-

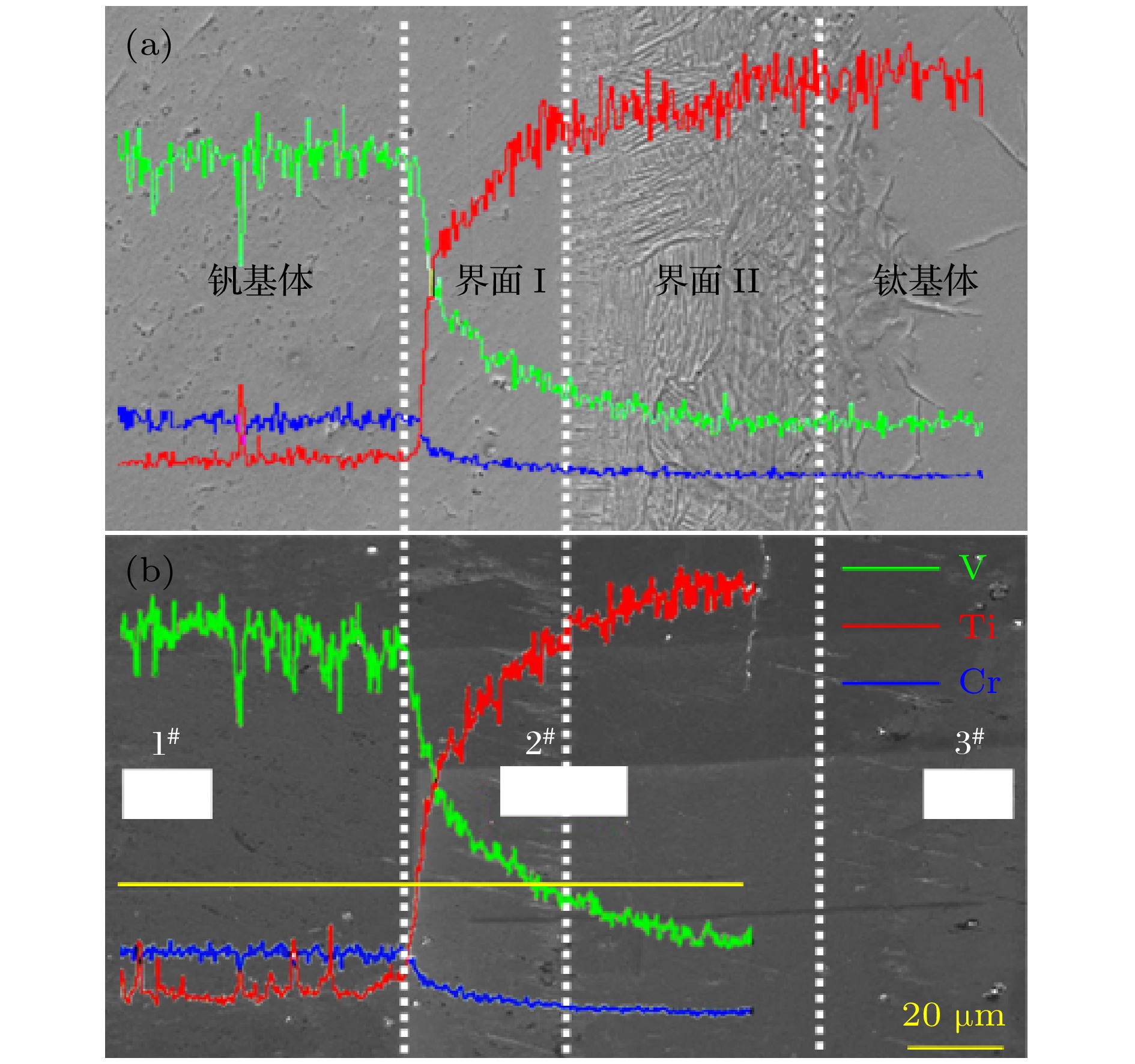

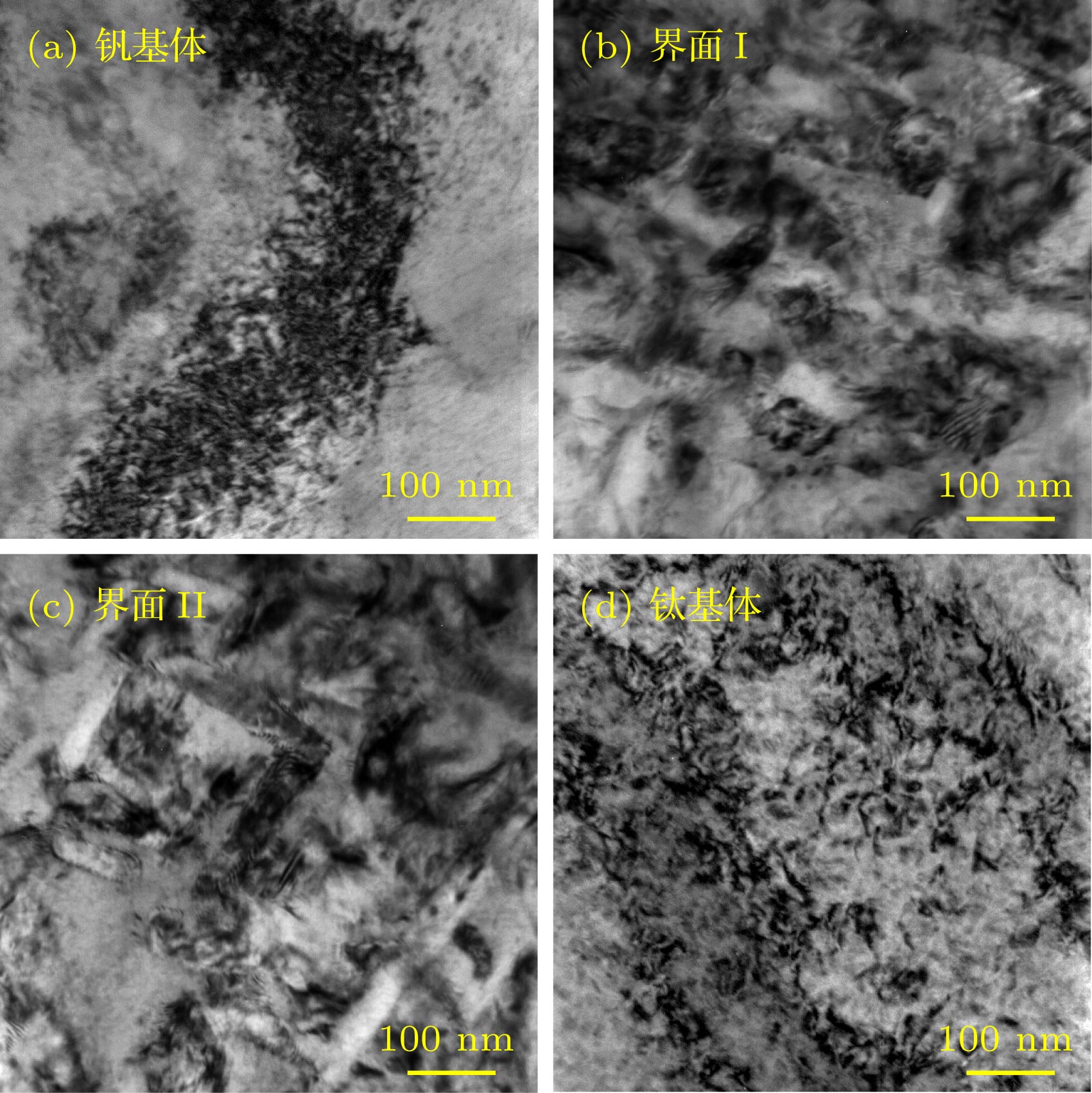

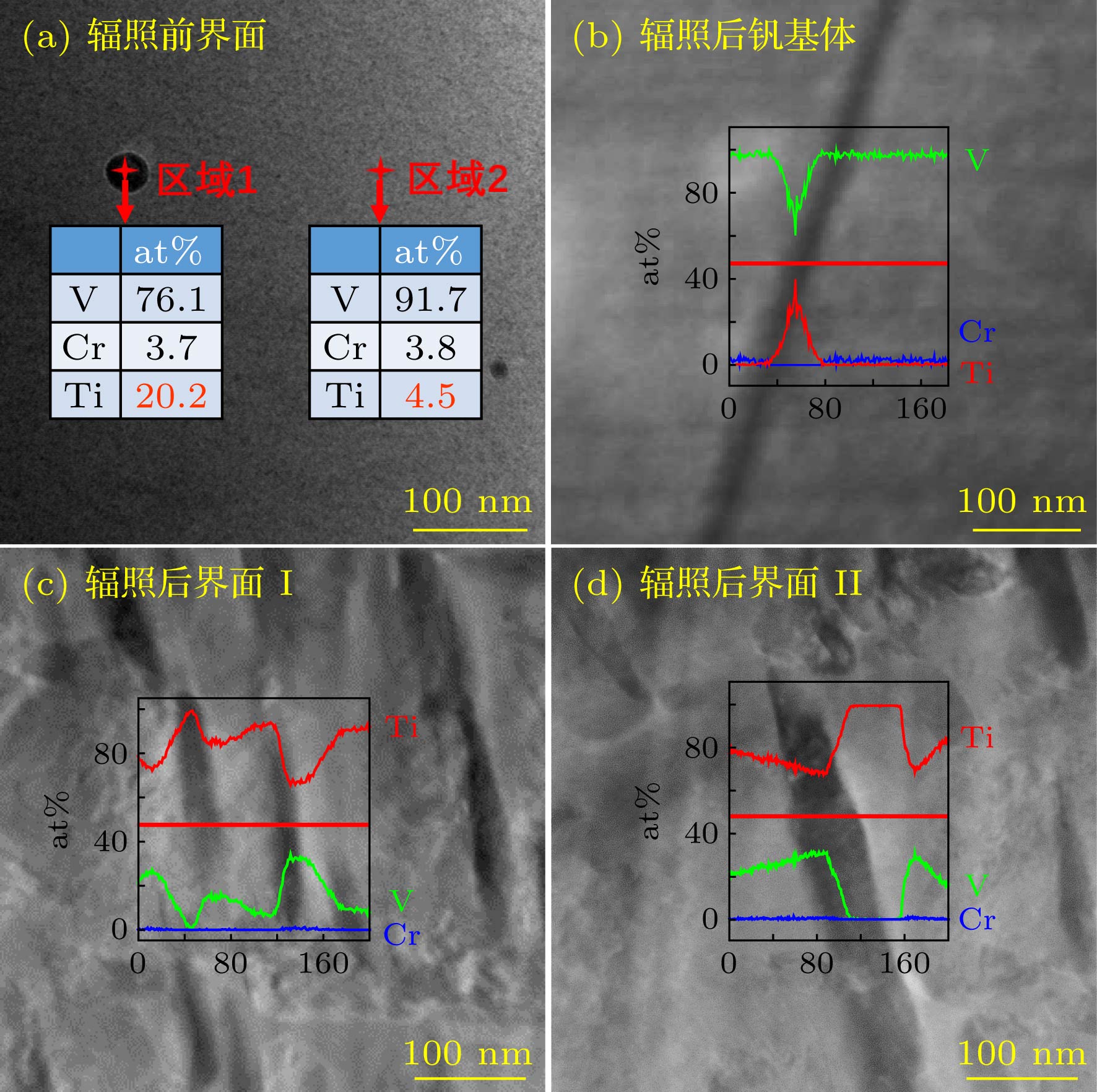

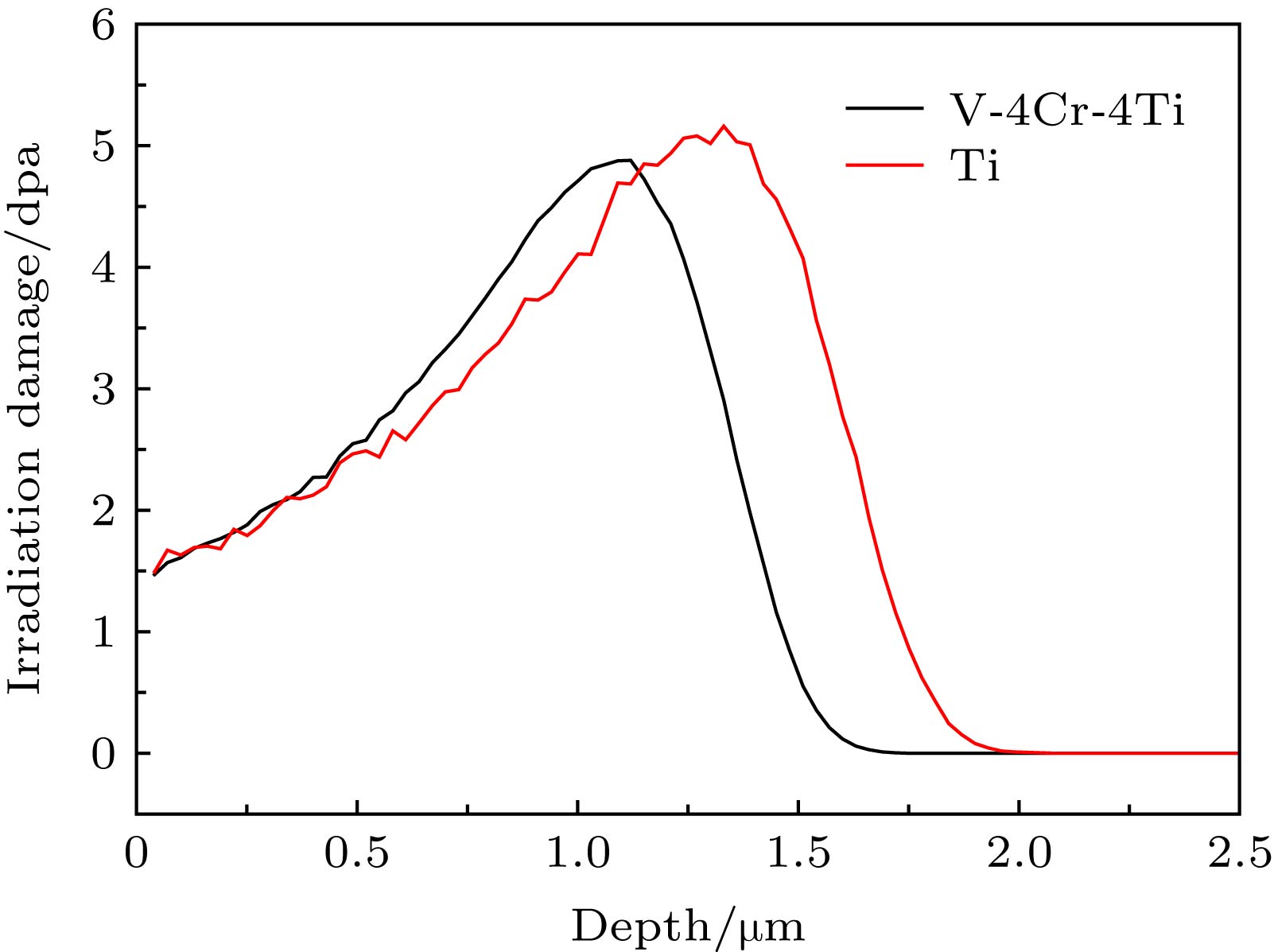

The development of electrically insulating coatings is extremely important for the lithium/vanadium (Li/V) blanket of the fusion reactor. However, Li/V cladding materials suffer many problems such as tritiumpermeation and material corrosion. Thus, it is very important to find suitable insulating, tritium-resistant and corrosion-resistant coatings. So, the " V-alloy/Ti/AlN” bilayer coating was proposed by our group in previous study for the first time. In this paper, the evolution of the hardness, irradiation defects and microstructure of the Ti-clad V-4Cr-4Ti composite material after Fe10+ implantation are studied by transmission electron microscopy (TEM) and nanoindentation. According to the characteristics of the composition and microstructure, V-4Cr-4Ti/Ti composite material can be divided into four zones: V-4Cr-4Ti matrix, interface I (the interface near V-4Cr-4Ti matrix), interface II (the interface near Ti matrix), and Ti matrix. The nanoindentation results show that radiation hardening occurs in all regions during irradiation. The radiation hardening in the interface is lower than in the V-4Cr-4Ti and Ti matrix. Thus, the interface of heterogeneous material exhibits fine resistance to radiation hardening. The experimental values of hardness are much higher than the values calculated by the dispersed barrier hardening model. One reason for the discrepancy is that the theoretical values are calculated under the hypothesis of the uniform loop distribution. Actually, a large number of dislocation loops accumulate and tangle with each other in the samples. In addition, the formation of the precipitates is also one of the key factors. The TEM results show that the irradiation defects in the interface are low in density, large in size, and uniform in distribution. As a contrast, high density, small size and twisted dislocation loops are observed in irradiated V-4Cr-4Ti and Ti matrix. These results indicate that the interface can play a critical role in the resistance to irradiation damage. Few tiny Ti-rich precipitates appear in the V-4Cr-4Ti matrix, while there are large quantities of Ti precipitates in the interface after irradiation. Moreover, the number and size of precipitates in the interface I are larger than those in the interface II due to the formation of a few V-rich precipitates in the interface I. The formation of precipitations changes the proportion of V/Ti, which leads to the transformation from β-Ti to α-Ti in the interface.

[1] 张高伟, 韩文妥, 崔丽娟, 万发荣 2018 稀有金属材料与工程 5 1537

Zhang G W, Han W T, Cui L J, Wan F R 2018 Rare Metal Mat. Eng. 5 1537

[2] Zhang G W, Han W T, Yi X O, Wan F R 2018 Appl. Sci. 8 577

Google Scholar

Google Scholar

[3] Gohar Y, Majumdar S, Smith D L 2000 Fusion Eng. Des. 49 551

[4] Smith D L, Billone M C, Natesan K 2000 Int. J. Refract. Met. H 18 213

Google Scholar

Google Scholar

[5] Jones R H, Heinisch H L, McCarthy K A 1999 J. Nucl. Mater. 271 518

[6] Kirillov I R, Danilov I V, Sidorenkov S I, Strebkov Y S, Mattas R F, Gohar Y, Hua T Q, Smith D L 1998 Fusion Eng. Des. 39 669

[7] Mattas R F, Smith D L, Reed C D, Parka J H, Kirillov I R, Strebkov Y S, Rusanov A E, Votinov S N 1998 Fusion Eng. Des. 39 659

[8] Muroga T 2005 Mater. Trans. 46 405

Google Scholar

Google Scholar

[9] Malang S, Bühler L 1994 MHD Pressure Drop in Ducts with Imperfectly Insulating Coatings (Chicago: Argonne National Laboratory Report) Report No. ANL/FPP/TM-269

[10] Vertkov A V, Evtikhin V A, Lyublinski I E 2001 Fusion Eng. Des. 58 731

[11] Smith D L, Konys J, Muroga T, Evitkhin V 2002 J. Nucl. Mater. 307 1314

[12] Muroga T, Pint B A 2010 Fusion Eng. Des. 85 1301

Google Scholar

Google Scholar

[13] Wang J, Li Q, Xiang Q Y, Cao J L 2016 Fusion Eng. Des. 102 94

Google Scholar

Google Scholar

[14] Suzuki A, Muroga T, Pint B A, Yoneoka T, Tanaka S 2003 Fusion Eng. Des. 69 397

Google Scholar

Google Scholar

[15] Pint B A, DeVan J H, DiStefano J R 2002 J. Nucl. Mater. 307 1344

[16] Pint B A, Tortorelli P F, JankowskiA, Hayes J, Muroga T, Suzuki A, Yeliseyeva O I, Chernov V M 2004 J. Nucl. Mater. 329 119

[17] Jiří M, Pavel C 2010 Adv. Sci. Technol. 66 19

[18] Vitkovsky I V, Gorunov A V, Kirillov I R, Khoroshikh V M, Kraev V D, Ogorodnikov A P, Petrovsky V Y, Rusanov A E 2002 Fusion Eng. Des. 61 739

[19] Demkowicz M J, Hoagland R G, Hirth J P 2008 Phys. Rev. Lett. 100 136102

Google Scholar

Google Scholar

[20] Kolluri K, Demkowicz M J 2012 Phys. Rev. B 85 205416

Google Scholar

Google Scholar

[21] Stoller R E, Toloczko M B, Was G S, Certain A G, Dwaraknath S, Garner F A 2013 Nucl. Instrum. Meth. B 310 75

Google Scholar

Google Scholar

[22] ASTM Committee E521–96 2003 Standard Practice for Neutron Radiation Damage Simulation by Charged-Particle Irradiation (vol.12.02) (West Conshohocken: Copyright © ASTM International) p8

[23] 万发荣 1993 金属材料的辐照损伤 (北京: 科学出版社) 第143页

Wan F R 1993 Irradiation Damage of Metal Materials (Vol. 1) (Beijing: Science Press) p143 (in Chinese)

[24] Fu E G, Carter J, Swadener G, Misra A, Shao L, Wang H, Zhang X 2009 J. Nucl. Mater. 385 629

Google Scholar

Google Scholar

[25] Watanabe H, Nagamine M, Yamasaki K, Yoshida N, Heo N J, Nagasaka T, Muroga T 2005 Mater. Sci. Forum 475 1491

[26] Heo N J, Nagasaka T, Muroga T, Nishimura A, Shinozaki K, Watanabe H 2003 Fusion Sci. Technol. 44 470

Google Scholar

Google Scholar

[27] Han W Z, Demkowicz M J, Fu E G, Wang Y Q, Misra A 2012 Acta Mater. 60 6341

Google Scholar

Google Scholar

[28] Zhang Y F, Zhan Q, Ohnuki S, Kimura A, Wan F R, Yoshida K, Nagai Y 2019 J. Nucl. Mater. 517 1

Google Scholar

Google Scholar

[29] Bergner F, Pareige C, Hernández-Mayoral M, Malerba L, Heintze C 2014 J. Nucl. Mater. 448 96

Google Scholar

Google Scholar

[30] 张高伟 2018 博士学位论文 (北京: 北京科技大学)

Zhang G W 2018 Ph. D. Dissertation (Beijing: University of Science and Technology Beijing) (in Chinese)

-

表 1 通过纳米压痕所得硬化实验值与采用DBH模型对辐照硬化进行的估算值

Table 1. Experimental hardness values by nanoindentation and the estimated hardness values calculated by the DBH model

钒基体 界面I 界面II 钛基体 ΔHV实验值 207 136 55 247 N/m–3 1.5 × 1022 8.0 × 1021 8.4 × 1021 1.3 × 1022 d/nm 7.3 ± 1.5 19.9 ± 5.0 20.3 ± 4.8 11.2 ± 2.0 N·d 1.09 × 1014 1.59 × 1014 1.70 × 1014 1.46 × 1014 $ \sqrt {N\cdot d} $ 1.05 × 107 1.26 × 107 1.31 × 107 1.21 × 107 ΔHV计算值 39.5 27.7 38.6* 44.8 注: *表示界面II处α + β Ti区的硬化按α-Ti和β-Ti各占50%进行计算. -

[1] 张高伟, 韩文妥, 崔丽娟, 万发荣 2018 稀有金属材料与工程 5 1537

Zhang G W, Han W T, Cui L J, Wan F R 2018 Rare Metal Mat. Eng. 5 1537

[2] Zhang G W, Han W T, Yi X O, Wan F R 2018 Appl. Sci. 8 577

Google Scholar

Google Scholar

[3] Gohar Y, Majumdar S, Smith D L 2000 Fusion Eng. Des. 49 551

[4] Smith D L, Billone M C, Natesan K 2000 Int. J. Refract. Met. H 18 213

Google Scholar

Google Scholar

[5] Jones R H, Heinisch H L, McCarthy K A 1999 J. Nucl. Mater. 271 518

[6] Kirillov I R, Danilov I V, Sidorenkov S I, Strebkov Y S, Mattas R F, Gohar Y, Hua T Q, Smith D L 1998 Fusion Eng. Des. 39 669

[7] Mattas R F, Smith D L, Reed C D, Parka J H, Kirillov I R, Strebkov Y S, Rusanov A E, Votinov S N 1998 Fusion Eng. Des. 39 659

[8] Muroga T 2005 Mater. Trans. 46 405

Google Scholar

Google Scholar

[9] Malang S, Bühler L 1994 MHD Pressure Drop in Ducts with Imperfectly Insulating Coatings (Chicago: Argonne National Laboratory Report) Report No. ANL/FPP/TM-269

[10] Vertkov A V, Evtikhin V A, Lyublinski I E 2001 Fusion Eng. Des. 58 731

[11] Smith D L, Konys J, Muroga T, Evitkhin V 2002 J. Nucl. Mater. 307 1314

[12] Muroga T, Pint B A 2010 Fusion Eng. Des. 85 1301

Google Scholar

Google Scholar

[13] Wang J, Li Q, Xiang Q Y, Cao J L 2016 Fusion Eng. Des. 102 94

Google Scholar

Google Scholar

[14] Suzuki A, Muroga T, Pint B A, Yoneoka T, Tanaka S 2003 Fusion Eng. Des. 69 397

Google Scholar

Google Scholar

[15] Pint B A, DeVan J H, DiStefano J R 2002 J. Nucl. Mater. 307 1344

[16] Pint B A, Tortorelli P F, JankowskiA, Hayes J, Muroga T, Suzuki A, Yeliseyeva O I, Chernov V M 2004 J. Nucl. Mater. 329 119

[17] Jiří M, Pavel C 2010 Adv. Sci. Technol. 66 19

[18] Vitkovsky I V, Gorunov A V, Kirillov I R, Khoroshikh V M, Kraev V D, Ogorodnikov A P, Petrovsky V Y, Rusanov A E 2002 Fusion Eng. Des. 61 739

[19] Demkowicz M J, Hoagland R G, Hirth J P 2008 Phys. Rev. Lett. 100 136102

Google Scholar

Google Scholar

[20] Kolluri K, Demkowicz M J 2012 Phys. Rev. B 85 205416

Google Scholar

Google Scholar

[21] Stoller R E, Toloczko M B, Was G S, Certain A G, Dwaraknath S, Garner F A 2013 Nucl. Instrum. Meth. B 310 75

Google Scholar

Google Scholar

[22] ASTM Committee E521–96 2003 Standard Practice for Neutron Radiation Damage Simulation by Charged-Particle Irradiation (vol.12.02) (West Conshohocken: Copyright © ASTM International) p8

[23] 万发荣 1993 金属材料的辐照损伤 (北京: 科学出版社) 第143页

Wan F R 1993 Irradiation Damage of Metal Materials (Vol. 1) (Beijing: Science Press) p143 (in Chinese)

[24] Fu E G, Carter J, Swadener G, Misra A, Shao L, Wang H, Zhang X 2009 J. Nucl. Mater. 385 629

Google Scholar

Google Scholar

[25] Watanabe H, Nagamine M, Yamasaki K, Yoshida N, Heo N J, Nagasaka T, Muroga T 2005 Mater. Sci. Forum 475 1491

[26] Heo N J, Nagasaka T, Muroga T, Nishimura A, Shinozaki K, Watanabe H 2003 Fusion Sci. Technol. 44 470

Google Scholar

Google Scholar

[27] Han W Z, Demkowicz M J, Fu E G, Wang Y Q, Misra A 2012 Acta Mater. 60 6341

Google Scholar

Google Scholar

[28] Zhang Y F, Zhan Q, Ohnuki S, Kimura A, Wan F R, Yoshida K, Nagai Y 2019 J. Nucl. Mater. 517 1

Google Scholar

Google Scholar

[29] Bergner F, Pareige C, Hernández-Mayoral M, Malerba L, Heintze C 2014 J. Nucl. Mater. 448 96

Google Scholar

Google Scholar

[30] 张高伟 2018 博士学位论文 (北京: 北京科技大学)

Zhang G W 2018 Ph. D. Dissertation (Beijing: University of Science and Technology Beijing) (in Chinese)

Catalog

Metrics

- Abstract views: 9919

- PDF Downloads: 84

- Cited By: 0

DownLoad:

DownLoad: