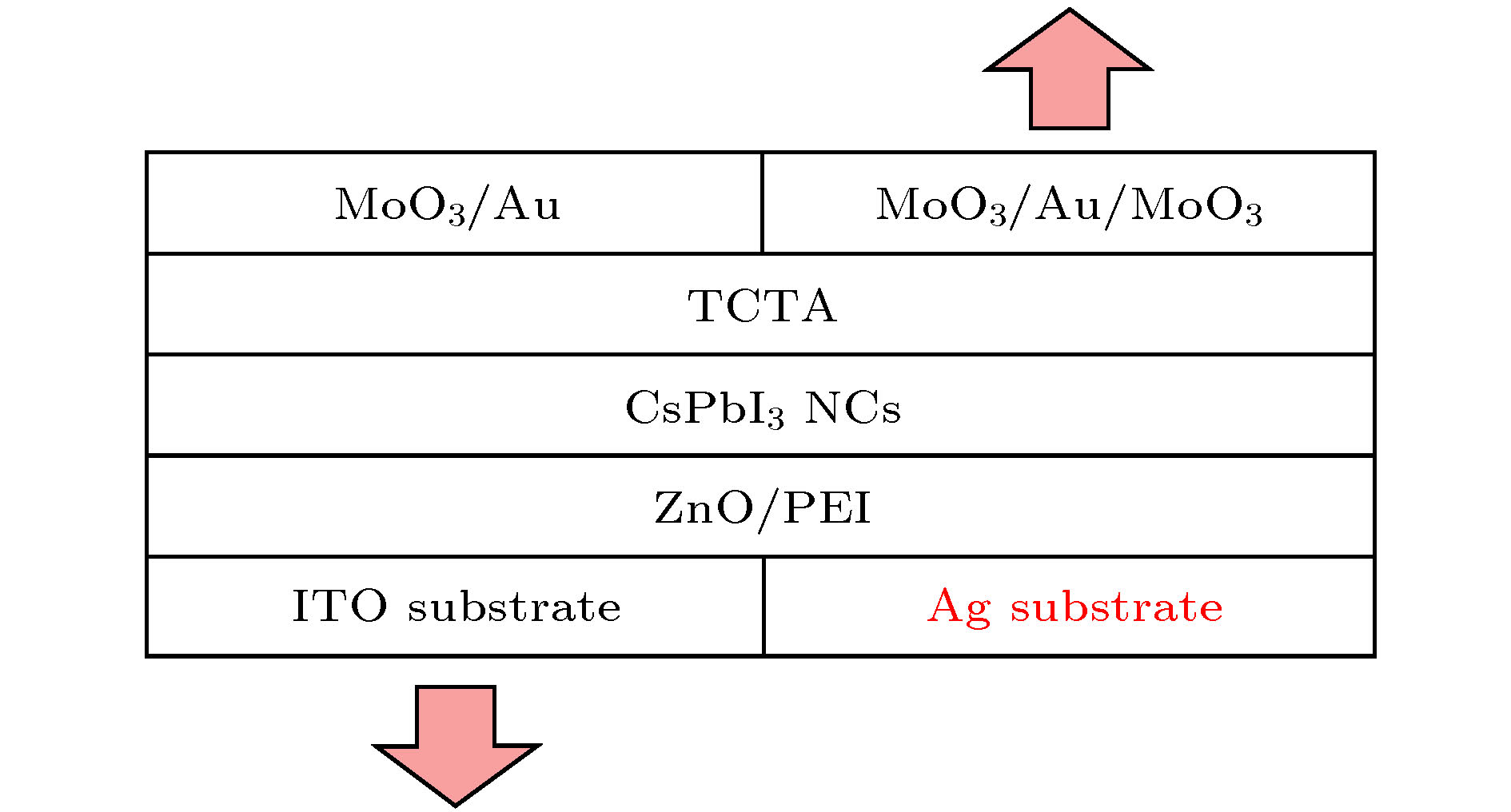

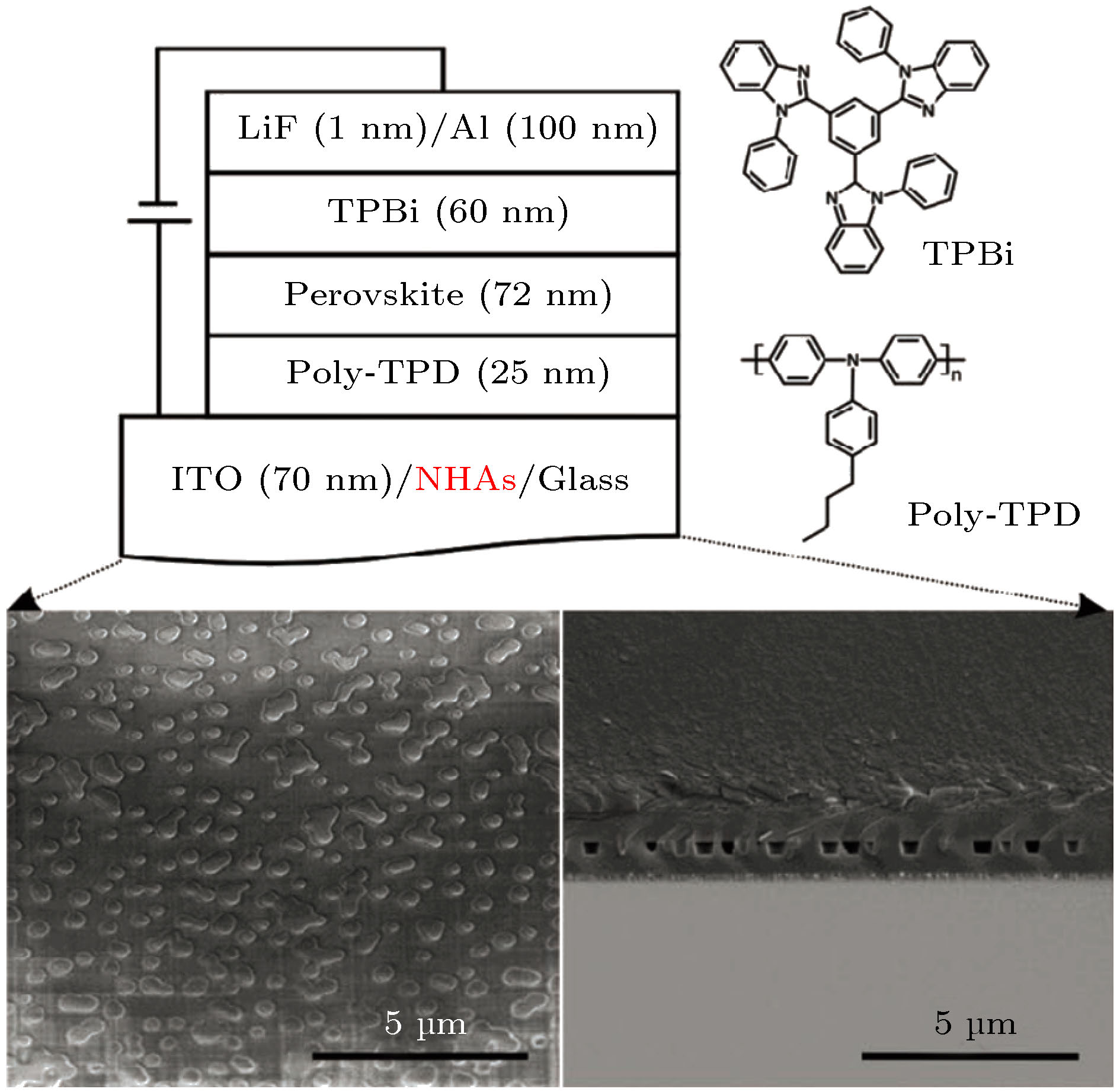

图 4 PeLED电极为ZnO-Ag-ZnO结构: (a) ZnO-Ag-ZnO结构示意图: 底部为ZnO, 中间为Ag层, 顶部为ZnO层; (b)电极分别为ITO和m-ZnO-Ag-ZnO的器件电压-电流效率图(插图显示了在5 V条件下器件的辐射性)[28]

Fig. 4. PeLED with ZnO-Ag-ZnO electrode: (a) ZnO-Ag-ZnO structure: bottom wetting ZnO layer, middle patterned Ag layer and top continuous ZnO layer; (b) current efficiency-voltage curves with ITO and ZnO-Ag-ZnO electrode (insets show the magnified view of emission uniformity on 5 V)[28].

表 1 PeLEDs光提取研究进展

Table 1. Research progress of PeLEDs light extraction.

发表

时间器件结构 光提取方法 CEmax/cd·A–1 EQEmax/% 最大亮度/cd·m–2 寿命参数T50 参考

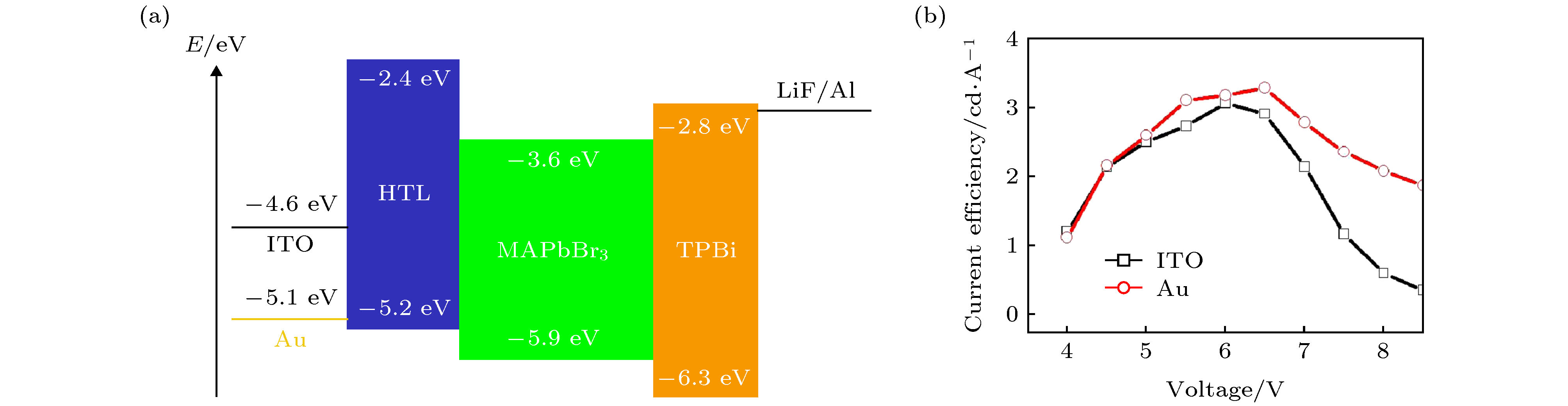

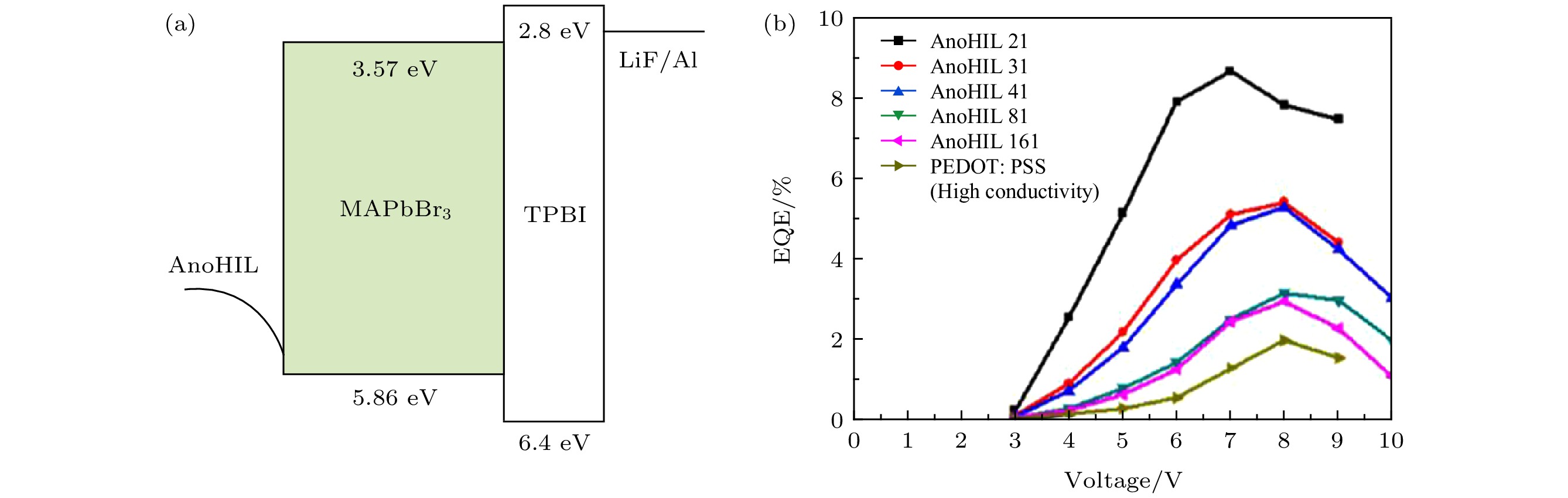

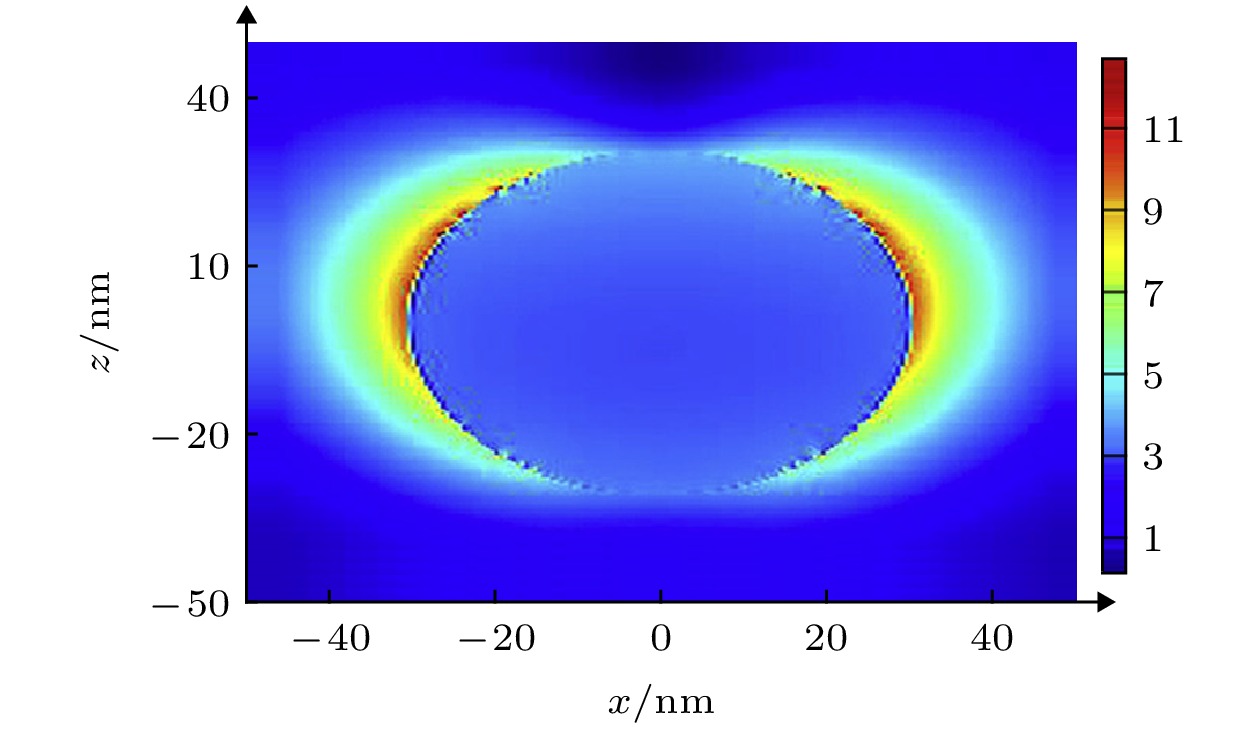

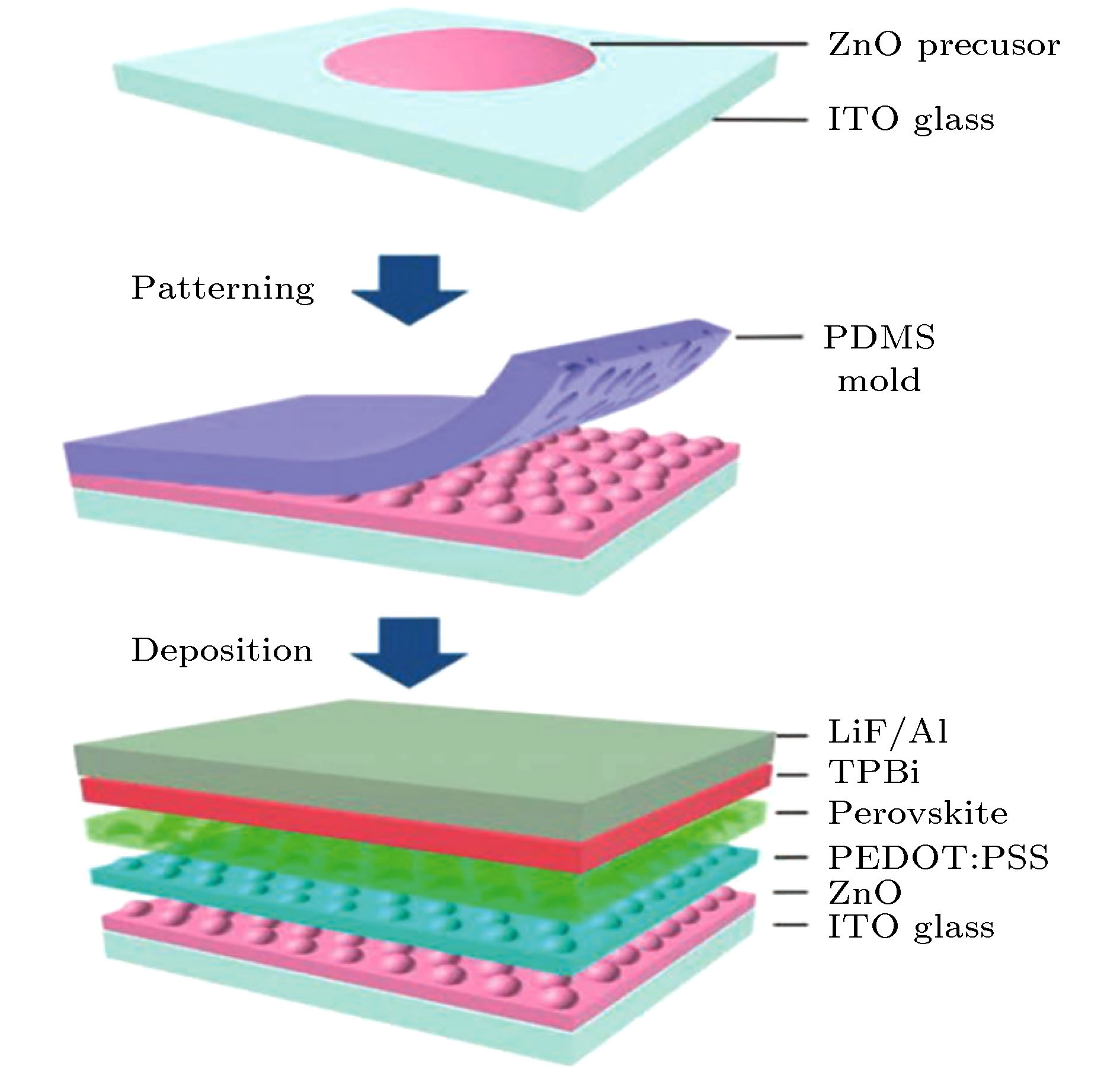

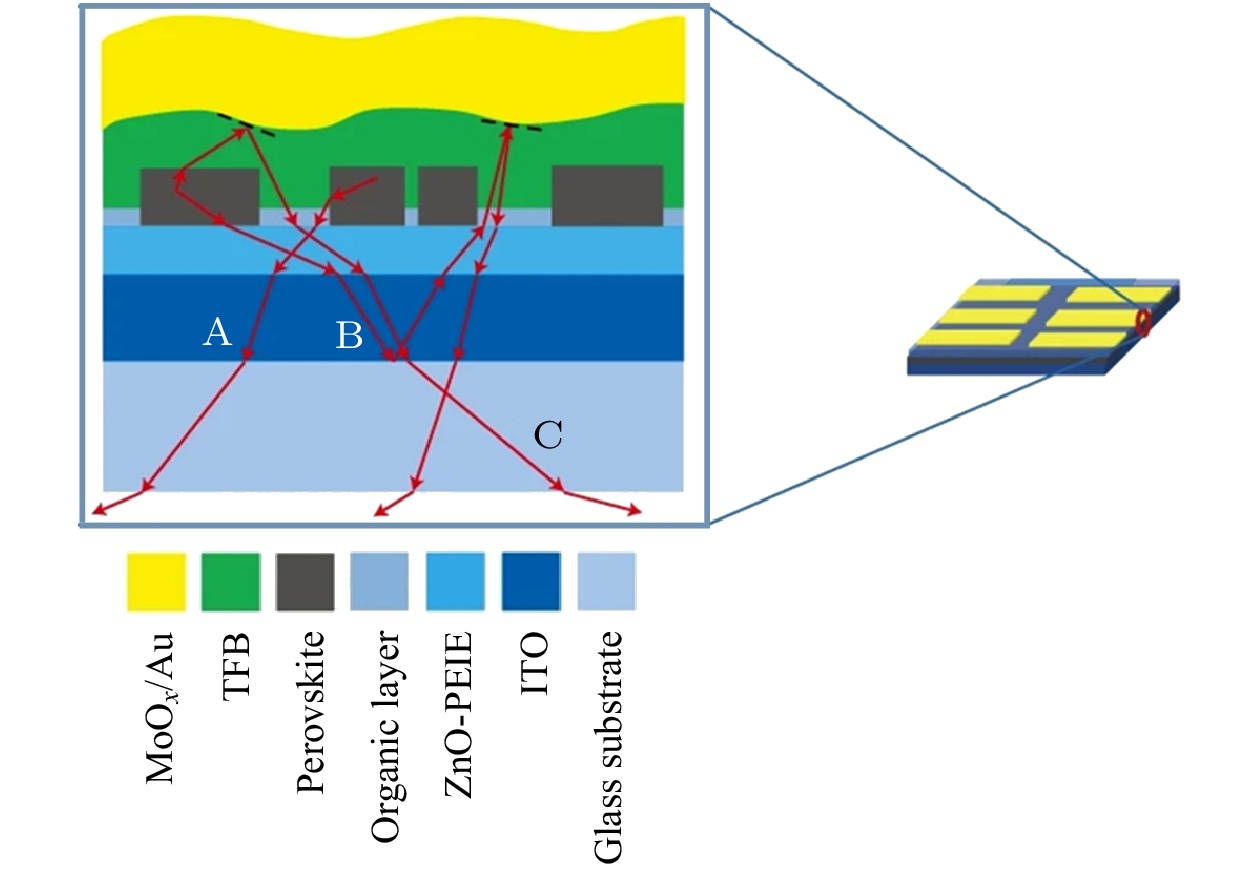

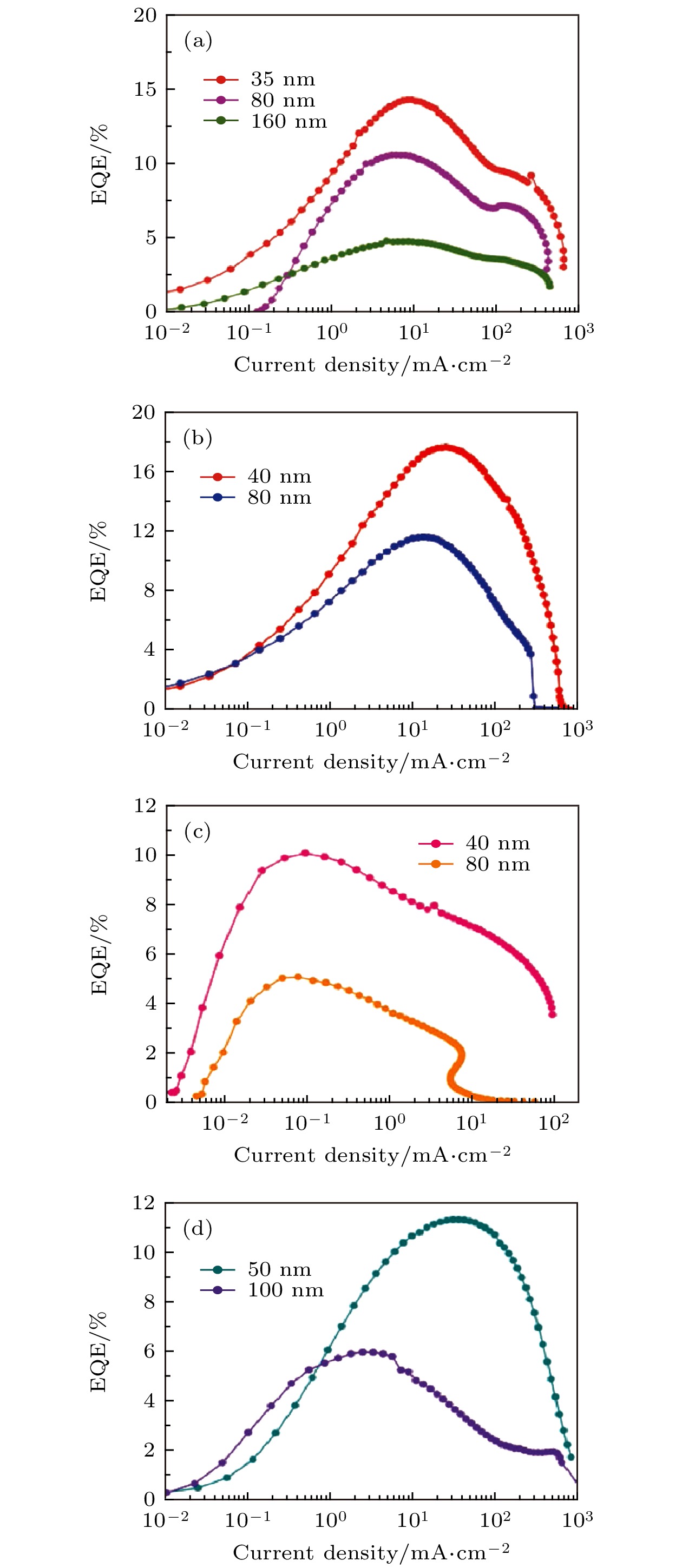

文献2017 4LG/Buf-HIL/MAPbBr3/TPBi/LiF/Al 电极 18.0 3.8 13000 — [25] 2018 Ag/(ZnO/PEI)/CsPbI3NC /TCTA/(MoO3/Au/MoO3) 电极 — 11.2 1106 — [26] 2018 Au/HIL/MAPbBr3/TPBi/LiF/AL 电极 3.3 — 11270 — [27] 2019 m-ZAgZ/HAT-CN/TAPC/CsPbBr3/TPBi/Liq/Al 电极 7.21 — 4846 — [28] 2018 Glass/AnoHIL/MAPbBr3/TPBi/Li/AL 电极 42 8.66 — — [29] 2020 Glass/Au/ZnO/MQW perovskite/

TFB/MoO3/Au电极

微腔— 20.2 — — [31] 2017 Glass/ITO/PEDOT:PSS/(Agrods NPB)/

CsPbBr3 NC/TPBi/LiF/Al激元 1.42 0.43 8911 — [33] 2017 Au NPs/PVK:MAPbBr3:TPBi/

TPBi/Cs2CO3/Al激元 7.64 1.83 16050 — [34] 2019 Glass/NHAs/ITO/Poly-TPD/MAPbI3/TPBi/LiF/Al 微纳 — 0.012 0.53 W·sr –1·m–2 — [36] 2019 Glass/Epoxy/AAM(TiO2)/ITO/PEDOT:PSS/

BA: CH3 NH3 PbBr3/F8/Ca/Ag微纳 — 17.5 48668 120 s [38] 2019 Glass/ITO/ZnO/PEDOT:PSS/

CsPbBr3/TPBi/LiF/Al微纳 88.7 28.2 ~25000 — [12] 2018 Glass/ITO/ZnO/ZnO-PEIE/

FAPbI3/TFB/MoOx/Au薄膜形貌 — 20.7 390 W·sr –1· m–2 20 h [11] 2020 Glass/ITO/ PEDOT:PSS/Perovskite/

B3PyMPM/LiF/Al器件结构 — 17.6 79700 — [39] -

[1] Wang J P, Wang N N, Jin Y Z, Si J J, Tan Z K, Du H, Cheng L, Dai X L, Bai S, He H P, Ye Z Z, Lai M L, Friend R H, Huang W 2015 Adv. Mater. 27 2311

Google Scholar

Google Scholar

[2] Meng F Y, Liu X Y, Chen Y X, Cai X Y, Li M K, Shi T T, Chen Z M, Chen D C, Yip H L, Ramanan C, Blom P W M, Su S J 2020 Adv. Funct. Mater. 2020 1910167

Google Scholar

Google Scholar

[3] Lee S J, Park J H, Nam Y S, Lee B R, Zhao B D, Nuzzo D D, Jung E D, Jeon H, Kim J Y, Jeong H Y, Friend R H, Song M H 2018 ACS Nano 12 3417

Google Scholar

Google Scholar

[4] Tan Z K, Moghaddam R S, Lai M L, Docampo P, Higler R, Deschler F, Price M, Sadhanala A, Pazos L M, Credgington D, Hanusch F, Bein T, Snaith H J, Friend R H 2014 Nat. Nanotechnol. 9 687

Google Scholar

Google Scholar

[5] Quan L N, Arquer F P G D, Sabatini R P, Sargent E H 2018 Adv. Mater. 30 1801996

Google Scholar

Google Scholar

[6] Wei Z H, Xing J 2019 J. Phys. Chem. Lett. 10 3035

Google Scholar

Google Scholar

[7] Zou Y, Yuan Z, Bai S, Gao F, Sun B 2019 Mater. Today Nano 5 100028

Google Scholar

Google Scholar

[8] Veldhuis S A, Boix P P, Yantara N, Li M, Sum T C, Mathews N, Mhaisalkar S G 2016 Adv. Mater. 28 6804

Google Scholar

Google Scholar

[9] Park M H, Park J, Lee J, So H S, Kim H, Jeong S H, Han T H, Wolf C, Lee H, Yoo S, Lee T W 2019 Adv. Funct. Mater. 29 1902017

Google Scholar

Google Scholar

[10] Fang Z B, Chen W J, Shi Y L, Zhao J, Chu S L, Zhang J, Xiao Z G 2020 Adv. Funct. Mater. 30 1909754

Google Scholar

Google Scholar

[11] Cao Y, Wang N N, Tian H, Guo J S, Wei Y Q, Chen H, Miao Y F, Zou W, Pan K, He Y R, Cao H, Ke Y, Xu M M, Wang Y, Yang M, Du K, Fu Z, Kong D C, Dai D X, Jin Y Z, Li G Q, Li H, Peng Q M, Wang J P, Huang W 2018 Nature 562 249

Google Scholar

Google Scholar

[12] Shen Y, Cheng L P, Li Y Q, Li W, Chen J D, Lee S T, Tang J X 2019 Adv. Mater. 31 1901517

Google Scholar

Google Scholar

[13] Lin K B, Xing J, Quan L N, Arquer F P G D, Gong X W, Lu J X, Xie L Q, Zhao W J, Zhang D, Yan C Z, Li W Q, Liu X Y, Lu Y, Kirman J, Sargent E H, Xiong Q H, Wei Z H 2018 Nature 562 245

Google Scholar

Google Scholar

[14] Zhao B D, Bai S, Kim V, Lamboll R, Shivanna R, Auras F, Richter J M, Yang L, Dai L J, Alsari M, She X J, Liang L S, Zhang J B, Lilliu S, Gao P, Snaith H J, Wang J P, Greenham N C, Friend R H, Di D W 2018 Nat. Photonics 12 783

Google Scholar

Google Scholar

[15] Zhao X F, Tan Z K 2019 Nat. Photonics 4851 50

[16] Xu W D, Hu Q, Bai S, Bao C X, Miao Y F, Yuan Z C, Borzda T, Barker A J, Tyukalova E, Hu Z J, Kawecki M, Wang H Y, Yan Z B, Liu X J, Shi X B, Uvdal K, Fahlman M, Zhang W J, Duchamp M, Liu J M, Petrozza A, Wang J P, Liu L M, Huang W, Gao F 2019 Nat. Photonics 13 418

[17] Bao C X, Xu W D, Yang J, Bai S, Teng P P, Yang Y, Wang J P, Zhao N, Zhang W J, Huang W, Gao F 2020 Nat. Electron. 3 156

Google Scholar

Google Scholar

[18] 方晓敏, 江孝伟, 赵建伟 2018 激光与光电子学进展 55 082302

Google Scholar

Google Scholar

Fang X M, Jiang X W, Zhao J W 2018 Laser Optoelectronics Progress 55 082302

Google Scholar

Google Scholar

[19] Hong K, Lee J L 2011 Electron. Mater. Lett. 7 77

Google Scholar

Google Scholar

[20] Meng S S, Li Y Q, Tang J X 2018 Org. Electron. 61 351

Google Scholar

Google Scholar

[21] 李国龙, 黄卓寅, 李衎, 甄红宇, 沈伟东, 刘旭 2011 60 077207

Google Scholar

Google Scholar

Li G L, Huang Z Y, Li K, Zhen H Y, Shen W D, Liu X 2011 Acta. Phys. Sin. 60 077207

Google Scholar

Google Scholar

[22] Hsu C W, Lee Y C, Chen H L, Chou Y F 2012 Photonic. Nanostruct. 10 523

Google Scholar

Google Scholar

[23] Gao C H, Zhang Y, Ma X J, Yu F X, Jia Y L, Lei Y L, Chen P, Sun W W, Xiong Z H 2018 Org. Electron. 58 88

Google Scholar

Google Scholar

[24] Zhou Y, Wu G M, Gao D W, Xing G J, Zhu Y Y, Zhang Z Q, Cao Y 2012 Adv. Mat. Res. 465 268

Google Scholar

Google Scholar

[25] Seo H K, Kim H, Lee J, Park M H, Jeong S H, Kim Y H, Kwon S J, Han T H, Yoo S, Lee T W 2017 Adv. Mater. 29 1605587

Google Scholar

Google Scholar

[26] Lu M, Zhang X Y, Bai X, Wu H, Shen X Y, Zhang Y, Zhang W, Zheng W T, Song H W, Yu W W, Rogach A L 2018 ACS Energy Lett. 3 1571

Google Scholar

Google Scholar

[27] Liu Y S, Guo S, Yi F S, Feng J, Sun H B 2018 Opt. Lett. 43 5524

Google Scholar

Google Scholar

[28] Liu Y F, Ding T, Wang H R, Zhang Y T, Chen C, Chen X T, Duan Y 2020 Appl. Surf. Sci. 504 144442

Google Scholar

Google Scholar

[29] Jeong S H, Woo S H, Han T H, Park M H, Cho H, Kim Y H, Cho H, Kim Y H, Cho H, Kim H, Yoo S, Lee T W 2017 Npg. Asia. Mater. 9 e411

Google Scholar

Google Scholar

[30] Wu H, Zhang Y, Zhang X Y, Lu M, Sun C, Bai X, Zhang T Q, Sun G, Yu W W 2018 Adv. Electron. Mater. 4 1700285

Google Scholar

Google Scholar

[31] Miao Y F, Cheng L, Zou W, Gu L H, Zhang J, Guo Q, Peng Q M, Xu M M, He Y R, Zhang S T, Cao Y, Li R Z, Wang N N, Huang W, Wang J P 2020 Light Sci. Appl. 9 89

Google Scholar

Google Scholar

[32] Woo R W 1902 Proc. Phys. Soc. London 18 269

Google Scholar

Google Scholar

[33] Zhang X L, Xu B, Wang W G, Liu S, Zheng Y J, Chen S M, Wang K, Sun X W 2017 ACS. Appl. Mater. Inter. 9 4926

Google Scholar

Google Scholar

[34] Chen P, Xiong Z Y, Wu X Y, Shao M, Meng Y, Xiong Z H, Gao C H 2017 J. Phys. Chem. Lett. 8 3961

Google Scholar

Google Scholar

[35] Zhang Y H, Sun H Q, Zhang S, Li S P, Wang X, Zhang X, Liu T Y, Guo Z Y 2019 Opt. Mater. 89 563

Google Scholar

Google Scholar

[36] Mao J, Sha W E I, Zhang H, Ren X G, Zhuang J Q, Roy V A L, Wong K S, Choy W C H 2017 Adv. Funct. Mater. 27 1606525

Google Scholar

Google Scholar

[37] Jeon S H, Zhao L F, Jung Y J, Kim J W, Kim S Y, Kang H, Jeong J H, Rand B P, Lee J H 2019 Small 15 1900135

Google Scholar

Google Scholar

[38] Zhang Q P, Tavakoli M M, Gu L L, Zhang D Q, Tang L, Gao Y, Guo J, Lin Y J, Leung S F, Poddar S, Fu Y, Fan Z Y 2019 Nat. Commun. 10 727

Google Scholar

Google Scholar

[39] Zhao L F, Lee K M, Roh K D, Khan S U Z, Rand B P 2019 Adv. Mater. 31 1805836

Google Scholar

Google Scholar

[40] Lu J X, Feng W J, Mei G D, Sun J Y, Yan C Z, Zhang D, Lin K B, Wu D, Wang K, Wei Z H 2020 Adv. Sci. 7 2000689

Google Scholar

Google Scholar

计量

- 文章访问数: 13563

- PDF下载量: 302

- 被引次数: 0

下载:

下载: