-

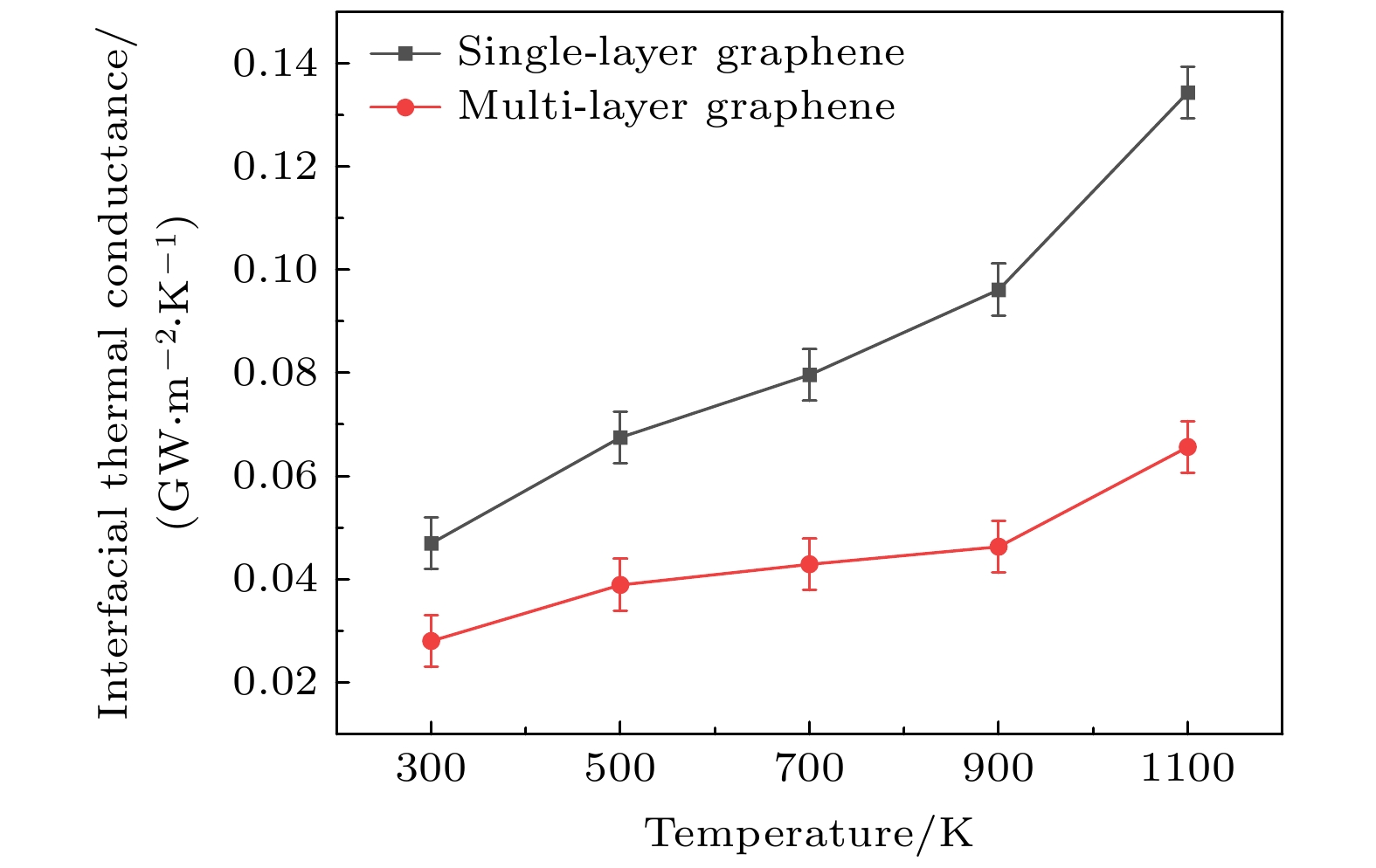

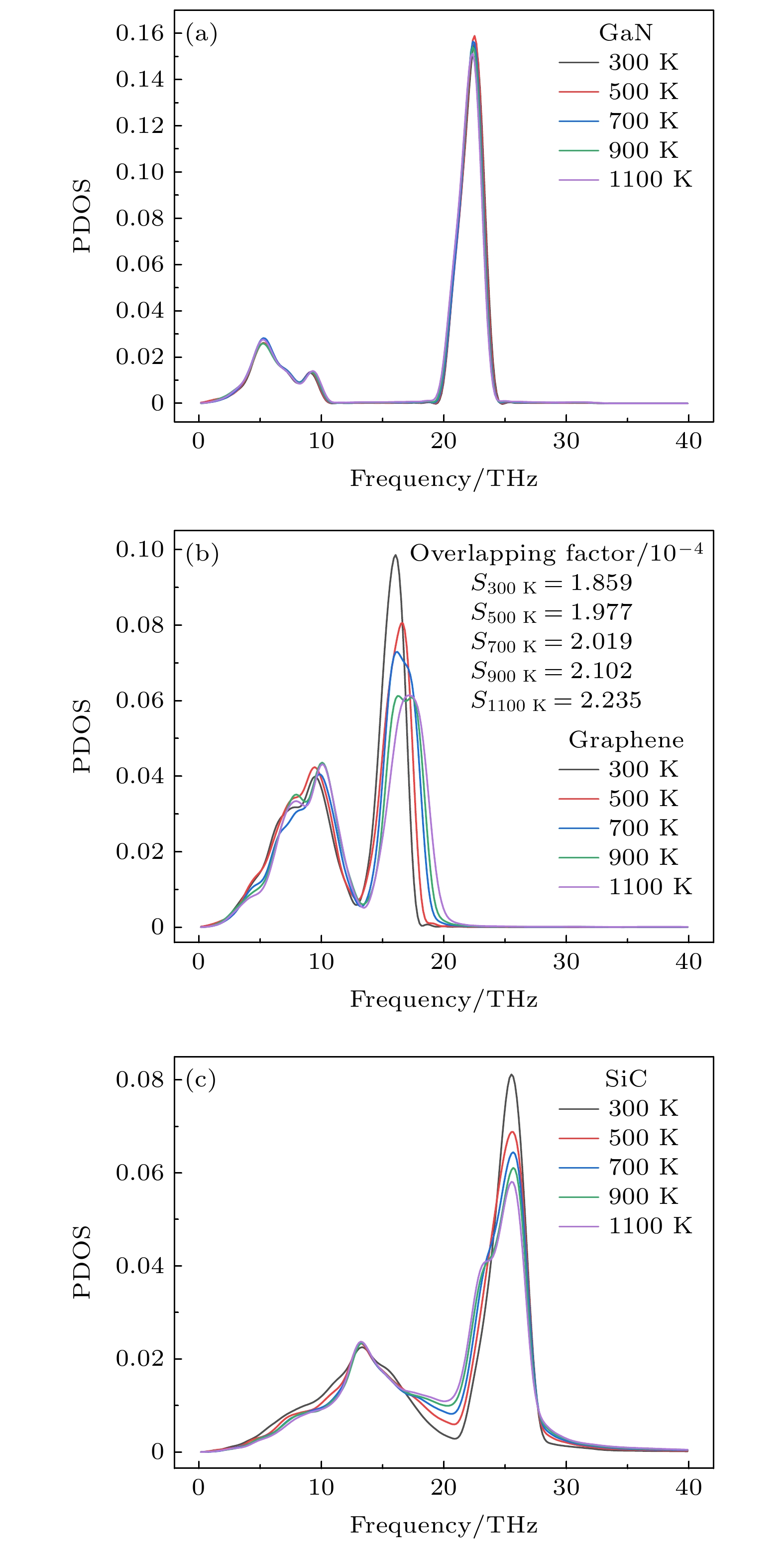

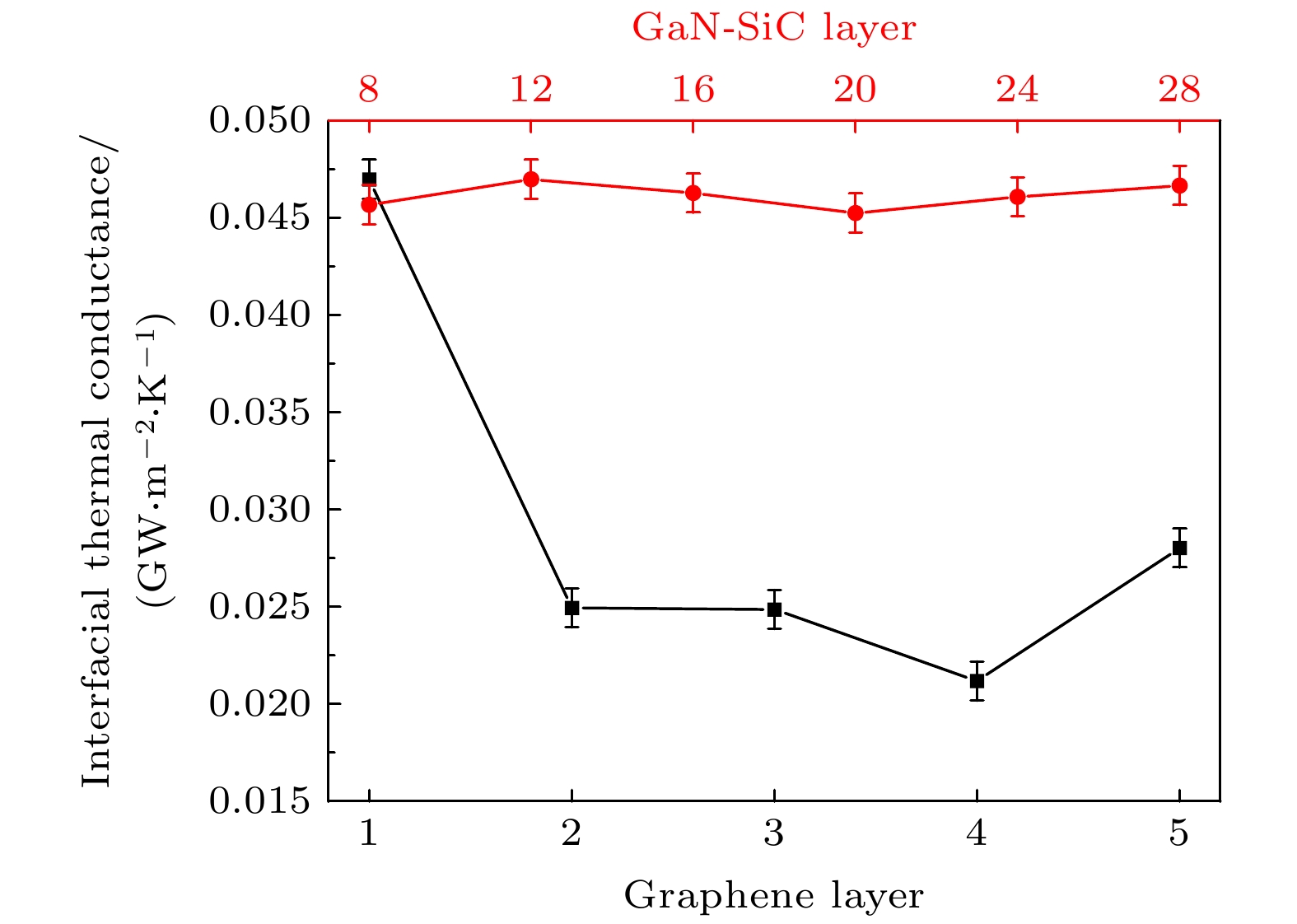

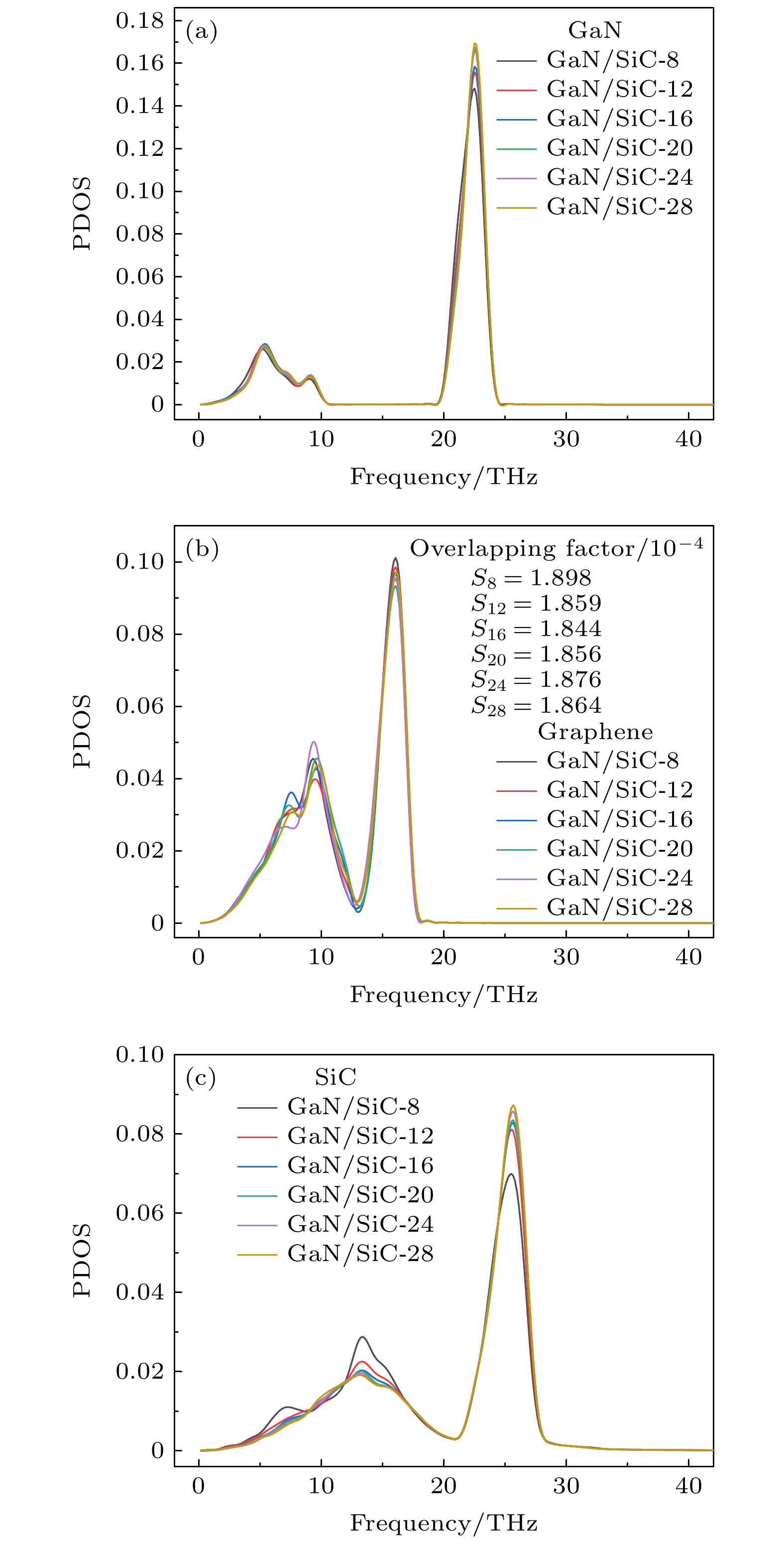

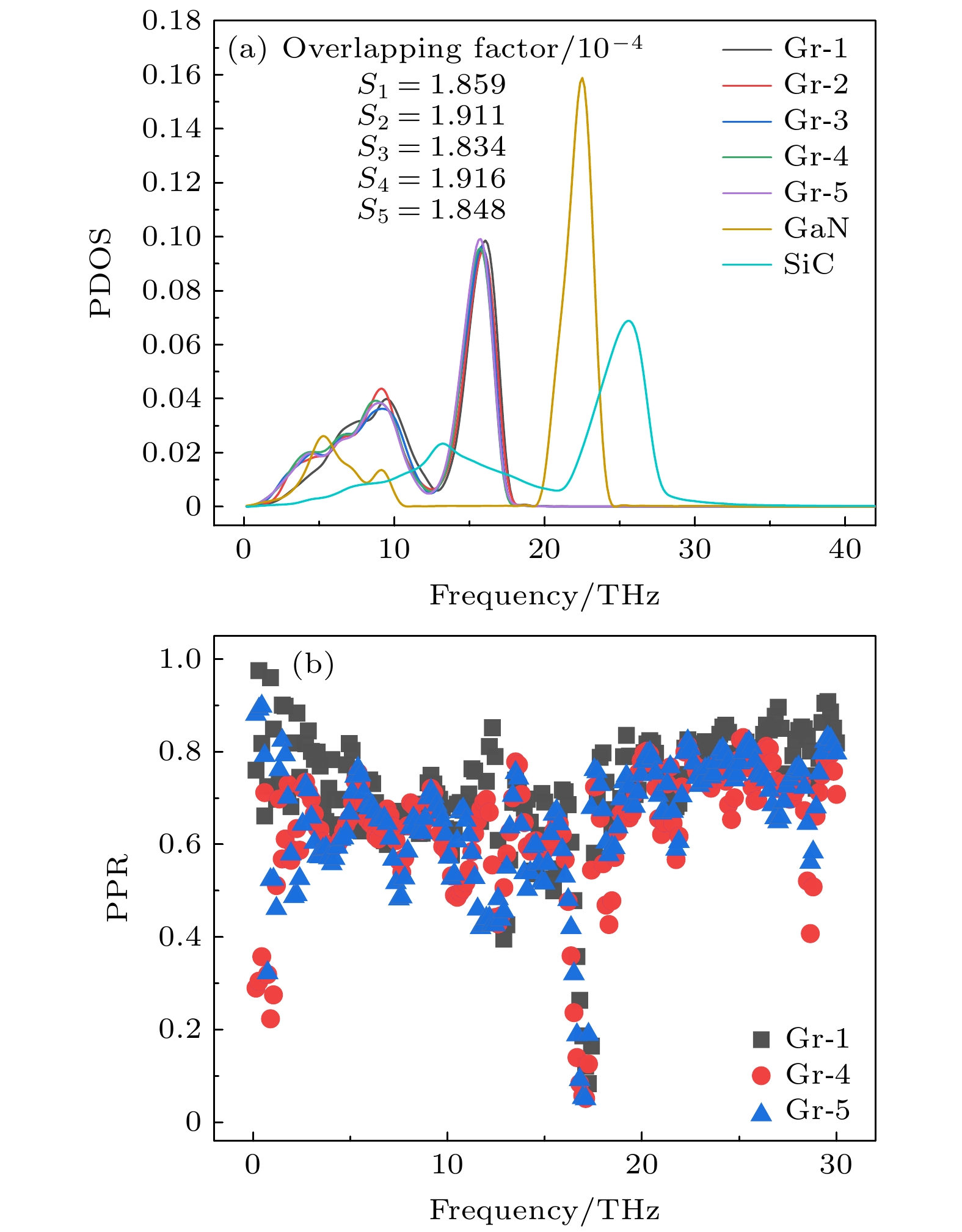

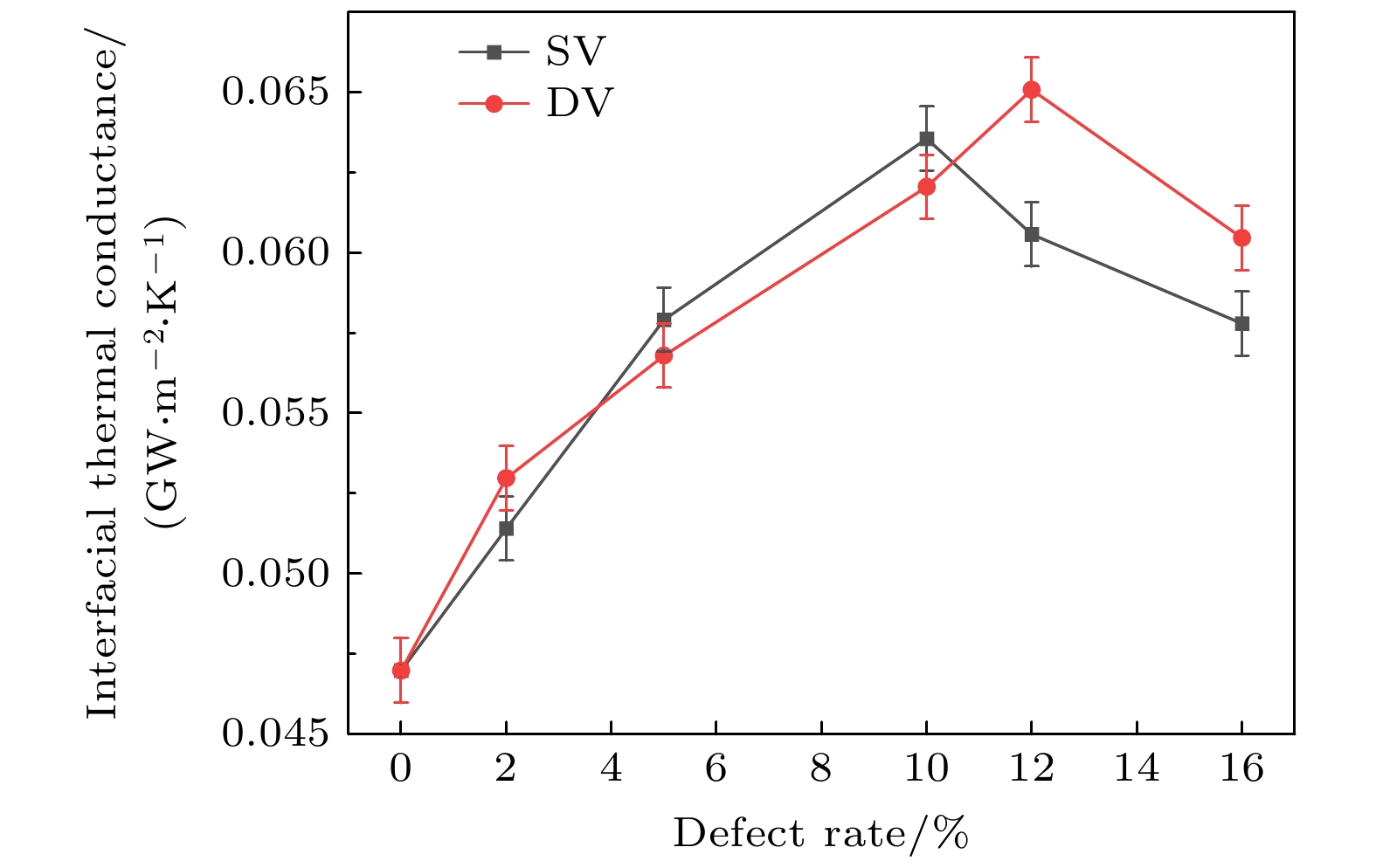

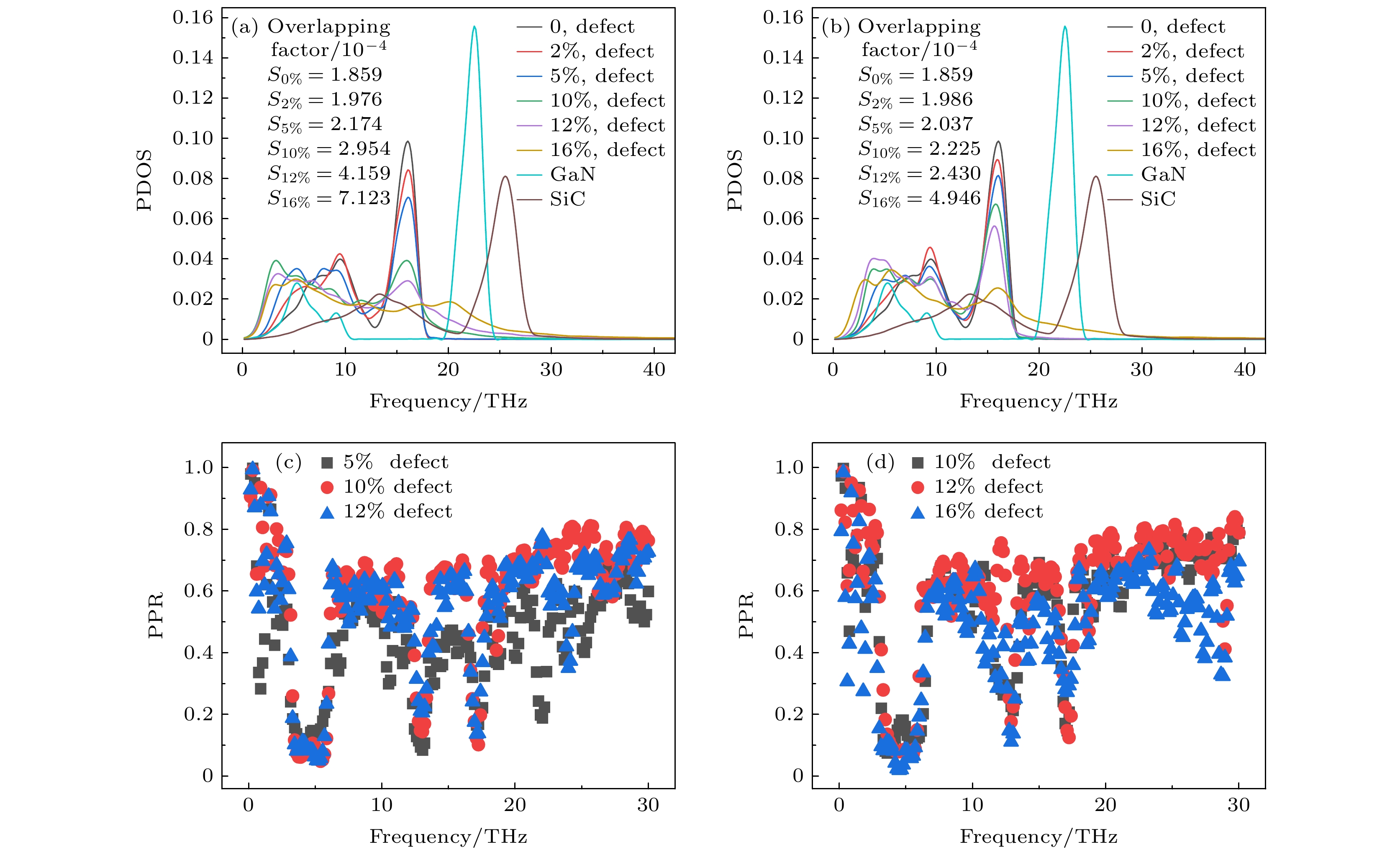

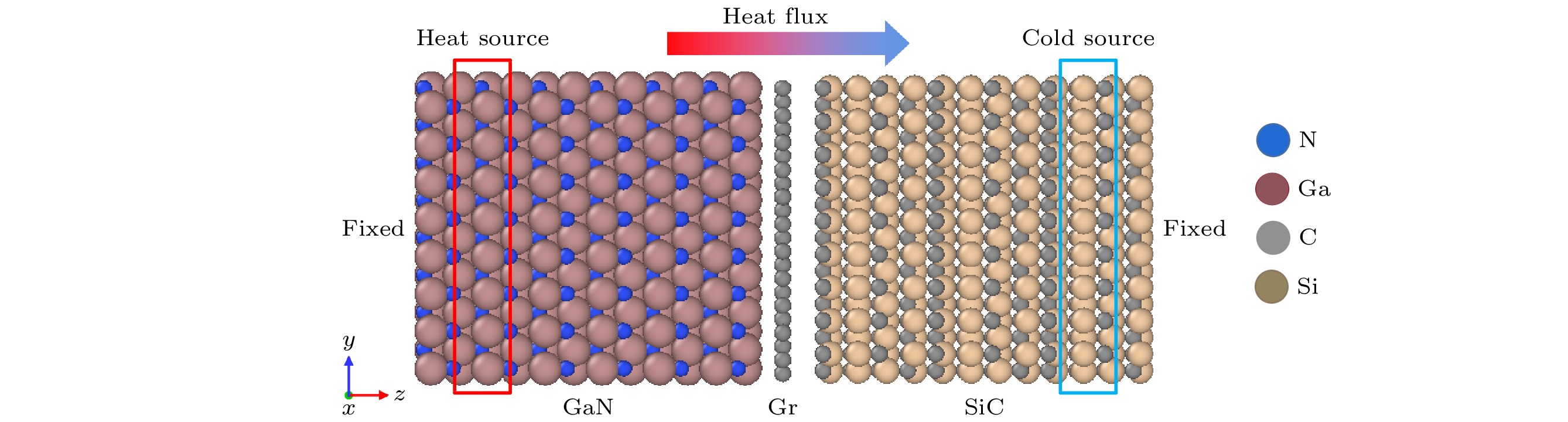

为了探究氮化镓/石墨烯/碳化硅异质界面热输运特性, 采用非平衡分子动力学方法从温度、尺寸以及空位缺陷三个方面研究其对界面热导的影响, 通过声子态密度和声子参与率对界面热导的变化进一步阐述分析. 研究表明: 温度升高使界面热导增大, 分析认为随着温度升高晶格振动加剧, 低频声子态密度变大, 参与热输运声子数量增加; 其中单层石墨烯层结构界面热导的改变要高于多层石墨烯结构的界面热导. 当热输运方向的结构尺寸变化时, 同时改变氮化镓和碳化硅的层数, 界面热导无明显变化, 界面热输运声子散射几乎不受影响; 但中间石墨烯层从1层增加至5层时, 界面热导率先减小后缓慢增大, 由于在4层时低频声子参与率变小, 更多的声子局域化, 不参与传热声子数量更多, 故界面热导到达最小值0.021 GW/(m2·K). 随空位缺陷浓度增加界面热导先逐步增大后减小, 区别在于单空位缺陷在浓度为10%时, 界面热导达到最大值0.064 GW/(m2·K); 而双空位缺陷在浓度为12%时, 界面热导率达到最大值0.065 GW/(m2·K), 分析认为更多的声子从局域进入离域, 参与该传热声子较多, 导致界面热导增大. 研究结果有助于调控氮化镓器件的热输运性能, 可以为异质界面器件的设计提供理论依据.In order to study the thermal transport properties of heterogeneous gallium nitride/graphene/silicon carbide interface, the effects of temperature, size and vacancy defects on the thermal conductance of the interface are investigated by non-equilibrium molecular dynamics method, and the effects of changes of phonon state density and phonon participation rate on the thermal conductance of the interface are further analyzed. The results show that the thermal conductance of the interface increases with temperature increasing. The analysis shows that as temperature rises, the lattice vibration intensity, the density of low frequency phonon states, and the number of phonons involved in heat transport all increase. The change of thermal conductance at the interface of single-layer graphene is higher than that of multi-layer graphene. When the structural size of the heat transport direction is changed and the number of layers of gallium nitride and silicon carbide are changed at the same time, the thermal conductance at the interface does not change significantly, and the phonon scattering of the thermal transport at the interface is almost unaffected. However, as the number of graphene interlayers increases from the first layer to the fifth layer, the interface thermal conductance first decreases and then slowly increases. Because of the fourth layer, the participation rate of low frequency phonons decreases, more phonons are localized, and the number of phonons that do not participate in heat transfer increases, and the interfacial thermal conductance reaches a minimum value of 0.024 GW/(m2·K). As the vacancy defect concentration increases, the interfacial thermal conductance first increases gradually and then decreases. The difference is that when the concentration of single vacancy defects is 10%, the interface thermal conductance reaches a maximum value of 0.063 GW/(m2·K). When the concentration of double vacancy defects is 12%, the interfacial thermal conductance reaches a maximum value of 0.065 GW/(m2·K). The analysis shows that more phonons enter into the delocalisation from the local region and more phonons participate in the heat transfer, leading to the increase of the interface thermal conductance. The results are useful in adjusting the thermal transport performance of GaN devices and provide a theoretical basis for designing the devices with heterogeneous interfaces.

-

Keywords:

- heterogeneous interface thermal conductance /

- temperature effect /

- size effect /

- vacancy defect

[1] Lee J Y, Shin J H, Lee G H, Lee C H 2016 Nanomaterials (Basel) 6 193

Google Scholar

Google Scholar

[2] Liu Y, Fang Y, Yang D, Pi X, Wang P 2022 J. Phys. Condens. Matter. 34 183001

Google Scholar

Google Scholar

[3] Xu H, Akbari M K, Zhuiykov S 2021 Nanoscale Res. Lett. 16 94

Google Scholar

Google Scholar

[4] Islam M S, Mia I, Ahammed S, Stampfl C, Park J 2020 Sci. Rep. 10 22050

Google Scholar

Google Scholar

[5] Zanane F Z, Sadki K, Drissi L B, Saidi E H 2022 J. Mol. Model. 28 88

Google Scholar

Google Scholar

[6] Wu D, Ding H, Fan Z Q, Jia P Z, Xie H Q, Chen X K 2022 Appl. Surf. 581 152344

Google Scholar

Google Scholar

[7] Li M, Zheng B, Duan K, Zhang Y, Huang Z, Zhou H 2018 J. Phys. Chem. C 122 14945

Google Scholar

Google Scholar

[8] Littlejohn A J, Xiang Y, Rauch E, Lu T M, Wang G C 2017 J. Appl. Phys. 122 185305

Google Scholar

Google Scholar

[9] Utama M I B, de la Mata M, Magen C, Arbiol J, Xiong Q 2013 Adv. Funct. Mater. 23 1636

Google Scholar

Google Scholar

[10] Balandin A A 2011 Nat. Mater. 10 569

Google Scholar

Google Scholar

[11] Yan Z, Liu G, Khan J M, Balandin A A 2012 Nat. Commun. 3 827

Google Scholar

Google Scholar

[12] Kim Y, Cruz S S, Lee K, Alawode B O, Choi C, Song Y, Johnson J M, Heidelberger C, Kong W, Choi S, Qiao K, Almansouri I, Fitzgerald E A, Kong J, Kolpak A M, Hwang J, Kim J 2017 Nature 544 340

Google Scholar

Google Scholar

[13] Zollner C J, Almogbel A, Yao Y, SaifAddin B K, Wu F, Iza M, DenBaars S P, Speck J S, Nakamura S 2019 Appl. Phys. Lett. 115 161101

Google Scholar

Google Scholar

[14] Xu Y, Wang J, Cao B, Xu K 2022 Chin. Phys. B 31 117702

Google Scholar

Google Scholar

[15] Al Balushi Z Y, Miyagi T, Lin Y C, Wang K, Calderin L, Bhimanapati G, Redwing J M, Robinson J A 2015 Surf. Sci. 634 81

Google Scholar

Google Scholar

[16] Feldberg N, Klymov O, Garro N, Cros A, Mollard N, Okuno H, Gruart M, Daudin B 2019 Nanotechnology 30 375602

Google Scholar

Google Scholar

[17] Fernandez-Garrido S, Ramsteiner M, Gao G, Galves L A, Sharma B, Corfdir P, Calabrese G, de Souza Schiaber Z, Pfuller C, Trampert A, Lopes J M J, Brandt O, Geelhaar L 2017 Nano Lett. 17 5213

Google Scholar

Google Scholar

[18] Puybaret R, Patriarche G, Jordan M B, Sundaram S, El Gmili Y, Salvestrini J P, Voss P L, de Heer W A, Berger C, Ougazzaden A 2016 Appl. Phys. Lett. 108 103105

Google Scholar

Google Scholar

[19] Xu Y, Cao B, Li Z, Zheng S, Cai D, Wang M, Zhang Y, Wang J, Wang C, Xu K 2019 Cryst. Eng. Comm. 21 6109

Google Scholar

Google Scholar

[20] Hu M, Poulikakos D 2013 Int. J. Heat Mass Transfer 62 205

Google Scholar

Google Scholar

[21] Yang B, Yang H, Li T, Yang J, Yang P 2021 Appl. Surf. Sci. 536 147828

Google Scholar

Google Scholar

[22] 刘东静, 王韶铭, 杨平 2021 70 187302

Google Scholar

Google Scholar

Liu D J, Wang S M, Yang P 2021 Acta Phys. Sin. 70 187302

Google Scholar

Google Scholar

[23] Xiong Y, Wu H, Gao J, Chen W, Zhang J, Yue Y 2019 Acta Phys. Chim. Sin. 35 1150

Google Scholar

Google Scholar

[24] Yang Y, Ma J, Yang J, Zhang Y 2022 ACS Appl. Mater. Interfaces 14 45742

Google Scholar

Google Scholar

[25] Teshome T, Datta A 2017 ACS Appl. Mater. Interfaces 9 34213

Google Scholar

Google Scholar

[26] Liu Z, Su Z, Li Q, Sun L, Zhang X, Yang Z, Liu X, Li Y, Yu F, Zhao X 2019 RSC Adv. 9 32226

Google Scholar

Google Scholar

[27] Stillinger F H, Weber T A 1985 Phys. Rev. B 31 5262

Google Scholar

Google Scholar

[28] Liu D J 2020 Phys. Lett. A. 384 126077

Google Scholar

Google Scholar

[29] Li M, Zhang J C, Hu X J, Yue Y N 2015 Appl. Phys. A. 119 415

Google Scholar

Google Scholar

[30] Farago O 2019 Physica A 534 122210

Google Scholar

Google Scholar

[31] 叶振强, 曹炳阳, 过增元 2014 63 154704

Google Scholar

Google Scholar

Ye Z Q, Cao B Y, Guo Z Y 2014 Acta Phys. Sin. 63 154704

Google Scholar

Google Scholar

[32] Han D, Wang X, Ding W, Chen Y, Zhang J, Xin G, Cheng L 2019 Nanotechnology 30 075403

Google Scholar

Google Scholar

[33] Guo Y, Bescond M, Zhang Z, Xiong S, Hirakawa K, Nomura M, Volz S 2021 APL Materials 9 091104

Google Scholar

Google Scholar

[34] Schulz J 2003 J. Reprod. Infant. Psyc. 21 363

Google Scholar

Google Scholar

-

表 1 LJ势函数参数

Table 1. Lennard-Jones parameter.

参数 $\varepsilon /{\text{eV}}$ σ/Å C-C 0.00455 3.851 Si-C 0.00891 4.073 Ga-C 0.00905 4.117 N-C 0.00617 3.757 Si-Ga 0.01771 4.339 Si-N 0.01207 3.979 -

[1] Lee J Y, Shin J H, Lee G H, Lee C H 2016 Nanomaterials (Basel) 6 193

Google Scholar

Google Scholar

[2] Liu Y, Fang Y, Yang D, Pi X, Wang P 2022 J. Phys. Condens. Matter. 34 183001

Google Scholar

Google Scholar

[3] Xu H, Akbari M K, Zhuiykov S 2021 Nanoscale Res. Lett. 16 94

Google Scholar

Google Scholar

[4] Islam M S, Mia I, Ahammed S, Stampfl C, Park J 2020 Sci. Rep. 10 22050

Google Scholar

Google Scholar

[5] Zanane F Z, Sadki K, Drissi L B, Saidi E H 2022 J. Mol. Model. 28 88

Google Scholar

Google Scholar

[6] Wu D, Ding H, Fan Z Q, Jia P Z, Xie H Q, Chen X K 2022 Appl. Surf. 581 152344

Google Scholar

Google Scholar

[7] Li M, Zheng B, Duan K, Zhang Y, Huang Z, Zhou H 2018 J. Phys. Chem. C 122 14945

Google Scholar

Google Scholar

[8] Littlejohn A J, Xiang Y, Rauch E, Lu T M, Wang G C 2017 J. Appl. Phys. 122 185305

Google Scholar

Google Scholar

[9] Utama M I B, de la Mata M, Magen C, Arbiol J, Xiong Q 2013 Adv. Funct. Mater. 23 1636

Google Scholar

Google Scholar

[10] Balandin A A 2011 Nat. Mater. 10 569

Google Scholar

Google Scholar

[11] Yan Z, Liu G, Khan J M, Balandin A A 2012 Nat. Commun. 3 827

Google Scholar

Google Scholar

[12] Kim Y, Cruz S S, Lee K, Alawode B O, Choi C, Song Y, Johnson J M, Heidelberger C, Kong W, Choi S, Qiao K, Almansouri I, Fitzgerald E A, Kong J, Kolpak A M, Hwang J, Kim J 2017 Nature 544 340

Google Scholar

Google Scholar

[13] Zollner C J, Almogbel A, Yao Y, SaifAddin B K, Wu F, Iza M, DenBaars S P, Speck J S, Nakamura S 2019 Appl. Phys. Lett. 115 161101

Google Scholar

Google Scholar

[14] Xu Y, Wang J, Cao B, Xu K 2022 Chin. Phys. B 31 117702

Google Scholar

Google Scholar

[15] Al Balushi Z Y, Miyagi T, Lin Y C, Wang K, Calderin L, Bhimanapati G, Redwing J M, Robinson J A 2015 Surf. Sci. 634 81

Google Scholar

Google Scholar

[16] Feldberg N, Klymov O, Garro N, Cros A, Mollard N, Okuno H, Gruart M, Daudin B 2019 Nanotechnology 30 375602

Google Scholar

Google Scholar

[17] Fernandez-Garrido S, Ramsteiner M, Gao G, Galves L A, Sharma B, Corfdir P, Calabrese G, de Souza Schiaber Z, Pfuller C, Trampert A, Lopes J M J, Brandt O, Geelhaar L 2017 Nano Lett. 17 5213

Google Scholar

Google Scholar

[18] Puybaret R, Patriarche G, Jordan M B, Sundaram S, El Gmili Y, Salvestrini J P, Voss P L, de Heer W A, Berger C, Ougazzaden A 2016 Appl. Phys. Lett. 108 103105

Google Scholar

Google Scholar

[19] Xu Y, Cao B, Li Z, Zheng S, Cai D, Wang M, Zhang Y, Wang J, Wang C, Xu K 2019 Cryst. Eng. Comm. 21 6109

Google Scholar

Google Scholar

[20] Hu M, Poulikakos D 2013 Int. J. Heat Mass Transfer 62 205

Google Scholar

Google Scholar

[21] Yang B, Yang H, Li T, Yang J, Yang P 2021 Appl. Surf. Sci. 536 147828

Google Scholar

Google Scholar

[22] 刘东静, 王韶铭, 杨平 2021 70 187302

Google Scholar

Google Scholar

Liu D J, Wang S M, Yang P 2021 Acta Phys. Sin. 70 187302

Google Scholar

Google Scholar

[23] Xiong Y, Wu H, Gao J, Chen W, Zhang J, Yue Y 2019 Acta Phys. Chim. Sin. 35 1150

Google Scholar

Google Scholar

[24] Yang Y, Ma J, Yang J, Zhang Y 2022 ACS Appl. Mater. Interfaces 14 45742

Google Scholar

Google Scholar

[25] Teshome T, Datta A 2017 ACS Appl. Mater. Interfaces 9 34213

Google Scholar

Google Scholar

[26] Liu Z, Su Z, Li Q, Sun L, Zhang X, Yang Z, Liu X, Li Y, Yu F, Zhao X 2019 RSC Adv. 9 32226

Google Scholar

Google Scholar

[27] Stillinger F H, Weber T A 1985 Phys. Rev. B 31 5262

Google Scholar

Google Scholar

[28] Liu D J 2020 Phys. Lett. A. 384 126077

Google Scholar

Google Scholar

[29] Li M, Zhang J C, Hu X J, Yue Y N 2015 Appl. Phys. A. 119 415

Google Scholar

Google Scholar

[30] Farago O 2019 Physica A 534 122210

Google Scholar

Google Scholar

[31] 叶振强, 曹炳阳, 过增元 2014 63 154704

Google Scholar

Google Scholar

Ye Z Q, Cao B Y, Guo Z Y 2014 Acta Phys. Sin. 63 154704

Google Scholar

Google Scholar

[32] Han D, Wang X, Ding W, Chen Y, Zhang J, Xin G, Cheng L 2019 Nanotechnology 30 075403

Google Scholar

Google Scholar

[33] Guo Y, Bescond M, Zhang Z, Xiong S, Hirakawa K, Nomura M, Volz S 2021 APL Materials 9 091104

Google Scholar

Google Scholar

[34] Schulz J 2003 J. Reprod. Infant. Psyc. 21 363

Google Scholar

Google Scholar

计量

- 文章访问数: 6927

- PDF下载量: 263

- 被引次数: 0

下载:

下载: