-

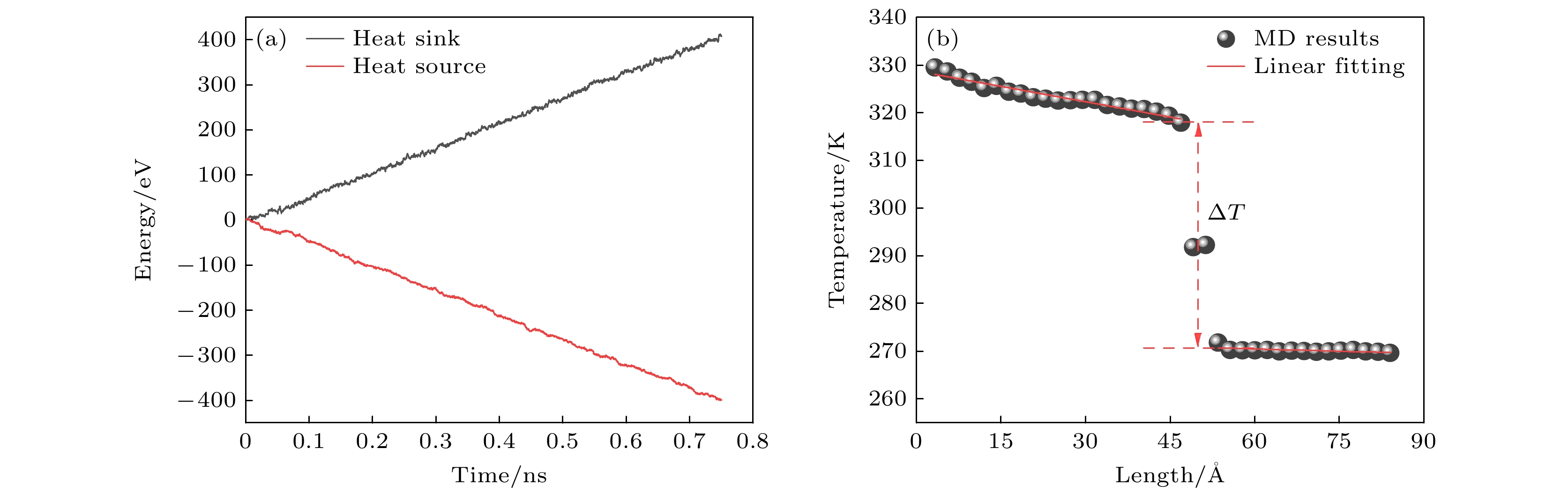

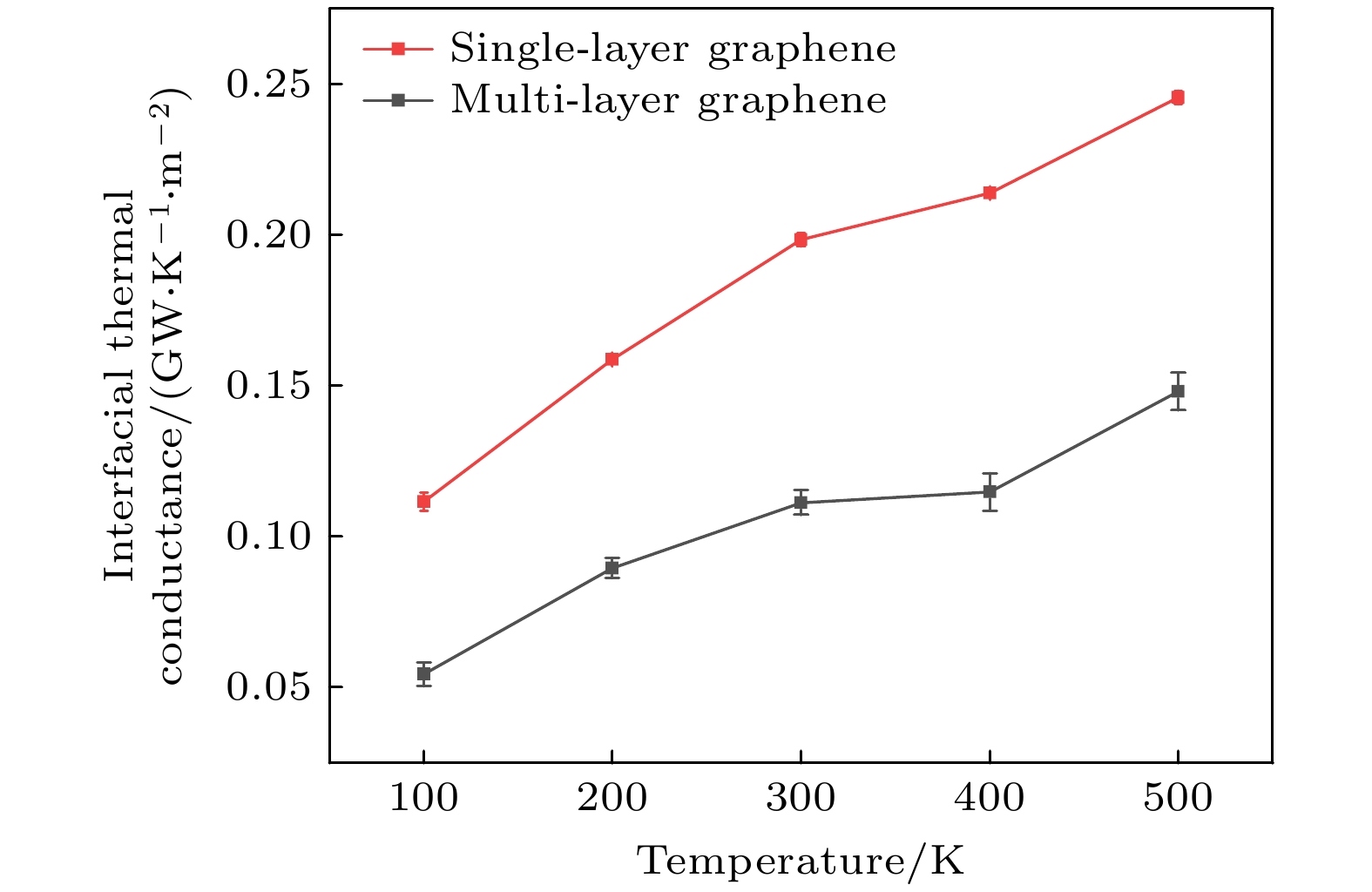

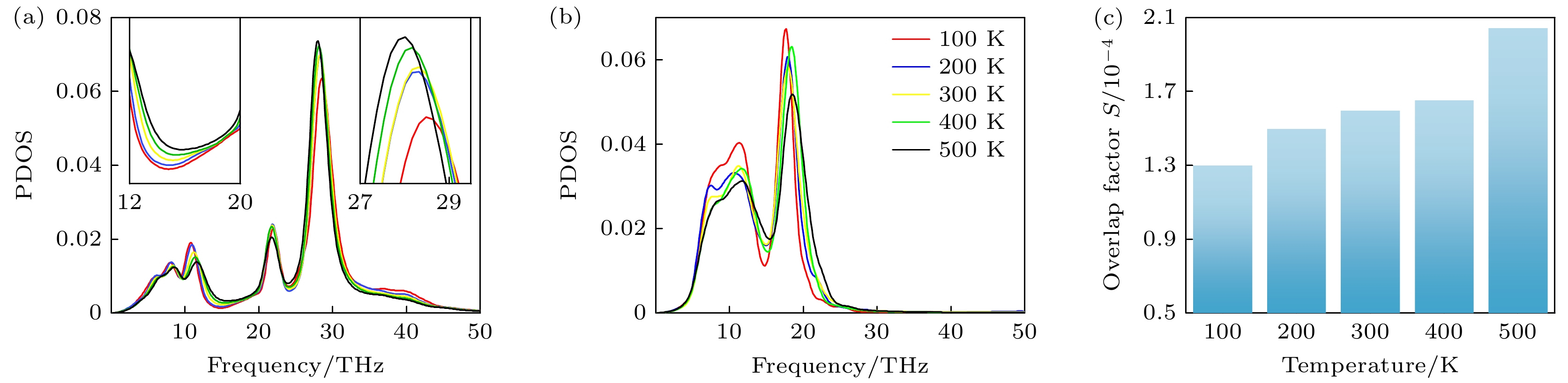

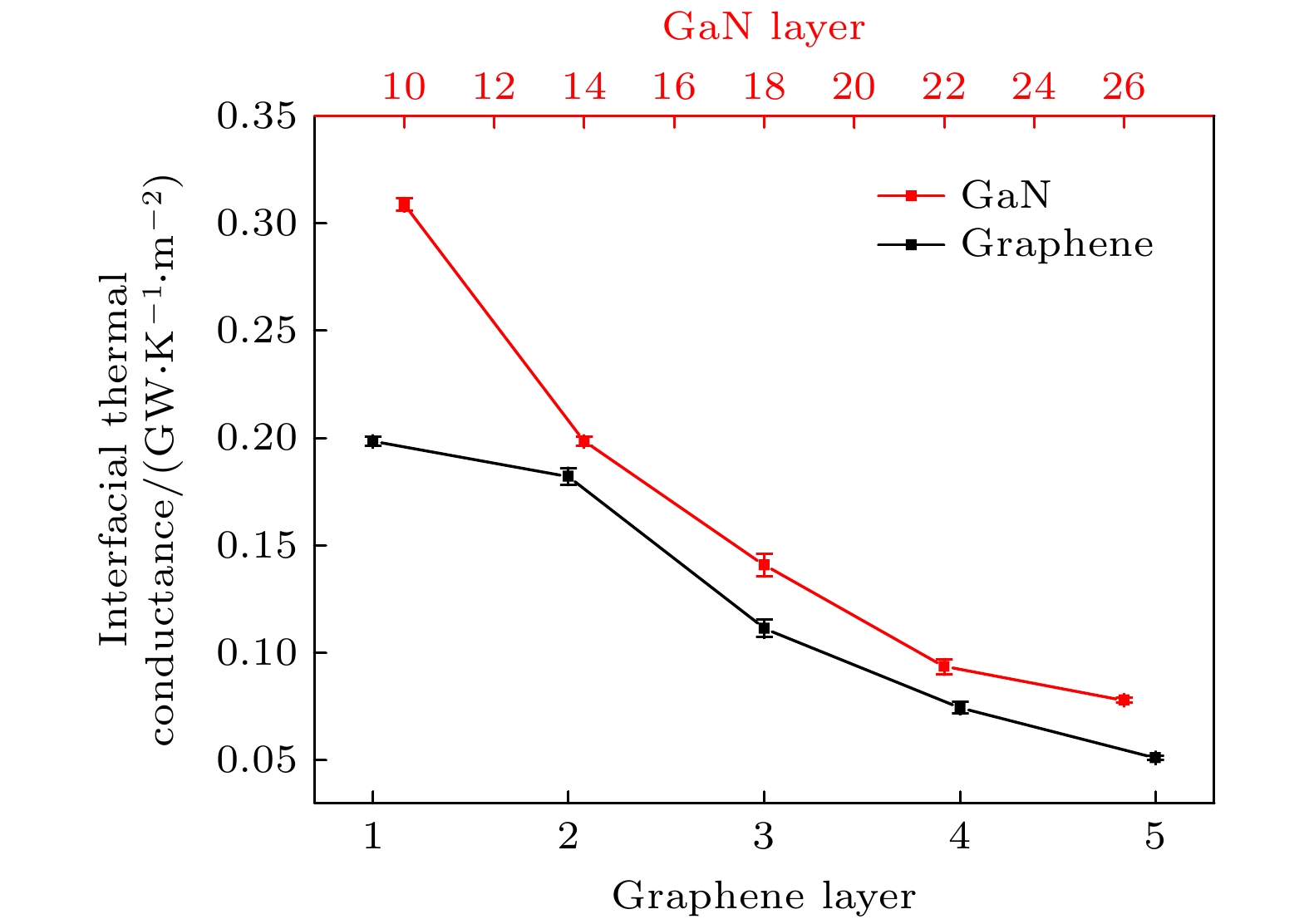

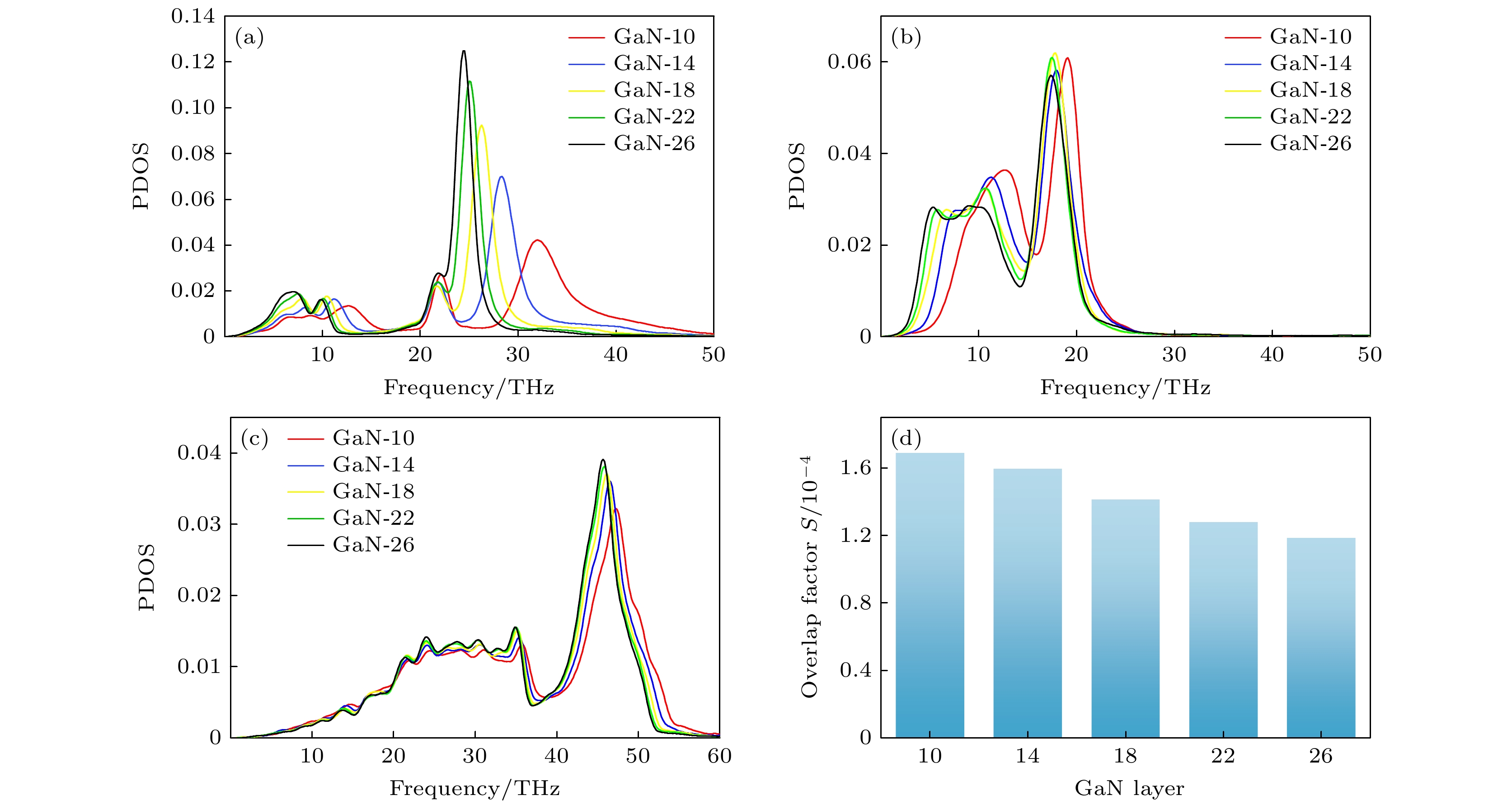

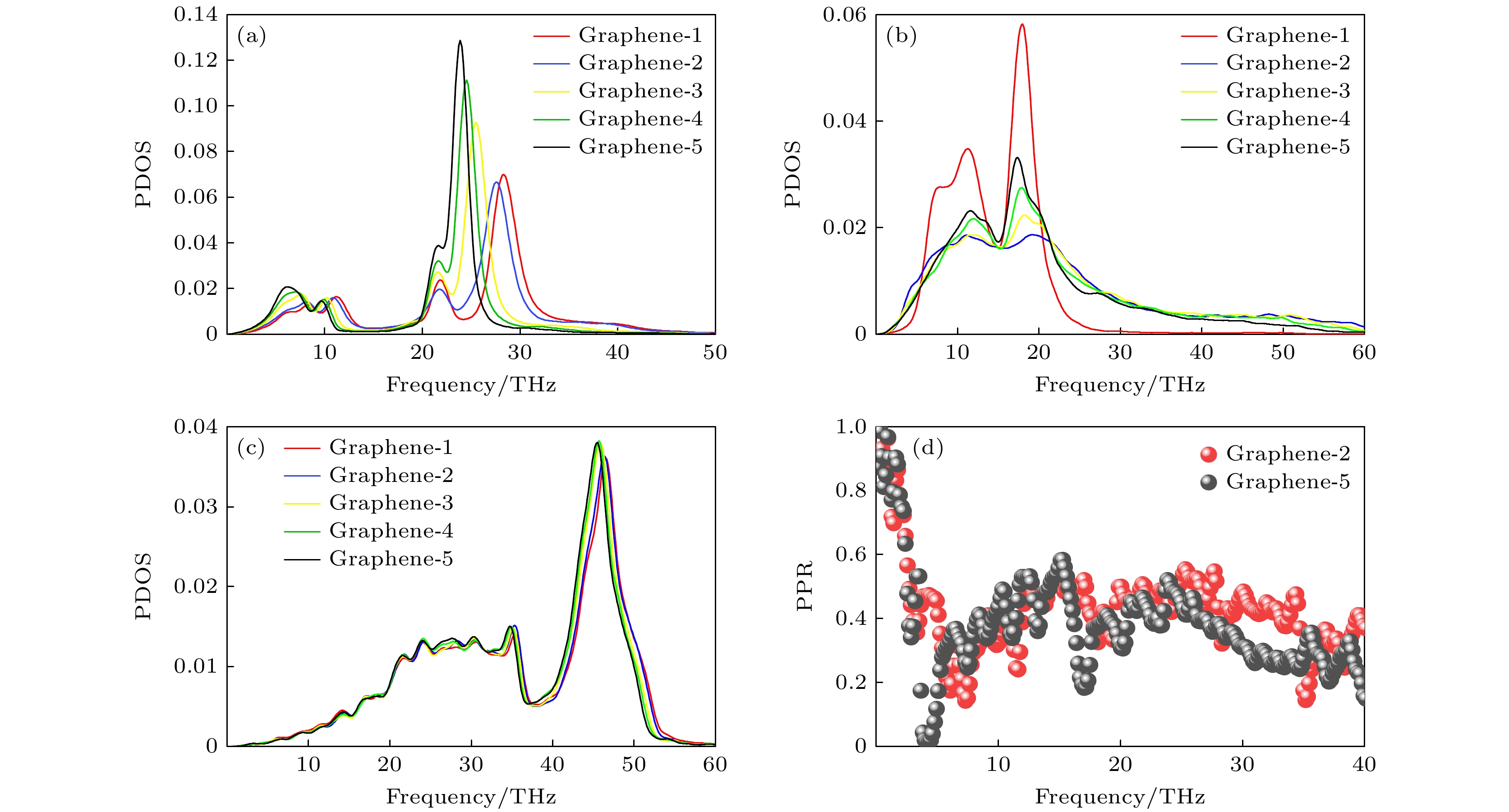

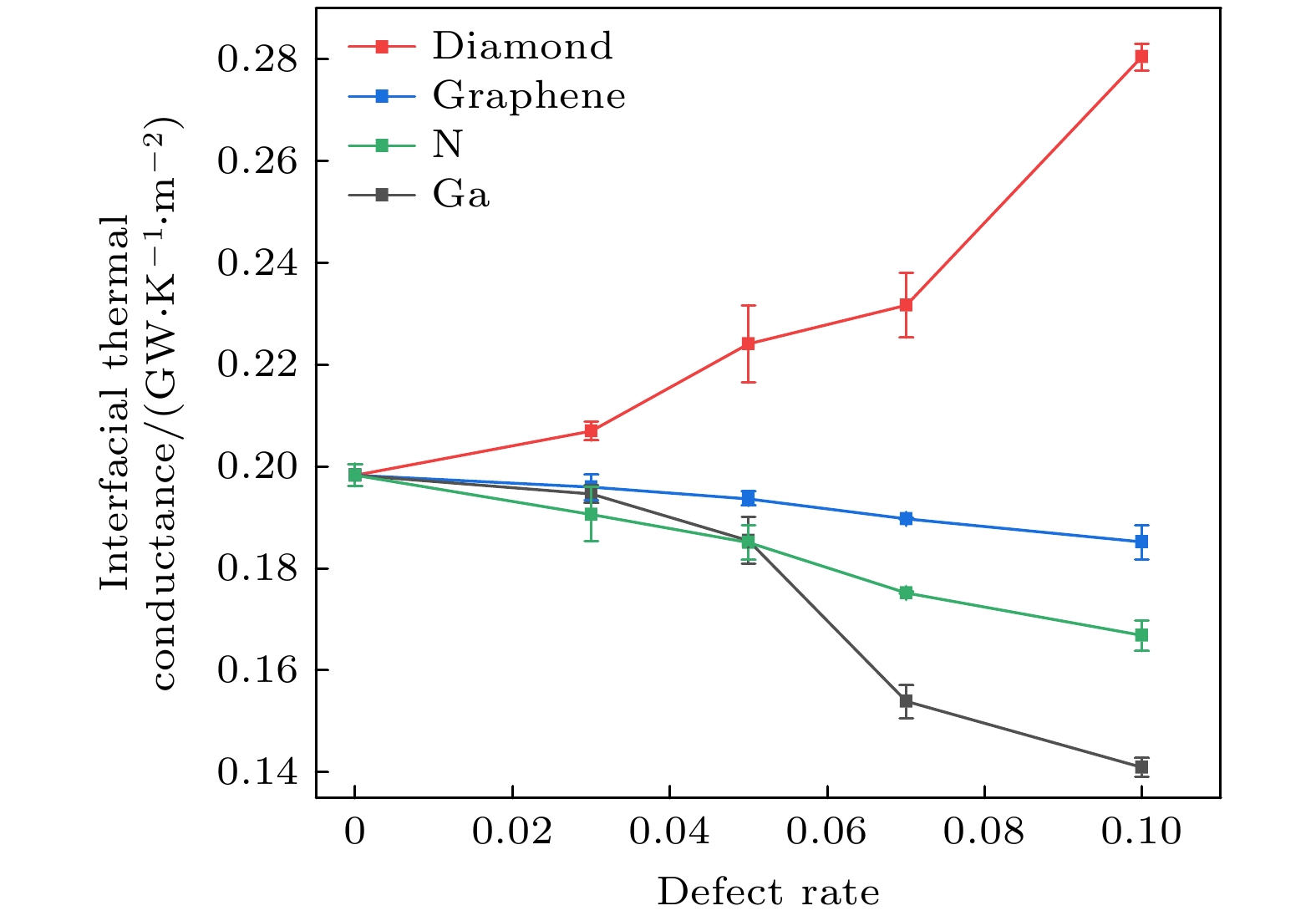

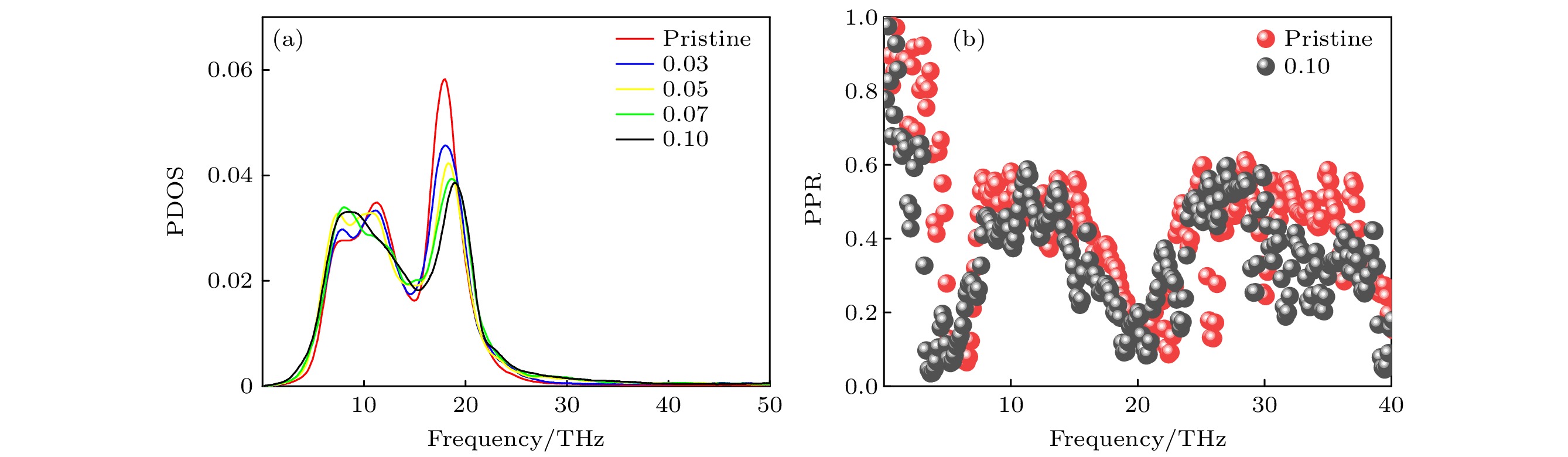

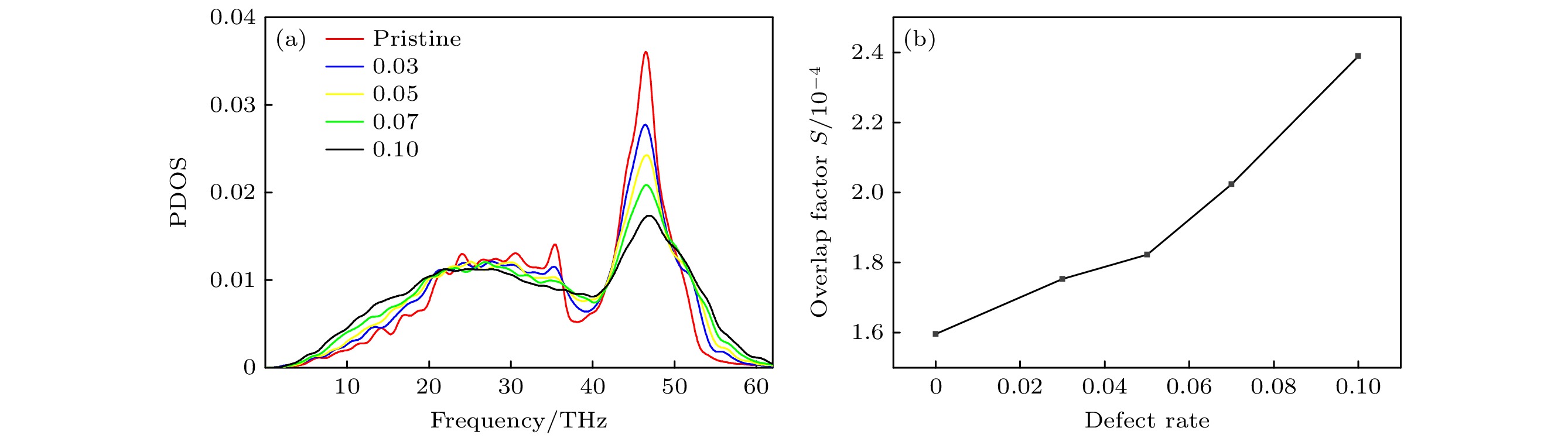

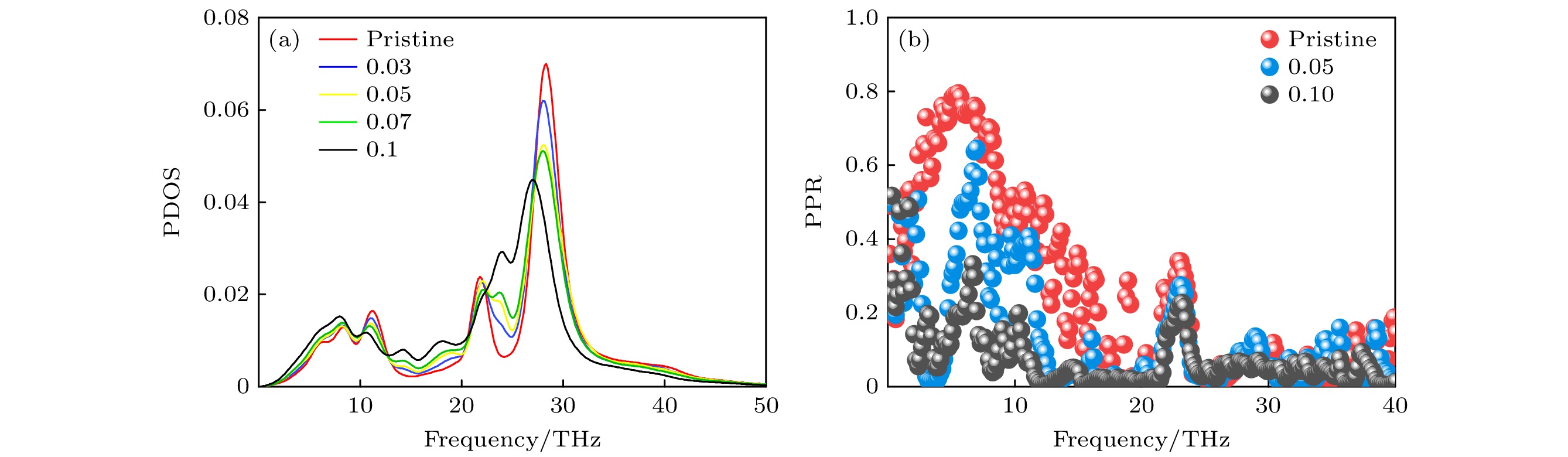

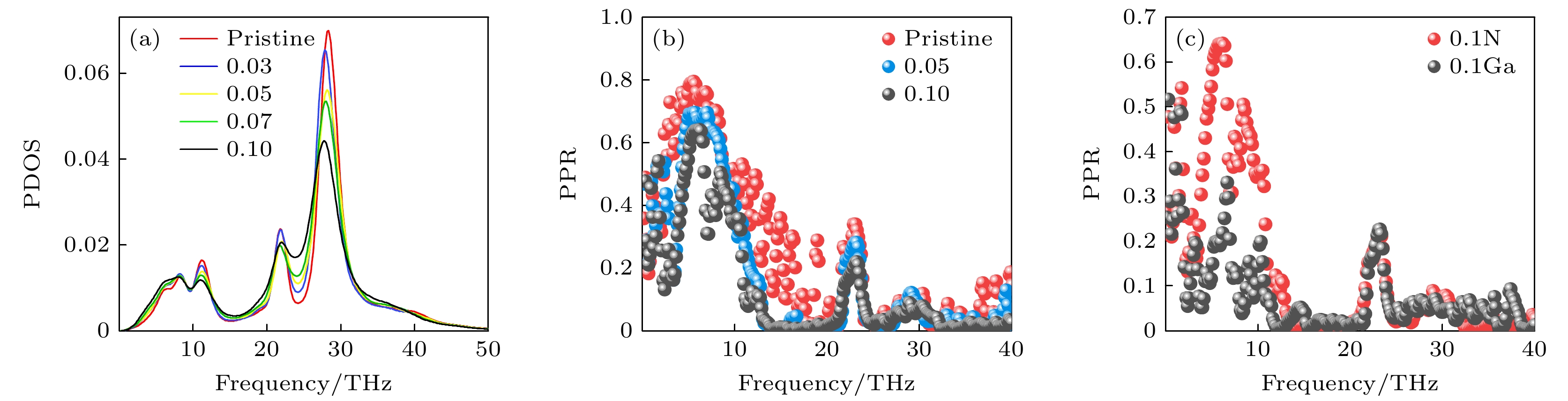

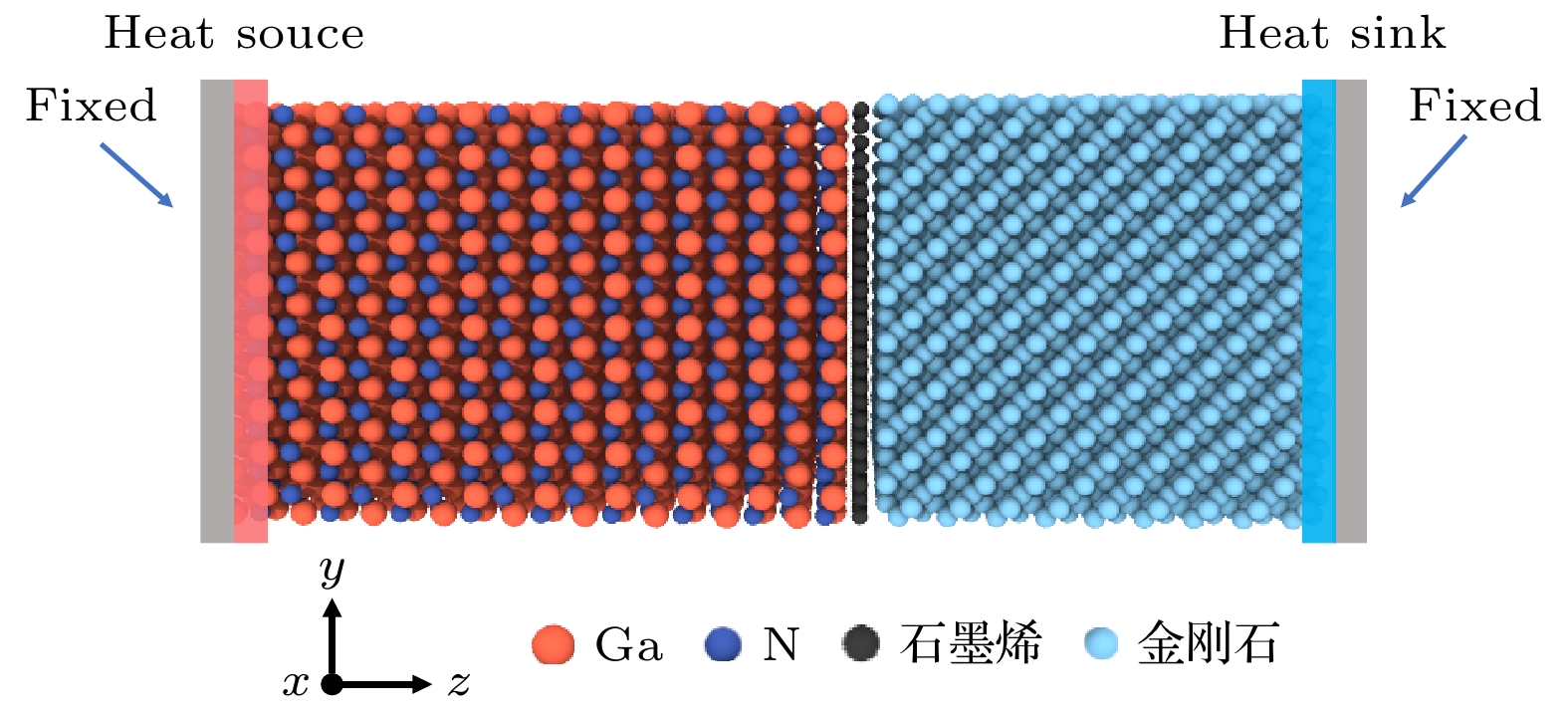

Gallium nitride chips are widely used in high-frequency and high-power devices. However, thermal management is a serious challenge for gallium nitride devices. To improve thermal dissipation of gallium nitride devices, the nonequilibrium molecular dynamics method is employed to investigate the effects of operating temperature, interface size, defect density and defect types on the interfacial thermal conductance of gallium nitride/graphene/diamond heterostructure. Furthermore, the phonon state densities and phonon participation ratios under various conditions are calculated to analyze the interface thermal conduction mechanism. The results indicate that interfacial thermal conductance increases with temperatures rising, highlighting the inherent self-regulating heat dissipation capabilities of heterogeneous. The interfacial thermal conductance of monolayer graphene structures is increased by 2.1 times as the temperature increases from 100 to 500 K. This is attributed to the overlap factor increasing with temperature rising, which enhances the phonon coupling between interfaces, leading the interfacial thermal conductance to increase. Additionally, in the study it is found that increasing the number of layers of both gallium nitride and graphene leads the interfacial thermal conductance to decrease. When the number of gallium nitride layers increases from 10 to 26, the interfacial thermal conductance decreases by 75%. The overlap factor diminishing with the layer number increasing is ascribed to the decreased match of phonon vibrations between interfaces, resulting in lower thermal transfer efficiency. Similarly, when the number of graphene layers increases from 1 to 5, the interfacial thermal conductance decreases by 74%. The increase in graphene layers leads the low-frequency phonons to decrease, consequently lowering the interfacial thermal conductance. Moreover, multilayer graphene enhances phonon localization, exacerbates the reduction in interfacial thermal conductance. It is found that introducing four types of vacancy defects can affect the interfacial thermal conductance. Diamond carbon atom defects lead its interfacial thermal conductance to increase, whereas defects in gallium, nitrogen, and graphene carbon atoms cause their interfacial thermal conductance to decrease. As the defect concentration increases from 0 to 10%, diamond carbon atom defects increase the interfacial thermal conductance by 40% due to defect scattering, which increases the number of low-frequency phonon modes and expands the channels for interfacial heat transfer, thus improving the interfacial thermal conductance. Defects in graphene intensify the degree of graphene phonon localization, consequently leading the interfacial thermal conductance to decrease. Gallium and nitrogen defects both intensify the phonon localization of gallium nitride, impeding phonon transport channels. Moreover, gallium defects induce more severe phonon localization than nitrogen defects, consequently leading to lower interfacial thermal conductance. This research provides the references for manufacturing highly reliable gallium nitride devices and the widespread use of gallium nitride heterostructures. -

Keywords:

- interface thermal conductance /

- temperature effect /

- size effect /

- vacancy defect

[1] 刘庆彬, 蔚翠, 郭建超, 马孟宇, 何泽召, 周闯杰, 高学栋, 余浩, 冯志红 2023 72 098104

Google Scholar

Google Scholar

Liu Q B, Yu C, Guo J C, Ma M Y, He Z Z, Zhou C J, Gao X D, Yu H, Feng Z H 2023 Acta Phys. Sin. 72 098104

Google Scholar

Google Scholar

[2] 贾鑫, 魏俊俊, 黄亚博, 邵思武, 孔月婵, 刘金龙, 陈良贤, 李成明, 叶海涛 2020 表面技术 49 111

Jia X, Wei J J, Huang Y B, Shao S W, Kong Y C, Liu J L, Chen L X, Li C M, Ye H T 2020 Surf. Technol. 49 111

[3] Wu Y J, Fang L, Xu Y 2019 npj Comput. Mater. 5 1

Google Scholar

Google Scholar

[4] 冯家驹, 范亚明, 房丹, 邓旭光, 于国浩, 魏志鹏, 张宝顺 2022 人工晶体学报 51 730

Google Scholar

Google Scholar

Feng J J, Fan Y M, Fang D, Deng X G, Yu G H, Wei Z P, Zhang B S 2022 J. Synth. Cryst. 51 730

Google Scholar

Google Scholar

[5] Francis D, Faili F, Babić D, Ejeckam F, Nurmikko A, Maris H 2010 Diamond Relat. Mater. 19 229

Google Scholar

Google Scholar

[6] Cho J, Francis D, Altman D H, Asheghi M, Goodson K E 2017 J. Appl. Phys. 121 055105

Google Scholar

Google Scholar

[7] Zhou Y, Anaya J, Pomeroy J, Sun H, Gu X, Xie A, Beam E, Becker M, Grotjohn T A, Lee C, Kuball M 2017 ACS Appl. Mater. Interfaces 9 34416

Google Scholar

Google Scholar

[8] Huang X, Guo Z 2021 Int. J. Heat Mass Transfer 178 121613

Google Scholar

Google Scholar

[9] Mu F, Xu B, Wang X, et al. 2022 J. Alloys Compd. 905 164076

Google Scholar

Google Scholar

[10] Tao L, Theruvakkattil Sreenivasan S, Shahsavari R 2017 ACS Appl. Mater. Interfaces 9 989

Google Scholar

Google Scholar

[11] Jia X, Huang L, Sun M, Zhao X, Wei J, Li C 2022 Coatings 12 672

Google Scholar

Google Scholar

[12] Qi Z, Shen W, Li R, Sun X, Li L, Wang Q, Wu G, Liang K 2023 Appl. Surf. Sci. 615 156419

Google Scholar

Google Scholar

[13] Middleton C, Chandrasekar H, Singh M, et al. 2019 Appl. Phys. Express 12 024003

Google Scholar

Google Scholar

[14] Wu L, Sun X, Gong F, Luo J, Yin C, Sun Z, Xiao R 2022 Nanomaterials 12 894

Google Scholar

Google Scholar

[15] Liu F, Zou R, Hu N, Ning H, Yan C, Liu Y, Wu L, Mo F, Fu S 2019 Nanoscale 11 4067

Google Scholar

Google Scholar

[16] Hu S, Ju S, Shao C, Guo J, Xu B, Ohnishi M, Shiomi J 2021 Mater. Today Phys. 16 100324

Google Scholar

Google Scholar

[17] Hu M, Poulikakos D 2013 Int. J. Heat Mass Transfer 62 205

Google Scholar

Google Scholar

[18] Mischke J, Pennings J, Weisenseel E, Kerger P, Rohwerder M, Mertin W, Bacher G 2020 2D Mater. 7 035019

Google Scholar

Google Scholar

[19] Suntornwipat N, Aitkulova A, Djurberg V, Majdi S 2023 Thin Solid Films 770 139766

Google Scholar

Google Scholar

[20] Shen B, Ji Z, Lin Q, Gong P, Xuan N, Chen S, Liu H, Huang Z, Xiao T, Sun Z 2022 Chem. Mater. 34 3941

Google Scholar

Google Scholar

[21] Jiang M, Chen C, Wang P, Guo D, Han S, Li X, Lu S, Hu X 2022 Proc. Natl. Acad. Sci. U. S. A. 119 e2201451119

Google Scholar

Google Scholar

[22] Li D, Zou W, Jiang W, Peng X, Song S, Qin Q H, Xue J M 2020 Ceram. Int. 46 10885

Google Scholar

Google Scholar

[23] Badokas K, Kadys A, Mickevičius J, Ignatjev I, Skapas M, Stanionytė S, Radiunas E, Juška G, Malinauskas T 2021 J. Phys. D: Appl. Phys. 54 205103

Google Scholar

Google Scholar

[24] Barbier C, Largeau L, Gogneau N, et al. 2023 Cryst. Growth Des. 23 6517

Google Scholar

Google Scholar

[25] Sun H, Simon R, Pomeroy J, Francis D, Faili F, Twitchen D, Kuball M 2015 Appl. Phys. Lett. 106 111906

Google Scholar

Google Scholar

[26] Wang J, Shen Y, Yang P 2023 Compos. Commun. 40 101616

Google Scholar

Google Scholar

[27] Tang Y, Liu J K, Yu Z H, Sun L G, Zhu L L 2023 Chin. Phys. B 32 066502

Google Scholar

Google Scholar

[28] Liu D 2020 Phys. Lett. A 384 126077

Google Scholar

Google Scholar

[29] Ou B, Yan J, Wang Q, Lu L 2022 Molecules 27 905

Google Scholar

Google Scholar

[30] Sang L X, Li Z K 2024 Acta Phys. Sin. 73 103105 [桑丽霞, 李志康 2024 73 103105]

Google Scholar

Google Scholar

Sang L X, Li Z K 2024 Acta Phys. Sin. 73 103105

Google Scholar

Google Scholar

[31] 刘东静, 周福, 陈帅阳, 胡志亮 2023 72 157901

Google Scholar

Google Scholar

Liu D J, Zhou F, Chen S Y, Hu Z L, 2023 Acta Phys. Sin. 72 157901

Google Scholar

Google Scholar

[32] Qu G D, Deng Z Y, Guo W, et al. 2023 IEEE Trans. Compon. Packag. Manuf. Technol. 13 816

Google Scholar

Google Scholar

[33] Wu B Y, Zhou M, Xu D J, Liu J J, Tang R J, Zhang P 2022 Surf. Interfaces 32 102119

Google Scholar

Google Scholar

[34] Tang Y Q, Zhang Z, Li L, Guo J, Yang P 2022 Int. J. Therm. Sci. 171 107231

Google Scholar

Google Scholar

[35] Wu X, Han Q 2021 ACS Appl. Mater. Interfaces 13 32564

Google Scholar

Google Scholar

[36] Huang H, Zhong Y, Cai B, Wang J, Liu Z, Peng Q 2023 Surf. Interfaces 37 102736

Google Scholar

Google Scholar

[37] Ma D, Zhang L 2020 J. Phys. Condens. Matter 32 425001

Google Scholar

Google Scholar

[38] Danilchenko B A, Paszkiewicz T, Wolski S, JeŻowski A, Plackowski T 2006 Appl. Phys. Lett. 89 061901

Google Scholar

Google Scholar

[39] 刘东静, 王韶铭, 杨平 2021 70 187302

Google Scholar

Google Scholar

Liu D J, Wang S M, Yang P 2021 Acta Phys. Sin. 70 187302

Google Scholar

Google Scholar

[40] Yang N, Luo T, Esfarjani K, et al. 2015 J. Comput. Theor. Nanosci. 12 168

Google Scholar

Google Scholar

[41] Liu Y, Qiu L, Liu J, Feng Y 2023 Int. J. Heat Mass Transfer 209 124123

Google Scholar

Google Scholar

[42] Wei N, Zhou C, Li Z, Ou B, Zhao K, Yu P, Li S, Zhao J 2022 Mater. Today Commun. 30 103147

Google Scholar

Google Scholar

[43] Li M, Zhou H, Zhang Y, Liao Y, Zhou H 2018 Carbon 130 295

Google Scholar

Google Scholar

[44] Esfahani M N, Jabbari M, Xu Y, Soutis C 2021 Mater. Today Commun. 26 101856

Google Scholar

Google Scholar

[45] Liu X, Zhang G, Zhang Y W 2016 Nano Lett. 16 4954

Google Scholar

Google Scholar

[46] Wu K, Zhang L, Li F, et al. 2024 Carbon 223 119021

Google Scholar

Google Scholar

[47] Loh G C, Teo E, Tay B K 2011 Diamond Relat. Mater. 20 1137

Google Scholar

Google Scholar

[48] Yang B, Yang H, Li T, Yang J, Yang P 2021 Appl. Surf. Sci. 536 147828

Google Scholar

Google Scholar

[49] Koh Y R, Bin Hoque M S, Ahmad H, et al. 2021 Phys. Rev. Mater. 5 104604

Google Scholar

Google Scholar

[50] Li Y, Zhao Q, Liu Y, Huang M, Ouyang X P 2024 Phys. Scr. 99 025944

Google Scholar

Google Scholar

[51] Liu Y, Qiu L, Wang Z, Li H, Feng Y 2024 Composites, Part A 178 108008

Google Scholar

Google Scholar

[52] Wu S, Wang J, Xie H, Guo Z 2020 Energies 13 5851

Google Scholar

Google Scholar

[53] Yang Y, Ma J, Yang J, Zhang Y 2022 ACS Appl. Mater. Interfaces 14 45742

Google Scholar

Google Scholar

[54] Yang C, Wang J, Ma D, Li Z, He Z, Liu L, Fu Z, Yang J Y 2023 Int. J. Heat Mass Transfer 214 124433

Google Scholar

Google Scholar

-

表 1 晶格参数

Table 1. Lattice parameters.

方向 氮化镓 石墨烯 金刚石 x 3.21629 2.46000 3.56679 y 5.57078 4.26084 3.56679 z 5.23966 3.56679 表 2 L-J势函数参数

Table 2. Lennard-Jones parameters.

原子1 原子2 $ \varepsilon $/eV $ \sigma $/Å C C 0.00361 3.671 C Ga 0.00905 3.668 C N 0.00369 3.346 -

[1] 刘庆彬, 蔚翠, 郭建超, 马孟宇, 何泽召, 周闯杰, 高学栋, 余浩, 冯志红 2023 72 098104

Google Scholar

Google Scholar

Liu Q B, Yu C, Guo J C, Ma M Y, He Z Z, Zhou C J, Gao X D, Yu H, Feng Z H 2023 Acta Phys. Sin. 72 098104

Google Scholar

Google Scholar

[2] 贾鑫, 魏俊俊, 黄亚博, 邵思武, 孔月婵, 刘金龙, 陈良贤, 李成明, 叶海涛 2020 表面技术 49 111

Jia X, Wei J J, Huang Y B, Shao S W, Kong Y C, Liu J L, Chen L X, Li C M, Ye H T 2020 Surf. Technol. 49 111

[3] Wu Y J, Fang L, Xu Y 2019 npj Comput. Mater. 5 1

Google Scholar

Google Scholar

[4] 冯家驹, 范亚明, 房丹, 邓旭光, 于国浩, 魏志鹏, 张宝顺 2022 人工晶体学报 51 730

Google Scholar

Google Scholar

Feng J J, Fan Y M, Fang D, Deng X G, Yu G H, Wei Z P, Zhang B S 2022 J. Synth. Cryst. 51 730

Google Scholar

Google Scholar

[5] Francis D, Faili F, Babić D, Ejeckam F, Nurmikko A, Maris H 2010 Diamond Relat. Mater. 19 229

Google Scholar

Google Scholar

[6] Cho J, Francis D, Altman D H, Asheghi M, Goodson K E 2017 J. Appl. Phys. 121 055105

Google Scholar

Google Scholar

[7] Zhou Y, Anaya J, Pomeroy J, Sun H, Gu X, Xie A, Beam E, Becker M, Grotjohn T A, Lee C, Kuball M 2017 ACS Appl. Mater. Interfaces 9 34416

Google Scholar

Google Scholar

[8] Huang X, Guo Z 2021 Int. J. Heat Mass Transfer 178 121613

Google Scholar

Google Scholar

[9] Mu F, Xu B, Wang X, et al. 2022 J. Alloys Compd. 905 164076

Google Scholar

Google Scholar

[10] Tao L, Theruvakkattil Sreenivasan S, Shahsavari R 2017 ACS Appl. Mater. Interfaces 9 989

Google Scholar

Google Scholar

[11] Jia X, Huang L, Sun M, Zhao X, Wei J, Li C 2022 Coatings 12 672

Google Scholar

Google Scholar

[12] Qi Z, Shen W, Li R, Sun X, Li L, Wang Q, Wu G, Liang K 2023 Appl. Surf. Sci. 615 156419

Google Scholar

Google Scholar

[13] Middleton C, Chandrasekar H, Singh M, et al. 2019 Appl. Phys. Express 12 024003

Google Scholar

Google Scholar

[14] Wu L, Sun X, Gong F, Luo J, Yin C, Sun Z, Xiao R 2022 Nanomaterials 12 894

Google Scholar

Google Scholar

[15] Liu F, Zou R, Hu N, Ning H, Yan C, Liu Y, Wu L, Mo F, Fu S 2019 Nanoscale 11 4067

Google Scholar

Google Scholar

[16] Hu S, Ju S, Shao C, Guo J, Xu B, Ohnishi M, Shiomi J 2021 Mater. Today Phys. 16 100324

Google Scholar

Google Scholar

[17] Hu M, Poulikakos D 2013 Int. J. Heat Mass Transfer 62 205

Google Scholar

Google Scholar

[18] Mischke J, Pennings J, Weisenseel E, Kerger P, Rohwerder M, Mertin W, Bacher G 2020 2D Mater. 7 035019

Google Scholar

Google Scholar

[19] Suntornwipat N, Aitkulova A, Djurberg V, Majdi S 2023 Thin Solid Films 770 139766

Google Scholar

Google Scholar

[20] Shen B, Ji Z, Lin Q, Gong P, Xuan N, Chen S, Liu H, Huang Z, Xiao T, Sun Z 2022 Chem. Mater. 34 3941

Google Scholar

Google Scholar

[21] Jiang M, Chen C, Wang P, Guo D, Han S, Li X, Lu S, Hu X 2022 Proc. Natl. Acad. Sci. U. S. A. 119 e2201451119

Google Scholar

Google Scholar

[22] Li D, Zou W, Jiang W, Peng X, Song S, Qin Q H, Xue J M 2020 Ceram. Int. 46 10885

Google Scholar

Google Scholar

[23] Badokas K, Kadys A, Mickevičius J, Ignatjev I, Skapas M, Stanionytė S, Radiunas E, Juška G, Malinauskas T 2021 J. Phys. D: Appl. Phys. 54 205103

Google Scholar

Google Scholar

[24] Barbier C, Largeau L, Gogneau N, et al. 2023 Cryst. Growth Des. 23 6517

Google Scholar

Google Scholar

[25] Sun H, Simon R, Pomeroy J, Francis D, Faili F, Twitchen D, Kuball M 2015 Appl. Phys. Lett. 106 111906

Google Scholar

Google Scholar

[26] Wang J, Shen Y, Yang P 2023 Compos. Commun. 40 101616

Google Scholar

Google Scholar

[27] Tang Y, Liu J K, Yu Z H, Sun L G, Zhu L L 2023 Chin. Phys. B 32 066502

Google Scholar

Google Scholar

[28] Liu D 2020 Phys. Lett. A 384 126077

Google Scholar

Google Scholar

[29] Ou B, Yan J, Wang Q, Lu L 2022 Molecules 27 905

Google Scholar

Google Scholar

[30] Sang L X, Li Z K 2024 Acta Phys. Sin. 73 103105 [桑丽霞, 李志康 2024 73 103105]

Google Scholar

Google Scholar

Sang L X, Li Z K 2024 Acta Phys. Sin. 73 103105

Google Scholar

Google Scholar

[31] 刘东静, 周福, 陈帅阳, 胡志亮 2023 72 157901

Google Scholar

Google Scholar

Liu D J, Zhou F, Chen S Y, Hu Z L, 2023 Acta Phys. Sin. 72 157901

Google Scholar

Google Scholar

[32] Qu G D, Deng Z Y, Guo W, et al. 2023 IEEE Trans. Compon. Packag. Manuf. Technol. 13 816

Google Scholar

Google Scholar

[33] Wu B Y, Zhou M, Xu D J, Liu J J, Tang R J, Zhang P 2022 Surf. Interfaces 32 102119

Google Scholar

Google Scholar

[34] Tang Y Q, Zhang Z, Li L, Guo J, Yang P 2022 Int. J. Therm. Sci. 171 107231

Google Scholar

Google Scholar

[35] Wu X, Han Q 2021 ACS Appl. Mater. Interfaces 13 32564

Google Scholar

Google Scholar

[36] Huang H, Zhong Y, Cai B, Wang J, Liu Z, Peng Q 2023 Surf. Interfaces 37 102736

Google Scholar

Google Scholar

[37] Ma D, Zhang L 2020 J. Phys. Condens. Matter 32 425001

Google Scholar

Google Scholar

[38] Danilchenko B A, Paszkiewicz T, Wolski S, JeŻowski A, Plackowski T 2006 Appl. Phys. Lett. 89 061901

Google Scholar

Google Scholar

[39] 刘东静, 王韶铭, 杨平 2021 70 187302

Google Scholar

Google Scholar

Liu D J, Wang S M, Yang P 2021 Acta Phys. Sin. 70 187302

Google Scholar

Google Scholar

[40] Yang N, Luo T, Esfarjani K, et al. 2015 J. Comput. Theor. Nanosci. 12 168

Google Scholar

Google Scholar

[41] Liu Y, Qiu L, Liu J, Feng Y 2023 Int. J. Heat Mass Transfer 209 124123

Google Scholar

Google Scholar

[42] Wei N, Zhou C, Li Z, Ou B, Zhao K, Yu P, Li S, Zhao J 2022 Mater. Today Commun. 30 103147

Google Scholar

Google Scholar

[43] Li M, Zhou H, Zhang Y, Liao Y, Zhou H 2018 Carbon 130 295

Google Scholar

Google Scholar

[44] Esfahani M N, Jabbari M, Xu Y, Soutis C 2021 Mater. Today Commun. 26 101856

Google Scholar

Google Scholar

[45] Liu X, Zhang G, Zhang Y W 2016 Nano Lett. 16 4954

Google Scholar

Google Scholar

[46] Wu K, Zhang L, Li F, et al. 2024 Carbon 223 119021

Google Scholar

Google Scholar

[47] Loh G C, Teo E, Tay B K 2011 Diamond Relat. Mater. 20 1137

Google Scholar

Google Scholar

[48] Yang B, Yang H, Li T, Yang J, Yang P 2021 Appl. Surf. Sci. 536 147828

Google Scholar

Google Scholar

[49] Koh Y R, Bin Hoque M S, Ahmad H, et al. 2021 Phys. Rev. Mater. 5 104604

Google Scholar

Google Scholar

[50] Li Y, Zhao Q, Liu Y, Huang M, Ouyang X P 2024 Phys. Scr. 99 025944

Google Scholar

Google Scholar

[51] Liu Y, Qiu L, Wang Z, Li H, Feng Y 2024 Composites, Part A 178 108008

Google Scholar

Google Scholar

[52] Wu S, Wang J, Xie H, Guo Z 2020 Energies 13 5851

Google Scholar

Google Scholar

[53] Yang Y, Ma J, Yang J, Zhang Y 2022 ACS Appl. Mater. Interfaces 14 45742

Google Scholar

Google Scholar

[54] Yang C, Wang J, Ma D, Li Z, He Z, Liu L, Fu Z, Yang J Y 2023 Int. J. Heat Mass Transfer 214 124433

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 5841

- PDF Downloads: 123

- Cited By: 0

DownLoad:

DownLoad: